吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (2): 639-652.doi: 10.13229/j.cnki.jdxbgxb.20230420

• 交通运输工程·土木工程 • 上一篇

考虑骨料形态的沥青混合料细观数值建模方法

念腾飞1,2( ),韩召1,魏智强1,王国伟2,戈锦果1,3,李萍1

),韩召1,魏智强1,王国伟2,戈锦果1,3,李萍1

- 1.兰州理工大学 土木工程学院,兰州 730050

2.甘肃路桥善建科技有限公司,兰州 730314

3.长沙理工大学 交通运输工程学院,长沙 410114

Mesoscopic numerical modeling method of asphalt mix considering aggregate morphology

Teng-fei NIAN1,2( ),Zhao HAN1,Zhi-qiang WEI1,Guo-wei WANG2,Jin-guo GE1,3,Ping LI1

),Zhao HAN1,Zhi-qiang WEI1,Guo-wei WANG2,Jin-guo GE1,3,Ping LI1

- 1.School of Civil Engineering,Lanzhou University of Technology,Lanzhou 730050,China

2.Gansu Luqiao Shanjian Technology Co. ,Ltd. ,Lanzhou 730314,China

3.School of Traffic and Transportation Engineering,Changsha University of Science and Technology,Changsha 410114,China

摘要:

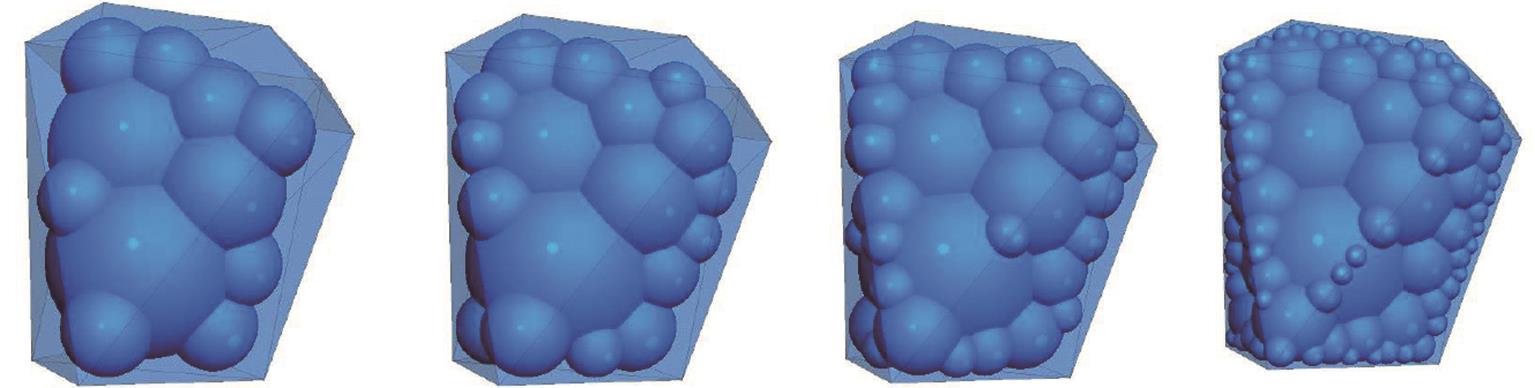

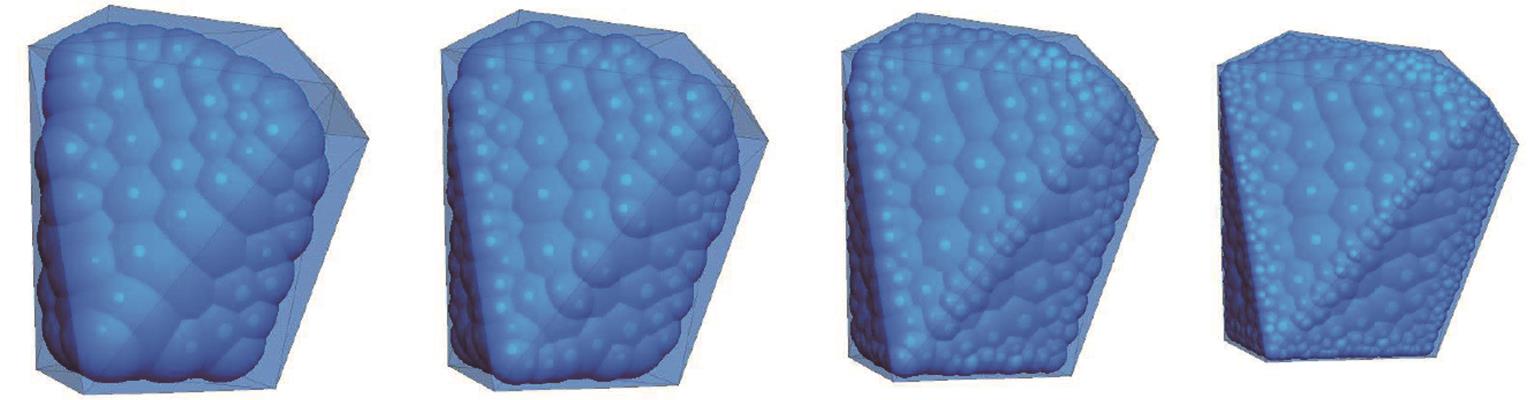

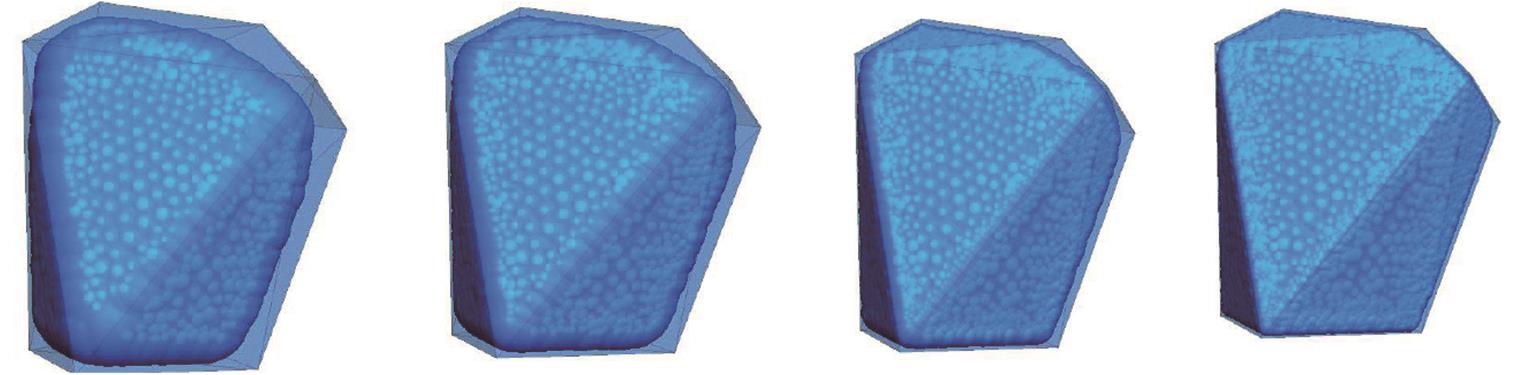

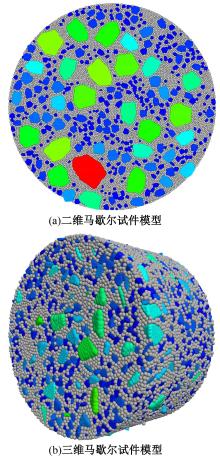

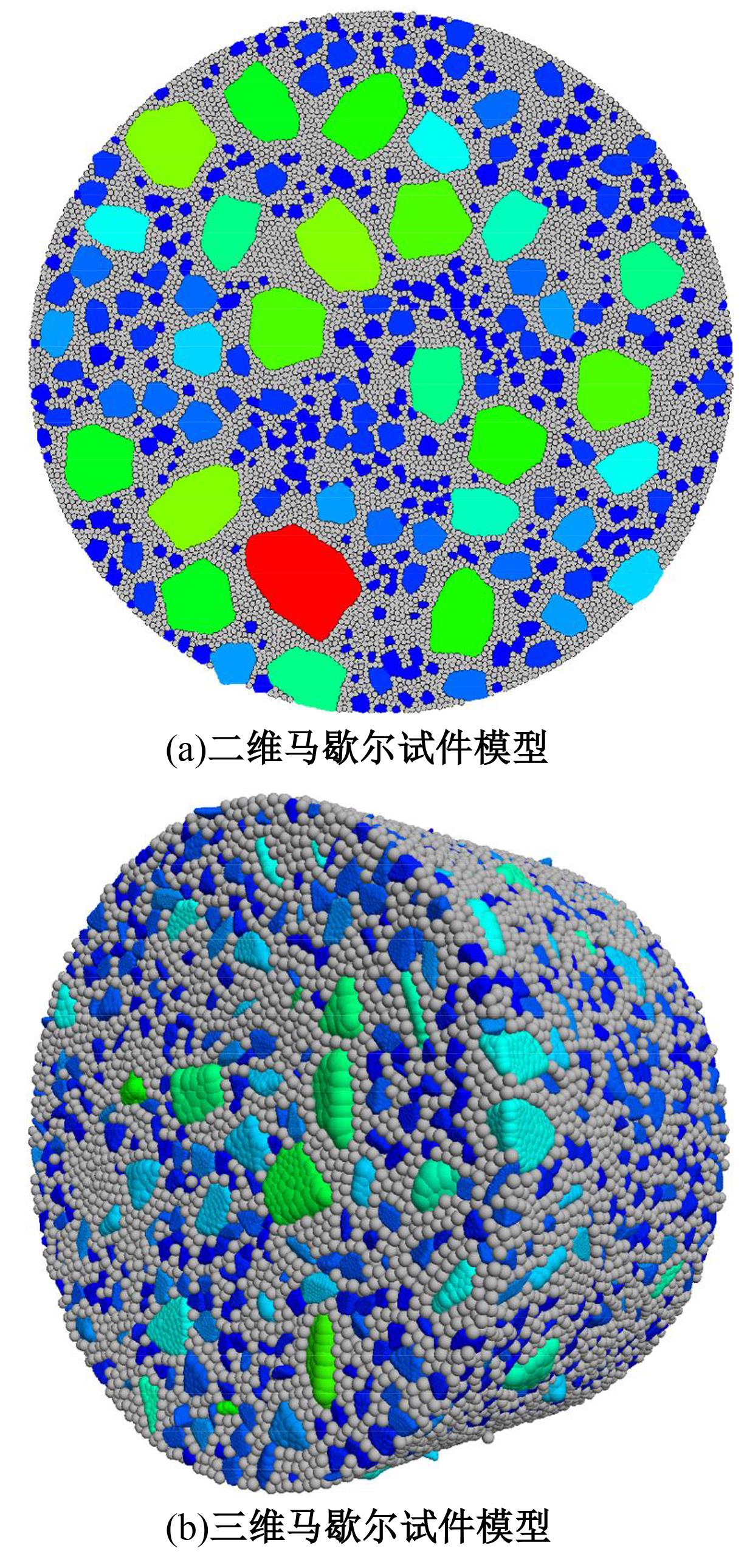

针对目前采用宏观均匀介质法与室内试验研究沥青混合料性能的局限性,本文提出一种沥青混合料细观尺度的数值建模计算方法。采用离散元PFC软件,构建具有真实形态的沥青混合料骨料,并利用缩放法建立沥青混合料离散元模型;通过动态剪切流变(DSR)试验和弯曲梁流变(BBR)试验,基于时温等效原理确定了沥青砂浆颗粒间Burgers模型的细观参数;采用单轴压缩和马歇尔劈裂试验,验证了离散元建模方法的可靠性。结果表明:通过ODEC算法填充包围盒可生成不规则形态的clump骨料;将遍历试件得到的浮点进行半径放大使浮点与相邻颗粒的距离缩短从而生成接触,可用于消除沥青混合料离散元模型内部浮点;利用离散元软件PFC所建立的沥青混合料模型,能够较好地模拟沥青混合料在低温状态下的力学行为。研究结果对开展沥青混合料细观力学研究与数值建模计算具有重要意义。

中图分类号:

- U414.1

| 1 | 巨宏伟. 有限元强度折减法在边坡稳定性分析中的应用[J]. 市政技术, 2023, 41(3): 122-128. |

| Ju Hong-wei. Analysis of slope stability by finite element strength reduction method[J]. Journal of Municipal Technology, 2023, 41(3): 122-128. | |

| 2 | Yu H N, Ge J G, Qian G P, et al. Evaluation on the rejuvenation and diffusion characteristics of waste cooking oil on aged SBS asphalt based on molecular dynamics method[J]. Journal of Cleaner Production, 2023, 406: No.136998. |

| 3 | Peng Y, Gao H, Lu X Y, et al. Micromechanical discrete element modeling of asphalt mixture shear fatigue performance[J]. Journal of Materials in Civil Engineering, 2020, 32(7): 04020183. |

| 4 | 彭勇, 杨汉铎, 陆学元, 等. 基于离散元法的空隙特征对沥青混合料虚拟剪切疲劳寿命的影响[J]. 吉林大学学报: 工学版, 2021, 51(3): 956-964. |

| Peng Yong, Yang Han-duo, Lu Xue-yuan, et al. Effect of void characteristics on virtual shear fatigue life of asphalt mixtures using discrete element method[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(3): 956-964. | |

| 5 | 蔡旭, 张睿达, 陈莉, 等. 基于界面剪切试验的沥青混合料集料切向弹性刚度研究[J]. 中国公路学报, 2020, 33(10): 221-229. |

| Cai Xu, Zhang Rui-da, Chen Li, et al. Tangential elastic stiffness of asphalt mixture aggregate based on interfacial shear test[J]. China Journal of Highway and Transport, 2020, 33(10): 221-229. | |

| 6 | Yang X C, Tang H Z, Cai X, et al. Evaluating reclaimed asphalt mixture homogeneity using force chain transferring stress efficiency[J]. Construction and Building Materials, 2023, 365: 130050. |

| 7 | You Z P, Liu Y, Dai Q L. Three-dimensional microstructural-based discrete element viscoelastic modeling of creep compliance tests for asphalt mixtures[J]. Journal of Materials in Civil Engineering, 2011, 23(1): 79-87. |

| 8 | 谭忆秋, 邢超, 任俊达, 等. 基于颗粒堆积理论的沥青混合料细观结构特性研究[J]. 中国公路学报, 2017, 30(7): 1-8. |

| Tan Yi-qiu, Xing Chao, Ren Jun-da, et al. Research on mesostructured characteristics of asphalt mixture based on particle packing theory[J]. China Journal of Highway and Transport, 2017, 30(7): 1-8. | |

| 9 | 吴星怡. 基于CT图像的玄武岩纤维长度级配与沥青混合料骨架结构特征参数的关系研究[D]. 扬州: 扬州大学建筑科学与工程学院, 2021. |

| Wu Xing-yi. Study on the relationship between the basalt fiber mixing length gradation and asphalt mixture skeleton sructure characteristic parameters on CT images[D]. Yangzhou: School of Architectural Science and Engineering, Yangzhou University, 2021. | |

| 10 | Kollmann J, Liu P F, Lu G Y, et al. Investigation of the microstructural fracture behaviour of asphalt mixtures using the finite element method[J]. Construction and Building Materials, 2019, 227: 117078. |

| 11 | 马翔, 袁则瑜, 陈满军, 等. 基于数字图像的大空隙沥青混凝土离散元模型[J]. 江苏大学学报: 自然科学版, 2019, 40(6): 734-739. |

| Ma Xiang, Yuan Ze-yu, Chen Man-jun, et al. Discrete element model for porous asphalt concrete based on digital images[J]. Journal of Jiangsu Univercity (Nature Science Edition), 2019, 40(6): 734-739. | |

| 12 | 李浩, 张硕, 赵聚成. 基于物元理论模型的沥青路面使用性能评价[J]. 市政技术, 2022, 40(8): 214-219. |

| Li Hao, Zhang Shuo, Zhao Ju-cheng. Evaluation of asphalt pavement performance by matter-element theory model[J]. Journal of Municipal Technology, 2022, 40(8): 214-219. | |

| 13 | 梁何浩, 王端宜, 邓志刚, 等. 内聚力模型在泡沫沥青混合料离散元模拟中的应用[J]. 湖南大学学报: 自然科学版, 2019, 46(5): 115-123. |

| Liang He-hao, Wang Duan-yi, Deng Zhi-gang, et al. Application of cohesive zone model in discrete element simulation of foamed asphalt mixture[J]. Journal of Hunan University (Natural Sciences), 2019, 46(5): 115-123. | |

| 14 | Nian T F, Ge J G, Li P, et al. Improved discrete element numerical simulation and experiment on low-temperature anti-cracking performance of asphalt mixture based on PFC2D[J]. Construction and Building Materials, 2021, 283: 122792. |

| 15 | Dondi G, Vignali V, Pettinari M, et al. Modeling the DSR complex shear modulus of asphalt binder using 3D discrete element approach[J]. Construction and Building Materials, 2013, 54: 236-246. |

| 16 | 韩丁, 李阳, 刘东泽, 等. 表征真实骨料形态的三维数值骨料建模[J]. 建筑材料学报, 2017, 20(3): 339-344. |

| Han Ding, Li Yang, Liu Dong-ze, et al. 3D numerical modeling methods to characterize real aggregate shapes[J]. Journal of Building Materials, 2017, 20(3): 339-344. | |

| 17 | Ren J L, Sun L. Generalized maxwell viscoelastic contact model-based discrete element method for characterizing low-temperature properties of asphalt concrete[J]. Journal of Materials in Civil Engineering, 2016, 28(2): 04015122. |

| [1] | 韦万峰,孔令云,禤炜安,杨帆,郭鹏. 沥青发泡特性及温拌混合料水分敏感性综述[J]. 吉林大学学报(工学版), 2025, 55(1): 20-35. |

| [2] | 郭风春,毕海鹏,王海涛,吴树正,杨泓雨. 基于时温等效的纳米碳粉改性沥青黏弹行为[J]. 吉林大学学报(工学版), 2025, 55(1): 221-229. |

| [3] | 谢朋书,崔达,王国强,李凯. 基于离散元方法的立式螺旋搅拌磨机工作性能[J]. 吉林大学学报(工学版), 2024, 54(9): 2423-2431. |

| [4] | 顿国强,吴星澎,纪欣鑫,张福利,纪文义,朱礼贵. 玉米条带摆管式撒肥装置设计及试验[J]. 吉林大学学报(工学版), 2024, 54(9): 2697-2707. |

| [5] | 崔亚宁,司春棣,凡涛涛,王飞. 水-荷耦合作用下沥青桥面铺装层裂缝扩展分析[J]. 吉林大学学报(工学版), 2024, 54(7): 1988-1996. |

| [6] | 罗蓉,梁宇,牛茏昌,黄婷婷,苗强. 多温度条件沥青混合料水稳定性评价指标阈值[J]. 吉林大学学报(工学版), 2024, 54(7): 1966-1977. |

| [7] | 高英力,谷小磊,廖美捷,胡新浪,谢雨彤. SiO2气凝胶/反应性弹性体三元共聚物/多聚磷酸复合改性沥青流变性能与改性机理[J]. 吉林大学学报(工学版), 2024, 54(7): 1978-1987. |

| [8] | 徐永丽,杨煦兰,周吉森,杨松翰,孙明刚. 温拌沥青的沥青烟成分及温拌剂抑烟性能[J]. 吉林大学学报(工学版), 2024, 54(6): 1701-1707. |

| [9] | 李祖仲,李梦园,刘卫东,庞萧萧,唐豪,张学磊,马晨杨. 蔗渣纤维表面改性及其沥青混合料路用性能[J]. 吉林大学学报(工学版), 2024, 54(6): 1738-1745. |

| [10] | 孙雅珍,薛博欣,孙岩,王志臣,潘嘉伟. 考虑非均匀性的沥青混合料开裂行为细观模拟[J]. 吉林大学学报(工学版), 2024, 54(6): 1708-1718. |

| [11] | 赵晓康,胡哲,牛振兴,张久鹏,裴建中,温永. 基于非均质模型的水稳碎石材料细观开裂行为[J]. 吉林大学学报(工学版), 2024, 54(5): 1258-1266. |

| [12] | 万铜铜,汪海年,郑文华,冯珀楠,陈玉,张琛. 级配碎石层协调沥青混合料层温度收缩变形行为[J]. 吉林大学学报(工学版), 2024, 54(4): 1045-1057. |

| [13] | 徐进,陈正欢,廖祺硕,郑展骥,张河山. 基于心电数据的高速公路高密度互通立交驾驶负荷[J]. 吉林大学学报(工学版), 2024, 54(10): 2807-2818. |

| [14] | 蒋应军,苏洪建,李明杰,何岩,白雅伟,王鹏飞,鲍豫豪,蔡敏锋. 振动成型设计下AC-16沥青混合料的耐久性能[J]. 吉林大学学报(工学版), 2024, 54(10): 2849-2858. |

| [15] | 朱洪洲,苏春力,唐乃膨,魏俊尧,孙宏军. 胶粉改性沥青排放物采样及定量分析方法[J]. 吉林大学学报(工学版), 2024, 54(10): 2922-2929. |

|

||