吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (1): 206-216.doi: 10.13229/j.cnki.jdxbgxb20190836

• 交通运输工程·土木工程 • 上一篇

基于滑移率辨识的汽车制动时序视觉检测方法

- 1.吉林大学 交通学院,长春 130022

2.吉林大学 生物与农业工程学院,长春 130022

3.吉林大学 机械与 航空航天工程学院,长春 130022

Visual detection method for vehicle braking time sequence based on slip rate identification

Dao WU1( ),Li-bin ZHANG1(

),Li-bin ZHANG1( ),Yun-xiang ZHANG2,Hong-ying SHAN3,Hong-mei SHAN1

),Yun-xiang ZHANG2,Hong-ying SHAN3,Hong-mei SHAN1

- 1.College of Transportation,Jilin University,Changchun 130022,China

2.College of Biological and Agricultural Engineering,Jilin University,Changchun 130022,China

3.School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

摘要:

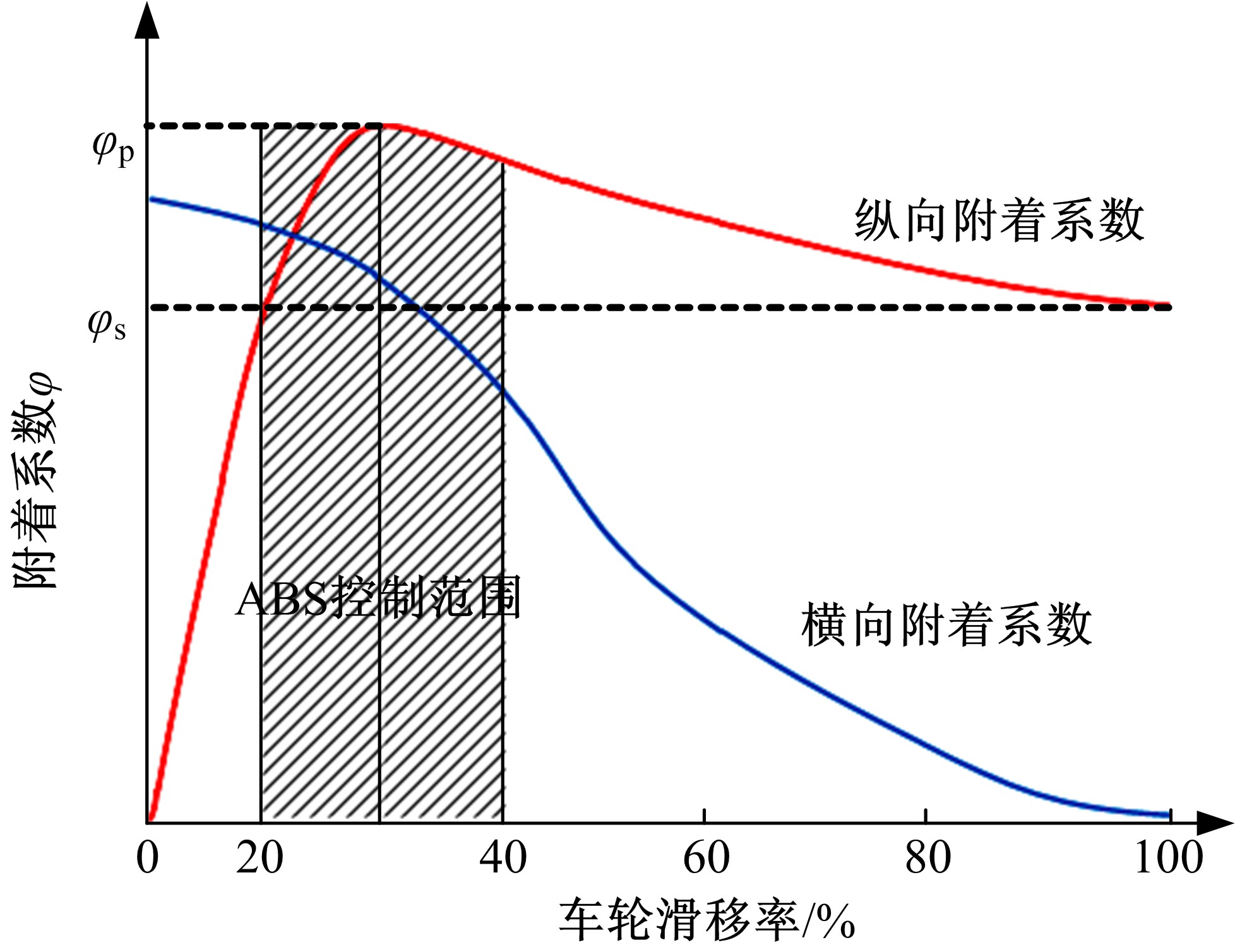

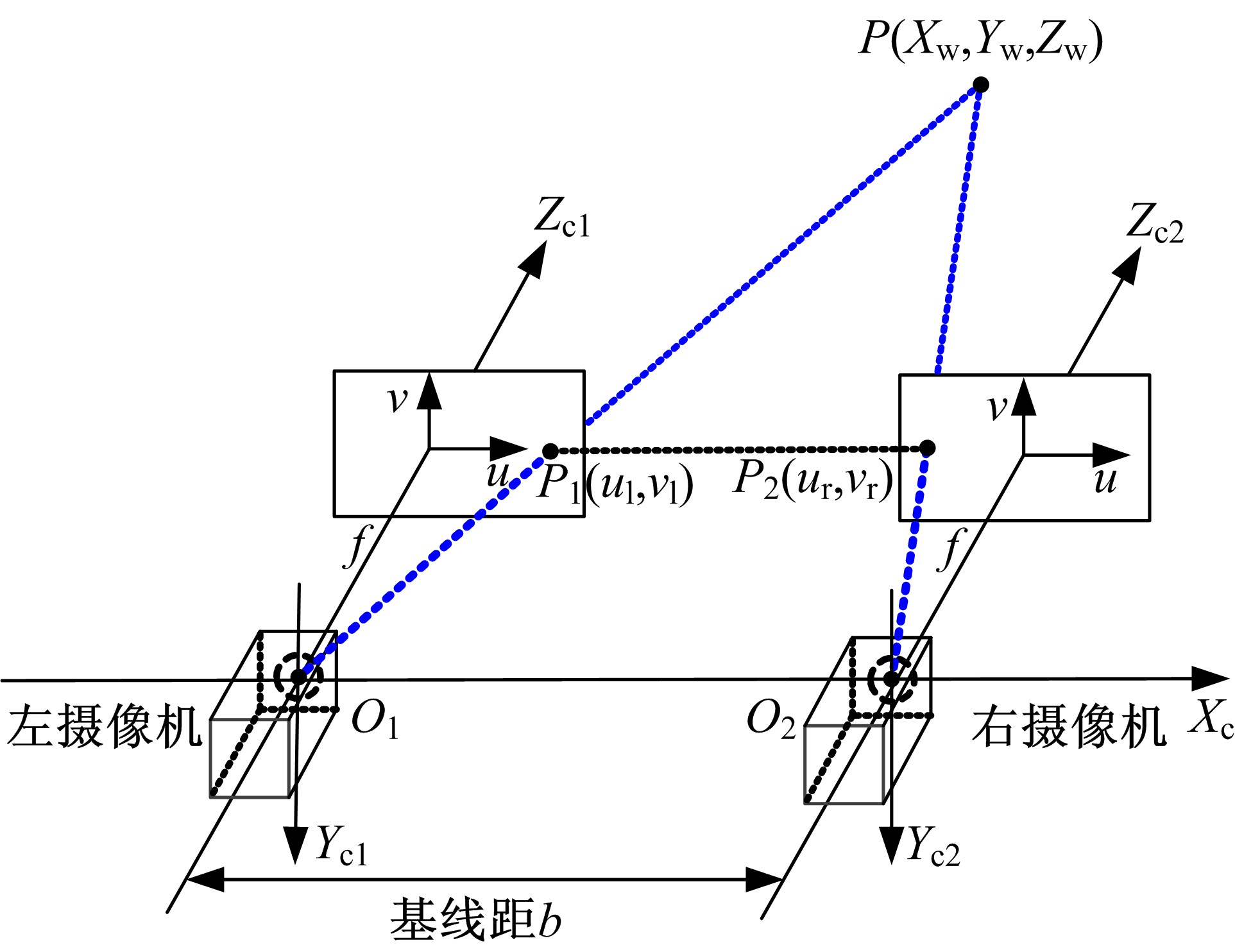

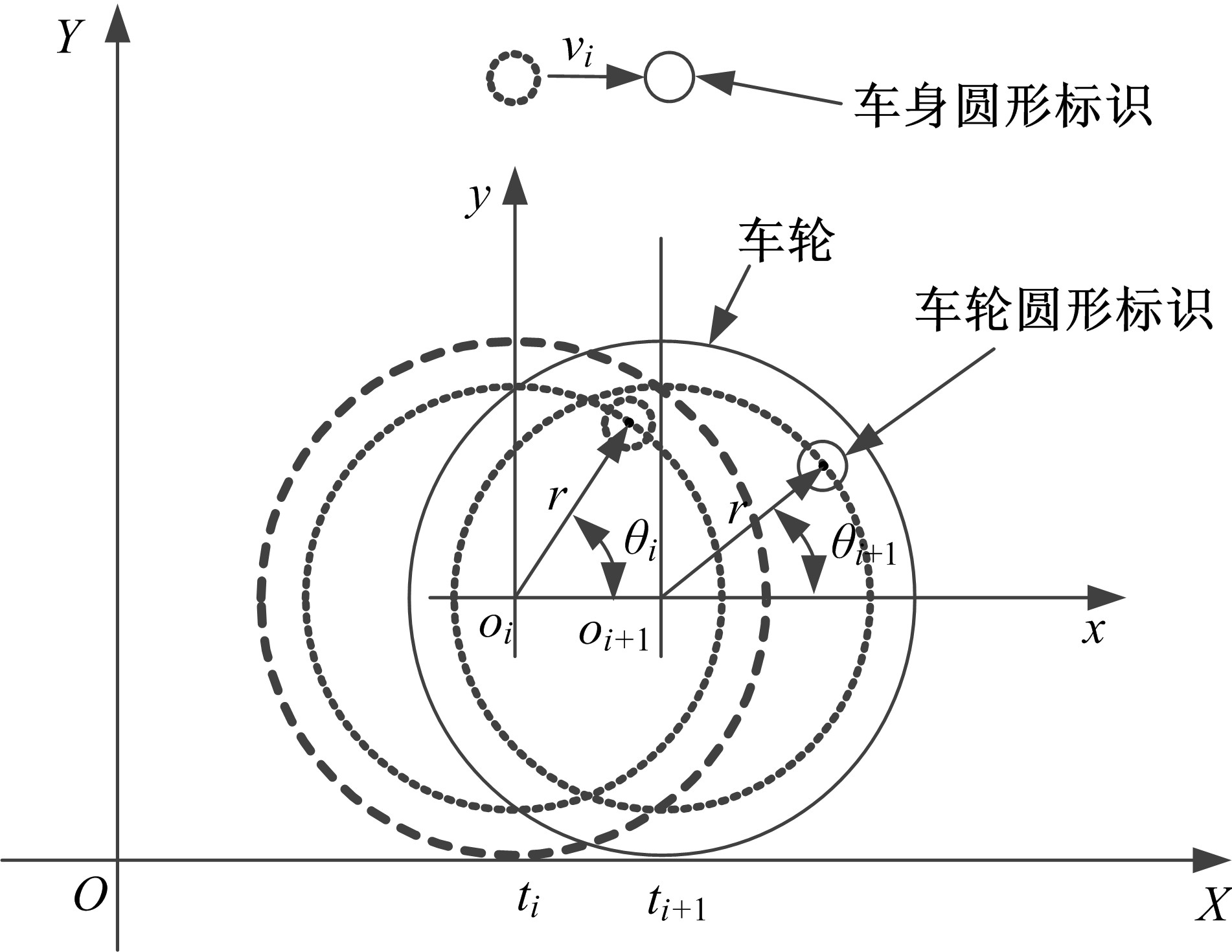

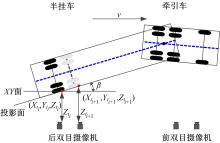

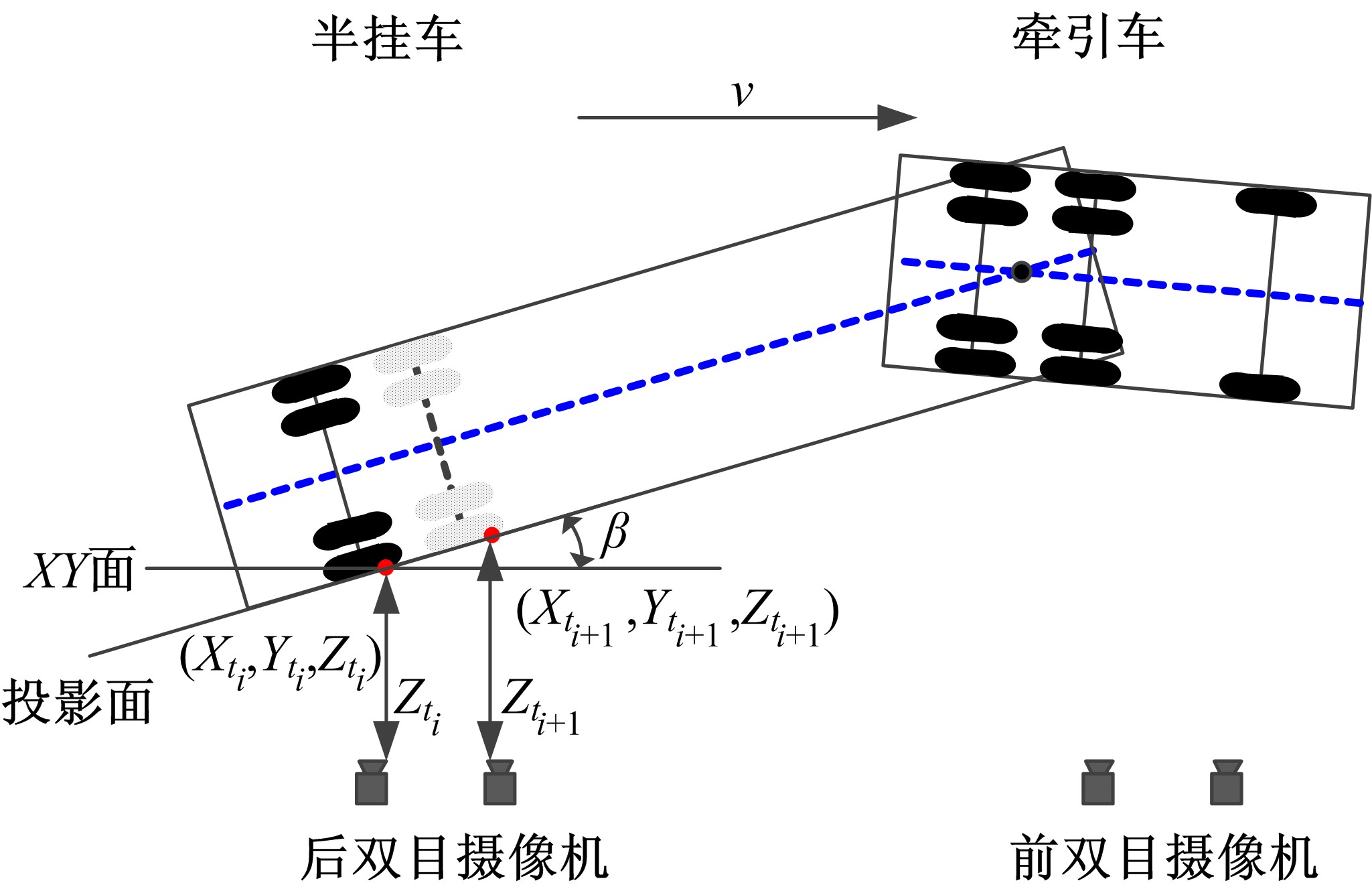

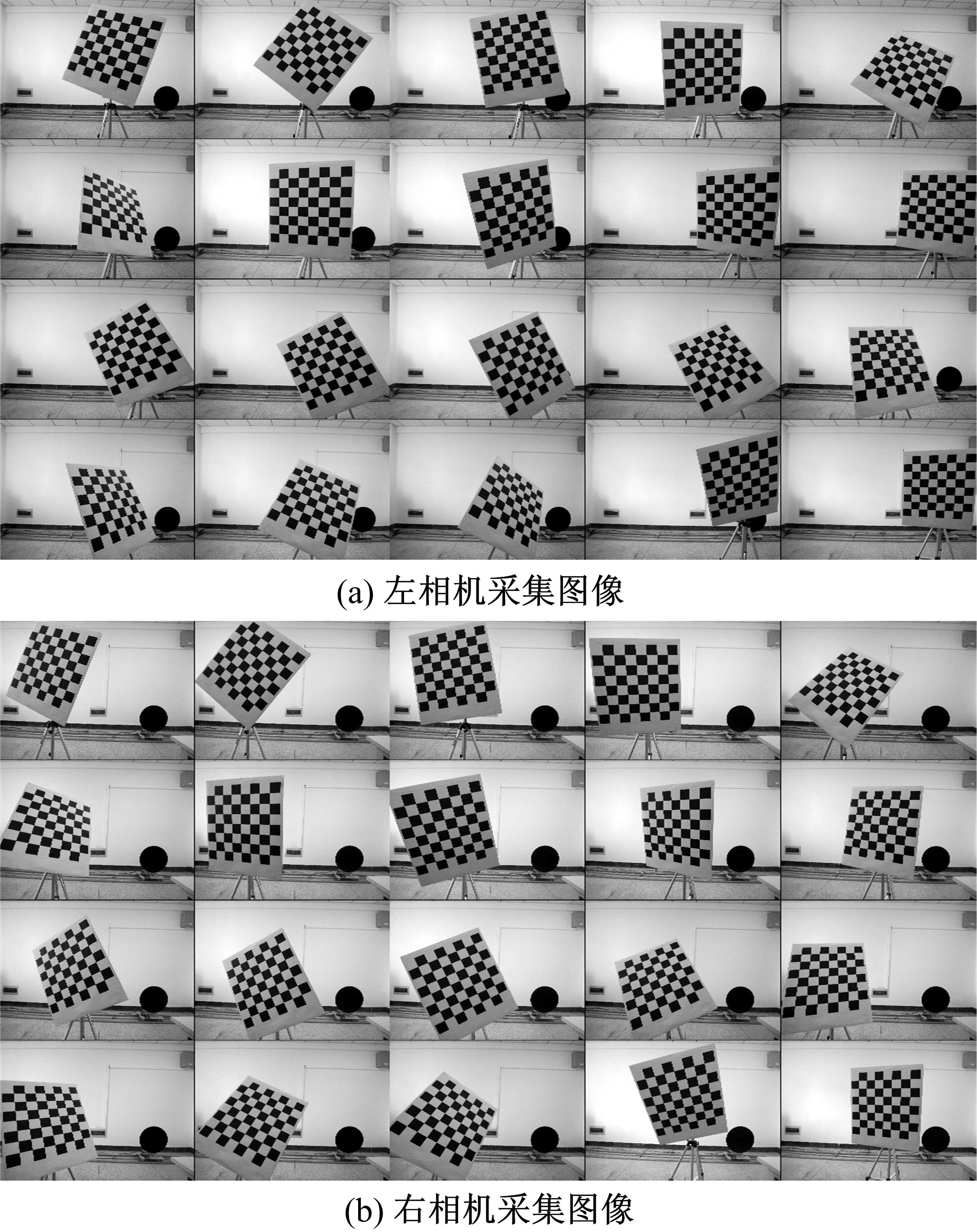

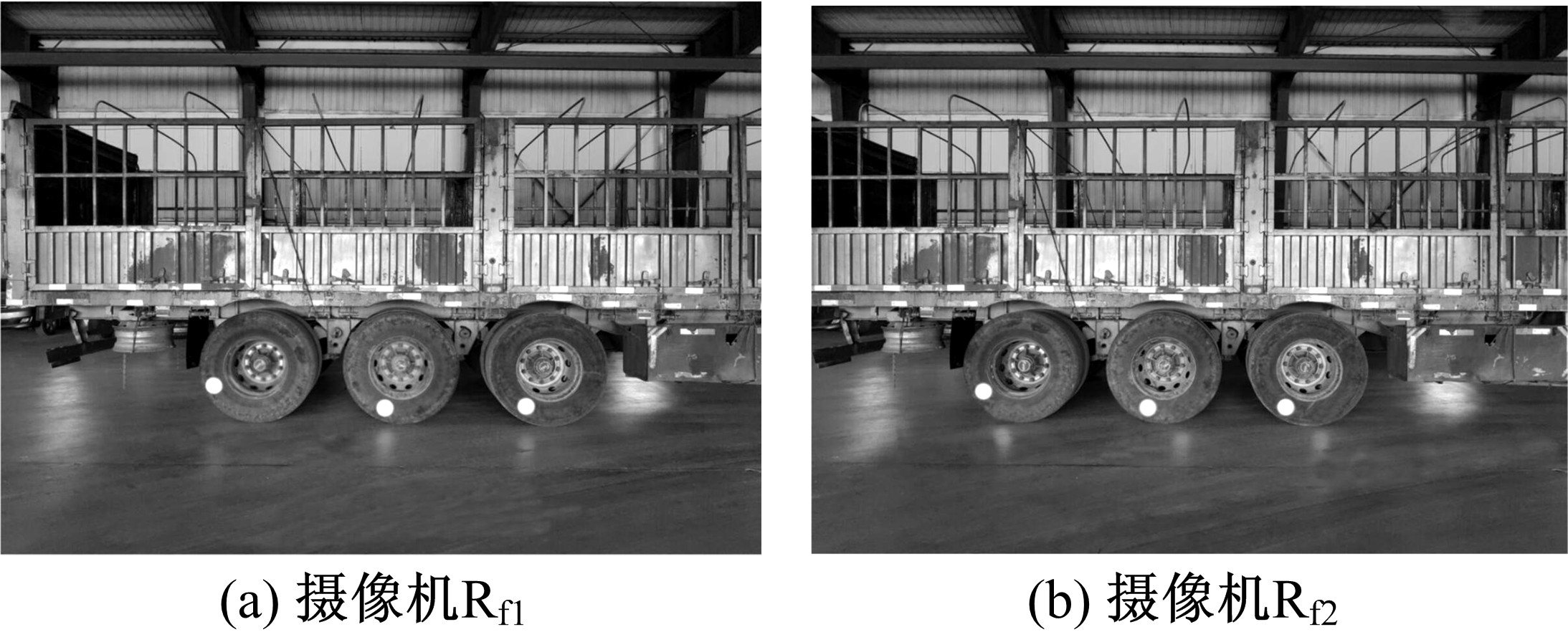

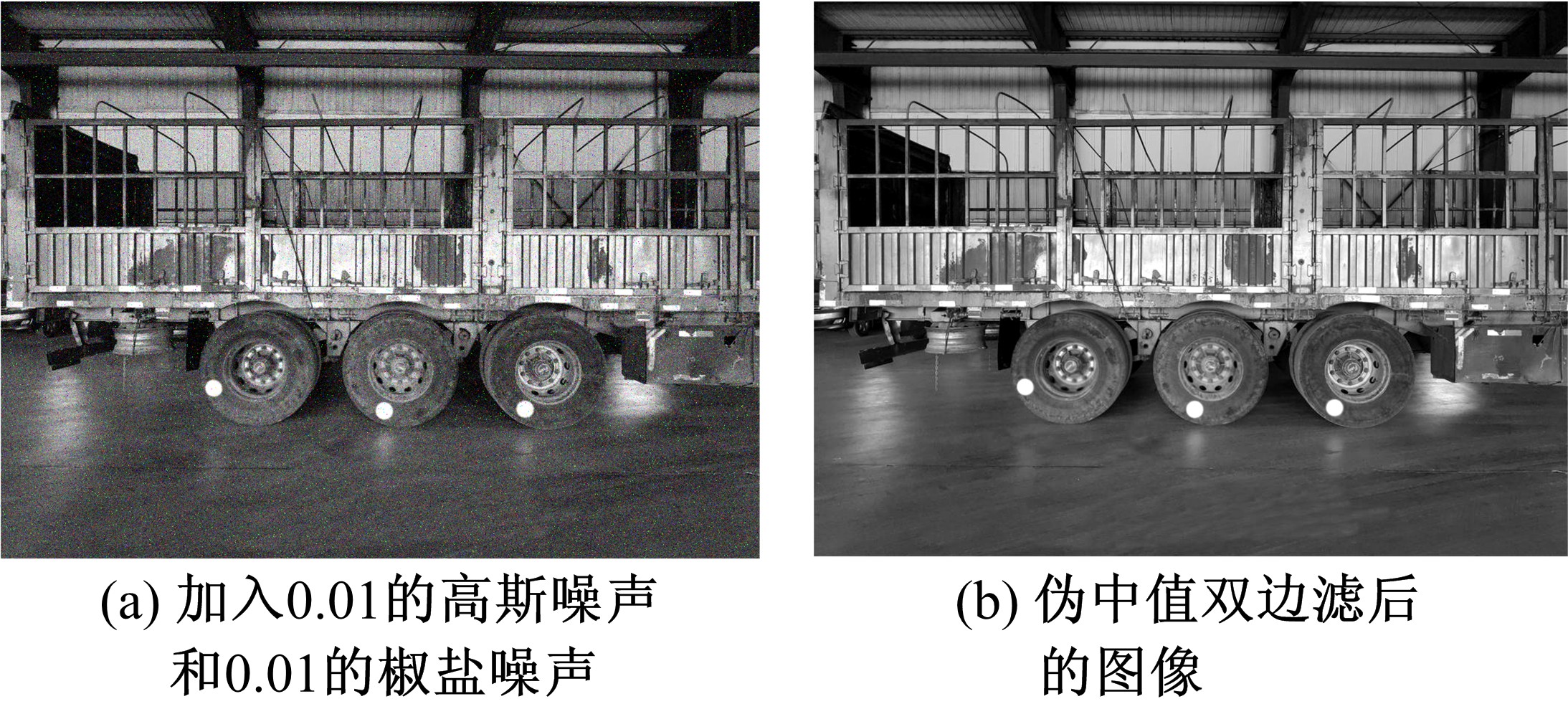

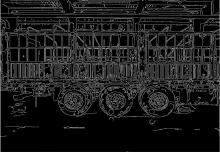

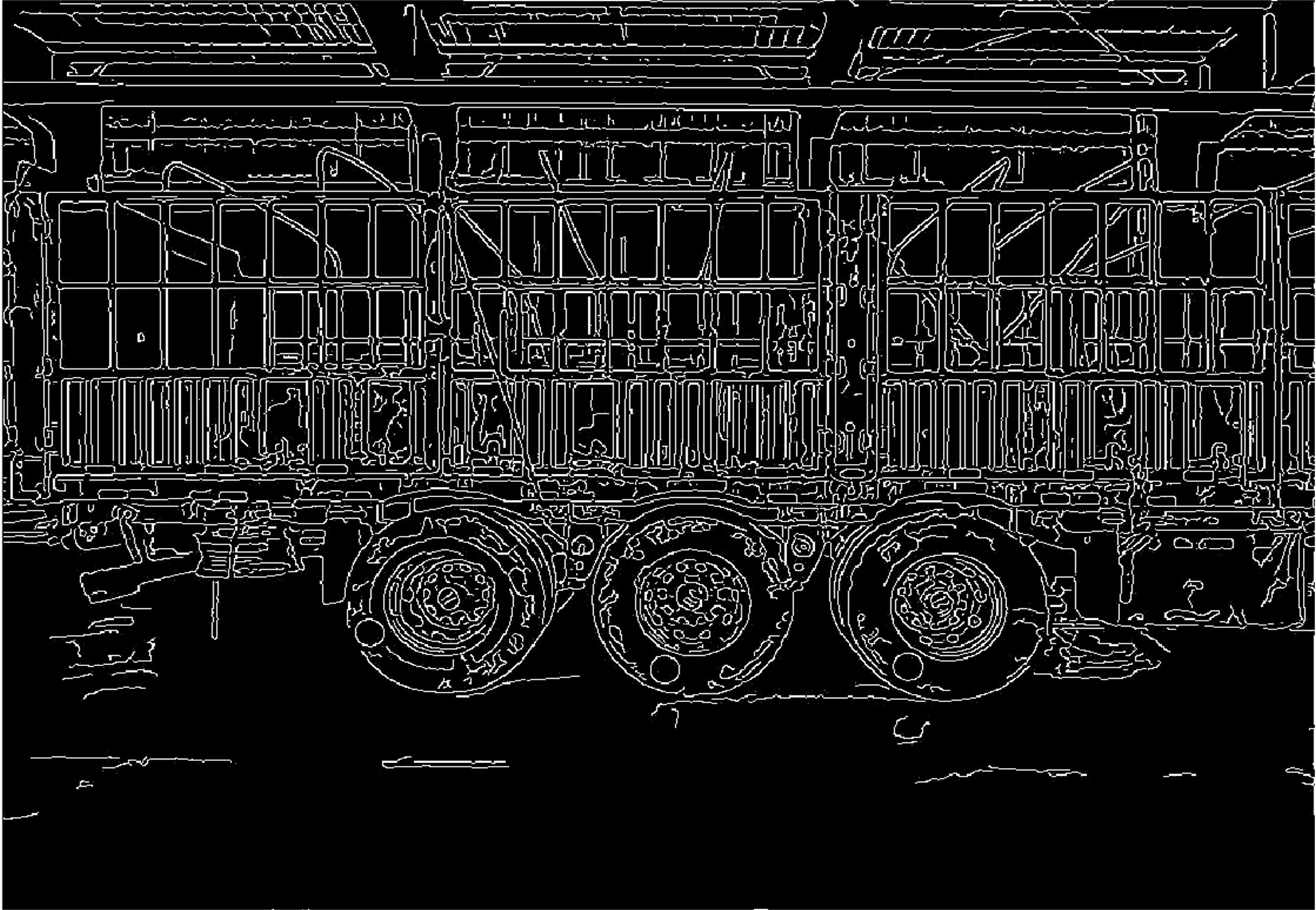

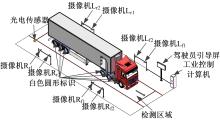

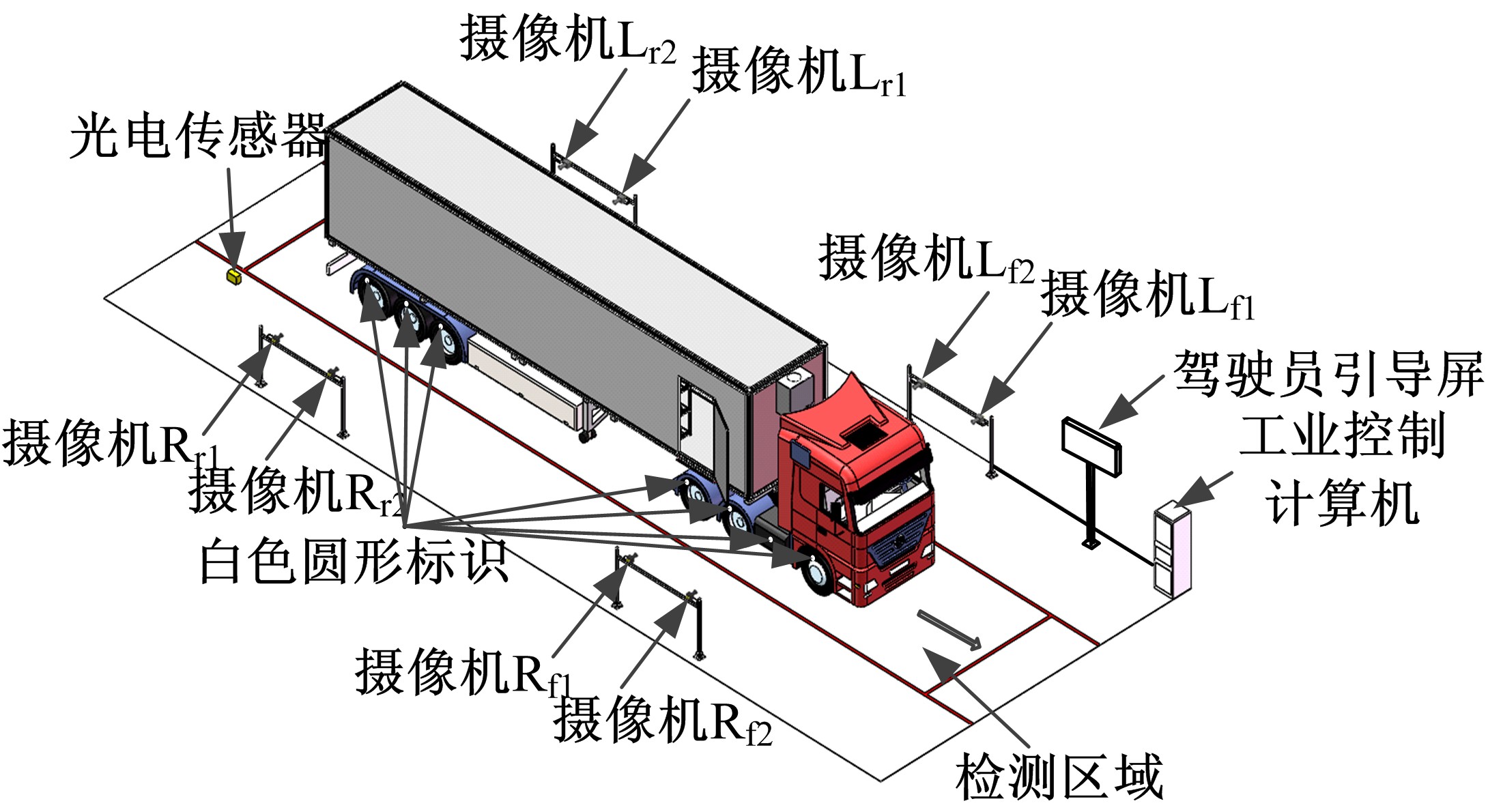

针对现有制动性能检测方法存在的缺陷,提出了一种非接触式汽车制动时序动态检测方法。该方法以汽车制动过程中车轮滑移率变化作为切入点,根据滑移率与附着系数的关系,提出了基于滑移率的制动时序测量目标;基于双目立体视觉测量原理,建立了基于视觉的车轮滑移率测量模型;借助LM(Levenberg-Marquardt)算法对标定参数进行非线性优化,运用伪中值双边滤波、Canny边缘检测、冗余边界清除及Hough变换等图像处理技术,对图像分别进行去噪、边缘提取、精简和特征提取,得到圆形标识的中心坐标。为验证所提方法的可行性,进行了实车试验,并给出测量误差的标准不确定度评定结果。结果表明:在拓展不确定度U=2.52、置信因子k=2的条件下,本文方法最大相对误差为2.74%,重复性误差最大为3.88%。

中图分类号:

- U472.9

| 1 | 郭正康. 现代汽车列车设计与使用[M]. 北京:北京理工大学出版社, 2006. |

| 2 | 机动车安全技术检验项目和方法[S]. |

| 3 | Chen L K, Hsu J Y. Investigation of jack-knife prevention in an articulated scaled vehicle[J]. Vehicle System Dynamics, 2008, 46(Sup.1): 765-777. |

| 4 | Goodarzi A, Behmadi M, Esmailzadeh E. An optimised braking force distribution strategy for articulated vehicles[J]. Vehicle System Dynamics, 2008, 46(Sup.1): 849-856. |

| 5 | 李臣, 李兴虎, 张红卫, 等. 半挂汽车列车转弯制动试验方法研究[J]. 汽车工程, 2015, 37(7): 777-781, 801. |

| Li Chen, Li Xing-hu, Zhang Hong-wei, et al. A study on the test methods of cornering braking for tractor-semitrailer combination[J]. Automotive Engineering, 2015, 37(7): 777-781, 801. | |

| 6 | 何仁, 陈珊珊. 基于液力缓速器换挡控制的半挂汽车列车制动稳定性[J]. 吉林大学学报:工学版, 2017, 47(6): 1677-1687. |

| He Ren, Chen Shan-shan. Braking stability of tractor-semitrailer based on gear-shifting strategy of hydraulic retarder[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(6): 1677-1687. | |

| 7 | 庄汉忠, 吴庆友. 车辆制动时序的测试[J]. 实验室研究与探索, 1991(1): 95-96, 103. |

| Zhuang Han-zhong, Wu Qing-you. Test of Vehicle Braking time sequence[J]. Research and Exploration In Laboratory, 1991(1): 95-96, 103. | |

| 8 | 李宁. 载货汽车气压制动系统制动时序检测方法研究[D]. 长春: 吉林大学交通学院, 2015. |

| Li Ning. Research on detection method of braking time sequence of truck's air brake system[D]. Changchun: College of Transportation, Jilin University, 2015. | |

| 9 | Li X, Chen W, Xu Q. A novel dynamic measurement system for evaluating the braking coordination of articulated vehicles[J]. Journal of Sensors, 2016: 1-10. |

| 10 | ―2016道路运输车辆综合性能要求和检验方法[S]. |

| 11 | 陈南峰, 谷占勋, 应朝阳. 未来汽车列车制动技术改进建议及其检测技术探讨[J]. 汽车与安全, 2015(4):114-119. |

| Chen Nan-feng, Gu Zhan-xun, Ying Zhao-yang. Combination of vehicles braking technology improvement suggestions for future and discussion on the detection technology[J]. Auto & Safety, 2015(4): 114-119. | |

| 12 | 敬天龙. 一种汽车列车制动性能检测台[P]. 2016. |

| 13 | 余志生. 汽车理论[M]. 5版.北京: 机械工业出版社, 2009. |

| 14 | 张广军. 视觉测量[M]. 北京:科学出版社, 2008. |

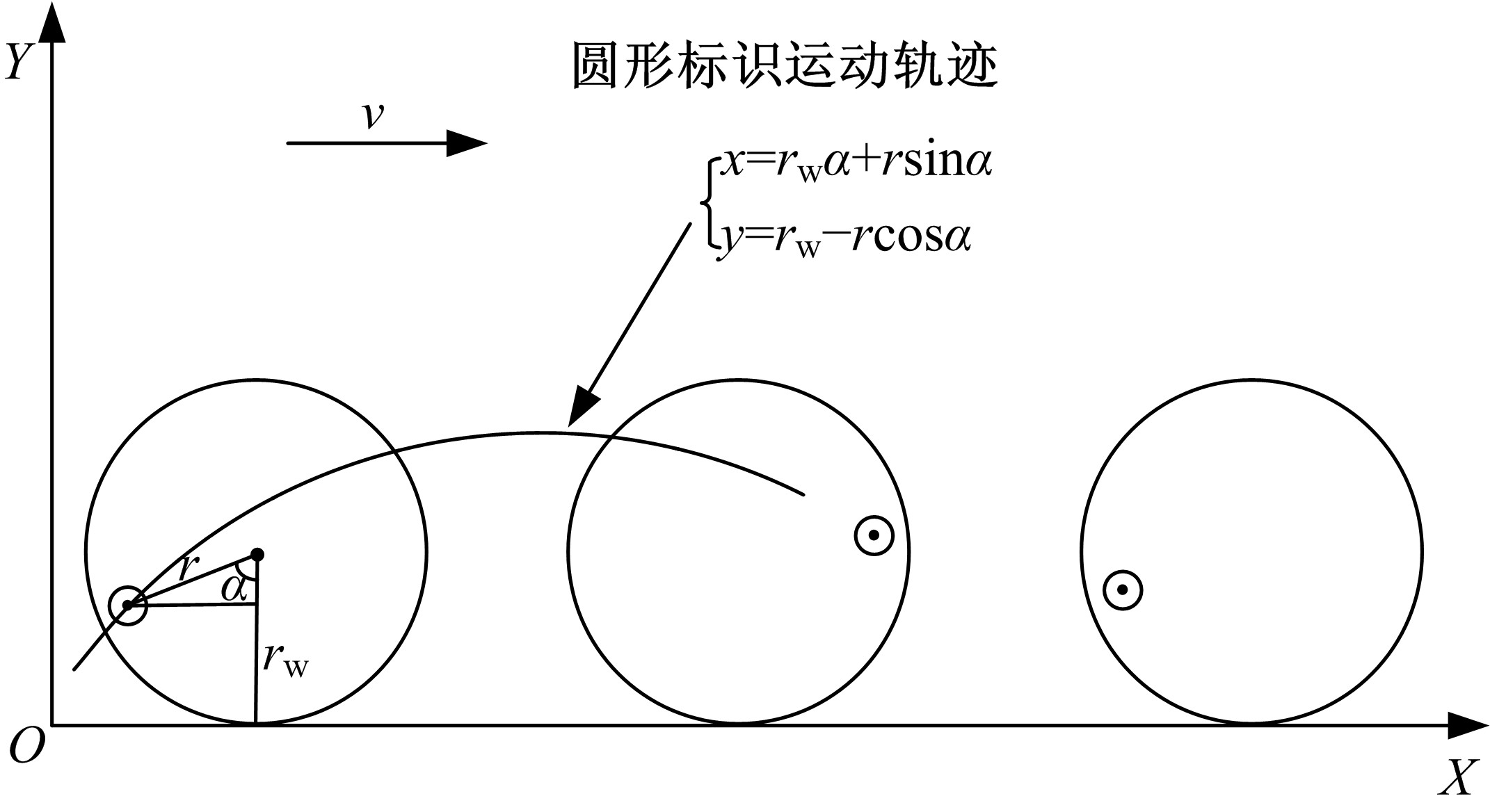

| 15 | 关立文, 赵肖, 王立平. 基于次摆线轨迹的铣削层厚度模型[J]. 清华大学学报:自然科学版, 2017, 57(11): 1185-1189. |

| Guan Li-wen, Zhao Xiao, Wang Li-ping. et al. Milling-layer thickness model based on a trochoid trajectory[J]. Journal of Tsinghua University (Science and Technology), 2017, 57(11): 1185-1189. | |

| 16 | Zhang Z Y. A flexible new technique for camera calibration[J]. IEEE Transactions on Pattern Analysis & Machine Intelligence, 2000, 22(11): 1330-1334. |

| 17 | Madsen K, Nielsen H B, Tingleff O. Methods for non-linear least squares problems [M]. 2nd ed. Copenhagen: Technical University of Denmark, 2004: 5-24. |

| 18 | 王玉灵. 基于双边滤波的图像处理算法研究[D]. 西安:西安电子科技大学理学院, 2010. |

| Wang Yu-ling. Study of Algorithm in Image Processing Based on the Bilateral Filter[D]. Xi'an: School of Science, Xidian University, 2010. | |

| 19 | Canny J. A computational approach to edge detection[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 1986(6): 679-698. |

| 20 | Djekoune A O, Messaoudi K, Amara K. Incremental circle hough transform: an improved method for circle detection[J]. Optik, 2017, 133: 17-31. |

| 21 | ―2017.测量不确定度评定和表示[S]. |

| [1] | 马芳武,梁鸿宇,王强,蒲永锋. 双材料负泊松比结构的面内冲击动力学性能[J]. 吉林大学学报(工学版), 2021, 51(1): 114-121. |

| [2] | 熊璐,魏琰超,高乐天. 基于惯性测量单元/轮速融合的车辆零速检测方法[J]. 吉林大学学报(工学版), 2021, 51(1): 134-138. |

| [3] | 陈吉清,蓝庆生,兰凤崇,刘照麟. 基于轮胎力预判与拟合的轨迹跟踪控制[J]. 吉林大学学报(工学版), 2020, 50(5): 1565-1573. |

| [4] | 杨志刚,范亚军,夏超,储世俊,单希壮. 基于双稳态尾迹的方背Ahmed模型减阻[J]. 吉林大学学报(工学版), 2020, 50(5): 1635-1644. |

| [5] | 沈哲,王毅刚,杨志刚,贺银芝. 风洞中未知声源漂移误差的逼近修正[J]. 吉林大学学报(工学版), 2020, 50(5): 1584-1589. |

| [6] | 刘钊,程江琳,朱玉田,郑立辉. 轨道车辆垂向振动建模及运动关联分析[J]. 吉林大学学报(工学版), 2020, 50(5): 1600-1607. |

| [7] | 杜常清,曹锡良,何彪,任卫群. 基于混合粒子群算法的双离合变速器参数优化设计[J]. 吉林大学学报(工学版), 2020, 50(5): 1556-1564. |

| [8] | 李静,石求军,洪良,刘鹏. 基于车辆状态估计的商用车ESC神经网络滑模控制[J]. 吉林大学学报(工学版), 2020, 50(5): 1545-1555. |

| [9] | 高菲,肖阳,张文华,祁锦轩,李子樵,马骁远. 高温和荷电状态对锂离子电池单体力学响应的耦合影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1574-1583. |

| [10] | 李小雨,许男,仇韬,郭孔辉. 各向异性刚度对轮胎力学特性及车辆操纵性的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 389-398. |

| [11] | 陈鑫,王宁,沈传亮,冯晓,杨昌海. 后视镜造型对前侧窗气动噪声的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 426-436. |

| [12] | 李银平,靳添絮,刘立. 纯电动铲运机弓网续能系统设计与动态特性仿真[J]. 吉林大学学报(工学版), 2020, 50(2): 454-463. |

| [13] | 赖晨光,王擎宇,胡博,文凯平,陈彦宇. 静气动弹性影响下带小翼汽车尾翼的设计与优化[J]. 吉林大学学报(工学版), 2020, 50(2): 399-407. |

| [14] | 叶辉,刘畅,闫康康. 纤维增强复合材料在汽车覆盖件中的应用[J]. 吉林大学学报(工学版), 2020, 50(2): 417-425. |

| [15] | 马芳武,梁鸿宇,赵颖,杨猛,蒲永锋. 内凹三角形负泊松比结构耐撞性多目标优化设计[J]. 吉林大学学报(工学版), 2020, 50(1): 29-35. |

|

||