吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (10): 2754-2763.doi: 10.13229/j.cnki.jdxbgxb.20221624

• 车辆工程·机械工程 • 上一篇

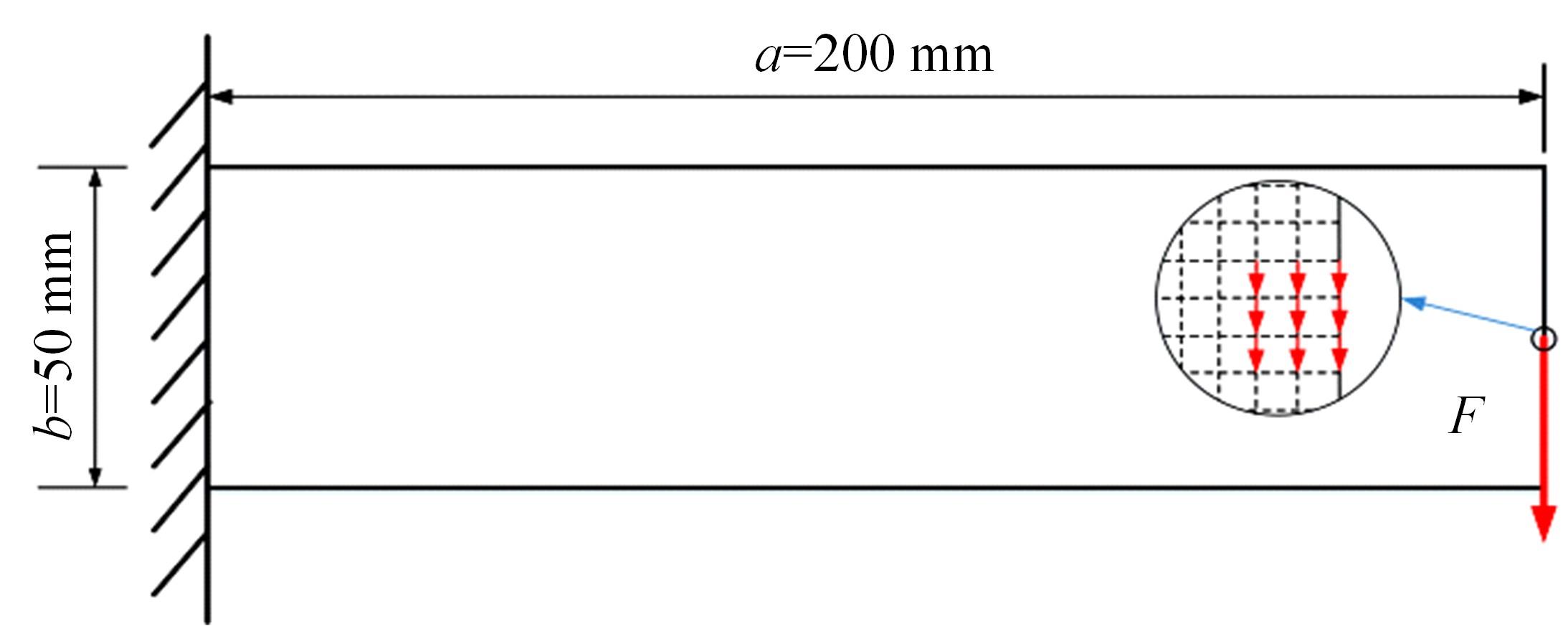

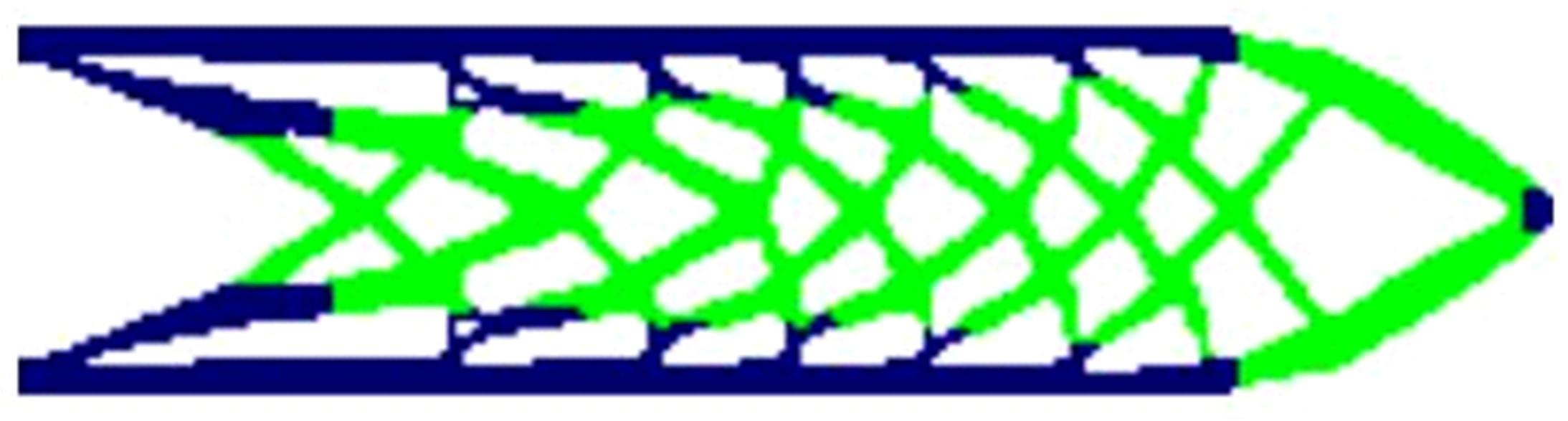

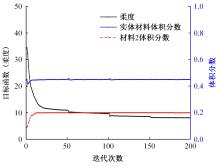

考虑几何非线性的多相多孔结构拓扑优化设计

- 1.合肥工业大学 土木与水利工程学院,合肥 230009

2.天津大学 机械工程学院,天津 300072

3.华北电力 大学 新能源电力系统国家重点实验室,北京 102206

Topology optimization design of multiphase porous structures considering geometric nonlinearity

Huan-lin ZHOU1( ),Xin GUO1,Xuan WANG1,2(

),Xin GUO1,Xuan WANG1,2( ),Li-xue FANG1,Kai LONG3

),Li-xue FANG1,Kai LONG3

- 1.College of Civil Engineering,Hefei University of Technology,Hefei 230009,China

2.School of Mechanical Engineering,Tianjin University,Tianjin 300072,China

3.State Key Laboratory for Alternate Electrical Power System with Renewable Energy Sources,North China Electric Power University,Beijing 102206,China

摘要:

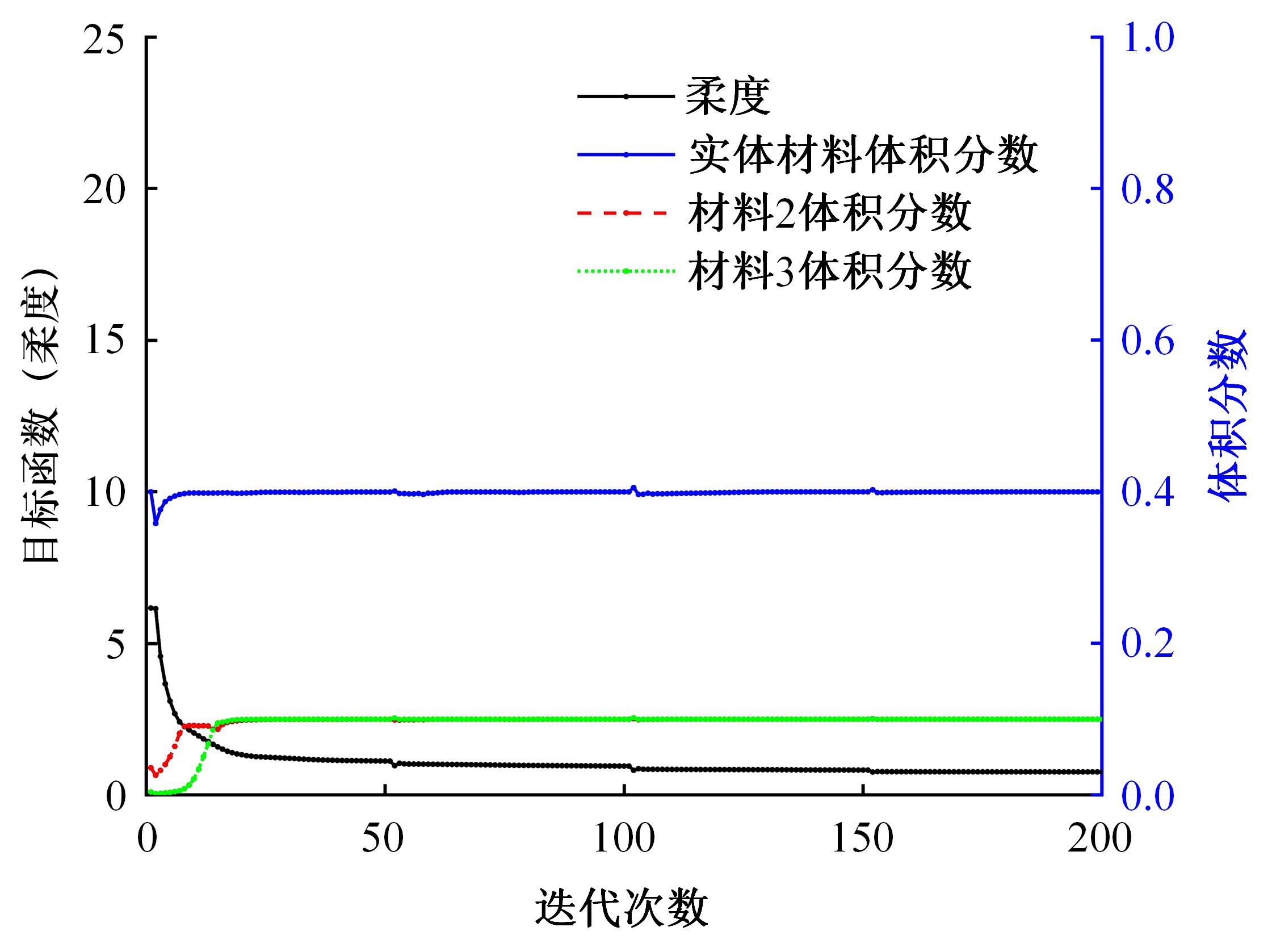

本文基于固体各向同性材料惩罚(solid lsotropic material with penalization,SIMP)插值模型提出一种考虑几何非线性效应的多相多孔结构拓扑优化设计方法。通过控制不同材料相的局部体积分数来形成多相多孔结构,利用

中图分类号:

- O342

| 1 | Nazir A, Jeng J Y. Buckling behavior of additively manufactured cellular columns: experimental and simulation validation[J]. Materials & Design, 2020, 186: No.108349. |

| 2 | Clausen A, Aage N, Sigmund O. Exploiting additive manufacturing infill in topology optimization for improved buckling load[J]. Engineering, 2016, 2(2): 250-257. |

| 3 | Bai J, Zuo W. Hollow structural design in topology optimization via moving morphable component method[J]. Structural and Multidisciplinary Optimization, 2020, 61(1): 187-205. |

| 4 | Wu J, Niels A, Rudiger W, et al. Infill optimization for additive manufacturing-approaching bone-like porous structures[J]. IEEE Transactions on Visualization and Computer Graphics, 2017,4(2): 1127-1140. |

| 5 | Wu J, Clausen A, Sigmund O. Minimum compliance topology optimization of shell-infill composites for additive manufacturing[J]. Computer Methods in Applied Mechanics and Engineering, 2017, 326: 358-375. |

| 6 | Liu C, Du Z, Zhang W, et al. Additive manufacturing-oriented design of graded lattice structures through explicit topology optimization[J]. Journal of Applied Mechanics, 2017, 84(8): No.081008. |

| 7 | Liu C, Du Z, Zhu Y, et al. Optimal design of shell-graded-infill structures by a hybrid MMC-MMV approach[J]. Computer Methods in Applied Mechanics and Engineering, 2020, 369: No. 113187. |

| 8 | Das S, Sutradhar A. Multi-phys ics topology optimization of functionally graded controllable porous structures: application to heat dissipating problems[J]. Materials & Design, 2020, 193: No.108775. |

| 9 | Hoang V N, Tran P, Nguyen N L, et al. Adaptive concurrent topology optimization of coated structures with nonperiodic infill for additive manufacturing[J]. Computer-Aided Design, 2020, 129: No.102918. |

| 10 | Hoang V N, Wang X, Nguyen-Xuan H. A three-dimensional multiscale approach to optimal design of porous structures using adaptive geometric components[J]. Composite Structures, 2021, 273: No.114296. |

| 11 | Dou S G. A projection approach for topology optimization of porous structures through implicit local volume control[J]. Structural and Multidisciplinary Optimization, 2020, 62(2): 835-850. |

| 12 | Long K, Chen Z, Zhang C W, et al. An aggregation-free local volume fraction formulation for topological design of porous structure[J]. Materials, 2021, 14(19): No.5726. |

| 13 | Zhao Z, Zhang X S. Design of graded porous bone-like structures via a multi-material topology optimization approach[J]. Structural and Multidisciplinary Optimization, 2021, 64(2): 677-698. |

| 14 | 胡传丰, 任靖雯, 胡慧,等. 基于等几何分析的参数多孔结构拓扑优化[J]. 吉林大学学报:理学版, 2021, 59(1): 65-76. |

| Hu Chuan-feng, Ren Jing-wen, Hu Hui, et al. Topology optimization for parametric porous structure based on iso-geometric analysis[J]. Journal of Jilin University Science Edition, 2021, 59(1): 65-76. | |

| 15 | Garaigordobil A, Ansola R, Querin O M, et al. Infill topology optimization of porous structures with discrete variables by the sequential element rejection and admission method[J]. Engineering Optimization, 2021, 55(3): 457-475. |

| 16 | Gan N, Wang Q. Topology optimization design of porous infill structure with thermo-mechanical buckling criteria[J]. International Journal of Mechanics and Materials in Design, 2022, 18(2): 267-288. |

| 17 | Huang J, Xu S, Ma Y, et al. A topology optimization method for hyperelastic porous structures subject to large deformation[J]. International Journal of Mechanics and Materials in Design, 2022, 18(2): 289-308. |

| 18 | Xue R, Liu C, Zhang W, et al. Explicit structural topology optimization under finite deformation via moving morphable void (MMV) approach[J]. Computer Methods in Applied Mechanics and Engineering, 2019, 344: 798-818. |

| 19 | 文桂林, 刘杰, 陈梓杰, 等. 非线性连续体拓扑优化方法综述[J]. 力学学报, 2022, 54(10): 2659-2675. |

| Wen Gui-lin, Liu Jie, Chen Zi-jie, et al. A survey of nonlinear continuum topology optimization methods[J]. Chinese Journal of Theoretical and Applied Mechanics, 2022, 54(10): 2659-2675 . | |

| 20 | 陆念力,张宏生. 计及纵横变形效应的几何非线性三次样条梁单元[J]. 吉林大学学报:工学版, 2010, 40(3): 745-751. |

| Lu Nian-li, Zhang Hong-sheng. Geometric nonlinear cubic spline beam element with lateral and axial deformation effects[J]. Journal of Jilin University(Engineering and Technology Edition), 2010, 40(3): 745-751. | |

| 21 | 朱本亮, 张宪民, 李海, 等. 基于节点密度插值的多材料柔顺机构拓扑优化[J]. 机械工程学报, 2021, 57(15): 53-61. |

| Zhu Ben-liang, Zhang Xian-min, Li Hai, et al. Topology optimization of multi-material compliant mechanisms using node-density interpolation scheme[J]. Journal of Mechanical Engineering, 2021, 57(15): 53-61. | |

| 22 | Zuo W, Saitou K. Multi-material topology optimization using ordered SIMP interpolation[J]. Structural and Multidisciplinary Optimization, 2017, 55(2): 477-491. |

| 23 | 王选,胡平,龙凯.考虑嵌入移动孔洞的多相材料布局优化[J].力学学报,2019,51(3): 852-862. |

| Wang Xuan, Hu Ping, Long Kai. Multiphase material layout optimization considering embedding movable holes[J]. Chinese Journal of Theoretical and Applied Mechanics, 2019, 51(3): 852-862. | |

| 24 | Guo X, Zhang W, Zhong W. Stress-related topology optimization of continuum structures involving multi-phase materials[J]. Computer Methods in Applied Mechanics and Engineering, 2014, 268: 632-655. |

| 25 | Lazarov B S, Sigmund O. Filters in topology optimization based on Helmholtz‐type differential equations[J]. International Journal for Numerical Methods in Engineering, 2011, 86(6): 765-781. |

| 26 | Wang F, Lazarov B S, Sigmund O. On projection methods, convergence and robust formulations in topology optimization[J]. Structural and Multidisciplinary Optimization, 2011, 43(6): 767-784. |

| 27 | Luo Y J, Wang M Y, Kang Z. Topology optimization of geometrically nonlinear structures based on an additive hyperelasticity technique[J]. Computer Methods in Applied Mechanics and Engineering, 2015, 286: 422-441. |

| 28 | Chen Q, Zhang X M, Zhu B L. A 213-line topology optimization code for geometrically nonlinear structures[J]. Structural and Multidisciplinary Optimization, 2019, 59(5): 1863-1879. |

| 29 | Buhl T, Pedersen C B W, Sigmund O. Stiffness design of geometrically nonlinear structures using topology optimization[J]. Structural and Multidisciplinary Optimization, 2000,19(2): 93-104. |

| 30 | Wang F, Lazarov B S, Sigmund O, et al. Interpolation scheme for fictitious domain techniques and topology optimization of finite strain elastic problems[J]. Computer Methods in Applied Mechanics and Engineering, 2014, 276: 453-472. |

| [1] | 商蕾,杨萍,杨祥国,潘建欣,杨军,张梦如. 基于APSO-BP-PID控制的质子交换膜燃料电池热管理系统温度控制[J]. 吉林大学学报(工学版), 2024, 54(9): 2401-2413. |

| [2] | 蒋林,李国龙,王时龙,徐凯,李喆裕. 基于主成分回归的进给轴热膨胀误差建模[J]. 吉林大学学报(工学版), 2024, 54(8): 2149-2155. |

| [3] | 张则强,王灿,刘俊琦,计丹,刘思璐. 基于改进麻雀搜索算法的平行行排序问题[J]. 吉林大学学报(工学版), 2024, 54(7): 1851-1861. |

| [4] | 回丽,金磊,宋万万,周松,安金岚. 转向架用SMA490BW钢不同焊接区域裂纹扩展速率[J]. 吉林大学学报(工学版), 2024, 54(3): 650-656. |

| [5] | 杨志军,张驰,黄观新. 基于浮动坐标法的刚柔耦合定位平台力学模型[J]. 吉林大学学报(工学版), 2024, 54(2): 385-393. |

| [6] | 石林榕,赵武云. 西北寒旱农区胡麻滚勺式精量穴播器的设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2706-2717. |

| [7] | 柴博森,王广义,闫东,朱国仁,张进,吕恒升. 液力变矩器空化数值模拟及对性能的影响[J]. 吉林大学学报(工学版), 2023, 53(8): 2236-2244. |

| [8] | 陈国辉,徐业银,焦映厚. 考虑偏转的斜齿轮啮合刚度及其振动分析[J]. 吉林大学学报(工学版), 2023, 53(7): 1902-1910. |

| [9] | 陈贵升,罗国焱,李靓雪,黄震,李一. 柴油机颗粒捕集器孔道流场及其高原环境下噪声特性分析[J]. 吉林大学学报(工学版), 2023, 53(7): 1892-1901. |

| [10] | 王峰,刘双瑞,王佳盈,宋佳玲,王俊,张久鹏,黄晓明. 尺寸和形状效应对多孔结构风阻系数的影响[J]. 吉林大学学报(工学版), 2023, 53(6): 1677-1685. |

| [11] | 李胜,朱佳,黄德惠,陈存福,费洪庆,丰伟,胡兴军. 空冷中冷器百叶窗翅片结构参数优化[J]. 吉林大学学报(工学版), 2023, 53(4): 998-1006. |

| [12] | 王建,于威,王斌. 高原状态下甲醇替代率对柴油机燃烧与排放的影响[J]. 吉林大学学报(工学版), 2023, 53(4): 954-963. |

| [13] | 于立娟,安阳,何佳龙,李国发,王升旭. 机电装备载荷谱外推技术研究进展及发展趋势[J]. 吉林大学学报(工学版), 2023, 53(4): 941-953. |

| [14] | 柴博森,闫东,王广义,左文杰. 制动工况桃腔偶合器三维涡特征分析及仿真评价[J]. 吉林大学学报(工学版), 2023, 53(11): 3045-3055. |

| [15] | 孙舒杨,程玮斌,张浩桢,邓向萍,齐红. 基于深度学习的两阶段实时显式拓扑优化方法[J]. 吉林大学学报(工学版), 2023, 53(10): 2942-2951. |

|

||