吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (2): 772-780.doi: 10.13229/j.cnki.jdxbgxb20191177

• 农业工程·仿生工程 • 上一篇

工业大麻收割机切割⁃输送关键部件作业参数优化

黄继承1,2( ),沈成2,3,纪爱敏1(

),沈成2,3,纪爱敏1( ),李显旺2,张彬2,3,田昆鹏2,刘浩鲁2

),李显旺2,张彬2,3,田昆鹏2,刘浩鲁2

- 1.河海大学 机电工程学院,江苏 常州 2130221

2.农业农村部 南京农业机械化研究所,南京 210014

3.东南大学 机械工程学院,南京 211189

Optimization of cutting⁃conveying key working parameters of hemp harvester

Ji-cheng HUANG1,2( ),Cheng SHEN2,3,Ai-min JI1(

),Cheng SHEN2,3,Ai-min JI1( ),Xian-wang LI2,Bin ZHANG2,3,Kun-peng TIAN2,Hao-lu LIU2

),Xian-wang LI2,Bin ZHANG2,3,Kun-peng TIAN2,Hao-lu LIU2

- 1.College of Mechanical and Electrical Engineering,Hohai University,Changzhou 213022,China

2.Nanjing Research Institute for Agricultural Mechanization,Ministry of Agriculture,Nanjing 210014,China

3.School of Mechanical Engineering,Southeast University,Nanjing 211189,China

摘要:

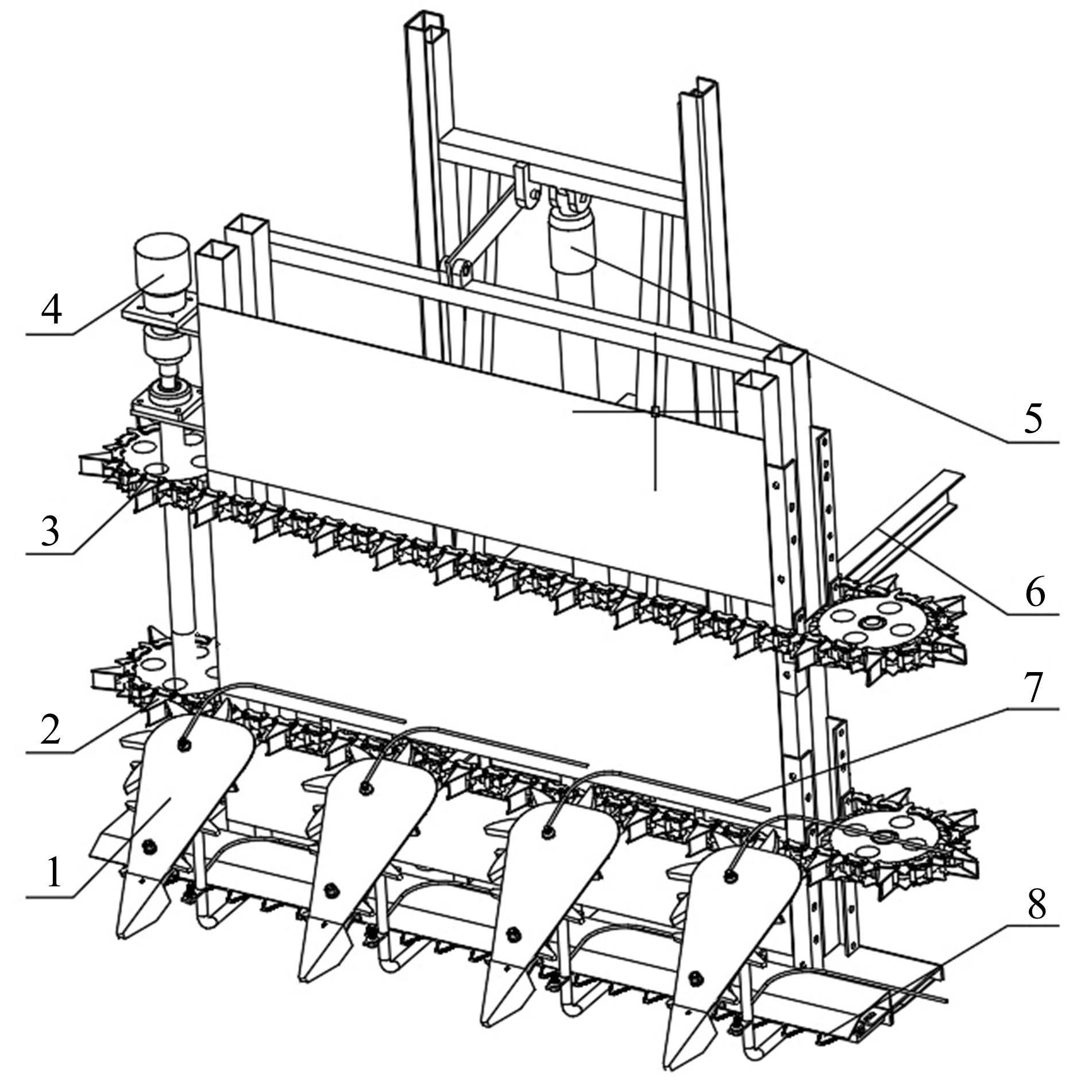

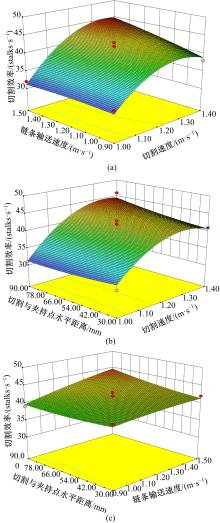

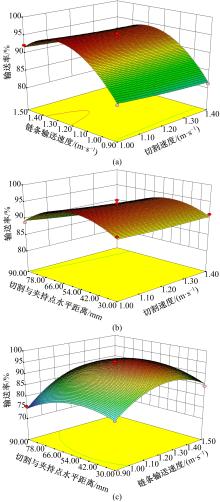

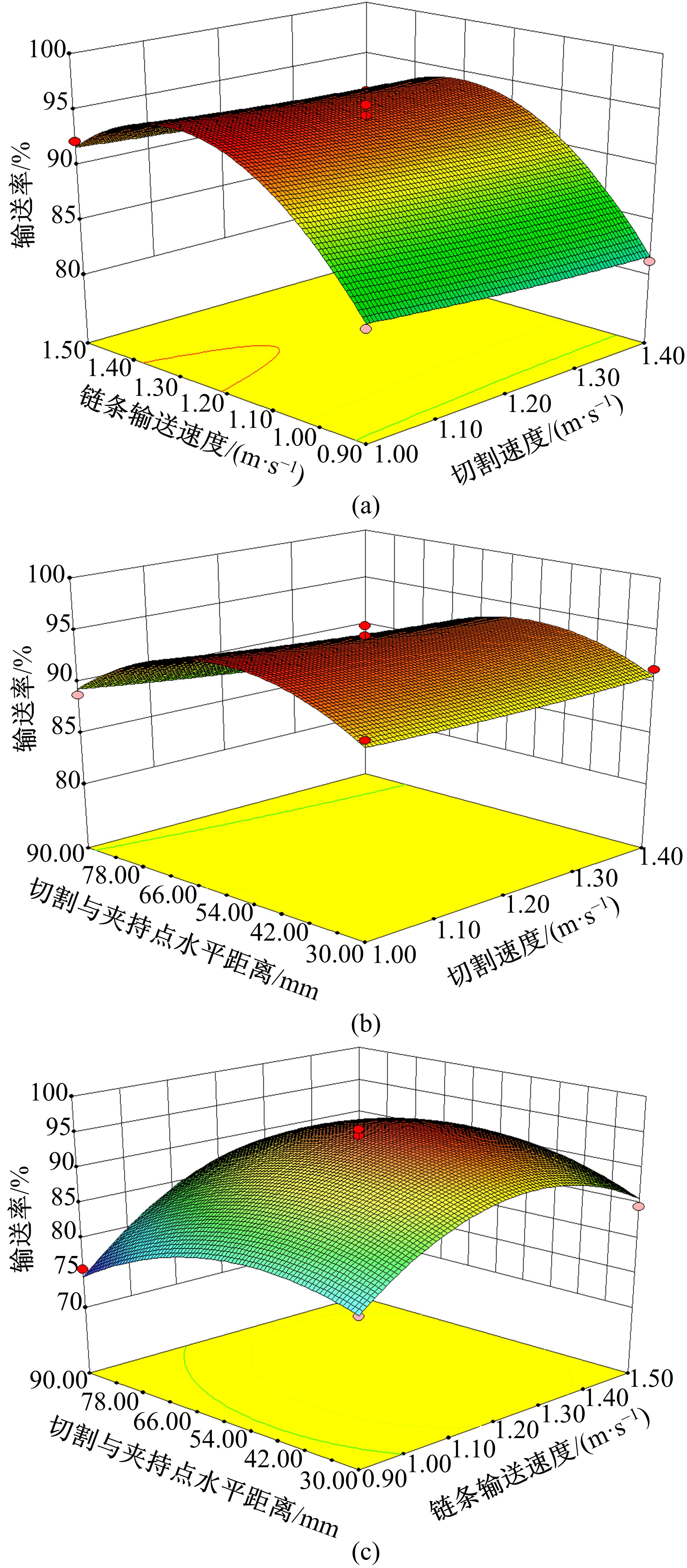

针对工业大麻收割机茎秆切割效率低、输送率低,以及关键作业参数研究空白的现状,本文结合工业大麻茎秆物理特性,运用中心组合试验设计理论开展关键部件作业参数试验与优化,重点研究工业大麻收割机切割-输送作业关键参数中切割速度、链条输送速度、切割位置与夹持点水平间距对切割效率、输送率的影响规律,并以切割效率、输送率为响应指标进行多目标优化。首先对主产区工业大麻茎秆物理和机械力学特性进行研究,并进行与收割相关的物理参数测定,然后采用二次正交旋转组合试验方法设计试验,并用Design-Expert进行数据处理,建立切割效率、输送率的回归数学模型并进行方差分析。通过响应曲面方法分析各因素交互作用对切割效率、输送率的影响,并根据优化目标的重要程度(输送率较切割效率更重要)对回归模型进行多目标优化,得出工业大麻收割机切割-输送关键作业参数的最优组合如下:切割速度为1.33 m/s,链条输送速度为1.35 m/s,切割与夹持点水平距离为63.9 mm。此时切割效率最高、输送率最高,其值分别为44.35 株/s、93.93%。最优参数组合下田间试验切割效率为44.7 株/s、输送率为92.21%,作业性能大幅提升,达到了较为理想的效果。

中图分类号:

- S225.5

| 1 | 张晓艳, 孙宇峰, 韩承伟, 等. 我国工业大麻产业发展现状及策略分析[J]. 特种经济动植物, 2019, 22(8): 26-28. |

| 2 | 郭丽, 王明泽, 王殿奎, 等. 工业大麻综合利用研究进展与前景展望[J]. 黑龙江农业科学, 2014(8): 132-134. |

| Guo Li, Wang Ming-ze, Wang Dian-kui, et al. Research progress and prospect of comprehensive utilization of industrial hemp[J]. Heilongjiang Agricultural Sciences, 2014(8): 132-134. | |

| 3 | Cassano R, Trombino S, Ferrarelli T, et al. Hemp fiber(cannabis sativa L.)derivatives with antibacterial and chelating properties[J]. Cellulose, 2013, 20(1): 547-557. |

| 4 | Kumar N, Singh T, Grewal J S, et al. Experimental investigation on the physical,mechanical and tribological properties of hemp fiber-based non-asbestos organic brake friction composites[J/OL]. [2019-03-29] 91/ab2399#references |

| 5 | Musio S, Mussig J, Amaducci S. Optimizing hemp fiber production for high performance composite applications[J]. Frontiers in Plant Science, 2018, 9: 1-14. |

| 6 | Malomo S A, Aluko R E. Kinetics of acetylcholinesterase inhibition by hemp seed protein-derived peptides[J/OL]. [2019-03-15] |

| 7 | Rodriguez-Martin N M, Toscano R, Villanueva A, et al. Neuroprotective protein hydrolysates from hemp (cannabis sativa L.) seeds[J]. Food & Function, 2019, 10: 6732-6739. |

| 8 | 唐斌, 李显旺, 袁建宁, 等. 工业大麻微型收获机械的技术与发展分析[J]. 中国农机化学报, 2018, 39(2): 17-21. |

| Tang Bin, Li Xian-wang, Yuan Jian-ning, et al. Analysis of technology and development for hemp micro-harvesting machinery[J]. Journal of Chinese Agricultural Mechanization, 2018, 39(2): 17-21. | |

| 9 | 黄继承, 李显旺, 张彬, 等. 4LMZ160型履带式苎麻联合收割机的研究[J]. 农机化研究, 2015(9): 155-158, 163. |

| Huang Ji-cheng, Li Xian-wang, Zhang Bin, et al. Research on the 4LMZ160 crawler ramie combine harvester[J]. Journal of Agricultural Mechanization Research, 2015(9): 155-158, 163. | |

| 10 | 吕江南, 马兰, 刘佳杰, 等. 黑龙江省工业大麻产业发展及收获加工机械情况调研[J]. 中国麻业科学, 2017, 39(2): 94-102. |

| Lv Jiang-nan, Ma Lan, Liu Jia-jie, et al. The investigation on the development of industrial hemp and its harvesting machinery of Heilongjiang province[J], Plant Fiber Sciences in China, 2017, 39(2): 94-102. | |

| 11 | 朱浩, 张治国, 于革. 汉麻割晒机研制与试验[J]. 农业工程, 2018, 8(2): 95-98. |

| Zhu Hao, Zhang Zhi-guo, Yu Ge. Development and test of hemp swather[J]. Agricultural Engineering, 2018, 8(2): 95-98. | |

| 12 | 熊和平. 2016-2017国家麻类产业技术发展报告[M]. 北京: 中国农业科学技术出版社, 2019. |

| 13 | Zhou Y, Li X W, Shen C, et al. Experimental analysis on mechanical model of industrial hemp stalk[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(9): 22-29. |

| 14 | Shen C, Zhang B, Li X W, et al. Bench cutting tests and analysis for harvesting hemp stalk[J]. International Journal of Agricultural and Biological Engineering, 2017, 10(6): 56-67. |

| 15 | Kakitis A, Berzins U, Berzins R, et al. Cutting properties of hemp fibre[J]. Engineering for Rural Development, 2012, 11: 245-250. |

| 16 | Adamovics A, Kakitis A. Productivity and tensile endurance determination of hemp fiber[J]. Chemical Engineering Transactions, 2013, 35: 805-810. |

| 17 | 马兰, 刘佳杰, 周韦, 等. 工业大麻干茎秆轴向压缩力学特性试验研究[J]. 中国农机化学报, 2018, 39(11): 34-40, 50. |

| Ma Lan, Liu Jia-jie, Zhou Wei, et al. Test of axial mechanical compressive properties for industial hemp dry stalk[J]. Journal of Chinese Agricultural Mechanization, 2018, 39(11): 34-40, 50. | |

| 18 | Huang J C, Shen C, Li X W, et al. Design and tests of hemp harvester[J]. International Agricultural Engineering Journal, 2017, 26(2): 117-127. |

| 19 | Pari L, Alfano V, Scarfone A. An innovative harvesting system for multipurpose hemp[C]∥24th International European Biomass Conference on Setting the Course for a Biobased Economy. Florence: Amsterdam, 2016: 356-358. |

| 20 | Kaniewski R, Mankowski J, Rynduch W, et al. Modemized hemp mower[C]∥Natural Fiber Wokna Naturalne. Flax and Other Bast Plants Symposium, Poznon, Poland, 1997: 25-27. |

| 21 | Chen Y, Liu J, Gratton J L. Engineering perspectives of the hemp plant, harvesting and processing[J]. Journal of Industrial Hemp, 2004, 9(2): 23-39. |

| 22 | 周杨. 工业大麻圆盘切割装置的设计与试验研究[D]. 北京: 中国农业科学院研究生院, 2017. |

| Zhou Yang. Design and expeirmental research of hemp disc cutter[D]. Beijing: Graduate School, Chinese Academy of Agricultural Sciences, 2017. | |

| 23 | 王法昌, 周学建, 师清翔, 等. 新型玉米收获机横向输送装置的参数研究[J]. 农机化研究, 2010, 32(5): 152-155. |

| Wang Fa-chang, Zhou Xue-jian, Shi Qing-xiang, et al. Parameters study on transverse transport of new corn combine[J]. Journal of Agricultural Mechanization Research, 2010, 32(5): 152-155. | |

| 24 | 张宗玲, 韩增德, 李树君, 等. 玉米穗茎兼收收割台切割夹持输送装置仿真与试验[J]. 农业机械学报, 2016, 47(): 215-221. |

| Zhang Zong-ling, Han Zeng-de, Li Shu-jun, et al. Simulation and test on straw cutting and clamping device of corn combine harvester for stalk and ears[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(Sup.1): 215-221. | |

| 25 | 徐向宏, 何明珠. 试验设计与Design-Expert SPSS应用[M]. 北京: 科学出版社责任有限公司, 2016. |

| 26 | 王利民, 肖志刚, 刘宇欣, 等. 响应面法优化板栗基营养米挤压加工参数[J]. 吉林大学学报: 工学版, 2013, 43(2): 550-556. |

| Wang Li-min, Xiao Zhi-gang, Liu Yu-xin, et al. Optimization of extrusion process parameters of nutritious rice rich in chestnut by response surface method[J]. Journal of Jilin University (Engineering and Technology Edition), 2013, 43(2): 550-556. | |

| 27 | 王建楠, 刘敏基, 曹明珠, 等. 薏苡脱壳机关键部件作业参数优化与试验[J]. 农业工程学报, 2018, 34(13): 288-295. |

| Wang Jian-nan, Liu Min-ji, Cao Ming-zhu, et al. Working parameter optimization and experiment of key components of coix lacryma-jobi sheller[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(13): 288-295. | |

| 28 | 薛钊, 付君, 陈志, 等. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报: 工学版, 2020, 50(2): 739-748. |

| Xue Zhao, Fu Jun, Chen Zhi, et al. Optimization experiment on parameters of chopping device of forage maize harvester[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(2): 739-748. | |

| 29 | 陈魁. 试验设计与分析[M]. 北京: 清华大学出版社, 2005. |

| 30 | 杨德. 试验设计与分析[M]. 北京: 中国农业出版社, 2002. |

| [1] | 周炳海,吴琼. 基于多目标的机器人装配线平衡算法[J]. 吉林大学学报(工学版), 2021, 51(2): 720-727. |

| [2] | 马芳武,韩丽,吴量,李金杭,杨龙帆. 基于遗传与粒子群算法的隔振平台减振性能优化[J]. 吉林大学学报(工学版), 2020, 50(5): 1608-1616. |

| [3] | 陈学深,陈涛,武涛,马旭,曾令超,陈林涛. 覆草冬种马铃薯收获机稻草分离机构设计与试验[J]. 吉林大学学报(工学版), 2020, 50(2): 749-757. |

| [4] | 付君,张屹晨,程超,陈志,唐心龙,任露泉. 刚柔耦合式小麦脱粒弓齿设计及试验[J]. 吉林大学学报(工学版), 2020, 50(2): 730-738. |

| [5] | 李银平,靳添絮,刘立. 纯电动铲运机弓网续能系统设计与动态特性仿真[J]. 吉林大学学报(工学版), 2020, 50(2): 454-463. |

| [6] | 薛钊,付君,陈志,王锋德,韩少平,任露泉. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报(工学版), 2020, 50(2): 739-748. |

| [7] | 程超,付君,郝付平,陈志,周德义,任露泉. 清选筛运动参数对玉米芯轴堵筛规律的影响[J]. 吉林大学学报(工学版), 2020, 50(1): 351-360. |

| [8] | 马芳武,梁鸿宇,赵颖,杨猛,蒲永锋. 内凹三角形负泊松比结构耐撞性多目标优化设计[J]. 吉林大学学报(工学版), 2020, 50(1): 29-35. |

| [9] | 蔡中义,孟凡响,陈庆敏,赵轩. 复杂钩舌锻件近净成形的预锻形状优化设计[J]. 吉林大学学报(工学版), 2020, 50(1): 84-90. |

| [10] | 贾富淳,孟宪皆,雷雨龙. 基于多目标遗传算法的二自由度动力吸振器优化设计[J]. 吉林大学学报(工学版), 2019, 49(6): 1969-1976. |

| [11] | 程超,付君,唐心龙,陈志,任露泉. 振动形式对水稻脱出物界面粘附规律的影响[J]. 吉林大学学报(工学版), 2019, 49(4): 1228-1235. |

| [12] | 王家序,蒋倩倩,李俊阳,韩彦峰,张雷,唐挺. 双圆弧谐波传动柔轮齿形参数多目标优化设计[J]. 吉林大学学报(工学版), 2019, 49(4): 1194-1202. |

| [13] | 李欣,王丹,陈军绪,孙延朋,谷诤巍,徐虹. 手刹固定板冲压成形数值模拟[J]. 吉林大学学报(工学版), 2019, 49(4): 1258-1265. |

| [14] | 夏利红, 邓兆祥. 电子机械制动执行器的整体最优匹配设计[J]. 吉林大学学报(工学版), 2018, 48(4): 998-1007. |

| [15] | 吉野辰萌, 樊璐璐, 闫磊, 徐涛, 林烨, 郭桂凯. 基于MBNWS算法的假人胸部结构多目标优化设计[J]. 吉林大学学报(工学版), 2018, 48(4): 1133-1139. |

|

||