吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (6): 1933-1942.doi: 10.13229/j.cnki.jdxbgxb20210186

• 车辆工程·机械工程 •

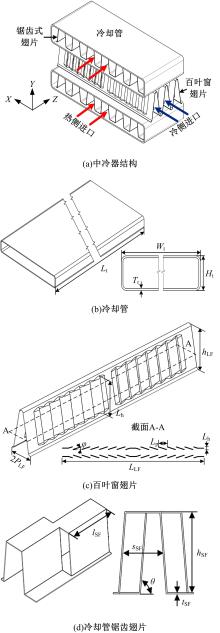

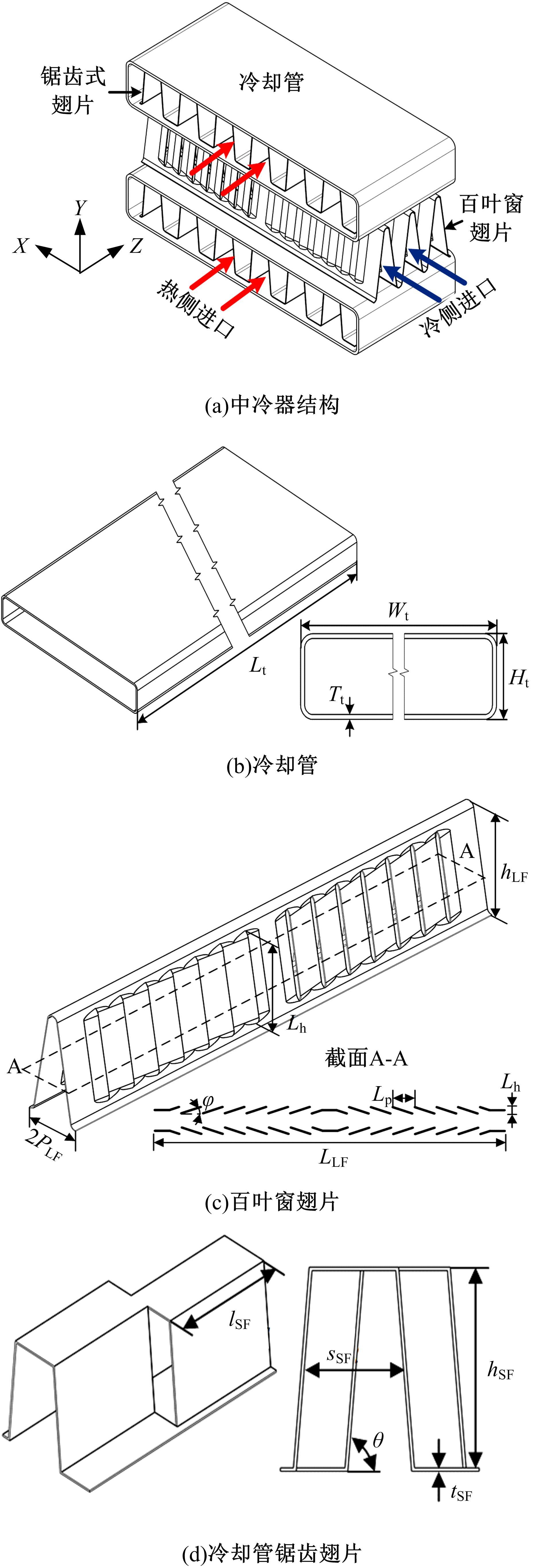

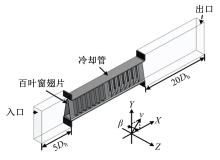

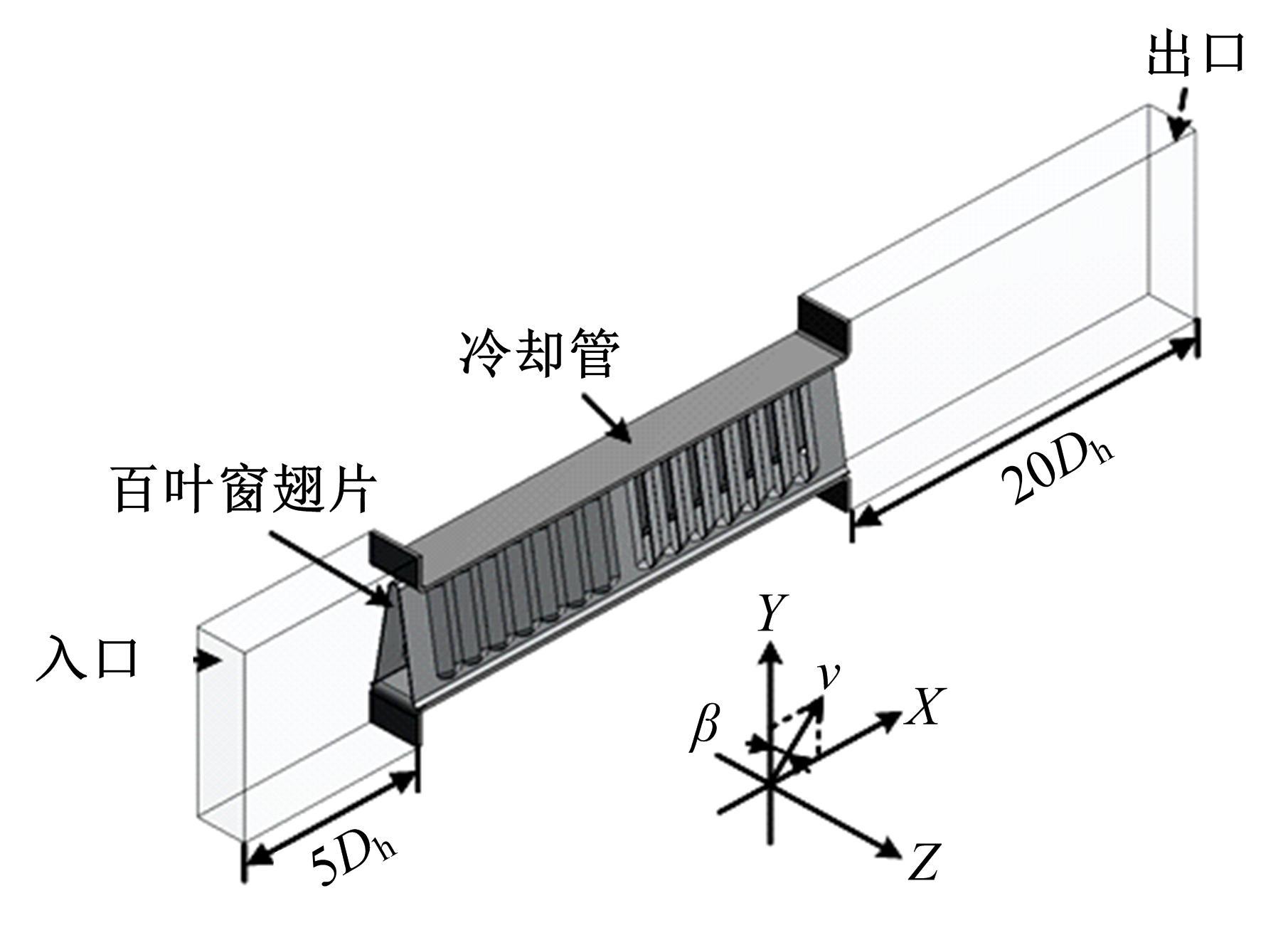

冷却管结构及进气方向对空冷中冷器性能的影响

胡兴军1( ),张靖龙1,罗雨霏1,辛俐1,李胜2,胡金蕊2,兰巍1(

),张靖龙1,罗雨霏1,辛俐1,李胜2,胡金蕊2,兰巍1( )

)

- 1.吉林大学 汽车仿真与控制国家重点实验室,吉林 长春,130032

2.一汽解放青岛汽车有限公司 山东 青岛 266043

Influence investigation of cooling tube structure and airflow direction on thermal⁃hydraulic performance of air⁃cooled charge air cooler

Xing-jun HU1( ),Jing-long ZHANG1,Yu-fei LUO1,Li XIN1,Sheng LI2,Jin-rui HU2,Wei LAN1(

),Jing-long ZHANG1,Yu-fei LUO1,Li XIN1,Sheng LI2,Jin-rui HU2,Wei LAN1( )

)

- 1.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

2.China FAW Jiefang Automotive Co. ,Ltd. ,Qingdao 266043,China

摘要:

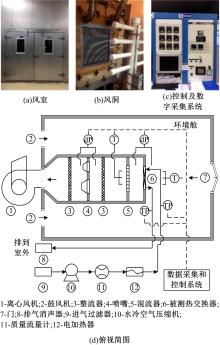

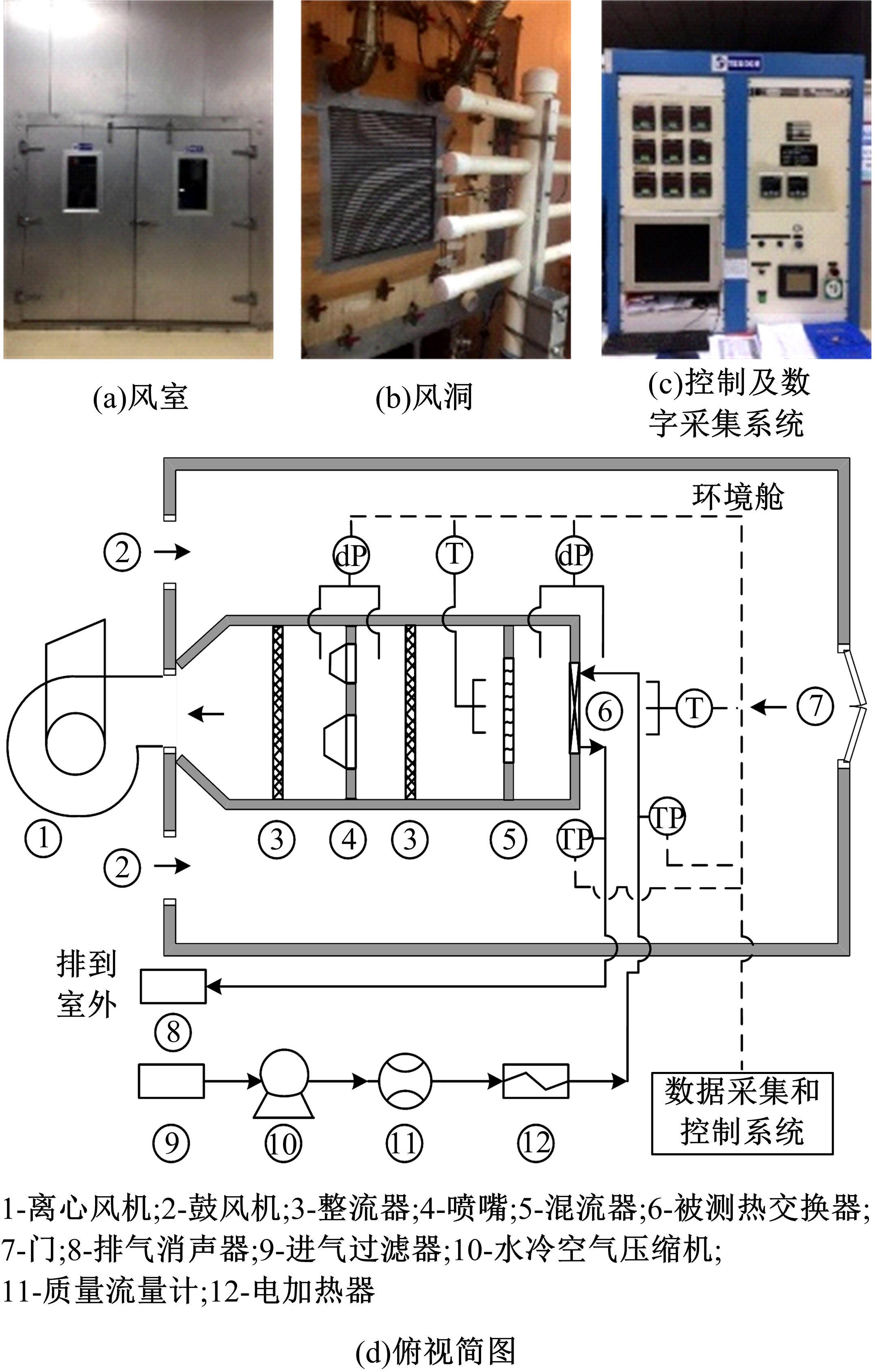

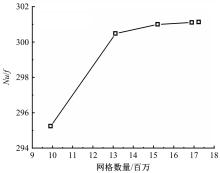

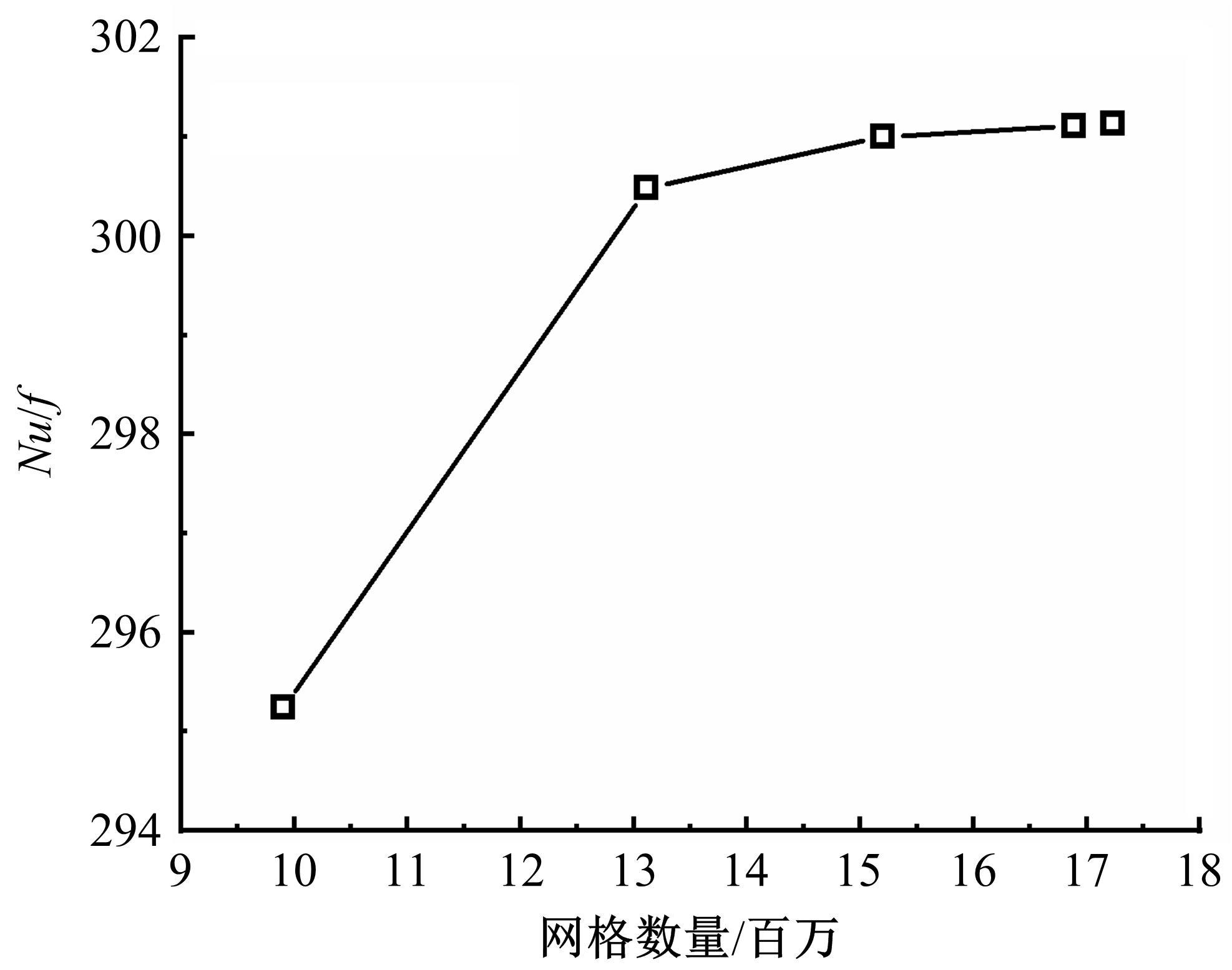

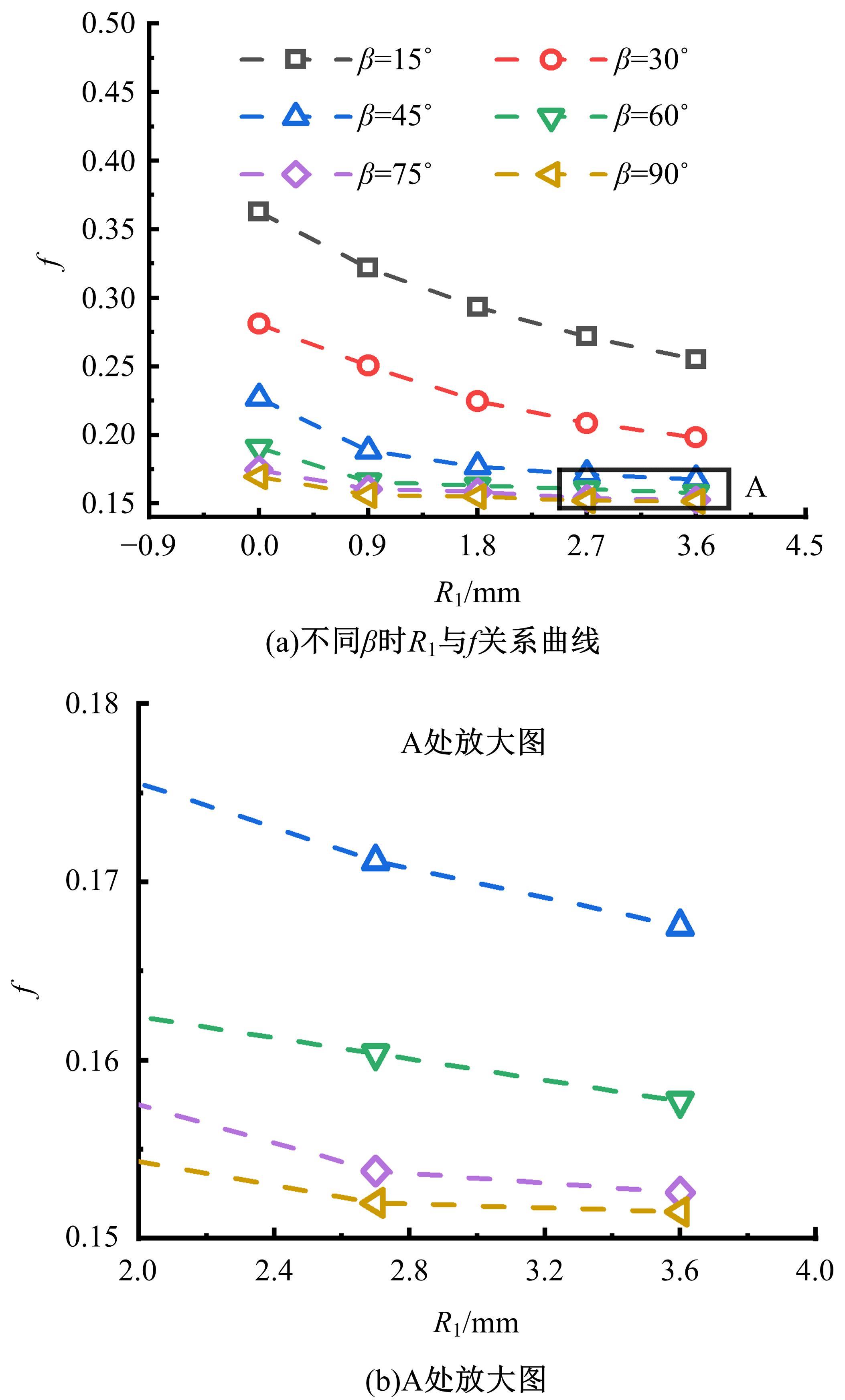

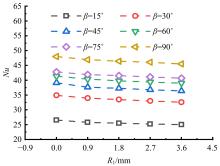

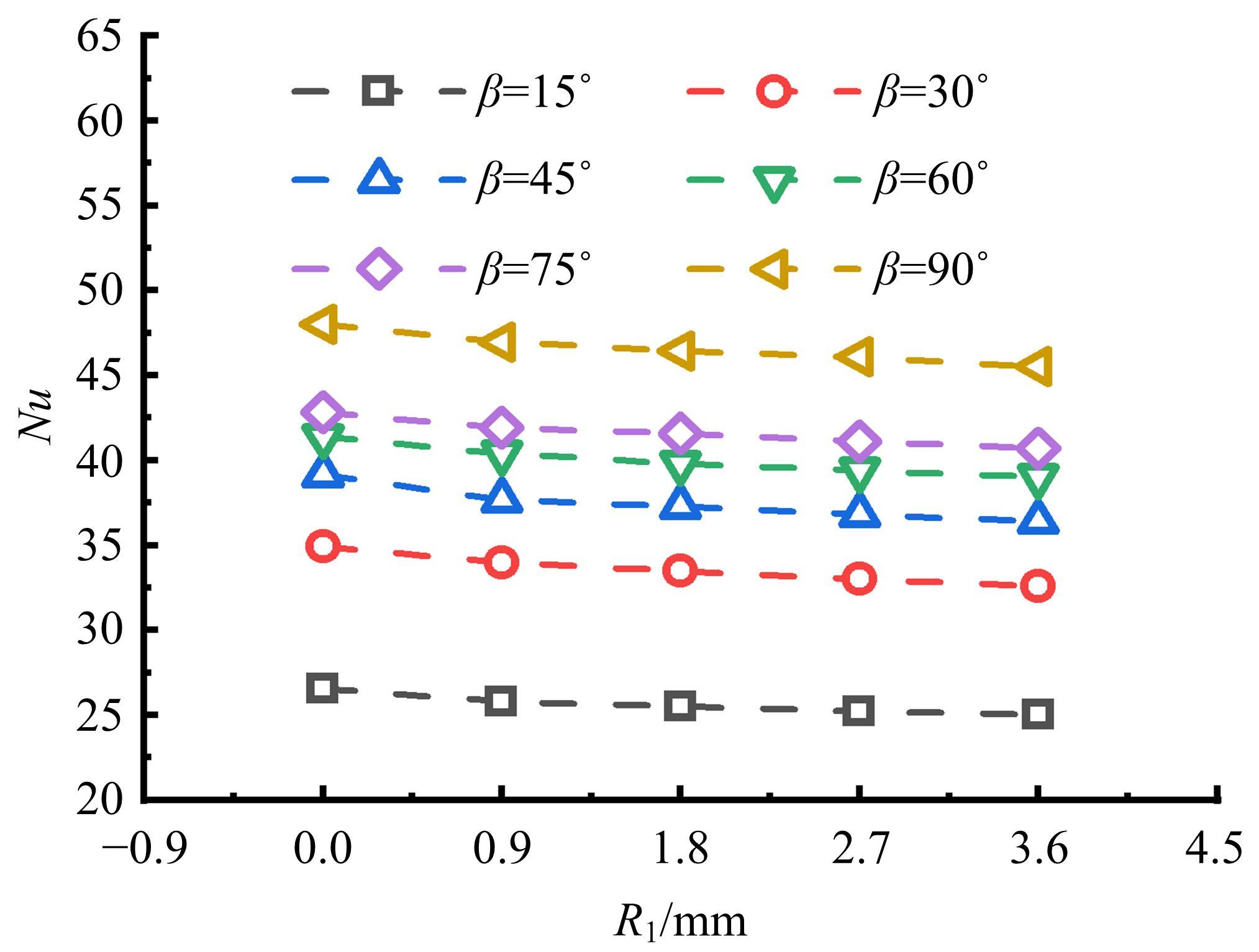

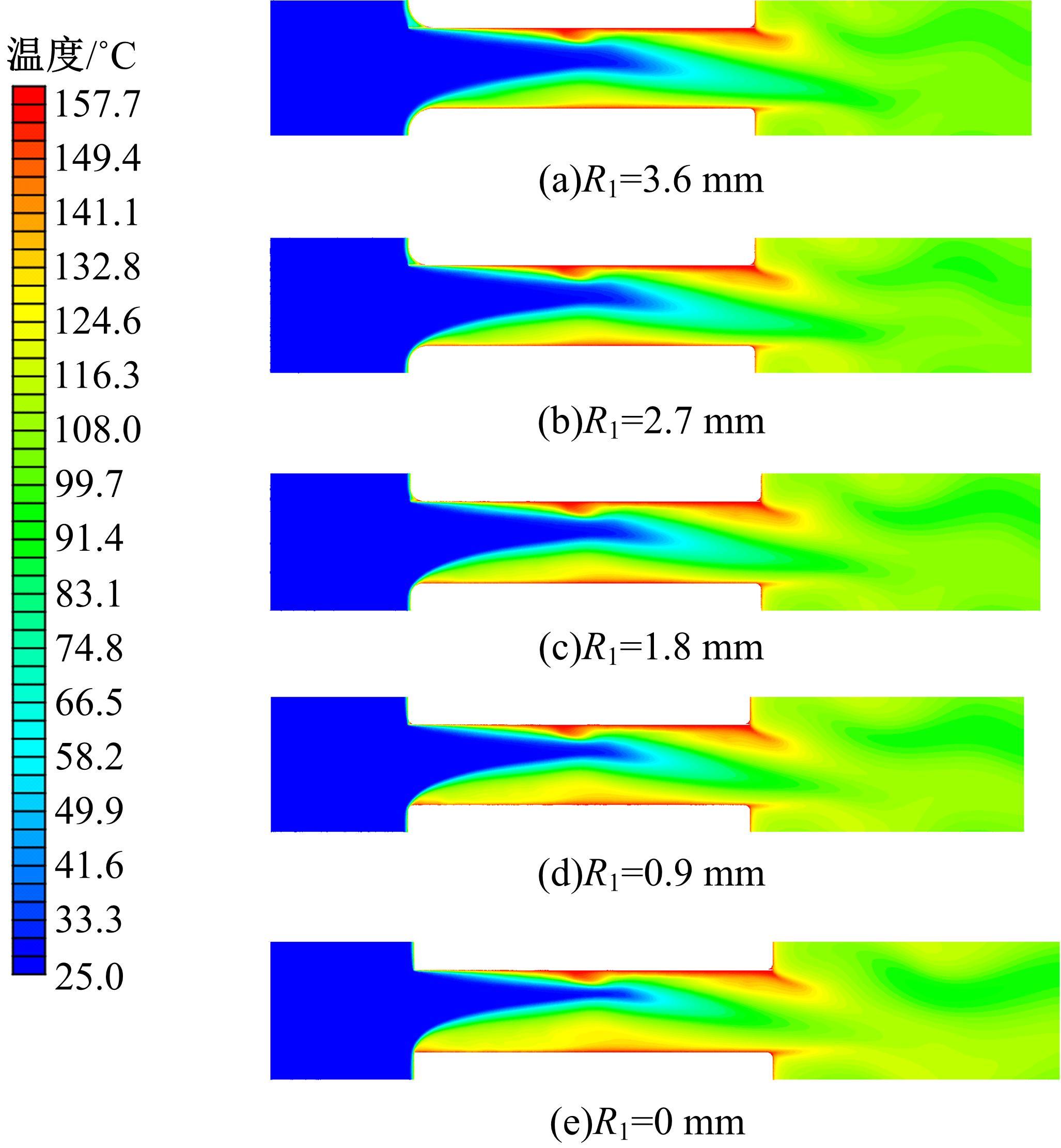

首先,通过试验方法获得了基准空冷中冷器在不同速度时的冷侧静压降和传热系数。然后,采用计算流体力学方法对试验值进行了验证,结果表明,对于静压降,试验值与仿真值的绝对误差不超过7%,而传热系数则不超过15%,说明当前仿真的准确性。接着,继续采用计算流体方法研究了冷侧风速为6 m/s时,不同冷却管前缘半径R1及进气方向β对空冷中冷器冷侧热工水力性能的影响,结果表明,当R1=3.6 mm且β=90°时,Fanning摩擦因子f取得各工况中的最小值;当R1=0 mm且β=90°时,努赛尔数Nu取得各工况中的最大值;当

中图分类号:

- U461.8

| 1 | Ramesh K S. 换热器设计技术[M]. 程林, 译. 北京:机械工业出版社, 2010: 168-172. |

| 2 | Djamel S, Ameur H, Mellal M. Effect of tube shape on the performance of a fin and tube heat exchanger[J]. Journal of Mechanical Engineering and Science, 2020, 14(2): 6709-6718. |

| 3 | Huminic G, Huminic A. A numerical approach on hybrid nanofluid behavior in laminar duct flow with various cross sections[J]. Journal of Thermal Analysis and Calorimetry, 2020, 140: 2097-2110. |

| 4 | Deepakkumar R, Jayavel S. Air side performance of finned-tube heat exchanger with combination of circular and elliptical tubes[J]. Applied Thermal Engineering, 2017, 119: 360-372. |

| 5 | Khoo K L, Lewpiriyawong N, Sun C, et al. Numerical investigation of thermal and hydraulic performances of a condenser coil with oblique-shaped tubes[J]. International Journal of Refrigeration, 2019, 103: 42-50. |

| 6 | 赵津,马秀勤,李梅珺,等. 收腰管散热器的耦合传热与试验[J]. 中国机械工程, 2016, 27(16): 2166-2171. |

| Zhao Jin, Ma Xiu-qin, Li Mei-jun, et al. Coupled heat transfer and experiments of waist tube heat exchanger[J]. China Mechanical Engineering, 2016, 27(16): 2166-2171. | |

| 7 | Jassim A H, Tahseen T A, Mustafa A W, et al. An experimental investigation in forced convective heat transfer and friction factor of air flow over aligned round and flattened tube banks[J]. Heat Transfer—Asian Research, 2019, 48(6): 2350-2369. |

| 8 | Liang Y Y, Liu C C, Li C Z, et al. Experimental and simulation study on the air side thermal hydraulic performance of automotive heat exchangers[J]. Applied Thermal Engineering, 2015, 87: 305-315. |

| 9 | Shojaeefard M H, Molaeimanesh G R, Yarmohammadi A, et al. Multi-objective optimization of an automotive louvered fin-flat tube condenser for enhancing HVAC system cooling performance[J]. Applied Thermal Engineering, 2017, 125: 546-558. |

| 10 | Karthik P, Kumaresan V, Velraj R. Experimental and parametric studies of a louvered fin and flat tube compact heat exchanger using computational fluid dynamics[J]. Alexandria Engineering Journal, 2015, 54(4): 905-915. |

| 11 | Deng J. Improved correlations of the thermal-hydraulic performance of large size multi-louvered fin arrays for condensers of high power electronic component cooling by numerical simulation[J]. Energy Conversation and Management, 2017, 153:504-514. |

| 12 | Ryu K, Lee K S. Generalized heat-transfer and fluid-flow correlations for corrugated louvered fins[J]. International Journal of Heat and Mass Transfer, 2015, 83: 604-612. |

| 13 | Dongan B, Altun O, Ugurlubilek N, et al. An experimental comparison of two multi-louvered fin heat exchangers with different numbers of fin rows[J]. Applied Thermal Engineering, 2015, 91: 270-278. |

| 14 | Toolthaisong S, Kasayapanand N. Effect of attack angles on air side thermal and pressure drop of the cross flow heat exchangers with staggered tube arrangement[J]. Energy Procedia, 2013, 34: 417-429. |

| 15 | Tang L H, Du X P, Pan J, et al. Air inlet angle influence on the air-side heat transfer and flow friction characteristics of a finned oval tube heat exchanger[J]. International Heat and Mass Transfer, 2019, 145: No.118702. |

| 16 | Kim M H, Youn B, Bullard C W. Effect of inclination on the air-side performance of a brazed aluminum heat exchanger under dry and wet conditions[J]. International Heat and Mass Transfer, 2001, 44(24): 4613-4623. |

| 17 | Henriksson L, Gullberg P, Dahl E, et al. CFD simulation of one period of a louvered fin where the airflow is inclined relative to the heat exchanger[J]. SAE International Journal of Engines, 2015, 8(4): 1733-1741. |

| 18 | Taylor J R. 误差分析导论——物理测量中的不确定度[M]. 王中宇,译. 北京: 高等教育出版社, 2015. |

| 19 | 傅佳宏, 俞小莉, 药凌宇, 等. 工程机械独立式冷却模块流动传热仿真对比[J].吉林大学学报:工学版, 2016, 46(2): 451-456. |

| Fu Jia-hong, Yu Xiao-li, Yao Ling-yu, et al. Numerical comparison of flow and heat transfer in detached cooling module for construction machinery[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(2): 451-456. | |

| 20 | Manglik R M, Bergles A E. Heat transfer and pressure drop correlations for the rectangular offset strip fin compact heat exchanger[J]. Experimental Thermal and Fluid Science, 1995, 10(2): 171-180. |

| 21 | 胡兴军,张靖龙,辛俐,等.冷却管结构及风速对空冷中冷器性能的影响[J]. 吉林大学学报:工学版,2021, 51(5): 1557-1564. |

| Hu Xing-jun, Zhang Jing-long, Xin Li, et al. Investigation on influence of cooling tube structure and airflow speed on cold side performance of air⁃cooled charge air cooler[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(5): 1557-1564. | |

| 22 | Kays W M, London A L. Compact heat exchangers[M]. Florida: Krieger Publishing Company, 1984. |

| 23 | Karthik P, Kumaresan V, Velraj R. Experimental and parametric studies of a louvered fin and flat tube compact heat exchanger using computational fluid dynamics[J]. Alexandria Engineering Journal, 2015, 54(4): 905-915. |

| 24 | 林建忠, 阮晓东, 陈邦国,等. 流体力学[M]. 2版. 北京:清华大学出版社, 2013. |

| 25 | Perrotin T, Clodic D. Thermal-hydraulic CFD study in louvered fin-and-flat-tube heat exchangers[J]. International Journal of Refrigeration, 2004, 27(4): 422-432. |

| 26 | Versteeg H K, Malalasekera W. 计算流体动力学导论:有限体积法[M]. 北京:世界图书出版公司, 2007. |

| 27 | Webb R L, Kim N. Principle of Enhanced Heat Transfer[M]. New York: Taylor and Francis Group, 2005. |

| [1] | 罗勇,韦永恒,黄欢,肖人杰,任淋,崔环宇. 驾驶员意图识别的P2.5插混构型双离合器起步控制[J]. 吉林大学学报(工学版), 2021, 51(5): 1575-1582. |

| [2] | 曾小华,宋美洁,宋大凤,王越. 基于车联网信息的公交客车行驶工况数据处理方法[J]. 吉林大学学报(工学版), 2021, 51(5): 1692-1699. |

| [3] | 胡兴军,张靖龙,辛俐,罗雨霏,王靖宇,余天明. 冷却管结构及风速对空冷中冷器性能的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1557-1564. |

| [4] | 马超,高云凯,刘哲,段月星,田林雳. 骨架式车身多材料及梁截面形状和尺寸优化[J]. 吉林大学学报(工学版), 2021, 51(5): 1583-1592. |

| [5] | 兰凤崇,李继文,陈吉清. 面向动态场景复合深度学习与并行计算的DG-SLAM算法[J]. 吉林大学学报(工学版), 2021, 51(4): 1437-1446. |

| [6] | 杨建,夏琦,周海超,王国林. 修正胎体弦轮廓载重子午线轮胎的降噪机理[J]. 吉林大学学报(工学版), 2021, 51(4): 1198-1203. |

| [7] | 龙江启,向锦涛,俞平,王骏骋. 适用于非线性主动悬架滑模控制的线性干扰观测器[J]. 吉林大学学报(工学版), 2021, 51(4): 1230-1240. |

| [8] | 陈鑫,于贵申,张彪,潘凯旋,杨立飞. 搅拌摩擦点焊接头拉伸-剪切行为的等效建模[J]. 吉林大学学报(工学版), 2021, 51(4): 1190-1197. |

| [9] | 宋大凤,杨丽丽,曾小华,王星琦,梁伟智,杨南南. 基于行驶工况合成的混合动力汽车电池寿命优化[J]. 吉林大学学报(工学版), 2021, 51(3): 781-791. |

| [10] | 张家旭,王欣志,赵健,施正堂. 汽车高速换道避让路径规划及离散滑模跟踪控制[J]. 吉林大学学报(工学版), 2021, 51(3): 1081-1090. |

| [11] | 何仁,赵晓聪,杨奕彬,王建强. 基于驾驶人风险响应机制的人机共驾模型[J]. 吉林大学学报(工学版), 2021, 51(3): 799-809. |

| [12] | 王波,何洋扬,聂冰冰,许述财,张金换. 底部爆炸条件下车内乘员的腹部损伤[J]. 吉林大学学报(工学版), 2021, 51(3): 792-798. |

| [13] | 庄蔚敏,王鹏跃,高瑞娟,解东旋. 温热成形对AA5754铝合金静态力学性能的影响[J]. 吉林大学学报(工学版), 2021, 51(3): 847-854. |

| [14] | 宋强,孙丹婷,章伟. 纯电动车机械式自动变速器换挡非线性建模及控制[J]. 吉林大学学报(工学版), 2021, 51(3): 810-819. |

| [15] | 张斌,程国赞,洪昊岑,赵春晓,杨华勇. 基于计算流体仿真的双作用叶片泵气蚀机理分析[J]. 吉林大学学报(工学版), 2021, 51(3): 831-839. |

|

||