吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (5): 1557-1564.doi: 10.13229/j.cnki.jdxbgxb20200598

• 车辆工程·机械工程 •

冷却管结构及风速对空冷中冷器性能的影响

- 吉林大学 汽车仿真与控制国家重点实验室,长春 130022

Investigation on influence of cooling tube structure and airflow speed on cold side performance of air⁃cooled charge air cooler

Xing-jun HU( ),Jing-long ZHANG,Li XIN,Yu-fei LUO,Jing-yu WANG,Tian-ming YU(

),Jing-long ZHANG,Li XIN,Yu-fei LUO,Jing-yu WANG,Tian-ming YU( )

)

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

摘要:

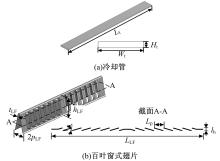

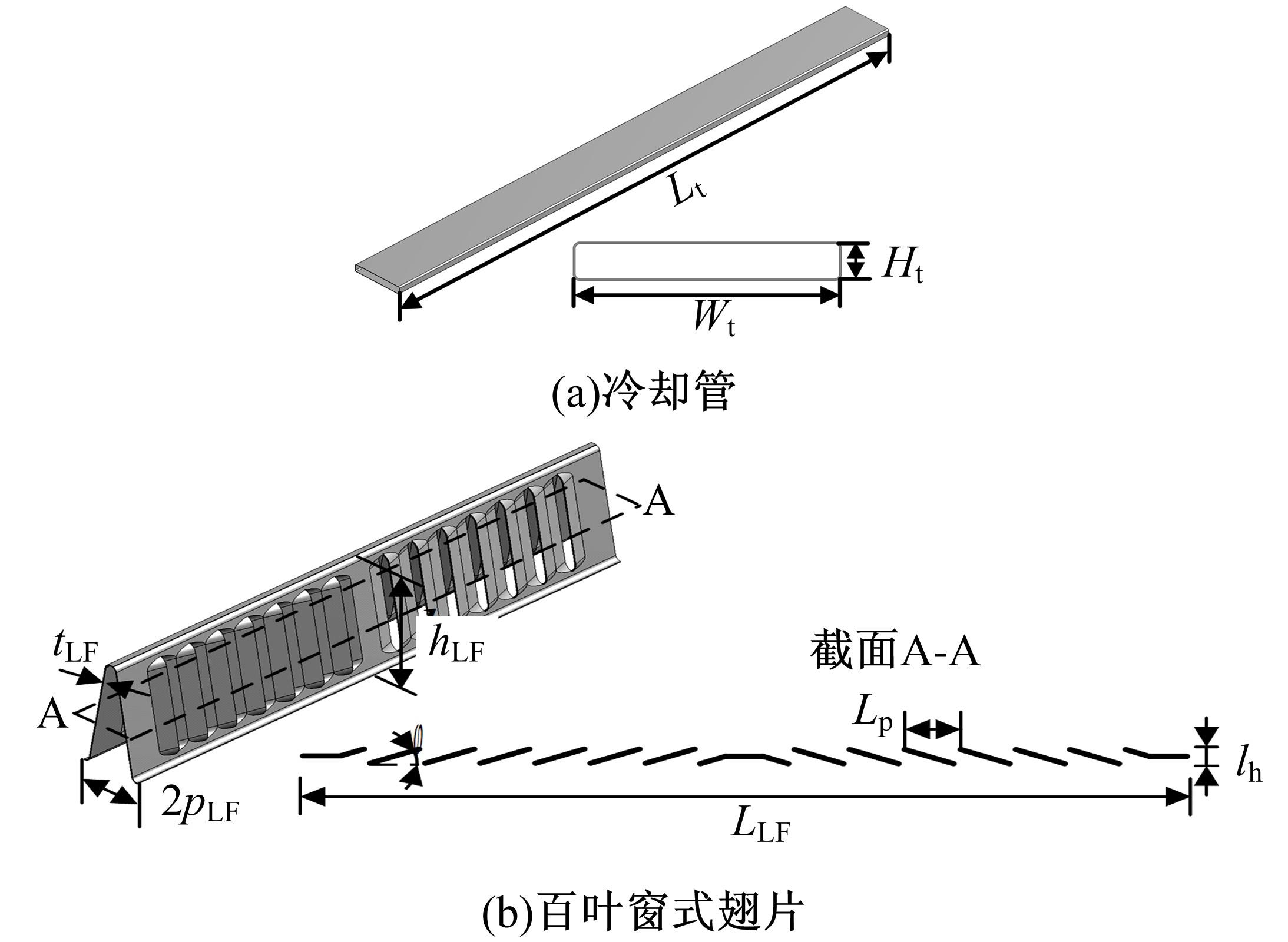

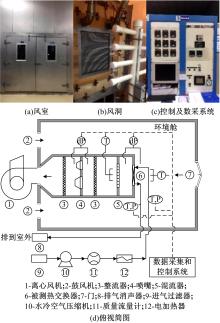

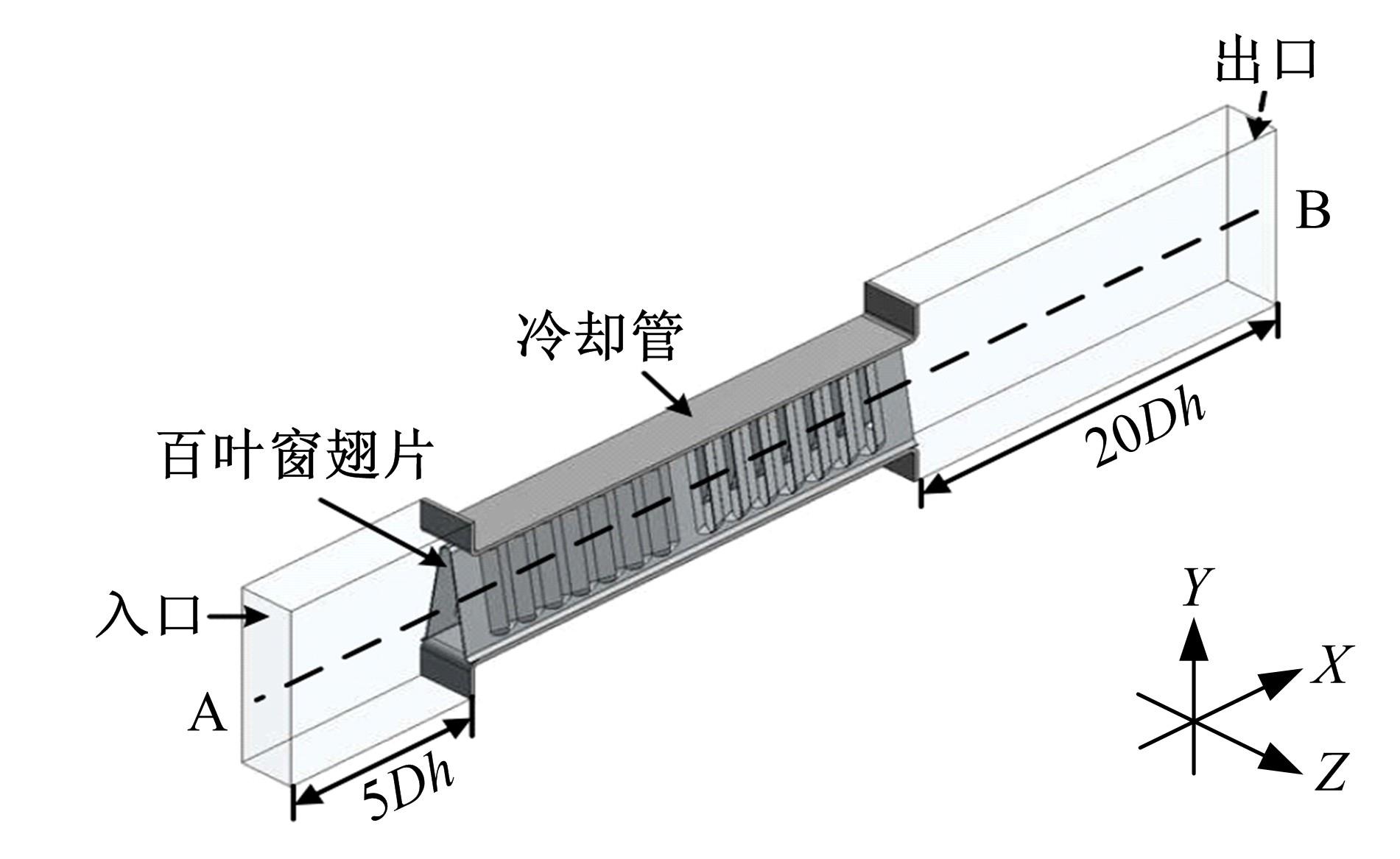

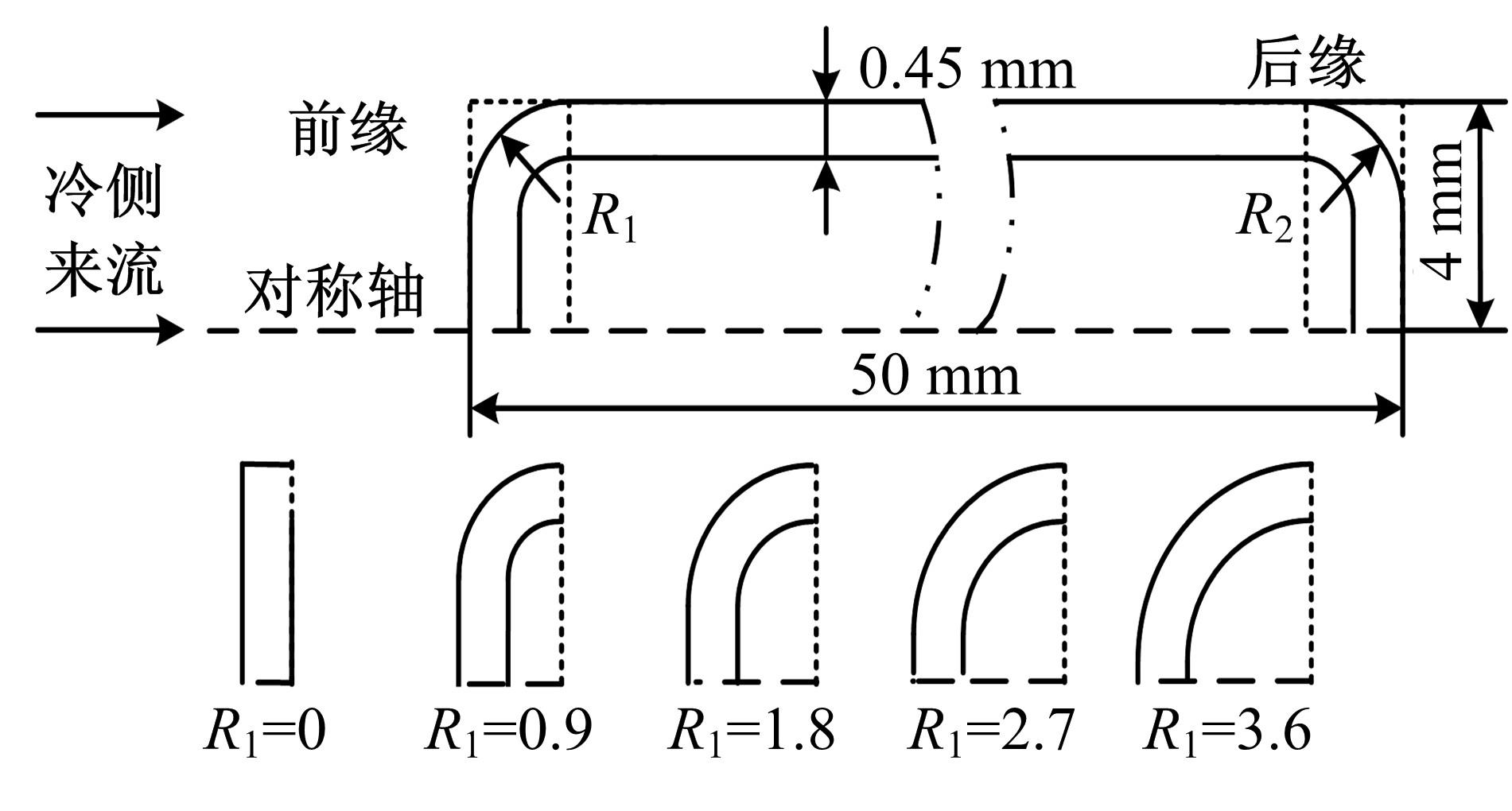

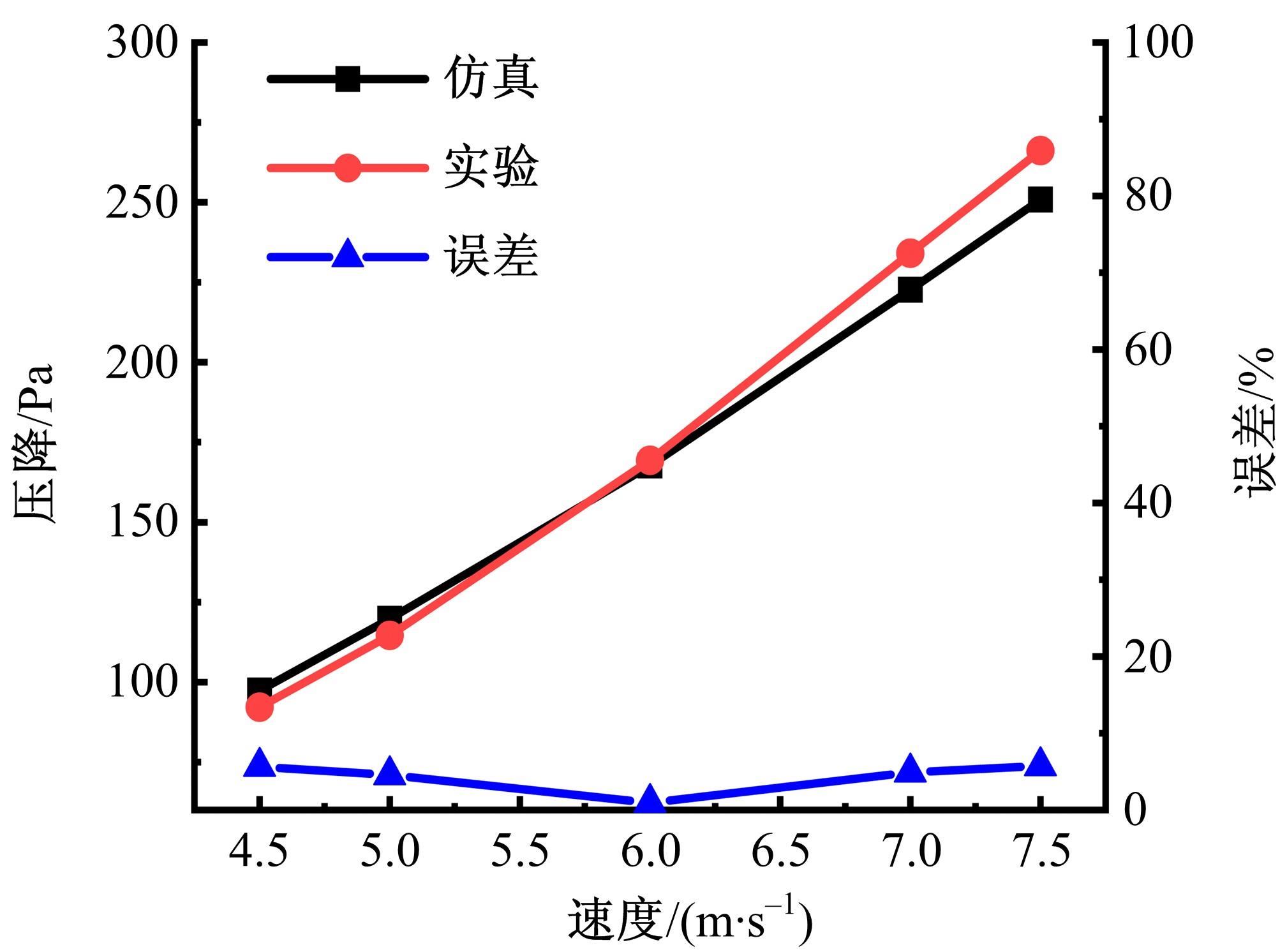

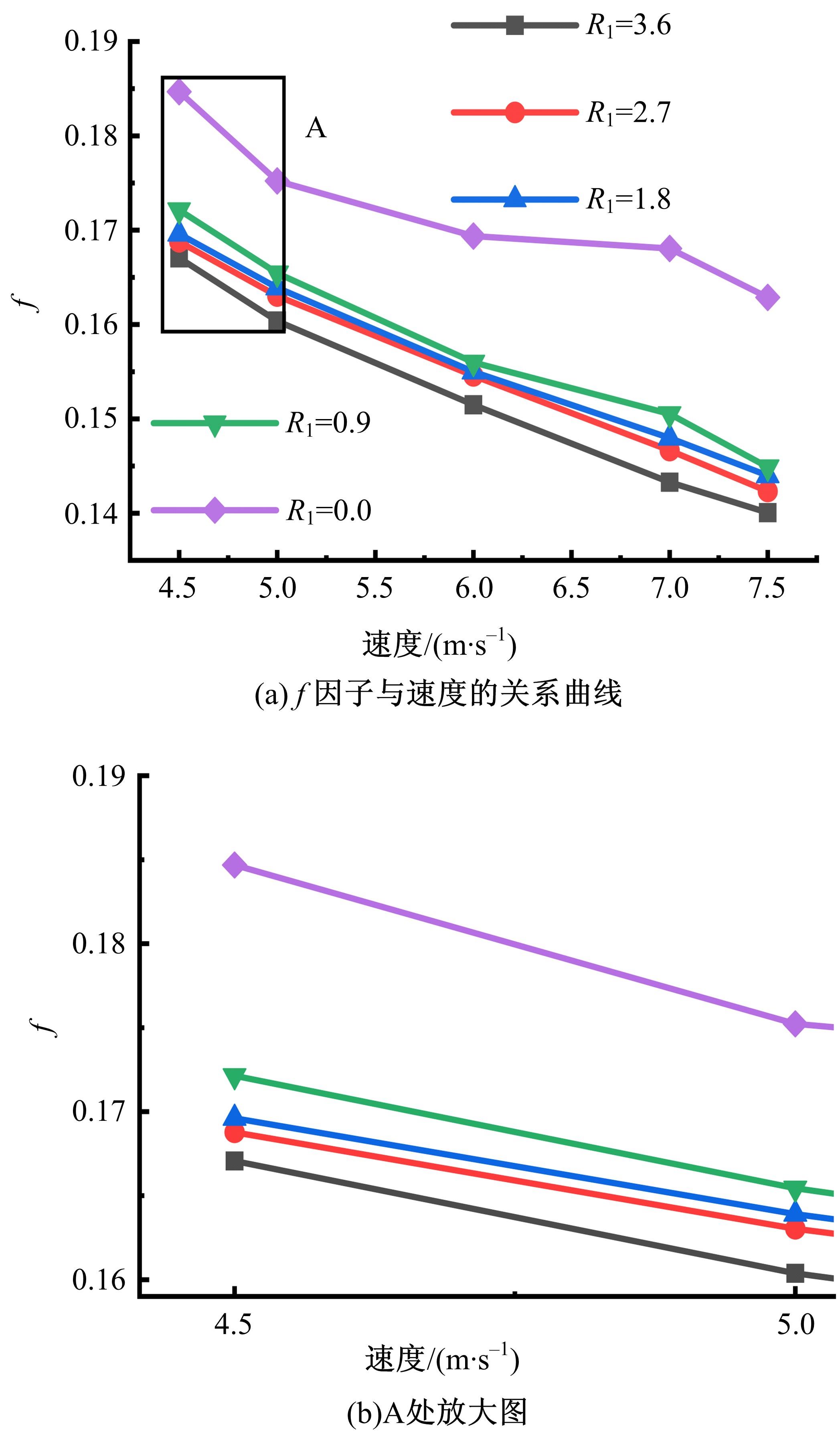

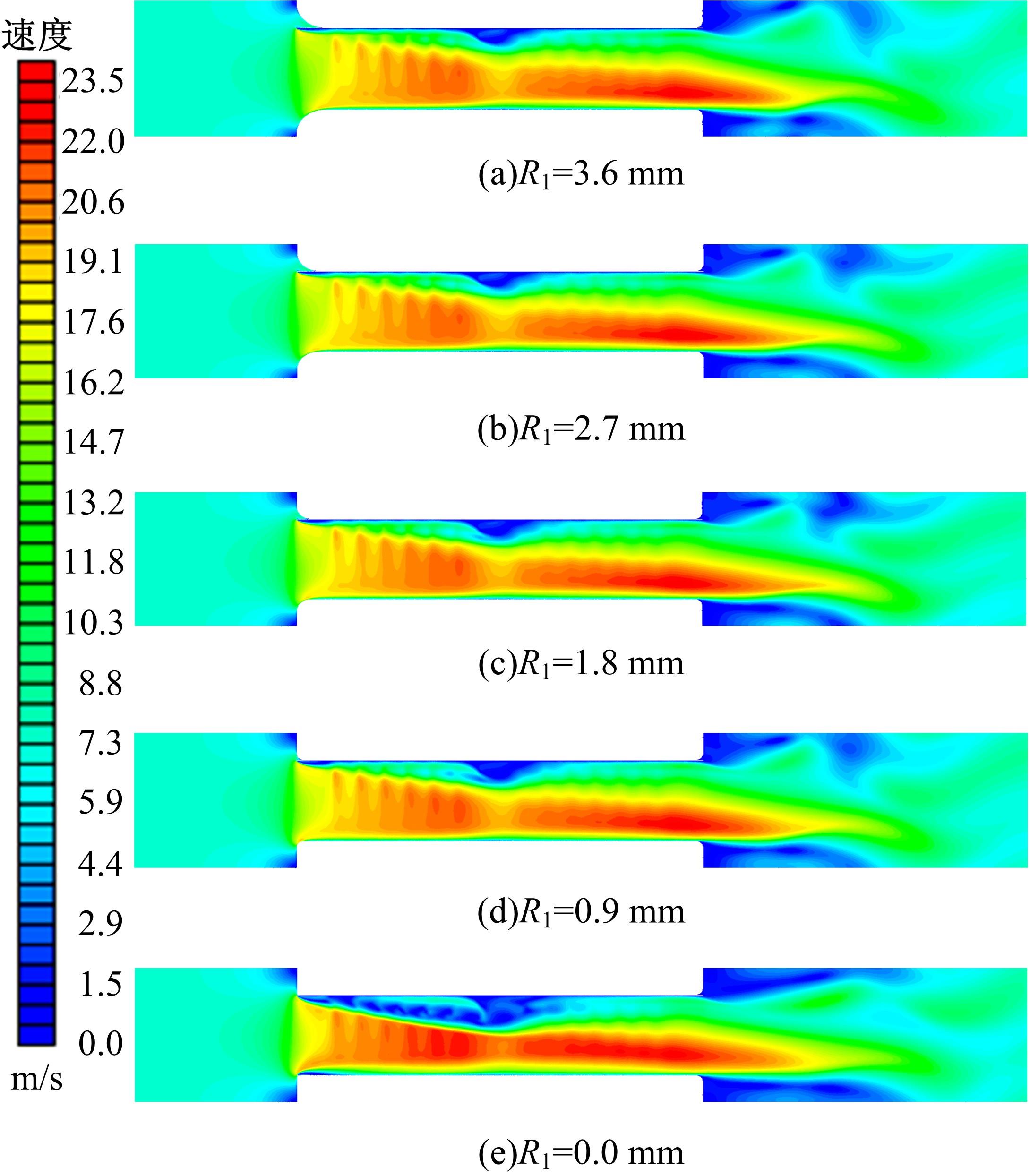

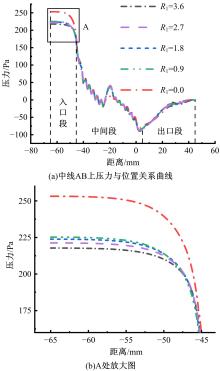

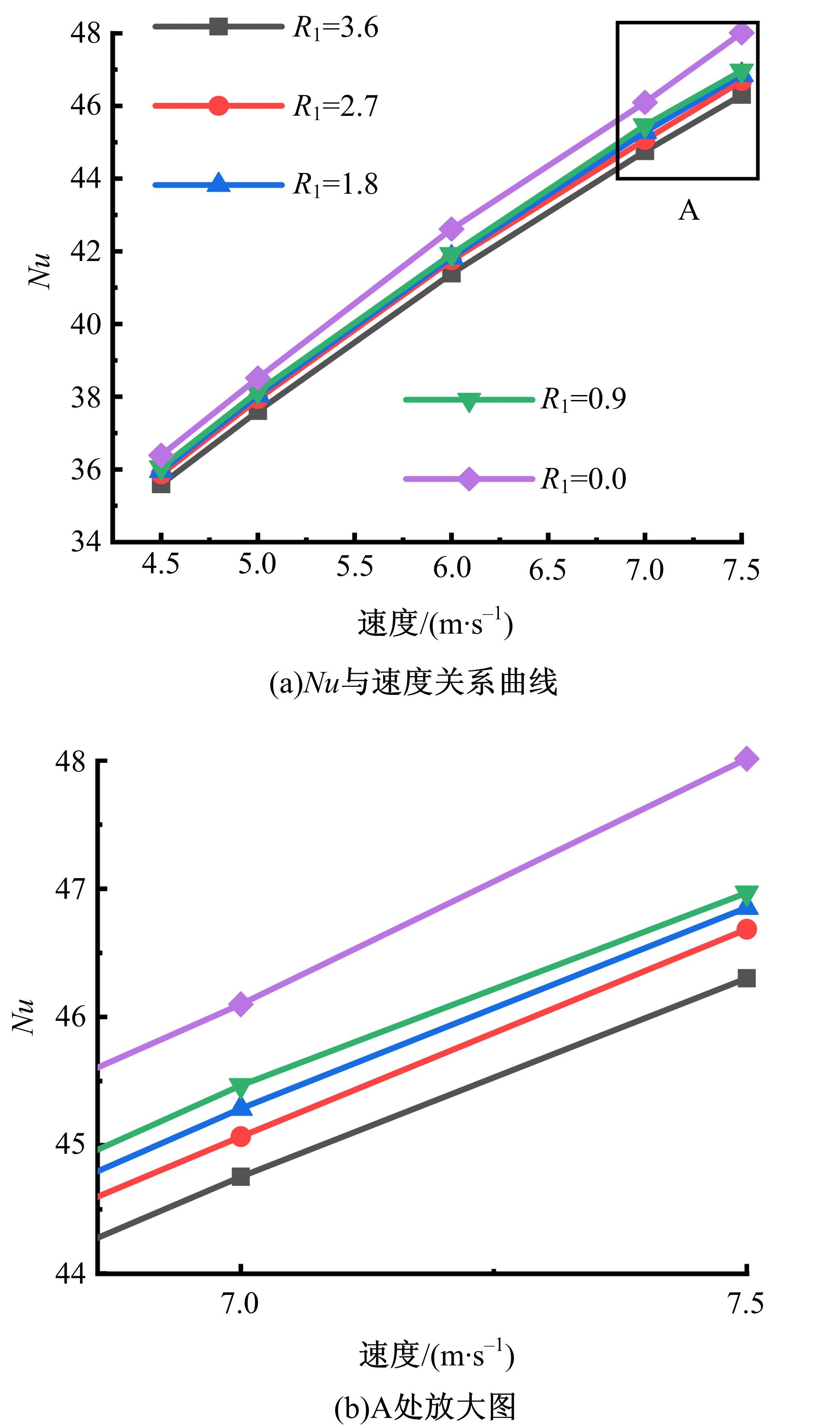

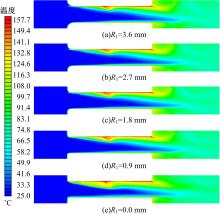

本文在实验基础上,使用计算流体动力学方法研究了不同空冷中冷器冷却管前缘结构及风速对其冷侧热工水力性能的影响。研究发现,冷却管前缘半径R1相同时,Fanning摩擦因子f随风速的增加而减小,而相同风速不同R1时,f同样随R1的增加而减小,在以R1=0.9 mm为基准时,R1=0 mm的f因子值最大增加12.42%,R1=3.6 mm的f因子值最大减小5.41%;冷却管前缘半径R1相同时,努赛尔数Nu随风速的增加而增大,相同风速不同R1时,Nu同样随R1的增大而减小,在以R1=0.9 mm为基准时,R1=0 mm的Nu最大增加2.22%,而R1=3.6 mm的Nu最大减小1.49%;对于性能评价准则PEC,冷却管前缘半径R1相同时,PEC随风速的增加而增大,而相同风速不同R1时,PEC随R1的增大而增大,在以R1=0.9 mm为基准时,R1=0 mm的PEC值最大降低10.13%,R1=3.6 mm的PEC最大增加3.40%。综上,在R1=3.6 mm、冷侧风速为7.5 m/s时,空冷中冷器冷侧热工水力性能最佳,因此增大R1及风速有助于空冷中冷器冷侧热工水力性能的改善。

中图分类号:

- U461.8

| 1 | Han H, He Y L, Li Y S, et al. A numerical study on compact enhanced fin-and-tube heat exchangers with oval and circular tube configurations[J]. International Journal of Heat and Mass Transfer, 2013, 65: 686-695. |

| 2 | Deepakkumar R, Jayavel S. Air side performance of finned-tube heat exchanger with combination of circular and elliptical tubes [J]. Applied Thermal Engineering, 2017, 119: 360-372. |

| 3 | Jassim A H, Tahseen T A, Mustafa A W, et al. An experimental investigation in forced convective heat transfer and friction factor of air flow over aligned round and flattened tube banks[J]. Heat Transfer—Asian Research, 2019, 48(6): 2350-2369. |

| 4 | Khoo K L, Lewpiriyawong N, Sun C, et al. Numerical investigation of thermal and hydraulic performances of a condenser coil with oblique-shaped tubes[J]. International Journal of Refrigeration, 2019, 103: 42-50. |

| 5 | Sahel D, Ameur H, Mellal M. Effect of tube shape on the performance of a fin and tube heat exchanger[J]. Journal of Mechanical Engineering and Science, 2020, 14(2): 6709-6718. |

| 6 | Du X P, Zeng M, Wang Q W, et al. Experimental investigation of heat transfer and resistance characteristics of a finned oval-tube heat exchanger with different air inlet angles[J]. Heat Transfer Engineering, 2014, 35(6-8): 703-710. |

| 7 | 赵津, 马秀勤, 李梅珺, 等. 收腰管散热器的耦合传热与试验[J]. 中国机械工程, 2016, 27(16): 2166-2171. |

| Zhao Jin, Ma Xiu-qin, Li Mei-jun, et al. Coupled heat transfer and experiments of waist tube radiator[J]. China Mechanical Engineering, 2016, 27(16): 2166-2171. | |

| 8 | 张利, 杨昆, 刘伟. 椭圆形和圆形翅片管流动与传热的数值研究[J]. 工程热物理学报, 2009, 30(9): 1571-1574. |

| Zhang Li, Yang Kun, Liu Wei. Numerical study on flow and heat transfer in a elliptical and circular finned tube[J]. Journal of Engineering Thermophysics, 2009, 30(9): 1571-1574. | |

| 9 | 张富强, 万长园, 龚玉霞. 矩形翅片椭圆管气侧流动与换热规律的数值研究[J]. 能源与环境, 2017, 33(4): 21-22. |

| Zhang Fu-qiang, Wan Chang-yuan, Gong Yu-xia. Numerical study on air side flow and heat transfer of rectangular finned elliptic tube heat exchanger[J]. Energy and Environment, 2017, 33(4): 21-22. | |

| 10 | Kim N, Cho J. Air-side performance of louver-finned flat aluminum heat exchangers at a low velocity region[J]. Heat and Mass Transfer, 2008, 44(9): 1127-1139. |

| 11 | Li W, Wang X L. Heat transfer and pressure drop correlations for compact heat exchangers with multi-region louver fins[J]. International Journal of Heat and Mass Transfer, 2010, 53(15): 2955-2962. |

| 12 | Karthik P, Kumaresan V, Velraj R. Experimental and parametric studies of a louvered fin and flat tube compact heat exchanger using computational fluid dynamics[J]. Alexandria Engineering Journal, 2015, 54(4): 905-915. |

| 13 | Henriksson L, Gullberg P, Dahl E, et al. CFD simulation of one period of a louvered fin where the airflow is inclined relative to the heat exchanger[J]. SAE International Journal of Engines, 2015, 8(4): 1733-1742. |

| 14 | 袁哲, 马文星, 李华龙, 等. 重型车液力减速器的换热器匹配与仿真分析[J]. 吉林大学学报: 工学版, 2013, 43(): 526-529. |

| Yuan Zhe, Ma Wen-xing, Li Hua-long, et al. Match of heat exchanger and simulation analysis based on hydrodynamic retarder of heavy vehicle[J]. Journal of Jilin University(Engineering and Technology Edition), 2013, 43(Sup.1): 526-529. | |

| 15 | 傅佳宏, 俞小莉, 药凌宇, 等. 工程机械独立式冷却模块流动传热仿真对比[J]. 吉林大学学报: 工学版, 2016, 46(2): 451-456. |

| Fu Jia-hong, Yu Xiao-li, Yao Ling-yu, et al. Numerical comparison of flow and heat transfer in detached cooling module for construction machinery[J]. Journal of Jilin University(Engineering and Technology Edition), 2016, 46(2): 451-456. | |

| 16 | 林建忠, 阮晓东, 陈邦国, 等. 流体力学[M]. 北京:清华大学出版社, 2013. |

| 17 | Perrotin T, Clodic D. Thermal-hydraulic CFD study in louvered fin-and-flat-tube heat exchangers[J]. International Journal of Refrigeration, 2004, 27(4): 422-432. |

| 18 | Menter F R. Performance of popular turbulence models for attached and separated adverse pressure gradient flow[J]. AIAA Journal, 1992, 30: 2066-2072. |

| 19 | 沙拉, 塞库利克, 程林. 换热器设计技术[M]. 北京:机械工业出版社, 2010. |

| 20 | Webb R L, Kim N. Principle of Enhanced Heat Transfer[M]. New York: Taylor and Francis Group, 2005. |

| [1] | 李志军,刘浩,张立鹏,李振国,邵元凯,李智洋. 过滤壁结构对颗粒捕集器深床过滤影响的模拟[J]. 吉林大学学报(工学版), 2021, 51(2): 422-434. |

| [2] | 赵庆武,程勇,杨雪,王宁. 高重频纳秒脉冲放电点火系统设计[J]. 吉林大学学报(工学版), 2021, 51(2): 414-421. |

| [3] | 翟富刚,尹燕斌,李超,田纬,乔子石. 伺服电动缸传动系统刚度建模与前馈控制[J]. 吉林大学学报(工学版), 2021, 51(2): 442-449. |

| [4] | 王忠,李游,张美娟,刘帅,李瑞娜,赵怀北. 柴油机排气阶段颗粒碰撞过程动力学特征分析[J]. 吉林大学学报(工学版), 2021, 51(1): 39-48. |

| [5] | 胡云峰,丁一桐,赵志欣,蒋冰晶,高金武. 柴油发动机燃烧过程数据驱动建模与滚动优化控制[J]. 吉林大学学报(工学版), 2021, 51(1): 49-62. |

| [6] | 王勃,董元正,董丽欣. 基于短期风速资料的基本风压计算方法[J]. 吉林大学学报(工学版), 2020, 50(5): 1739-1746. |

| [7] | 王建,许鑫,顾晗,张多军,刘胜吉. 基于排气热管理的柴油机氧化催化器升温特性[J]. 吉林大学学报(工学版), 2020, 50(2): 408-416. |

| [8] | 陈学深,陈涛,武涛,马旭,曾令超,陈林涛. 覆草冬种马铃薯收获机稻草分离机构设计与试验[J]. 吉林大学学报(工学版), 2020, 50(2): 749-757. |

| [9] | 刘长铖,刘忠长,田径,许允,杨泽宇. 重型增压柴油机燃烧过程中的缸内㶲损失[J]. 吉林大学学报(工学版), 2019, 49(6): 1911-1919. |

| [10] | 胡潇宇,李国祥,白书战,孙柯,李思远. 考虑加热面粗糙度和材料的沸腾换热修正模型[J]. 吉林大学学报(工学版), 2019, 49(6): 1945-1950. |

| [11] | 宋昌庆,陈文淼,李君,曲大为,崔昊. 不同当量比下单双点火对天然气燃烧特性的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 1929-1935. |

| [12] | 朱一骁,何小民,金义. 联焰板宽度对单凹腔驻涡燃烧室流线形态的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 1936-1944. |

| [13] | 王德军,吕志超,王启明,张建瑞,丁建楠. 基于EKF及调制傅式级数的缸压辨识[J]. 吉林大学学报(工学版), 2019, 49(4): 1174-1185. |

| [14] | 臧鹏飞,王哲,高洋,孙晨乐. 直线电机/发动机系统稳态运行综合控制策略[J]. 吉林大学学报(工学版), 2019, 49(3): 798-804. |

| [15] | 贾拓,赵丁选,崔玉鑫. 铰接式装载机倾翻预警方法[J]. 吉林大学学报(工学版), 2018, 48(6): 1762-1769. |

|

||