吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (5): 1653-1662.doi: 10.13229/j.cnki.jdxbgxb20190514

• 材料科学与工程 • 上一篇

Ti添加量对球墨铸铁组织及力学性能的影响

王金国1,2( ),王志强1,2,任帅1,2,闫瑞芳1,2,黄恺1,2,郭劲1,2

),王志强1,2,任帅1,2,闫瑞芳1,2,黄恺1,2,郭劲1,2

- 1.吉林大学 汽车材料教育部重点实验室,长春 130022

2.吉林大学 材料科学与工程学院,长春 130022

Effect of Ti addition on microstructure and mechanical properties of ductile iron

Jin-guo WANG1,2( ),Zhi-qiang WANG1,2,Shuai REN1,2,Rui-fang YAN1,2,Kai HUANG1,2,Jin GUO1,2

),Zhi-qiang WANG1,2,Shuai REN1,2,Rui-fang YAN1,2,Kai HUANG1,2,Jin GUO1,2

- 1.Key Laboratory of Automotive Materials Ministry of Education, Jilin University, Changchun 130022, China

2.College of Materials Science and Engineering, Jilin University, Changchun 130022, China

摘要:

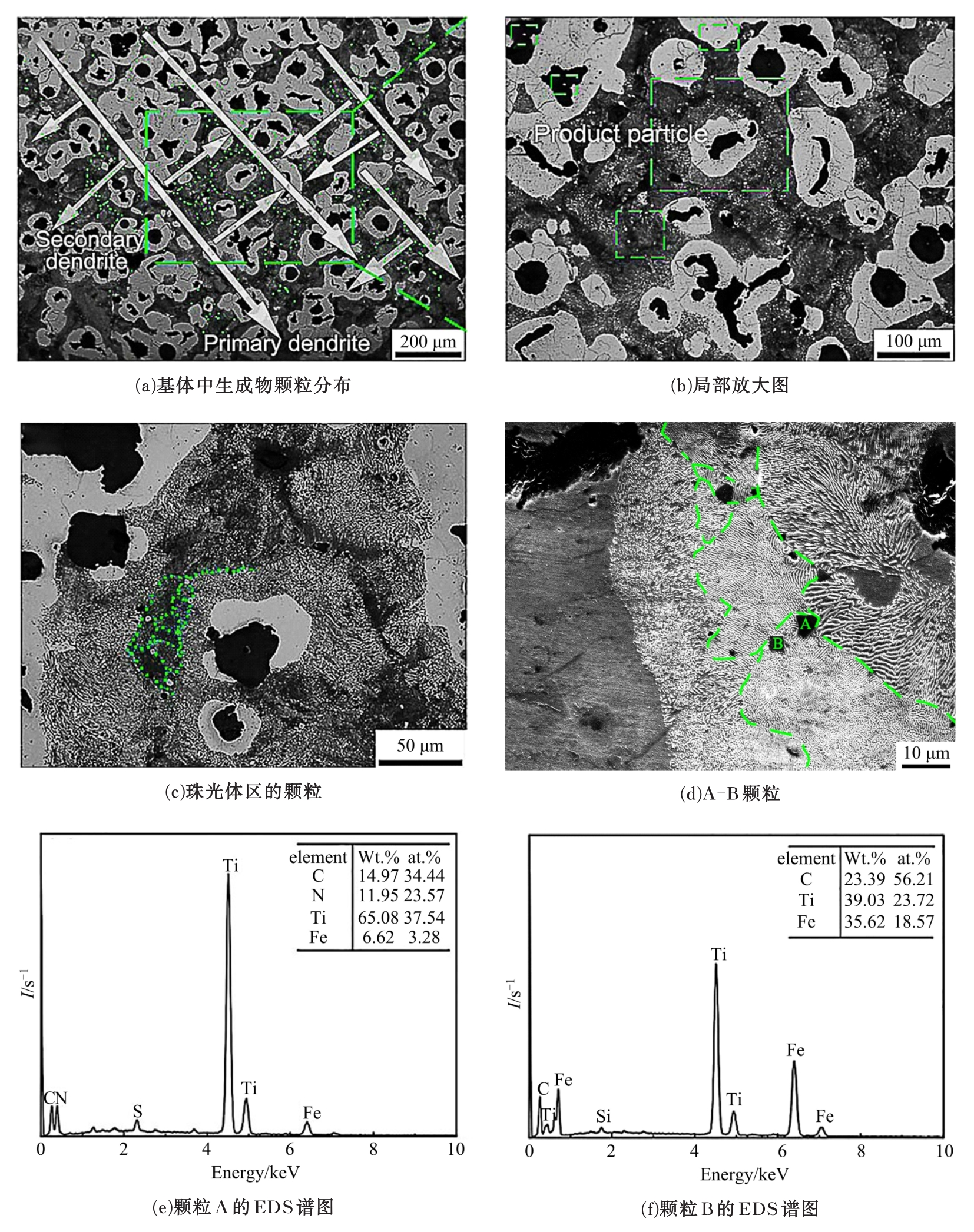

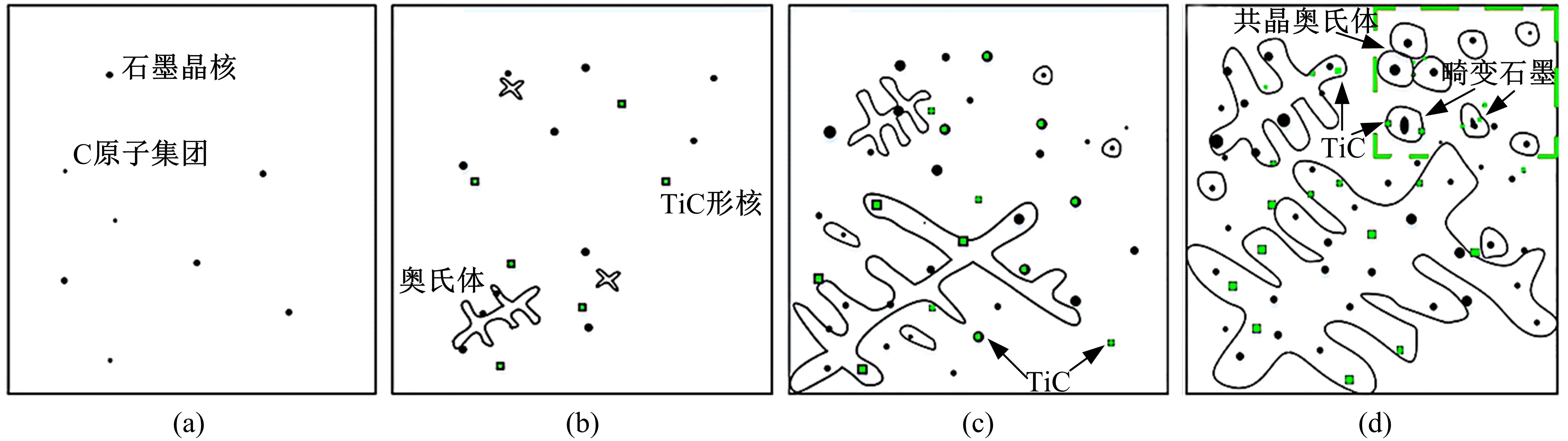

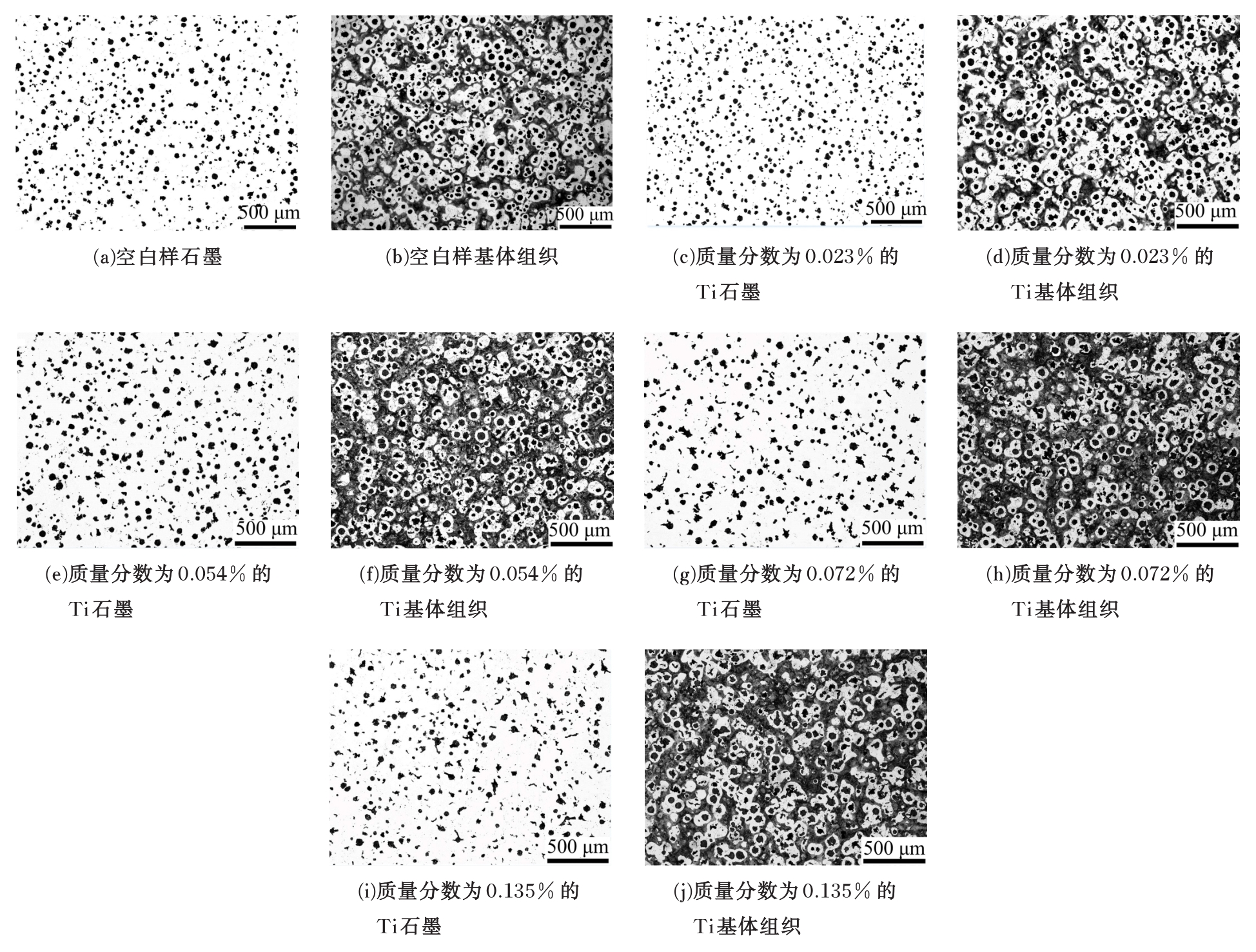

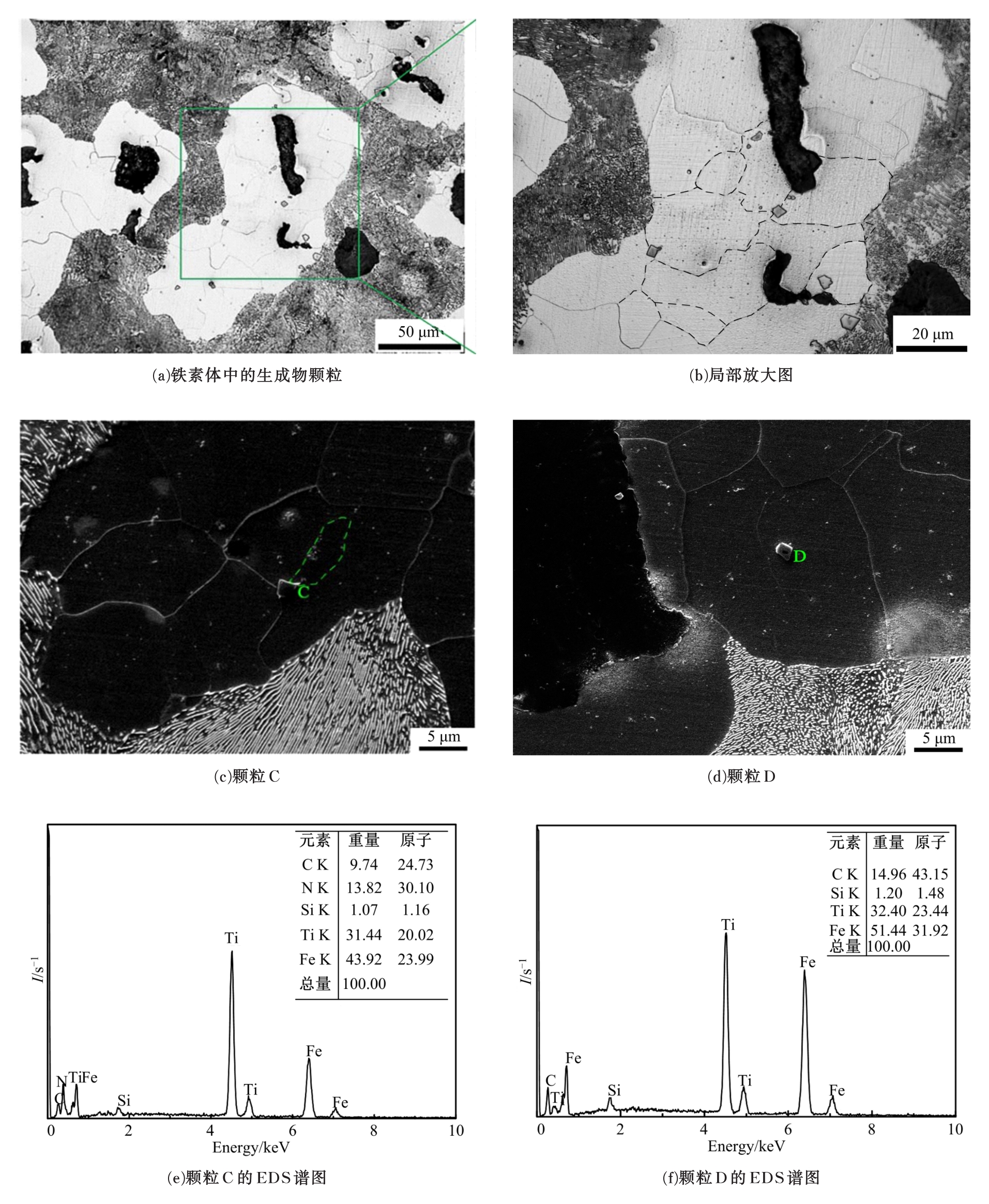

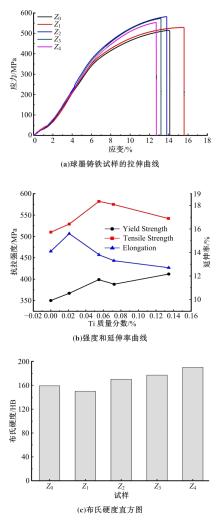

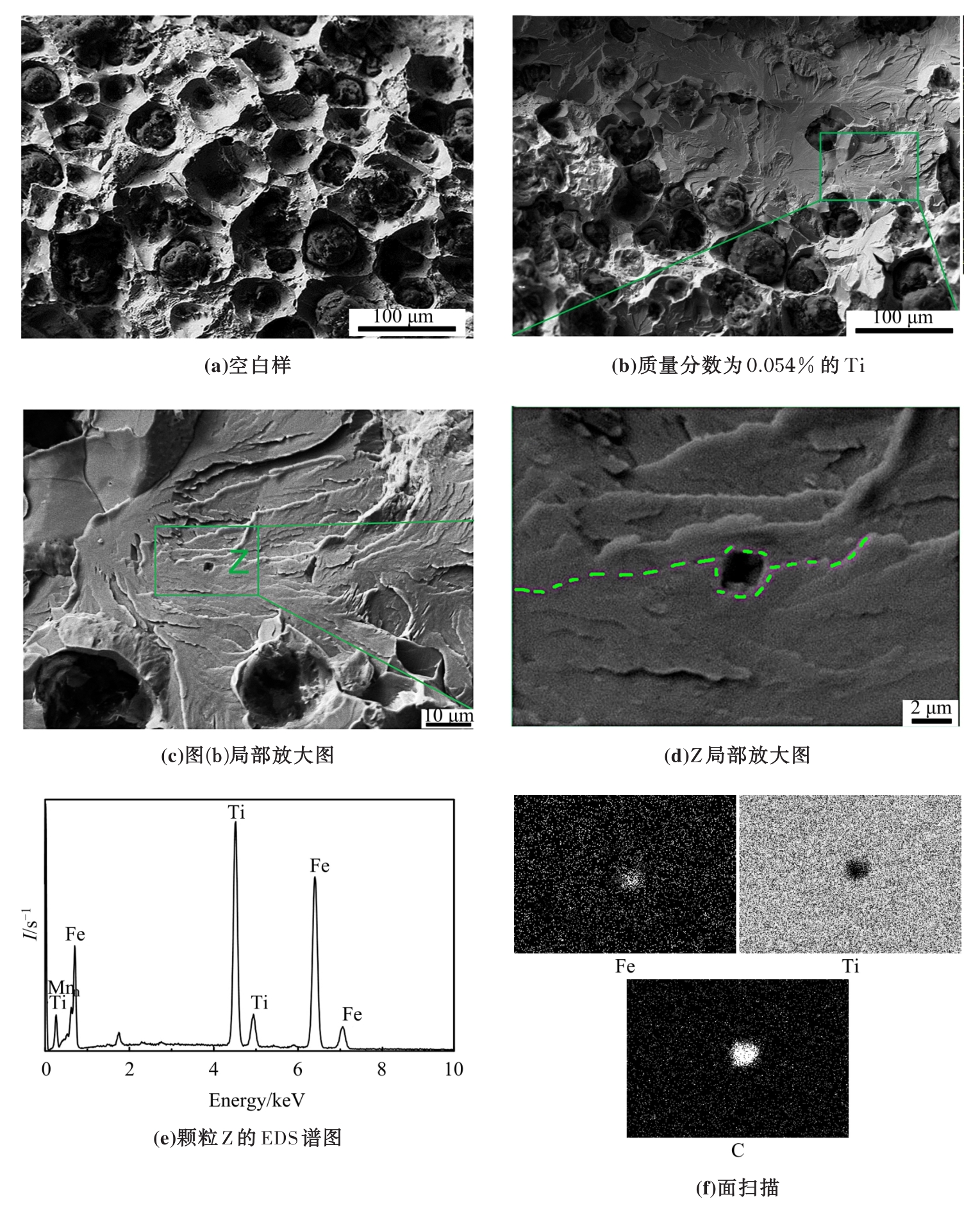

将Ti-C-Fe预制块添加到球墨铸铁中,考察了不同Ti含量对球墨铸铁组织及力学性能的影响。结果表明:Ti添加后,在铁液中主要以TiC和Ti(C,N)的形式存在,并使珠光体和铁素体组织得到细化;Ti的质量分数为0.023%时,石墨数目、球化率以及铁素体含量提高;随着Ti含量的升高,生成的TiC颗粒会阻碍C原子的扩散,使石墨球出现畸变,球化率下降,铁素体含量降低。力学性能测试表明:Ti的质量分数为0.023%的试样具有良好的综合力学性能,其屈服强度和抗拉强度分别提高了5.43%、3.73%,延伸率提高了10.64%;当Ti的质量分数为0.054%~0.072%时,试样有较高的抗拉强度;Ti质量分数达到最高0.135%时,试样的屈服强度和布氏硬度达到最大。

中图分类号:

- TG143.5

| 1 | 李艳霞, 王文韶, 刘俊友, 等. 钛含量对中铬铸铁组织和性能的影响[J]. 材料导报, 2015, 29(1): 406-408, 416. |

| Li Yan-xia, Wang Wen-shao, Liu Jun-you, et al. Influences of Ti content on microstructure and property of medium-chromium cast iron[J]. Materials Reports, 2015, 29(1): 406-408, 416. | |

| 2 | 钟兵. 高Ti对灰铸铁组织及性能的影响[J]. 铸造技术, 2017, 38(8): 1949-1952. |

| Zhong Bing. Influence of high Ti on microstructure and properties of gray cast iron[J]. Foundry Technology, 2017, 38(8): 1949-1952. | |

| 3 | 赵玉谦, 方世杰, 赵宇光, 等. (Ti,Fe)-Al-C体系钢铁基复合材料的热力学计算与分析[J]. 吉林大学学报: 工学版, 2005, 35(4): 343-347. |

| Zhao Yu-qian, Fang Shi-jie, Zhao Yu-guang, et al. Thermodynamic calculation and analysis of steel matrix composite of(Ti, Fe)-Al-C system[J]. Journal of Jilin University(Engineering and Technology Edition), 2005, 35(4): 343-347. | |

| 4 | 赵宇光, 姜启川, 任露泉, 等. Fe-C-Ti-Mn合金系中TiC原位生成反应的热力学分析[J]. 吉林大学学报: 工学版, 2004, 34(1): 1-6. |

| Zhao Yu-guang, Jiang Qi-chuan, Ren Lu-quan, et al. Thermodynamic analysis on in-situ TiC synthesis in Fe-C-Ti-Mn system[J]. Journal of Jilin University(Engineering and Technology Edition), 2004, 34(1): 1-6. | |

| 5 | 郭文涛, 陈淑英, 李青春, 等. 球墨铸铁中含Ti夹杂物的研究[J]. 铸造, 2012, 61(1): 92-96. |

| Guo Wen-tao, Chen Shu-ying, Li Qing-chun, et al. Study on Ti-inclusions in ductile iron[J]. China Foundry, 2012, 61(1): 92-96. | |

| 6 | 吕维洁, 杨志峰, 张荻, 等. 原位合成钛基复合材料增强体TiC的微结构特征[J]. 中国有色金属学报, 2002, 12(3): 511-516. |

| Lv Wei-jie, Yang Zhi-feng, Zhang Di, et al. Microstructural characterization of TiC in in situ synthesized titanium matrix composites[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 511-516. | |

| 7 | Lv W J, Zhang D, Zhang X N, et al. Growth mechanism of reinforcements in in-situ synthesized(TiB+TiC)/Ti composites[J]. Transactions of Nonferrous Metals Society of China, 2001, 11(1): 67-71. |

| 8 | Li Y, Li Y Q, Fruehan R J. Foamation of titanium carbonitride from hot metal[J]. ISIJ International, 2001, 41(12): 1417-1422. |

| 9 | 申志清, 田学雷, 郑洪亮, 等. 球墨铸铁石墨球核心组成及形核机制的研究[J]. 铸造, 2012, 61(4): 357-361. |

| Shen Zhi-qing, Tian Xue-lei, Zheng Hong-liang, et al. Phase composition and nucleation mechanism of spheroidal graphite nucleus in ductile iron[J]. China Foundry, 2012, 61(4): 357-361. | |

| 10 | Fraś E, Górny M. Inoculation effects of cast iron[J]. Arichives of Foundry Engineering, 2012, 12(4): 39-46. |

| 11 | Xu Z M, Liang G F, Guan Q F, et al. TiC as heterogeneous nuclei of the(Fe, Mn)3C and austenite intergrowth eutectic in austenite steel matrix wear resistant composite[J]. Materials Research Bulletin, 2003, 39(3): 457-463. |

| 12 | 韩悦. 内生纳米/亚微米TiC增强铁基复合材料组织与力学性能[D]. 长春: 吉林大学材料科学与工程学院, 2016. |

| Han Yue. Microstructures and mechanical properties of in situ synthesized nano/sub-micron-sized TiC reinforced iron composites[D]. Changchun: School of Materials Science and Engineering, Jilin University, 2016. | |

| 13 | 陈刚, 毛永锋, 赵玉涛, 等. 一种原位碳化钛颗粒增强铁基复合材料及其制备方法[P]. 中国: CN201210054540.9, 2012-07-18. |

| 14 | 刘志科. 原位合成铁基复合材料的微结构特征、生长机制以及界面反应机理的研究[D]. 南宁: 广西大学机械工程学院, 2009. |

| Liu Zhi-ke. Study on the microstructure, grow mechanism of reinforcement and interface in in situ synthesized ferrous matrix composite[D]. Nanning: College of Mechanical Engineering, Guangxi University, 2009. |

| [1] | 向红亮,陈盛涛,邓丽萍,张伟,詹土生. 微合金化2205双相不锈钢组织及性能[J]. 吉林大学学报(工学版), 2020, 50(5): 1645-1652. |

| [2] | 李明,王浩然,赵唯坚. 单向带抗剪键叠合板的受力性能试验[J]. 吉林大学学报(工学版), 2020, 50(2): 654-667. |

| [3] | 宫文彪,朱芮,郄新哲,崔恒,宫明月. 6082铝合金超厚板搅拌摩擦焊接头组织与性能[J]. 吉林大学学报(工学版), 2020, 50(2): 512-519. |

| [4] | 修文翠,吴化,韩英,刘云旭. 等温热处理温度对超级贝氏体组织与性能的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 520-525. |

| [5] | 尹超英,邵春福,王晓全,熊志华. 考虑空间异质性的建成环境对通勤方式选择的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 543-548. |

| [6] | 陈学文,王继业,杨喜晴,皇涛,宋克兴. Cr8合金钢热变形行为及位错密度演变规律[J]. 吉林大学学报(工学版), 2020, 50(1): 91-99. |

| [7] | 王金国,任帅,闫瑞芳,黄恺,王志强. TiC颗粒对铸态球墨铸铁组织和力学性能的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 2010-2018. |

| [8] | 佟鑫,张雅娇,黄玉山,胡正正,王庆,张志辉. 选区激光熔化304L不锈钢的组织结构及力学性能分析[J]. 吉林大学学报(工学版), 2019, 49(5): 1615-1621. |

| [9] | 李明,王浩然,赵唯坚. 带抗剪键叠合板的力学性能[J]. 吉林大学学报(工学版), 2019, 49(5): 1509-1520. |

| [10] | 徐戊矫,刘承尚,鲁鑫垚. 喷丸处理后6061铝合金工件表面粗糙度的模拟计算及预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1280-1287. |

| [11] | 李于朋,孙大千,宫文彪. 6082⁃T6铝合金薄板双轴肩搅拌摩擦焊温度场[J]. 吉林大学学报(工学版), 2019, 49(3): 836-841. |

| [12] | 关庆丰,张福涛,彭韬,吕鹏,李姚君,许亮,丁佐军. 含硼、钴9%Cr耐热钢的热变形行为[J]. 吉林大学学报(工学版), 2018, 48(6): 1799-1805. |

| [13] | 姜秋月,杨海峰,檀财旺. 22MnB5超高强钢焊接接头强化性能[J]. 吉林大学学报(工学版), 2018, 48(6): 1806-1810. |

| [14] | 庄蔚敏, 赵文增, 解东旋, 李兵. 超高强钢/铝合金热铆连接接头性能[J]. 吉林大学学报(工学版), 2018, 48(4): 1016-1022. |

| [15] | 关庆丰, 董书恒, 郑欢欢, 李晨, 张从林, 吕鹏. 强流脉冲电子束作用下45#钢表面Cr合金化[J]. 吉林大学学报(工学版), 2018, 48(4): 1161-1168. |

|

||