吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (5): 1923-1933.doi: 10.13229/j.cnki.jdxbgxb20190467

• 农业工程·仿生工程 • 上一篇

玉米柔性脱粒滚筒脱粒元件设计与试验

耿端阳1( ),谭德蕾1,于兴瑞1,苏国粱1,王骞1,鹿秀凤2,金诚谦1

),谭德蕾1,于兴瑞1,苏国粱1,王骞1,鹿秀凤2,金诚谦1

- 1.山东理工大学 农业工程与食品科学学院, 山东 淄博 255000

2.山东理工职业学院 机电工程学院, 山东 济宁 272000

Design and test of corn flexible threshing cylinder element

Duan-yang GENG1( ),De-lei TAN1,Xing-rui YU1,Guo-liang SU1,Qian WANG1,Xiu-feng LU2,Cheng-qian JIN1

),De-lei TAN1,Xing-rui YU1,Guo-liang SU1,Qian WANG1,Xiu-feng LU2,Cheng-qian JIN1

- 1.School of Agricultural Engineering and Food Science, Shandong University of Technology, Zibo 255000, China

2.College of Mechanical and Electrical Engineering, Shandong Career Development College, Jining 272000, China

摘要:

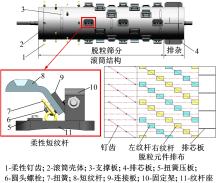

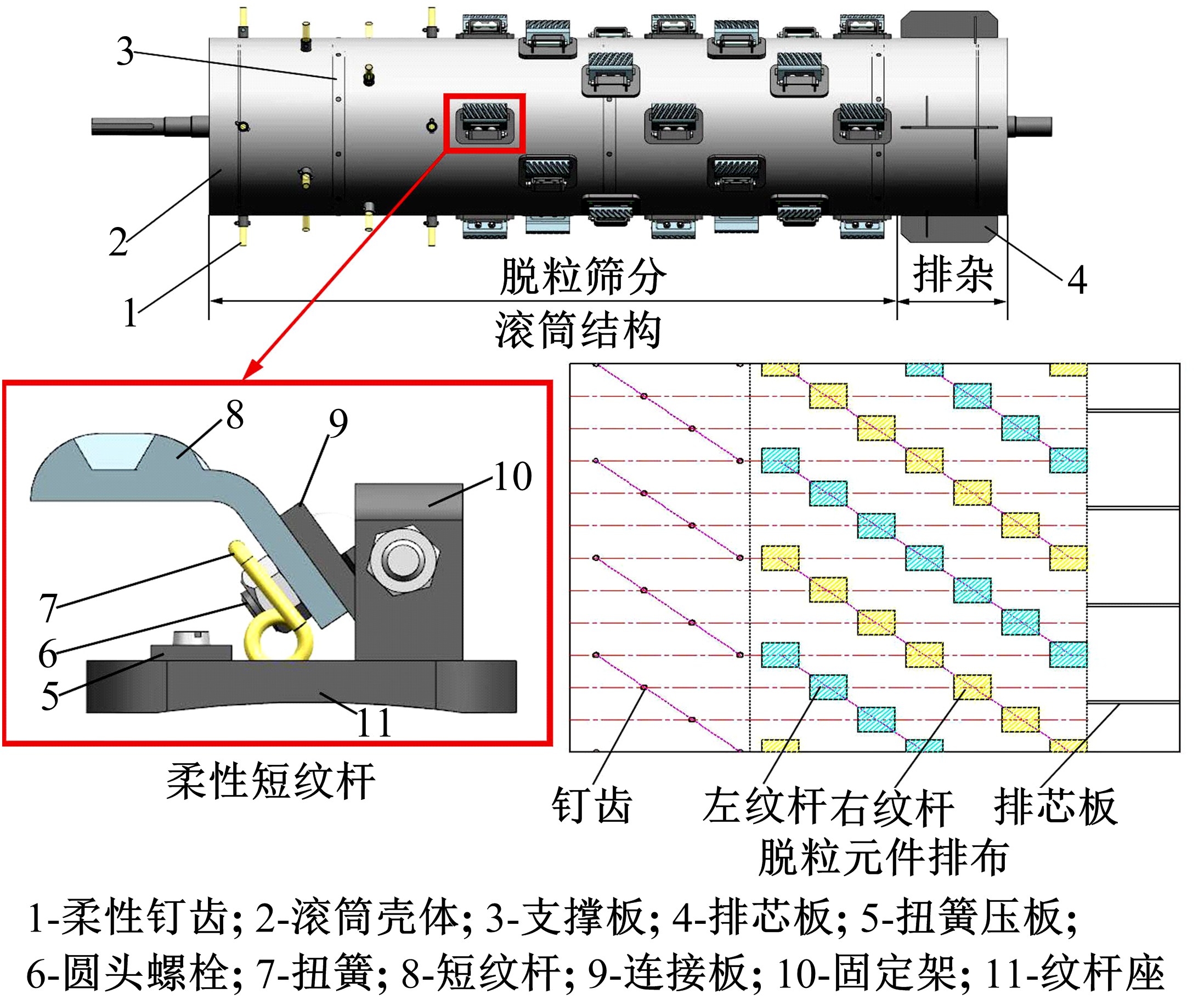

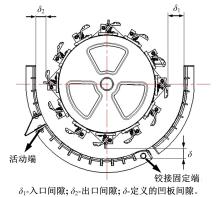

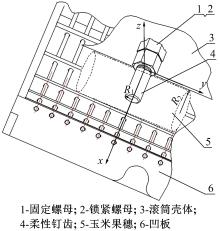

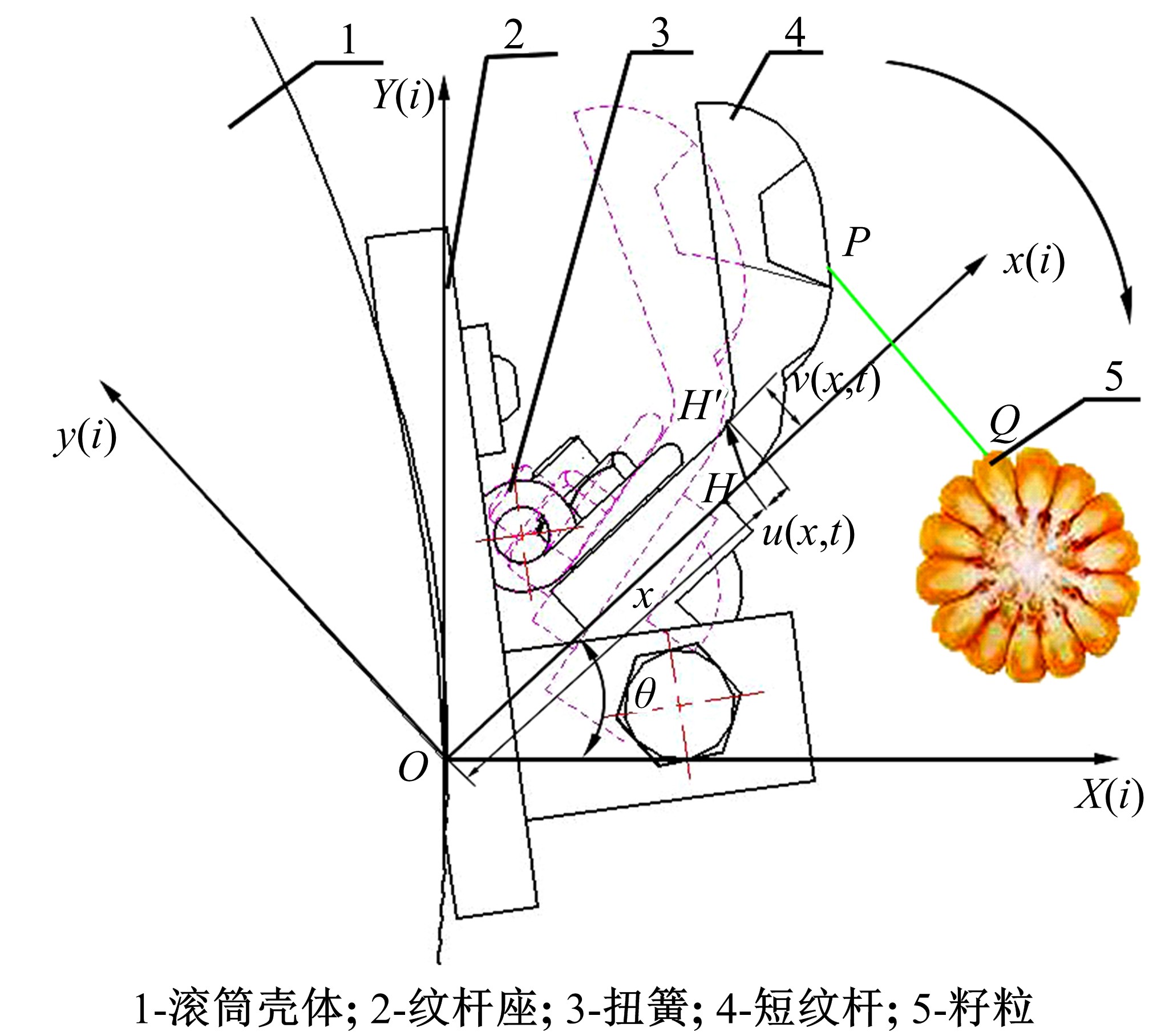

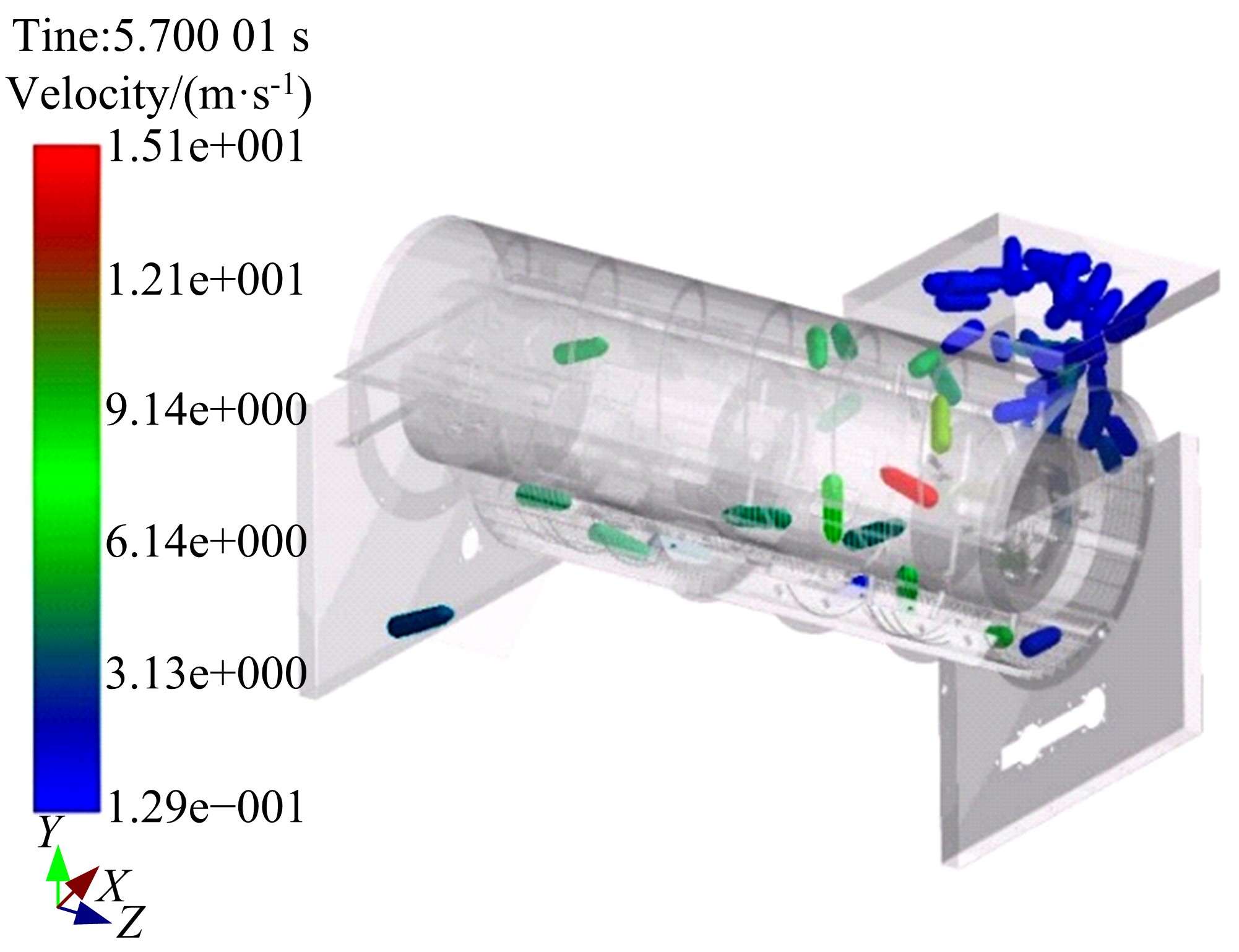

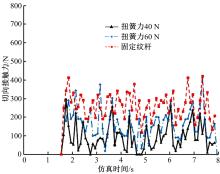

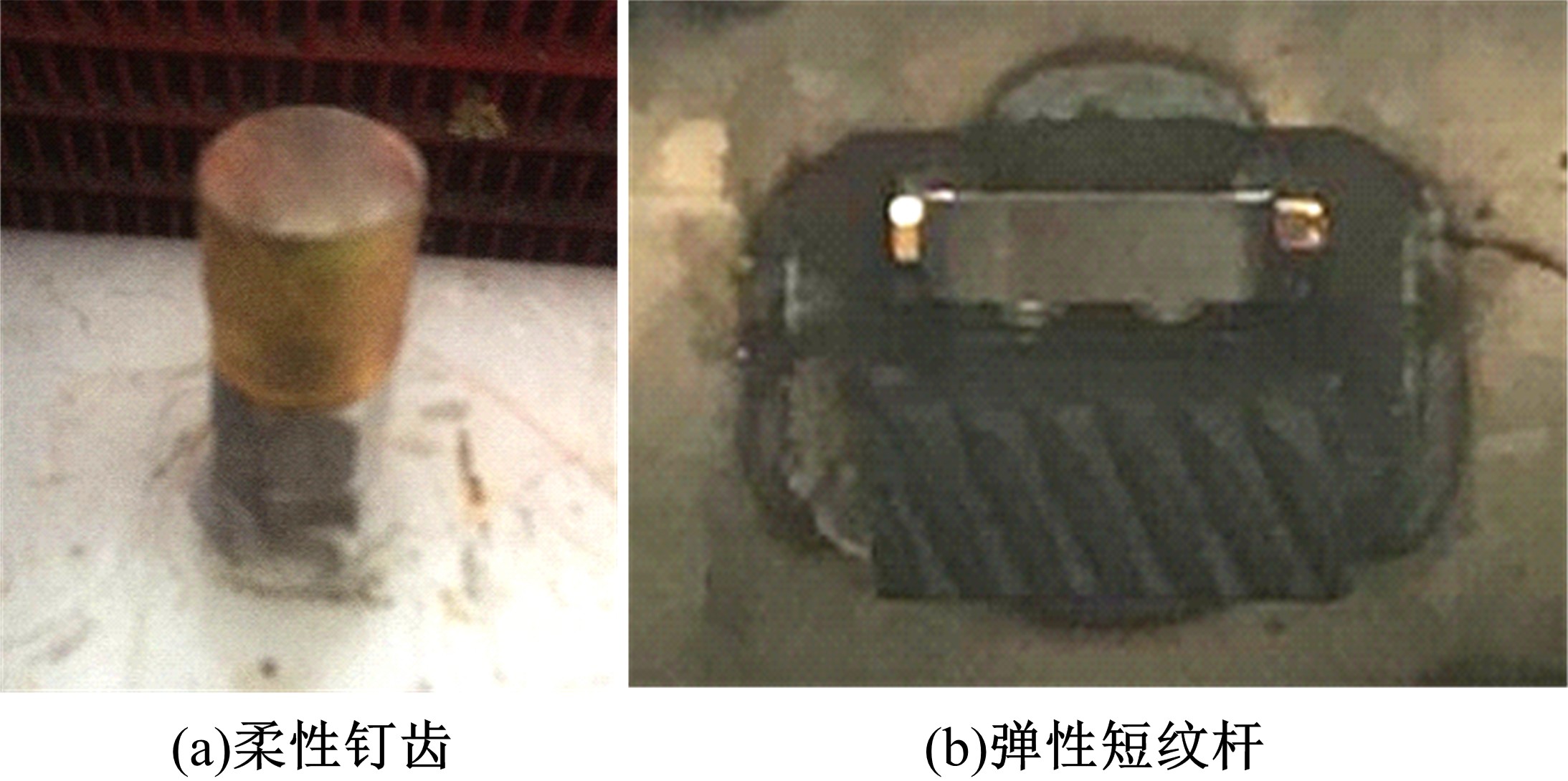

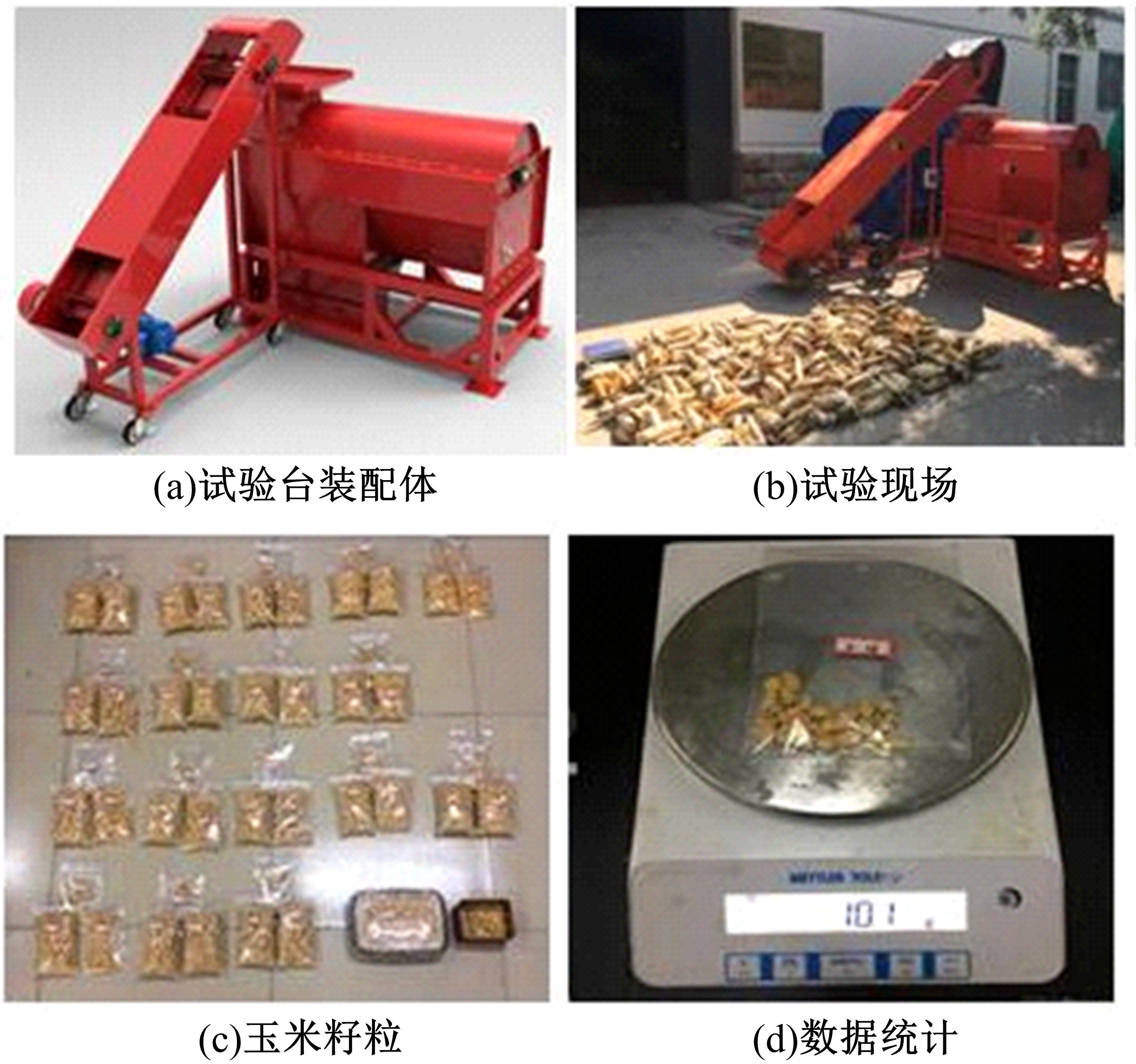

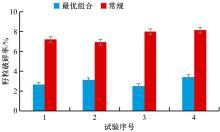

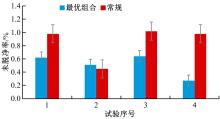

针对黄淮海地区玉米收获过程中籽粒破碎率和未脱净率高的问题,研发了横轴流式玉米柔性脱粒装置,该装置内安装有带柔性钉齿和弹性短纹杆的脱粒滚筒。基于Hertz接触理论对柔性钉齿与玉米果穗碰撞接触进行了力学分析;基于刚柔系统耦合理论对弹性短纹杆与果穗碰撞进行了动力学分析;通过离散元分析完善了弹性短纹杆参数设计;选取滚筒转速、脱粒间隙和喂入量作为试验因素进行了单因素试验和最优参数组合对比试验。试验结果表明:装置最优参数组合如下:滚筒转速为450 r/min,凹板间隙为40 mm,喂入量为8 kg/s,此时平均籽粒破碎率为2.91%,未脱净率为0.51%,优于常规脱粒装置。

中图分类号:

- S225.5

| 1 | 中国国家统计局. 中国统计年鉴2018[EB/OL]. [2018-10-24]. |

| 2 | 邸志峰, 崔中凯, 张华, 等. 纹杆块与钉齿组合式轴流玉米脱粒滚筒的设计与试验[J]. 农业工程学报, 2018, 34(1): 28-34. |

| Di Zhi-feng, Cui Zhong-kai, Zhang Hua, et al. Design and experiment of rasp bar and nail tooth combined axial flow corn threshing cylinder[J]. Transactions of the CSAE, 2018, 34(1): 28-34. | |

| 3 | 相茂国. 玉米籽粒直收机械适应性研究[D]. 淄博: 山东理工大学农业工程与食品科学学院, 2014. |

| Xiang Mao-guo. Study on the adaptability of corn grain harvesting device[D]. Zibo: College of Agricultural Engineering and Food Science, Shandong University of Technology, 2014. | |

| 4 | 雷晓鹏. 黄淮海地区玉米机械收获籽粒可行性研究[D]. 保定: 河北农业大学农学院, 2015. |

| Lei Xiao-peng. Studies on the feasibility of maize mechanically harvesting grain in huanghuaihai regions[D]. Baoding: College of Agronomy, Hebei Agricultural University, 2015. | |

| 5 | 赵武云. 组合式螺旋板齿种子玉米脱粒装置研究[D]. 杨凌: 西北农林科技大学机械与电子工程学院, 2012. |

| Zhao Wu-yun. Research on combined type of spiral bar tooth threshing mechanism for seed corn[D]. Yangling: College of Mechanical and Electronic Engineering, Northwest A&F University,2012. | |

| 6 | 徐立章, 李耀明, 王成红, 等. 切纵流双滚筒联合收获机脱粒分离装置[J]. 农业机械学报, 2014, 45(2): 105-108, 135. |

| Xu Li-zhang, Li Yao-ming, Wang Cheng-hong, et al. A combinational threshing and separating unit of combine harvesterwith with a transverse tangential cylinder and an axial rotor[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(2): 105-108, 135. | |

| 7 | 杨立权, 王万章, 张红梅, 等. 切流-横轴流玉米脱粒系统改进设计及台架试验[J]. 农业工程学报, 2018, 34(1): 35-43. |

| Yang Li-quan, Wang Wan-zhang, Zhang Hong-mei, et al. Improved design and bench test based on tangential flow-transverse axial flow threshing system[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(1): 35-43. | |

| 8 | Burkhardt T H, Stout B A. Laboratory investigations of corn shelling utilizing high-velocity impact loading[J]. Trans Asae Gen Ed Am Soc Agric Eng, 1974, 17(1): 11-14. |

| 9 | Miu P I, Kutzbach H D. Mathematical model of material kinematics in an axial threshing unit[J]. Computers & Electronics in Agriculture, 2007, 58(2): 93-99. |

| 10 | Miu P I, Kutzbach H D. Modeling and simulation of grain threshing and separation in threshing units—part I[J]. Computers & Electronics in Agriculture, 2008, 60(1): 96-104. |

| 11 | Petkevichius S, Shpokas L, Kutzbach H D. Investigation of the maize ear threshing process[J]. Biosystems Engineering, 2008, 99(4): 532-539. |

| 12 | Srison W, Chuan-Udom S, Saengprachatanarug K. Design factors affecting losses and power consumptionof an axial flow corn shelling unit[J]. Songklanakarin Journal of Science & Technology, 2016, 38(5): 591-598. |

| 13 | 何晓鹏, 蔡学斌, 师建芳,等. 挤搓式玉米脱粒机的研制[J]. 农业工程学报, 2003, 19(2): 105-108. |

| He Xiao-peng, Cai Xue-bin, Shi Jian-fang. Research and design on corn sheller by extruding and rubbing method[J]. Transactions of the Chinese Society of Agricultural Engineering, 2003, 19(2): 105-108. | |

| 14 | 李心平, 李玉柱, 高吭, 等. 种子玉米籽粒仿生脱粒机理分析[J]. 农业机械学报, 2011, 42(2): 99-103. |

| Li Xin-ping, Li Yu-zhu, Gao Hang, et al. Bionic threshing progress analysis ofseed corn kernel[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(2): 99-103. | |

| 15 | 李心平, 马义东, 金鑫, 等. 玉米种子仿生脱粒机设计与试验[J]. 农业机械学报, 2015, 46(7): 97-101. |

| Li Xin-ping, Ma Yi-dong, Jin Xin, et al. Design and test of corn seed bionic threshing[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(7): 97-101. | |

| 16 | 李心平, 熊师, 杜哲, 等. 浮动式玉米单穗脱粒装置设计与试验[J]. 农业机械学报, 2017, 48(7): 104-111. |

| Li Xin-ping, Xiong Shi, Du Zhe, et al. Design and experiment on floating corn single panicle threshing device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(7): 104-111. | |

| 17 | 耿端阳, 何珂, 王骞, 等. 横轴流式玉米柔性脱粒装置设计与试验[J]. 农业机械学报, 2019, 50(3): 101-108. |

| Geng Duan-yang, He Ke, Wang Qian, et al. Design and experiment on transverse axial flow flexible threshing device for corn[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(3): 101-108. | |

| 18 | 屈哲, 张东兴, 杨丽, 等. 纵轴流玉米脱粒分离装置喂入量与滚筒转速试验[J]. 农业机械学报, 2018, 49(2): 58-65. |

| Qu Zhe, Zhang Dong-xing, Yang Li, et al. Experiment on feed rate and cylinder speed of longitudinal axial flow threshing and separating device for maize[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(2): 58-65. | |

| 19 | Qian Z J, Jin C Q, Zhang D G. Multiple frictional impact dynamics of threshing process between flexible tooth and grain kernel[J]. Computers & Electronics in Agriculture, 2017, 141: 276-285. |

| 20 | 蔡超杰, 陈志, 韩增德, 等. 种子玉米生物力学特性与脱粒性能的关系研究[J]. 农机化研究, 2017, 39(4): 192-196. |

| Cai Chao-jie, Chen Zhi, Han Zeng-de, et al. Stduy on relationship of biomechanical characteristics of corn seed and threshing perforcane[J]. Journal of Agricultural Mechanization Research, 2017, 39(4): 192-196. | |

| 21 | 许大兴, 杨健明. 卧式轴流脱粒分离装置研究[J]. 农业机械学报, 1984, 15(3): 57-66. |

| Xu Da-xing, Yang Jian-ming. Study of horizontal axial-flow threshing-separating unit characteristics[J]. Transactions of the Chinese Society for Agricultural Machinery, 1984, 15(3): 57-66. | |

| 22 | 徐立章, 李耀明, 丁林峰. 水稻谷粒与脱粒元件碰撞过程的接触力学分析[J]. 农业工程学报, 2008, 24(6): 146-149. |

| Xu Li-zhang, Li Yao-ming, Ding Lin-feng. Contacting mechanics analysis during impact process between rice and threshing component[J]. Transactions of the Chinese Society of Agricultural Engineering, 2008, 24(6): 146-149. | |

| 23 | 邵志威, 陈智, 侯占峰, 等. BYW-400型冰草种子振动丸粒化包衣机种子丸化运动特性[J]. 农业工程学报, 2018, 34(3): 57-64. |

| Shao Zhi-wei, Chen Zhi, Hou Zhan-feng, et al. Analysis of pelleting movement characteristics of BYW-400 type vibrating seed coating machine for wheatgrass[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(3): 57-64. | |

| 24 | 丁林峰, 李耀明, 徐立章. 稻谷压缩试验的接触力学分析[J]. 农机化研究, 2007(12): 112-115. |

| Ding Lin-feng, Li Yao-ming, Xu Li-zhang. Research and analysis in the compressing experimentation about corn with contact mechanicals[J]. Journal of Agricultural Mechanization Research, 2007(12): 112-115. | |

| 25 | 段玥晨, 章定国, 洪嘉振. 作大范围运动柔性梁的一种碰撞动力学求解方法[J]. 机械工程学报, 2012, 48(19): 95-102. |

| Duan Yue-chen, Zhang Ding-guo, Hong Jia-zhen. Method for solving the impact problem of a flexible beam with large overall motion[J]. Journal of Mechanical Engineering, 2012, 48(19): 95-102. | |

| 26 | 方建士, 李宝玉, 章定国. 大范围运动柔性梁的连续力法撞击动力学分析[J]. 南京理工大学学报: 自然科学版, 2008, 32(6): 661-665. |

| Fang Jian-shi, Li Bao-yu, Zhang Ding-guo. Continus force approach for impact dynamics of flexible beam in large overall motion[J]. Journal of Nanjing University of Science and Technology(Natural Science), 2008, 32(6): 661-665. | |

| 27 | 刘锦阳, 洪嘉振. 刚-柔耦合动力学系统的建模理论研究[J]. 力学学报, 2002, 34(3): 408-415. |

| Liu Jin-yang, Hong Jia-zhen. Study on dynamic modeling theory of rigid-flexible coupling system[J]. Theoretical and Applied Mechanics, 2002, 34(3): 408-415. | |

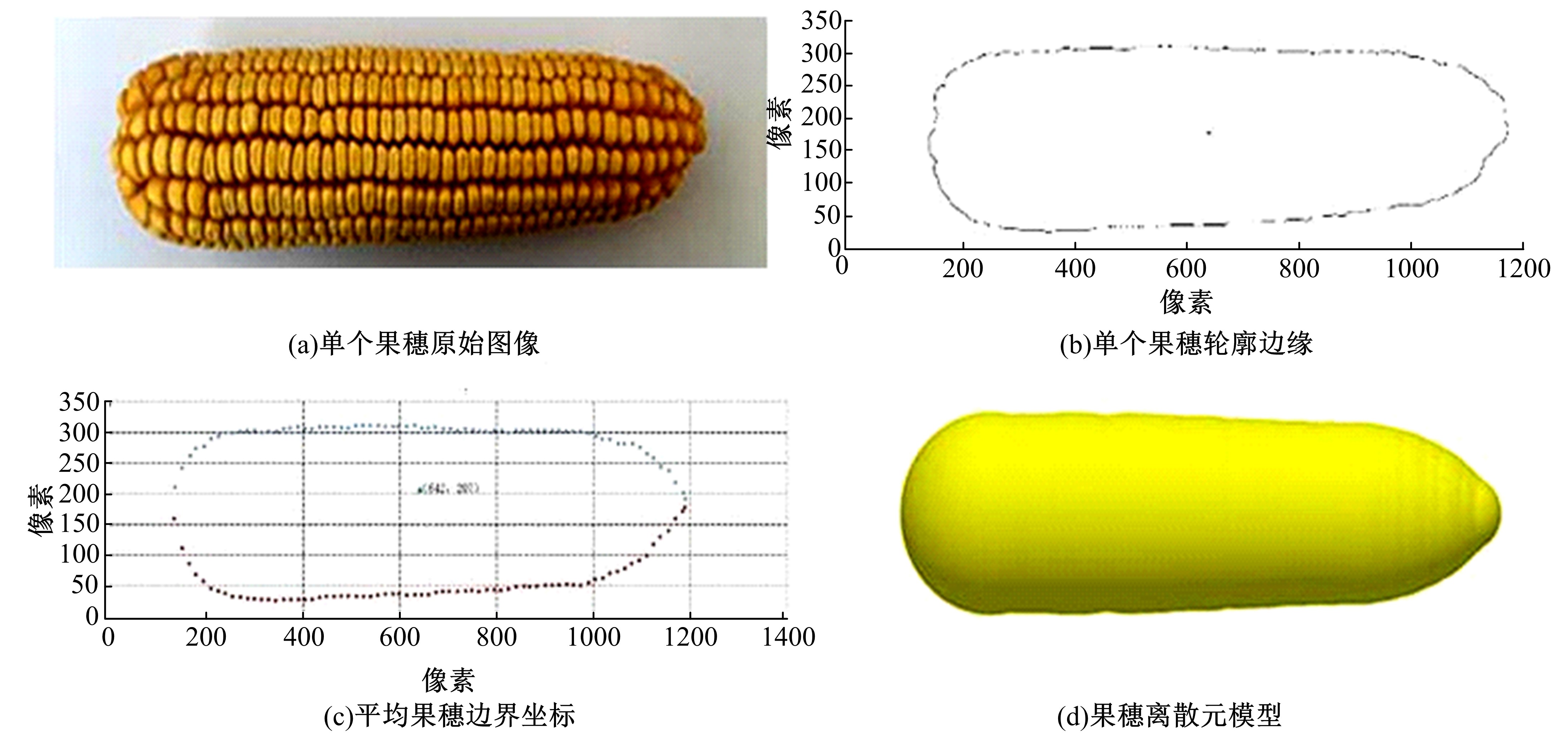

| 28 | 于亚军, 周海玲, 付宏, 等. 基于颗粒聚合体的玉米果穗建模方法[J]. 农业工程学报, 2012, 28(8): 167-174. |

| Yu Ya-jun, Zhou Hai-ling, Fu Hong, et al. Modeling method of corn ears based on particles agglomerate[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(8): 167-174. | |

| 29 | 于亚军, 于建群, 陈仲, 等. 三维离散元法边界建模软件设计[J]. 农业机械学报, 2011, 42(8): 98-103. |

| Yu Ya-jun, Yu Jian-qun, Chen Zhong, et al. Design of 3-D DEM boundary modeling software[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(8): 98-103. | |

| 30 | Kovacs A, Kerenyi G. Modeling of corn ears by discrete element method(DEM)[C]∥Conference on Modelling and Simulation, Cambridge, 2017: 355-361. |

| 31 | 刘长青, 陈兵旗. 基于机器视觉的玉米果穗参数的图像测量方法[J]. 农业工程学报, 2014, 30(6): 131-138. |

| Liu Chang-qing, Chen Bing-qi. Method of image detection for ear of corn based on computer vision[J]. Transactions of the Chinese Society of Agricultural Engineering, 2014, 30(6): 131-138. | |

| 32 | 王立军, 彭博, 宋慧强. 玉米收获机聚氨酯橡胶筛筛分性能仿真与试验[J]. 农业机械学报, 2018, 49(7): 90-96. |

| Wang Li-jun, Peng Bo, Song Hui-qiang. Cleaning of maize mixture based on polyurethane rubber sieve[J] Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(7): 90-96. | |

| 33 | 王云霞, 梁志杰, 张东兴, 等. 基于离散元的玉米种子颗粒模型种间接触参数标定[J]. 农业工程学报, 2016, 32(22): 36-42. |

| Wang Yun-xia, Liang Zhi-jie, Zhang Dong-xing, et al. Calibration method of contact characteristic parameters for corn seeds based on EDEM[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(22): 36-42. | |

| 34 | 付宏, 吕游, 李艳双, 等. 基于离散元法的玉米脱粒过程分析[J]. 吉林大学学报: 工学版, 2012, 42(4): 997-1002. |

| Fu Hong, Lyu You, Li Yan-shuang, et al. Analysis for corn threshing process based DEM[J]. Journal of Jilin University(Engineering and Technology Edition), 2012, 42(4): 997-1002. | |

| 35 | 王扬, 王晓梅, 陈泽仁, 等. 基于离散元法的玉米籽粒建模[J]. 吉林大学学报: 工学版, 2018, 48(5): 1537-1547. |

| Wang Yang, Wang Xiao-mei, Chen Ze-ren, et al. Modeling method of maize kernels based on discrete element method[J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1537-1547. |

| [1] | 薛钊,付君,陈志,王锋德,韩少平,任露泉. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报(工学版), 2020, 50(2): 739-748. |

| [2] | 程超,付君,郝付平,陈志,周德义,任露泉. 清选筛运动参数对玉米芯轴堵筛规律的影响[J]. 吉林大学学报(工学版), 2020, 50(1): 351-360. |

| [3] | 高锐涛,单建,杨洲,文晟,兰玉彬,张泉勇,汪洋. 植保无人机变量喷雾处方图实时解译系统的设计与试验[J]. 吉林大学学报(工学版), 2020, 50(1): 361-374. |

| [4] | 刘恩泽,吴文福. 基于综合指标品质评价算法的单色水果生长状态检测互联网架构[J]. 吉林大学学报(工学版), 2019, 49(6): 2019-2026. |

| [5] | 秦嘉浩,李臻,光岡宗司,井上英二,宋正河,朱忠祥. 基于模型实验的拖拉机配置对稳定性的影响差异[J]. 吉林大学学报(工学版), 2019, 49(4): 1236-1245. |

| [6] | 梁方,尤泳,王德成,王光辉,贺长彬,李帅. 运动参数对草地切根刀具与土壤作用关系的影响[J]. 吉林大学学报(工学版), 2019, 49(3): 903-911. |

| [7] | 王扬, 王晓梅, 陈泽仁, 于建群. 基于离散元法的玉米籽粒建模[J]. 吉林大学学报(工学版), 2018, 48(5): 1537-1547. |

| [8] | 陈东辉, 吕建华, 龙刚, 张宇晨, 常志勇. 基于ADAMS的半悬挂式农业机组静侧翻稳定性[J]. 吉林大学学报(工学版), 2018, 48(4): 1176-1183. |

| [9] | 贾洪雷, 王万鹏, 陈志, 庄健, 王文君, 刘慧力. 基于土壤坚实度的仿形弹性镇压辊镇压力实时测量方法[J]. 吉林大学学报(工学版), 2018, 48(4): 1169-1175. |

| [10] | 王扬, 吕凤妍, 徐天月, 于建群. 大豆籽粒形状和尺寸分析及其建模[J]. 吉林大学学报(工学版), 2018, 48(2): 507-517. |

| [11] | 贾洪雷, 郑嘉鑫, 袁洪方, 郭明卓, 王文君, 于路路. 大豆播种机双V型筑沟器设计与试验[J]. 吉林大学学报(工学版), 2017, 47(1): 323-331. |

| [12] | 刘震涛, 孙朝晖, 潘俊, 黄瑞, 陈俊玄, 俞小莉. 机械约束对缸盖热疲劳模拟试验的影响[J]. 吉林大学学报(工学版), 2015, 45(5): 1450-1454. |

| [13] | 肖志锋, 乐建波, 吴南星, 刘相东. 操作压力对过热蒸汽流化床干燥的影响[J]. 吉林大学学报(工学版), 2015, 45(4): 1375-1380. |

| [14] | 刘坤, 赵建琛, 曹恩国, 韩宣. 基于下肢动力学检测分析的站起康复训练机器人控制[J]. 吉林大学学报(工学版), 2015, 45(3): 837-843. |

| [15] | 张金波,佟金,马云海. 仿生肋条结构表面深松铲刃的磨料磨损特性[J]. 吉林大学学报(工学版), 2015, 45(1): 174-180. |

|

||