吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (4): 1220-1230.doi: 10.13229/j.cnki.jdxbgxb.20210788

• 农业工程·仿生工程 • 上一篇

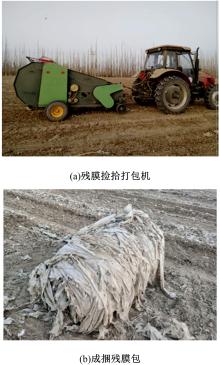

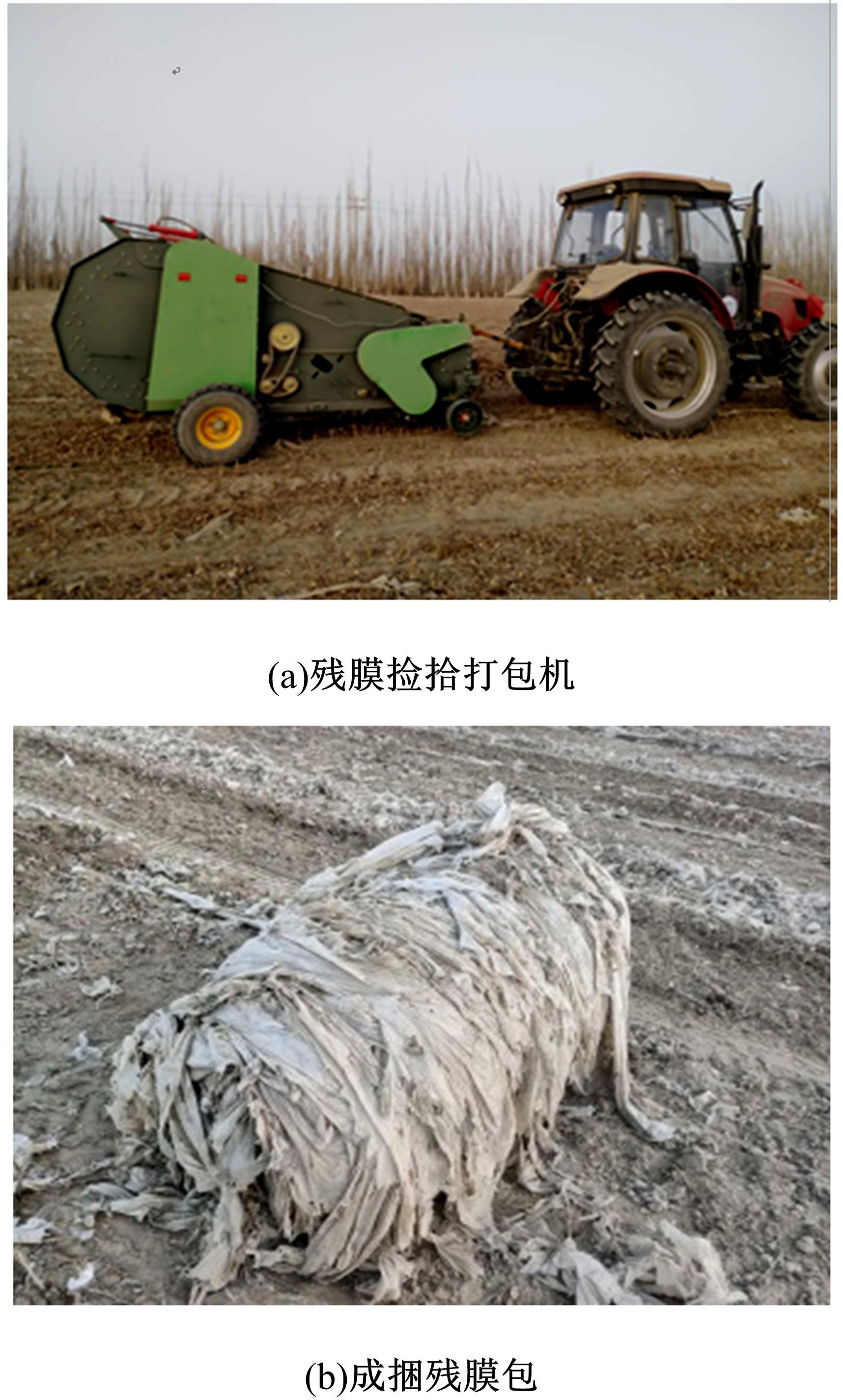

残膜捡拾打包机的设计与试验

张学军1,2( ),黄爽1,史增录1,2,于永良3,周鑫城1,靳伟1,2,陈勇1,洪佳1

),黄爽1,史增录1,2,于永良3,周鑫城1,靳伟1,2,陈勇1,洪佳1

- 1.新疆农业大学 机电工程学院,乌鲁木齐 830052

2.新疆农业工程装备创新设计实验室重点实验室,乌鲁木齐 830052

3.新疆天诚农机具制造有限公司,新疆 铁门关 841007

Design and test of the remaining film picking and baling machine

Xue-jun ZHANG1,2( ),Shuang HUANG1,Zeng-lu SHI1,2,Yong-liang YU3,Xin-cheng ZHOU1,Wei JIN1,2,Yong CHEN1,Jia HONG1

),Shuang HUANG1,Zeng-lu SHI1,2,Yong-liang YU3,Xin-cheng ZHOU1,Wei JIN1,2,Yong CHEN1,Jia HONG1

- 1.College of Mechanical and Electrical Engineering,Xinjiang Agricultural University,Urumqi 830052,China

2.Key Laboratory of Innovation Design laboratory,Xinjiang Agricultural Engineering Equipment,Urumqi 830052,China

3.Xinjiang Tiancheng Agricultural Machinery Manufacturing Co. Ltd. ,Tiemenguan 841007,China

摘要:

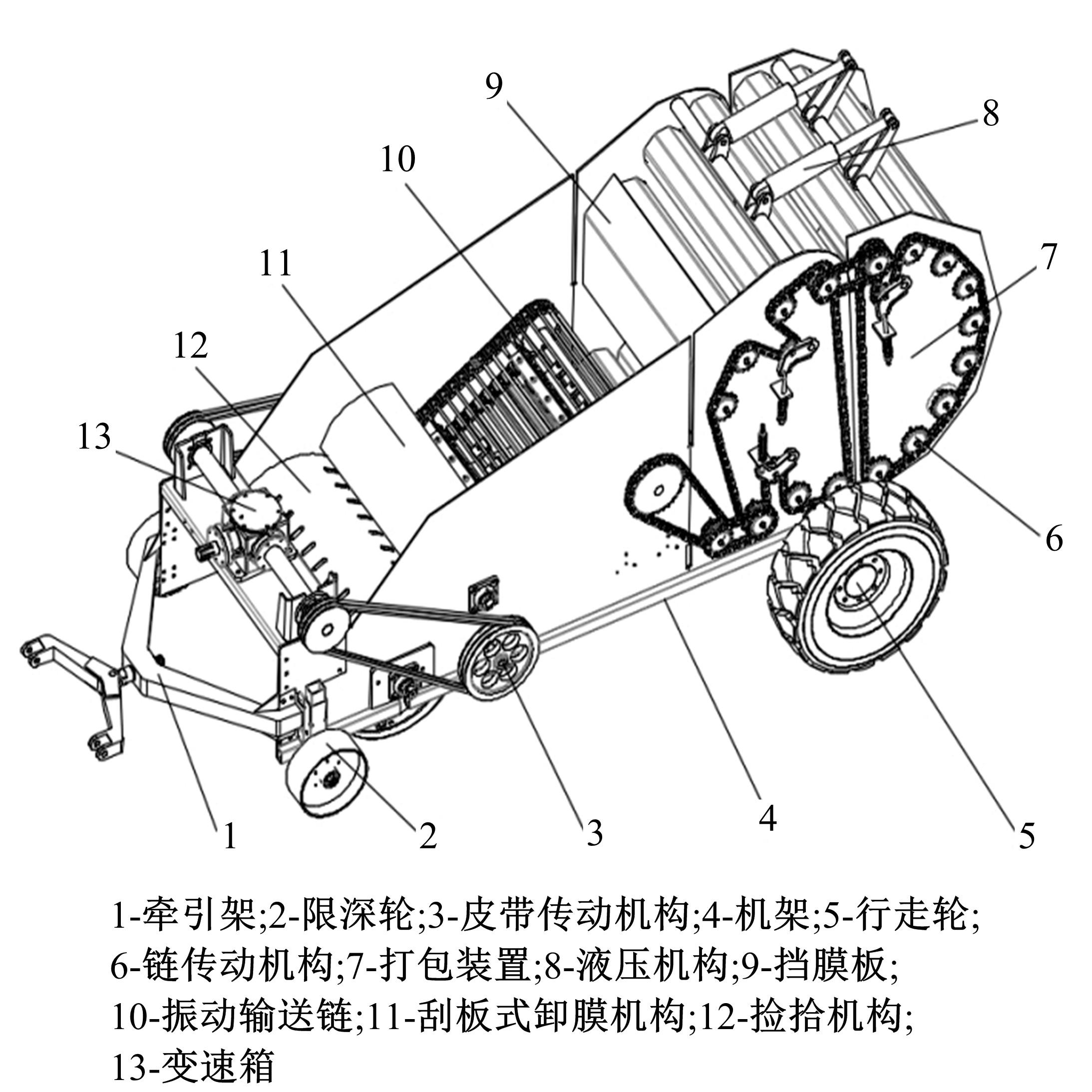

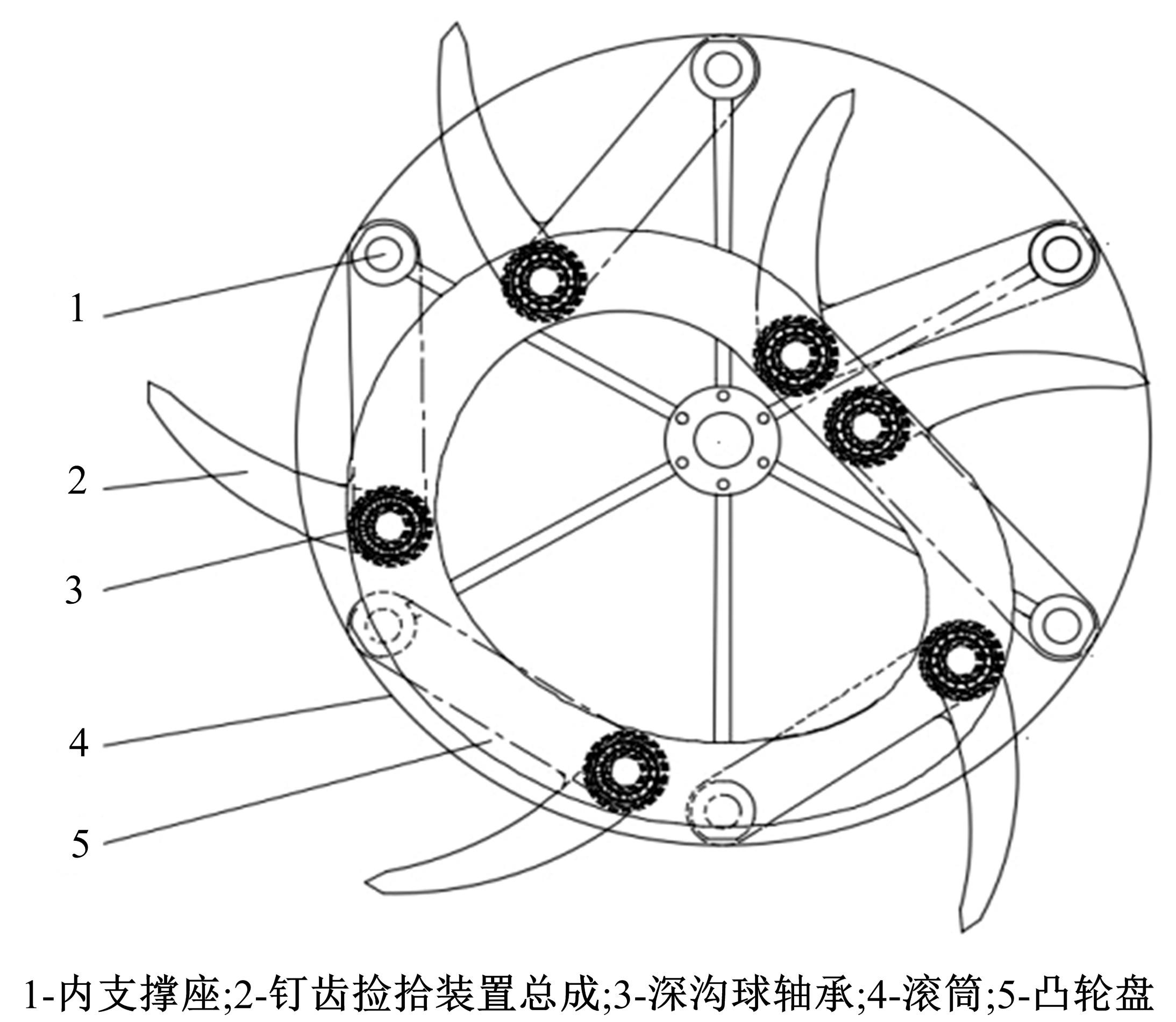

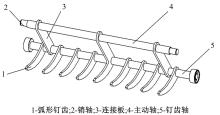

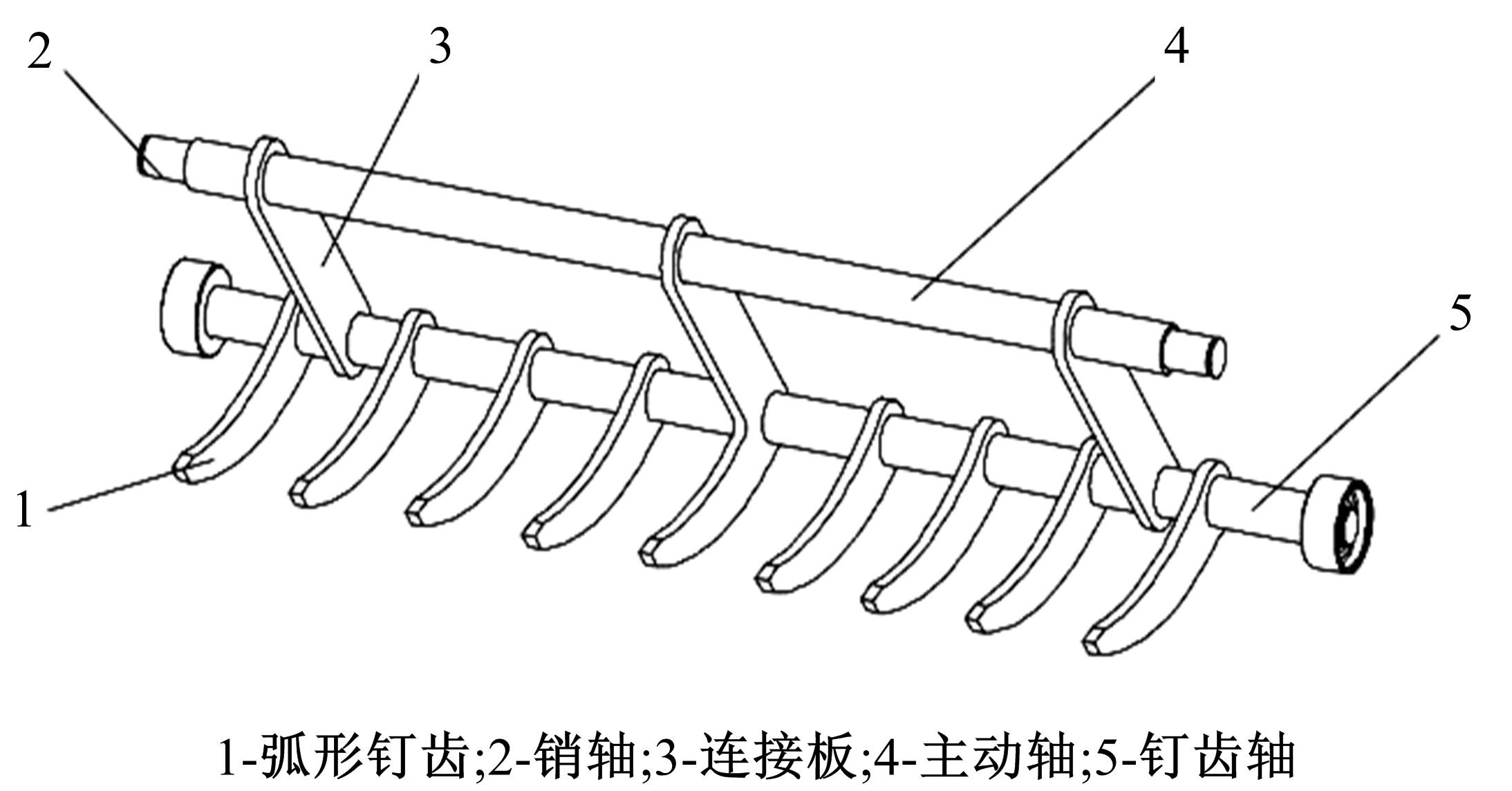

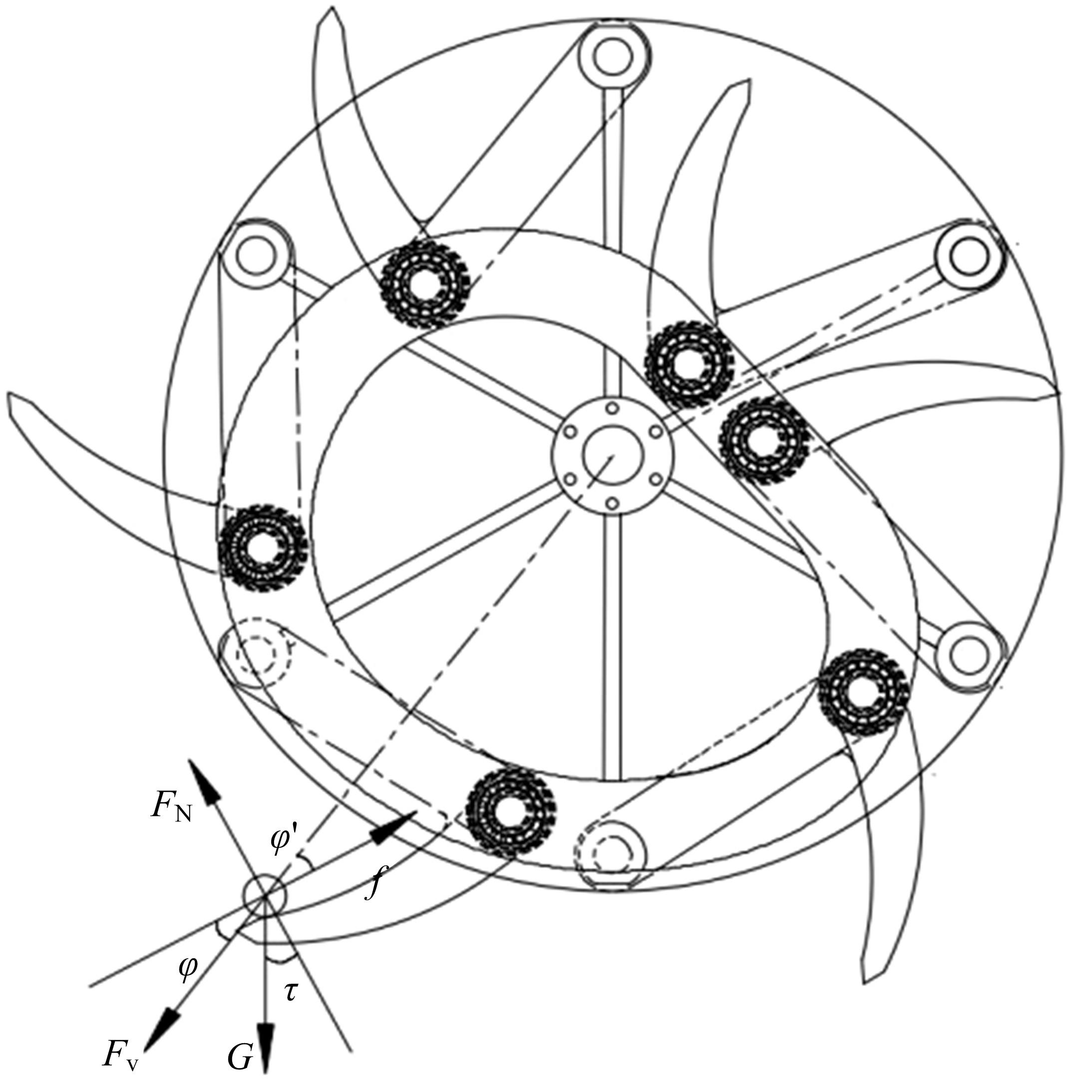

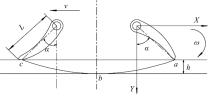

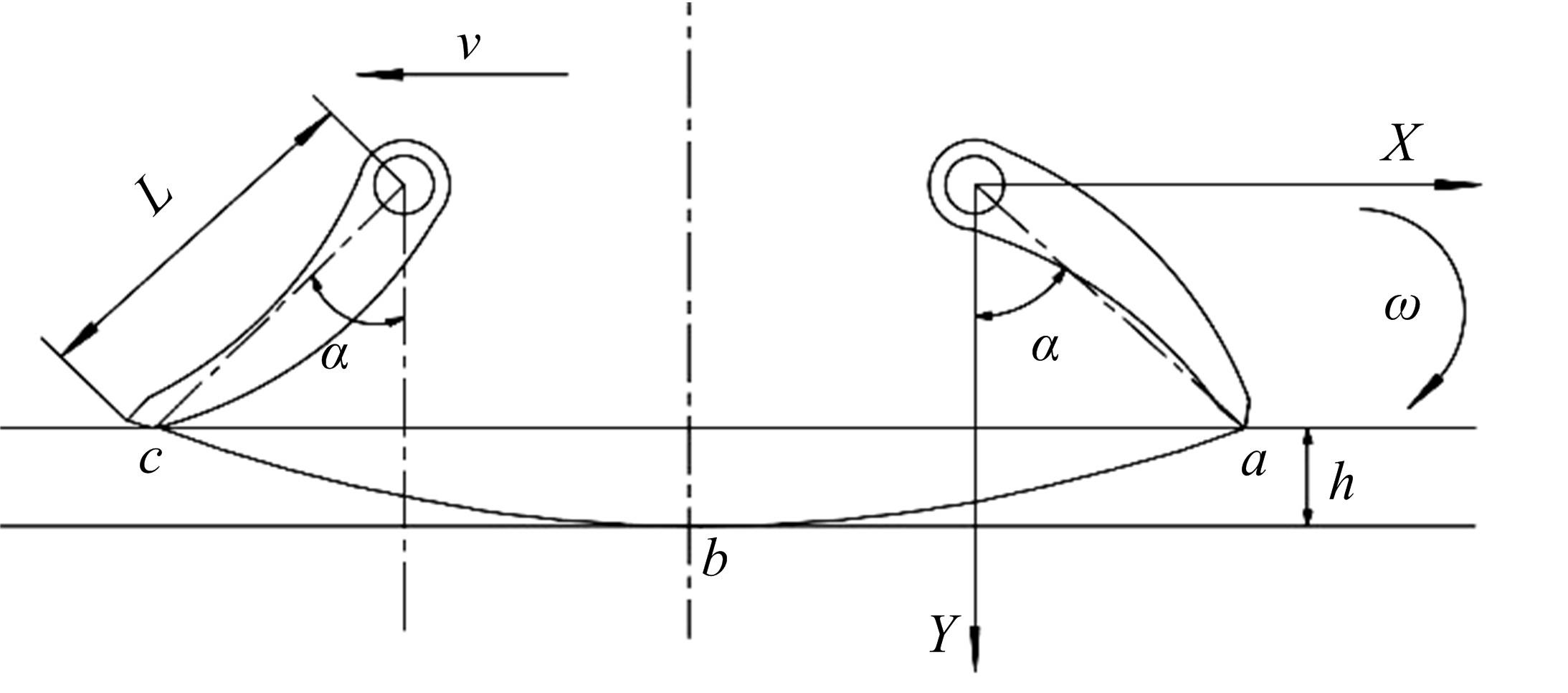

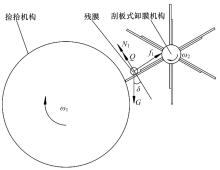

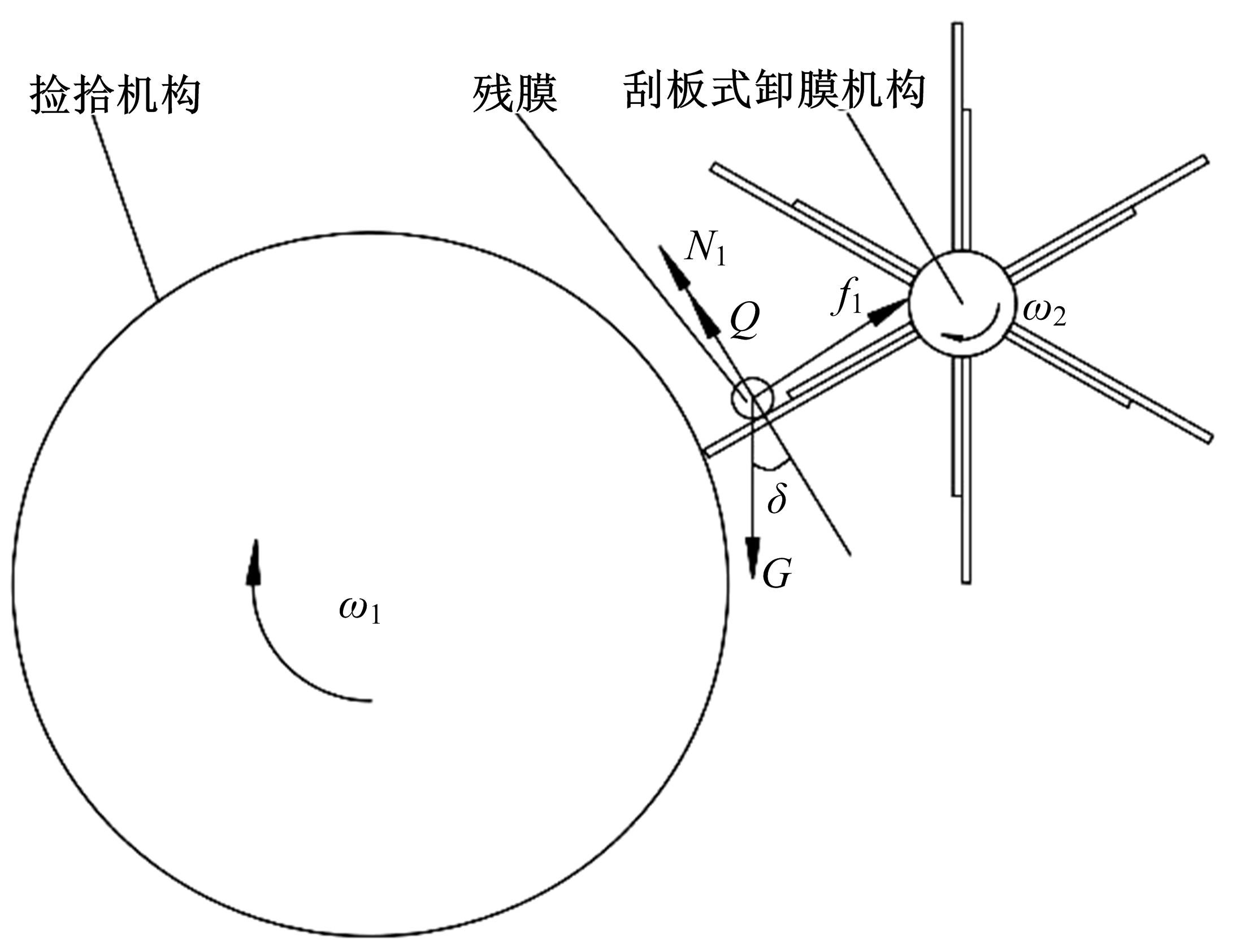

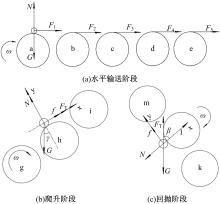

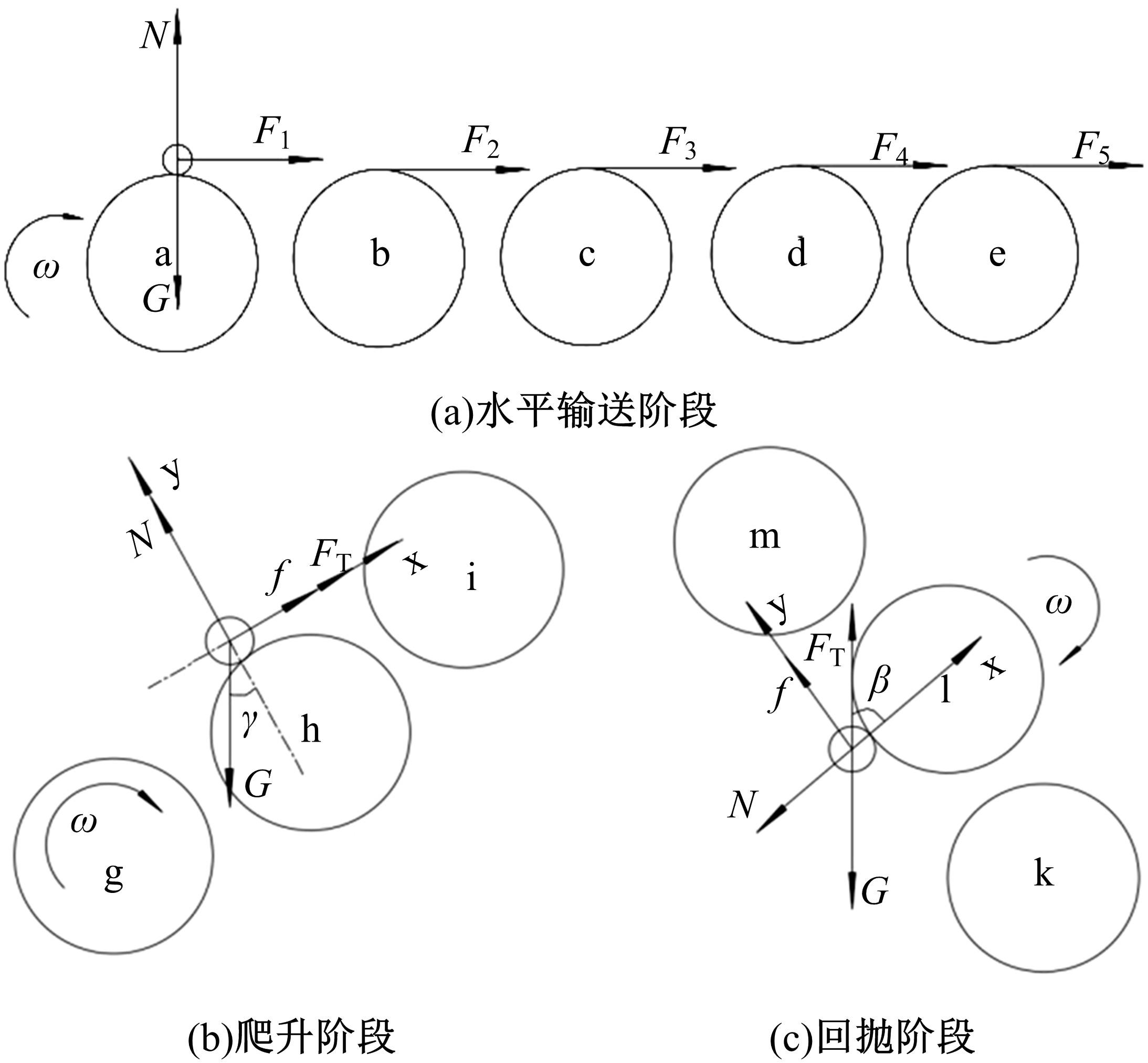

为了减少农田残膜回收过程中造成的二次污染,降低残膜储运成本,实现农田废旧残膜的规范化管理,设计开发了一种残膜捡拾打包机构。该机构主要由传动系统、捡拾机构、刮板式卸膜机构、打包机构等组成。通过对残膜捡拾过程及受力进行分析,确定了弧形钉齿的安装角度和当前工作条件下的捡拾滚筒转速范围;分析了刮板式卸膜机构的刮膜过程,明确了刮板式卸膜机构的角速度范围;研究了残膜打包装置膜芯形成的水平输送、爬升和回抛3个阶段,分析了其运动过程中的受力,确定了促成膜芯形成的主要因素为后续残膜的推力和钢辊与残膜间的摩擦导送力。选择机具前进速度、捡拾滚筒转速、钢辊转速为试验因素,残膜捡拾率与成捆率为试验指标进行正交试验,得到了影响残膜捡拾率和成捆率因素的主次顺序为:机具前进速度>滚筒转速>打包钢辊转速,在保证残膜捡拾率的前提下,最大限度地提升成捆率,确定了残膜捡拾打包机的较优工作参数:机具前进速度为4 km/h,捡拾滚筒转速为60 r/min,钢辊转速为300 r/min,取较优工作参数进行田间验证试验得到残膜捡拾率和成捆率分别为90.3%和98.4%。残膜捡拾打包机运行平稳可靠,故障率低,具有较高的使用与推广价值。

中图分类号:

- S223.5

| 1 | 由佳翰,陈学庚,张本华,等.4JSM-2000型棉秆粉碎与残膜回收联合作业机的设计与试验[J].农业工程学报,2017, 33(10): 10-16. |

| You Jia-han, Chen Xue-geng, Zhang Ben-hua, et al. Design and experiment of 4JSM-2000 cotton stalk crushing and residual film recovery combined operation machine[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(10): 10-16. | |

| 2 | 田辛亮,赵岩,陈学庚,等. 4JSM-2000A型棉秆粉碎及搂膜联合作业机的研制[J].农业工程学报,2018, 34(10):25-35. |

| Tian Xin-liang, Zhao Yan, Chen Xue-geng, et al. Development of 4JSM-2000A cotton stalk crushing and film coating combined operation machine[J].Transactions of the Chinese Society of Agricultural Engineering,2018, 34(10): 25-35. | |

| 3 | 国家统计局农村社会经济调查司.中国农村统计年鉴[M].北京:中国统计出版社,2020. |

| 4 | 赵岩,陈学庚,温浩军,等.农田残膜污染治理技术研究现状与展望[J].农业机械学报,2017, 48(6): 1-14. |

| Zhao Yan, Chen Xue-geng, Wen Hao-jun, et al. Research status and prospects of farmland residual film pollution treatment technology[J].Transactions of the Chinese Society of Agricultural Machinery, 2017, 48(6): 1-14. | |

| 5 | 王振华, 贺怀杰, 郑旭荣, 等. 新疆典型绿洲棉秆还田对覆膜滴灌棉田残膜分布的影响[J]. 农业工程学报,2018, 34(21): 120-127. |

| Wang Zhen-hua, He Huai-jie, Zheng Xu-rong, et al. Effectof returning cotton stalks to fields in Xinjiang typicaloasis on residual film distribution in drip irrigation cotton fields[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(21): 120-127. | |

| 6 | 史增录,唐学鹏,甄军,等.钉齿式残膜捡拾机构运动仿真分析及性能试验[J].农业工程学报,2019, 35(4): 64-71. |

| Shi Zeng-lu, Tang Xue-peng, Zhen Jun, et al. Motion simulation analysis and performance test of nail-tooth residual film pickup mechanism[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019,35(4): 64-71. | |

| 7 | 蒋德莉, 陈学庚, 颜利民, 等. 随动式残膜回收机清杂系统作业参数优化[J]. 农业工程学报, 2019, 35(19): 1-10. |

| Jiang De-li, Chen Xue-geng, Yan Li-min, et al. Optimization of operating parameters of cleaning system of follow-up residual film recovery machine[J].Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(19): 1-10. | |

| 8 | 罗凯,袁盼盼,靳伟,等.链筛式耕层残膜回收机设计与工作参数优化试验[J].农业工程学报,2018, 34(19): 19-27. |

| Luo Kai, Yuan Pan-pan, Jin Wei, et al. Design of chain screen type plough layer residual film recovery machine and optimization experiment of working parameters[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(19): 19-27. | |

| 9 | 唐永飞,赵永满,王吉奎,等.夹指链式残膜回收机脱膜装置设计与试验[J].农业工程学报,2020, 36(13): 11-19. |

| Tang Yong-fei, Zhao Yong-man, Wang Ji-kui, et al. Design and test of stripping device of finger chain type residual film recovery machine[J].Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(13): 11-19. | |

| 10 | 彭强吉,李成松,康建明,等.气力式圆筒筛膜杂分离机改进设计与试验[J].农业机械学报,2020, 51(8): 126-135. |

| Peng Qiang-ji, Li Cheng-song, Kang Jian-ming, et al.Improved design and test of pneumatic cylindrical sieve membrane separator[J].Transactions of the Chinese Society of Agricultural Machinery, 2020, 51(8): 126-135. | |

| 11 | 田辛亮,赵岩,陈学庚,等.棉秆粉碎与搂膜联合作业机关键部件设计与试验[J].甘肃农业大学学报,2019, 54(4): 190-198. |

| Tian Xin-liang, Zhao Yan, Chen Xue-geng, et al. Design and test of key components of the combined operation machine for cotton stalk crushing and film coating[J] .Journal of Gansu Agricultural University,2019,54(4): 190-198. | |

| 12 | 赵岩,郑炫,陈学庚,等.CMJY-1500型农田残膜捡拾打包联合作业机设计与试验[J].农业工程学报,2017, 33(5): 1-9. |

| Zhao Yan, Zheng Xuan, Chen Xue-geng, et al. Design and test of CMJY-1500 farmland residual film picking and packing combined operation machine[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(5): 1-9. | |

| 13 | 谢建华,唐炜,曹肆林,等.齿链复合式残膜回收机设计与试验[J]. 农业工程学报,2020, 36(1): 11-19. |

| Xie Jian-hua, Tang Wei, Cao Si-lin, et al. Design and experiment of tooth chain compound residual film recovery machine[J].Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(1): 11-19. | |

| 14 | 牛琪,纪超,赵岩,等.集条残膜打包机捡拾清理装置设计与试验[J].农业机械学报,2017, 48(5): 101-107. |

| Niu Qi, Ji Chao, Zhao Yan, et al. Design and test of the picking and cleaning device of the strip residual film baler[J].Transactions of the Chinese Society of Agricultural Machinery, 2017, 48(5): 101-107. | |

| 15 | 严伟,胡志超,吴努,等.铲筛式残膜回收机输膜机构参数优化与试验[J].农业工程学报, 2017, 33(1): 17-24. |

| Yan Wei, Hu Zhi-chao, Wu Nu, et al. Optimization and experiment on parameters of film conveying mechanism of shovel-screen residual film recovery machine[J].Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(1): 17-24. | |

| 16 | 谢建华,张凤贤,陈学庚,等.弧形齿滚扎式残膜回收机的设计及参数优化[J]. 农业工程学报,2019, 35(11): 26-37. |

| Xie Jian-hua, Zhang Feng-xian, Chen Xue-geng, et al. Design and parameter optimization of arc-tooth rolling-type residual film recovery machine[J]. Transactions of the Chinese Society of Agricultural Engineering,2019, 35(11): 26-37. | |

| 17 | 郭博,贺敬良,王德成,等.秸秆打捆机研究现状及发展趋势[J].农机化研究,2018, 40(1): 264-268. |

| Guo Bo, He Jing-liang, Wang De-cheng, et al. Research status and development trend of straw baler[J].Journalof Agricultural Mechanization Research, 2018, 40(1): 264-268. | |

| 18 | 操子夫.圆捆秸秆打捆机工作参数的试验研究[D]. 长春: 吉林农业大学工程技术学院, 2016. |

| Cao Zi-fu. Experimental research on working parameters of round straw baler[D]. Changchun: College of Engineering and Technology, Jilin Agricultural University,2016. | |

| 19 | 徐俊.9YG-2200型圆捆打捆机改进设计研究[D].哈尔滨: 东北农业大学工程学院,2017. |

| Xu Jun. Research on the improved design of 9YG-2200 round baler[D]. Harbin: College of Engineering, Northeast Agricultural University, 2017. | |

| 20 | 王春光.钢辊外卷式圆捆机结构与原理[J].农业机械,2008, 50(34): 43-45. |

| Wang Chun-guang.Structure and principle of steel roll outer-coiling round baler[J]. Agricultural Machinery, 2008, 50(34): 43-45. | |

| 21 | 李东,赵武云,辛尚龙,等.膜面清洁打捆自卸式残膜回收机的设计[J]. 中国农业大学学报,2020, 25(11): 117-125. |

| Li Dong, Zhao Wu-yun, Xin Shang-long, et al. Design of a self-unloading residual film recovery machine for film surface cleaning and bundling[J]. Journal of China Agricultural University, 2020, 25(11): 117-125. | |

| 22 | 王国富.青贮稻秆圆捆打捆机的设计与试验研究[D]. 哈尔滨: 东北农业大学工程学院,2019. |

| Wang Guo-fu. Design and experimental research of silage rice straw round baler[D]. Harbin: College of Engineering, Northeast Agricultural University, 2019. | |

| 23 | 江志国.钢辊式卷捆机构中钢辊对稻秆导送性能影响的试验研究[D].哈尔滨: 东北农业大学工程学院,2018. |

| Jiang Zhi-guo. Experiment on influence of conveying performance of steel-roll on rice straw in steel-roll baling mechanism[D]. Harbin: Colleg of Engineering,Northeast Agricultural University,2018. | |

| 24 | . 残地膜回收机 [S]. |

| 25 | . 圆草捆打捆机试验方法 [S]. |

| 26 | 张海春,张丽,蒋永新,等.棉田地膜回收打捆机关键参数设计及试验研究[J]. 中国农机化学报,2017, 38(5): 28-31. |

| Zhang Hai-chun, Zhang Li, Jiang Yong-xin, et al. Design and experimental research on key parameters of cotton field film recycling baler[J].Chinese Journal of Agricultural Machinery Chemistry, 2017, 38(5): 28-31. |

| [1] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [2] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

| [3] | 高文英,林静,李宝筏,王伟,谷士艳. 秸秆深埋还田机振动特性分析与结构优化[J]. 吉林大学学报(工学版), 2022, 52(4): 970-980. |

| [4] | 刘佳杰,马兰,向伟,颜波,文庆华,吕江南. 4QM-4.0型麻类青饲料联合收获机研制[J]. 吉林大学学报(工学版), 2022, 52(12): 3039-3048. |

| [5] | 史瑞杰,戴飞,赵武云,刘小龙,瞿江飞,张锋伟. 丘陵山地胡麻联合收割机作业参数优化与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2746-2755. |

| [6] | 曾百功,黎奎良,叶进,任丽丽,Rashidov Jaloliddin,张明. 工厂化上海青流水线收割装置的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2756-2764. |

| [7] | 万星宇,廖庆喜,蒋亚军,单伊尹,周宇,廖宜涛. 饲用油菜机械化收获切碎过程离散元仿真与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2735-2745. |

| [8] | 朱光强,李天宇,周福君. 鲜食玉米仿生摘穗柔性夹持输送装置设计与试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2486-2500. |

| [9] | 梁荣庆,钟波,蒙贺伟,孙志民,坎杂. 4QJ⁃3型青贮燕麦捡拾割台的研制[J]. 吉林大学学报(工学版), 2021, 51(5): 1887-1896. |

| [10] | 袁佳诚,王昌,何坤,万星宇,廖庆喜. 油菜联合收获机筛下物组分质量比对清选性能的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1897-1907. |

| [11] | 李景彬,杨禹锟,温宝琴,坎杂,孙雯,杨朔. 基于根茬检测的秋后残膜回收导航路径提取方法[J]. 吉林大学学报(工学版), 2021, 51(4): 1528-1539. |

| [12] | 王刚,刘慧力,贾洪雷,郭春江,丛永健,屈明浩. 触碰定位式玉米行间除草装置的设计与试验[J]. 吉林大学学报(工学版), 2021, 51(4): 1518-1527. |

| [13] | 黄继承,沈成,纪爱敏,李显旺,张彬,田昆鹏,刘浩鲁. 工业大麻收割机切割⁃输送关键部件作业参数优化[J]. 吉林大学学报(工学版), 2021, 51(2): 772-780. |

| [14] | 陈学深,陈涛,武涛,马旭,曾令超,陈林涛. 覆草冬种马铃薯收获机稻草分离机构设计与试验[J]. 吉林大学学报(工学版), 2020, 50(2): 749-757. |

| [15] | 付君,张屹晨,程超,陈志,唐心龙,任露泉. 刚柔耦合式小麦脱粒弓齿设计及试验[J]. 吉林大学学报(工学版), 2020, 50(2): 730-738. |

|

||