吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (4): 1007-1018.doi: 10.13229/j.cnki.jdxbgxb.20210836

• 车辆工程·机械工程 •

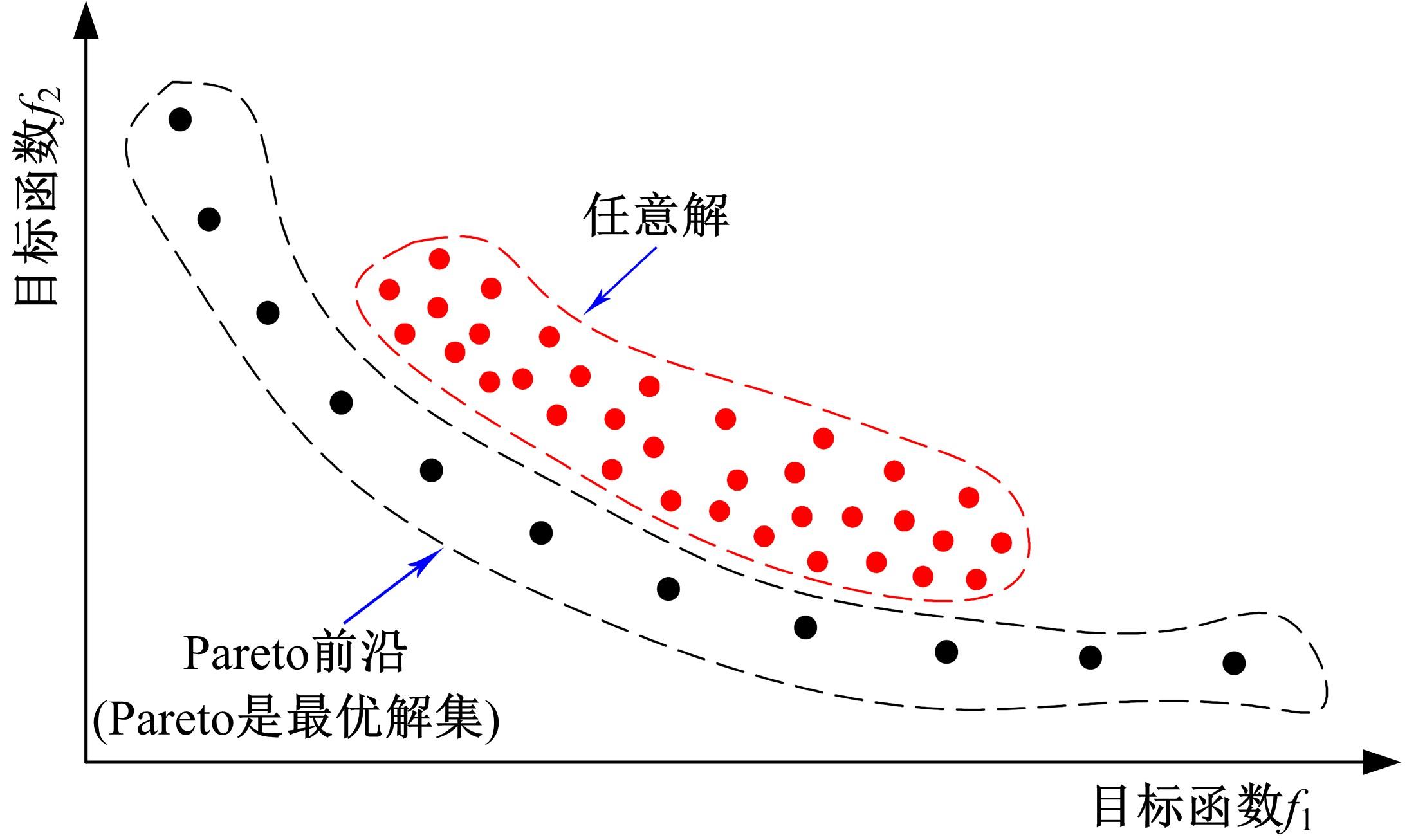

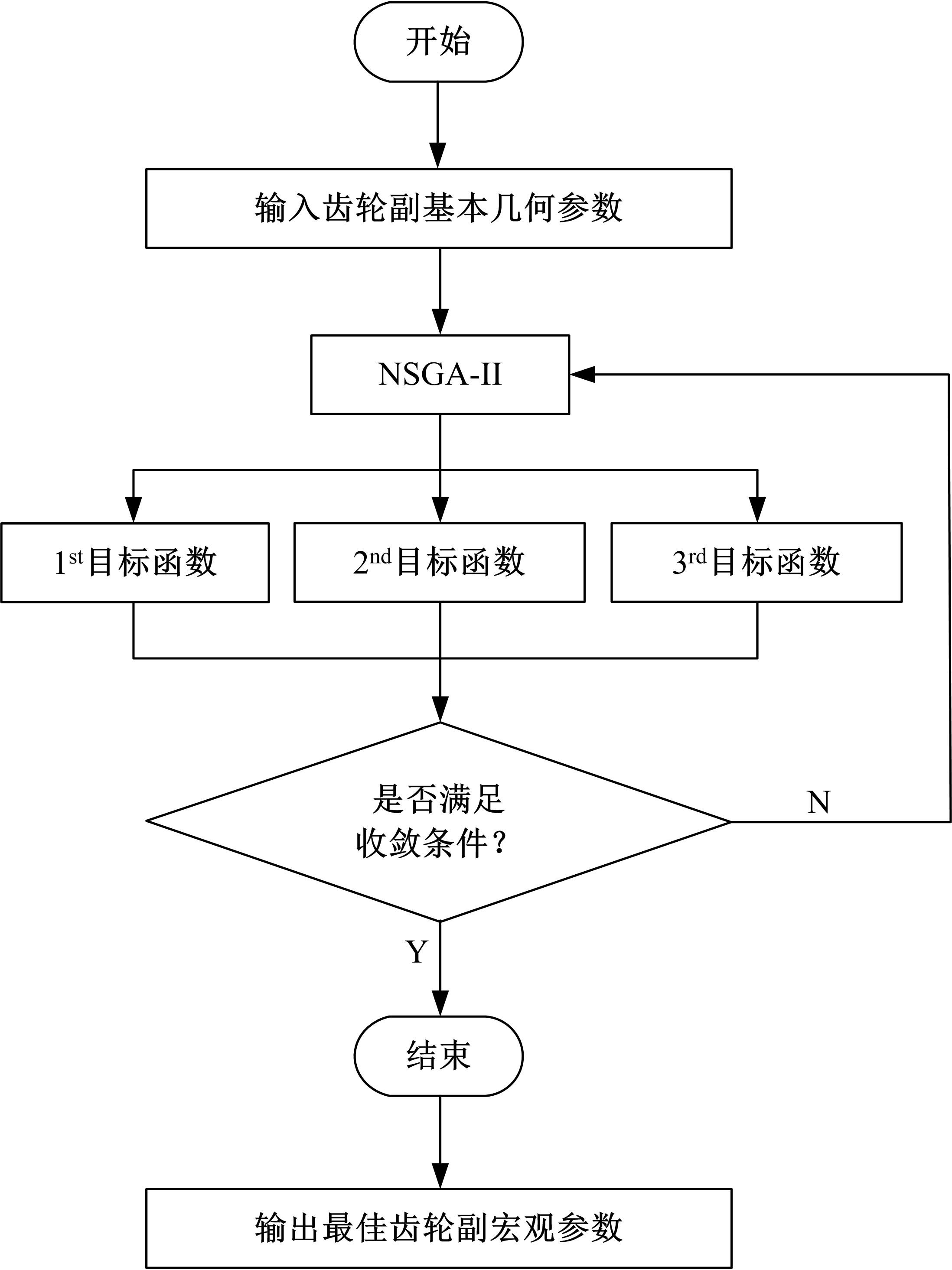

基于NSGA⁃II的斜齿轮宏观参数多目标优化

- 1.吉林大学 汽车仿真与控制国家重点实验室,长春 130022

2.中国重汽集团 汽车研究总院,济南 250100

Multi⁃objective optimization of macro parameters of helical gear based on NSGA⁃Ⅱ

Hong-bo YANG1( ),Wen-ku SHI1(

),Wen-ku SHI1( ),Zhi-yong CHEN1,Nian-cheng GUO2,Yan-yan ZHAO2

),Zhi-yong CHEN1,Nian-cheng GUO2,Yan-yan ZHAO2

- 1.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

2.Automotive Research Institute,China National Heavy Duty Truck (Group Corp. ),Jinan 250100,China

摘要:

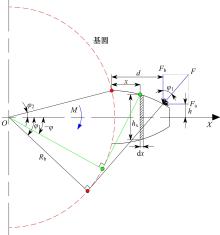

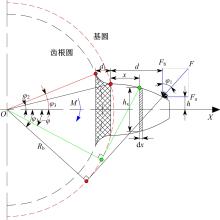

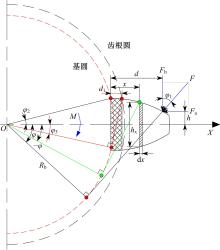

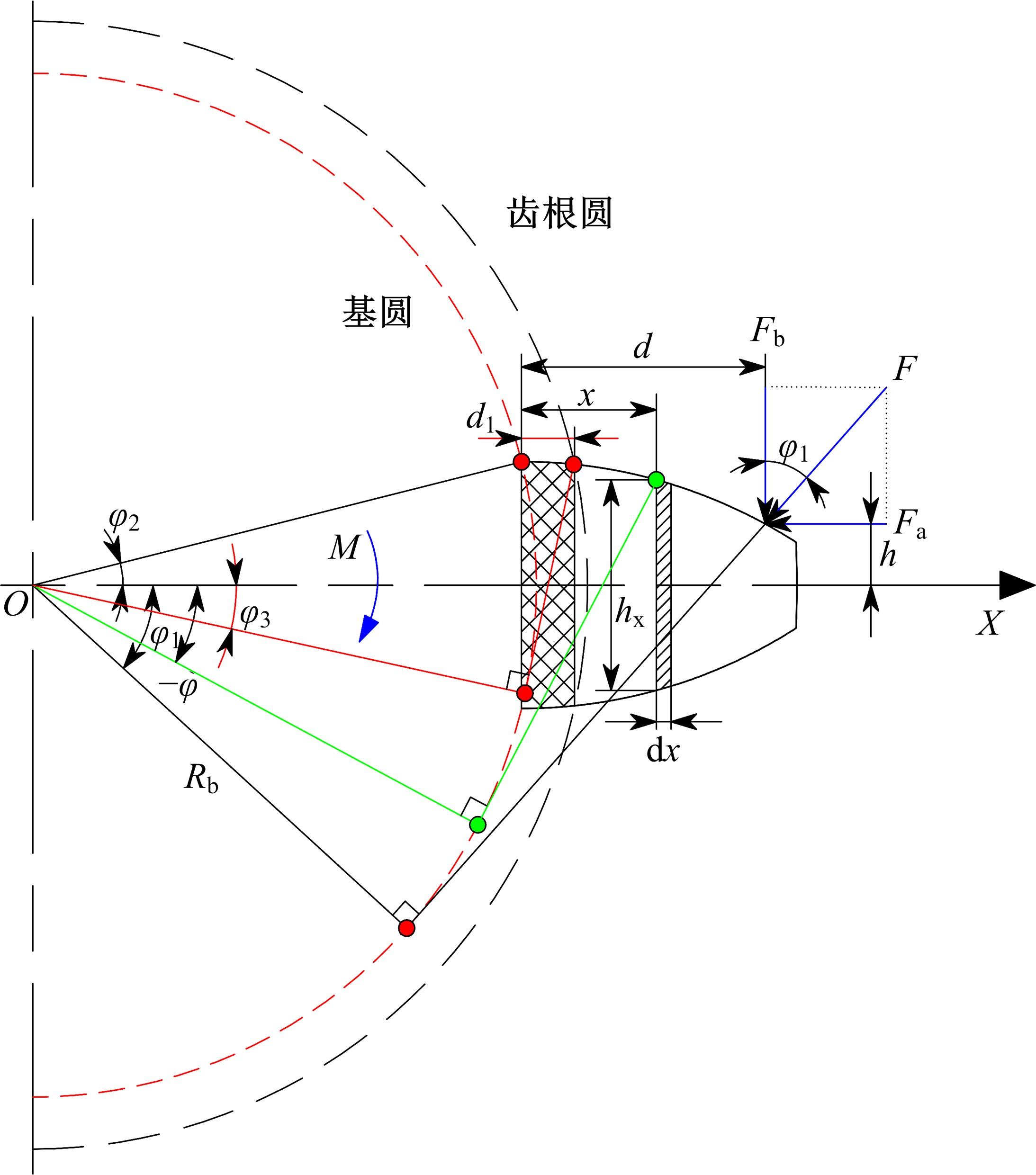

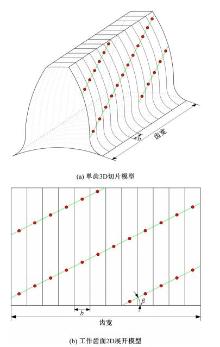

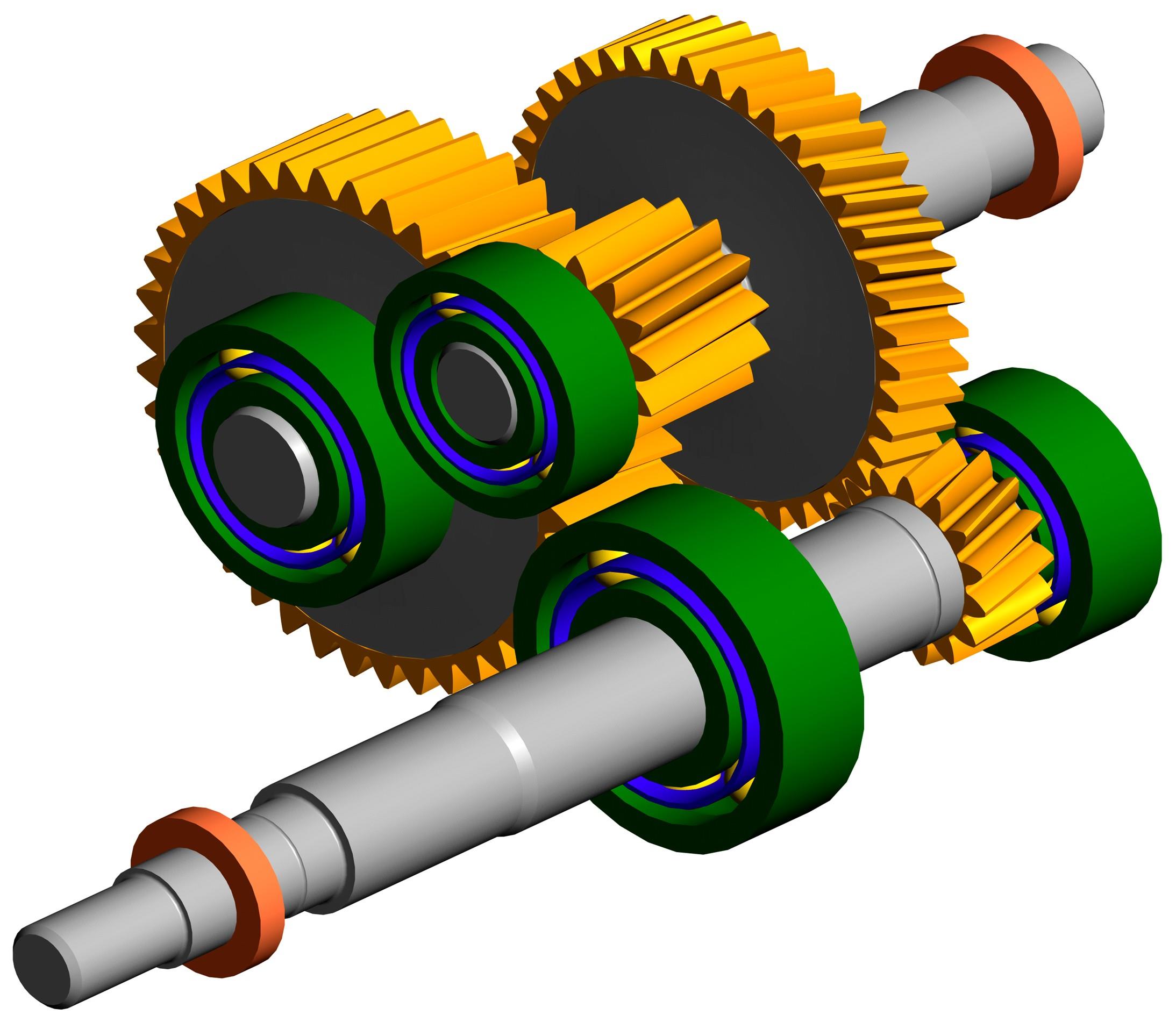

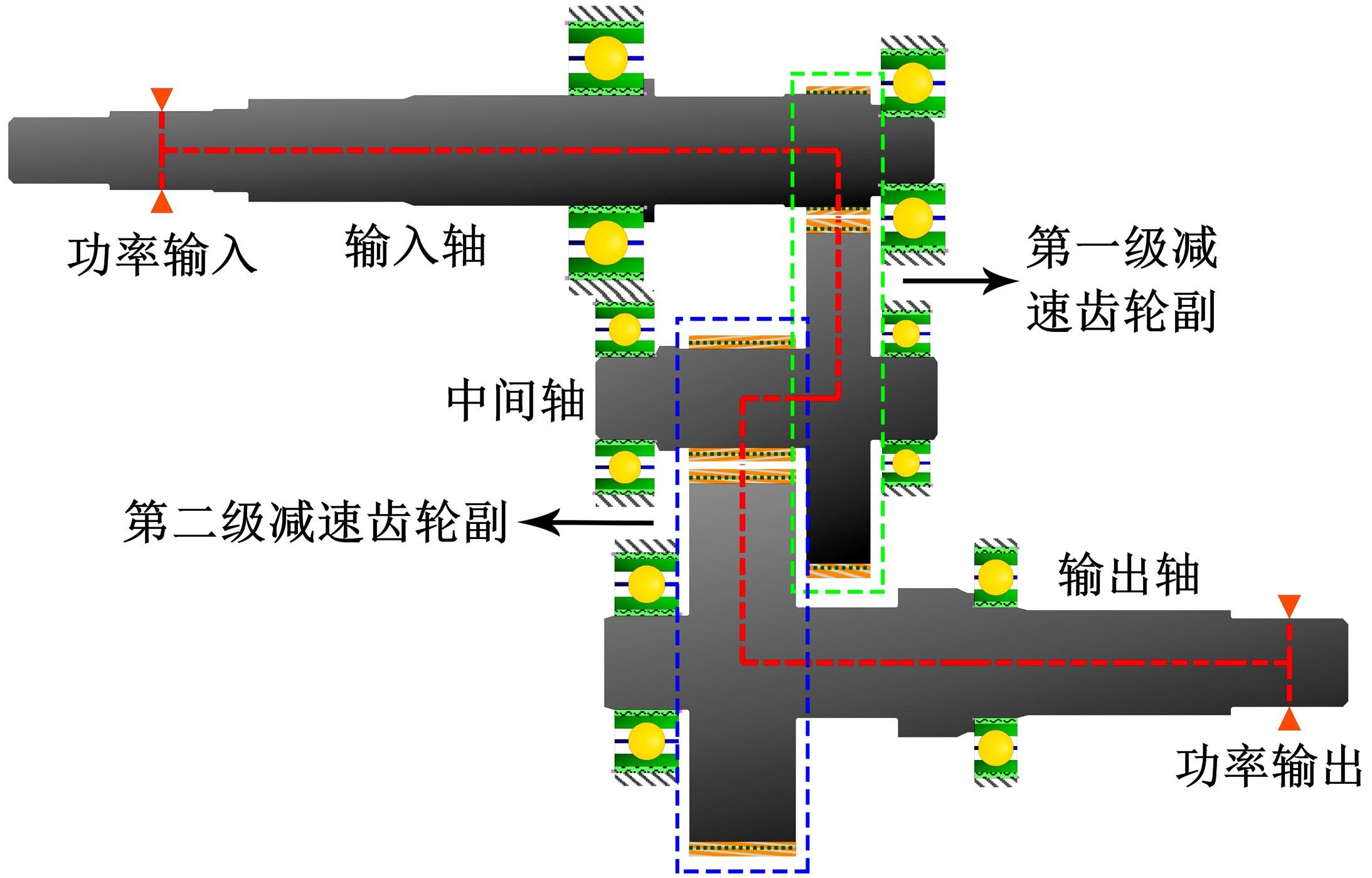

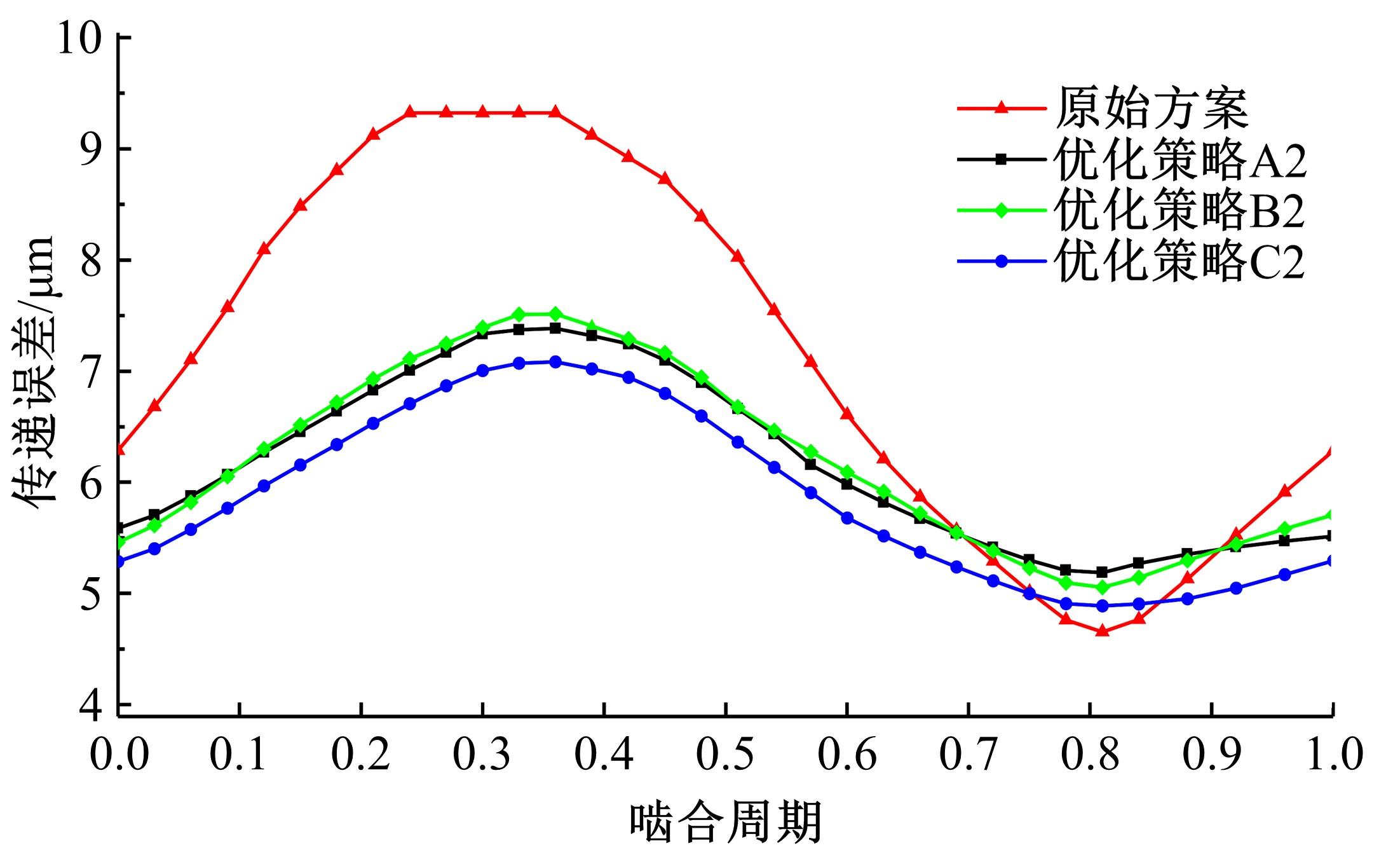

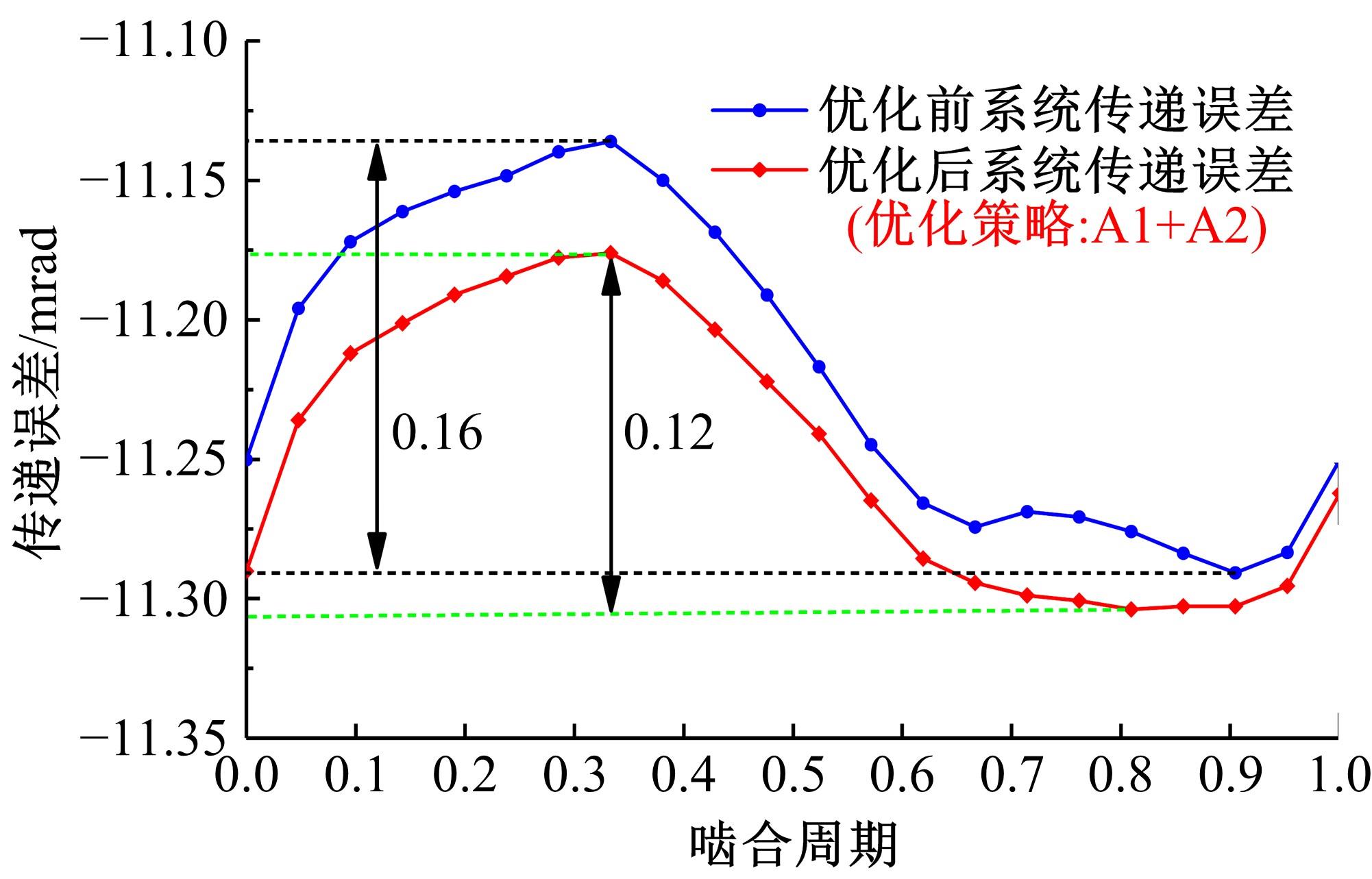

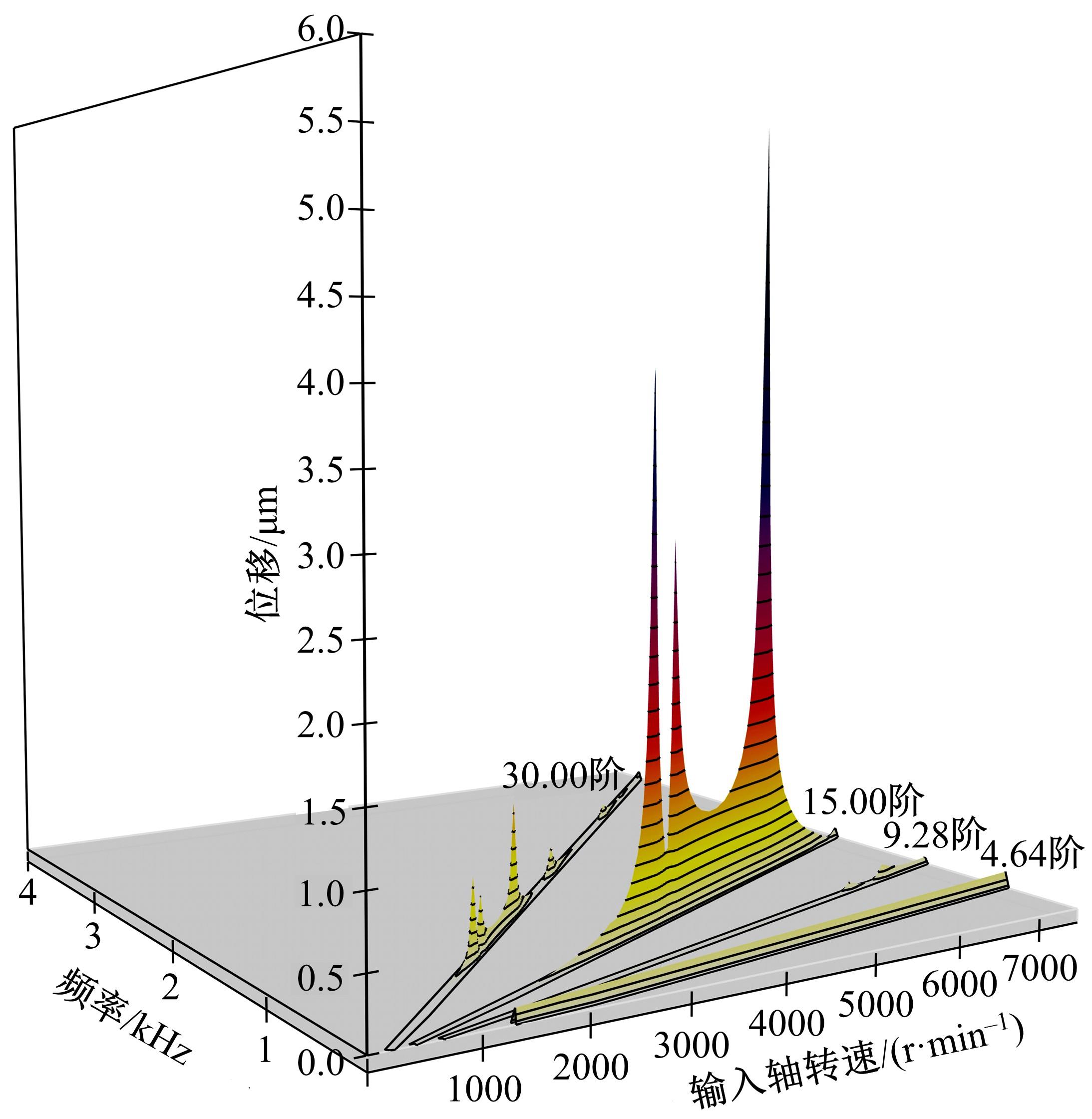

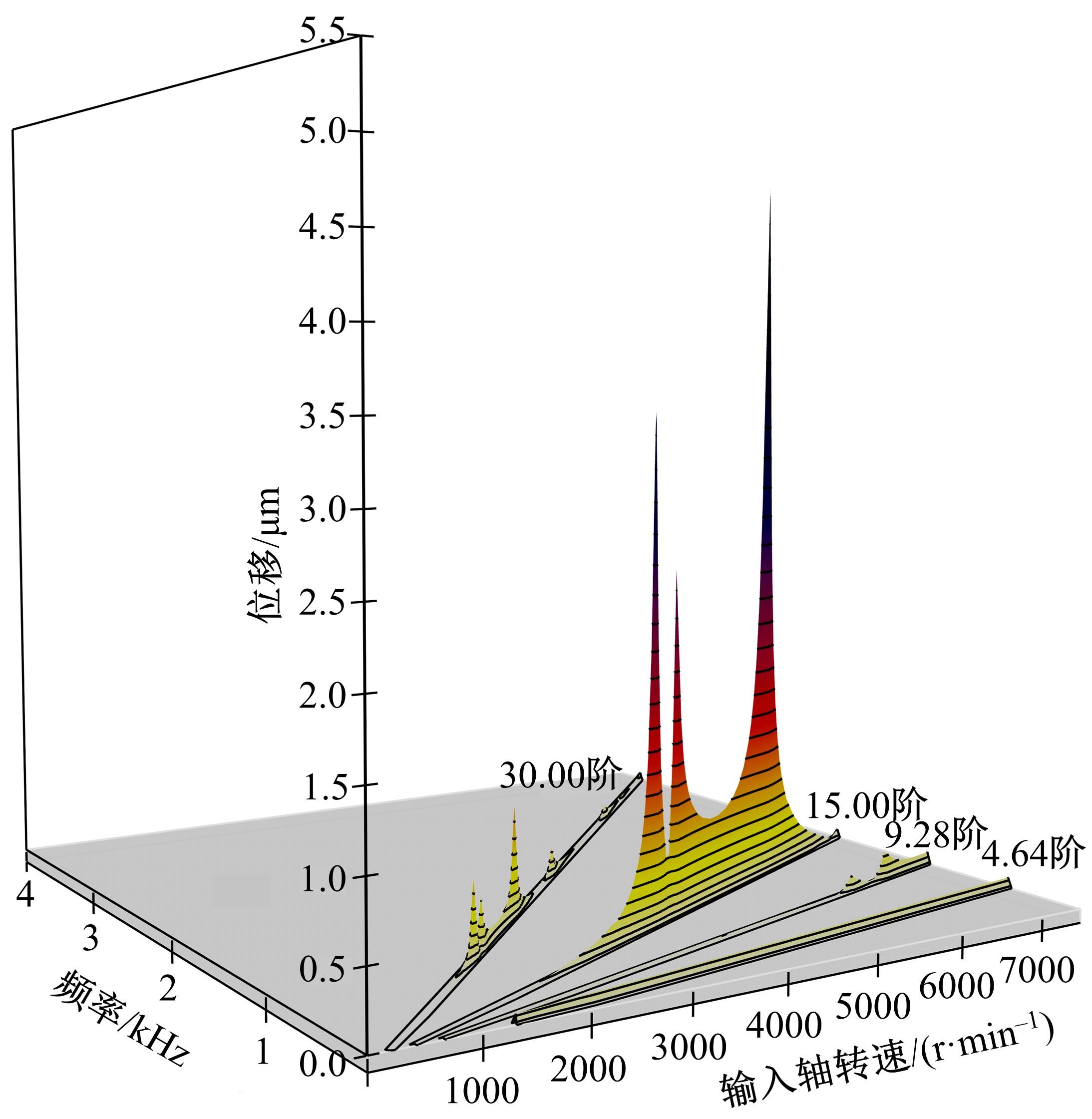

针对齿轮系统在初始设计阶段存在传递误差波动量大,进而导致的振动噪声突出等问题,提出了一种齿轮副宏观参数多目标优化方法。基于势能法和切片法推导出了斜齿轮传递误差解析计算公式,并以齿轮副总重合度最大、传递误差波动量最小和齿轮副总体积最小为优化目标,以齿轮宏观参数为设计变量,以带精英策略的快速非支配排序遗传算法(NSGA-Ⅱ)为优化算法,建立了齿轮系统宏观参数优化模型。以某二级减速齿轮系统为算例,采用优化模型对齿轮副宏观参数进行了优化设计,基于MASTA软件对优化前、后的动力学指标进行了仿真。结果表明,不同工况下,经过宏观参数优化后的齿轮系统啮合传递误差波动量、系统传递误差波动量和轴承座振动位移幅值均得到不同程度的降低,系统动力学性能得到整体改善。

中图分类号:

- TH132.41

| 1 | 齿轮手册编委会. 齿轮手册(上册) [M]. 北京:机械工业出版社, 1990. |

| 2 | 李润方, 王建军. 齿轮系统动力学—振动·冲击·噪声 [M]. 北京: 科学出版社, 1997. |

| 3 | 刘艳芳, 赖俊斌, 岳会军, 等. 斜齿轮振动噪声分析方法[J]. 振动、测试与诊断, 2016, 36(5): 960-966, 1027-1028. |

| Liu Yan-fang, Lai Jun-bin, Yue Hui-jun, et al. Research on the noise and vibration of the helical gear[J]. Journal of Vibration, Measurement & Diagnosis, 2016, 36(5): 960-966, 1027-1028. | |

| 4 | Cai Y, Hayashi T. The optimum modification of tooth profile for a pair of spur gears to make its rotational vibration equal zero[C]∥Proceedings of International Power Transmission and Gearing Conference,Tokyo,Japan, 1992, 57: 3957-3963. |

| 5 | 付学中, 方宗德, 贾超, 等. 面齿轮传动啮合刚度分析与修形减振优化[J]. 振动与冲击, 2019, 38(5): 265-272. |

| Fu Xue-zhong, Fang Zong-de, Jia Chao, et al. Meshing stiffness analysis and optimization of vibration reduction and modification for face-gear drives[J]. Journal of Vibration and Shock, 2019, 38(5): 265-272. | |

| 6 | 张容川, 周云山, 胡哓岚, 等. 双排行星齿轮系统的齿轮优化修形[J]. 汽车工程, 2018, 40(9): 1118-1124. |

| Zhang Rong-chuan, Zhou Yun-shan, Hu Xiao-lan, et al. The optimized gear modification for double-row planetary gear train[J]. Automotive Engineering, 2018, 40(9): 1118-1124. | |

| 7 | 赵宁, 康士朋, 郭辉, 等. 基于遗传算法的弧齿锥齿轮动态特性优化设计[J]. 航空动力学报, 2010, 25(10): 2396-2402. |

| Zhao Ning, Kang Shi-peng, Guo Hui, et al. Optimization design of spiral bevel gear's dynamic characteristics based on genetic algorithm[J]. Journal of Aerospace Power, 2010, 25(10): 2396-2402. | |

| 8 | 赵宁, 秋朋园, 刘贵立. 高重合度人字齿轮传动动态性能优化设计[J]. 国防科技大学学报, 2015, 37(2): 166-174. |

| Zhao Ning, Qiu Peng-yuan, Liu Gui-li. Optimized design of dynamic behavior of double helical gears with high contact ratio[J]. Journal of National University of Defense Technology, 2015, 37(2): 166-174. | |

| 9 | 杨硕文, 唐进元. 一种新的直齿轮复合修形设计方法 [J]. 中南大学学报: 自然科学版, 2019, 50(5): 1082-1088. |

| Yang Shuo-wen, Tang Jin-yuan. A new design method for compound modification of spur gear[J]. Journal of Central South University (Science and technology), 2019, 50(5): 1082-1088. | |

| 10 | 贾超, 方宗德. 高速齿轮传递误差和啮入冲击的激励模拟及齿面优化修形[J]. 振动与冲击, 2019, 38(23): 103-109, 138. |

| Jia Chao, Fang Zong-de. Simulation for transmission error and mesh-in impact excitation of high speed gears and their tooth surface optimal modification[J]. Journal of Vibration and Shock, 2019, 38(23): 103-109, 138. | |

| 11 | 赵宁, 秋朋园, 刘贵立. 高重合度人字齿轮轮齿最佳修形优化设计[J]. 国防科技大学学报, 2015, 37(1): 165-170. |

| Zhao Ning, Qiu Peng-yuan, Liu Gui-li. Modification optimization of double helical gears with high contact ratio [J]. Journal of National University of Defense Technology, 2015, 37(1): 165-170. | |

| 12 | 王峰, 方宗德, 李声晋, 等. 人字齿轮系统振动传递分析优化与试验验证[J]. 机械工程学报, 2015, 51(1): 34-42. |

| Wang Feng, Fang Zong-de, Li Sheng-jin, et al. Analysis optimization and experimental verification of herringbone gear transmission system[J]. Journal of Mechanical Engineering, 2015, 51(1): 34-42. | |

| 13 | 贾超, 方宗德, 张永振. 高速内啮合人字齿轮多目标优化修形[J]. 哈尔滨工业大学学报, 2017, 49(1): 166-172. |

| Jia Chao, Fang Zong-de, Zhang Yong-zhen. Multi-objective optimal modification for internal double helical gears with high speed[J]. Journal of Harbin Institute of Technology, 2017, 49(1): 166-172. | |

| 14 | 刘玄, 方宗德, 赵宁. 人字齿轮小轮轴向窜动的多目标复合修形优化[J]. 西安交通大学学报, 2021, 55(1): 118-126. |

| Liu Xuan, Fang Zong-de, Zhao Ning. Multi-objective compound modification optimization of pinion axial floating for the double helical gears[J]. Journal of Xi'an Jiaotong University, 2021, 55(1): 118-126. | |

| 15 | 蒋春明, 阮米庆. 汽车机械式变速器多目标可靠性优化设计[J]. 汽车工程, 2007, 29(12): 1090-1093. |

| Jiang Chun-ming, Ruan Mi-qing. Multi-objective reliability optimal design of automotive mechanical transmission [J]. Automotive Engineering, 2007, 29(12): 1090-1093. | |

| 16 | Chen X, Song C S, Zhu C C, et al. Effect of macro-parameters on vibration and radiation noise for high speed wheel gear transmission in electric vehicles[J]. Journal of Mechanical Science and Technology, 2018, 32(9): 4153-4164. |

| 17 | 宗长富, 任明辉, 万滢, 等. 变速器斜齿轮宏观参数减振优化设[J]. 吉林大学学报: 工学版, 2016, 46(6): 1772-1779. |

| Zong Chang-fu, Ren Ming-hui, Wan Ying, et al. Optimization of macro-geometric parameters of helical gears of transmissions to reduce vibration[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(6): 1772-1779. | |

| 18 | 赵宁, 杨杰. 高重合度圆柱齿轮传动多目标优化设计 [J]. 机械传动, 2012, 36(7): 43-46. |

| Zhao Ning, Yang Jie. Multi-objective optimization design of high contact ratio cylindrical gear drive [J]. Journal of Mechanical Transmission, 2012, 36(7): 43-46. | |

| 19 | 何畅然, 贺敬良, 何渠. 基于MASTA的齿轮变速箱啸叫研究[J]. 北京信息科技大学学报, 2014, 29(5): 87-91. |

| He Chang-ran, He Jing-liang, He Qu. Research on geared transmission whine based on MASTA[J]. Journal of Beijing Information Science and Technology University, 2014, 29(5): 87-91. | |

| 20 | Garambois P, Perret-Liaudet J, Rigaud E. NVH robust optimization of gear macro and microgeometries using an efficient tooth contact model[J]. Mechanism and Machine Theory, 2017, 117: 78-95. |

| 21 | Garambois P, Rigaud E, Perret-Liaudet J. Robust optimization of gear macro and micro-geometries in order to minimize static transmission error and gear stiffness fluctuations[J]. International Conference on Gears, 2017, 2294(1/2): 927-938. |

| 22 | 蔡文奇. 纯电动汽车两挡变速箱齿轮振动噪声仿真分析与优化设计[D]. 长春: 吉林大学机械与航空航天工程学院, 2019. |

| Cai Wen-qi. Simulation analysis of gear vibration noise and optimization design of pure electic vehicle two-speed gearbox[D]. Changchun: College of Mechanical and Aerospace Engineering, Jilin University, 2019. | |

| 23 | 包英豪. 纯电动汽车两挡变速箱噪声与效率分析及参数优化[D]. 长春: 吉林大学汽车工程学院, 2020. |

| Bao Ying-hao. Noise and efficiency analysis and parameter optimization of two-speed transmission of pure electric vehicle[D]. Changchun: College of Automotive Engineering, Jilin University, 2020. | |

| 24 | 张利, 黄筱调, 谢杰, 等. 基于Romax的斜齿圆柱齿轮减速器参数优化[J]. 机械设计与制造, 2020, 57(6): 215-218. |

| Zhang Li, Huang Xiao-diao, Xie Jie, et al. Parameter optimization of helical cylindrical gear reducer based on Romax[J]. Machinery Design and Manufacture, 2020, 57(6): 215-218. | |

| 25 | 赵宁, 秋朋园, 刘贵立. 高重合度人字齿轮轮齿最佳修形优化设计[J]. 国防科技大学学报, 2015, 37(1): 165-170. |

| Zhao Ning, Qiu Peng-yuan, Liu Gui-li. Modification optimization of double helical gears with high contact ratio [J]. Journal of National University of Defense Technology, 2015, 37(1): 165-170. | |

| 26 | 王峰, 方宗德, 李声晋, 等. 人字齿轮系统振动传递分析优化与试验验证[J]. 机械工程学报, 2015, 51(1): 34-42. |

| Wang Feng, Fang Zong-de, Li Sheng-jin, et al. Analysis optimization and experimental verification of herringbone gear transmission system[J]. Journal of Mechanical Engineering, 2015, 51(1): 34-42. | |

| 27 | 刘宗晟. 变速器动力学建模与振动噪声分析[D]. 长春: 吉林大学机械与航空航天工程学院, 2016. |

| Liu Zong-sheng. Dynamics modeling and vibro-acoustic characteristics analysis of transmission [D]. Changchun: College of Mechanical and Aerospace Engineering, Jilin University, 2016. | |

| 28 | Yang D, Lin J Y. Hertzian damping, tooth friction and bending elasticity in gear impact dynamics[J]. Journal of Mechanisms, Transmissions, and Automation in Design, 1987, 109(2): 189-196. |

| 29 | Tian X. Dynamic simulation for system response of gearbox including localized gear faults[D]. Alberta, Canada: University of Alberta, 2004. |

| 30 | Sainsot P, Velex P, Duverger O. Contribution of gear body to tooth deflections——a new bidimensional analytical formula[J]. Journal of Mechanical Design, 2004, 126(4): 748-752. |

| 31 | Wan Z G, Cao H R, Zi Y Y, et al. An improved time-varying mesh stiffness algorithm and dynamic modeling of gear-rotor system with tooth root crack[J]. Engineering Failure Analysis, 2014, 42: 157-177. |

| 32 | 成大先. 机械设计手册[M].6版. 北京: 化学工业出版社, 2016. |

| 33 | Deb K, Member A, Pratap A, et al. A fast and elitist multiobjective genetic algorithm: NSGA-Ⅱ[J]. Transactions on Evolutionary Computation, 2002, 6(2): 182-197. |

| 34 | Ahmed F, Deb K. Multi-objective optimal path planning using elitist non-dominated sorting genetic algorithms[J]. Soft Computing, 2013, 17(7): 1283-1299. |

| 35 | 付学中, 方宗德, 关亚彬, 等. 基于NSGA-Ⅱ算法的面齿轮副小轮拓扑修形多目标优化[J]. 西安交通大学学报, 2017, 51(7): 98-104. |

| Fu Xue-zhong, Fang Zong-de, Guan Ya-bin, et al. NSGA-Ⅱ based multi-objective optimization on topologically modified pinions for face gear pairs[J]. Journal of Xi'an Jiaotong University, 2017, 51(7): 98-104. | |

| 36 | Yao Q Z. Multi-objective optimization design of spur gear based on NSGA-Ⅱ and decision making[J]. Advances in Mechanical Engineering, 2019, 11(3): 1-8. |

| [1] | 田彦涛,许富强,王凯歌,郝子绪. 考虑周车信息的自车期望轨迹预测[J]. 吉林大学学报(工学版), 2023, 53(3): 674-681. |

| [2] | 高松,王玉琼,王玉海,徐艺,周英超,王鹏伟. 智能汽车纵横向整体反馈线性化控制[J]. 吉林大学学报(工学版), 2023, 53(3): 735-745. |

| [3] | 郭洪艳,于文雅,刘俊,戴启坤. 复杂场景智能车辆车道与速度一体化滚动优化决策[J]. 吉林大学学报(工学版), 2023, 53(3): 693-703. |

| [4] | 谢波,高榕,许富强,田彦涛. 低附着路况条件下人车共享转向系统稳定控制[J]. 吉林大学学报(工学版), 2023, 53(3): 713-725. |

| [5] | 何科,丁海涛,赖宣淇,许男,郭孔辉. 基于Transformer的轮式里程计误差预测模型[J]. 吉林大学学报(工学版), 2023, 53(3): 653-662. |

| [6] | 刘嫣然,孟庆瑜,郭洪艳,李嘉霖. 图注意力模式下融合高精地图的周车轨迹预测[J]. 吉林大学学报(工学版), 2023, 53(3): 792-801. |

| [7] | 田彦涛,季言实,唱寰,谢波. 深度强化学习智能驾驶汽车增广决策模型[J]. 吉林大学学报(工学版), 2023, 53(3): 682-692. |

| [8] | 张建,刘金波,高原,刘梦可,高振海,杨彬. 基于多模交互的车载传感器定位算法[J]. 吉林大学学报(工学版), 2023, 53(3): 772-780. |

| [9] | 佘智勇,朱彤鸣,刘旺魁. 基于近端策略优化的高速无人飞行器上升段在线轨迹规划[J]. 吉林大学学报(工学版), 2023, 53(3): 863-870. |

| [10] | 何科,丁海涛,许男,郭孔辉. 基于摄像头和车道线的增强定位系统[J]. 吉林大学学报(工学版), 2023, 53(3): 663-673. |

| [11] | 朱冰,范天昕,赵健,张培兴,孙宇航. 基于危险边界搜索的自动驾驶系统加速测试方法[J]. 吉林大学学报(工学版), 2023, 53(3): 704-712. |

| [12] | 何颖,樊俊松,王巍,孙庚,刘衍珩. 无人机空地安全通信与航迹规划的多目标联合优化方法[J]. 吉林大学学报(工学版), 2023, 53(3): 913-922. |

| [13] | 马敏,胡大伟,舒兰,马壮林. 城市轨道交通网络韧性评估及恢复策略[J]. 吉林大学学报(工学版), 2023, 53(2): 396-404. |

| [14] | 王登峰,陈宏利,那景新,陈鑫. 单双搭接接头经高温老化后的失效对比[J]. 吉林大学学报(工学版), 2023, 53(2): 346-354. |

| [15] | 张佩,王志伟,杜常清,颜伏伍,卢炽华. 车用质子交换膜燃料电池空气系统过氧比控制方法[J]. 吉林大学学报(工学版), 2022, 52(9): 1996-2003. |

|

||