吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (12): 3740-3754.doi: 10.13229/j.cnki.jdxbgxb.20230122

基于履带底盘的宽幅可折叠油菜割晒机设计及试验

李运通1( ),万星宇1,廖庆喜1,2,刘银垒1,张青松1,2,廖宜涛1,2(

),万星宇1,廖庆喜1,2,刘银垒1,张青松1,2,廖宜涛1,2( )

)

- 1.华中农业大学 工学院,武汉 430070

2.农业农村部长江中下游农业装备重点实验室,武汉 430070

Design and experiment of wide folding rape windrower based on crawler type power chassis

Yun-tong LI1( ),Xing-yu WAN1,Qing-xi LIAO1,2,Yin-lei LIU1,Qing-song ZHANG1,2,Yi-tao LIAO1,2(

),Xing-yu WAN1,Qing-xi LIAO1,2,Yin-lei LIU1,Qing-song ZHANG1,2,Yi-tao LIAO1,2( )

)

- 1.College of Engineering,Huazhong Agricultural University,Wuhan 430070,China

2.Key Laboratory of Agricultural Equipment in Mid-lower Reaches of The Yangtze River,Ministry of Agriculture and Rural Affairs,Wuhan 430070,China

摘要:

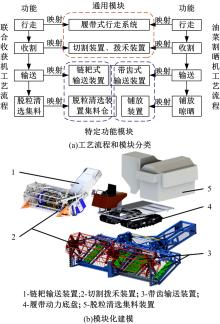

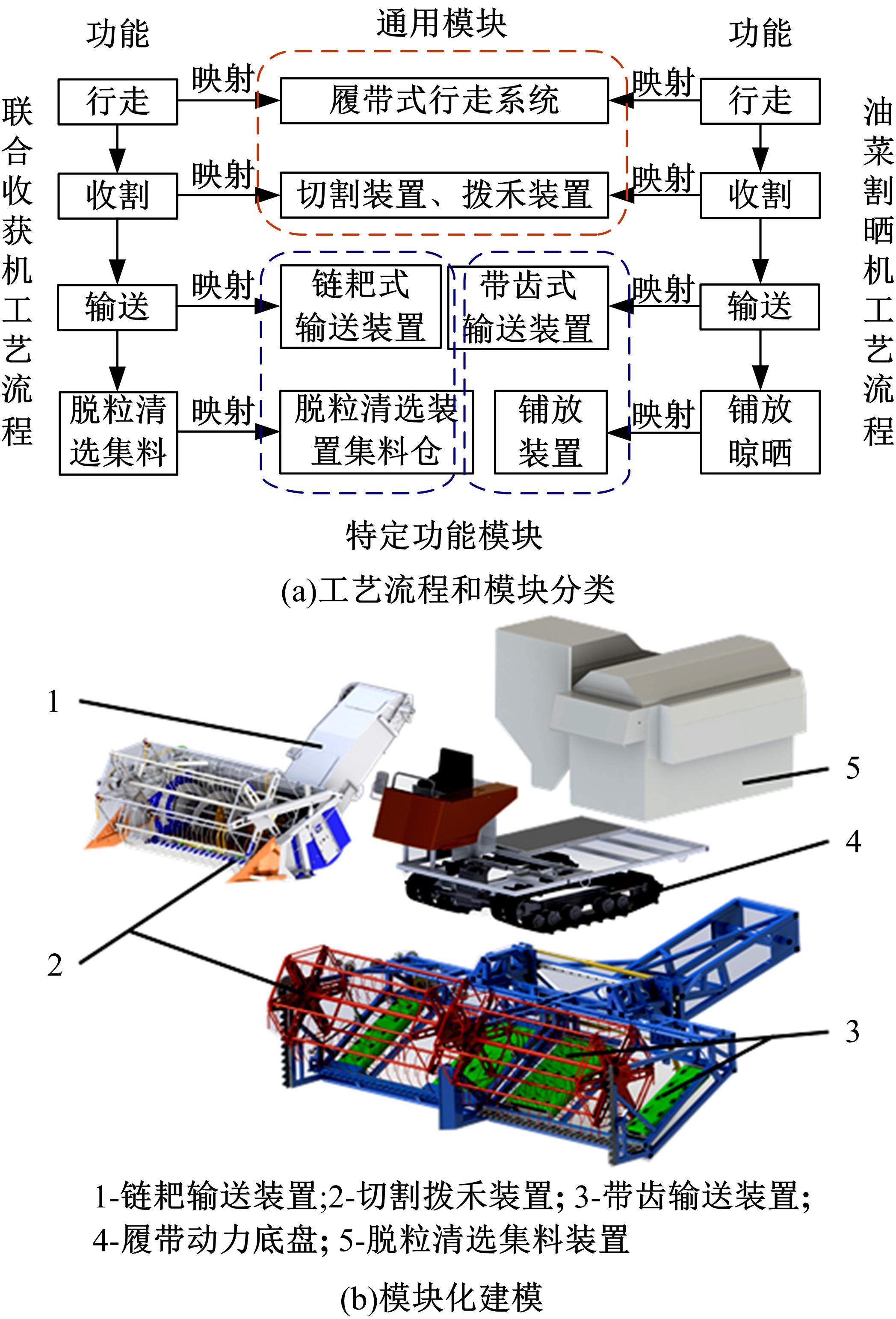

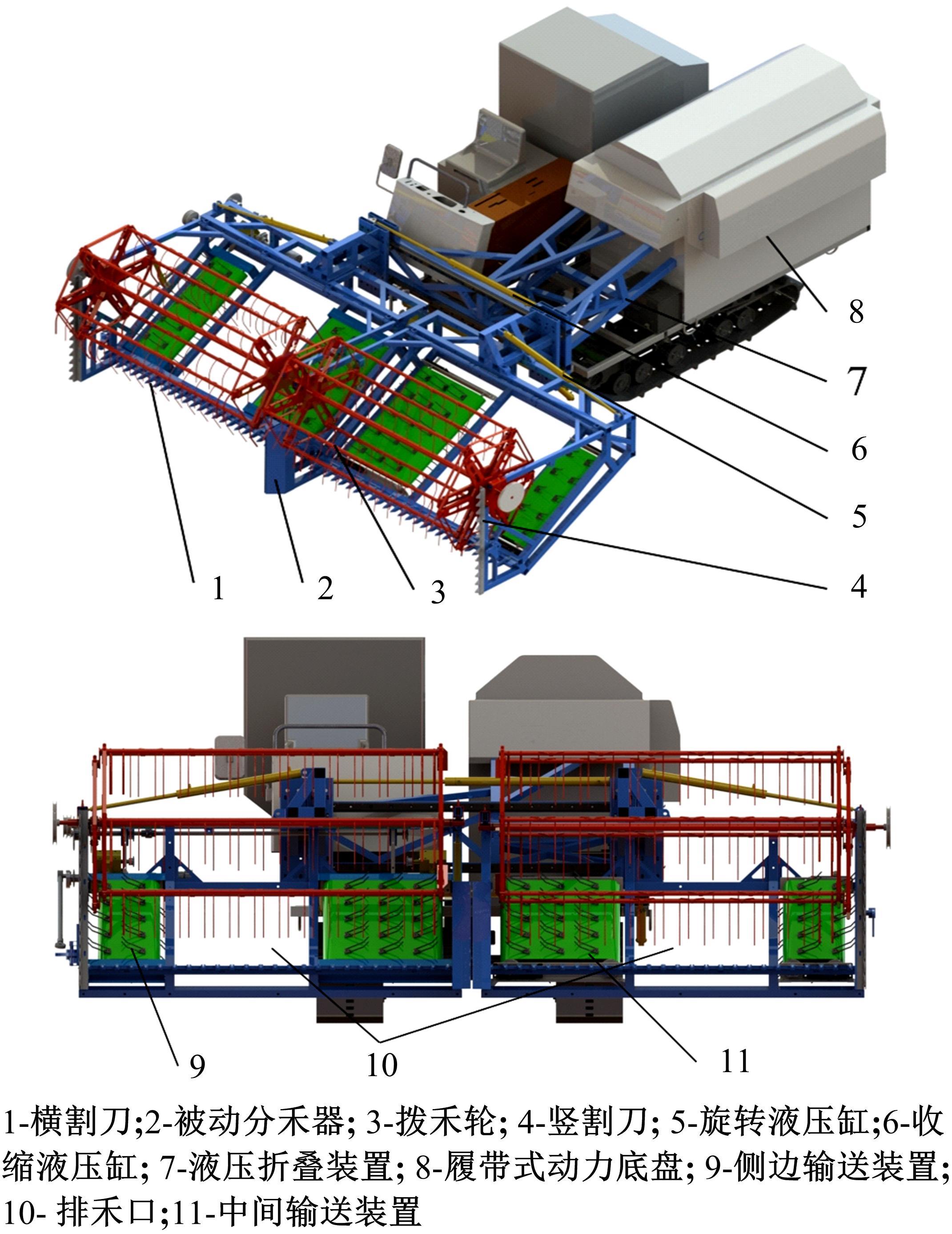

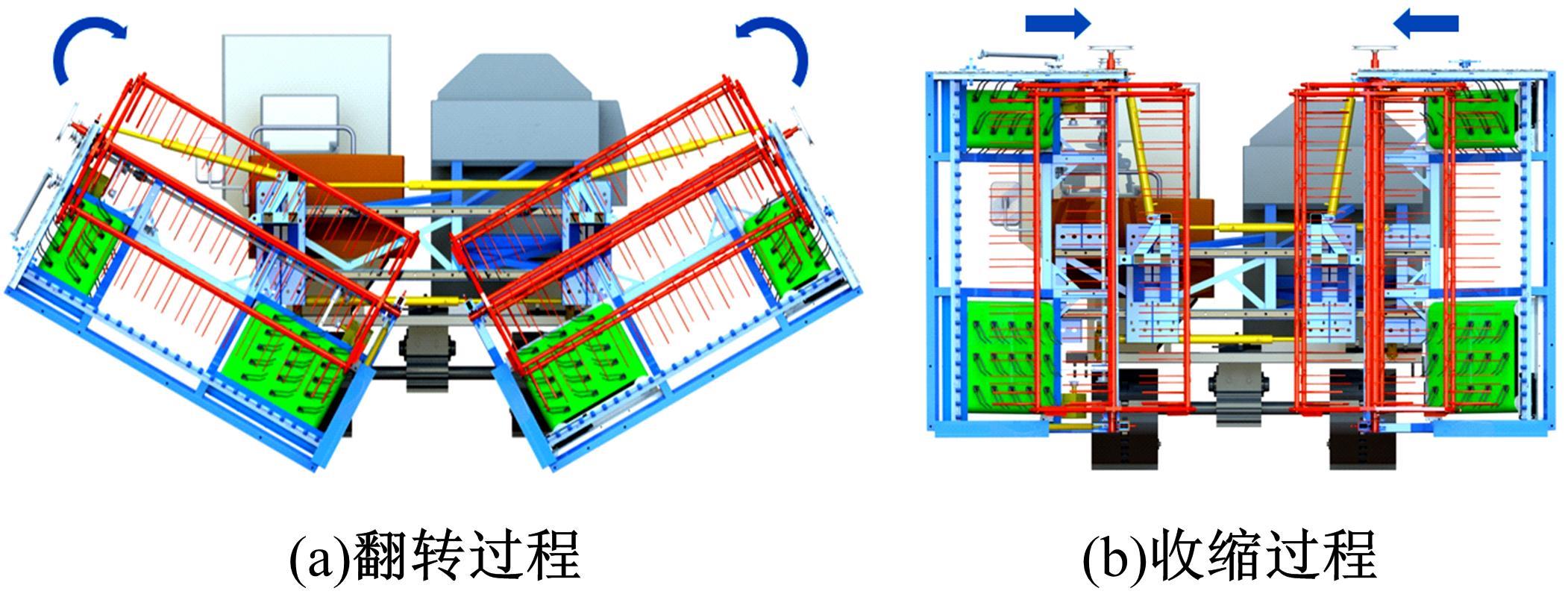

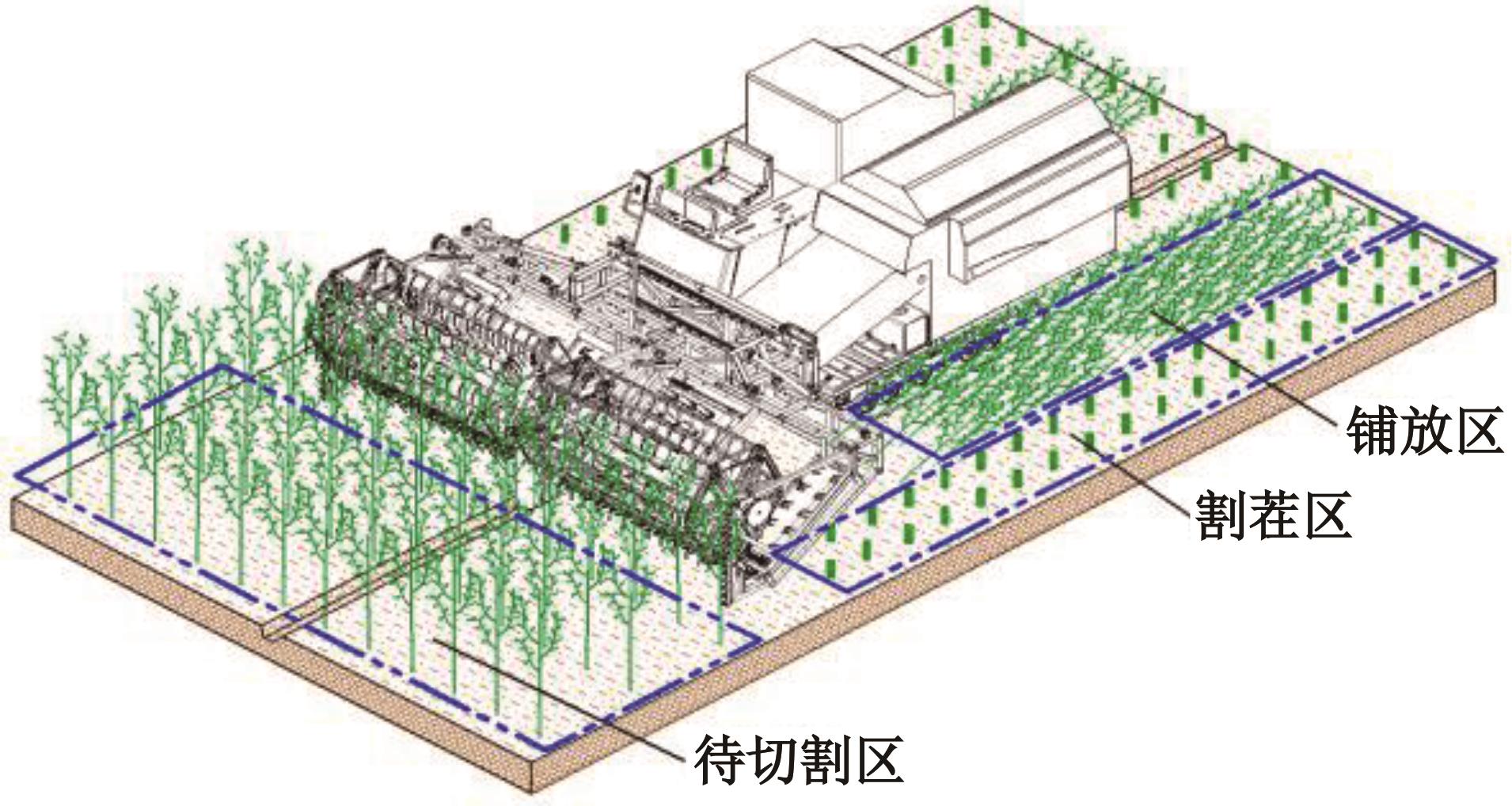

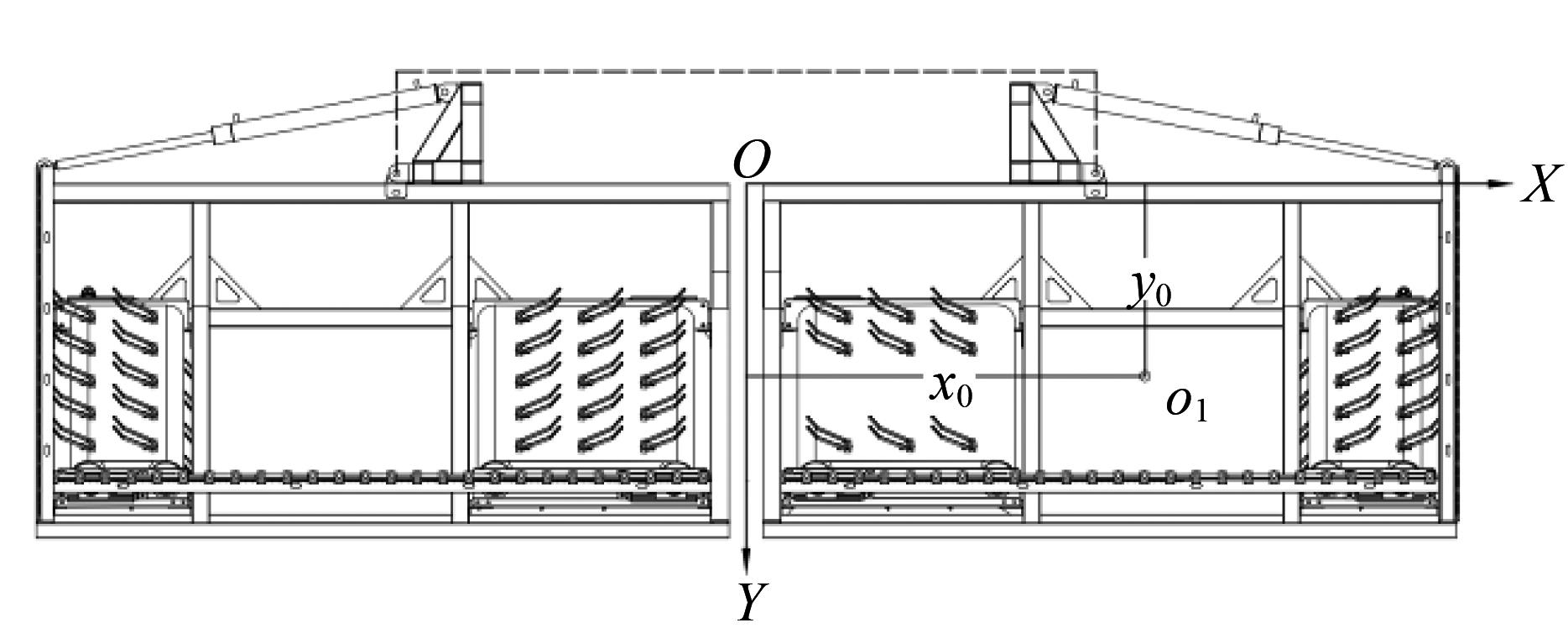

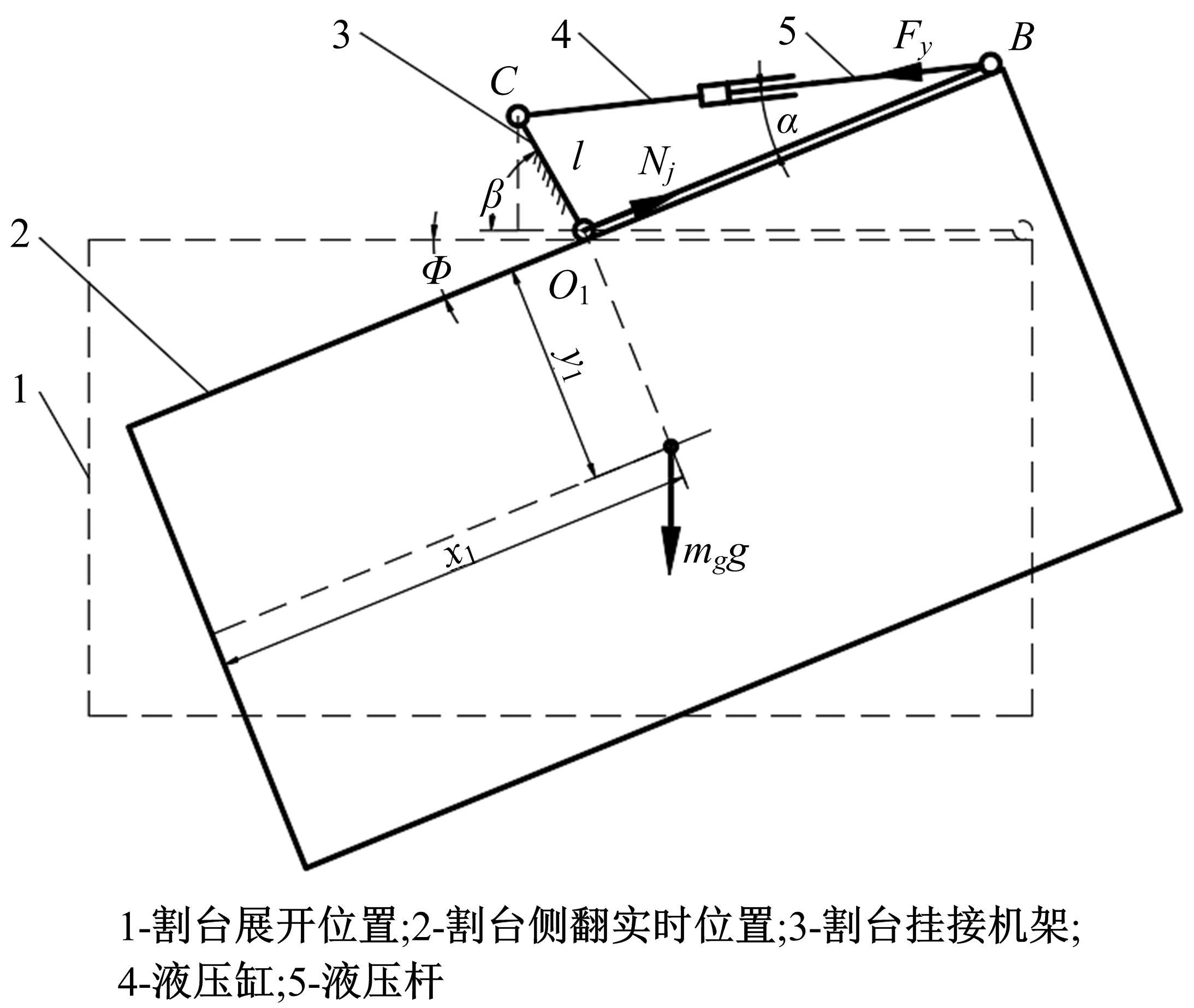

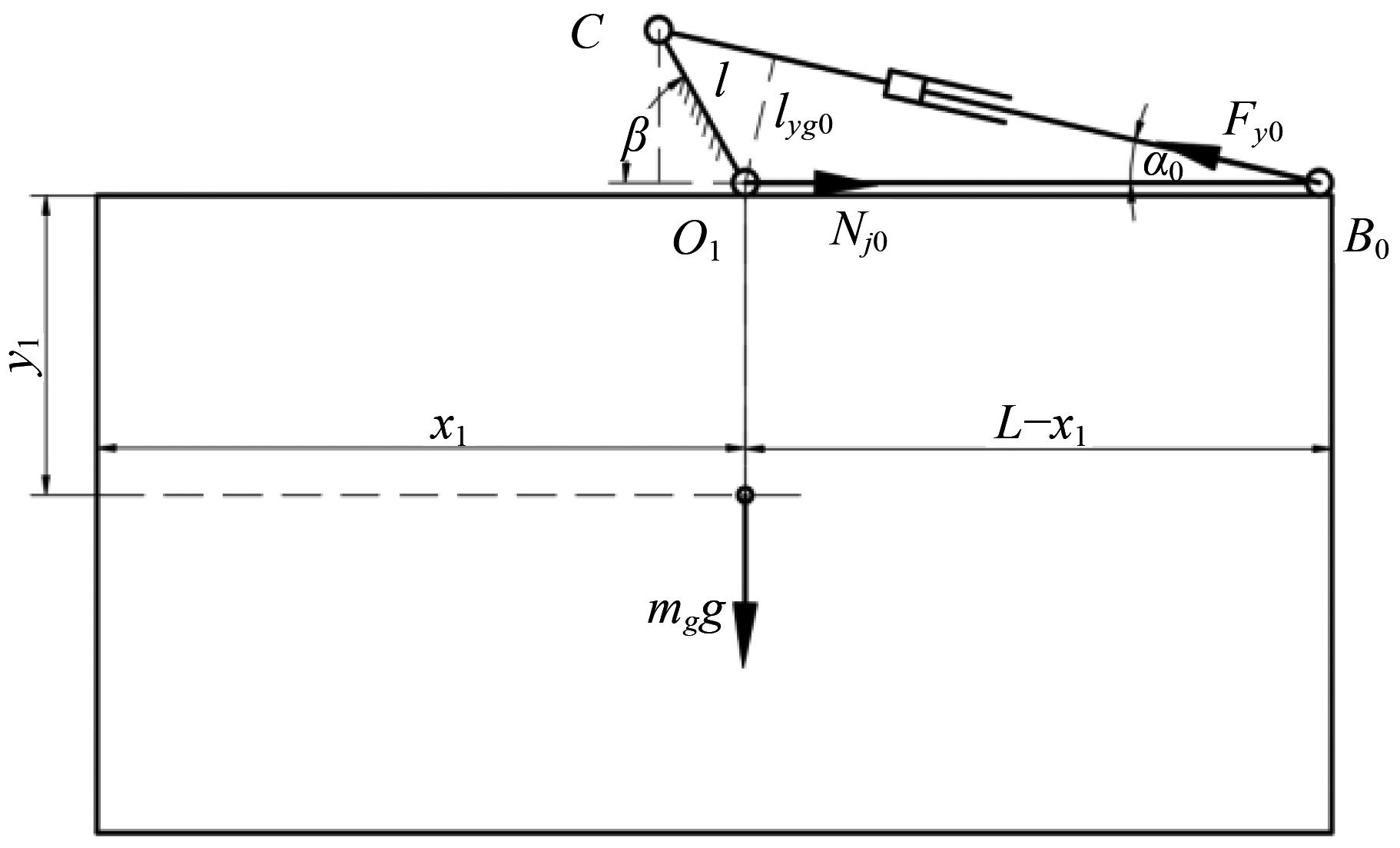

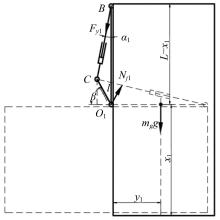

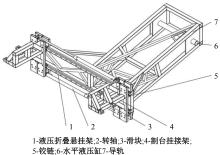

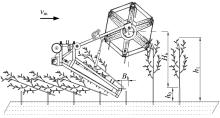

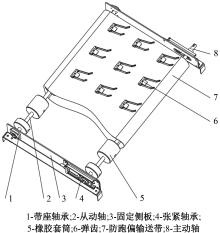

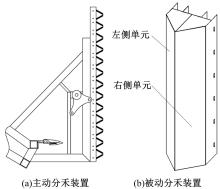

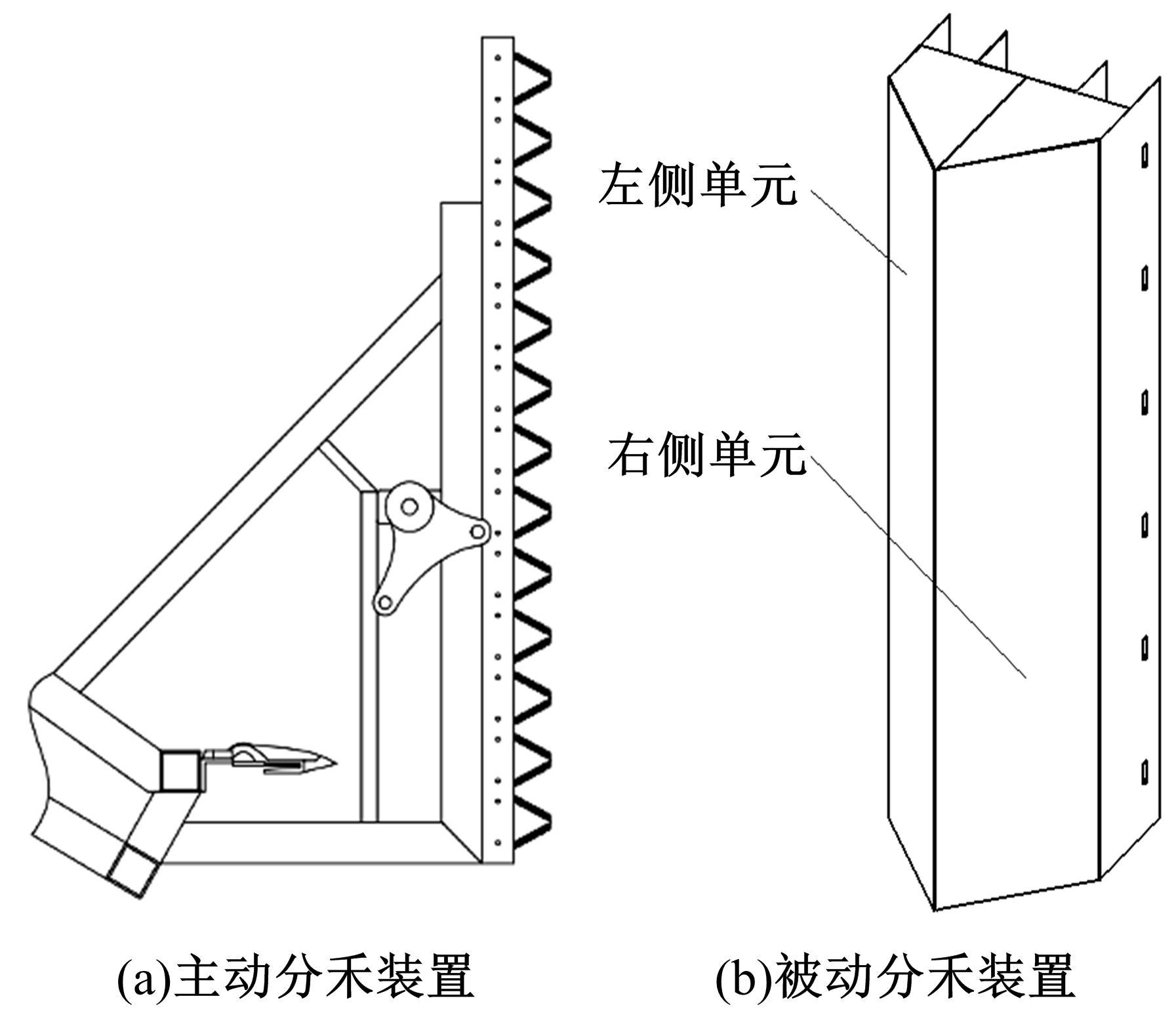

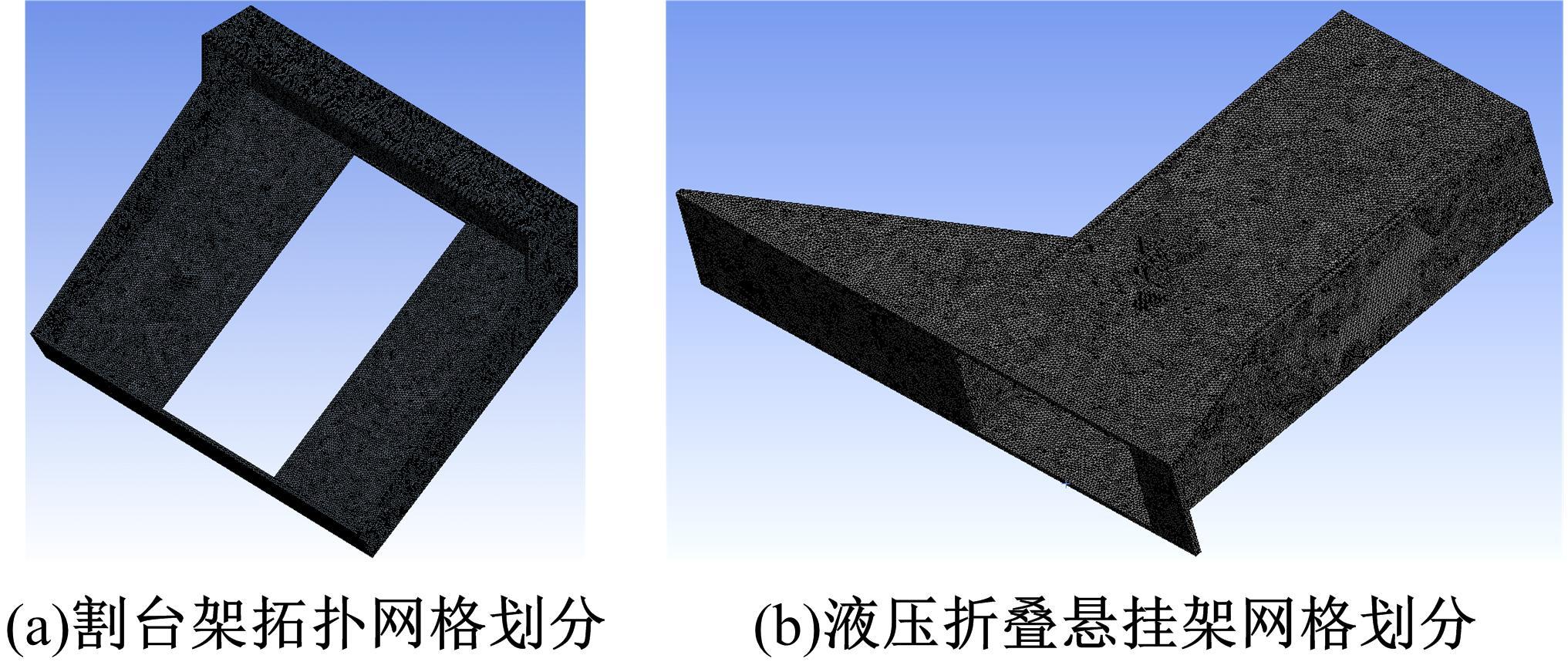

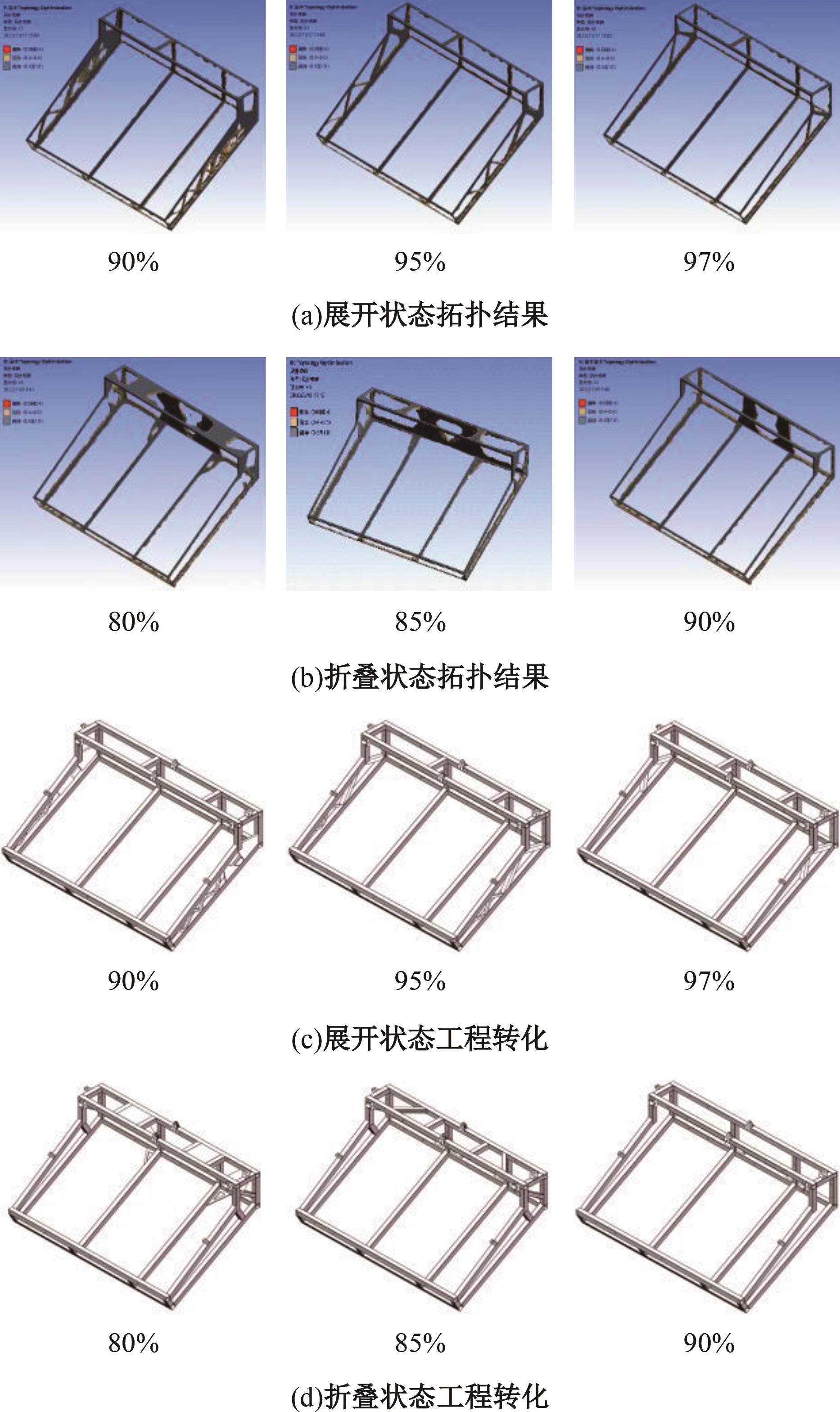

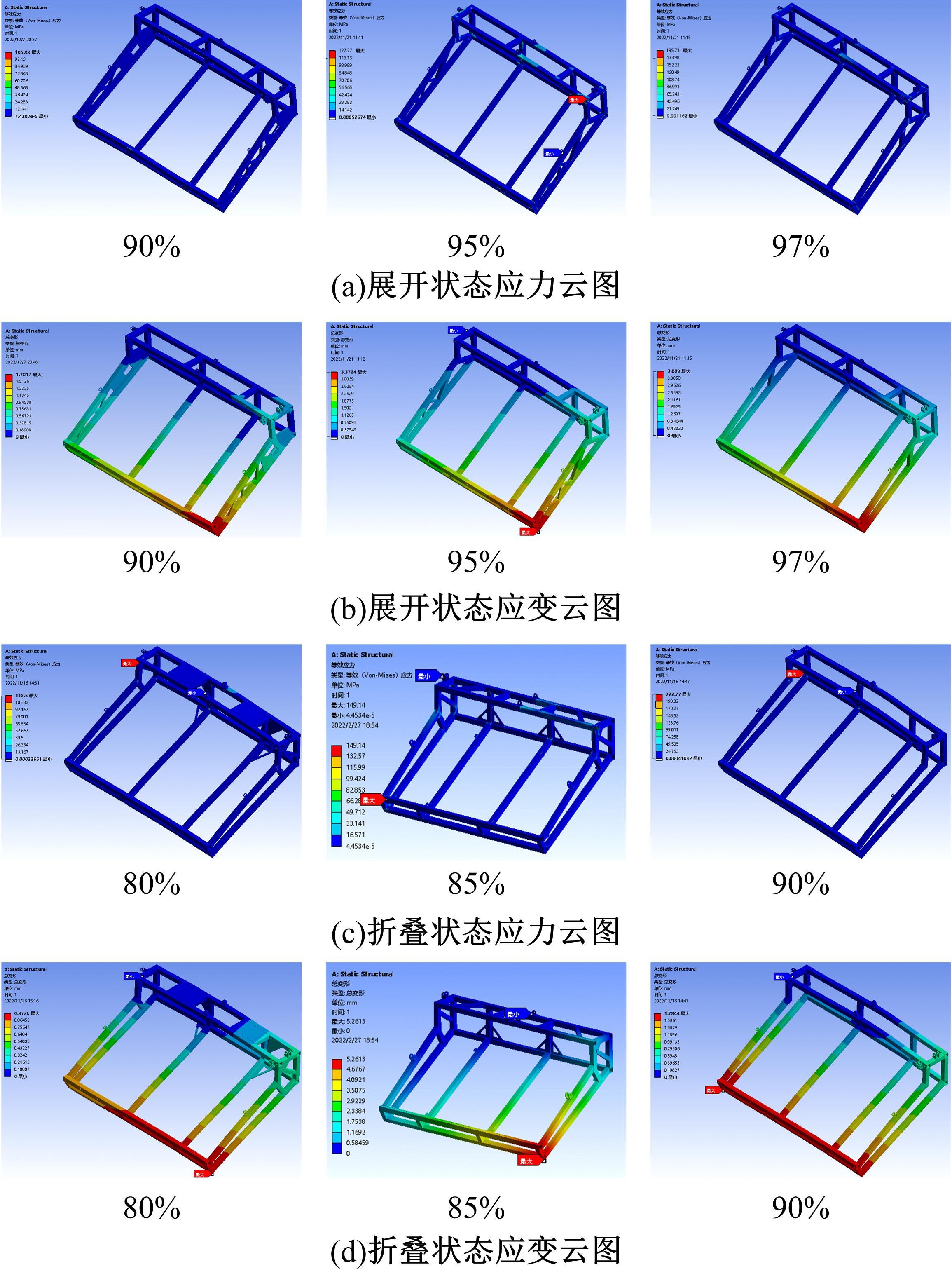

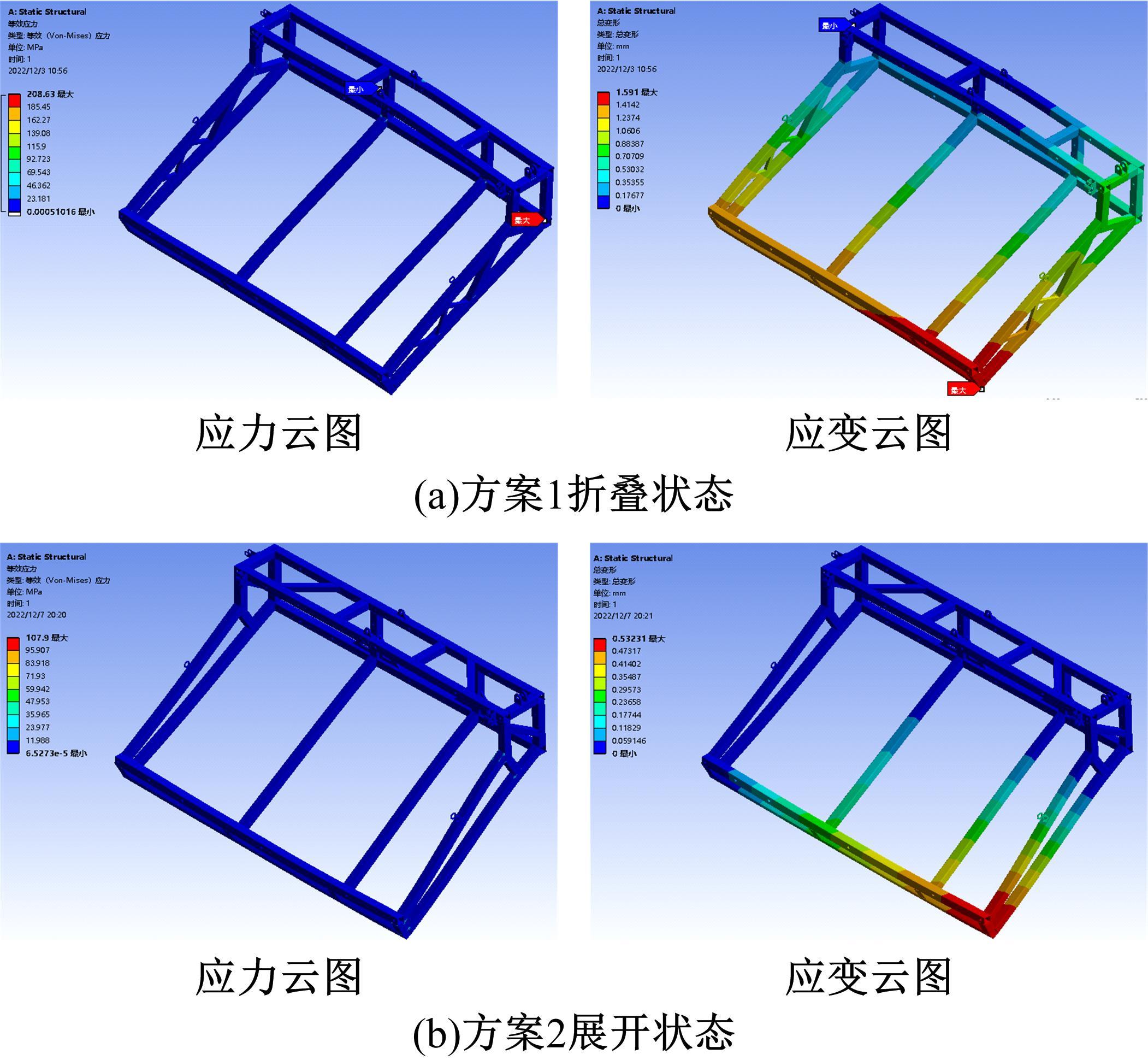

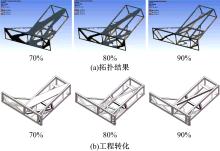

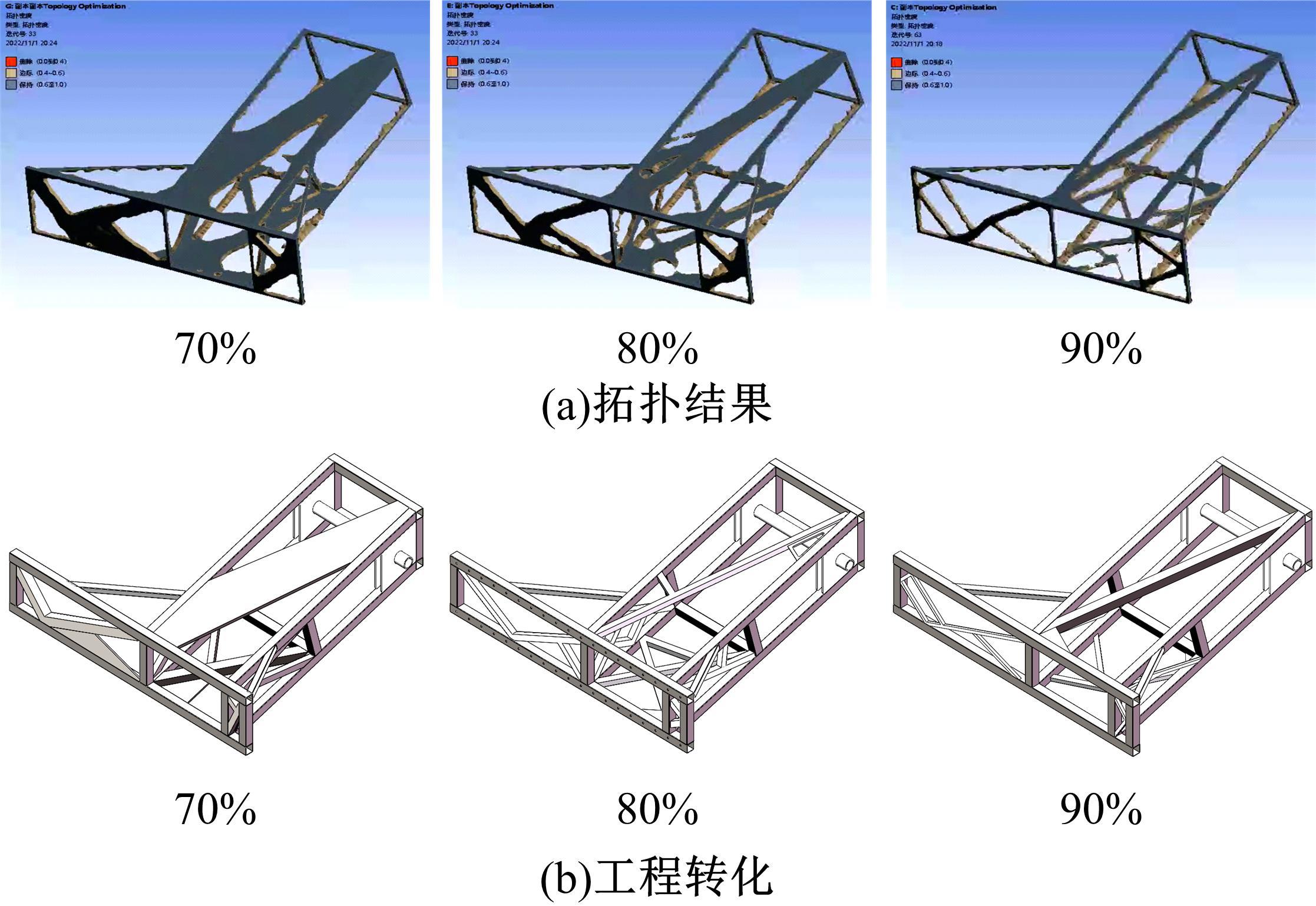

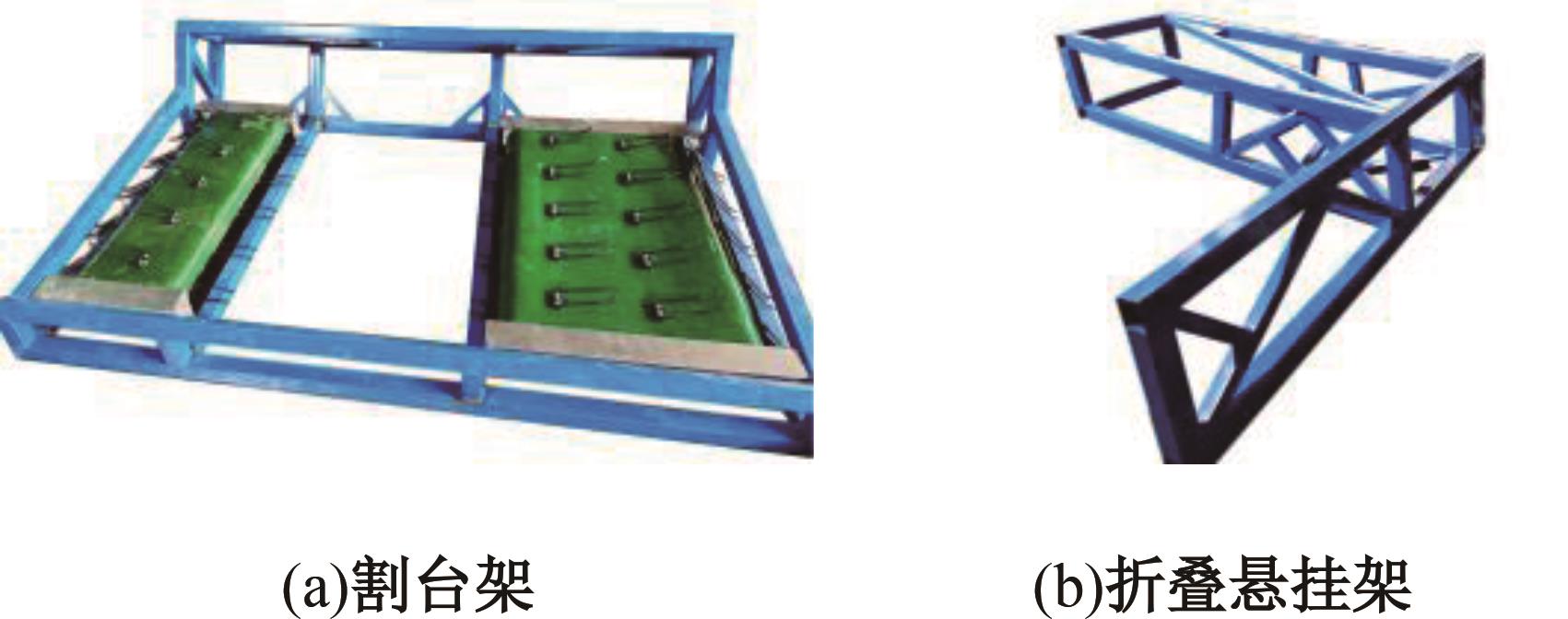

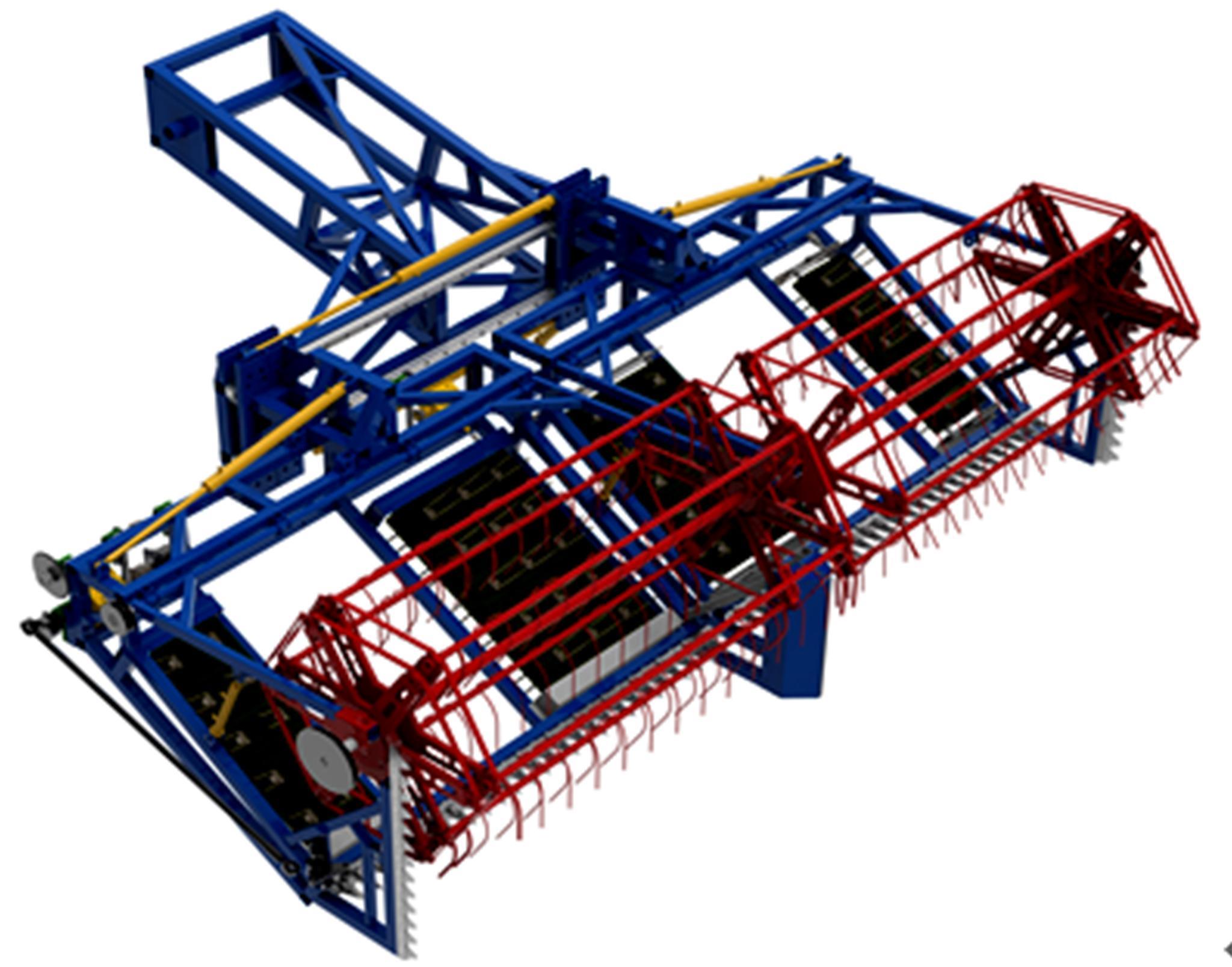

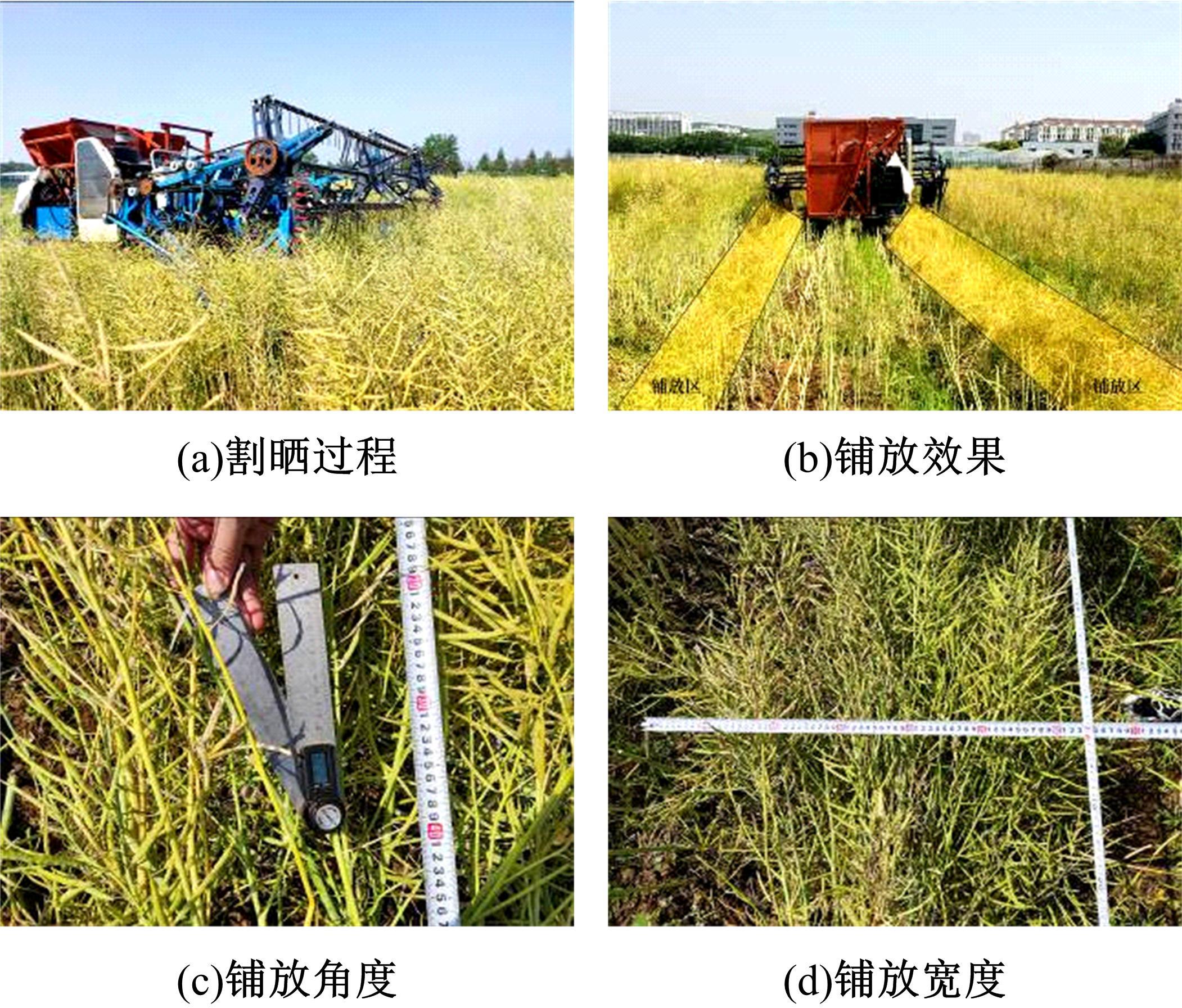

针对油菜机械化分段收获效率有待提升、专用底盘利用率不高的问题,结合我国联合收割机履带式动力底盘保有量大的优势,设计了一款基于履带底盘的宽幅可折叠油菜割晒机。采用模块化设计方法,开展油菜割晒机的整体设计。提出了“先旋转-再收缩”的宽幅割台折叠方案,实现宽幅可折叠割台与常规收割机底盘配套。基于动力学与运动学分析得到割台折叠位置参数与折叠液压缸负载之间的关系,确定割台旋转点为割台架上边框距离两割台对称面950 mm处,液压缸收缩行程为700 mm。分析确定了拨禾轮、割刀、输送装置的结构和工作参数。阐明割台架与液压折叠悬挂架的载荷和约束,开展了割台展开、折叠状态的静力学分析和拓扑优化结构设计,以应力应变最小为优化目标,经对比评估,采用割台架和悬挂架初始模型材料去除率分别为85%、80%的工程化方案试制样机并开展田间试验。田间试验结果表明:割晒机割台折叠顺畅、运行平稳,割晒后油菜平均铺放角为24.4°,铺放角度差为8.52°,各项指标均满足割晒机田间转移要求和作业质量标准。该研究可为收获机具折叠割台的结构设计优化提供参考。

中图分类号:

- S223.2

| 1 | 汪波, 宋丽君, 王宗凯, 等. 我国饲料油菜种植及应用技术研究进展[J]. 中国油料作物学报, 2018, 40(5): 695-701. |

| Wang Bo, Song Li-jun, Wang Zong-kai, et al. Production and feeding technology of fodder-rapeseed in China[J]. Chinese Journal of Oil Crop Sciences, 2018, 40(5): 695-701. | |

| 2 | 张哲, 殷艳, 刘芳, 等. 我国油菜多功能开发利用现状及发展对策[J]. 中国油料作物学报, 2018, 40(5): 618-623. |

| Zhang Zhe, Yin Yan, Liu Fang, et al. Current situation and development countermeasures of Chinese rapeseed multifunction development and utilization[J]. Chinese Journal of Oil Crop Sciences, 2018, 40(5): 618-623. | |

| 3 | 吴崇友, 丁为民, 石磊, 等. 油菜分段收获捡拾脱粒机捡拾损失响应面分析[J]. 农业机械学报, 2011, 42(8): 89-93. |

| Wu Chong-you, Ding Wei-min, Shi Lei, et al. Response surface analysis of pickup losses in two-stage harvesting for rapeseed[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(8): 89-93. | |

| 4 | 万星宇, 廖庆喜, 廖宜涛, 等. 油菜全产业链机械化智能化关键技术装备研究现状及发展趋势[J]. 华中农业大学学报, 2021, 40(2): 24-44. |

| Wan Xing-yu, Liao Qing-xi, Liao Yi-tao, et al. Situation and prospect of key technology and equipment in mechanization and intelligentization of rapeseed whole industry chain[J]. Journal of Huazhong Agricultural University, 2021, 40(2): 24-44. | |

| 5 | 刘德军, 赵秀荣, 高连兴, 等. 不同收获方式含水率对油菜收获物流损失的影响[J]. 农业工程学报, 2011, 27(10): 339-342. |

| Liu De-jun, Zhao Xiu-rong, Gao Lian-xing, et al. Effect of moisture content on rape harvest logistics losses under different harvest methods[J]. Transactions of the CSAE, 2011, 27(10): 339-342. | |

| 6 | 关卓怀, 江涛, 李海同, 等. 倾斜输送式油菜割晒机铺放质量分析与试验[J]. 农业工程学报, 2021, 37(4): 59-68. |

| Guan Zhuo-huai, Jiang Tao, Li Hai-tong, et al. Analysis and test of the laying quality of inclined transportation rape windrower[J]. Transactions of the CSAE, 2021, 37(4): 59-68. | |

| 7 | 万星宇, 舒彩霞, 廖庆喜, 等. 高地隙履带自走式中间条铺油菜割晒机设计与试验[J]. 农业机械学报, 2022, 53(9): 109-121. |

| Wan Xing-yu, Shu Cai-xia, Liao Qing-xi, et al. Design and experiment of self-propelled middle-placement rape windrower[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(9): 109-121. | |

| 8 | 陈延鑫. 玉米收获机折叠式割台的试验与研究[D]. 淄博:山东理工大学农业工程与食品科学学院, 2012. |

| Chen Yan-xin. Experiment and research on the foldable header of corn harvester[D]. Zibo: College of Agricultural Engineering and Food Science, Shandong University of Technology, 2012. | |

| 9 | 陈延鑫, 张道林, 许振冻, 等. 折叠式玉米收获机割台的试验[J]. 农机化研究, 2013, 35(2): 117-120. |

| Chen Yan-xin, Zhang Dao-lin, Xu Zhen-dong, et al. Experiment of the foldable header of corn harvester[J]. Journal of Agricultural Mechanization Research, 2013, 35(2): 117-120. | |

| 10 | 廖中源, 王英俊, 王书亭. 基于拓扑优化的变密度点阵结构体优化设计方法[J]. 机械工程学报, 2019, 55(8): 65-72. |

| Liao Zhong-yuan, Wang Ying-jun, Wang Shu-ting. Graded-density lattice structure optimization design based on topology optimization[J]. Journal of Mechanical Engineering, 2019, 55(8): 65-72. | |

| 11 | 张明, 刘文斌, 李闯, 等. 优化驱动的起落架结构设计方法[J]. 航空学报, 2015, 36(3): 857-864. |

| Zhang Ming, Liu Wen-bin, Li Chuang, et al. Optimization-driven design method of landing gear structure[J]. Acta Aeronautica Et Astronautica Sinica, 2015, 36(3): 857-864. | |

| 12 | 李天箭, 丁晓红, 李郝林. 机床结构轻量化设计研究进展[J]. 机械工程学报, 2020, 56 (21): 186-198. |

| Li Tian-jian, Ding Xiao-hong, Li Hao-lin. Research progress on lightweight design of machine tool structure[J]. Journal of Mechanical Engineering, 2020, 56 (21): 186-198. | |

| 13 | 才胜, 罗颖辉, 李青林. 农业机械轻量化技术研究现状与发展趋势[J]. 机械工程学报, 2021, 57(17): 35-52. |

| Cai Sheng, Luo Ying-hui, Li Qing-lin. State of the art of lightweight technology in agricultural machinery and its development trend[J]. Journal of Mechanical Engineering, 2021, 57(17): 35-52. | |

| 14 | 吴伟斌, 廖劲威, 洪添胜, 等. 山地果园轮式运输机车架结构分析与优化[J]. 农业工程学报, 2016, 32(11): 39-47. |

| Wu Wei-bin, Liao Jing-wei, Hong Tian-sheng, et al. Analysis and optimization of frame structure for wheeled transporter in hill orchard[J]. Transactions of the CSAE, 2016, 32(11): 39-47. | |

| 15 | 谢斌, 温昌凯, 杨子涵, 等. 基于实测载荷的蔬菜田间动力机械车架结构优化[J]. 农业机械学报, 2018, 49(): 463-469. |

| Xie Bin, Wen Chang-kai, Yang Zi-han, et al. Structure optimization of frame for field vegetable power machinery based on measured load data[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(Sup.): 463-469. | |

| 16 | 中华人民共和国交通部. 超限运输车辆行驶公路管理规定[J]. 中华人民共和国国务院公报, 2000(23): 33-36. |

| 17 | 李平, 廖庆喜, 李磊, 等. 4SY-1.8改进型油菜割晒机主要装置设计与试验[J]. 农业机械学报, 2014, 45(1): 53-58. |

| Li Ping, Liao Qing-xi, Li Lei, et al. Design and experiment of the main device of 4SY-1.8 modified rape windrower[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(1): 53-58. | |

| 18 | 王伟, 吕晓兰, 王士林, 等. 茎叶类蔬菜机械化收获技术研究现状与发展[J]. 中国农业大学学报, 2021, 26(4): 117-127. |

| Wang Wei, Xiao-lan Lyu, Wang Shi-lin, et al. Current status and development of stem and leaf vegetable mechanized harvesting technology[J]. Journal of China Agricultural University, 2021, 26(4): 117-127. | |

| 19 | 李海同, 吴崇友, 沐森林, 等. 基于ANSYS-ADAMS的立式油菜割晒机铺放角形成机理[J]. 农业工程学报, 2020, 36(14): 96-105. |

| Li Hai-tong, Wu Chong-you, Mu Sen-lin, et al. Formation mechanism of laying angle of vertical rape windrower based on ANSYS-ADAMS[J]. Transactions of the CSAE, 2020, 36(14): 96-105. | |

| 20 | 廖宜涛, 廖庆喜, 周宇, 等. 饲料油菜薹期收获茎秆破碎离散元仿真参数标定[J]. 农业机械学报, 2020, 51(6): 73-82. |

| Liao Yi-tao, Liao Qing-xi, Zhou Yu, et al. Parameters calibration of discrete element model of fodder rape crop harvest in bolting stage[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(6): 73-82. | |

| 21 | 李仲恺, 谢方平, 刘科, 等. 油菜收获圆盘式切割器的设计与性能试验[J]. 湖南农业大学学报:自然科学版, 2014, 40(1): 83-88. |

| Li Zhong-kai, Xie Fang-ping, Liu Ke, et al. Design and performance evaluation of a disc cutter for rape harvest[J]. Journal of Hunan Agricultural University(Natural Sciences), 2014, 40(1): 83-88. | |

| 22 | 廖宜涛, 陈传节, 舒彩霞, 等. 4SY-1.8型手扶式油菜割晒机设计与试验[J]. 农业机械学报, 2014, 45(): 94-100. |

| Liao Yi-tao, Chen Chuan-jie, Shu Cai-xia, et al. Design and experiment of 4SY-1.8 rape walking windrower[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(Sup.1): 94-100. | |

| 23 | 李平, 廖庆喜, 舒彩霞, 等. 油菜割晒机茎秆铺放质量的故障成因分析与参数匹配研究[J]. 应用基础与工程科学学报, 2016, 24(1): 197-209. |

| Li Ping, Liao Qing-xi, Shu Cai-xia, et al. Fault analysis of stem windrowing quality and parameters match on the rape windrower[J]. Journal of Basic Science and Engineering, 2016, 24(1): 197-209. | |

| 24 | 金文明, 李华军, 寇淑清, 等. 装配式凸轮轴悬臂式数控装配机的机架模态分析[J]. 吉林大学学报:工学版, 2009, 39(): 319-323. |

| Jin Wen-ming, Li Hua-jun, Kou Shu-qing, et al. Modal analysis of frame of cantilever NC assembling machine for assembled camshaft[J]. Journal of Jilin University (Engineering and Technology Edition) 2009, 39(Sup.2): 319-323. | |

| 25 | 汪泉, 陈进, 王君, 等. 气动载荷作用下复合材料风力机叶片结构优化设计[J]. 机械工程学报, 2014, 50(9): 114-121. |

| Wang Quan, Chen Jin, Wang Jun, et al. Structural optimization of composite wind turbine blade under aerodynamic loads[J]. Journal of Mechanical Engineering, 2014, 50(9): 114-121. | |

| 26 | 张娜娜, 赵匀, 刘宏新. 高速水稻插秧机车架的轻量化设计[J]. 农业工程学报, 2012, 28(3): 55-59. |

| Zhang Na-na, Zhao Yun, Liu Hong-xin. Light design of frame for self-propelled chassis rice transplanter[J]. Transactions of the CSAE, 2012, 28(3): 55-59. | |

| 27 | 邱白晶, 何耀杰, 盛云辉, 等. 喷雾机喷杆有限元模态分析与结构优化[J]. 农业机械学报, 2014, 45(8): 112-116. |

| Qiu Bai-jing, He Yao-jie, Sheng Yun-hui, et al. Finite element modal analysis and structure optimization of spray boom[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(8): 112-116. | |

| 28 | 廖庆喜, 何坤, 万星宇, 等. 履带联合收获机式动力平台油菜直播机设计与试验[J]. 农业机械学报, 2021, 52(12): 54-64. |

| Liao Qing-xi, He Kun, Wan Xing-yu, et al. Devices for rapeseed direct seeder on tracked combined harvesting power platform[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(12): 54-64. | |

| 29 | 王利鹤, 赵永来, 崔红梅, 等. 基于ANSYS Workbench的深松机机架静力学分析及轻量化设计[J]. 重庆理工大学学报:自然科学, 2019,33(2): 87-93. |

| Wang Li-he, Zhao Yong-lai, Cui Hong-mei, et al. Static analysis and lightweight design of subsoiler frame based on ANSYS Workbench[J]. Journal of Chongqing University of Technology(Natural Science), 2019, 33(2): 87-93. | |

| 30 | 李耀明, 孙朋朋, 庞靖, 等. 联合收获机底盘机架有限元模态分析与试验[J]. 农业工程学报, 2013, 29(3): 38-46. |

| Li Yao-ming, Sun Peng-peng, Pang Jing, et al. Finite element mode analysis and experiment of combine harvester chassis[J]. Transactions of the CSAE, 2013, 29(3): 38-46. | |

| 31 | 金诚谦, 尹文庆, 吴崇友. 4SY-2型油菜割晒机铺放质量数学模型与影响因素分析[J]. 农业工程学报, 2012, 28(2): 45-48. |

| Jin Cheng-qian, Yin Wen-qing, Wu Chong-you. Mathematical model and influencing factors analysis for windrow quality of 4SY-2 rape windrower[J]. Transactions of the CSAE, 2012, 28(2): 45-48. | |

| 32 | 金诚谦, 尹文庆, 吴崇友. 油菜割晒机拨指输送链式输送装置研制与试验[J]. 农业工程学报, 2013, 29(21): 11-18. |

| Jin Cheng-qian, Yin Wen-qing, Wu Chong-you. Development and experiment of rape windrower transportation device with poke finger conveyor chain[J]. Transactions of the CSAE, 2013, 29(21): 11-18. |

| [1] | 杨欣,刘玉肖,王阳,陈春皓,吕林硕. 果园多风管喷雾机风送系统流场仿真和试验[J]. 吉林大学学报(工学版), 2024, 54(9): 2723-2732. |

| [2] | 顿国强,吴星澎,纪欣鑫,张福利,纪文义,朱礼贵. 玉米条带摆管式撒肥装置设计及试验[J]. 吉林大学学报(工学版), 2024, 54(9): 2697-2707. |

| [3] | 王琛,雒特,惠倩倩,王忠昊,王方方. 面向分体式飞行汽车对接锁定的机电系统设计与验证[J]. 吉林大学学报(工学版), 2024, 54(8): 2130-2140. |

| [4] | 舒彩霞,杨佳,廖庆喜,万星宇,袁佳诚. 油菜联合收获导流式双筒旋风分离清选装置设计及试验[J]. 吉林大学学报(工学版), 2024, 54(6): 1807-1820. |

| [5] | 张国忠,丁凯权,李正博,陈龙,唐楠锐,刘婉茹,黄海东,周勇,王洪昌. 基于泥鳅体表的水稻直播机仿生滑板设计与试验[J]. 吉林大学学报(工学版), 2024, 54(5): 1482-1492. |

| [6] | 张伏,娄立民,钱丹,王世强,冯春凌,赵一荣. 大方捆打捆机压缩机构优化设计及试验[J]. 吉林大学学报(工学版), 2024, 54(4): 1166-1174. |

| [7] | 余建星,韦明秀,余杨,崔宇朋,潘宇. 加筋板结构可靠性拓扑优化与工程化设计[J]. 吉林大学学报(工学版), 2024, 54(10): 2781-2791. |

| [8] | 周焕林,郭鑫,王选,方立雪,龙凯. 考虑几何非线性的多相多孔结构拓扑优化设计[J]. 吉林大学学报(工学版), 2024, 54(10): 2754-2763. |

| [9] | 周鹏飞,陈学庚,蒙贺伟,梁荣庆,张炳成,坎杂. 滚筒式机收膜杂除土装置设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2718-2731. |

| [10] | 刘伟健,罗锡文,曾山,文智强,曾力. 履带式再生稻收获机田间转弯机理和性能试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2695-2705. |

| [11] | 张茂健,金敬福,陈奕颖,陈廷坤. 轮式拖拉机对称结构的振动特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2136-2142. |

| [12] | 朱光强,李天宇,周福君,王文明. 鲜食玉米仿生摘穗装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1231-1244. |

| [13] | 孙舒杨,程玮斌,张浩桢,邓向萍,齐红. 基于深度学习的两阶段实时显式拓扑优化方法[J]. 吉林大学学报(工学版), 2023, 53(10): 2942-2951. |

| [14] | 顿国强,刘文辉,毛宁,吴星澎,纪文义,马洪岩. 交替换岗式大豆小区育种排种器优化设计与试验[J]. 吉林大学学报(工学版), 2023, 53(1): 285-296. |

| [15] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

|