吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (12): 3415-3423.doi: 10.13229/j.cnki.jdxbgxb.20220092

• 交通运输工程·土木工程 • 上一篇

基于轮胎滑移率与单目视觉的半挂汽车列车制动时序检测

- 1.吉林大学 交通学院,长春 130022

2.吉林大学 机械与航空航天工程学院,长春 130022

Braking timing detection of tractor⁃trailer⁃train based on tire slip rate and monocular vision

Li-bin ZHANG1( ),Shi-yuan FENG1,Hong-ying SHAN2,Guan-ran WANG1

),Shi-yuan FENG1,Hong-ying SHAN2,Guan-ran WANG1

- 1.College of Transportation,Jilin University,Changchun 130022,China

2.School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

摘要:

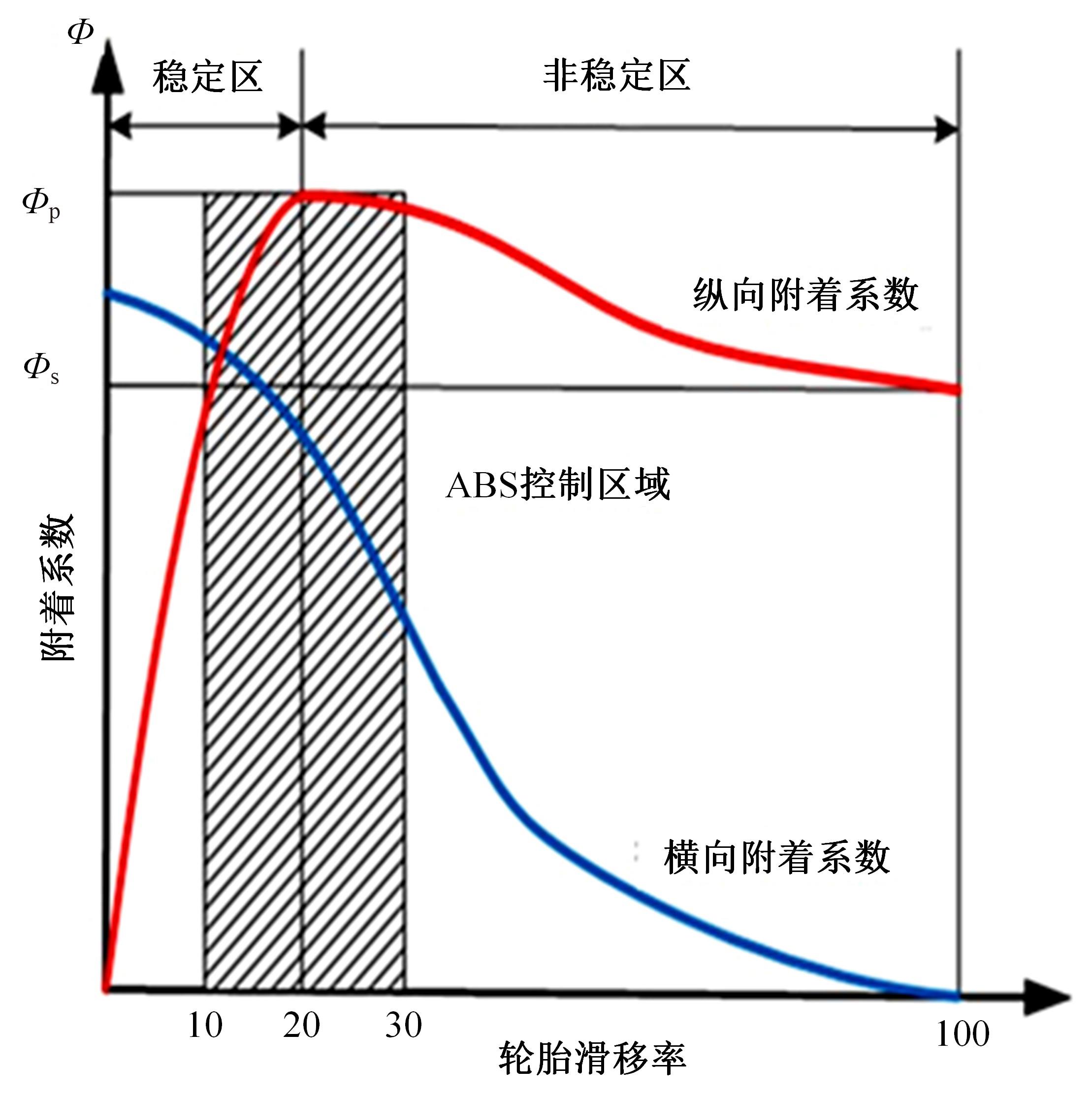

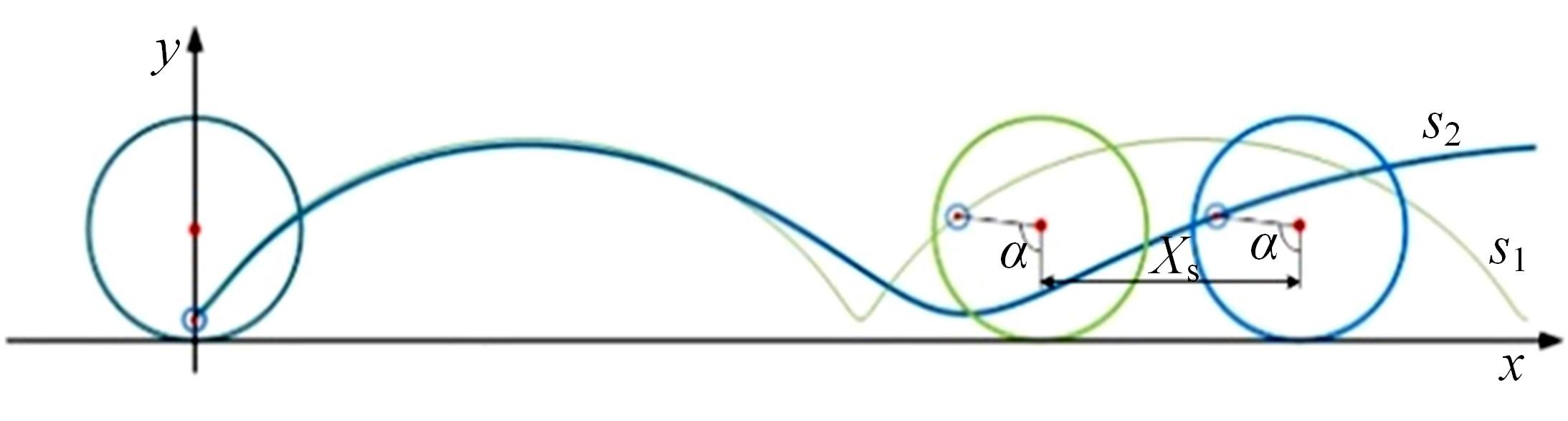

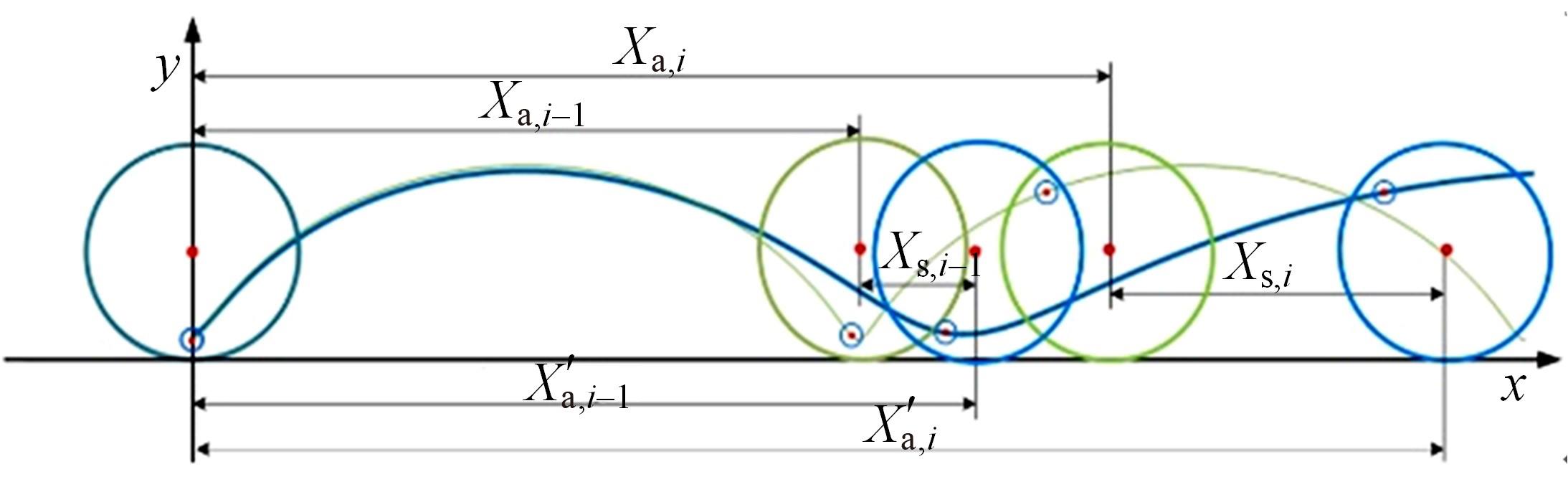

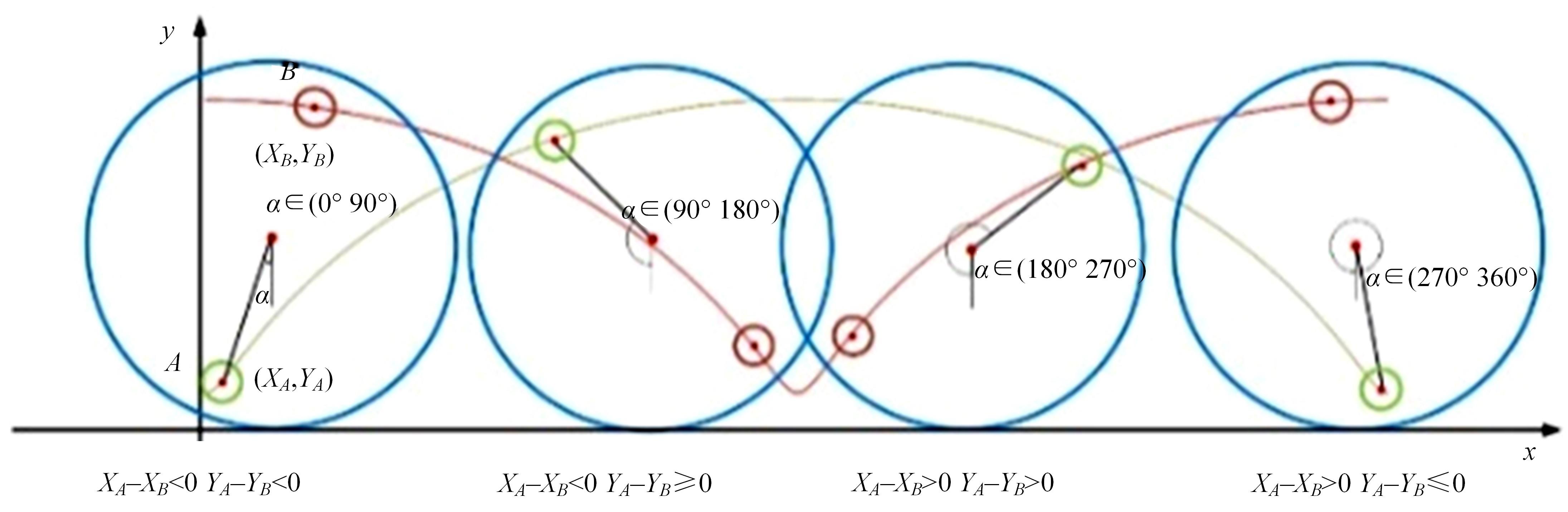

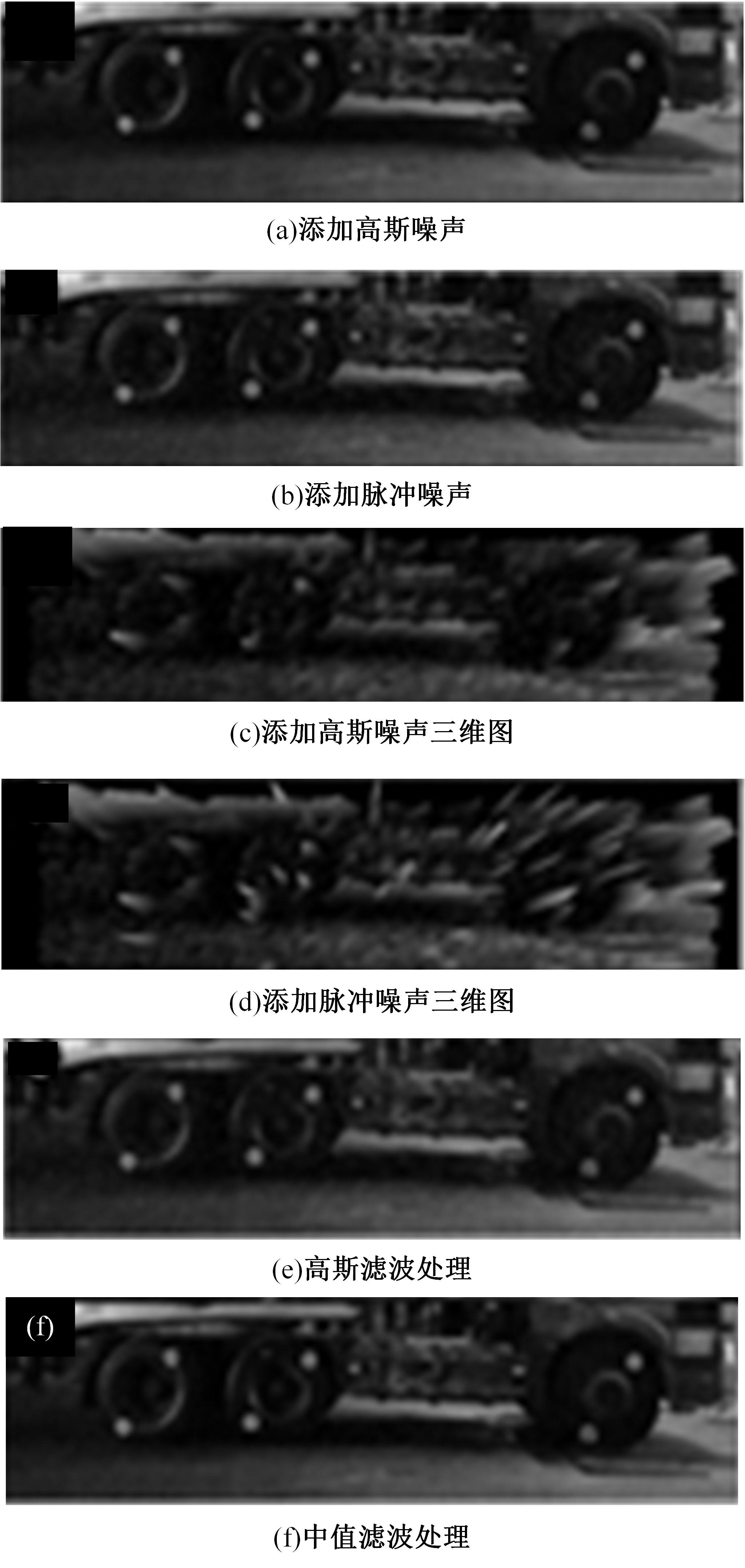

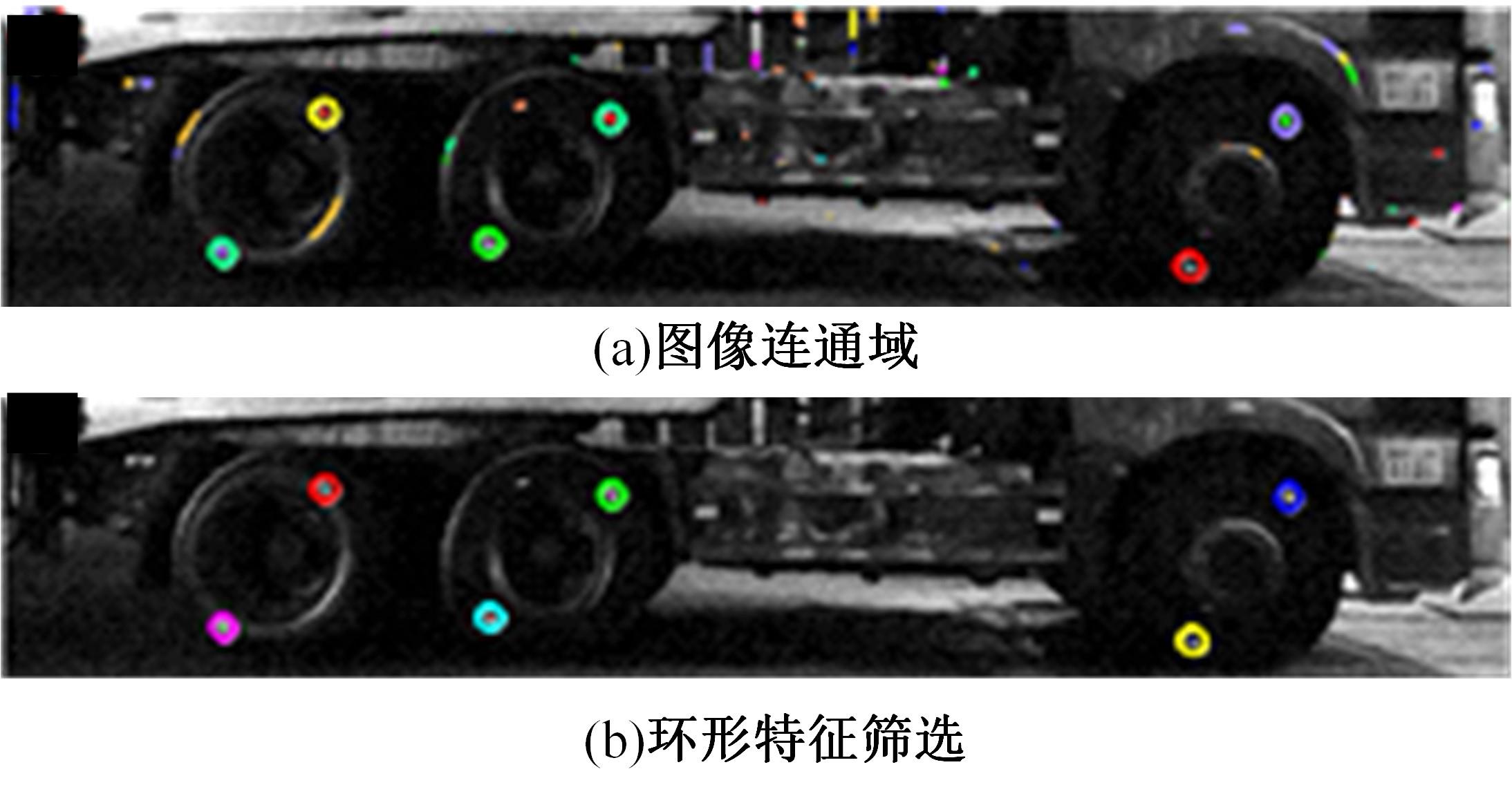

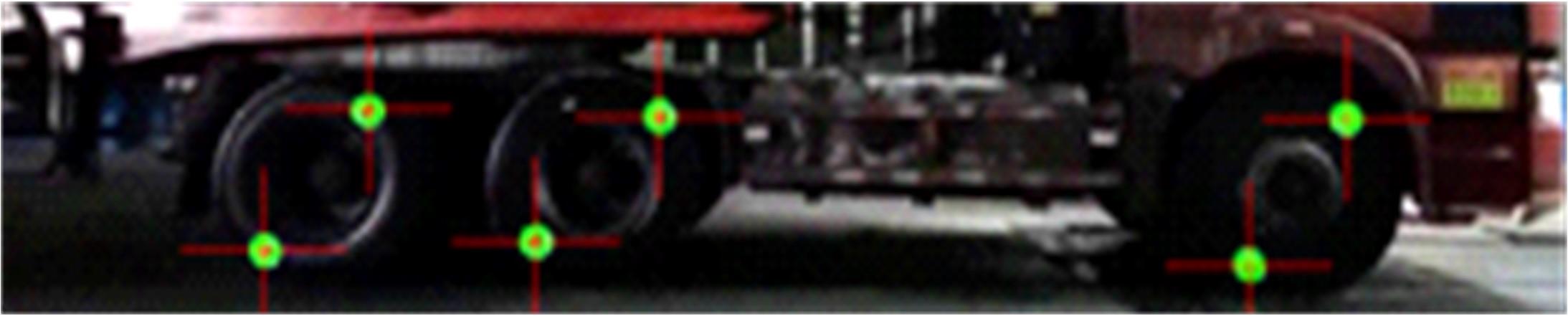

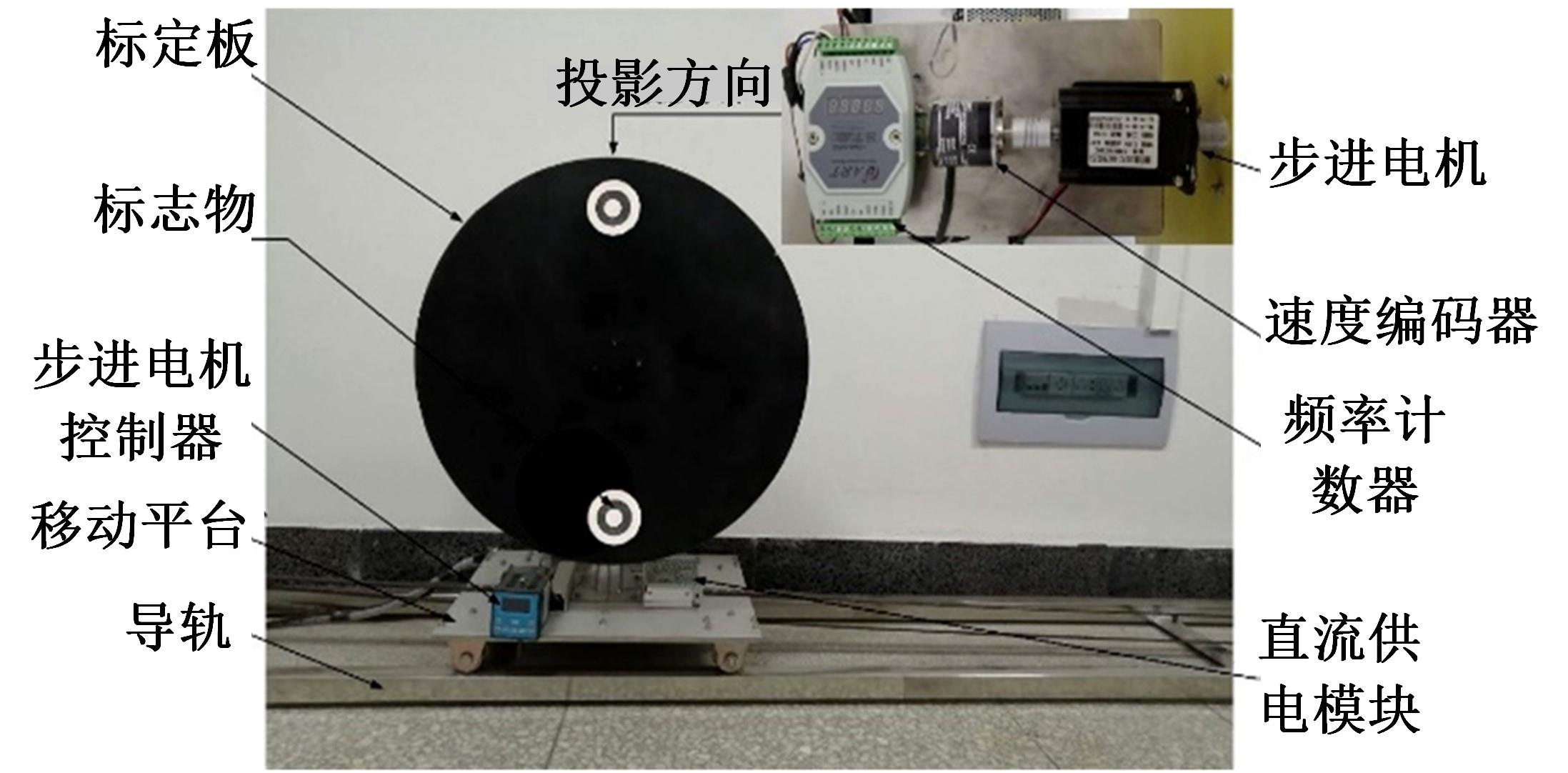

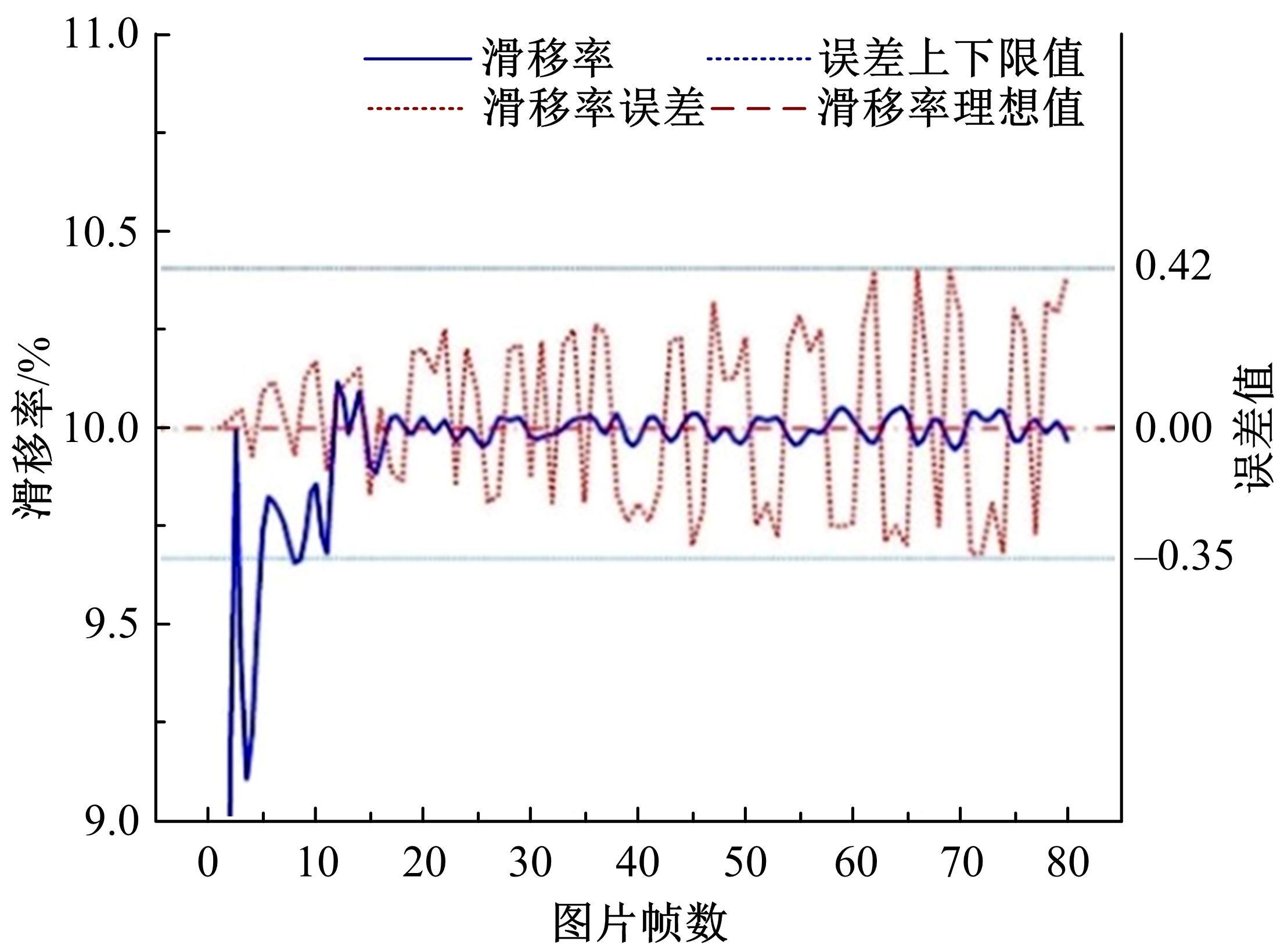

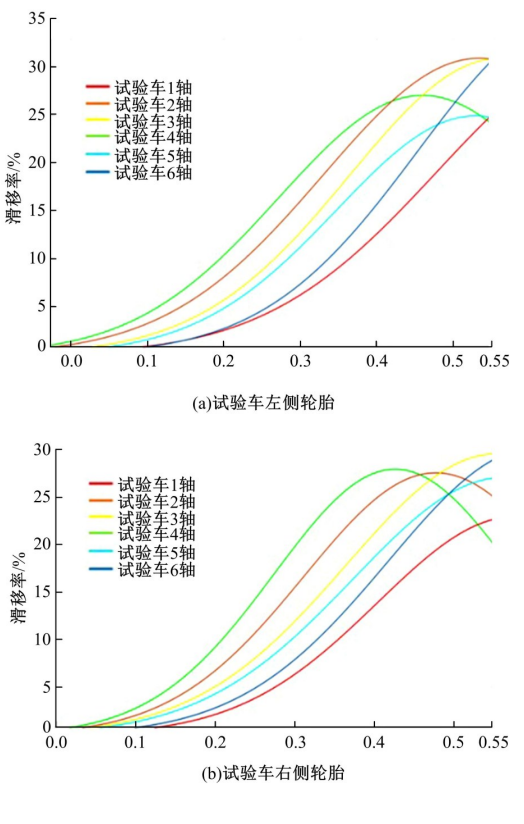

半挂汽车列车在制动过程中由于各车轴制动顺序的不同,导致车辆在特殊工况下制动时会出现车辆失稳现象。针对现有方案和设备无法对制动时序进行检测,本文提出了一种智能化非接触式的车辆制动时序动态检测方案。基于单目视觉原理,识别张贴在轮胎边缘的标志物,对采集的图像进行处理,求解出轮胎滑移率;利用基于轮廓的模板匹配算法识别待匹配图像中的标志物区域。最后,进行了实车试验,结果表明,本文方法的滑移率求解误差在4.2%以下。

中图分类号:

- U472.9

| 1 | Elhemly M, Fayed M. Simulation of tractor semitrailer manoeuvre at high speed using Matlab/Simulink[J]. International Journal of Heavy Vehicle Systems, 2011, 18(4): 341-358. |

| 2 | Jing Z, He R. Electronic structural improvement and experimental verification of a tractor-semitrailer air brake system[J]. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 2020, 234(8): 2154-2161. |

| 3 | Abroshan M, Hajiloo R, Hashemi E, et al. Model predictive-based tractor-trailer stabilisation using differential braking with experimental verification[J]. Vehicle System Dynamics, 2021, 59(8): 1190-1213. |

| 4 | Wang H, Wu S, Wang Q. Global sliding mode control for nonlinear vehicle antilock braking system[J]. IEEE Access, 2021, 9: 40349-40359. |

| 5 | 肖泽民. 汽车列车平板制动台检测系统[J].中国科技纵横, 2019(13): 55-56. |

| Xiao Ze-min. Detection system for flat brake table of automobile train[J]. China Science and Technology Panorama Magazine, 2019(13): 55-56. | |

| 6 | 唐松坡. 针对汽车制动时序检测的制动滑移率快速识别方法研究[D]. 长春: 吉林大学交通学院, 2019. |

| Tang Song-po. Research on rapid identification method of braking slip ratio for automobile brake timing detection[D]. Changchun: College of Transportation, Jilin University, 2019. | |

| 7 | 岳洪伟. 基于双目立体视觉的汽车制动性能检测系统研究[D]. 长春: 吉林大学交通学院, 2015. |

| Yue Hong-wei. Study on testing system of vehicle braking parameters based on binocular stereo vision[D]. Changchun: College of Transportation, Jilin University, 2015. | |

| 8 | 蒲富鹏, 赵军, 安喆. 基于机器视觉的车轮裂纹识别与提取[J]. 铁道科学与工程学报, 2018, 15(8): 2113-2122. |

| Pu Fu-peng, Zhao Jun, An Zhe. Recognition and extraction of wheel cracks based on machine vision[J]. Journal of Railway Science and Engineering, 2018, 15(8): 2113-2122. | |

| 9 | Ding W, Zhang Y, Bu Y, et al. Detection system of truck blind area based on machine vision[C]∥2021 International Wireless Communications and Mobile Computing (IWCMC), Harbin, China, 2021: 2086-2089. |

| 10 | Zhu S, Wang L, Zhu Z, et al. Measuring method of slip ratio for tractor driving wheels based on machine vision[J]. Agriculture, 2022, 12(2): No. 292. |

| 11 | 王治中, 于良耀, 宋健. 基于制动系统的汽车车轮滑移率控制研究现状[J]. 汽车工程, 2014, 36(1): 81-87. |

| Wang Zhi-zhong, Yu Liang-yao, Song Jian. The status quo of research on vehicle wheel slip control based on brake system[J]. Automotive Engineering, 2014, 36(1): 81-87. | |

| 12 | Li L, Wang F Y. Advanced Tire Friction Modeling and Monitoring[M]. New York: Springer, 2007. |

| 13 | 李辉. 全钢子午线轮胎载重状态下有限元模拟分析[D]. 青岛: 青岛科技大学机电工程学院, 2014. |

| Li Hui. All-steel radial tire finite element simulation analysis under the road condition[D]. Qingdao: College of Electromechanical Engineering, Qingdao University of Science and Technology, 2014. | |

| 14 | 姜胜林. 子午线轮胎的有限元网格生成及滑水仿真分析[D]. 济南: 山东大学机械工程学院, 2021. |

| Jiang Sheng-lin. Finite element mesh automatic modeling and hydroplaning analysis of radial tire[D]. Jinan: School of Mechanical Engineering, Shandong University, 2021. | |

| 15 | Zhang Z Y. A flexible new technique for camera calibration[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2000, 22(11): 1330-1334. |

| 16 | 董缘缘. 基于遗传算法与LM算法的摄像机标定方法研究[D]. 杭州:浙江工业大学信息工程学院, 2016. |

| Dong Yuan-yuan. Research on camera calibration method based on genetic algorithm and LM algorithm[D]. Hangzhou: College of Information Engineering, Zhejiang University of Technology, 2016. | |

| 17 | 蔡利梅. Matlab图像处理理论算法与实例分析[M]. 北京: 清华大学出版社, 2020: 217-225. |

| 18 | 李井元. 基于X射线图像的BGA焊球气泡缺陷检测技术研究[D]. 成都:电子科技大学航空航天学院, 2019. |

| Li Jing-yuan. Research on voids detection technology in BGA solder balls based on X-ray image[D]. Chengdu: School of Aeronautics and Astronautics, University of Electronic Science and Technology of China, 2019. | |

| 19 | 刘兆艳. 基于机器视觉的稻种品种识别研究[D]. 杭州: 浙江大学生物系统工程与食品科学学院, 2006. |

| Liu Zhao-yan. Research on variety identification of rice seed using computer vision[D]. Hangzhou: College of Biosystems Engineering and Food Science, Zhejiang University, 2006. | |

| 20 | 张立斌, 吴岛, 单红梅, 等. 基于立体视觉的汽车制动时序检测装置及方法[P]. 中 国: CN105510052, 2017. |

| [1] | 陈兆玮,蒲前华. 弹性车轮对大跨斜拉桥车桥耦合振动的抑制特性[J]. 吉林大学学报(工学版), 2023, 53(9): 2519-2532. |

| [2] | 刘平义,李晓婷,高偌霖,李海涛,魏文军,王亚. 车辆侧倾驱动机构设计与试验[J]. 吉林大学学报(工学版), 2023, 53(8): 2185-2192. |

| [3] | 黄学劲,钟锦星,路京雨,赵霁,肖伟,袁新枚. 基于用户画像的电动汽车充电负荷预测方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2193-2200. |

| [4] | 张树培,夏明悦,张玮,陈钊,陈义祥. 考虑非线性刚度的间隙球铰碰撞动力学建模与仿真[J]. 吉林大学学报(工学版), 2023, 53(8): 2227-2235. |

| [5] | 陈辉,邵亚军. 基于惯性基准多传感器耦合的路面谱测量方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2254-2262. |

| [6] | 陈磊,王杨,董志圣,宋亚奇. 一种基于转向意图的车辆敏捷性控制策略[J]. 吉林大学学报(工学版), 2023, 53(5): 1257-1263. |

| [7] | 陈鑫,张冠宸,赵康明,王佳宁,杨立飞,司徒德蓉. 搭接焊缝对铝合金焊接结构轻量化设计的影响[J]. 吉林大学学报(工学版), 2023, 53(5): 1282-1288. |

| [8] | 张勇,毛凤朝,刘水长,王青妤,潘神功,曾广胜. 基于Laplacian算法的汽车外流场畸变网格优化[J]. 吉林大学学报(工学版), 2023, 53(5): 1289-1296. |

| [9] | 汪少华,储堃,施德华,殷春芳,李春. 基于有限时间扩张状态观测的HEV鲁棒复合协调控制[J]. 吉林大学学报(工学版), 2023, 53(5): 1272-1281. |

| [10] | 尹燕莉,黄学江,潘小亮,王利团,詹森,张鑫新. 基于PID与Q⁃Learning的混合动力汽车队列分层控制[J]. 吉林大学学报(工学版), 2023, 53(5): 1481-1489. |

| [11] | 于贵申,陈鑫,武子涛,陈轶雄,张冠宸. AA6061⁃T6铝薄板无针搅拌摩擦点焊接头结构及性能分析[J]. 吉林大学学报(工学版), 2023, 53(5): 1338-1344. |

| [12] | 田彦涛,黄兴,卢辉遒,王凯歌,许富强. 基于注意力与深度交互的周车多模态行为轨迹预测[J]. 吉林大学学报(工学版), 2023, 53(5): 1474-1480. |

| [13] | 杨红波,史文库,陈志勇,郭年程,赵燕燕. 基于NSGA⁃II的斜齿轮宏观参数多目标优化[J]. 吉林大学学报(工学版), 2023, 53(4): 1007-1018. |

| [14] | 赵睿,李云,胡宏宇,高镇海. 基于V2I通信的交叉口车辆碰撞预警方法[J]. 吉林大学学报(工学版), 2023, 53(4): 1019-1029. |

| [15] | 陈小波,陈玲. 定位噪声统计特性未知的变分贝叶斯协同目标跟踪[J]. 吉林大学学报(工学版), 2023, 53(4): 1030-1039. |

|

||