吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (10): 2265-2277.doi: 10.13229/j.cnki.jdxbgxb20210256

• 车辆工程·机械工程 • 上一篇

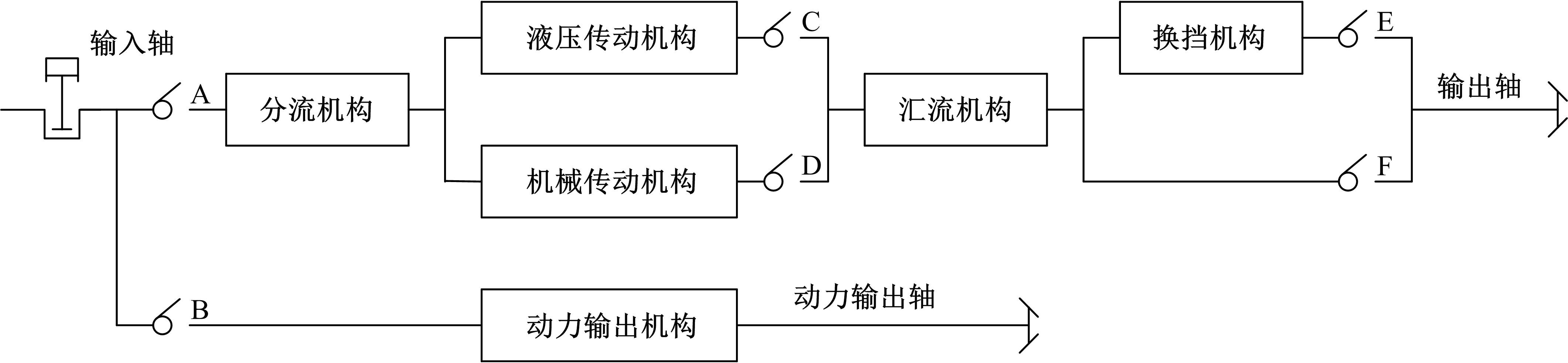

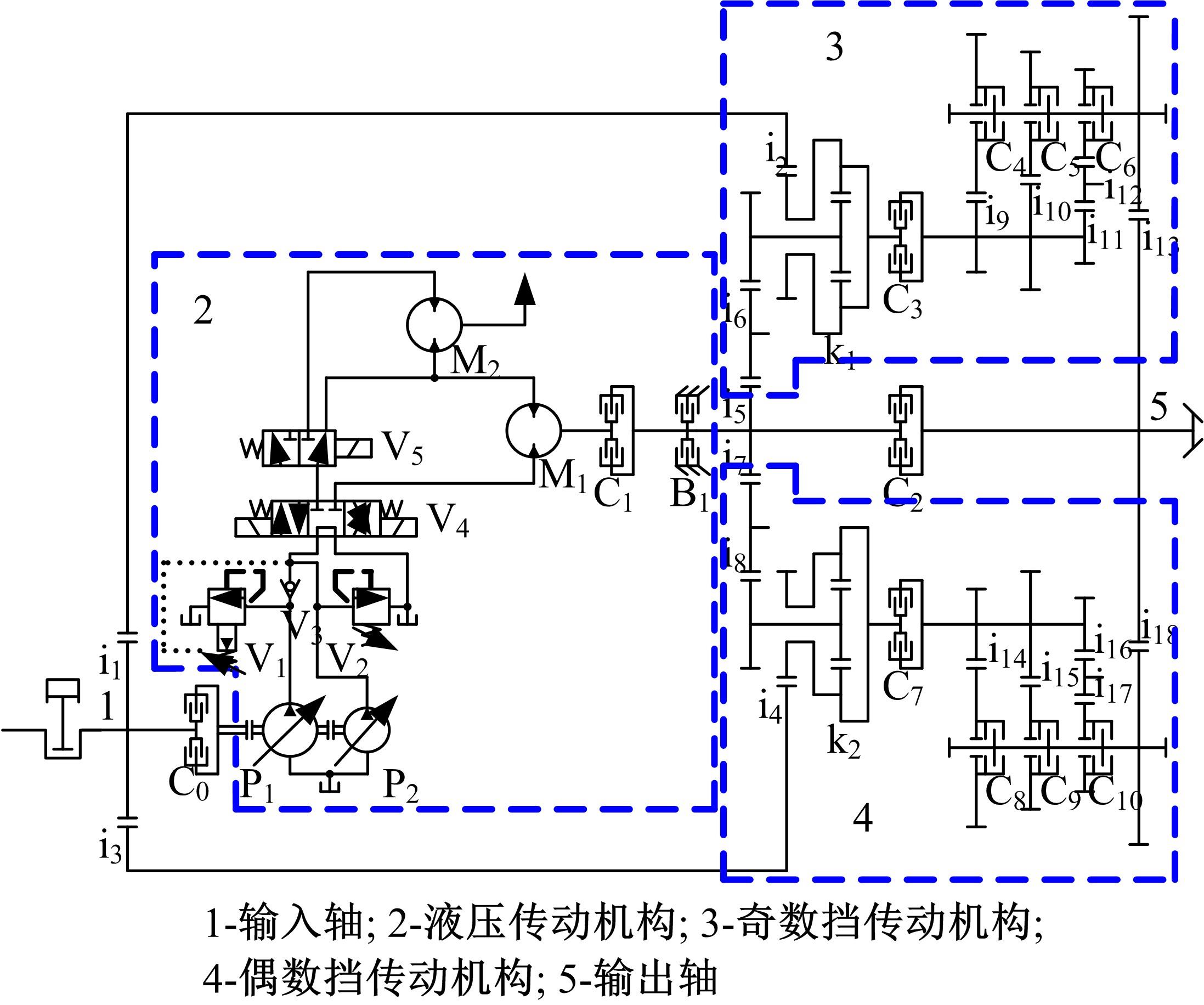

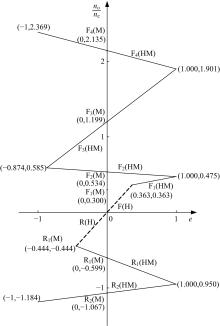

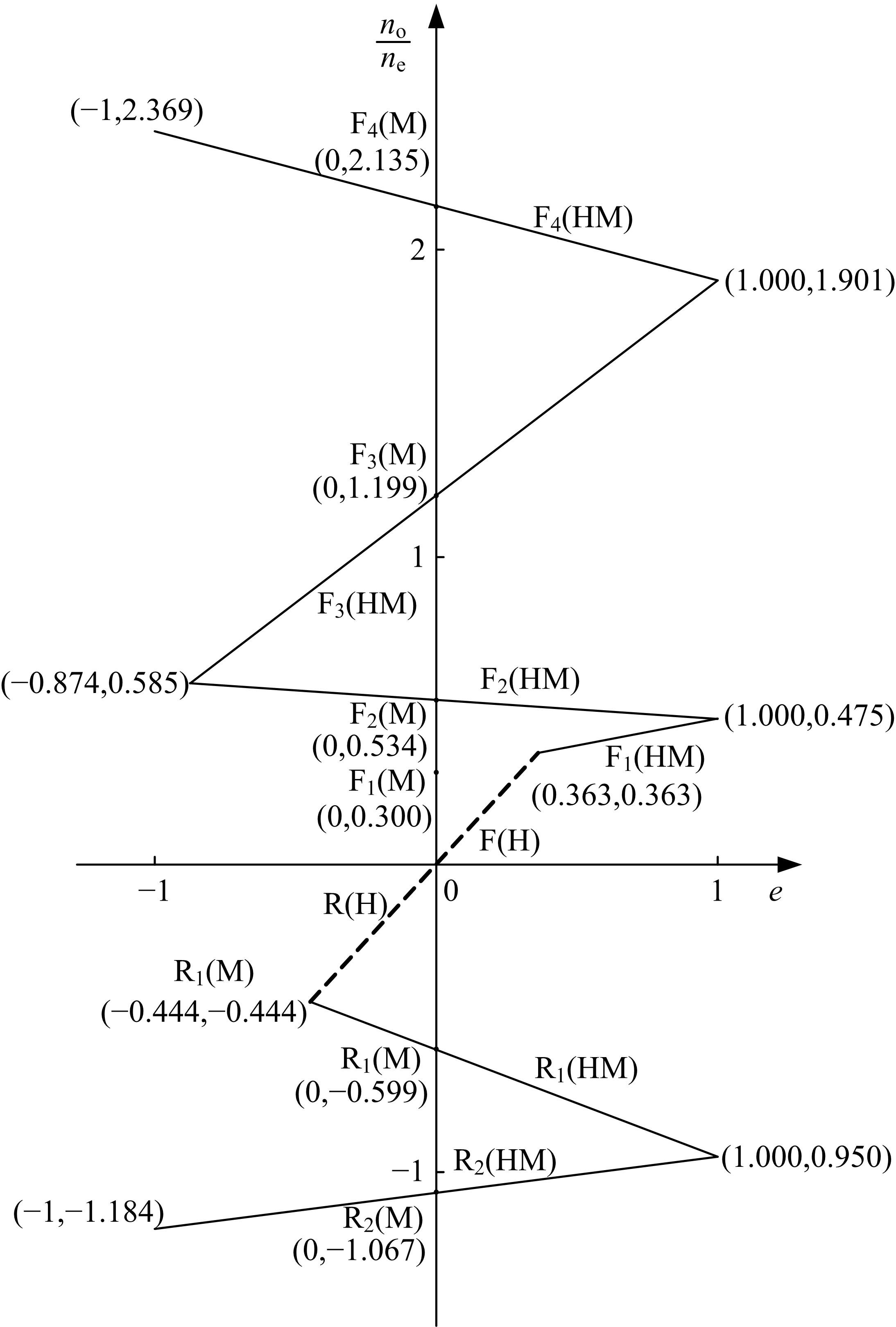

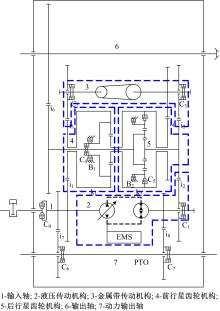

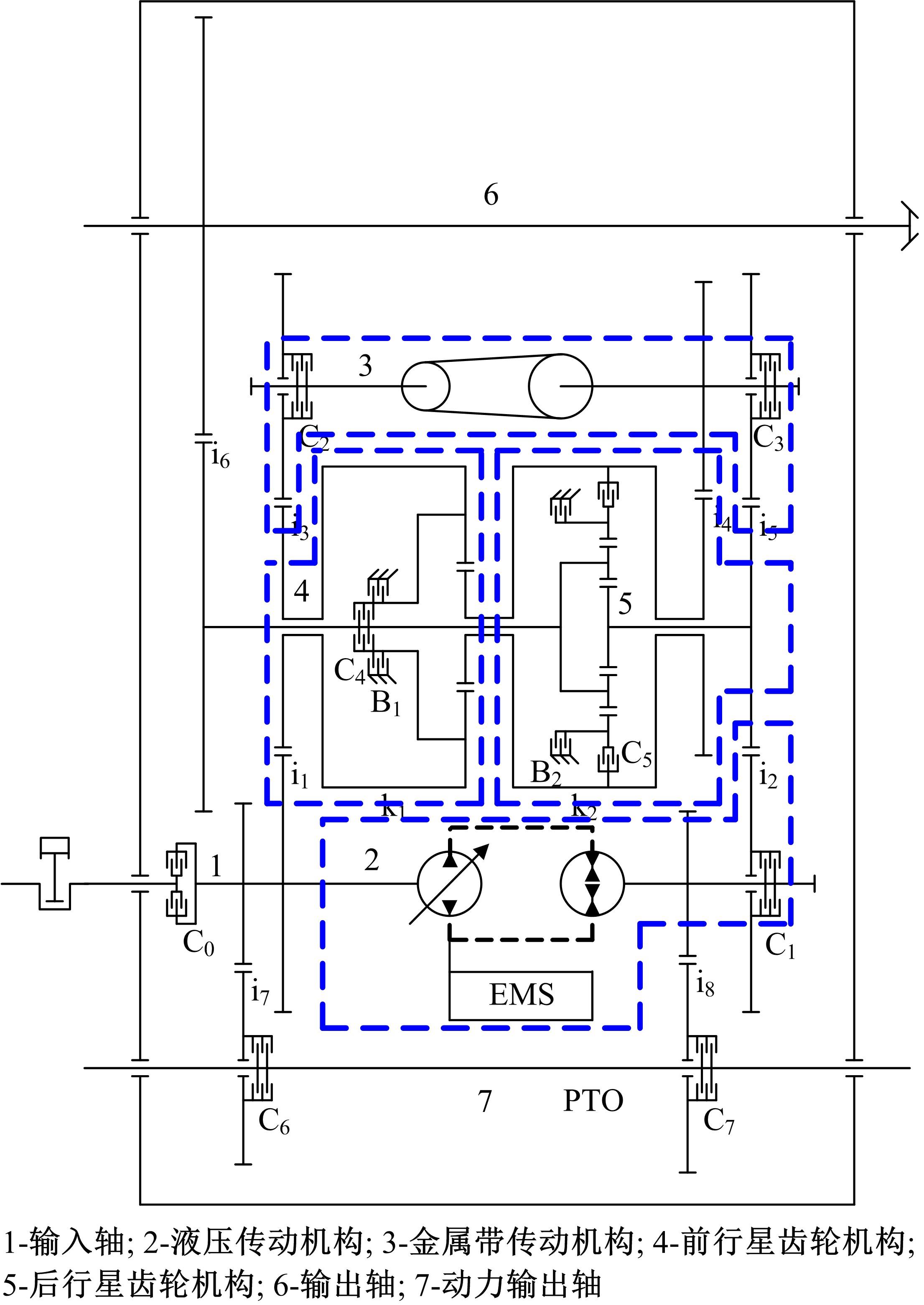

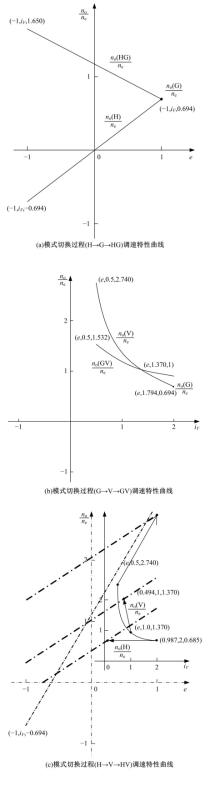

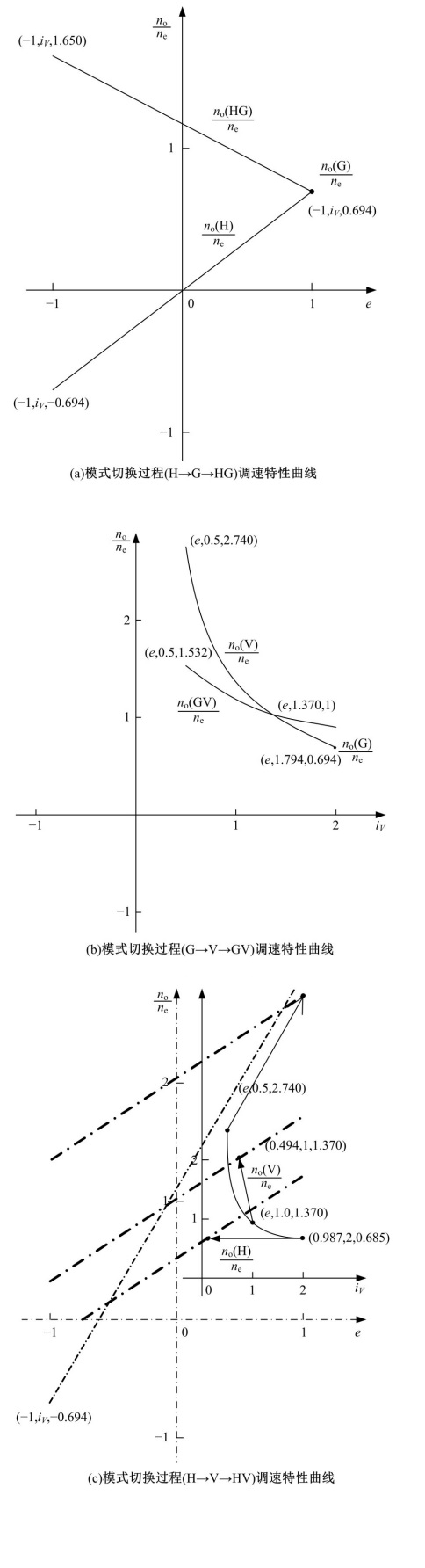

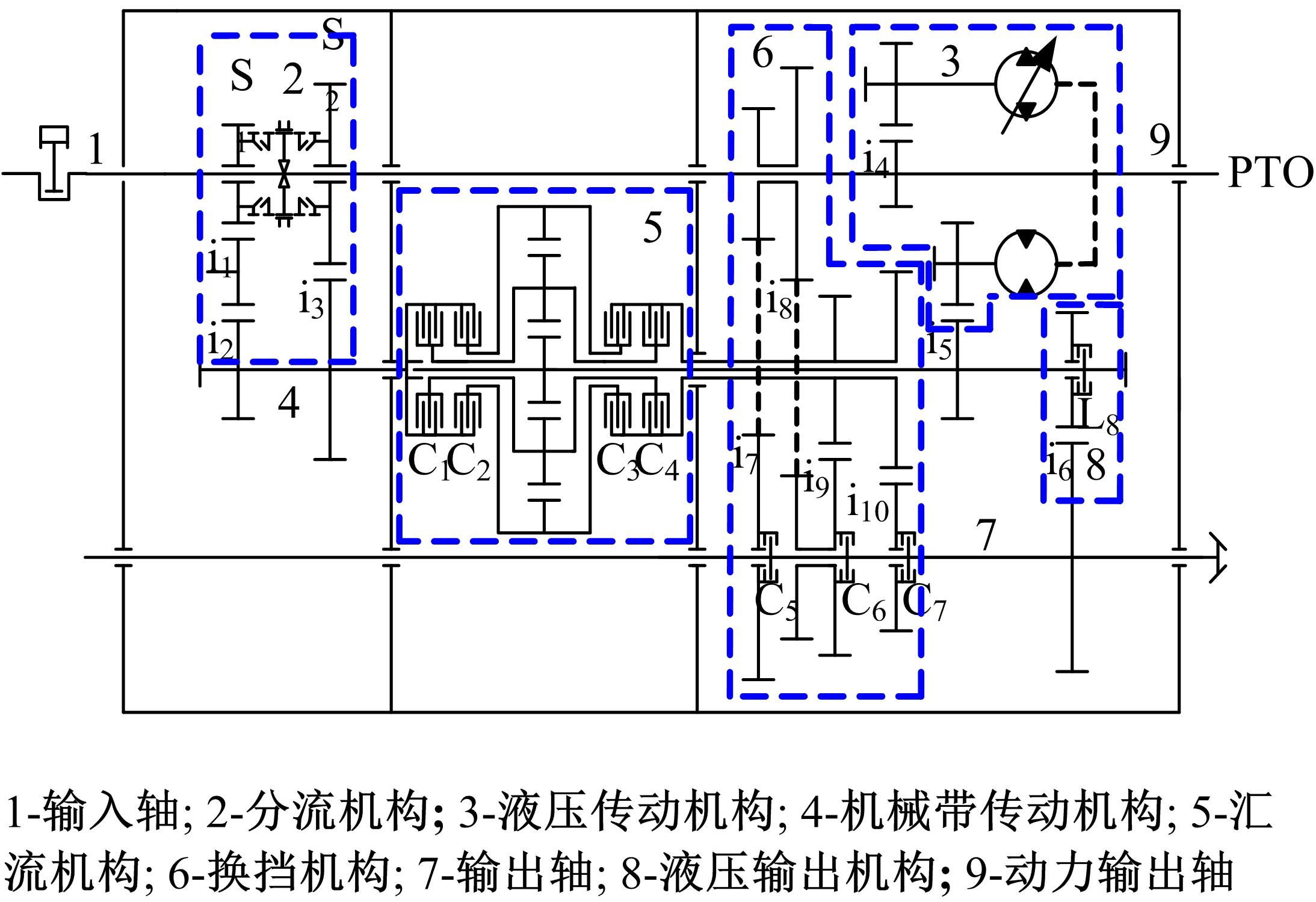

机液复合传动装置构型分析

朱镇1,2,3( ),王登峰1,孙晓东1,3(

),王登峰1,孙晓东1,3( ),曾令新3,蔡英凤3,陈龙3

),曾令新3,蔡英凤3,陈龙3

- 1.吉林大学 汽车仿真与控制国家重点实验室,长春 130022

2.拖拉机动力系统国家重点实验室,河南 洛阳 471000

3.江苏大学 汽车工程研究院,江苏 镇江 212013

Configuration analysis of hydro⁃mechanical composite transmission devices

Zhen ZHU1,2,3( ),Deng-feng WANG1,Xiao-dong SUN1,3(

),Deng-feng WANG1,Xiao-dong SUN1,3( ),Ling-xin ZENG3,Ying-feng CAI3,Long CHEN3

),Ling-xin ZENG3,Ying-feng CAI3,Long CHEN3

- 1.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

2.State Key Laboratory of Power System of Tractor,Luoyang 471000,China

3.Automobile Engineering Research;Institute,Jiangsu University,Zhenjiang 212013,China

摘要:

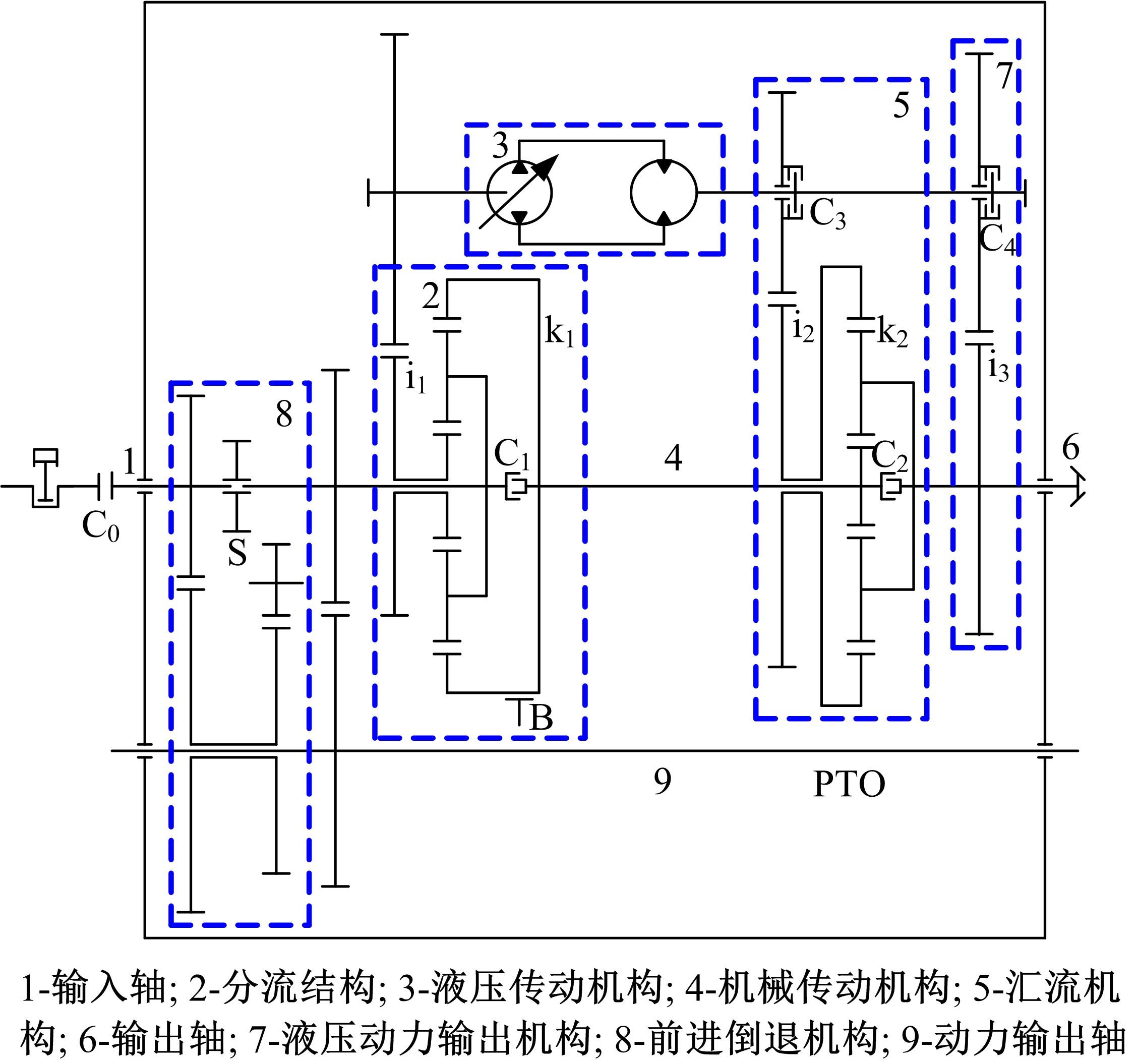

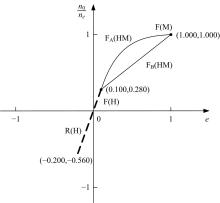

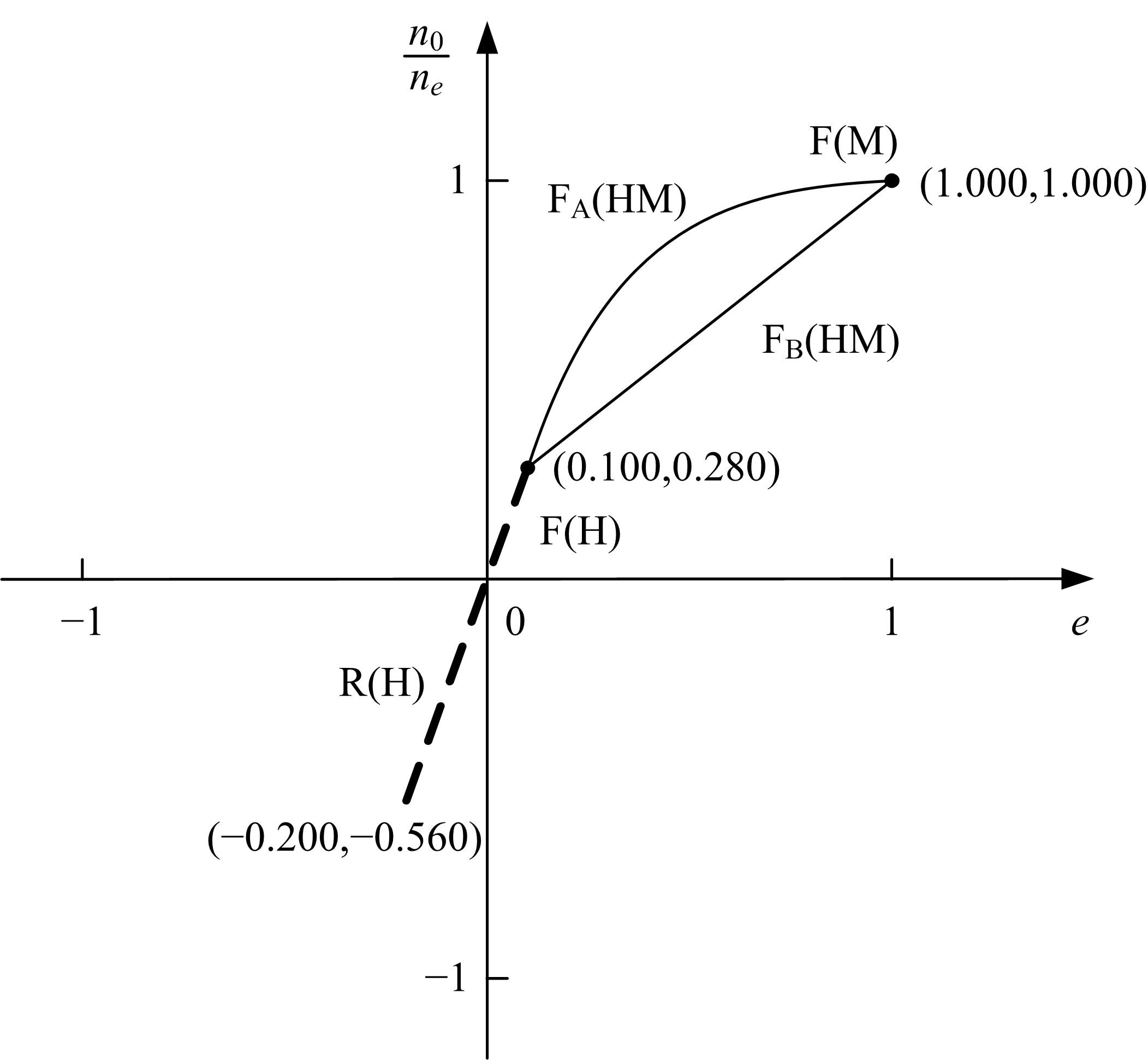

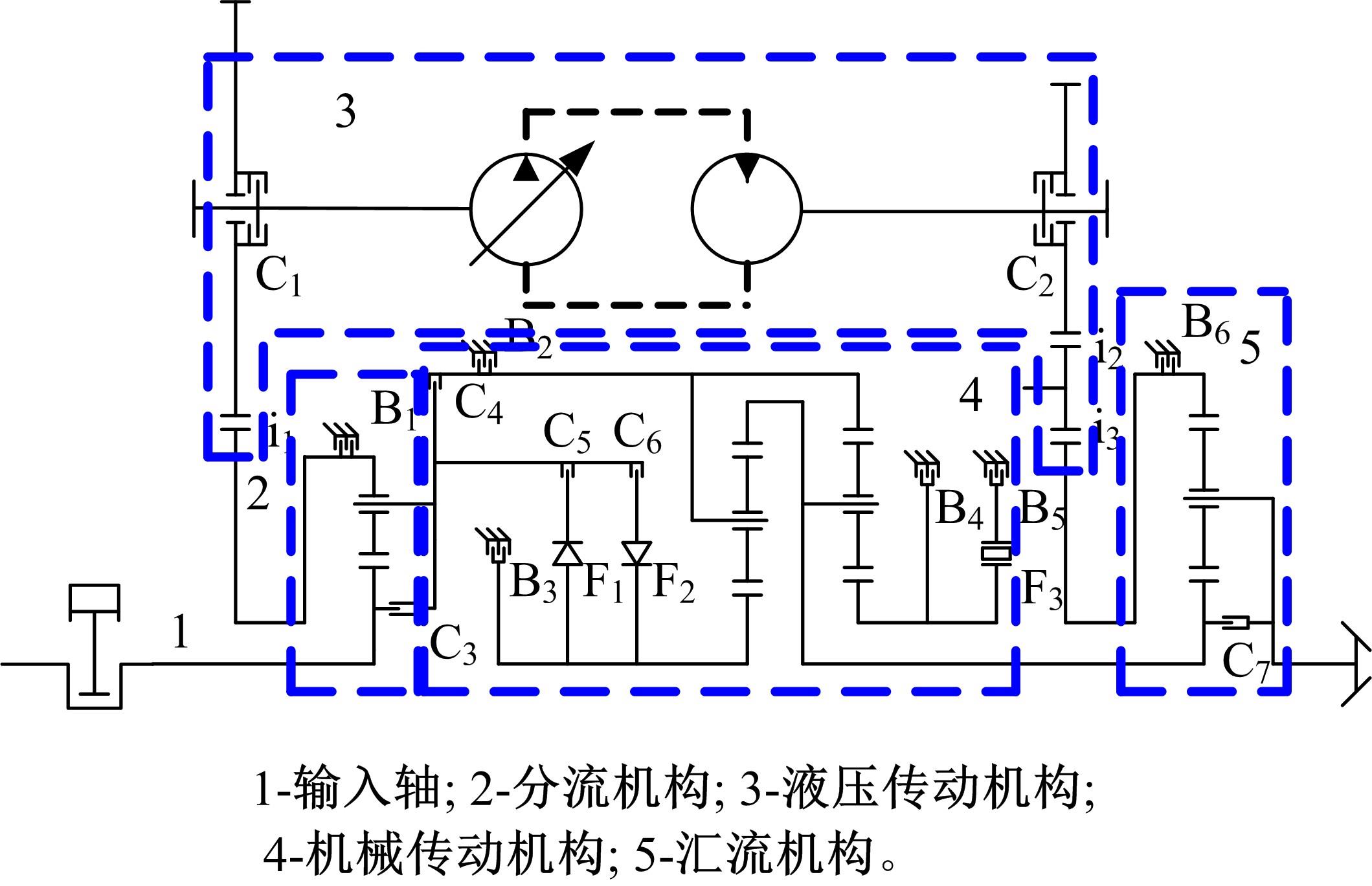

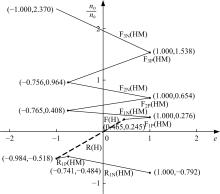

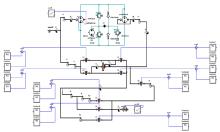

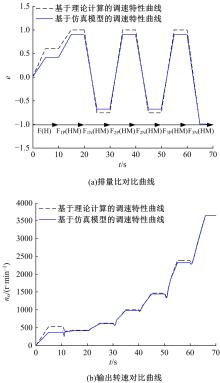

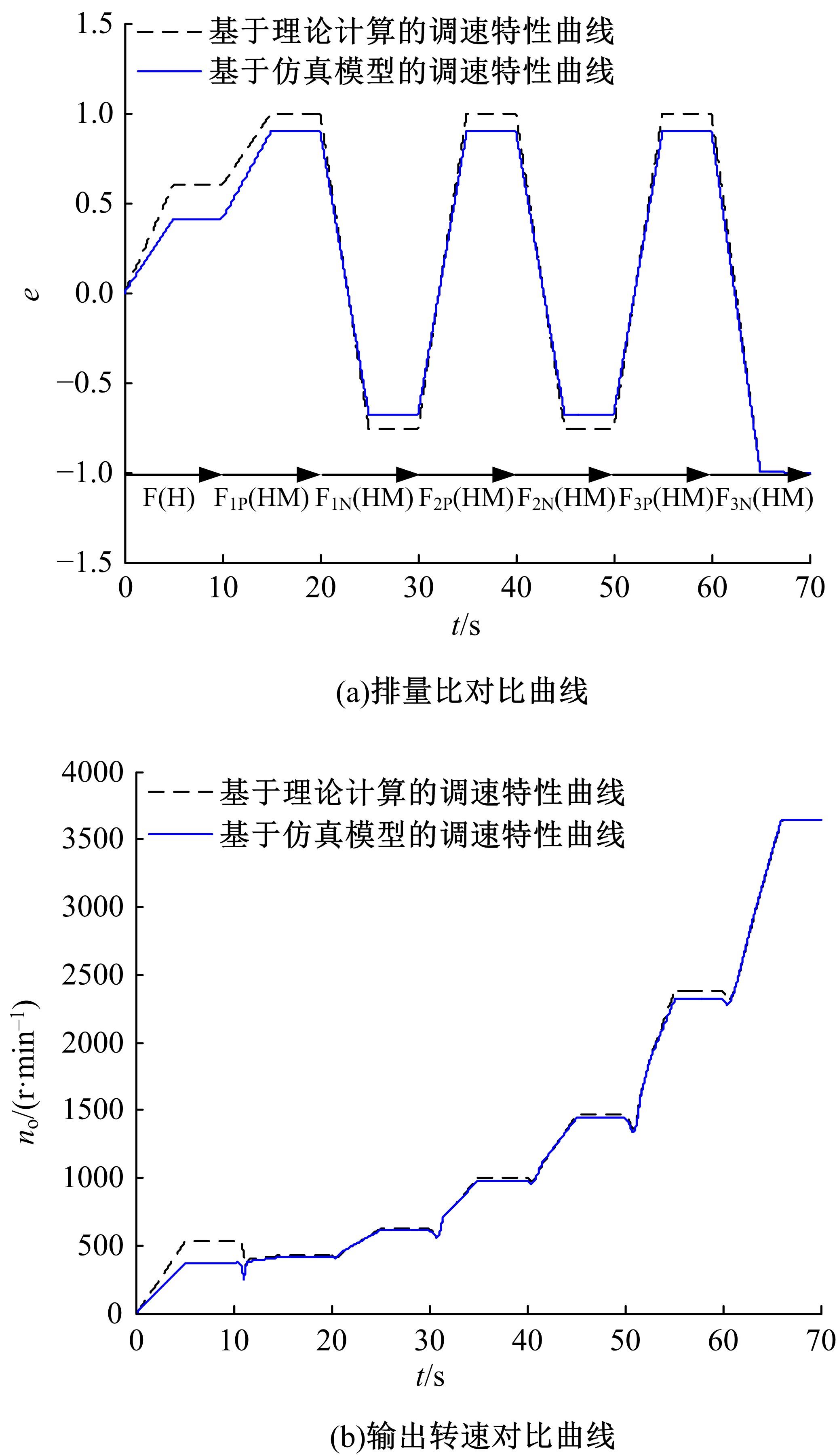

针对液压传动模式和机械传动模式各自的优缺点,结合功率分、汇流机构的特点,进行了构型分析,并提出5种典型的机液复合传动方案。根据机构运动学介绍了各传动方案的结构,结合各传动方案相应的调速特性曲线,分析了不同工作模式的特点。以其中一个具有典型的传动装置为研究对象,建立Simulation X仿真模型,设置离合器的接合顺序,分析了其在不同挡位下液压系统、汇流机构、输出轴的速度变化曲线。结果表明:该变速传动装置实际调速曲线与理论调速曲线基本一致,能在较大范围内实现良好的无级调速功能,相关研究成果可为机液复合传动的实际工程运用提供理论参考。

中图分类号:

- U463.2

| 1 | Xia Y, Sun D Y, Qin D T, et al. Study on the design method of a new hydromechanical continuously variable transmission system[J]. IEEE Access, 2020,8: 195411-195424. |

| 2 | Bao Y, Zhong Z M, Yang S J. Modeling of power transition in full power shift of hydro-mechanical transmission[J]. Mathematical Problems in Engineering, 2020, 2020(3): 1-14. |

| 3 | 罗俊林, 吴维, 苑士华, 等. 液压机械无级变速器速比自抗扰控制研究[J]. 汽车工程, 2021, 43(3): 374-380, 404. |

| Luo Jun-lin, Wu Wei, Yuan Shi-hua, et al. Study on active disturbance rejection control for speed ratio of hydro-mechanical continuously variable transmission[J]. Automotive Engineering, 2021, 43(3): 374-380, 404 | |

| 4 | 夏光, 夏岩, 唐希雯, 等. 采用滑转率-阻力区间划分法的拖拉机双流传动系统调速控制[J].农业工程学报, 2021, 37(3): 47-55. |

| Xia Guang, Xia Yan, Tang Xi-wen, et al. Speed regulation control of the dual-flow transmission system for a tractorusing slip rate-resistance interval division[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(3): 47-55. | |

| 5 | 曹付义, 李豪迪, 席志强, 等. 液压机械复合传动系统模式切换过程同步控制[J]. 西安交通大学学报, 2019, 53(8): 56-67, 75. |

| Cao Fu-yi, Li Hao-di, Xi Zhi-qiang, et al. Synchronous control of mode switching process for hydro-mechanical compound transmission system [J]. Journal of Xi'an Jiaotong University, 2019, 53(8): 56-67, 75. | |

| 6 | 杨树军, 张曼, 曾盼文, 等. 液压机械无级传动全功率换段过程排量比调节模型[J]. 农业工程学报, 2019, 35(13): 64-73. |

| Yang Shu-jun, Zhang Man, Zeng Pan-wen, et al. Model of regulating displacement ratio in full power shifting process of hydro-mechanical variable transmission[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(13): 64-73. | |

| 7 | Ahn S, Choi J, Son H,et al. Development of a new sub-shift schedule and control algorithm for a hydro-mechanical transmission[J]. Advances in Mechanical Engineering, 2016, 8(12):1-14. |

| 8 | Yu J, Cao Z, Cheng M, et al. Hydro-mechanical power split transmissions: Progress evolution and future trends[J]. Proceedings of the Institution of Mechanical Engineers, Part D:Journal of Automobile Engineering, 2019,233(3): 727-739. |

| 9 | Macora Alarico, Benatob Alberto, Rossettic Antonio, et al. Study and simulation of a hydraulic hybrid powertrain[J]. Energy Procedia, 2017, 126: 1131–1138. |

| 10 | Rossetti Antonio, Macor Alarico. Multi-objective optimization of hydro-mechanial power split transmissions[J]. Mechnism and Machine Theory, 2013, 62: 112-128. |

| 11 | Liu Fang-xu, Wu Wei, Hu Ji-bin, et al. Design of multi-range hydro-mechanical transmission using modular method[J]. Mechanical Systems and Signal Processing, 2019, 126: 1-20. |

| 12 | Yu Xia, Sun Dong-ye, Qin Da-tong, et al. Optimisation of the power-cycle hydro-mechanical parameters in a continuously variable transmission designed for agricultural tractors[J]. Biosystems Engineering, 2020, 193: 12-24. |

| 13 | 闫丽娟,孙辉,刘伟,等. 行走工程机械液压混合动力技术[J].吉林大学学报:工学版, 2014, 44(2): 364-368. |

| Yan Li-juan, Sun Hui, Liu Wei, et al. Hydraulic hybrid technology of moving construction machinery [J]. Journal of Jilin University (Engineering and Technology Edition), 2014, 44(2): 364-368. | |

| 14 | 唐新星,赵丁选,黄海东,等. 工程车辆等比三段式液压机械的复合传动[J].吉林大学学报:工学版, 2006, 36 (): 56-61. |

| Tang Xin-xing, Zhao Ding-xuan, Huang Hai-dong, et al. Three-stage with geometric ratios hydraulic-mechanical compound transmission for construction vehicle [J]. Journal of Jilin University (Engineering and Technology Edition), 2006, 36(): 56-61. | |

| 15 | 王浩然,曹付义,马可,等. 拖拉机多模式机液复合传动装置设计[J]. 机械传动, 2020, 44(3): 66-71. |

| Wang Hao-ran, Cao Fu-yi, Ma Ke, et al. Design of multi-mode hydraulic mechanical composite transmission device for tractor [J]. Journal of Mechanical Transmission, 2020, 44(3): 66-71. | |

| 16 | 黄国勤,罗莎祁,胡博,等. 风电系统的混合式液压机械无级变速技术[J]. 华南理工大学学报: 自然科学版,2019,47(1): 95-102. |

| Huang Guo-qin, Luo Sha-qi, Hu Bo, et al. Hybrid hydro-mechanical continuously variable transmission technology for wind power system[J]. Journal of South China University of Technology(Natural Science Edition), 2019,47 (1): 95-102. | |

| 17 | 张明柱, 王全胜, 白东洋, 等. 基于拖拉机整机效率最大化的液压机械无级变速规律[J].农业工程学报, 2016, 32(21): 74-78. |

| Zhang Ming-zhu, Wang Quan-sheng, Bai Dong-yang, et al. Speed changing law of hydro-mechanical CVT based on maximum efficiency of tractors[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32 (21): 74-78. | |

| 18 | 朱镇,蔡英凤,陈龙,等.一种混合动力多模式切换的无级变速传动系统[P].中国:201910041132.1,2019-01-16. |

| 19 | 朱镇,蔡英凤,陈龙,等.一种机械液压复合传动装置及控制方法[P].中国:201911076475.8,2019-11-06. |

| 20 | 朱镇,蔡英凤,陈龙,等.一种带双离合变速的液压机械传动装置及其控制方法[P].中国:202010101329.2,2020-02-19. |

| 21 | 朱镇,蔡英凤,陈龙,等.一种集齿轮-液压-金属带为一体的多模式机液复合传动装置[P].中国:202010066884.6,2020-01-20. |

| 22 | 朱镇,高翔,夏长高,等.单行星排汇流液压机械无级变速箱[P].中国:201410282040.X,2014-06-23. |

| 23 | 朱镇,高翔,夏长高,等.单行星排汇流液压机械无级变速箱的离合器液压控制系统[P].中国:201410298022.0,2014-06-27. |

| 24 | 朱镇. 液压机械无级变速器性能优化研究[D]. 镇江: 江苏大学汽车与交通工程学院, 2016. |

| Zhu Zhen. Optimization Research on the performance of hydro-mechanical continuously variable transmission [D]. Zhenjiang: School of Automotive and Traffic Engineering, Jiangsu University, 2016. | |

| 25 | Zhu Zhen, Chen Long, Xia Chang-gao, et al. Test research on the adhesive and tractive performance of a wheeled tractor[J]. International Journal of Heavy Vehicle Systems, 2020, 27(1/2): 65-82. |

| [1] | 王克勇,鲍大同,周苏. 基于数据驱动的车用燃料电池故障在线自适应诊断算法[J]. 吉林大学学报(工学版), 2022, 52(9): 2107-2118. |

| [2] | 曹起铭,闵海涛,孙维毅,于远彬,蒋俊宇. 质子交换膜燃料电池低温启动水热平衡特性[J]. 吉林大学学报(工学版), 2022, 52(9): 2139-2146. |

| [3] | 隗海林,王泽钊,张家祯,刘洋. 基于Avl-Cruise的燃料电池汽车传动比及能量管理策略[J]. 吉林大学学报(工学版), 2022, 52(9): 2119-2129. |

| [4] | 刘岩,丁天威,王宇鹏,都京,赵洪辉. 基于自适应控制的燃料电池发动机热管理策略[J]. 吉林大学学报(工学版), 2022, 52(9): 2168-2174. |

| [5] | 李丞,景浩,胡广地,刘晓东,冯彪. 适用于质子交换膜燃料电池系统的高阶滑模观测器[J]. 吉林大学学报(工学版), 2022, 52(9): 2203-2212. |

| [6] | 张佩,王志伟,杜常清,颜伏伍,卢炽华. 车用质子交换膜燃料电池空气系统过氧比控制方法[J]. 吉林大学学报(工学版), 2022, 52(9): 1996-2003. |

| [7] | 池训逞,侯中军,魏伟,夏增刚,庄琳琳,郭荣. 基于模型的质子交换膜燃料电池系统阳极气体浓度估计技术综述[J]. 吉林大学学报(工学版), 2022, 52(9): 1957-1970. |

| [8] | 裴尧旺,陈凤祥,胡哲,翟双,裴冯来,张卫东,焦杰然. 基于自适应LQR控制的质子交换膜燃料电池热管理系统温度控制[J]. 吉林大学学报(工学版), 2022, 52(9): 2014-2024. |

| [9] | 胡广地,景浩,李丞,冯彪,刘晓东. 基于高阶燃料电池模型的多目标滑模控制[J]. 吉林大学学报(工学版), 2022, 52(9): 2182-2191. |

| [10] | 陈凤祥,伍琪,李元松,莫天德,李煜,黄李平,苏建红,张卫东. 2.5吨燃料电池混合动力叉车匹配、仿真及优化[J]. 吉林大学学报(工学版), 2022, 52(9): 2044-2054. |

| [11] | 武小花,余忠伟,朱张玲,高新梅. 燃料电池公交车模糊能量管理策略[J]. 吉林大学学报(工学版), 2022, 52(9): 2077-2084. |

| [12] | 高青,王浩东,刘玉彬,金石,陈宇. 动力电池应急冷却喷射模式实验分析[J]. 吉林大学学报(工学版), 2022, 52(8): 1733-1740. |

| [13] | 王奎洋,何仁. 基于支持向量机的制动意图识别方法[J]. 吉林大学学报(工学版), 2022, 52(8): 1770-1776. |

| [14] | 王骏骋,吕林峰,李剑敏,任洁雨. 分布驱动电动汽车电液复合制动最优滑模ABS控制[J]. 吉林大学学报(工学版), 2022, 52(8): 1751-1758. |

| [15] | 刘汉武,雷雨龙,阴晓峰,付尧,李兴忠. 增程式电动汽车增程器多点控制策略优化[J]. 吉林大学学报(工学版), 2022, 52(8): 1741-1750. |

|

||