吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (10): 2244-2255.doi: 10.13229/j.cnki.jdxbgxb20210307

• 车辆工程·机械工程 • 上一篇

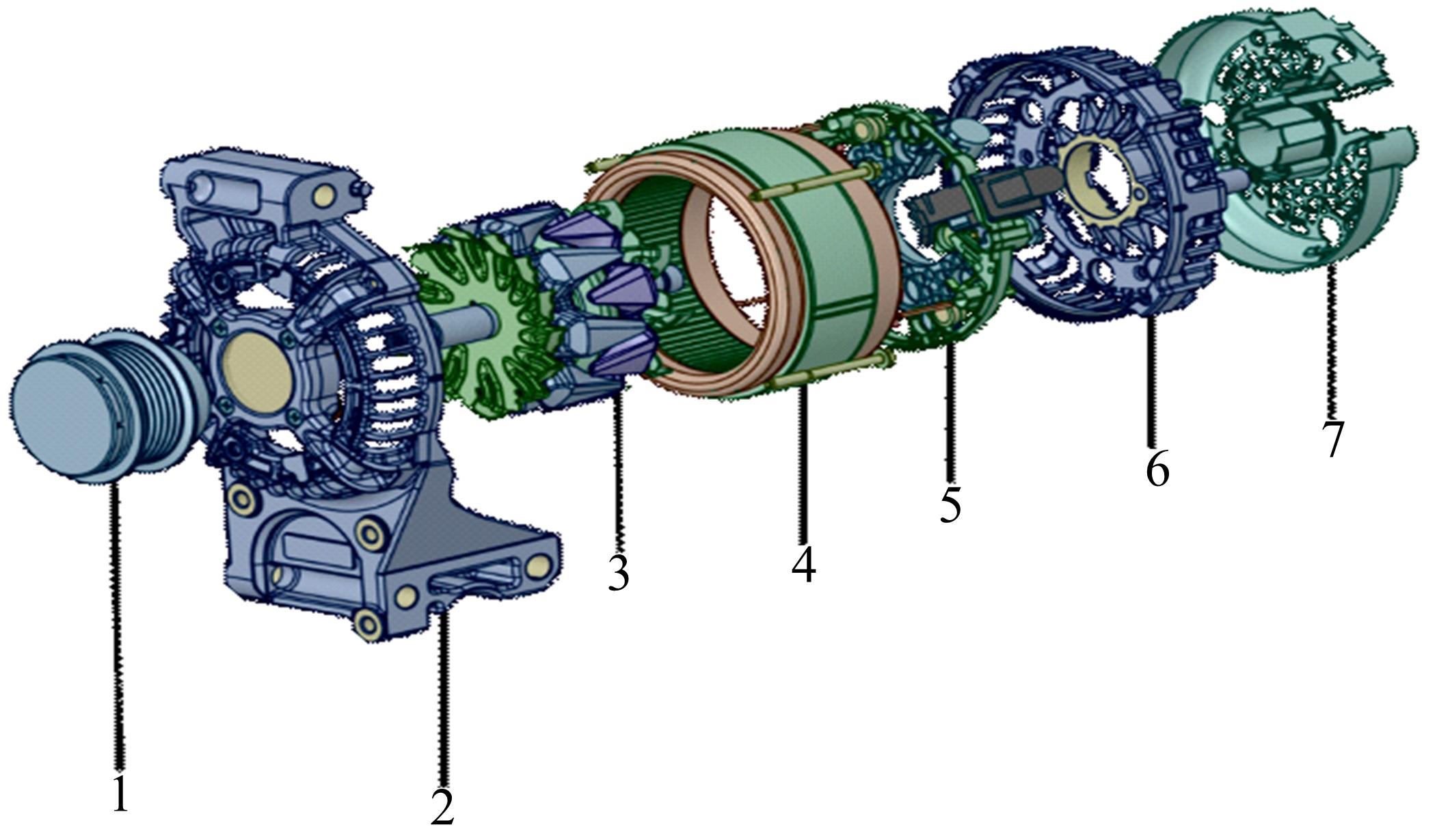

车用爪极发电机的气动噪声优化

黄泰明1( ),李伟平2(

),李伟平2( ),胡涛涛2,岳万昊2,纪念洲2,李域邦3

),胡涛涛2,岳万昊2,纪念洲2,李域邦3

- 1.湖南理工学院 机械工程学院,湖南 岳阳 414006

2.湖南大学 汽车车身先进设计制造国家重点实验室,长沙 410082

3.中南大学 材料科学与工程学院,长沙 410083

Aerodynamic noise optimization of vehicle claw-pole generator

Tai-ming HUANG1( ),Wei-ping LI2(

),Wei-ping LI2( ),Tao-tao HU2,Wan-hao YUE2,Nian-zhou JI2,Yu-bang LI3

),Tao-tao HU2,Wan-hao YUE2,Nian-zhou JI2,Yu-bang LI3

- 1.School of Mechanical Engineering,Hunan Institute of Science and Technology,Yueyang 414006,China

2.State Key Laboratory for Advanced Design and Manufacture of Automobile Body,Hunan University,Changsha 410082,China

3.School of Materials Science and Engineering,Central South University,Changsha 410083,China

摘要:

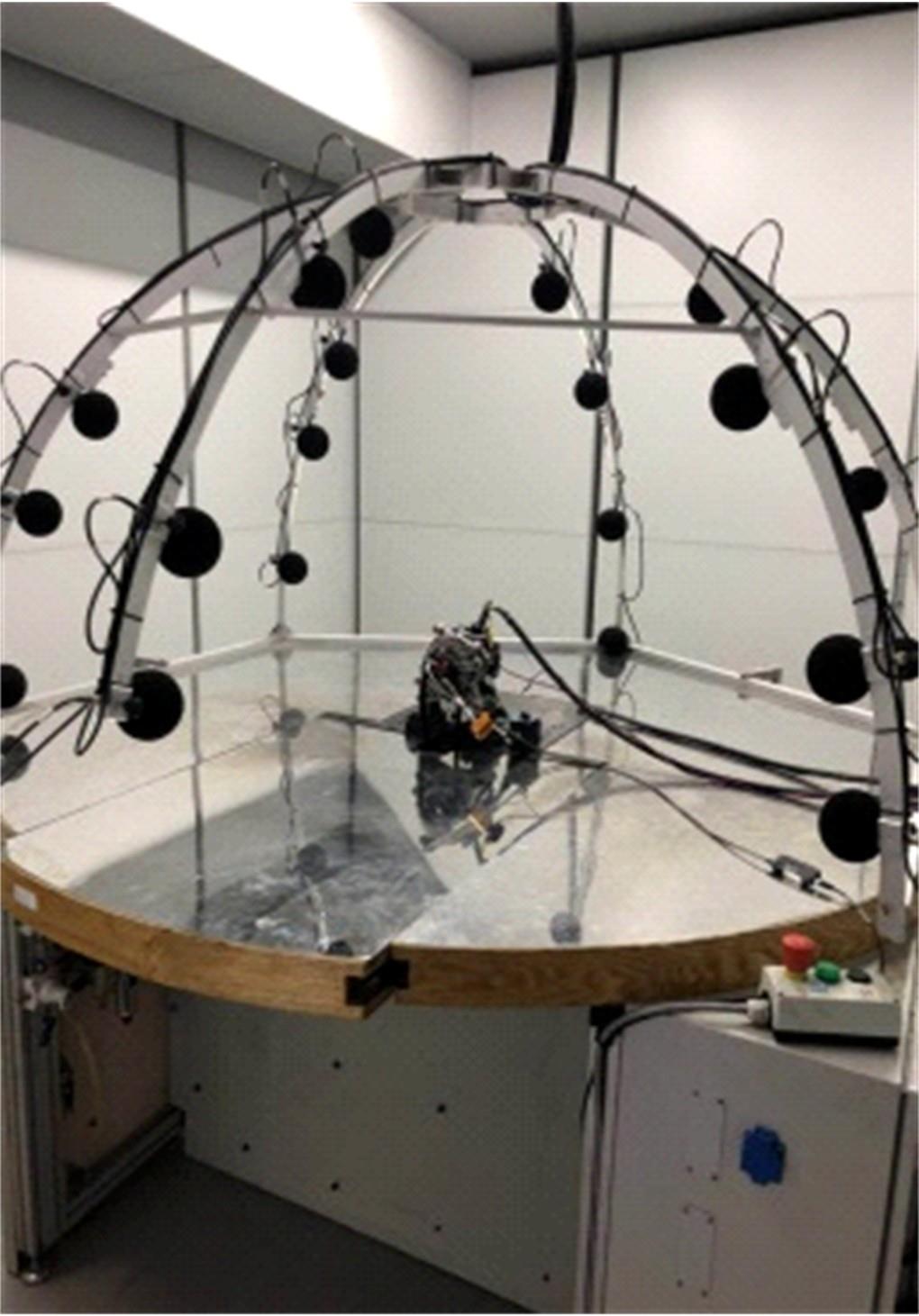

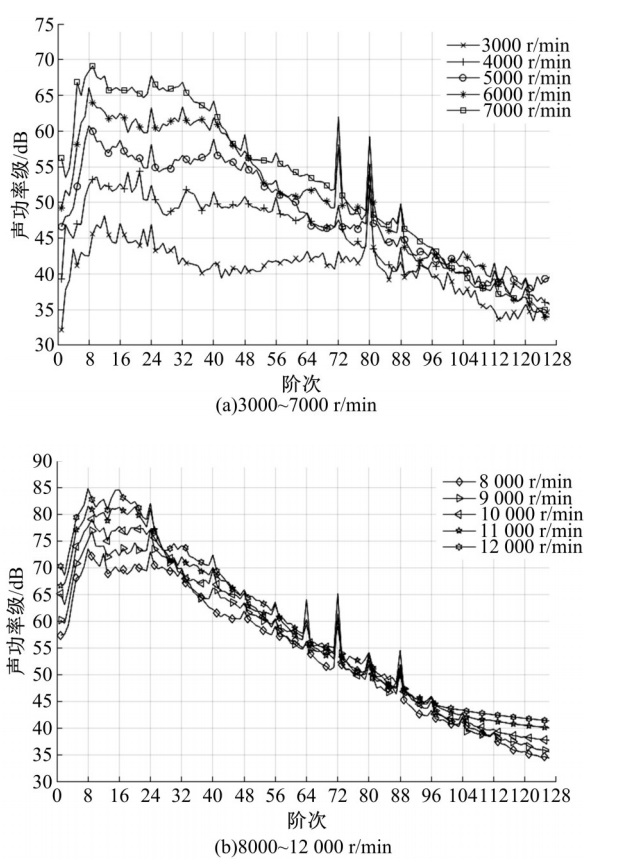

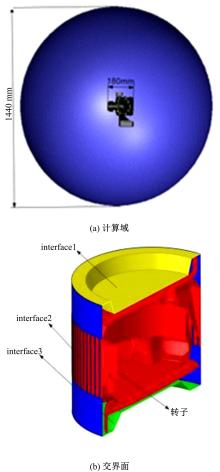

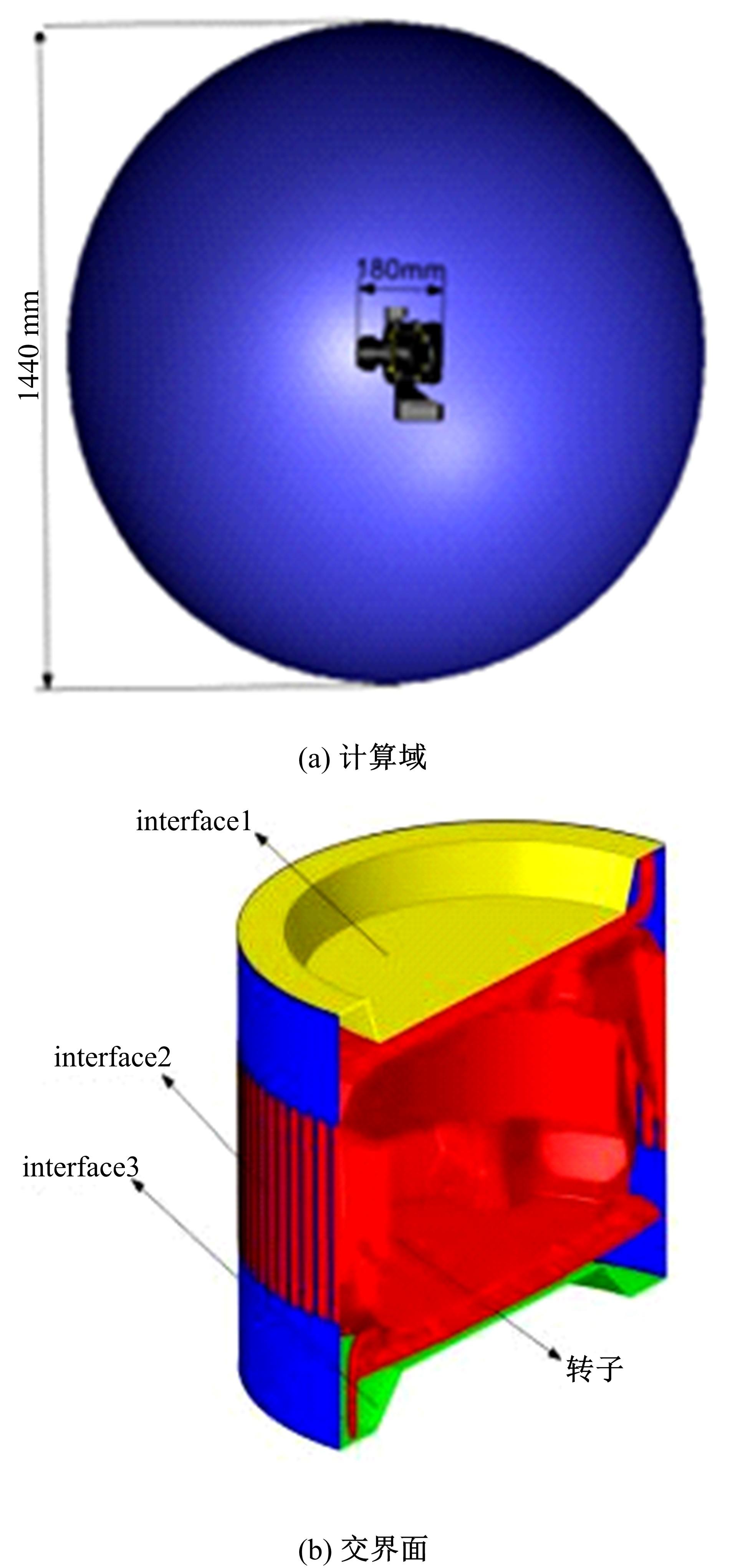

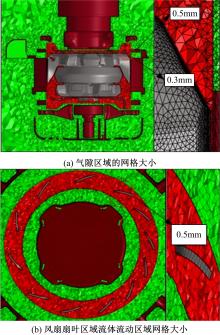

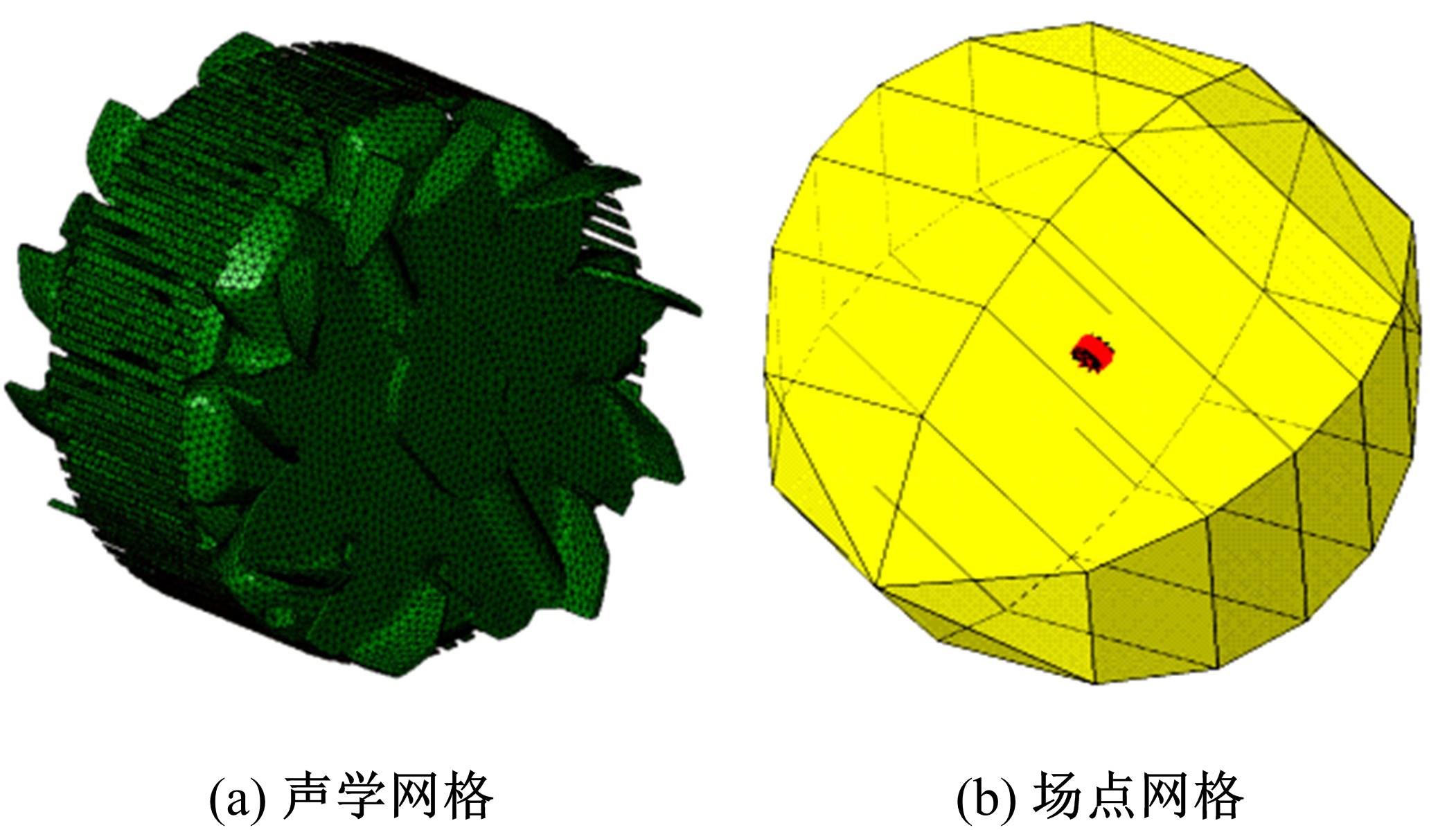

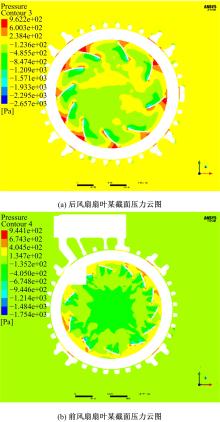

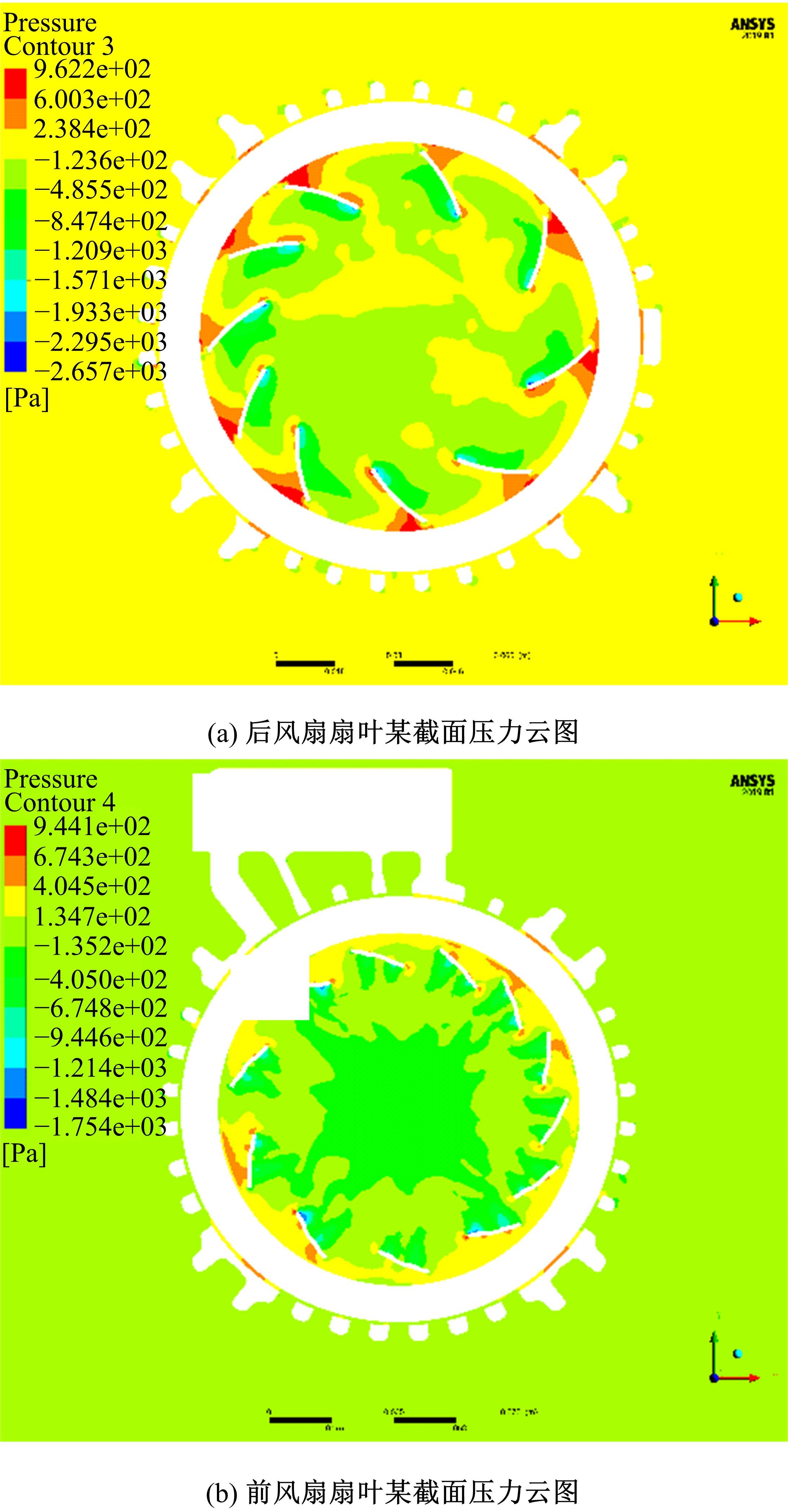

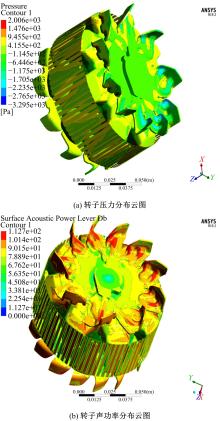

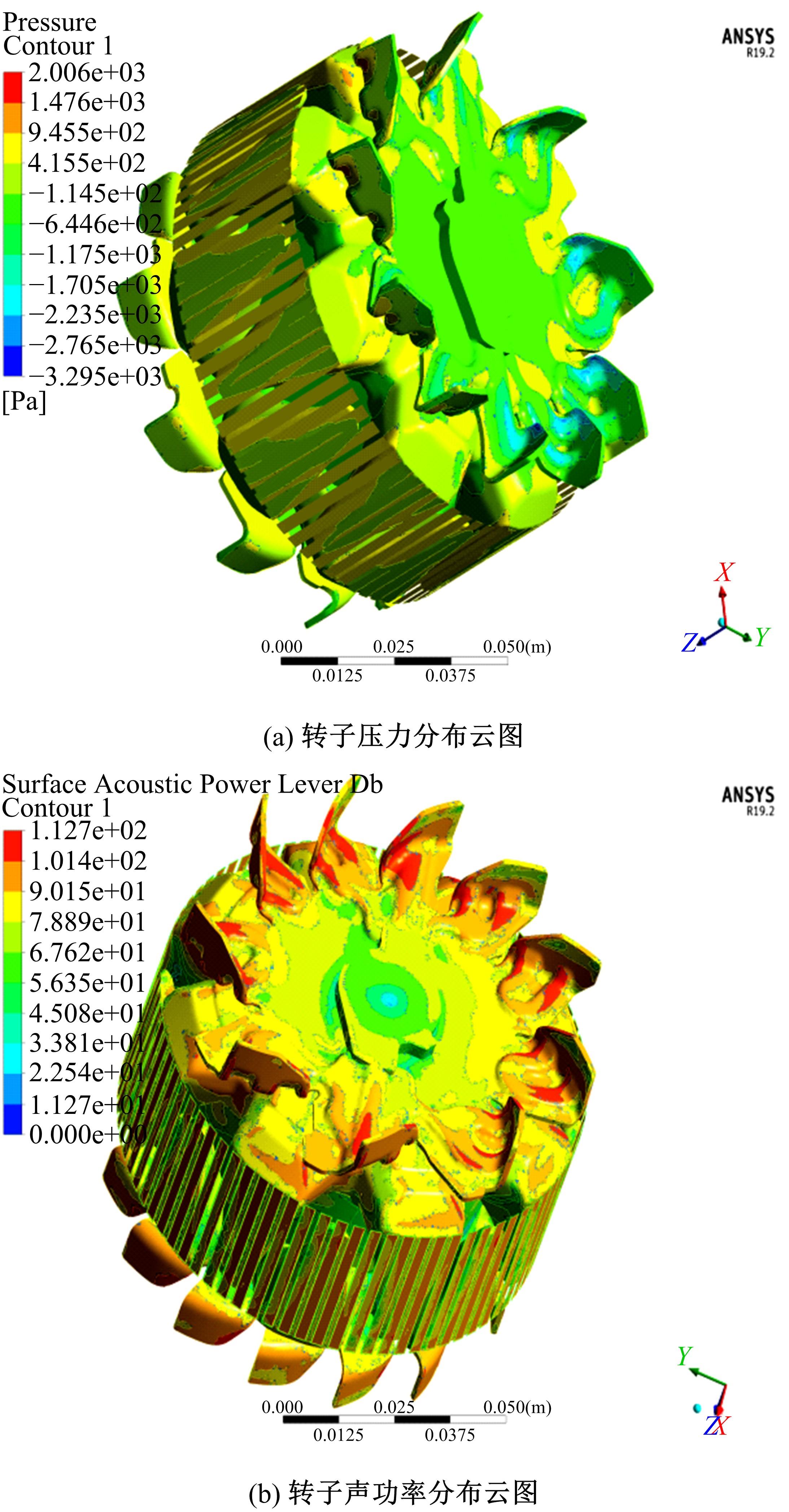

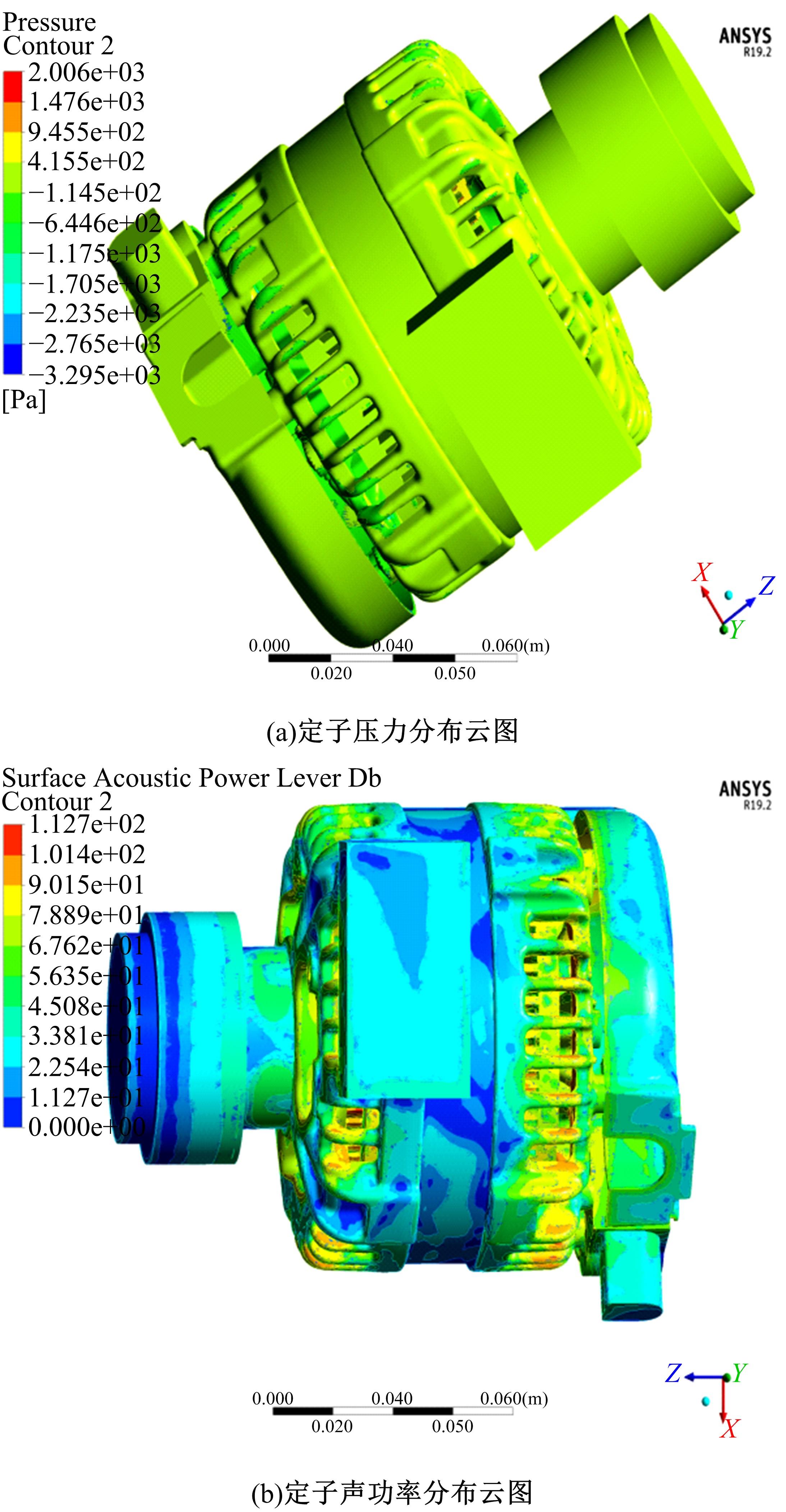

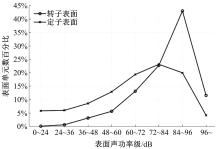

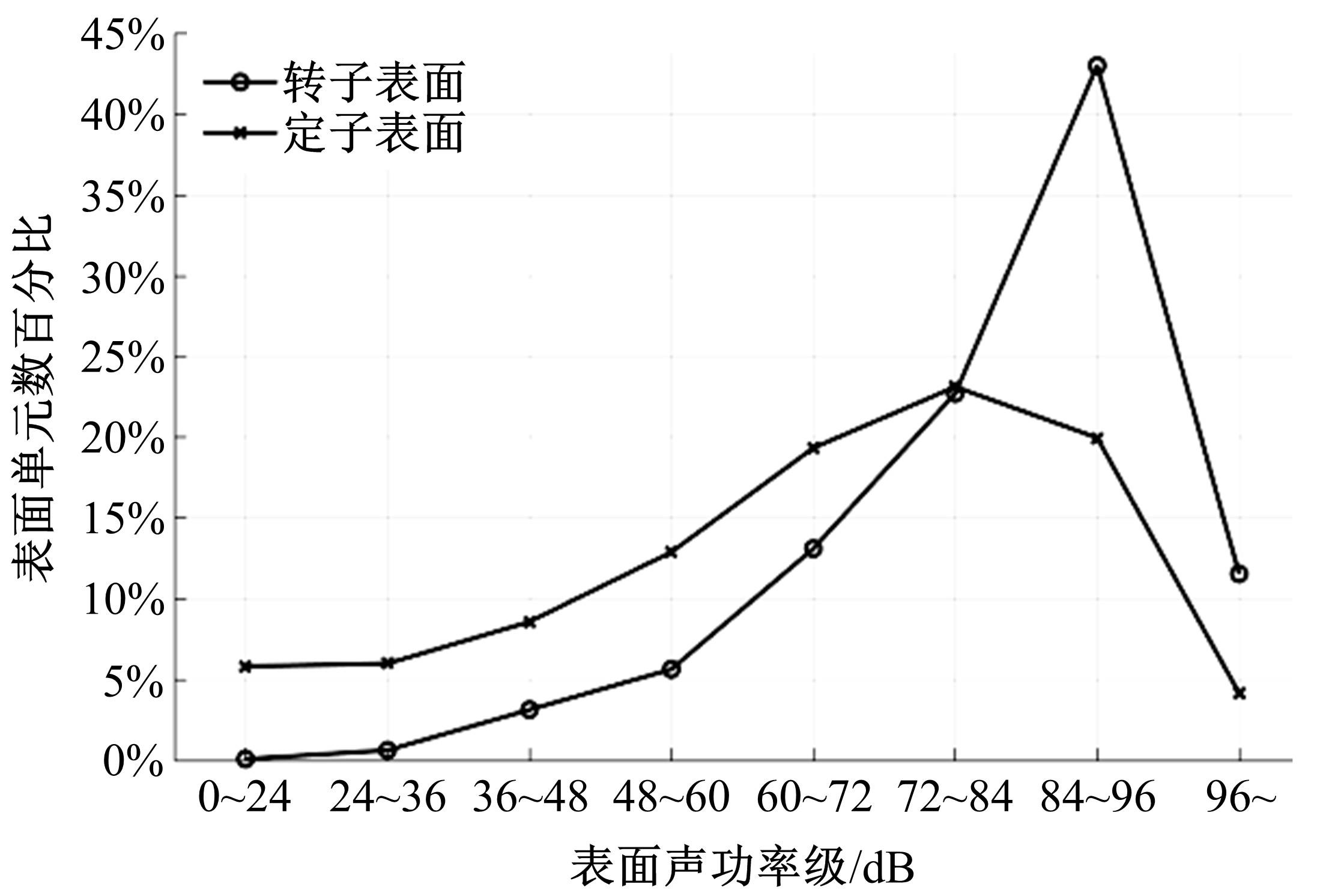

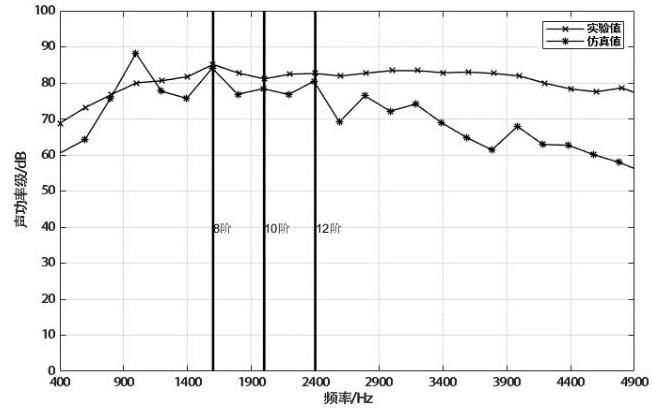

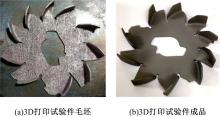

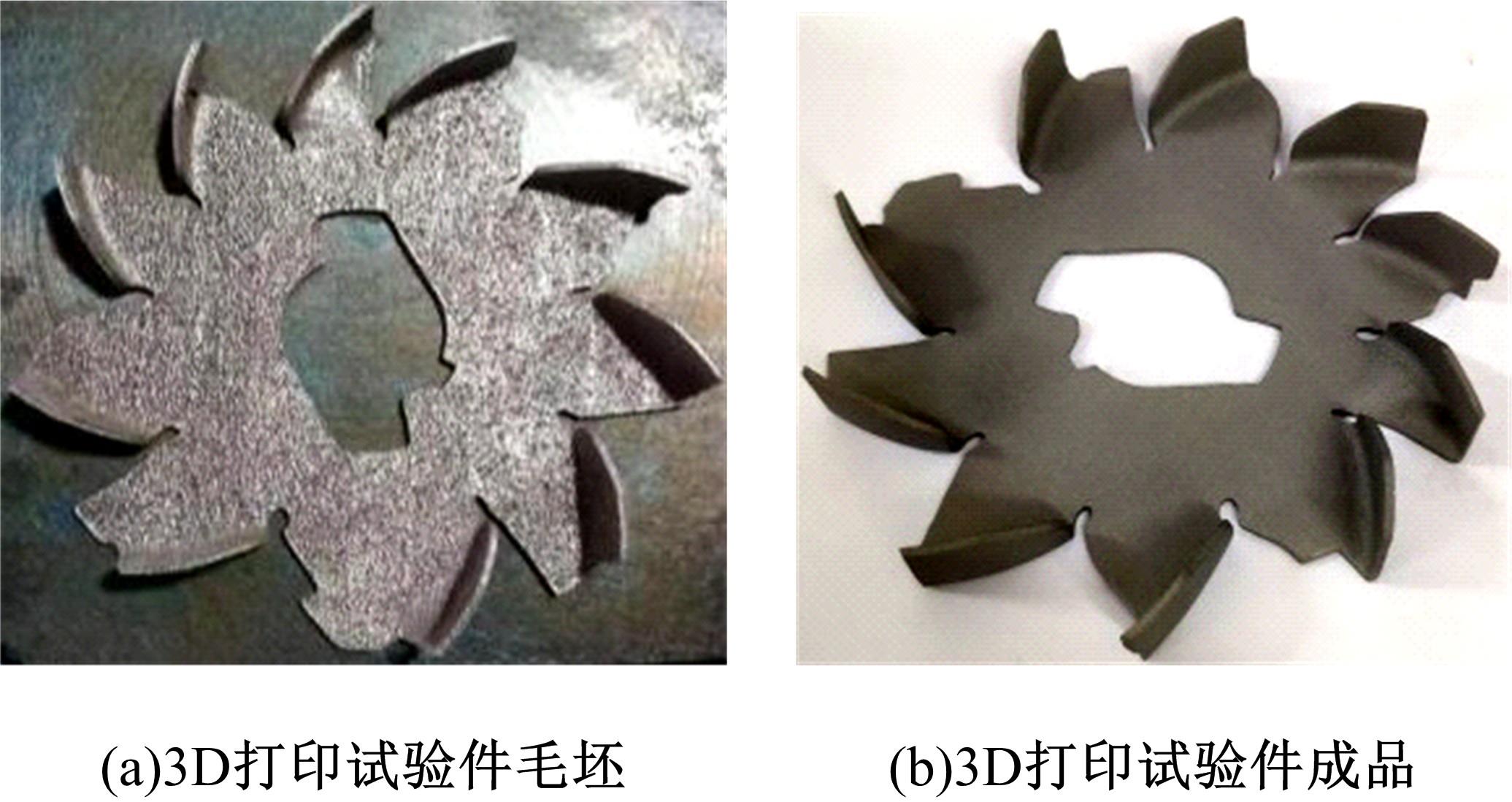

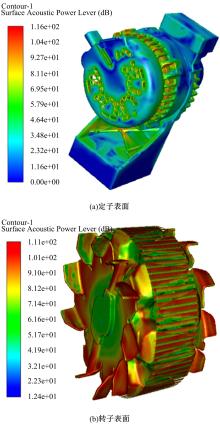

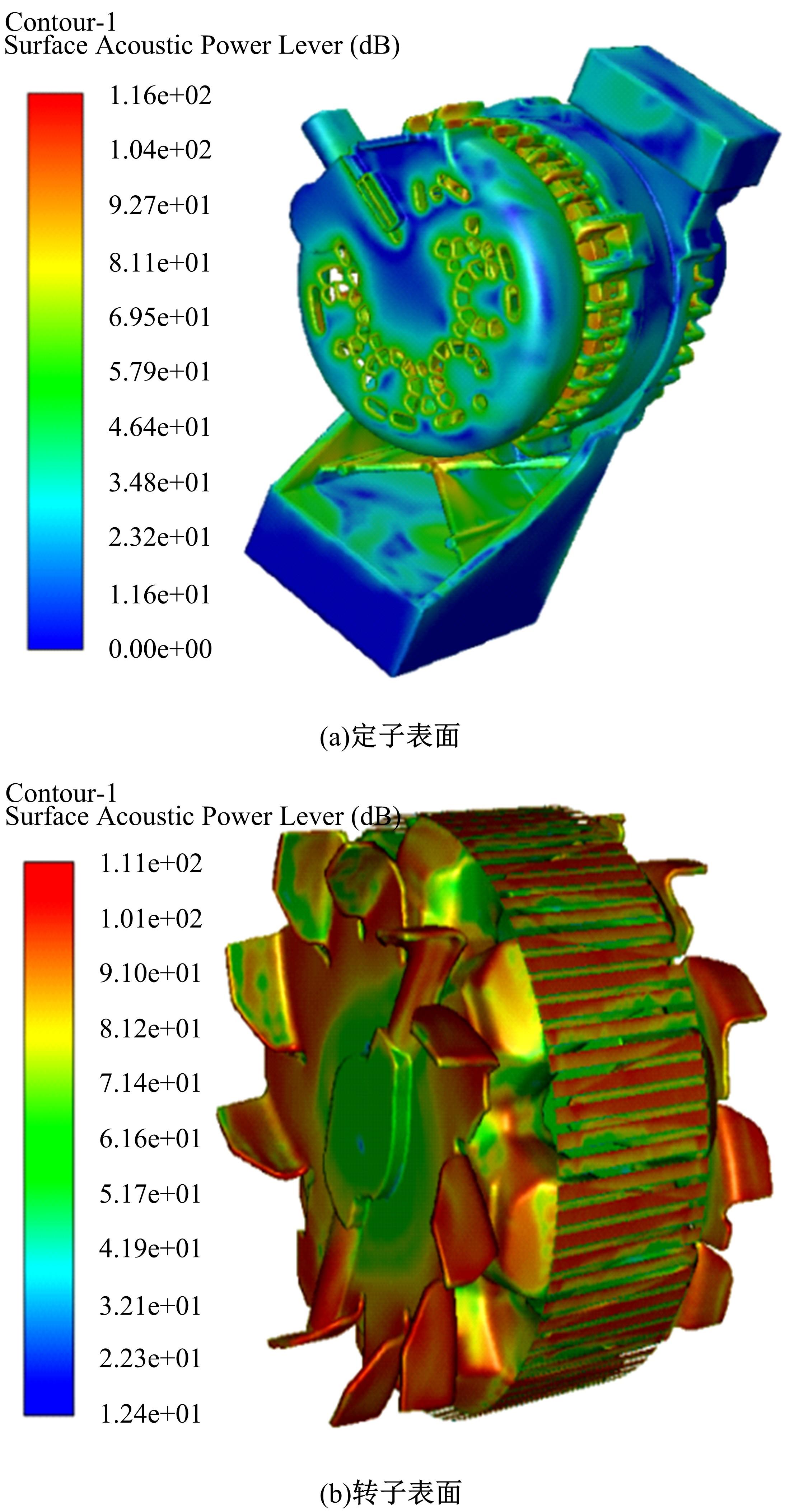

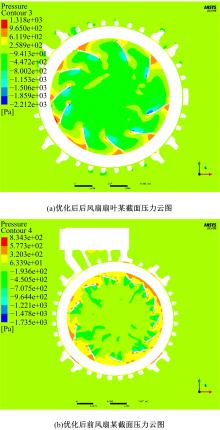

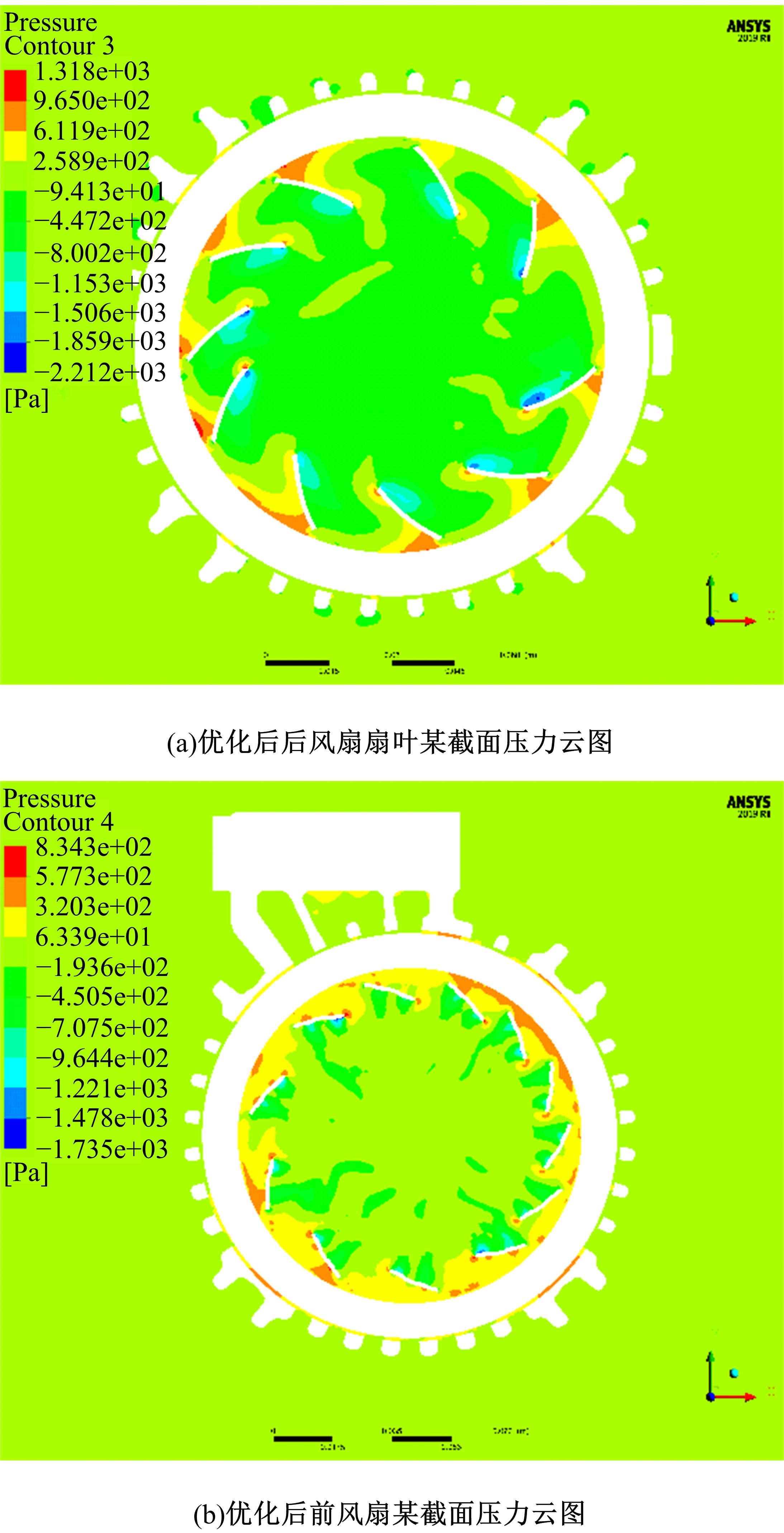

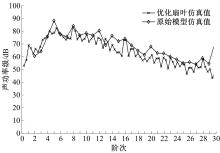

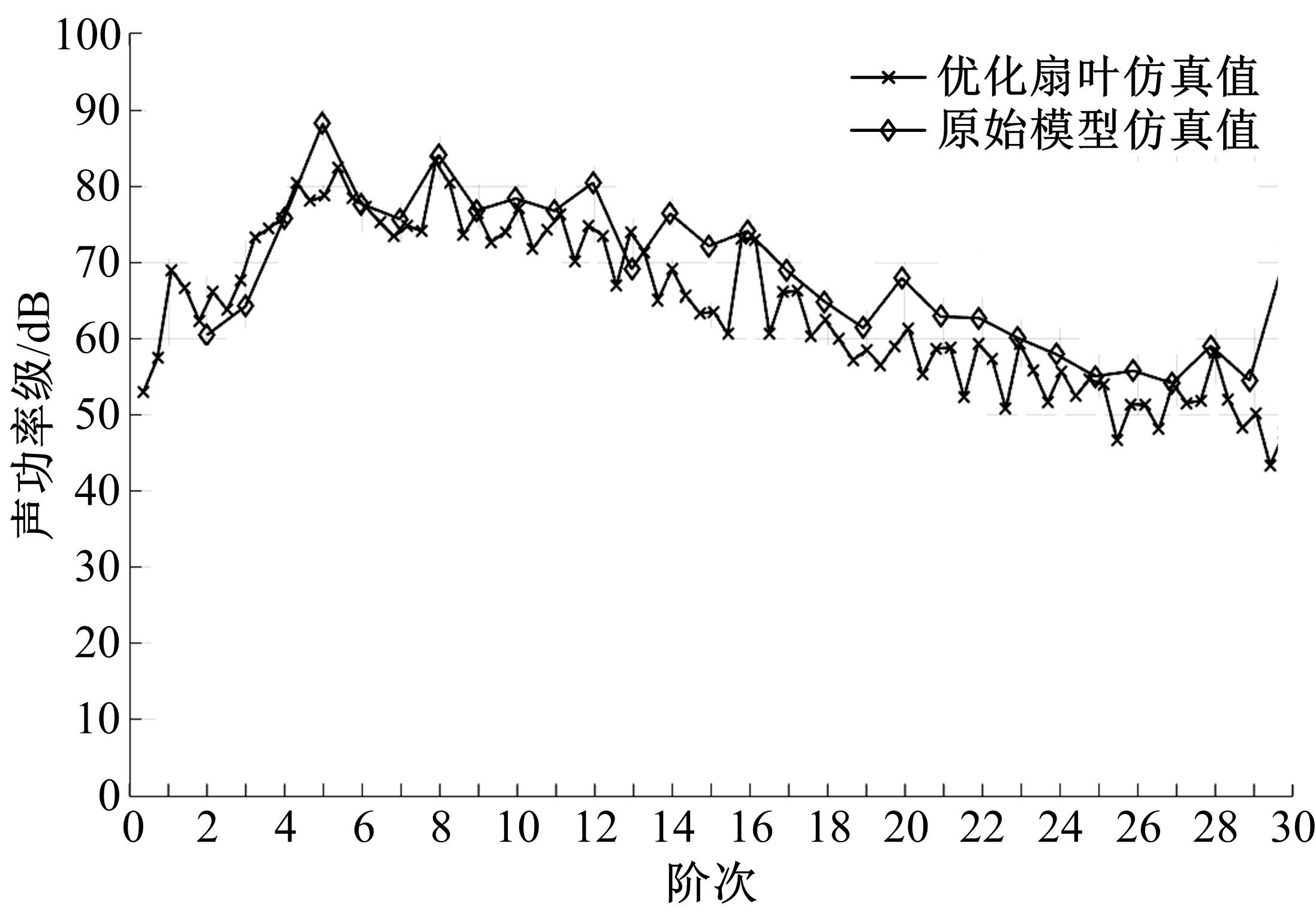

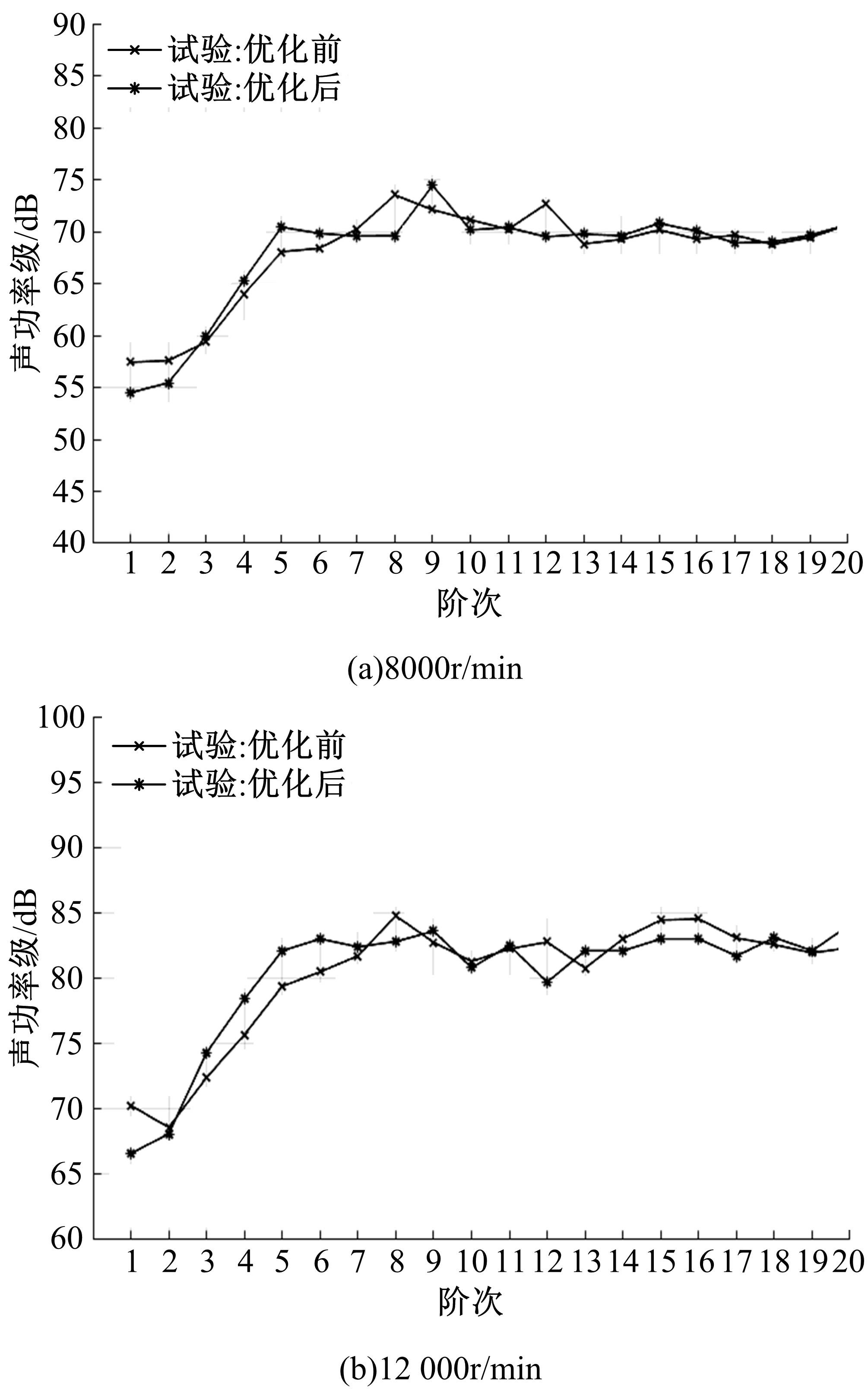

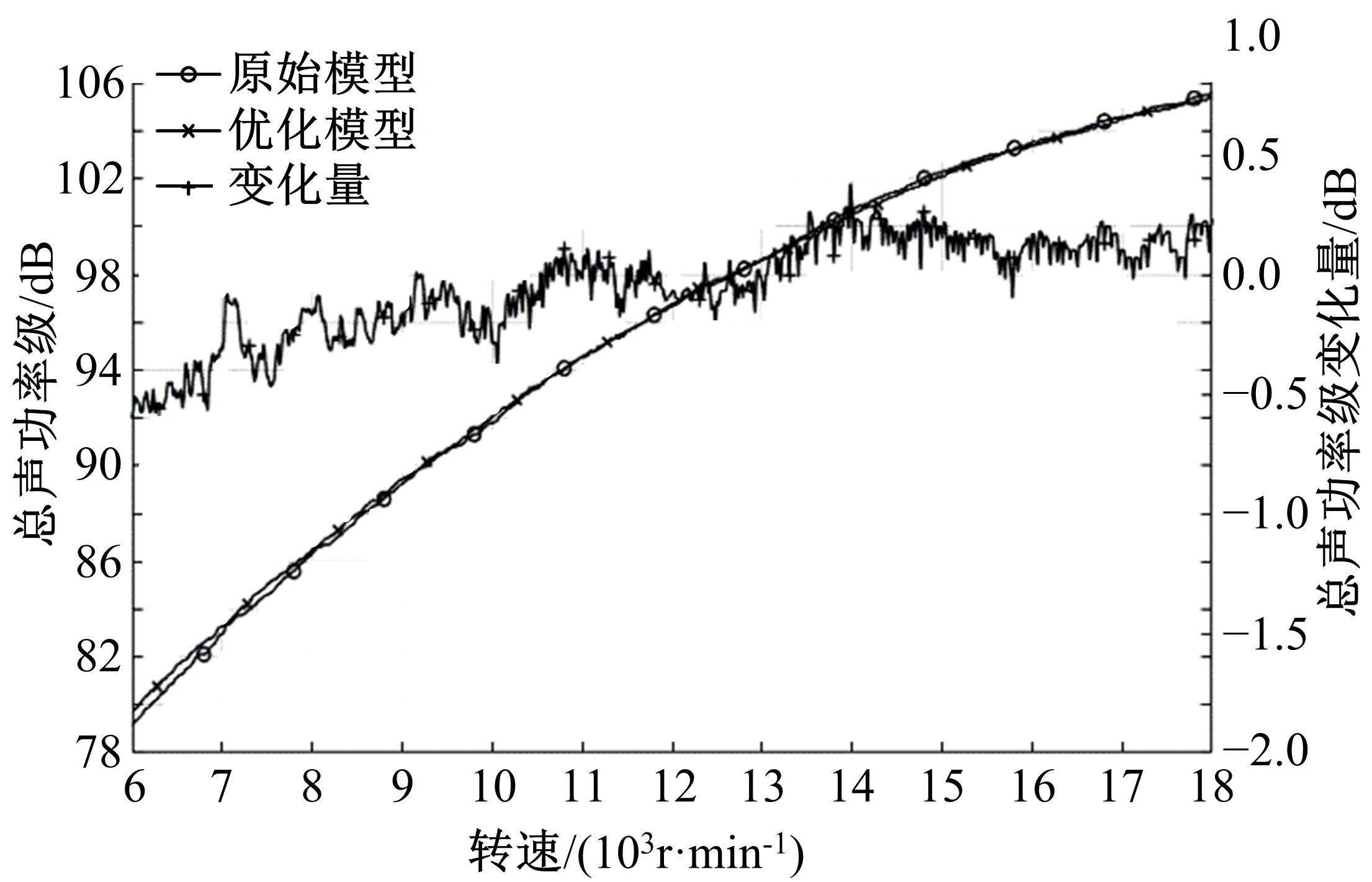

针对某型号车用爪极发电机在高转速工况下阶次气动噪声特性明显的问题,设计噪声测试实验获得主要阶次噪声,建立流场和声场数值仿真模型,分别对前、后风扇扇叶的压力分布、定子及转子的压力和声功率分布进行分析,研究不同部位对爪极发电机气动噪声的影响。通过矢量合成法对风扇扇叶分布角度进行了优化,对优化后的风扇扇叶分别进行仿真验证和装机试验,验证爪极发电机气动噪声优化效果。试验结果表明,优化后爪极发电机在整个转速范围内的8、12阶次的噪声平均减小量均达到了2.5 dB。

中图分类号:

- U463.63

| 1 | Le Goff V, Vidal V, Fakes M, et al. Flow induced noise predictions of an automotive alternator using a lattice boltzmann method[C]∥Turbo Expo: Power for Land, Sea, and Air. American Society of Mechanical Engineers, Düsseldorf, Germany, 2014: 45578. |

| 2 | Kim W, Jeon W H, Hur N, et al. Development of a low-noise cooling fan for an alternator using numerical and doe methods[J]. International Journal of Automotive Technology, 2011, 12(2): 307-314. |

| 3 | Khelladi S, Kouidri S, Bakir F, et al. Predicting tonal noise from a high rotational speed centrifugal fan[J]. Journal of Sound and Vibration, 2008, 313(1/2): 113-133. |

| 4 | Hua C, Zhang Y, Dong D, et al. Aerodynamic noise numerical simulation and noise reduction study on automobile alternator[J]. Journal of Mechanical Science and Technology, 2017, 31(5): 2047-2055. |

| 5 | Zhang J H, Chu W L, Zhang H G, et al. Numerical and experimental investigations of the unsteady aerodynamics and aero-acoustics characteristics of a backward curved blade centrifugal fan[J]. Applied Acoustics, 2016, 110: 256-267. |

| 6 | 陈鑫, 王宁, 沈传亮, 等. 后视镜造型对前侧窗气动噪声的影响[J]. 吉林大学学报: 工学版, 2020, 50(2): 426-436. |

| Chen Xin, Wang Ning, Shen Chuan-liang, et al. Effect of rearview mirror modeling on aerodynamic noise of front window[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 426-436. | |

| 7 | Zheng W L, Yan C, Liu H K, et al. Comparative assessment of SAS and DES turbulence modeling for massively separated flows[J]. Acta Mechanica Sinica, 2016, 32(1): 12-21. |

| 8 | Kaltenbacher M, Escobar M, Becker S, et al. Numerical simulation of flow‐induced noise using LES/SAS and Lighthill's acoustic analogy[J]. International Journal for Numerical Methods in Fluids, 2010, 63(9): 1103-1122. |

| 9 | 杨博, 胡兴军, 王夫亮. 轻型客车侧窗区域气动噪声的数值模拟与验证[J]. 吉林大学学报: 工学版, 2010, 40(4): 915-919. |

| Yang Bo, Hu Xing-jun, Wang Fu-liang. Numerical simulation and verification of aerodynamic noise from side window region of minivan[J]. Journal of Jilin University(Engineering and Technology Edition), 2010, 40(4): 915-919. | |

| 10 | 高富东, 王德心, 王海东, 等. 基于射流冲击作用的舰机适配性数值分析与优化[J]. 中国机械工程, 2020, 31(12): 1425-1436. |

| Gao Fu-dong, Wang De-xin, Wang Hai-dong,et al. Numerical analysis and optimization of carrier/air vehicle integrations based on jet impingements[J]. China Mechanical Engineering, 2020, 31(12): 1425-1436. | |

| 11 | Zheng W L, Yan C, Liu H K, et al. Comparative assessment of SAS and DES turbulence modeling for massively separated flows[J]. Acta Mechanica Sinica, 2016, 32(1): 12-21. |

| 12 | 詹福良, 徐俊伟. Virtual.Lab Acoustics声学仿真计算从入门到精通[M]. 陕西:西北工业大学出版社,2013: 336-408. |

| 13 | Curle N. The influence of solid boundaries upon aerodynamic sound[J]. Proceedings of the Royal Society of London. Series A. Mathematical and Physical Sciences, 1955, 231(1187): 505-514. |

| 14 | Zheng Z G, Li R X. The application of numerical simulation technology in the external aerodynamic noise field of high-speed train[J]. Applied Mechanics and Materials, 2012(101/102): 197-201. |

| 15 | Zheng Z Y, Li R X. Application of numerical simulation technology to prediction of aerodynamic dipole acoustics source on automobile surface[C]∥The 2nd International Conference on Digital Manufacturing & Automation, Zhangjiajie, China, 2011: 216-220. |

| 16 | 汪怡平, 谷正气, 李伟平, 等. 汽车气动噪声数值计算分析[J]. 汽车工程, 2009, 31(4): 385-388. |

| Wang Yi-ping, Gu Zheng-qi, Li Wei-ping, et al. Numerical analysis of automobile aerodynamic noise[J]. Automotive Engineering, 2009, 31(4): 385-388. | |

| 17 | 胡坤, 顾中浩, 马海峰. ANSYS CFD疑难问题实例详解[M]. 北京:人民邮电出版社,2017. |

| 18 | Li W, Yue W, Huang T, et al. Optimizing the aerodynamic noise of an automobile claw pole alternator using a numerical method[J]. Applied Acoustics, 2020, 171: No. 107629. |

| 19 | Zuo S, Xie C, Wu X, et al. Numerical simulation and optimization of aerodynamic noise for claw pole alternator[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2018, 233(3): 857-879. |

| 20 | 张亚东, 董大伟, 闫兵, 等. 车用交流发电机气动噪声数值分析[J]. 振动与冲击, 2016, 35(1): 174-182, 187. |

| Zhang Ya-dong, Dong Da-wei, Yan Bing, et al. Numerical simulation analysis for aerodynamic noise of a vehicle alternator[J]. Journal of Vibration and Shock, 2016, 35(1): 174-182, 187. |

| [1] | 王克勇,鲍大同,周苏. 基于数据驱动的车用燃料电池故障在线自适应诊断算法[J]. 吉林大学学报(工学版), 2022, 52(9): 2107-2118. |

| [2] | 曹起铭,闵海涛,孙维毅,于远彬,蒋俊宇. 质子交换膜燃料电池低温启动水热平衡特性[J]. 吉林大学学报(工学版), 2022, 52(9): 2139-2146. |

| [3] | 隗海林,王泽钊,张家祯,刘洋. 基于Avl-Cruise的燃料电池汽车传动比及能量管理策略[J]. 吉林大学学报(工学版), 2022, 52(9): 2119-2129. |

| [4] | 刘岩,丁天威,王宇鹏,都京,赵洪辉. 基于自适应控制的燃料电池发动机热管理策略[J]. 吉林大学学报(工学版), 2022, 52(9): 2168-2174. |

| [5] | 李丞,景浩,胡广地,刘晓东,冯彪. 适用于质子交换膜燃料电池系统的高阶滑模观测器[J]. 吉林大学学报(工学版), 2022, 52(9): 2203-2212. |

| [6] | 张佩,王志伟,杜常清,颜伏伍,卢炽华. 车用质子交换膜燃料电池空气系统过氧比控制方法[J]. 吉林大学学报(工学版), 2022, 52(9): 1996-2003. |

| [7] | 池训逞,侯中军,魏伟,夏增刚,庄琳琳,郭荣. 基于模型的质子交换膜燃料电池系统阳极气体浓度估计技术综述[J]. 吉林大学学报(工学版), 2022, 52(9): 1957-1970. |

| [8] | 裴尧旺,陈凤祥,胡哲,翟双,裴冯来,张卫东,焦杰然. 基于自适应LQR控制的质子交换膜燃料电池热管理系统温度控制[J]. 吉林大学学报(工学版), 2022, 52(9): 2014-2024. |

| [9] | 胡广地,景浩,李丞,冯彪,刘晓东. 基于高阶燃料电池模型的多目标滑模控制[J]. 吉林大学学报(工学版), 2022, 52(9): 2182-2191. |

| [10] | 陈凤祥,伍琪,李元松,莫天德,李煜,黄李平,苏建红,张卫东. 2.5吨燃料电池混合动力叉车匹配、仿真及优化[J]. 吉林大学学报(工学版), 2022, 52(9): 2044-2054. |

| [11] | 武小花,余忠伟,朱张玲,高新梅. 燃料电池公交车模糊能量管理策略[J]. 吉林大学学报(工学版), 2022, 52(9): 2077-2084. |

| [12] | 高青,王浩东,刘玉彬,金石,陈宇. 动力电池应急冷却喷射模式实验分析[J]. 吉林大学学报(工学版), 2022, 52(8): 1733-1740. |

| [13] | 王奎洋,何仁. 基于支持向量机的制动意图识别方法[J]. 吉林大学学报(工学版), 2022, 52(8): 1770-1776. |

| [14] | 王骏骋,吕林峰,李剑敏,任洁雨. 分布驱动电动汽车电液复合制动最优滑模ABS控制[J]. 吉林大学学报(工学版), 2022, 52(8): 1751-1758. |

| [15] | 刘汉武,雷雨龙,阴晓峰,付尧,李兴忠. 增程式电动汽车增程器多点控制策略优化[J]. 吉林大学学报(工学版), 2022, 52(8): 1741-1750. |

|

||