吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (2): 434-443.doi: 10.13229/j.cnki.jdxbgxb.20230462

• 车辆工程·机械工程 • 上一篇

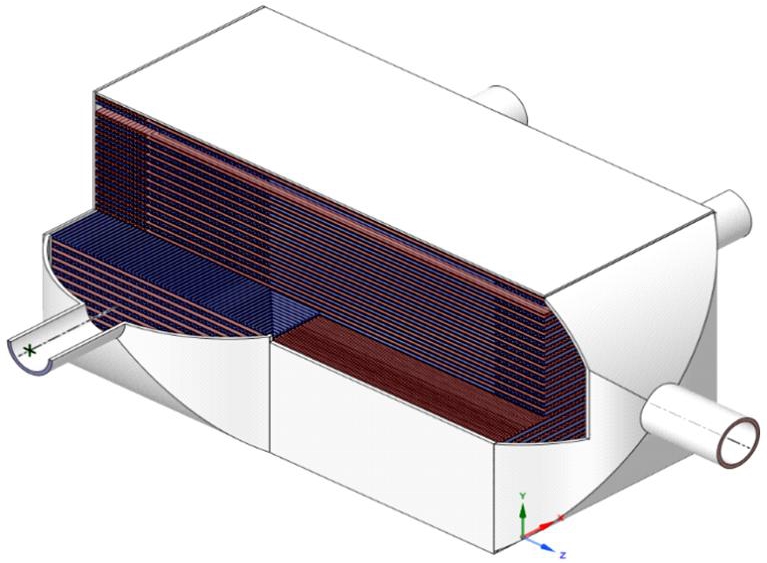

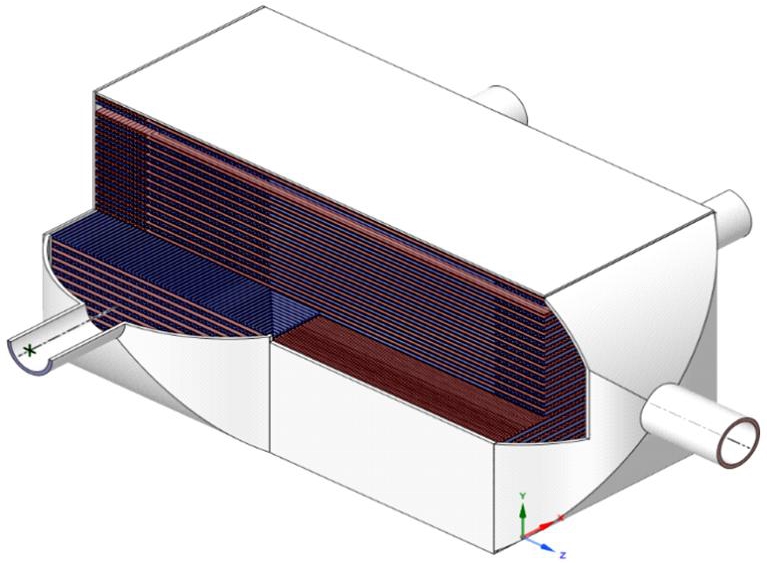

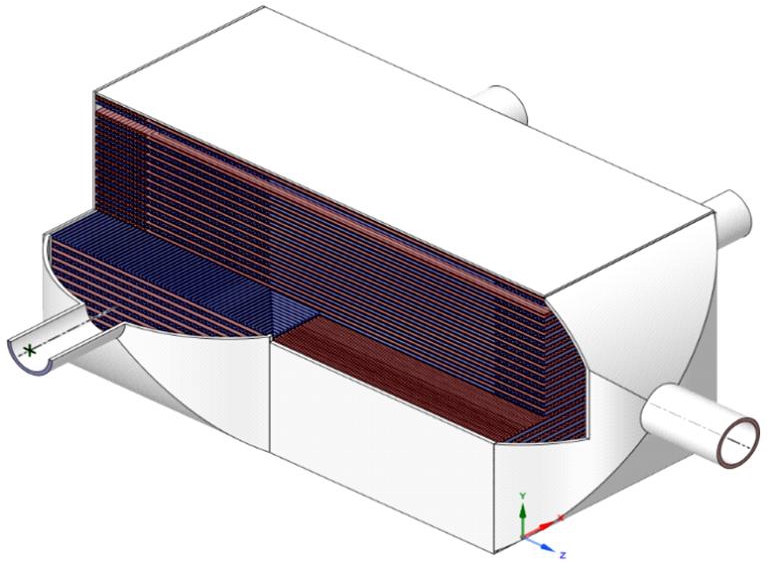

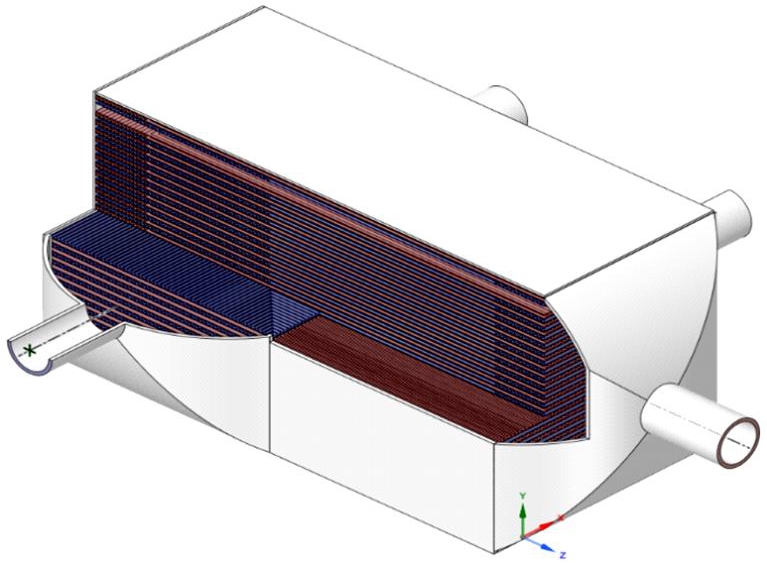

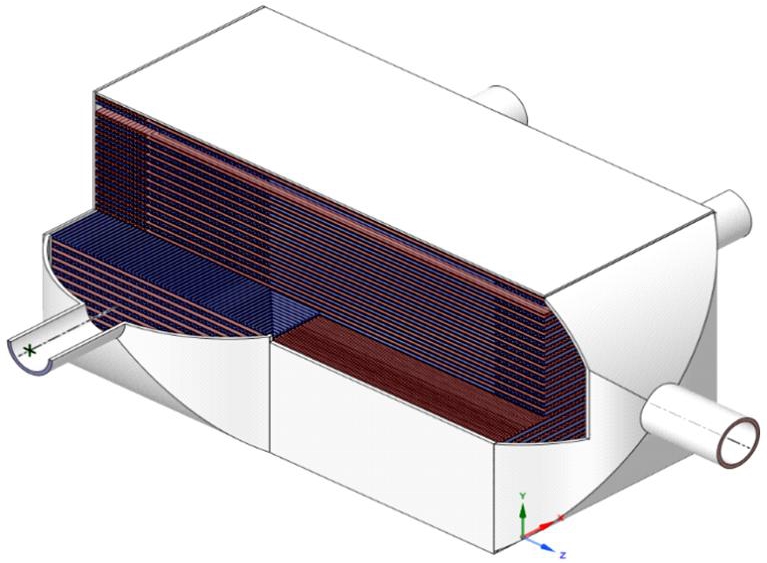

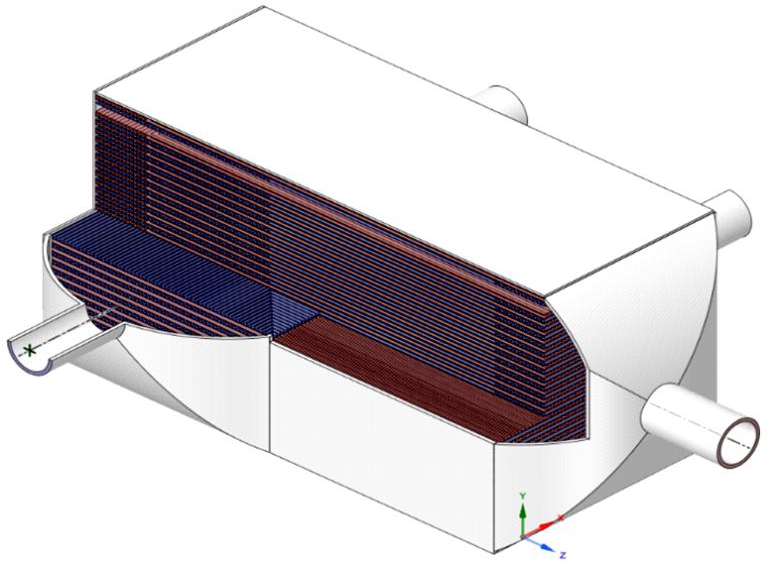

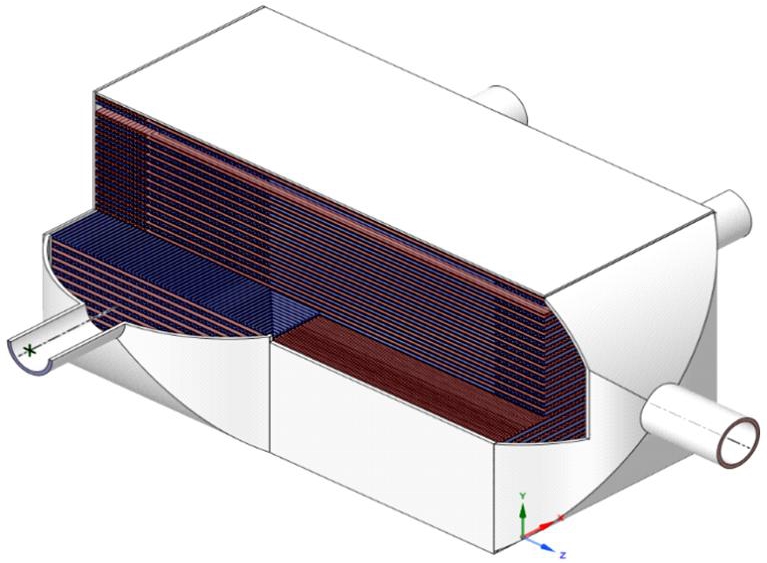

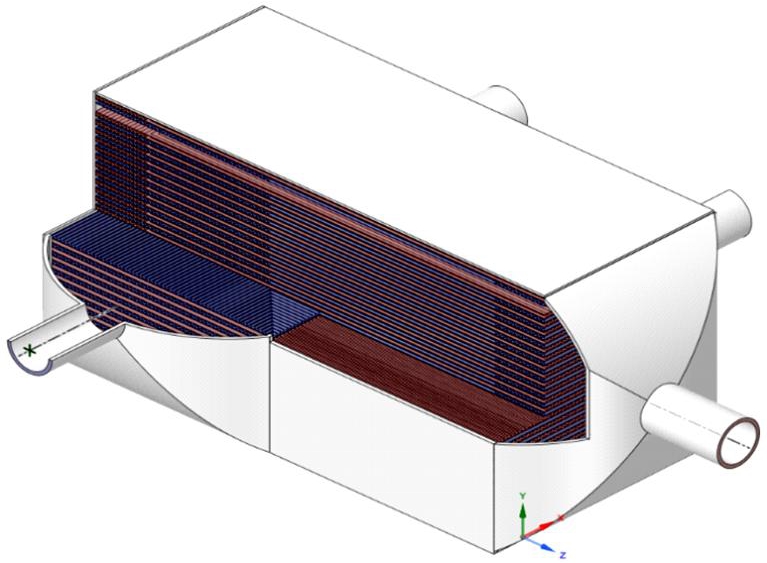

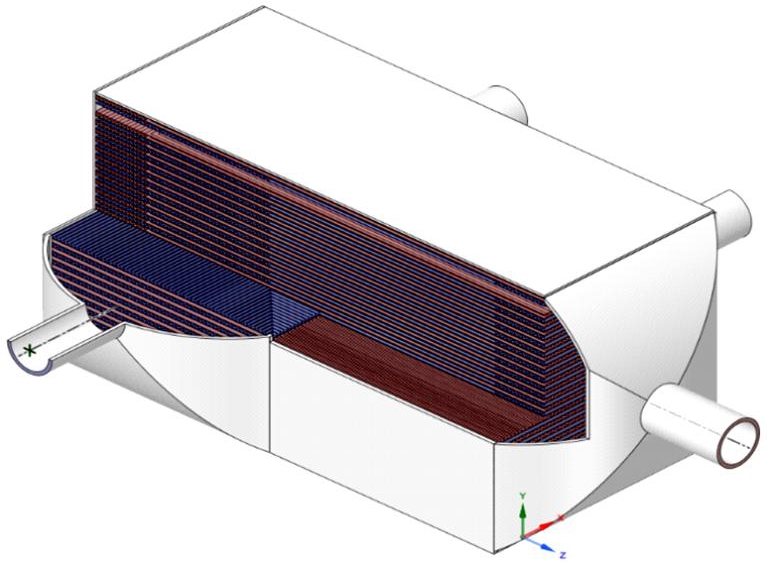

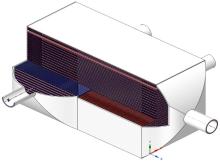

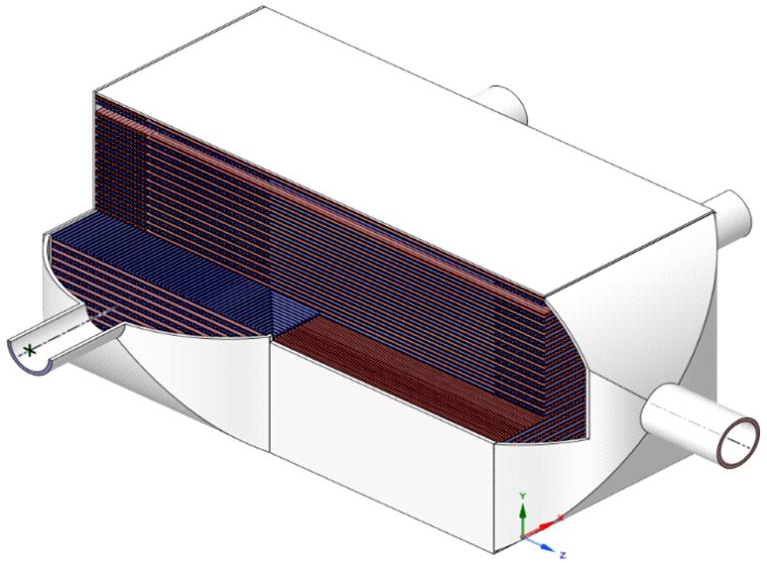

适用于紧凑SOFC的燃烧器耦合换热器实验

李思远1( ),白书战1(

),白书战1( ),李国祥1,马孔融2,李文聪2,韩宇浩1

),李国祥1,马孔融2,李文聪2,韩宇浩1

- 1.山东大学 能源与动力工程学院,济南 250061

2.中国重型汽车集团有限公司,济南 250000

Experimental study of a combustor-coupled heat exchanger for compact SOFC system

Si-yuan LI1( ),Shu-zhan BAI1(

),Shu-zhan BAI1( ),Guo-xiang LI1,Kong-rong MA2,Wen-cong LI2,Yu-hao HAN1

),Guo-xiang LI1,Kong-rong MA2,Wen-cong LI2,Yu-hao HAN1

- 1.School of Energy and Power Engineering,Shandong University,Jinan 250061,China

2.China National Heavy Duty Truck Group Co. ,Ltd. ,Jinan 250000,China

摘要:

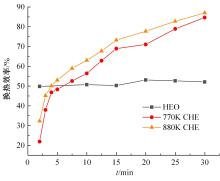

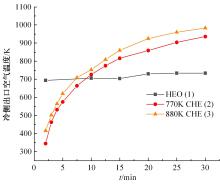

通过实验研究了紧凑固体氧化物燃料电池外围热管理系统中催化燃烧器和换热器的耦合器(CHE)的换热性能以及甲烷催化转化效果。测试、比较和分析了CHE只进行催化燃烧或热交换时的性能与正常工作时的性能。结果表明:正常工作时CHE的换热效率比只进行热交换时高10%,而甲烷的催化转化率比只进行催化反应时降低了4%。虽然CHE降低了部分催化转化性能,但提高了燃料利用率,因此,使用CHE替代系统中的燃烧器和换热器,可以提高换热性能,加速系统的启动或在相同的启动时间内更节省燃料,节约制造成本和系统空间,并降低其余热部件的热负荷。在紧凑型SOFC系统中具有潜在的应用性和广阔的前景。

中图分类号:

- TK91

| 1 | Kuyper J, Schroeder H, Linnér B. The evolution of the UNFCCC[J]. Annual Review of Environment and Resources, 2018, 43(1): 343-368. |

| 2 | 王灿, 张雅欣. 碳中和愿景的实现路径与政策体系[J]. 中国环境管理, 2020, 12(6): 58-64. |

| Wang Can, Zhang Ya-xin. The path to carbon neutral vision and policy system[J]. China Environmental Management, 2020, 12(6): 58-64. | |

| 3 | Choudhury A, Chandra H, Arora A. Application of solid oxide fuel cell technology for power generation—a review[J]. Renewable & Sustainable Energy Reviews, 2013, 20: 430-442. |

| 4 | O'Hayre R P, Cha S W, Colella W, et al. Fuel Cell Fundamentals[M]. 3rd Edition. Hoboken: Wiley, 2016. |

| 5 | Zeng Z Z, Qian Y P, Zhang Y J, et al. A review of heat exchange and thermal management methods for temperature gradient reduction in solid oxide fuel cell (SOFC) stacks[J]. Applied Energy, 2020, 280: No. 115899. |

| 6 | Crosbie G M, Murray E P, Bauer D R, et al. Solid oxide fuel cells for direct oxidation of liquid hydrocarbon fuels in automotive auxiliary power units: sulfur tolerance and operation on gasoline[J]. SAE International, 2002, 111(3): 832-839. |

| 7 | Rechberger J, Kaupert A, Hagerskans J, et al. Demonstration of the first European SOFC APU on a heavy duty truck[J]. Transportation Research Procedia, 2016, 14: 3676-3685. |

| 8 | Nissan Motor Company. Nissan SOFC powered vehicle system runs on bioethanol[J]. Fuel Cells Bulletin, 2016, 2016(7): 2-3. |

| 9 | Bessekon Y, Zielke P, Hagen A, et al. Simulation of a SOFC/Battery powered vehicle[J]. International Journal of Hydrogen Energy, 2019, 44(3): 1905-1919. |

| 10 | Crosbie G M, Murray E P, Bauer D R, et al. Solid oxide fuel cells for direct oxidation of liquid hydrocarbon fuels in automotive auxiliary power units: Sulfur tolerance and operation on gasoline[C]∥SAE Technical Paper, 2002-0410. |

| 11 | Botti J J, Grieve M J, MacBain J A. Electric vehicle range extension using an SOFC APU[C]∥SAE Technical Paper, 2005-1172. |

| 12 | Bessekon Y, Zielke P, Hagen A, et al. Simulation of a SOFC/battery powered vehicle[J]. International Journal of Hydrogen Energy, 2019, 44(3): 1905-1919. |

| 13 | Yen T H, Hong W T, Huang W P, et al. Experimental investigation of 1 kW solid oxide fuel cell system with a natural gas reformer and an exhaust gas burner[J]. Journal of Power Sources, 2010, 195(5): 1454-1462. |

| 14 | Martinez A S, Brouwer J, Samuelsen G S. Comparative analysis of SOFC-GT freight locomotive fueled by natural gas and diesel with onboard reformation[J]. Applied Energy, 2015, 148: 421-438. |

| 15 | Barzi Y M, Ghassemi M, Hamedi M H. Numerical analysis of start-up operation of a tubular solid oxide fuel cell[J]. International Journal of Hydrogen Energy, 2009, 34(4): 2015-2025. |

| 16 | 代安娜,许林峰,税安泽. 固体氧化物燃料电池的研究与进展[J]. 硅酸盐通报, 2015, 34(): 234-238. |

| Dai An-na, Xu Lin-feng, Shui An-ze. Research and progress of solid oxide fuel cells[J]. Guisuanyan Tongbao, 2015, 34(Sup.1): 234-238. | |

| 17 | Ghang T G, Lee S M, Ahn K Y, et al. An experimental study on the reaction characteristics of a coupled reactor with a catalytic combustor and a steam reformer for SOFC systems[J]. International Journal of Hydrogen Energy, 2012, 37(4): 3234-3241. |

| 18 | Shekhawat D, Berry D A, Gardner T H, et al. Effects of fuel cell anode recycle on catalytic fuel reforming[J]. Journal of Power Sources, 2007, 168(2): 477-483. |

| 19 | 杨博然, 陈志光, 秦朝葵. 固体氧化物燃料电池(SOFC)外围热管理系统研究进展[J]. 城市燃气, 2019, 2019(3): 4-10. |

| Yang Bo-ran, Chen Zhi-guang, Qin Zhao-kui. Research progress on the peripheral thermal management system of solid oxide fuel cell (SOFC)[J]. City Gas, 2019, 2019(3): 4-10. | |

| 20 | Baek S, Kim Y, Bae J. Effect of anode-off gas recirculation at solid oxide fuel cell system[C]∥ ASME 2008 6th International Conference on Fuel Cell Science, Engineering and Technology, Denver, USA, 2008: 645-651. |

| 21 | Dietrich R U, Oelze J, Lindermeir A, et al. Efficiency gain of solid oxide fuel cell systems by using anode off-gas recycle-results for a small scale propane driven unit[J]. Journal of Power Sources, 2011, 196(17): 7152-7160. |

| 22 | Yu S, Hong D J, Lee Y D, et al. Development of a catalytic combustor for a stationary fuel cell power generation system[J]. Renewable Energy, 2010, 35(5): 1083-1090. |

| 23 | Park J, Lim H, Rhee G H, et al. Catalyst filled heat exchanger for hydrogen liquefaction[J]. International Journal of Heat & Mass Transfer, 2021, 170: No.121007. |

| 24 | 韦小雄, 张淑文, 唐萍, 等. 铝制板翅式换热器导流结构优化设计[J]. 化工设备与管道, 2011, 48(1): 13-16. |

| Wei Xiao-xiong, Zhang Shu-wen, Tang Ping, et al. Optimal design of inflow structure of aluminum plate-fin heat exchanger[J]. Chemical Equipment and Piping, 2011, 48(1):13-16. | |

| 25 | Kim J, Myung C, Lee K. Exhaust emissions and conversion efficiency of catalytic converter for an ethanol‐fueled spark ignition engine[J]. Biofuels, Bioproducts & Biorefining, 2019, 13(5): 1211-1223. |

| 26 | Venkataraman V, Pacek A W, Steinberger W R. Thermal integration of SOFC and plate heat exchanger desorber[J]. ECS Transactions, 2015, 68(1):No. 068010221. |

| 27 | 骆潮明, 李艳霞, 刘中良, 等. 低浓度甲烷在微小燃烧器中的催化燃烧实验[J]. 化工学报, 2015, 66(): 216-221. |

| Luo Chao-ming, Li Yan-xia, Liu Zhong-liang, et al. Experimental catalytic combustion of low concentration methane in a tiny burner[J]. Journal of Chemical Industry and Engineering, China, 2015, 66(Sup.1): 216-221. | |

| 28 | Leah R T, Bone A, Hammer E, et al. Development progress on the ceres power steel cell technology platform: further progress towards commercialization[J]. ECS Transactions, 2017, 78(1): 87-95. |

| 29 | Leah R T, Bone A, Lankin M, et al. Ceres power steel cell technology: rapid progress towards a truly commercially viable SOFC[J]. ECS Transactions, 2015, 68(1): No.068010095. |

| 30 | He J, Yang Z Q, Ding C L, et al. Methane dehydrogenation and oxidation process over Ni-based bimetallic catalysts[J]. Fuel, 2018, 226: 400-409. |

| [1] | 王羽岱,王斌,苗福生,马楠. 水热耦合变化下衬砌渠道冻胀响应[J]. 吉林大学学报(工学版), 2025, 55(1): 256-268. |

| [2] | 商蕾,杨萍,杨祥国,潘建欣,杨军,张梦如. 基于APSO-BP-PID控制的质子交换膜燃料电池热管理系统温度控制[J]. 吉林大学学报(工学版), 2024, 54(9): 2401-2413. |

| [3] | 郑建校,王文博,刘金颂,周立明,李宇. 基于渐近均匀化的力-电-湿耦合光滑有限元法[J]. 吉林大学学报(工学版), 2024, 54(7): 1876-1886. |

| [4] | 崔亚宁,司春棣,凡涛涛,王飞. 水-荷耦合作用下沥青桥面铺装层裂缝扩展分析[J]. 吉林大学学报(工学版), 2024, 54(7): 1988-1996. |

| [5] | 王宏志,王婷婷,兰淼淼,徐硕. 基于位置跟踪的机械臂多电机新型滑模控制策略[J]. 吉林大学学报(工学版), 2024, 54(5): 1443-1458. |

| [6] | 万铜铜,汪海年,郑文华,冯珀楠,陈玉,张琛. 级配碎石层协调沥青混合料层温度收缩变形行为[J]. 吉林大学学报(工学版), 2024, 54(4): 1045-1057. |

| [7] | 韩智强,谢刚,卓亚娟,骆佐龙,李华腾. 基于车轮-桥面相干激励的大跨连续梁桥振动响应[J]. 吉林大学学报(工学版), 2024, 54(2): 436-444. |

| [8] | 杨志军,张驰,黄观新. 基于浮动坐标法的刚柔耦合定位平台力学模型[J]. 吉林大学学报(工学版), 2024, 54(2): 385-393. |

| [9] | 王天皓,李博,于全毅,徐琳琳,贾国强,关珊珊. 基于稀疏混沌多项式法的电动汽车无线电能传输效率不确定性量化[J]. 吉林大学学报(工学版), 2024, 54(12): 3433-3442. |

| [10] | 卜建清,郭至博,张吉仁,荀敬川,黄晓明. 多损伤钢-混组合梁桥力学性能有限元分析方法[J]. 吉林大学学报(工学版), 2023, 53(6): 1621-1637. |

| [11] | 金敬福,董新桔,贾志成,王康,贺连彬,邹猛,齐迎春. 板簧式弹性金属车轮胎面弹片结构优化[J]. 吉林大学学报(工学版), 2023, 53(4): 964-972. |

| [12] | 高松,王玉琼,王玉海,徐艺,周英超,王鹏伟. 智能汽车纵横向整体反馈线性化控制[J]. 吉林大学学报(工学版), 2023, 53(3): 735-745. |

| [13] | 韩智强,谢刚,周勇军,刘世忠,晋民杰. 曲线桥梁车桥耦合振动数值分析方法[J]. 吉林大学学报(工学版), 2023, 53(2): 515-522. |

| [14] | 陈兵,马凯璇,刘洋,任江,张晨曦,赵韬硕. 双电机驱动履带车辆直驶稳定性分层控制策略[J]. 吉林大学学报(工学版), 2023, 53(10): 2752-2760. |

| [15] | 宋剑锋,黄鑫磊,仪帅,杨振熙,董永刚,李树林. 列车制动过程踏面温度场及应力⁃应变分布特性[J]. 吉林大学学报(工学版), 2023, 53(10): 2773-2784. |

|

||