吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (7): 2067-2077.doi: 10.13229/j.cnki.jdxbgxb.20211010

• 交通运输工程·土木工程 • 上一篇

基于多元非线性回归的智能压实关键参数最优解

- 东南大学 交通学院,南京 211189

Optimal combination of key parameters of intelligent compaction based on multiple nonlinear regression

Tao MA( ),Yuan MA,Xiao-ming HUANG

),Yuan MA,Xiao-ming HUANG

- School of Transportation,Southeast University,Nanjing 211189,China

摘要:

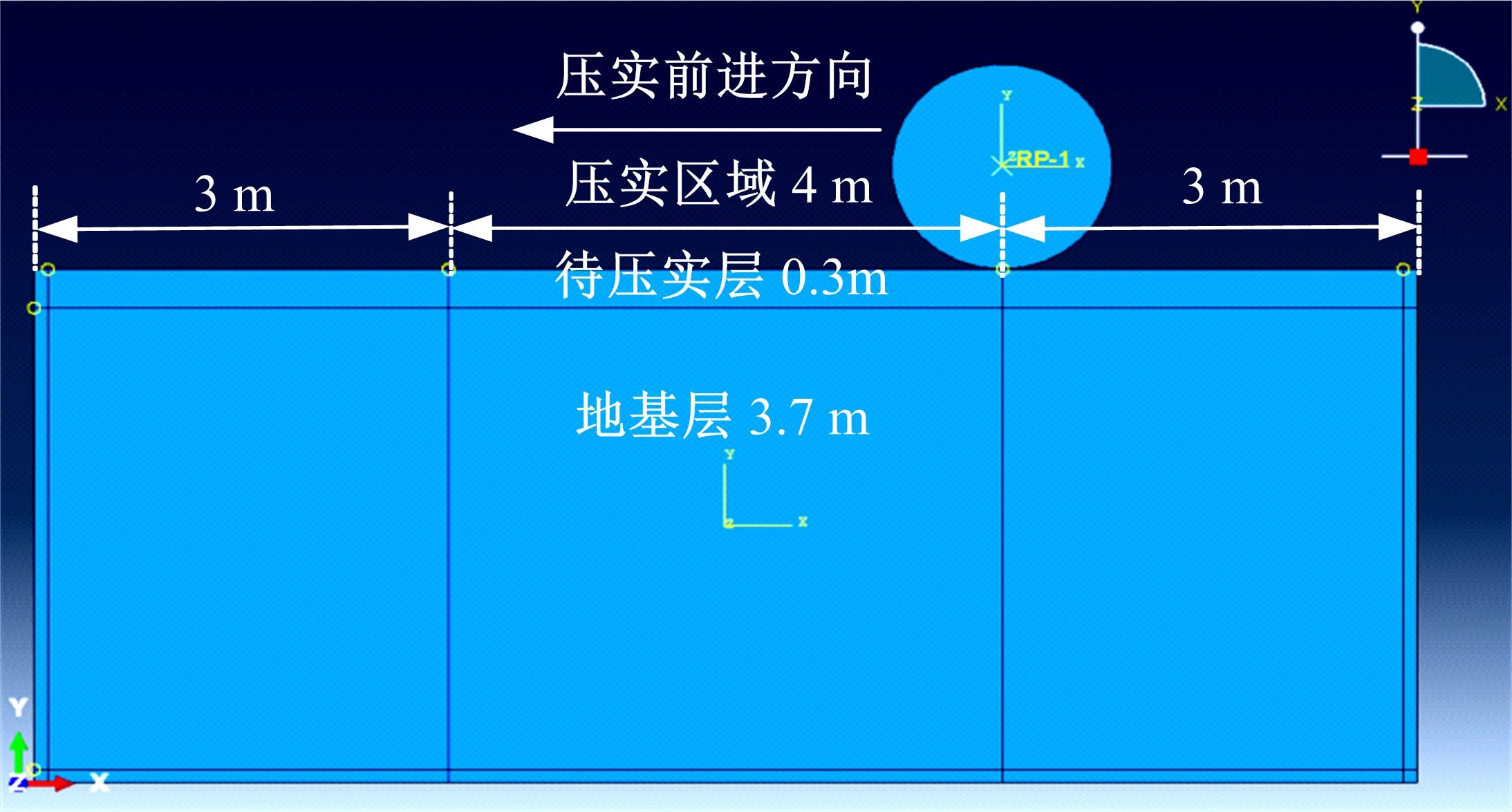

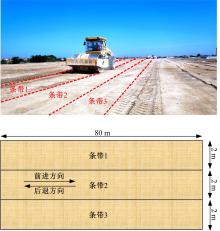

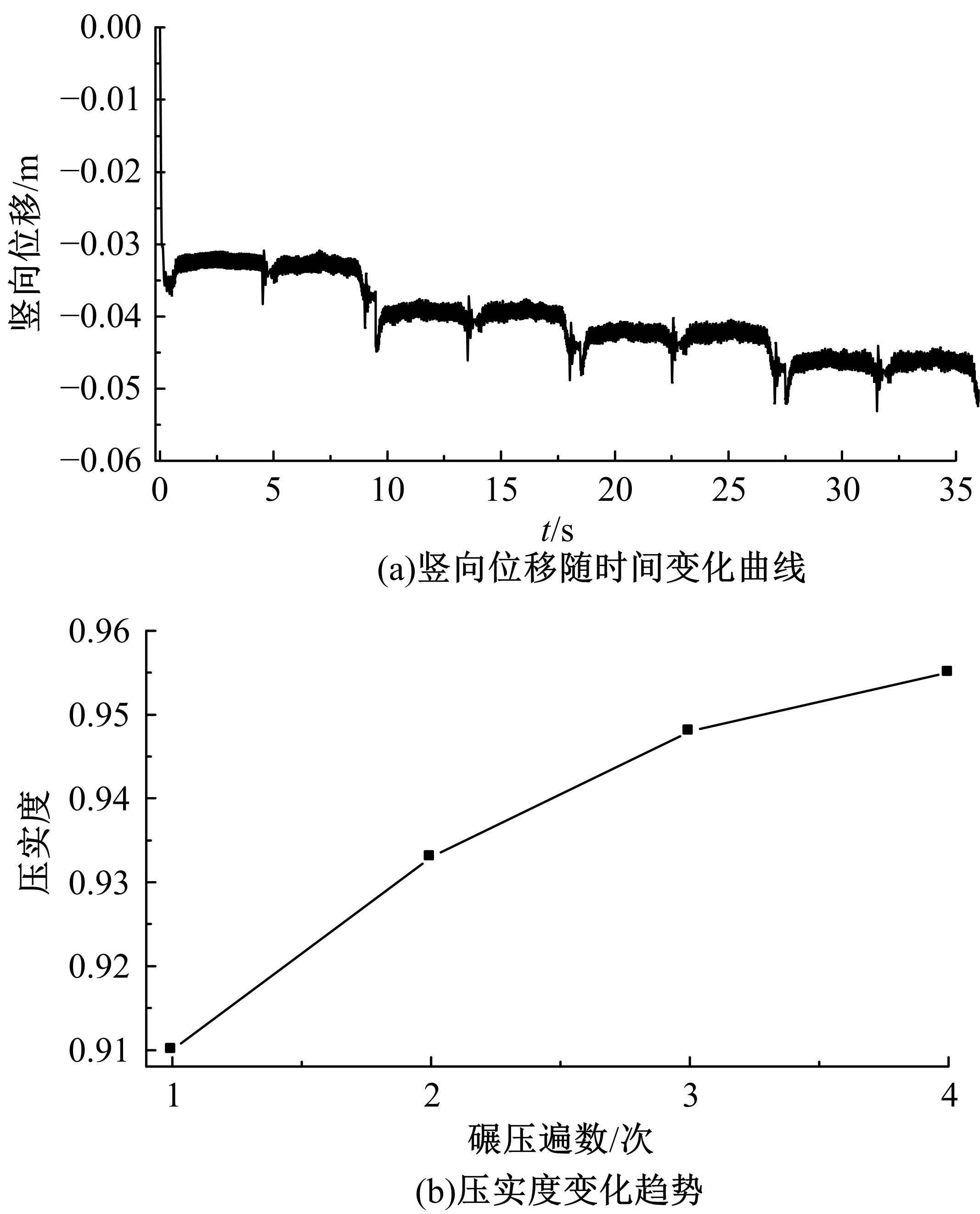

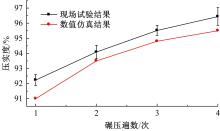

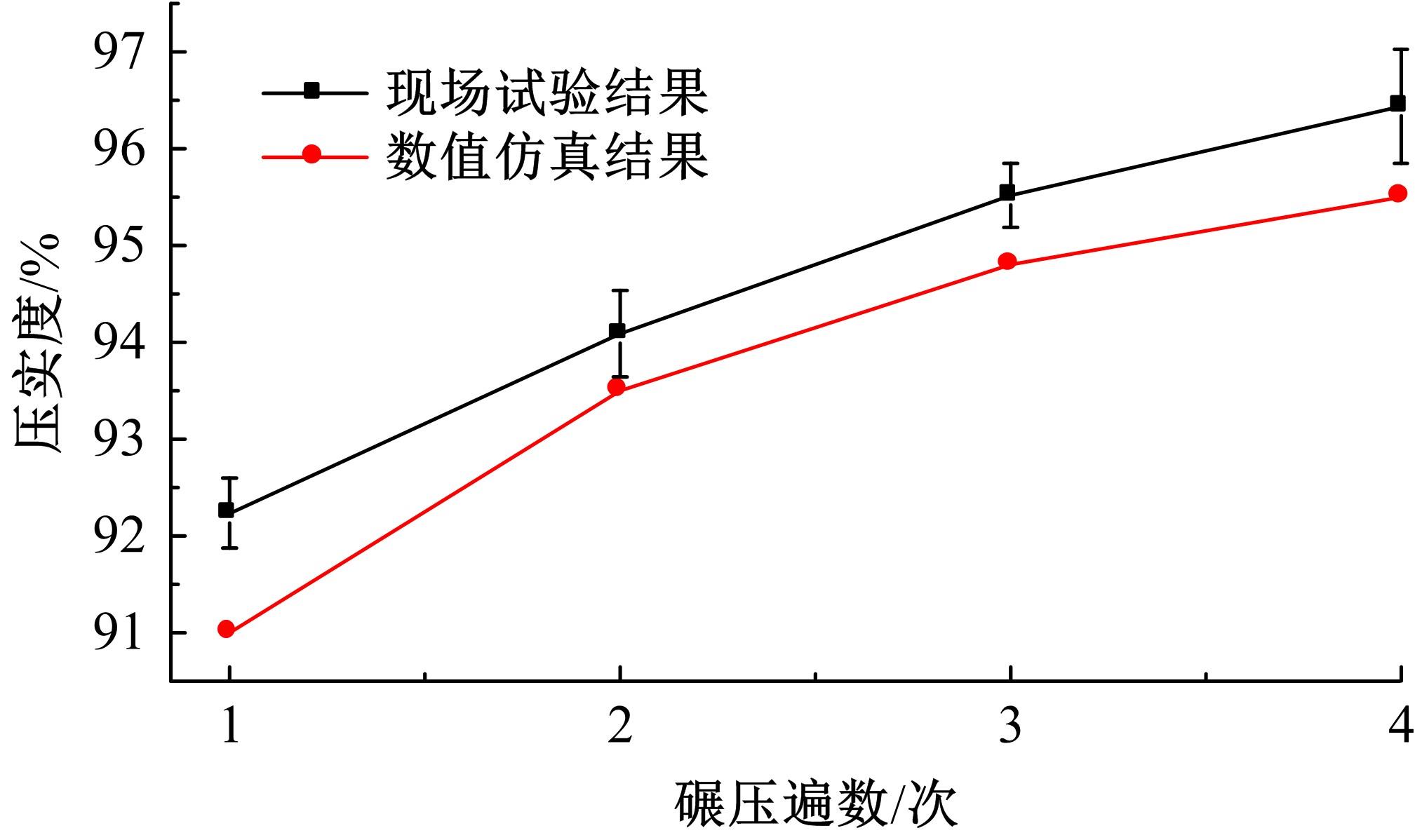

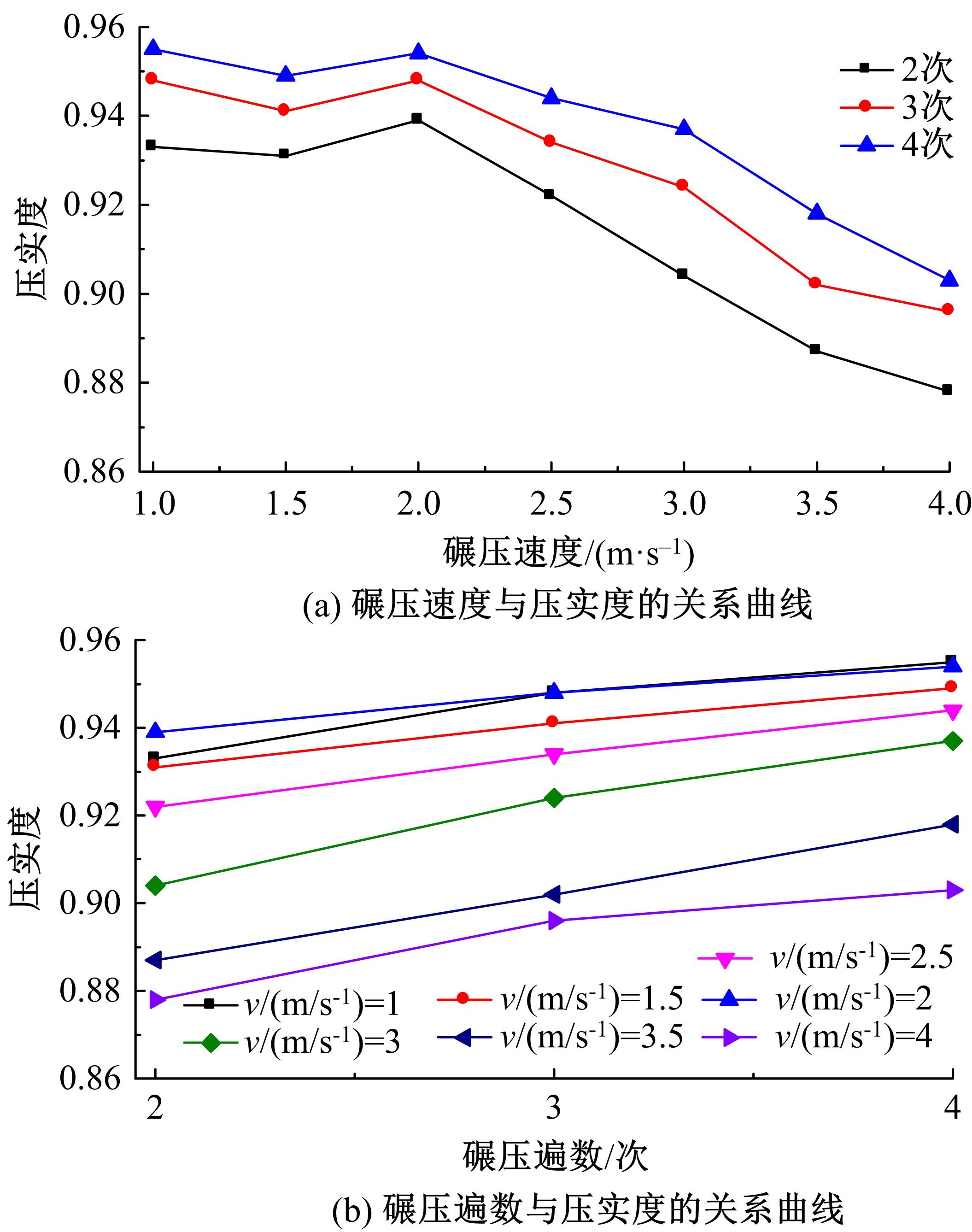

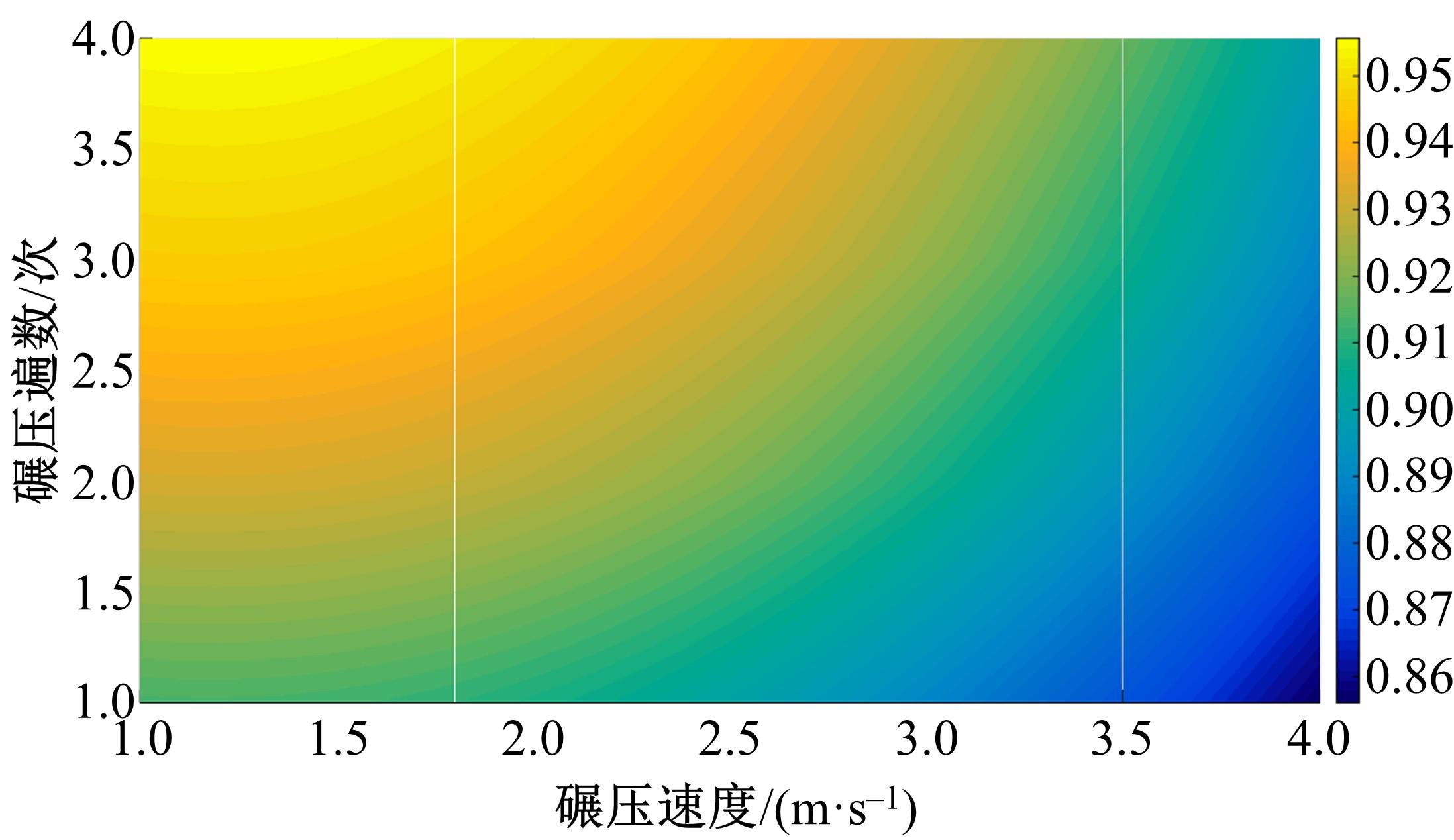

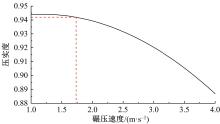

通过对有限元数值仿真软件进行二次开发,实现数值仿真精细化建模并设计所需工况,提供智能压实最优关键参数组合的基础数据,并通过现场试验验证其准确性。在此基础上,通过多元非线性回归的方法,对影响路基压实度参数进行拟合。通过线性搜索的方法,获取能达到最大压实质量对应参数。结果表明:当碾压速度为4 m/s、碾压遍数为2遍时,对应的最终压实度最小,为0.878;当碾压速度为1 m/s、碾压遍数为4遍时,对应的最终压实度最大,为0.955。本文得到如下结论:在常见的压实施工参数范围内,达到最优压实度的施工参数组合如下:碾压速度为1.3 m/s,碾压遍数为4遍。

中图分类号:

- U416

| 1 | Vennapusa P K R, White D J, Schram S. Roller-integrated compaction monitoring for hot-mix asphalt overlay construction[J]. Journal of Transportation Engineering, 2013, 139(12): 1164-1173. |

| 2 | Xu Q, Chang G K. Evaluation of intelligent compaction for asphalt materials[J]. Automation in Construction, 2013, 30: 104-112. |

| 3 | Xu Q, Chang G K, Gallivan V L. Development of a systematic method for intelligent compaction data analysis and management[J]. Construction and Building Materials, 2012, 37: 470-480. |

| 4 | Chen T, Ma T, Huang X, et al. Microstructure of synthetic composite interfaces and verification of mixing order in cold-recycled asphalt emulsion mixture[J]. Journal of Cleaner Production, 2020, 263:No.121467. |

| 5 | Zhu J, Ma T, Fan J, et al. Experimental study of high modulus asphalt mixture containing reclaimed asphalt pavement[J]. Journal of Cleaner Production, 2020, 263: No.121447. |

| 6 | Ding X, Chen L, Ma T, et al. Laboratory investigation of the recycled asphalt concrete with stable crumb rubber asphalt binder[J]. Construction and Building Materials, 2019, 203: 552-557. |

| 7 | 赵秀璞. 路基智能压实控制技术研究[D].西安: 长安大学机械工程学院, 2016. |

| Zhao Xiu-pu. Study on intelligent compaction control technology of subgrade[D]. Xi'an: College of Mechanical Engineering, Chang'an University, 2016. | |

| 8 | 陈博. 路基土压实度实时检测系统研究[D]. 西安: 长安大学机械工程学院, 2019. |

| Chen Bo. Research on real-time detection system of subgrade compaction degree[D]. Xi'an: College of Mechanical Engineering,Chang'an University, 2019. | |

| 9 | Minchin R E, Thomas H R. Validation of vibration-based onboard asphalt density measuring system[J]. Journal of Construction Engineering and Management-ASCE, 2003, 129(1): 1-7. |

| 10 | 赵海杰. 路基压实质量评价指标的研究[D]. 西安: 长安大学机械工程学院, 2015. |

| Zhao Hai-jie. Study on the evaluation index of roadbed compaction quality[D]. Xi'an: College of Mechanical Engineering, Chang'an University, 2015. | |

| 11 | 焦倓, 聂志红, 王翔. 基于连续压实质量检测的压实薄弱区域评价指标研究[J]. 铁道学报, 2015, 37(8): 66-71. |

| Jiao Tan, Nie Zhi-hong, Wang Xiang. Evaluation of compaction weak areas based on continuous compaction quality detction[J]. Journal of the China Railway Society, 2015, 37(8): 66-71. | |

| 12 | 崔浩. 基于智能压实技术对填筑体路基压实度试验研究[D]. 保定: 河北大学建筑工程学院, 2017. |

| Cui Hao. Based on intelligent compaction technology of filling roadbed compaction degree test research[D]. Baoding: College of Civil Engineering and Architecture, Hebei University,2017. | |

| 13 | 郝飞. “振动轮⁃土壤”模型的有限元分析[D]. 西安: 长安大学机械工程学院, 2007. |

| Hao Fei. Finite element analysis of "vibration wheel-soil" model[D]. Xi'an: College of Mechanical Engineering,Chang'an University, 2007. | |

| 14 | 庞国强,苟桂枝. 冲击压路机压实效果的有限元分析法[J]. 机械管理开发, 2003(4): 16-17. |

| Pang Guo-qiang, Gou Gui-zhi. Finite element analysis method for compaction effect of impact rollers[J]. Mechanical Management and Development, 2003(4): 16-17. | |

| 15 | Liu D, Lin M, Li S. Real-Time Quality Monitoring and Control of Highway Compaction[J]. Automation in Construction, 2016, 62: 114-123. |

| 16 | Zhang Q, Liu T, Zhang Z, et al. Unmanned rolling compaction system for rockfill materials[J]. Automation in Construction, 2019, 100: 103-117. |

| 17 | 吴泽兵, 张帅, 郭龙龙, 等. ABAQUS二次开发在Pdc单齿破岩仿真中的应用[J]. 西安石油大学学报:自然科学版, 2020, 35(1): 104-109. |

| Wu Ze-bing, Zhang Shuai, Guo Long-long, et al. Application of ABAQUS secondary development in rock breaking simulation of PDC cutter[J]. Journal of Xi'an Shiyou University(Natural Science Edition), 2020,35(1):104-109. | |

| 18 | 陈飞, 王成雨, 李伟刚, 等. Abaqus二次开发在航空弓形结构件喷丸强化模拟中的应用[J]. 计算机辅助工程, 2020, 29(2): 55-60. |

| Chen Fei, Wang Cheng-yu, Li Wei-gang, et al. Application of Abaqus secondary development in shot peening strengthening of aerospace arc-shaped frame[J]. Computer Aided Engineering,2020,29(2):55-60. | |

| 19 | Hu W, Jia X, Zhu X, et al. Influence of moisture content on intelligent soil compaction[J]. Automation in Construction, 2020, 113: No.103141. |

| 20 | Ma Y, Luan Y, Zhang W, et al. Numerical simulation of intelligent compaction for subgrade construction[J]. Journal of Central South University, 2020, 27(Sup.1): 2173-2184. |

| 21 | 马源, 方周, 韩涛, 等. 路基智能压实关键控制参数动态仿真及演变规律[J]. 中南大学学报:自然科学版, 2021, 52(7): 2246-2257. |

| Ma Yuan, Fang Zhou, Han Tao, et al. Dynamic simulation and evolution of key control parameters for intelligent compaction of subgrade[J]. Journal of Central South University(Science and Technology), 2021, 52(7): 2246-2257. | |

| 22 | 闫星宇. 函数型线性回归的若干研究[D]. 上海: 华东师范大学统计学院, 2020. |

| Yan Xing-yu. Some studies on functional linear regression[D]. Shanghai: School of Statistics, East China Normal University, 2020. | |

| 23 | 陈育民,徐鼎平. FLAC/FLAC3D基础与工程实例[M]. 北京:中国水利水电出版社, 2009:220-222. |

| 24 | 滕显飞. 黄泛区粉土路基强夯加固数值分析与质量控制技术研究[D]. 济南: 山东大学土建与水利学院,2017. |

| Teng Xian-fei. Numerical analysis and quality control of dynamic consolidation of silty soil subgrade in Yellow River alluvial plain[D]. Jinan: School of Civil Engineering, Shandong University,2017. | |

| 25 | 徐群. 非线性回归分析的方法研究[D]. 安徽:合肥工业大学数学学院, 2009. |

| Xu Qun. The research on non-linear regression analysis methods[D]. Anhui: School of Mathematics, Hefei University of Technology,2009. | |

| 26 | 周大力. 基于Laplace机制的差分隐私回归分析相关优化研究[D]. 哈尔滨: 黑龙江大学数据科学与技术学院, 2018. |

| Zhou Da-li. Research on correlation optimization of differential privacy regression analysis based on Laplace mechanism[D]. Harbin: School of Data Science and Technology, Heilongjiang University, 2018. | |

| 27 | White D J, Vennapusa P K R, Gieselman H H. Field assessment and specification review for roller-integrated compaction monitoring technologies[J]. Advances in Civil Engineering, 2011(1): No.783836. |

| [1] | 杨柳,王创业,王梦言,程阳. 设置自动驾驶小客车专用车道的六车道高速公路交通流特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2043-2052. |

| [2] | 郑睢宁,何锐,路天宇,徐紫祎,陈华鑫. RET/胶粉复合改性沥青制备及其混合料性能评价[J]. 吉林大学学报(工学版), 2023, 53(5): 1381-1389. |

| [3] | 魏海斌,韩栓业,毕海鹏,刘琼辉,马子鹏. 智能感知道路主动除冰雪系统及实验技术[J]. 吉林大学学报(工学版), 2023, 53(5): 1411-1417. |

| [4] | 杨帆,李琛琛,李盛,刘海伦. 温缩作用下双层连续配筋混凝土路面配筋率设计参数对比分析[J]. 吉林大学学报(工学版), 2023, 53(4): 1122-1132. |

| [5] | 关博文,邸文锦,王发平,吴佳育,张硕文,贾治勋. 干湿循环与交变荷载作用下混凝土硫酸盐侵蚀损伤[J]. 吉林大学学报(工学版), 2023, 53(4): 1112-1121. |

| [6] | 刘状壮,张有为,季鹏宇,Abshir Ismail Yusuf,李林,郝亚真. 电热型融雪沥青路面传热特性研究[J]. 吉林大学学报(工学版), 2023, 53(2): 523-530. |

| [7] | 魏海斌,马子鹏,毕海鹏,刘汉涛,韩栓业. 基于力学响应分析方法的导电橡胶复合路面铺装技术[J]. 吉林大学学报(工学版), 2023, 53(2): 531-537. |

| [8] | 时成林,王勇,吴春利,宋文祝. 路堤挡土墙主动土压力计算方法修正[J]. 吉林大学学报(工学版), 2022, 52(6): 1394-1403. |

| [9] | 郭庆林,刘强,吴春利,李黎丽,李懿明,刘富春. 导电沥青及混合料裂缝局部温度场及愈合效果[J]. 吉林大学学报(工学版), 2022, 52(6): 1386-1393. |

| [10] | 姚玉权,仰建岗,高杰,宋亮. 基于性能-费用模型的厂拌再生沥青混合料优化设计[J]. 吉林大学学报(工学版), 2022, 52(3): 585-595. |

| [11] | 夏全平,高江平,罗浩原,张其功,李志杰,杨飞. 用于高模量沥青砼的复合改性硬质沥青低温性能[J]. 吉林大学学报(工学版), 2022, 52(3): 541-549. |

| [12] | 叶奋,胡诗园. 考虑旧水泥路面接缝传荷能力的超薄罩面力学特性[J]. 吉林大学学报(工学版), 2022, 52(11): 2636-2643. |

| [13] | 于晓贺,罗蓉,柳子尧,黄婷婷,束裕. 沥青路面典型裂缝湿度场数值模拟[J]. 吉林大学学报(工学版), 2022, 52(10): 2343-2351. |

| [14] | 杨彦海,崔宏,杨野,张怀志,刘赫. 冻融循环作用对非饱和乳化沥青冷再生混合料性能的影响[J]. 吉林大学学报(工学版), 2022, 52(10): 2352-2359. |

| [15] | 冉武平,陈慧敏,李玲,冯立群. 干湿循环下粗粒土回弹模量演变规律及模型预估和修正[J]. 吉林大学学报(工学版), 2021, 51(6): 2079-2086. |

|

||