吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (7): 1862-1868.doi: 10.13229/j.cnki.jdxbgxb.20230031

• 车辆工程·机械工程 • 上一篇

考虑能耗与负载因素的抓取机械臂运动轨迹规划算法

- 中南林业科技大学 机电工程学院,长沙 410000

Trajectory planning algorithm for grasping manipulator considering energy consumption and load factors

Xiao-hong TANG( ),Yong-jian GONG

),Yong-jian GONG

- School of Mechanical and Electrical Engineering,Central South University of Forestry and Technology,Changsha 410000,China

摘要:

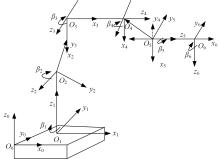

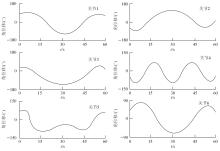

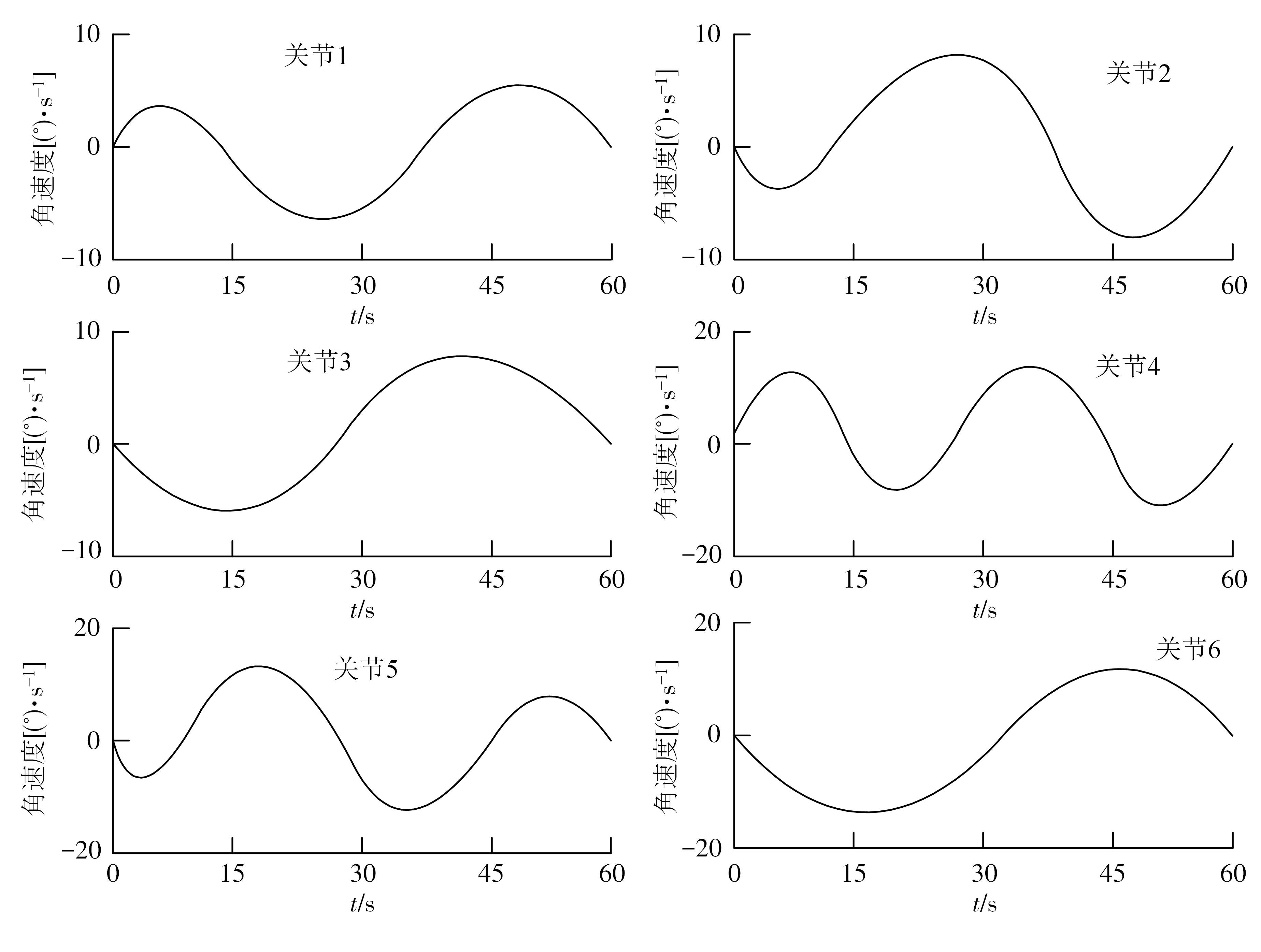

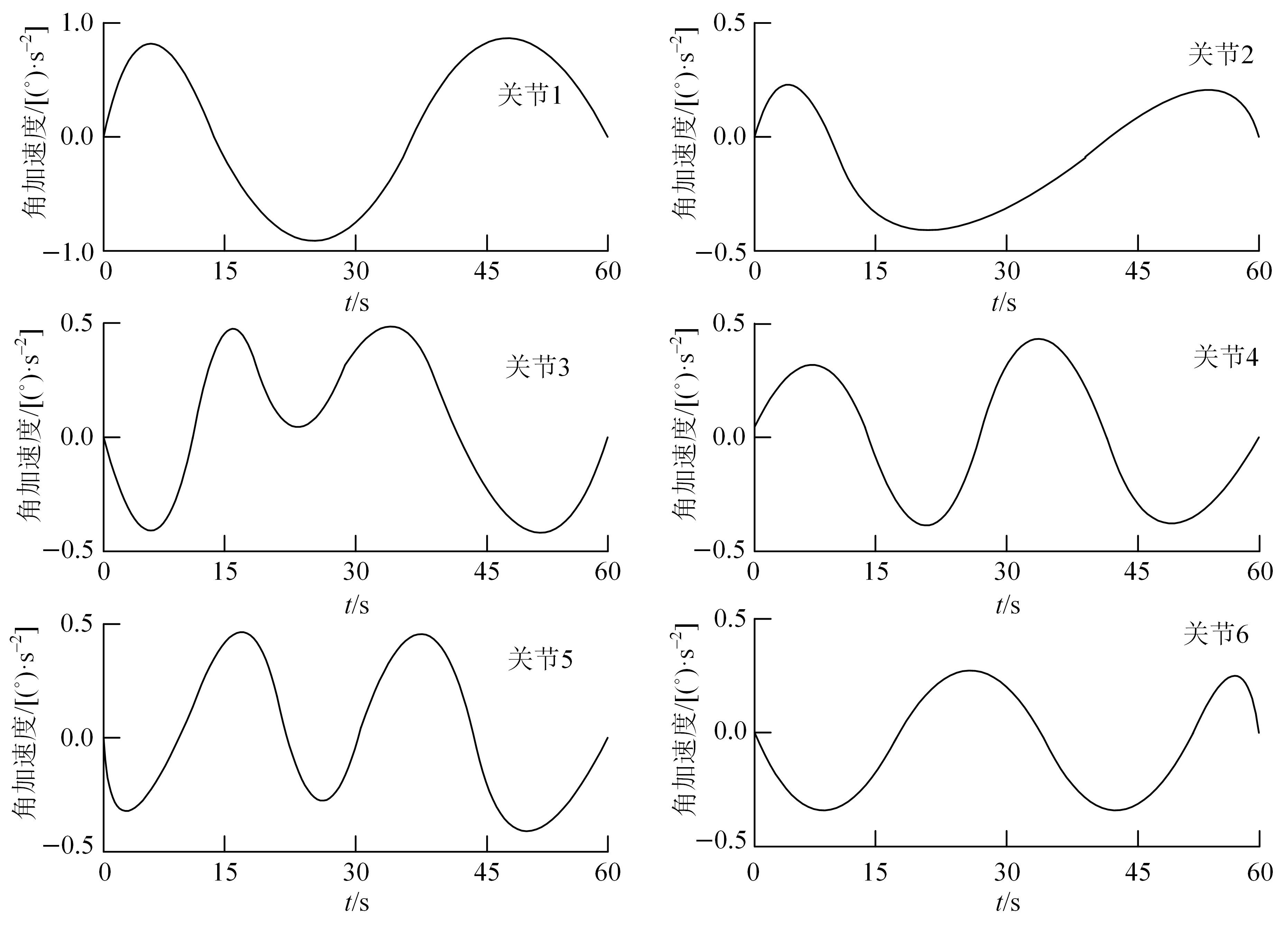

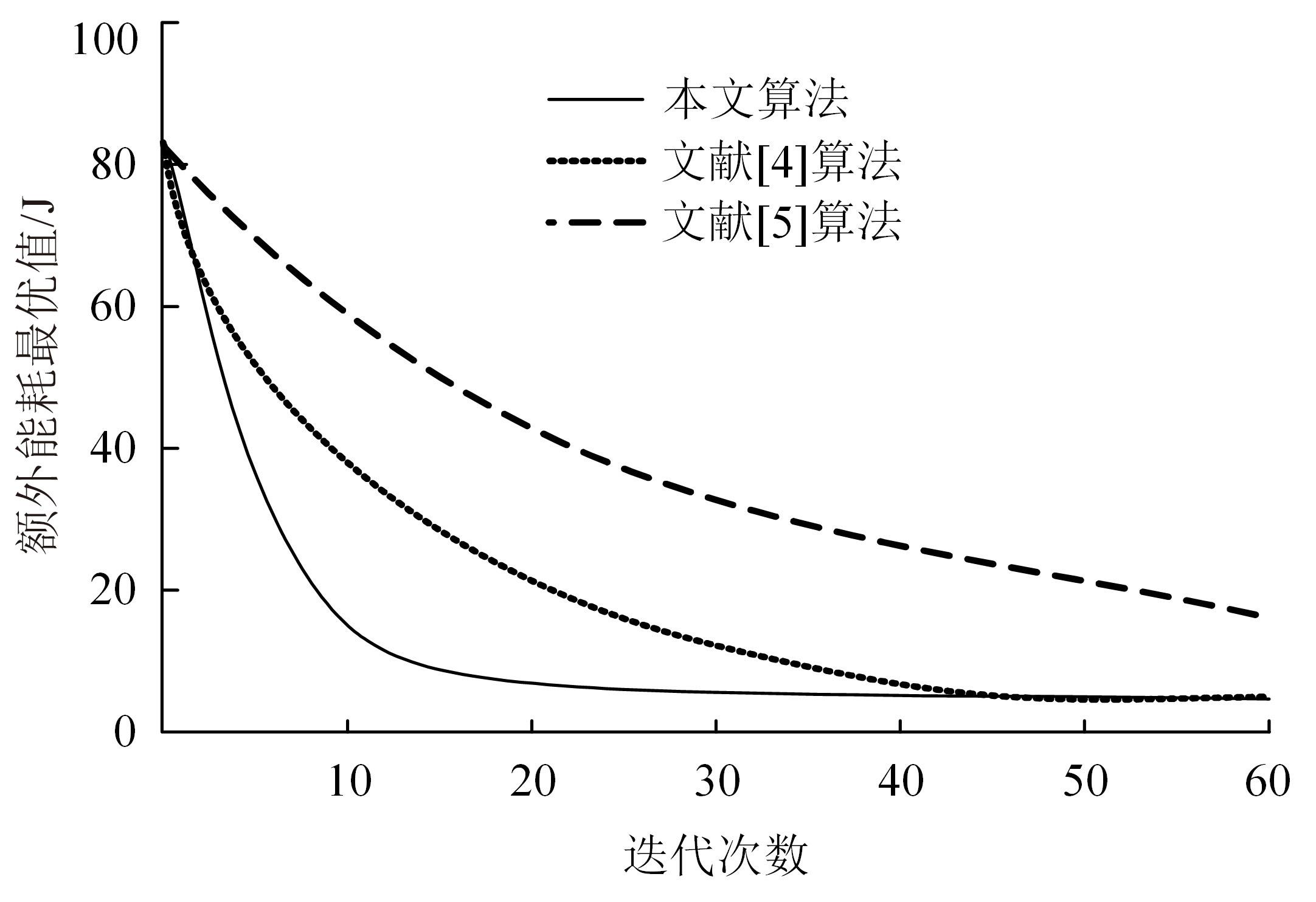

针对抓取机械臂运动轨迹规划不合理导致的运动路程增加及能耗加剧问题,提出了考虑能耗与负载因素的抓取机械臂运动轨迹规划算法。根据运动学原理建立抓取机械臂运动学模型,通过齐次变换矩阵求解各环节空间位置、姿态,利用时间间隔序列、三次非均匀B样条插值算法约束各个关节角度、速度及其加速度,使其运动轨迹能耗、负载最优;采用线性回归分析方程生成新的群体,找出该群体最优粒子并将其替换原群体中任意一个粒子,反复该过程,即可找出群体最优运动轨迹。实验结果表明,本文算法收敛速度快,且运动轨迹能耗最低。

中图分类号:

- TH16

| 1 | 李克讷,马玉如,王温鑫,等.基于伪逆的冗余度机械臂关节速度约束方案[J]. 仪器仪表学报,2022,43(2):225-233. |

| Li Ke-ne, Ma Yu-ru, Wang Wen-xin, et al. Redundant manipulator joint-velocity constraint scheme based on pseudoinverse[J]. Chinese Journal of Scientific Instrument, 2022, 43(2): 225-233. | |

| 2 | 李英立,赵忆文,王争,等.基于深度图像与三维栅格离线映射的机械臂环境建模方法[J].控制与决策,2020,35(7):1537-1546. |

| Li Ying-li, Zhao Yi-wen, Wang Zheng, et al. Environment modelling method for manipulator robot based online-mapping between depth image and OctoMap[J]. Control and Decision, 2020,35(7): 1537-1546. | |

| 3 | 白云飞,张奇峰,范云龙,等.基于能耗优化的深海电动机械臂轨迹规划[J].机器人,2020,42(3):301-308. |

| Bai Yun-fei, Zhang Qi-feng, Fan Yun-long, et al. Trajectory planning of deep-sea electric manipulator based on energy optimization[J]. Robot, 2020,42(3): 301-308. | |

| 4 | 彭见辉,陈军杰,李佳玉.基于DCNLP的分拣机械臂最优能耗控制[J].组合机床与自动化加工技术,2022(10):92-96. |

| Peng Jian-hui, Chen Jun-jie, Li Jia-yu. Research on the least-effort optimal control problem of sorting robotic manipulator using DCNLP[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2022 (10): 92-96. | |

| 5 | 孙颙琰,郭文勇,孙云岭,等.基于自适应变换蝙蝠算法的机械臂轨迹优化[J].机械传动,2022,46(5):35-41. |

| Sun Yong-yan, Guo Wen-yong, Sun Yun-ling, et al. Trajectory optimization of manipulator based on adaptive transformation bat algorithm[J]. Journal of Mechanical Transmission, 2022, 46(5): 35-41. | |

| 6 | 张昌,武玉强.基于P-Rob六自由度机械臂运动学建模与仿真[J].包装工程,2020,41(11):166-173. |

| Zhang Chang, Wu Yu-qiang. Kinematics modeling and simulation of six degrees of freedom manipulator based on P-rob[J]. Packaging Engineering, 2020,41(11): 166-173. | |

| 7 | 石建平,李培生,刘国平,等.基于改进克隆选择算法的机械臂运动学逆解[J].计算机集成制造系统,2021,27(10):2929-2939. |

| Shi Jian-ping, Li Pei-sheng, Liu Guo-ping, et al. Hybrid mutation clonal selection algorithm for solving inverse kinematics of manipulator[J]. Computer Integrated Manufacturing Systems, 2021,27(10): 2929-2939. | |

| 8 | 冯晨旭,胡三宝.基于改进天牛须搜索的机械臂运动学逆解[J]. 武汉大学学报:工学版,2020,53(12):1121-1128. |

| Feng Chen-xu, Hu San-bao. Kinematic inverse solution of mechanical arm based on improved beetle antennae search[J]. Engineering Journal of Wuhan University, 2020,53(12): 1121-1128. | |

| 9 | 宋成,袁杰. 一种冗余机械臂多目标轨迹优化方法[J].机械科学与技术,2020,39(12):1852-1858. |

| Song Cheng, Yuan Jie. A method for multi-objective optimization of redundant manipulator's trajectory[J]. Mechanical Science and Technology for Aerospace Engineering, 2020,39(12): 1852-1858. | |

| 10 | 谭月胜,詹登辉,张彭豪.刚柔耦合串联机械臂末端位置误差分析与补偿[J].农业机械学报,2021,52(2):416-426. |

| Tan Yue-sheng, Zhan Deng-hui, Zhang Peng-hao. Analysis and compensation of end position error of rigid-flexible coupling serial manipulator[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021,52(2): 416-426. | |

| 11 | 郑涛,刘满禄. 一种机械臂分段插值轨迹规划方法[J].机械设计与制造,2020(3):261-264. |

| Zheng Tao, Liu Man-lu. A method of segmental interpolation trajectory planning for robotic arm[J]. Machinery Design & Manufacture, 2020(3): 261-264. | |

| 12 | 田会方,潘宁静.纤维缠绕机芯模自动装卸机械臂轨迹仿真与分析[J]. 机床与液压,2020,48(3):52-57. |

| Tian Hui-fang, Pan Ning-jing. Simulation and analysis of trajectory of automatic loading and unloading manipulator for filament winding machine[J]. Machine Tool & Hydraulics, 2020,48(3): 52-57. | |

| 13 | 方春恩,曾春燕,薛涛,等.基于混沌粒子群算法的IGBT参数提取研究[J].电力电子技术,2020,54(7):133-135, 140. |

| Fang Chun-en, Zeng Chun-yan, Xue Tao, et al. IGBT parameter extraction based on chaotic particle swarms optimization[J]. Power Electronics, 2020,54(7): 133-135, 140. | |

| 14 | 袁蒙恩,陈立家,冯子凯.基于单目视觉的多种群粒子群机械臂路径规划算法[J].计算机应用,2020,40(10):2863-2871. |

| Yuan Meng-en, Chen Li-jia, Feng Zi-kai. Path planning algorithm of multi-population particle swarm manipulator based on monocular vision[J]. Journal of Computer Applications, 2020,40(10): 2863-2871. | |

| 15 | 江鸿怀,金晓怡,邢亚飞,等.基于粒子群优化算法的五自由度机械臂轨迹规划[J].机械设计与研究,2020,36(1):107-110. |

| Jiang Hong-huai, Jin Xiao-yi, Xing Ya-fei, et al. Five-degree-of-freedom manipulator trajectory planning based on psoparticle algorithm[J]. Machine Design & Research, 2020,36(1): 107-110. |

| [1] | 李光保,高栋,路勇,平昊,周愿愿. 基于改进神经网络和Fluent的气液固技术的内表面处理[J]. 吉林大学学报(工学版), 2024, 54(6): 1537-1547. |

| [2] | 陈涛,周志刚,雷楠南. 粒子群算法下汽车机械式自动变速系统参数多目标优化[J]. 吉林大学学报(工学版), 2024, 54(5): 1214-1220. |

| [3] | 刘平义,李晓婷,高偌霖,李海涛,魏文军,王亚. 车辆侧倾驱动机构设计与试验[J]. 吉林大学学报(工学版), 2023, 53(8): 2185-2192. |

| [4] | 李岩,张久鹏,陈子璇,黄果敬,王培. 基于PCA-PSO-SVM的沥青路面使用性能评价[J]. 吉林大学学报(工学版), 2023, 53(6): 1729-1735. |

| [5] | 刘洋,刘吉成. 基于大数据与粒子群的清洁能源协同优化调度方法[J]. 吉林大学学报(工学版), 2023, 53(5): 1443-1448. |

| [6] | 吴剑,许斌. 基于CEEMDAN理论的堆积层滑坡位移区间预测模型及仿真[J]. 吉林大学学报(工学版), 2023, 53(2): 562-568. |

| [7] | 李杰,贾长旺,赵旗. 车辆转向非线性平衡状态求解及其稳定性确定[J]. 吉林大学学报(工学版), 2023, 53(12): 3326-3334. |

| [8] | 张铮,朱齐丹,吕晓龙,樊星. 冗余机械臂运动学逆解的求解优化方法[J]. 吉林大学学报(工学版), 2023, 53(12): 3379-3387. |

| [9] | 应沛然,曾小清,沈拓,袁腾飞,宋海峰,王奕曾. 基于冗余工序编码的高速列车节能驾驶智能算法[J]. 吉林大学学报(工学版), 2023, 53(12): 3404-3414. |

| [10] | 陈永刚,许继业,王海涌,熊文祥. 基于自适应神经模糊网络的转辙机故障诊断方法[J]. 吉林大学学报(工学版), 2023, 53(11): 3274-3280. |

| [11] | 管仁初,贺宝润,梁艳春,时小虎. 基于亲缘关系选择的粒子群优化算法[J]. 吉林大学学报(工学版), 2022, 52(8): 1842-1849. |

| [12] | 陈昭明,邹劲松,王伟,石明全. 改进粒子群神经网络融合有限元分析的铸锻双控动态成型多目标优化[J]. 吉林大学学报(工学版), 2022, 52(7): 1524-1533. |

| [13] | 邢海燕,刘超,徐成,陈玉环,王松弘泽. 基于粒子群优化模糊C焊缝等级磁记忆定量识别模型[J]. 吉林大学学报(工学版), 2022, 52(3): 525-532. |

| [14] | 罗巍,卢博,陈菲,马腾. 基于PSO-SVM及时序环节的数控刀架故障诊断方法[J]. 吉林大学学报(工学版), 2022, 52(2): 392-399. |

| [15] | 李翠玉,胡雅梦,康亚伟,张德良. 应用自适应遗传算法的电动汽车充放电协同调度[J]. 吉林大学学报(工学版), 2022, 52(11): 2508-2513. |

|

||