吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (10): 2849-2858.doi: 10.13229/j.cnki.jdxbgxb.20221538

• 交通运输工程·土木工程 • 上一篇

振动成型设计下AC-16沥青混合料的耐久性能

蒋应军1( ),苏洪建1,李明杰2,何岩3,白雅伟4,王鹏飞5,鲍豫豪1,蔡敏锋1

),苏洪建1,李明杰2,何岩3,白雅伟4,王鹏飞5,鲍豫豪1,蔡敏锋1

- 1.长安大学 特殊地区公路工程教育部重点实验室,西安 710064

2.河南省交通基本建设质量检测站,郑州 450005

3.许昌市公路事业发展中心,河南 许昌 461670

4.金华市交通投资集团有限公司,浙江 金华 321017

5.中交二公局东萌有限公司,西安 710119

Durability of AC-16 asphalt mixture under vibration molding design

Ying-jun JIANG1( ),Hong-jian SU1,Ming-jie LI2,Yan HE3,Ya-wei BAI4,Peng-fei WANG5,Yu-hao BAO1,Min-feng CAI1

),Hong-jian SU1,Ming-jie LI2,Yan HE3,Ya-wei BAI4,Peng-fei WANG5,Yu-hao BAO1,Min-feng CAI1

- 1.Key Laboratory of Highway Engineering in Special Areas,Ministry of Education,Chang'an University,Xi'an 710064,China

2.Transportation Infrastructure Quality Inspection Station of Henan Province,Zhengzhou 450005,China

3.Xuchang City Highway Development Center,Xuchang 461670,China

4.Jinhua Communications Investment Group Co. ,Ltd. ,Jinhua 321017,China

5.China Communications Second Office Dongmeng Co. ,Ltd. ,Xi'an 710119,China

摘要:

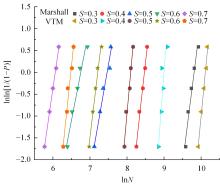

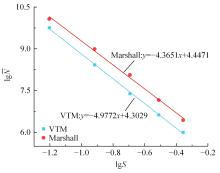

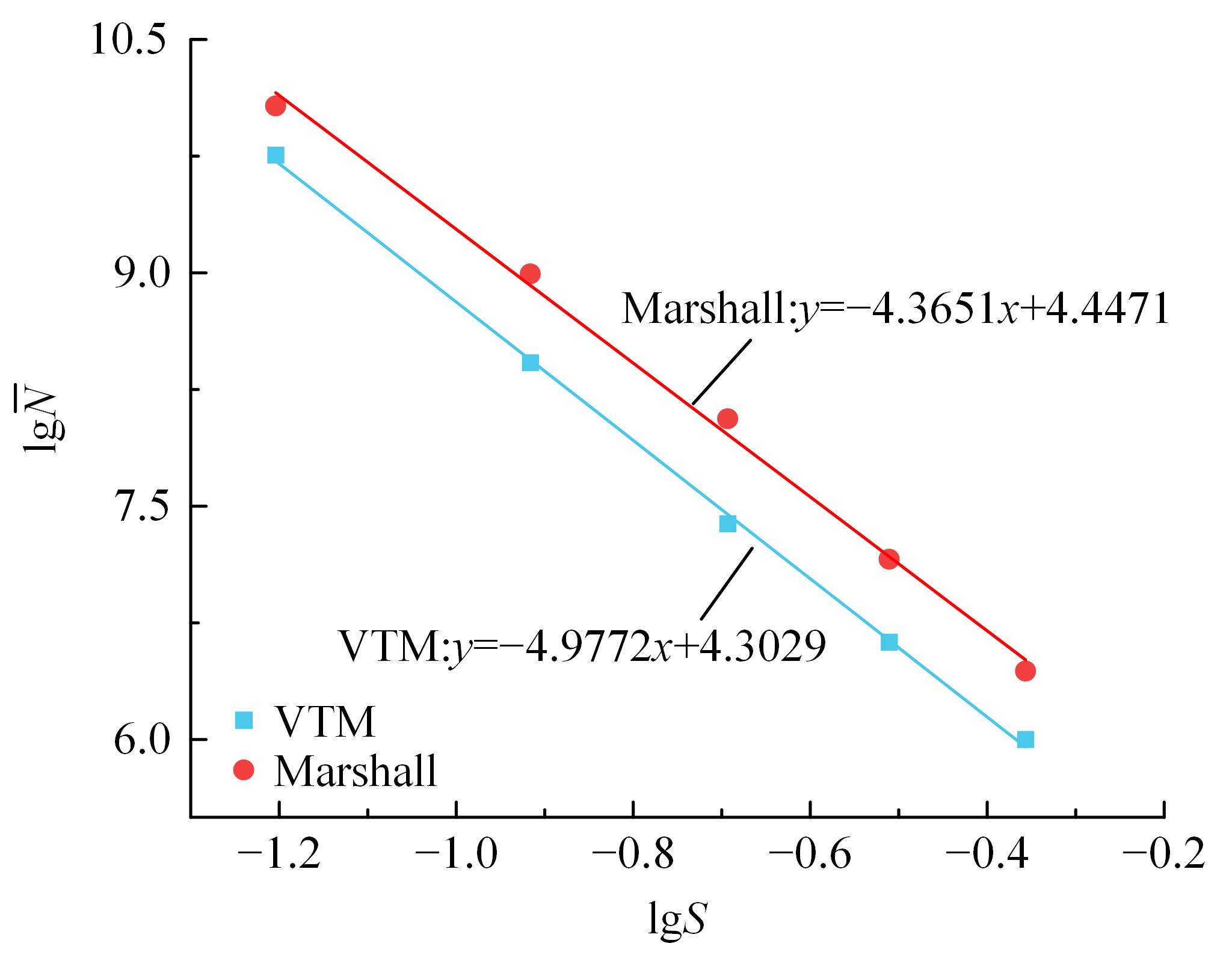

为论证垂直振动法(VTM)设计沥青混合料在光照环境与荷载反复作用环境下的耐久性能,本文首先对VTM法、马歇尔法(Marshall)和旋转压实法(GTM)成型的AC-16混合料力学性能进行对比,并深入分析VTM、Marshall两种设计方法的抗老化性能和耐疲劳特性,应用Weibull分布建立疲劳方程,对疲劳寿命进行对比。结果表明:VTM成型试件具有密实度高、空隙率和矿料间隙率低的特点;GTM、VTM沥青混合料力学性能较Marshall至少提高35%;GTM法、VTM法、Marshall法与现场相关性分别为94%、92%和72%;老化后两种方法设计沥青混合料低温性能相当;短期老化后VTM设计沥青混合料回收沥青性能变化比Marshall的大;长期老化后VTM设计沥青混合料回收沥青性能变化比Marshall的小;建立的Weibull模型呈现良好的线性相关性;不同失效概率下,基于VTM设计的沥青混合料耐疲劳性能优于Marshall法。

中图分类号:

- U416

| 1 | 王聪,郭乃胜,赵颖华,等.不同成型方法和级配的沥青混合料内部空隙特征[J].吉林大学学报:工学版,2014,44(1):74-80. |

| Wang Cong, Guo Nai-Sheng, Zhao Ying-hua, et al. Air voids distribution of asphalt mixtures in different compaction methods and aggregate gradations[J]. Journal of Jilin University(Engineering and Technology Edition), 2014, 44(1): 74-80. | |

| 2 | 季节,高超.基于不同成型方式的热再生沥青混合料性能试验研究[J].公路,2014,59(3):174-177. |

| Ji Jie, Gao Chao. Experimental study on properties of hot reclaimed asphalt mixture based on different forming methods[J]. Highway, 2014,59(3):174-177. | |

| 3 | 易勇,蒋应军,谭云鹏,等.不同成型方式乳化沥青冷再生混合料力学特性研究[J].重庆大学学报,2021,44(5):50-58. |

| Yi Yong, Jiang Ying-jun, Tan Yun-peng, et al. Mechanical properties of emulsified asphalt cold recycling mixture with different forming methods[J]. Journal of Chongqing University, 2021, 44(5):50-58. | |

| 4 | 李正中,魏如喜,宋晓燕,等.基于GTM法的温拌胶粉改性沥青混合料设计研究[J].建筑材料学报,2013,16(6):968-974. |

| Li Zheng-zhong, Wei Ru-xi, Song Xiao-yan, et al. Design and research on the warm-mix rubber-modified asphalt mixture based on the GTM method[J]. Journal of Building Materials, 2013, 16(6):968-974. | |

| 5 | Han D, Wei L, Zhang J. Experimental study on performance of asphalt mixture designed by different method[J]. Procedia Engineering, 2016, 137:407-414. |

| 6 | 任天琦,张海涛,张雪芹,等.不同成型方法对沥青混合料路用性能和细观结构的影响[J].森林工程,2022,38(4):172-180. |

| Ren Tian-qi, Zhang Hai-tao, Zhang Xue-qin, et al. Influence of different forming methods on road performance and meso-structure of asphalt mixture[J]. Forest Engineering, 2022, 38(4):172-180. | |

| 7 | 周杰,王曦林,郑存艳,等.沥青混合料Superpave与马歇尔设计方法的比较[J].武汉理工大学学报,2007,174(9):68-70. |

| Zhou Jie, Wang Xi-lin, Zheng Cun-yan, et al. Comparison of superpave and marshall methodology on asphalt mixture design[J]. Journal of Wuhan University of Technology, 2007, 174(9):68-70. | |

| 8 | 李鹏飞,张海涛,马盛盛,等.不同成型方法对沥青混合料回弹模量的影响[J].科学技术与工程,2019,19(32):322-325. |

| Li Peng-fei, Zhang Hai-tao, Ma Sheng-sheng, et al. Influence of forming method on resilient modulus of asphalt mixture[J]. Science Technology and Engineering, 2019, 19(32):322-325. | |

| 9 | Jiang Y J, Fan L F. An experimental investigation of optimal asphalt-aggregate ratio for different compaction methods[J]. Construction and Building Materials, 2015, 91: 111-115. |

| 10 | 蒋应军,韩占闯,胡永林.冷再生混合料垂直振动成型法设计与评价[J].南京理工大学学报,2019,43(2):186-192. |

| Jiang Ying-jun, Han Zhan-chuang, Hu Yong-lin. Design and evaluation of cold recycled mixture by vertical vibration forming method[J]. Journal of Nanjing University of Science and Technology, 2019, 43(2):186-192. | |

| 11 | 李志刚,郝培文,曾志武.泡沫沥青冷再生混合料成型方法[J].复合材料学报,2017,34(9):2038-2046. |

| Li Zhi-gang, Hao Pei-wen, Zeng Zhi-wu. Research on the compaction methods of cold recycled mixture using foamed asphalt[J]. Journal of Composite Materials, 2017, 34(9):2038-2046. | |

| 12 | 解晓光,马松林,王哲人.沥青混合料马歇尔击实法与振动压实法成型工艺的比较研究[J].中国公路学报,2001(1):11-14. |

| Xie Xiao-guang, Ma Song-lin, Wang Zhe-ren. Study of compacting properties of asphalt mixture with Marshall and vibratory compaction method[J]. China Journal of Highway and Transport, 2001(1):11-14. | |

| 13 | 沙爱民,王玲娟,耿超.大粒径碎石沥青混合料振动压实方法[J].长安大学学报:自然科学版,2008,123(2):1-4. |

| Sha Ai-min, Wang Ling-juan, Geng Chao. Vibrating compaction method of large stone asphalt mixture[J]. Journal of Chang'an University(Natural Science Edition), 2008, 123(2):1-4. | |

| 14 | 王天林,蒋应军.沥青混合料试件振动成型方法[J].武汉理工大学学报:交通科学与工程版,2014,38(3):558-561. |

| Wang Tian-lin, Jiang Ying-jun. Vibration forming method of asphalt mixture specimen[J]. Journal of Wuhan University of Technology(Transportation Science and Engineering), 2014, 38(3):558-561. | |

| 15 | 张毅,薛金顺,陈浙江,等.成型方法对ATB-30混合料性能的影响[J].公路交通科技,2014,31(10):1-6. |

| Zhang Yi, Xue Jin-shun, Chen Zhe-jiang, et al. Effect of compaction methods on performance of ATB-30 asphalt mixture[J]. Journal of Highway and Transportation Science and Technology, 2014, 31(10):1-6. | |

| 16 | 蒋应军,李湾湾,方剑,等.振动压实二灰碎石力学特性及影响因素[J].长安大学学报:自然科学版,2017,37(1):1-9. |

| Jiang Ying-jun, Li Wan-wan, Fang Jian, et al. Mechanical properties and influencing factors of lime-fly-ash crushed rock base on vertical vibration test method[J]. Journal of Chang 'an University(Natural Science Edition), 2017, 37(1):1-9. | |

| 17 | 魏海斌,王相焱,王富玉,等.基于振动成型AC-25沥青混合料力学性能及细观分析[J].吉林大学学报:工学版,2021,51(4):1269-1276. |

| Wei Hai-bin, Wang Xiang-yan, Wang Fu-yu, et al. Mechanical properties and micro analysis of AC-25 asphalt mixture based on vibration forming[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4):1269-1276. | |

| 18 | 洪亮,刘涛,杨三强.水泥稳定砾石骨料振动与击实成型对比试验[J].重庆交通大学学报:自然科学版,2014,33(6):63-67. |

| Hong Liang, Liu Tao, Yang San-qiang. Comparative experiment on vibrating compaction and modified proctor compaction of silt cement-stabilized gravel aggregate[J]. Journal of Chongqing Jiaotong University (Natural Science Edition), 2014, 33(6):63-67. | |

| 19 | Li P L, Ding Z, Zhang Z Q. Analysis of performance decay behavior for asphalt pavement based on aging[J]. Advanced Materials Research, 2013, 723:22-26. |

| 20 | 贾晓东,梁乃兴,赵毅,等.水-温-荷载耦合作用下沥青路面疲劳寿命预估[J].公路,2019,64(11):192-198. |

| Jia Xiao-dong, Liang Nai-xing, Zhao Yi, et al. Prediction on fatigue life of asphalt pavement under water-temperature-load coupling[J]. Highway, 2019, 64(11): 192-198. | |

| 21 | 张喜军,仝配配,蔺习雄,等.基于线性振幅扫描试验评价硬质沥青的疲劳性能[J].材料导报,2021,35(18):18083-18089. |

| Zhang Xi-jun, Tong Pei-pei, Lin Xi-xiong, et al. Fatigue characterization of hard petroleum asphalt based on the linear amplitude sweep test[J]. Materials Review, 2021, 35(18):18083-18089. | |

| 22 | 周亮,凌建明,林小平.考虑环境因素的沥青路面疲劳开裂预估模型[J].中国公路学报,2013,26(6):47-52. |

| Zhou Liang, Ling Jian-ming, Lin Xiao-ping. Prediction model for fatigue crack of asphalt pavement with environment factors considered[J]. China Journal of Highway and Transport, 2013, 26(6):47-52. | |

| 23 | 杨军,王昊鹏,廖辉.沥青混合料疲劳自愈性能关键影响因素[J].东南大学学报:自然科学版,2016,46(1):196-201. |

| Yang Jun, Wang Hao-peng, Liao Hui. Key influential factors of fatigue and self-healing properties of asphalt mixture[J]. Journal of Southeast University (Natural Science Edition), 2016, 46(1):196-201. | |

| 24 | 崔亚楠,郭靖,冯蕾,等.复杂环境因素影响下沥青混合料自愈合性能[J].建筑材料学报,2018,21(5):836-840. |

| Cui Ya-nan, Guo Jing, Feng Lei,et al. Self-healing properties of asphalt mixture under different factors[J]. Journal of Building Materials, 2018, 21(5):836-840. | |

| 25 | 彭勇,章秀芳,郭泽宇,等.离散元法分析集料接触特性对沥青混合料剪切疲劳寿命的影响[J].吉林大学学报:工学版,2023,53(1):178-187. |

| Peng Yong, Zhang Xiu-fang, Guo Ze-yu, et al. Influence of aggregate contact characteristics on shear fatigue life of asphalt mixtures using discrete element method[J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1):178-187. | |

| 26 | 张银生,马庆伟,蒋应军,等.成型方法对SMA-13沥青混合料技术性能的影响[J].公路,2022,67(7):380-387. |

| Zhang Yin-sheng, Ma Qing-wei, Jiang Ying-jun,et al. Effect of forming method on technical performance of SMA-13 asphalt mixture[J]. Highway, 2022, 67(7):380-387. | |

| 27 | 孙立军. 沥青路面结构行为理论[M].北京:人民交通出版社,2005. |

| 28 | 毕玉峰,孙立军. 沥青混合料抗剪试验方法研究[J]. 同济大学学报:自然科学版,2005,33(8):1036-1040. |

| Bi Yu-feng, Sun Li-jun. Research on test method of asphalt mixture's shearing properties[J]. Journal of Tongji University(Natural Science), 2005, 33(8): 1036-1040. | |

| 29 | Ayatollahi M R, Aliha M R M. Fracture parameters for cracked semi-circular specimen[J].International Journal of Rock Mechanics and Mining Sciences, 2004, 41(3): 1-5. |

| 30 | 曹轲铭. 沥青混合料半圆弯拉试验方法研究[D]. 长沙: 湖南大学土木工程学院, 2007. |

| Cao Ke-ming. Research on semi-circular bending test for asphalt mixtures[D]. Changsha: College of Civil Engineering, Hunan University, 2007. | |

| 31 | 邹桂莲,秦欢,吴欣.阿布森回收SBS改性沥青的试验研究[J].中外公路,2020,40(2):229-233. |

| Zou Gui-lian, Qin Huan, Wu Xin. Experimental study on recovery of SBS modified asphalt based on abson method[J]. Journal of China and Foreign Highway, 2020, 40(2):229-233. |

| [1] | 罗蓉,梁宇,牛茏昌,黄婷婷,苗强. 多温度条件沥青混合料水稳定性评价指标阈值[J]. 吉林大学学报(工学版), 2024, 54(7): 1966-1977. |

| [2] | 孙雅珍,薛博欣,孙岩,王志臣,潘嘉伟. 考虑非均匀性的沥青混合料开裂行为细观模拟[J]. 吉林大学学报(工学版), 2024, 54(6): 1708-1718. |

| [3] | 李祖仲,李梦园,刘卫东,庞萧萧,唐豪,张学磊,马晨杨. 蔗渣纤维表面改性及其沥青混合料路用性能[J]. 吉林大学学报(工学版), 2024, 54(6): 1738-1745. |

| [4] | 陈凯祥,张鹤年,席培胜,王长丹,余涛,张炳锌. 碳化湿度对碳化砌块力学与耐久性能的影响[J]. 吉林大学学报(工学版), 2024, 54(2): 445-452. |

| [5] | 金辰,曾孟源,吴荻非. 基于振动传递的水泥混凝土路面接缝损伤感知[J]. 吉林大学学报(工学版), 2023, 53(6): 1736-1745. |

| [6] | 朱俊清,赵学儒,马涛,黄晓明,朱洪洲. 基于卫星遥感的路域地质灾害监测方法[J]. 吉林大学学报(工学版), 2023, 53(6): 1861-1872. |

| [7] | 张阳,王傲鹏,张靖霖,马涛,陈思宇. 水泥稳定碎石材料干燥收缩研究综述[J]. 吉林大学学报(工学版), 2023, 53(2): 297-311. |

| [8] | 彭勇,章秀芳,郭泽宇,陆学元,李彦伟. 离散元法分析集料接触特性对沥青混合料剪切疲劳寿命的影响[J]. 吉林大学学报(工学版), 2023, 53(1): 178-187. |

| [9] | 刘聂玚子,荣鑫,刘洪海,边庆华,兰海. 沥青混合料的搅拌功率试验和黏度模型[J]. 吉林大学学报(工学版), 2023, 53(1): 220-225. |

| [10] | 何兆益,李金凤,周文,官志桃. 多孔沥青混合料的动态模量及其预估模型[J]. 吉林大学学报(工学版), 2022, 52(6): 1375-1385. |

| [11] | 郭庆林,刘强,吴春利,李黎丽,李懿明,刘富春. 导电沥青及混合料裂缝局部温度场及愈合效果[J]. 吉林大学学报(工学版), 2022, 52(6): 1386-1393. |

| [12] | 姚玉权,仰建岗,高杰,宋亮. 基于性能-费用模型的厂拌再生沥青混合料优化设计[J]. 吉林大学学报(工学版), 2022, 52(3): 585-595. |

| [13] | 汤东,韩宇彬,华伦,潘金冲,刘胜. 润滑油灰分对直喷汽油机颗粒捕集器性能影响[J]. 吉林大学学报(工学版), 2022, 52(11): 2501-2507. |

| [14] | 商拥辉,徐林荣,刘维正,蔡雨. 重载铁路改良土和A组填料过渡段的动力特性[J]. 吉林大学学报(工学版), 2021, 51(6): 2128-2136. |

| [15] | 董伟智,张爽,朱福. 基于可拓层次分析法的沥青混合料路用性能评价[J]. 吉林大学学报(工学版), 2021, 51(6): 2137-2143. |

|

||