吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (6): 1943-1952.doi: 10.13229/j.cnki.jdxbgxb20200656

• 车辆工程·机械工程 • 上一篇

电动汽车热泵空调系统性能分析

- 1.吉林大学 汽车仿真与控制国家重点实验室,长春 130022

2.中国一汽集团研发总院,长春 130013

3.江苏超力电器有限公司,江苏 镇江 212321

Performance analysis of electric vehicle heat pump air conditioning system

Ming LI1( ),Qing-feng XUE2,Ke-xin ZHANG1,Ran LYU1,Chang-hua WEI3

),Qing-feng XUE2,Ke-xin ZHANG1,Ran LYU1,Chang-hua WEI3

- 1.Sate Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

2.General Institute of FAW Vehicle Development Department,China Faw Group Co. ,Ltd. ,Changchun 130013,China

3.Jiangsu Chaoli Electric Manufacture Co. ,Ltd. ,Zhenjiang 212321,China

摘要:

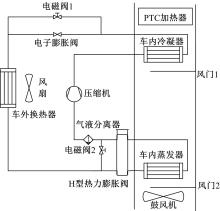

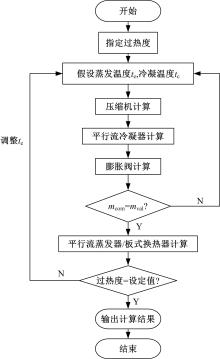

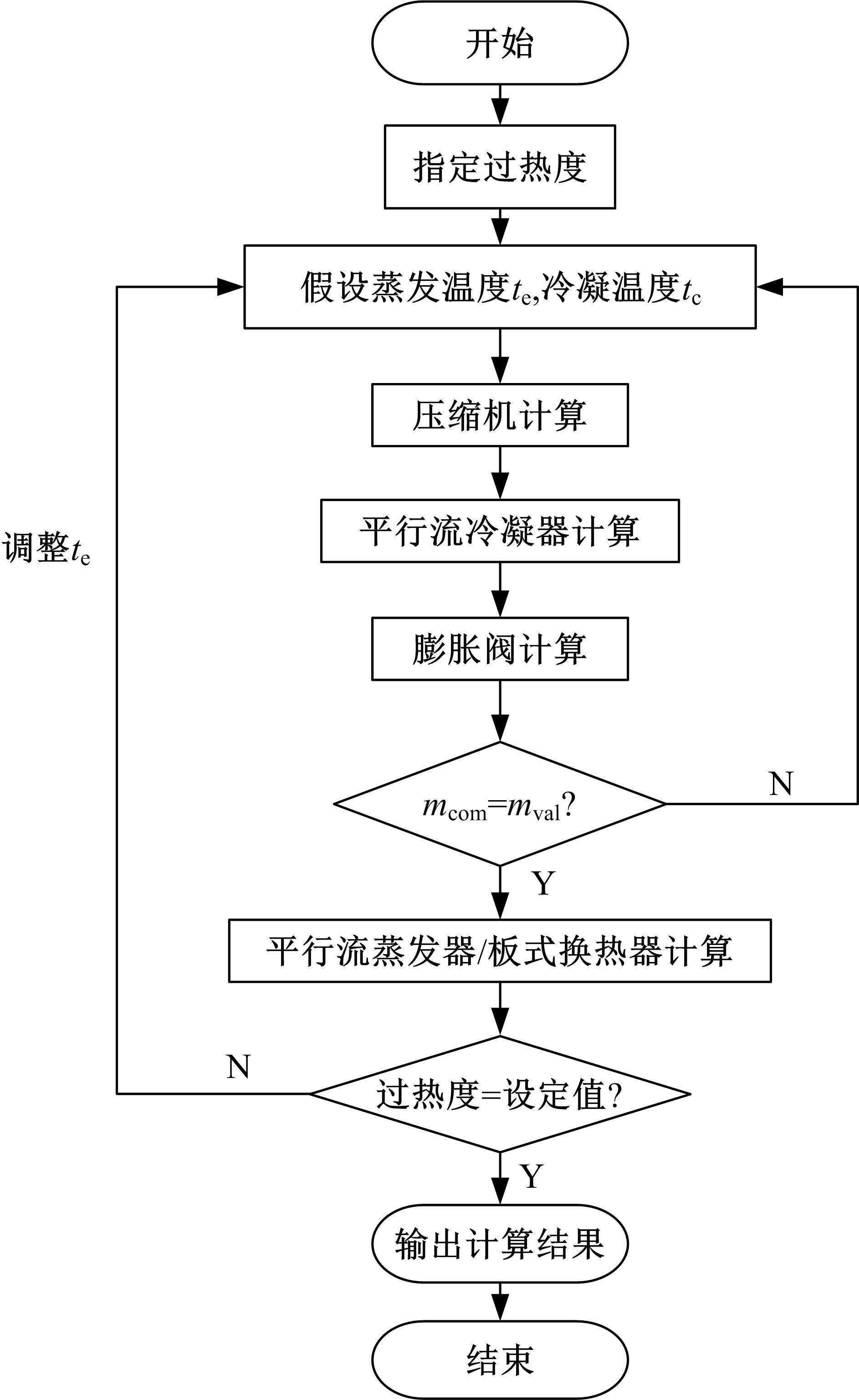

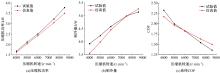

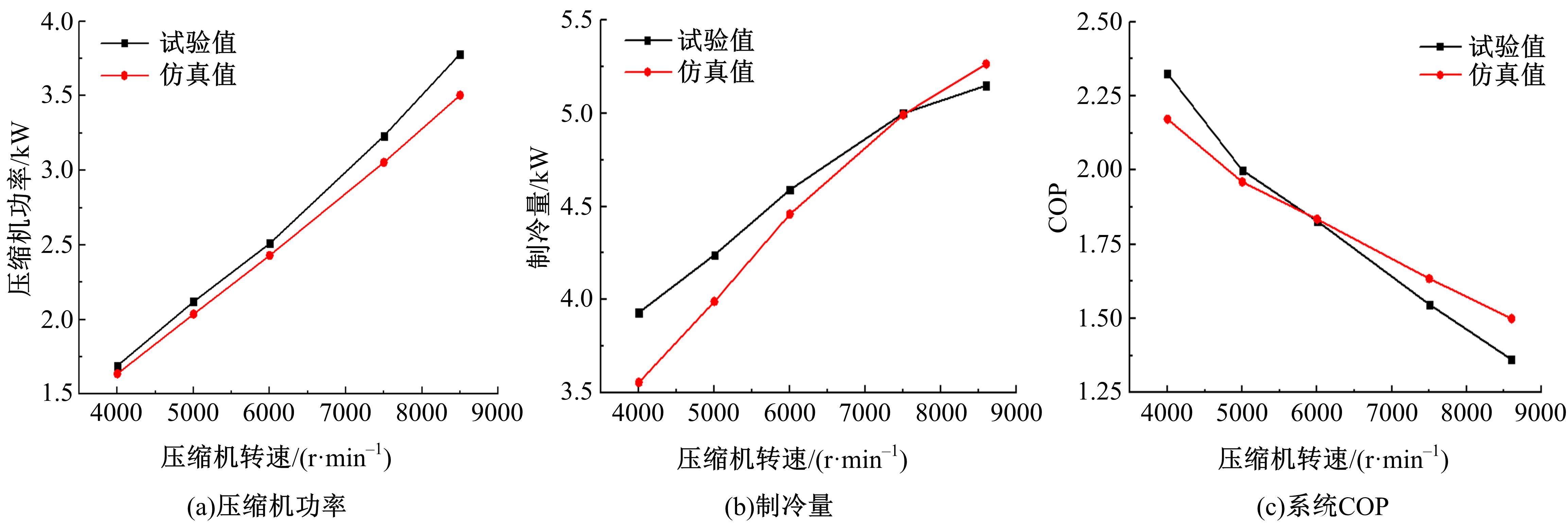

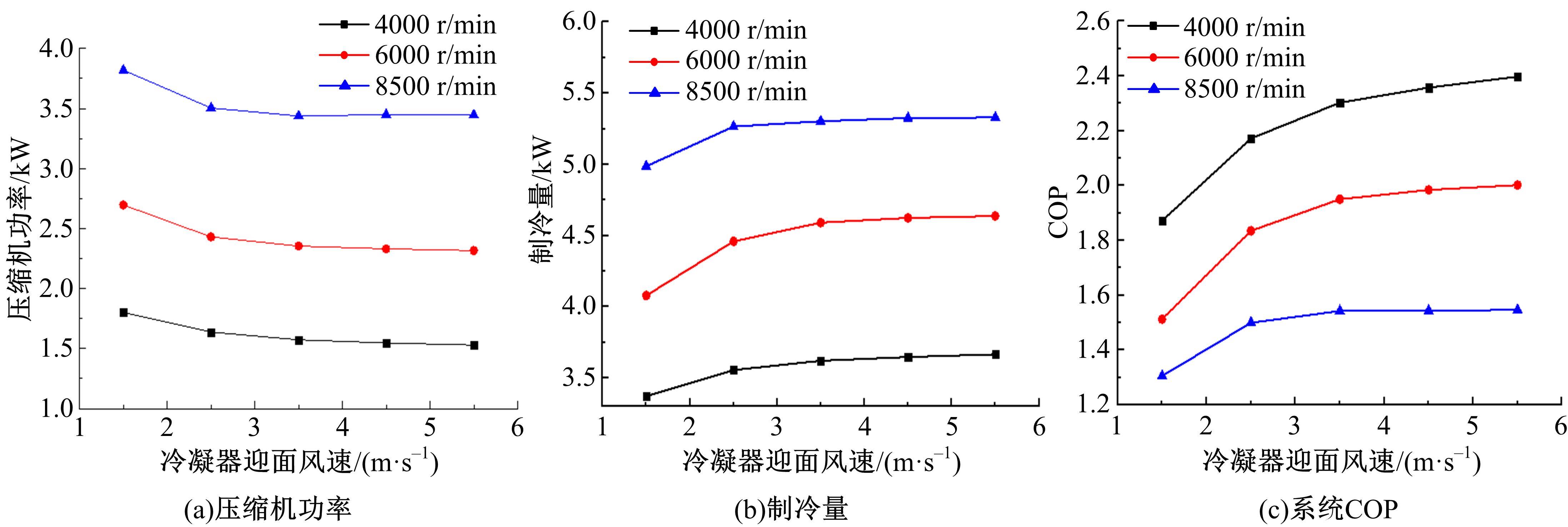

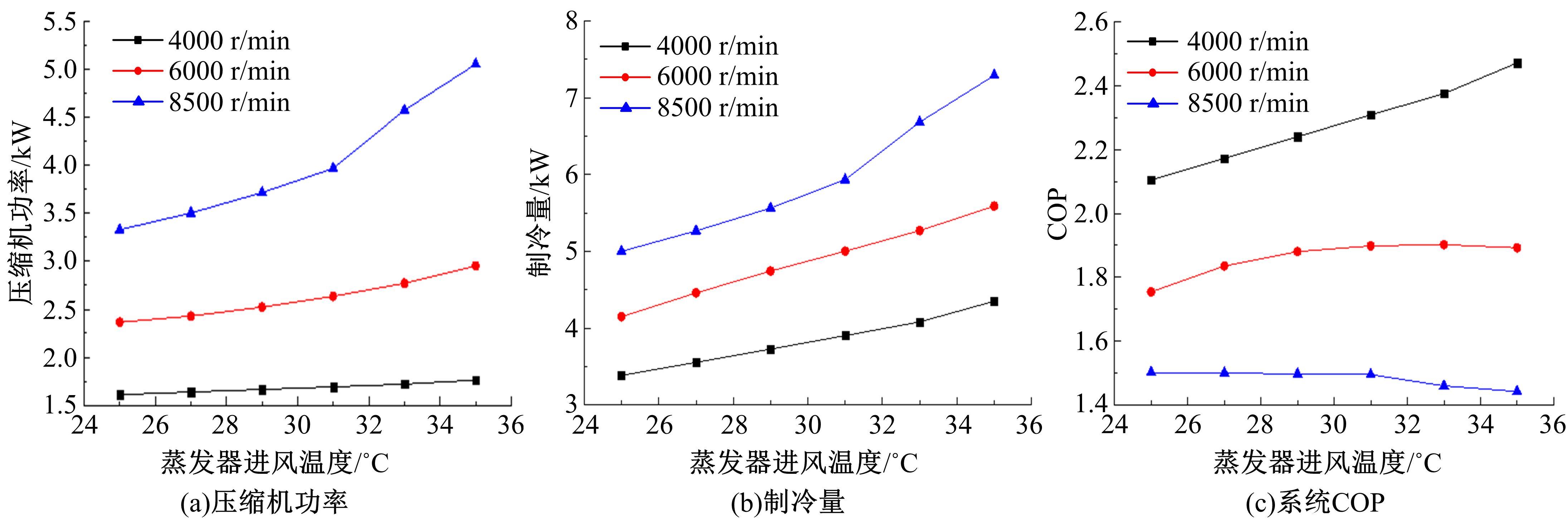

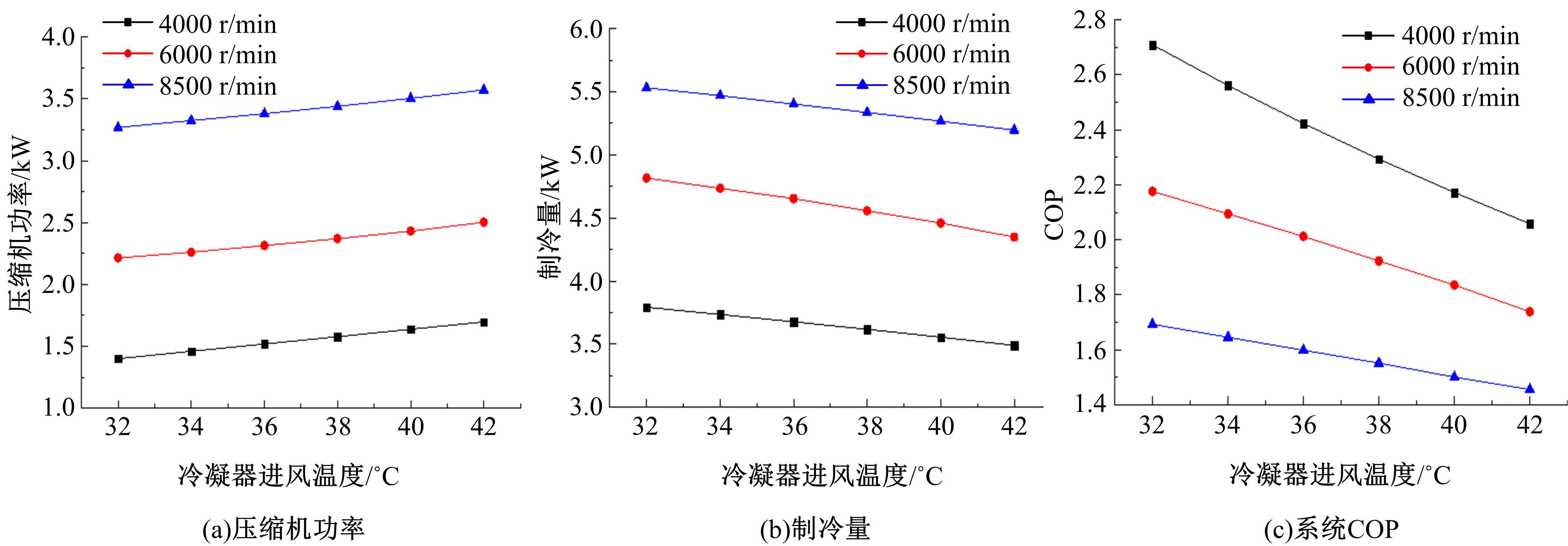

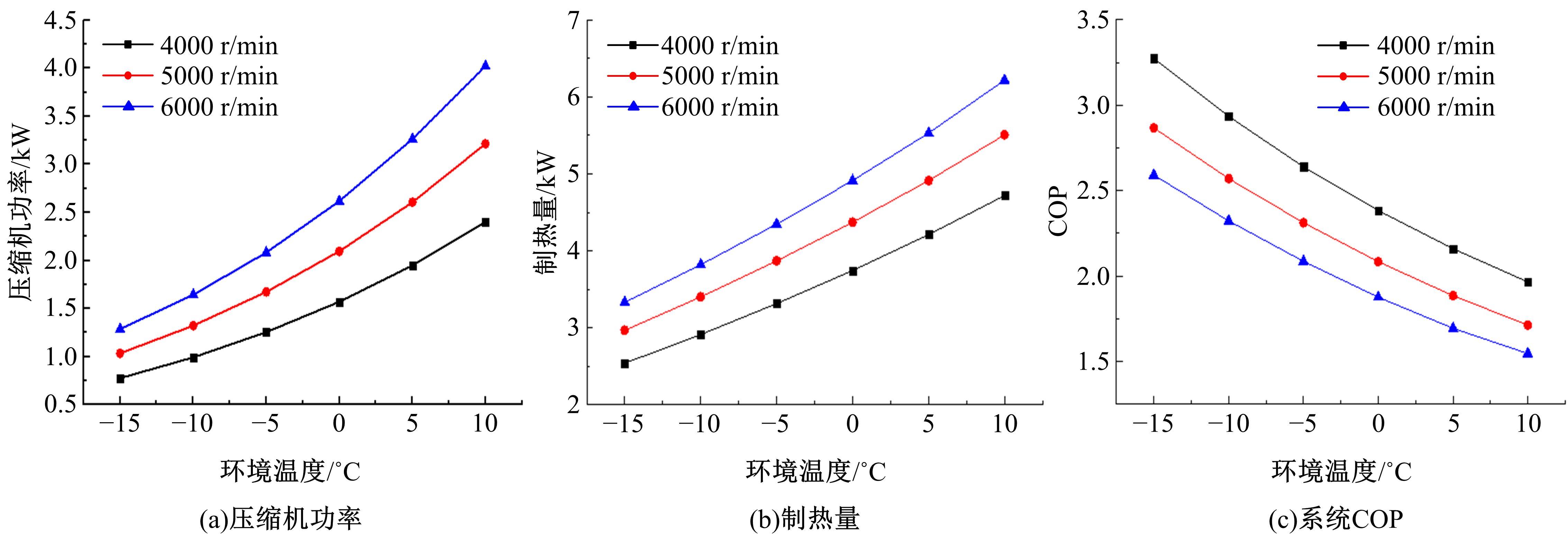

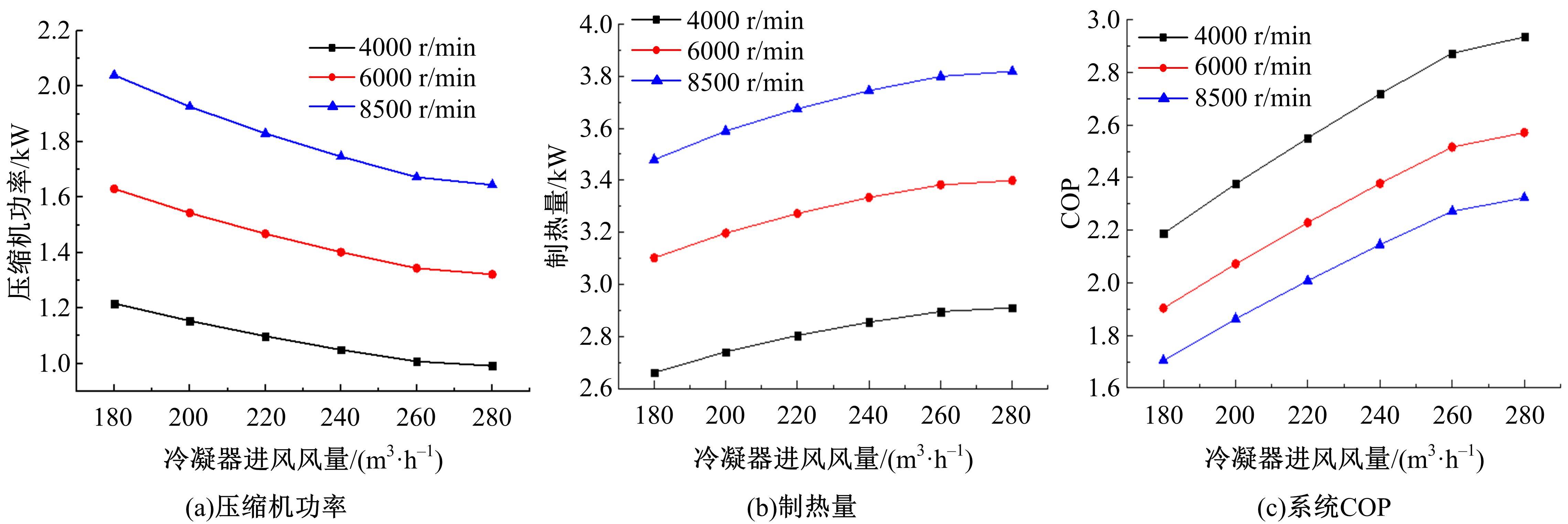

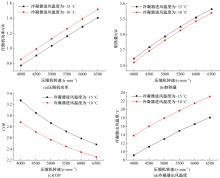

搭建了电动汽车热泵空调系统仿真模型和性能仿真分析平台,分析了热泵空调系统在不同模式下的性能,并采用试验结果对仿真模型进行验证。结果表明:试验得到压缩机功率、换热量、系统COP值与对应的仿真值之间的最大误差为4%~10.09%。在制冷模式和制热模式下,随着压缩机转速的增大,压缩机功率逐渐增大,换热量逐渐增大,系统COP逐渐减小。此外,研究了冷凝器、蒸发器进风风量、进风温度、进风方式等因素对制冷模式和制热模式下系统性能的影响,结果表明,制冷时采用大风量有利于提高制冷量,进风温度的影响取决于工况特征,而采用部分进风方式更有利于系统制热节能。

中图分类号:

- U463

| 1 | Zhao Gang-qi. Advances on air conditioning and heat pump system in electric vehicles——a review[J]. Renewable and Sustainable Energy Reviews, 2014, 38: 754-764. |

| 2 | 张天时,宋东鉴,高青,等.电动汽车动力电池液体冷却系统构建及其工作过程仿真[J].吉林大学学报:工学版,2018,48(2):387-397. |

| Zhang Tian-shi, Song Dong-jian, Gao Qing, et al. Electric vehicle power battery liquid cooling system construction and working process simulation[J]. Journal of Jilin University(Engineering and Technology Edition), 2018,48(2): 387-397. | |

| 3 | 闵海涛,曹云波,曾小华,等. 电动汽车空调系统建模及对整车性能的影响[J]. 吉林大学学报:工学版,2009,39():53-57. |

| Min Hai-tao, Cao Yun-bo, Zeng Xiao-hua, et al. Modeling of air conditioning system of electric vehicle and its influence on vehicle performance[J]. Journal of Jilin University(Engineering and Technology Edition), 2009,39(Sup.1): 53-57. | |

| 4 | 轩小波,陈斐,戎森杰. 电动汽车用热泵空调系统制热性能的试研究[J]. 制冷与空调, 2017, 17(3): 47-50, 40. |

| Xuan Xiao-bo, Chen Fei, Rong Sen-jie. Experimental study on heating performance of heat pump air conditioning system for electric vehicle[J]. Refrigeration and Air-Conditioning, 2017, 17(3): 47-50, 40. | |

| 5 | Park S H, Kim S C. Heating performance characteristics of high-voltage ptc heater for an electric vehicle[J]. Energies, 2017, 10(10): 1494. |

| 6 | Zhang K, Li M, Yang C. et al. Exergy analysis of electric vehicle heat pump air conditioning system with battery thermal management system[J]. Journal of Thermal Science, 2020, 29(2):408-422. |

| 7 | Tang X, Guo Q, Li M, et al. Heating performance characteristics of an electric vehicle heat pump air conditioning system based on exergy analysis[J]. Energies, 2020, 13(11):2868. |

| 8 | Li Ming,Cui Song, Huang Hai-zhen, et al. Effect of pipes in heat pump system on electric vehicle energy saving[J]. International Journal of Green Energy, 2020, 17(11): 1-10. |

| 9 | 彭发展,魏名山,黄海圣,等. 环境温度对电动汽车热泵空调系统性能的影响[J]. 北京航空航天大学学报, 2014, 40(12):1741-1746. |

| Peng Fa-zhan, Wei Ming-shan, Huang Hai-sheng, et al. Effect of ambient temperature on performance of heat pump air conditioning system for electric vehicle[J]. Journal of Beijing University of Aeronautics and Astronautics, 2014, 40(12):1741-1746. | |

| 10 | 张文嵘,刘丽娜,钱程,等. 热泵型纯电动汽车空调系统特性[J]. 制冷学报, 2018, 39(6):109-114. |

| Zhang Wen-rong, Liu Li-na, Qian Cheng, et al. Characteristics of air conditioning system for heat pump electric vehicle[J]. Journal of Refrigeration, 2018, 39(6):109-114. | |

| 11 | 彭庆丰,赵韩,陈祥吉,等. 电动汽车新型热泵空调系统的设计与试验研究[J]. 汽车工程, 2015, 37(12): 1467-1470, 1432. |

| Peng Qing-feng, Zhao Han, Chen Xiang-ji, et al. Design and experimental study of new heat pump air conditioning system for electric vehicle[J]. Automotive Engineering, 2015, 37(12): 1467-1470, 1432. | |

| 12 | 丁玮, 孙强, 徐庆春. AMESim仿真技术在汽车空调制冷系统中的应用[J]. 汽车实用技术, 2015, 39(8): 74-77. |

| Ding Wei, Sun Qiang, Xu Qing-chun. Application of AMESim simulation technology in automobile air conditioning refrigeration system[J]. Automobile Applied Technology, 2015, 39(8):74-77. | |

| 13 | 方继华. 基于微通道平行流蒸发器的电动汽车空调系统性能研究[D]. 上海:上海交通大学机械与动力工程学院, 2015. |

| Fang Ji-hua. Performance study of electric vehicle air conditioning system based on microchannel parallel flow evaporator[D]. Shanghai:School of Mechanical Engineering, Shanghai Jiao Tong University, 2015. | |

| 14 | 韩联进,巫江虹,薛志强. 电动客车热泵空调系统仿真与改进[J]. 浙江大学学报:工学版, 2018, 52(4): 641-648. |

| Han Lian-jin, Wu Jiang-hong, Xue Zhi-qiang. Simulation and improvement of heat pump air conditioning system for electric bus[J]. Journal of Zhejiang University(Engineering Science), 2018, 52(4): 641-648. | |

| 15 | 钟会球. 电动汽车空调系统仿真与实验研究[D]. 杭州:浙江大学能源工程学院, 2012. |

| Zhong Hui-qiu. Simulation and experimental study on air conditioning system of electric vehicle[D]. Hangzhou: College of Energy Engineering, Zhejiang University, 2012. | |

| 16 | Chang Y J, Wang C C. A generalized heat transfer correlation for louver fin geometry[J]. International Journal of Heat and Mass Transfer, 1997, 40(3): 533-544. |

| 17 | Kandlikar S G, Steinke M E. Predicting heat transfer during flow boiling in minichannels and microchannels[J]. Ashrae Transactions, 2003, 109(1): 1-9. |

| 18 | Akers W W, Deans A, Crosser O K. Condensation heat transfer within horizontal tubes[J]. Chemical Engineering Progress Symposium Series, 1959, 55(29): 171-176. |

| 19 | Dittus F W, Boelter L M K. Heat transfer in automobile radiators of the tubular type[J]. International Communications in Heat and Mass Transfer, 1985, 12(1):3-22. |

| 20 | Wile D D. The measurement of expansion valve capacity[J]. Refrigeration Engineering, 1935(8): 1-81. |

| [1] | 李浩,陈浩. 考虑充电排队时间的电动汽车混合交通路网均衡[J]. 吉林大学学报(工学版), 2021, 51(5): 1684-1691. |

| [2] | 王聪,马彦,王国光. 电动汽车充电站内的实时最优功率分配[J]. 吉林大学学报(工学版), 2021, 51(4): 1490-1495. |

| [3] | 宋强,孙丹婷,章伟. 纯电动车机械式自动变速器换挡非线性建模及控制[J]. 吉林大学学报(工学版), 2021, 51(3): 810-819. |

| [4] | 陈学深,黄柱健,马旭,齐龙,方贵进. 水稻机械除草避苗控制系统设计与试验[J]. 吉林大学学报(工学版), 2021, 51(1): 386-396. |

| [5] | 马苗苗,潘军军,刘向杰. 含电动汽车的微电网模型预测负荷频率控制[J]. 吉林大学学报(工学版), 2019, 49(5): 1644-1652. |

| [6] | 席利贺,张欣,孙传扬,王泽兴,姜涛. 增程式电动汽车自适应能量管理策略[J]. 吉林大学学报(工学版), 2018, 48(6): 1636-1644. |

| [7] | 常成,宋传学,张雅歌,邵玉龙,周放. 双馈电机驱动电动汽车变频器容量最小化[J]. 吉林大学学报(工学版), 2018, 48(6): 1629-1635. |

| [8] | 王扬, 王晓梅, 陈泽仁, 于建群. 基于离散元法的玉米籽粒建模[J]. 吉林大学学报(工学版), 2018, 48(5): 1537-1547. |

| [9] | 徐亮, 兰进, 王明森, 高建民, 李云龙. 旋度对旋转冲击射流传热特性的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1483-1491. |

| [10] | 金立生, 谢宪毅, 高琳琳, 郭柏苍. 基于二次规划的分布式电动汽车稳定性控制[J]. 吉林大学学报(工学版), 2018, 48(5): 1349-1359. |

| [11] | 王扬, 吕凤妍, 徐天月, 于建群. 大豆籽粒形状和尺寸分析及其建模[J]. 吉林大学学报(工学版), 2018, 48(2): 507-517. |

| [12] | 张天时, 宋东鉴, 高青, 王国华, 闫振敏, 宋薇. 电动汽车动力电池液体冷却系统构建及其工作过程仿真[J]. 吉林大学学报(工学版), 2018, 48(2): 387-397. |

| [13] | 孙文, 王庆年, 王军年. 基于横摆力矩控制的电动轮汽车转弯节能控制[J]. 吉林大学学报(工学版), 2018, 48(1): 11-19. |

| [14] | 邵赛, 毕军, 关伟. 基于电动汽车的动态需求车辆路径问题[J]. 吉林大学学报(工学版), 2017, 47(6): 1688-1695. |

| [15] | 李俊烨, 乔泽民, 杨兆军, 张心明. 介观尺度下磨料浓度对磨粒流加工质量的影响[J]. 吉林大学学报(工学版), 2017, 47(3): 837-843. |

|

||