吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (2): 346-354.doi: 10.13229/j.cnki.jdxbgxb20210087

单双搭接接头经高温老化后的失效对比

- 吉林大学 汽车仿真与控制国家重点实验室,长春 130022

Failure comparison of single and double lap joints after high temperature aging

Deng-feng WANG( ),Hong-li CHEN,Jing-xin NA,Xin CHEN(

),Hong-li CHEN,Jing-xin NA,Xin CHEN( )

)

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

摘要:

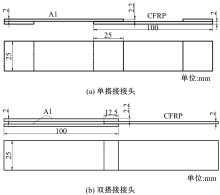

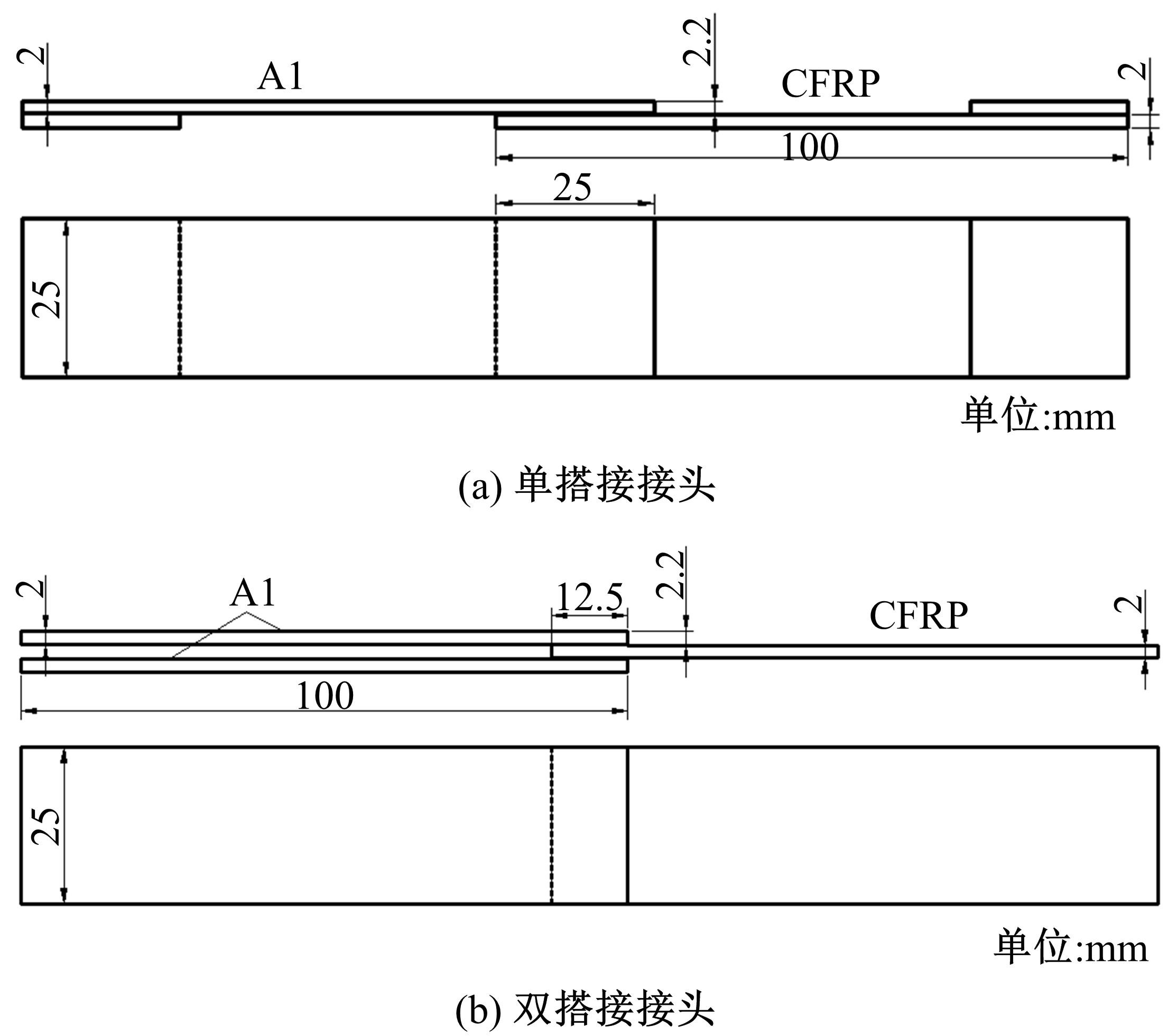

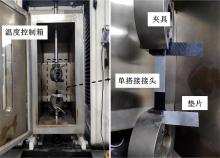

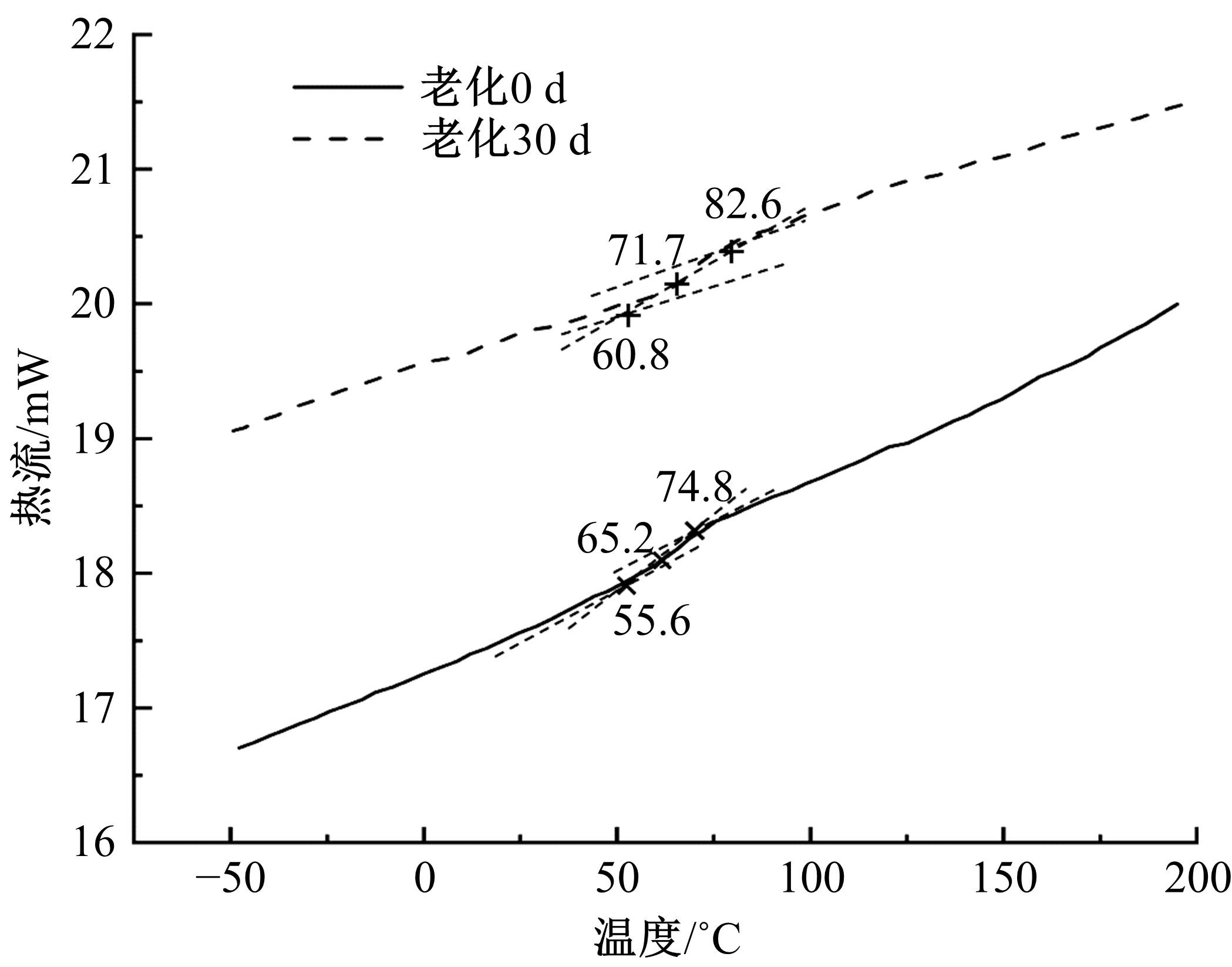

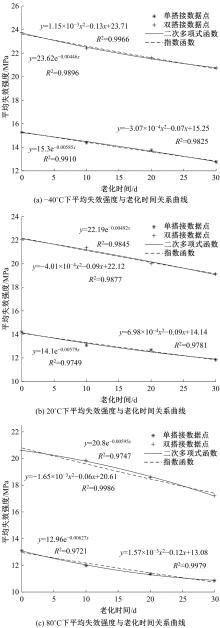

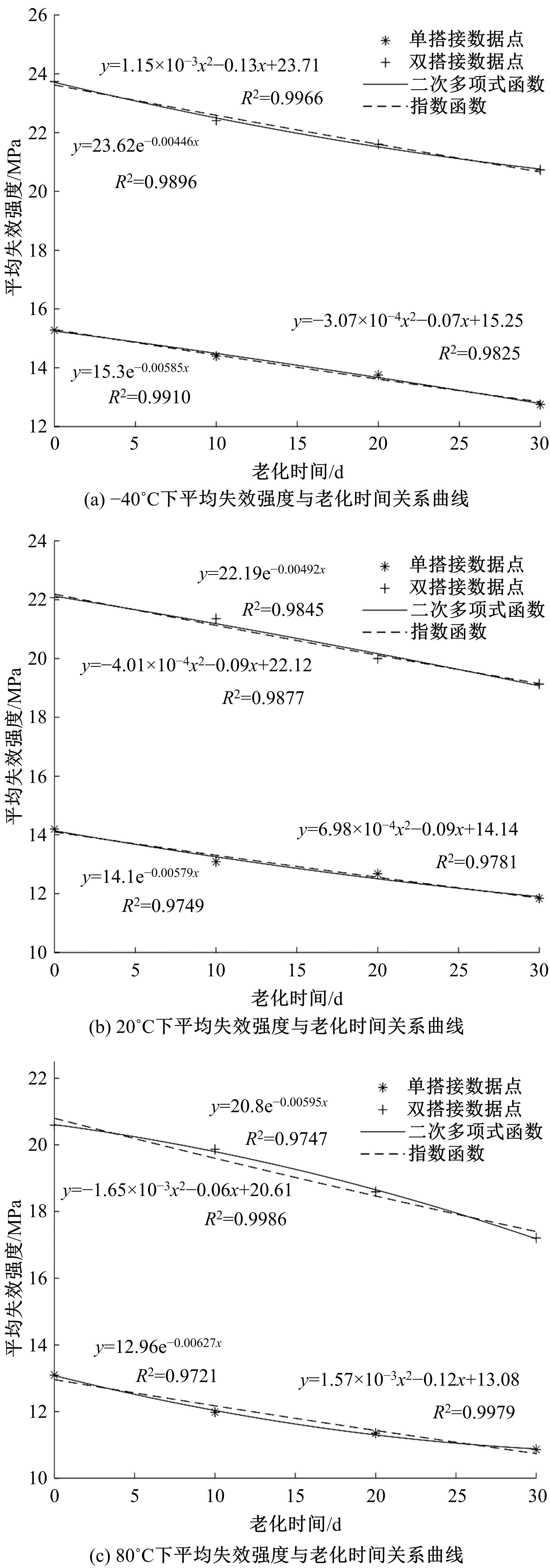

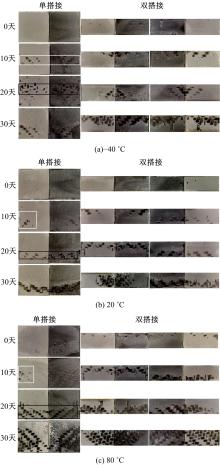

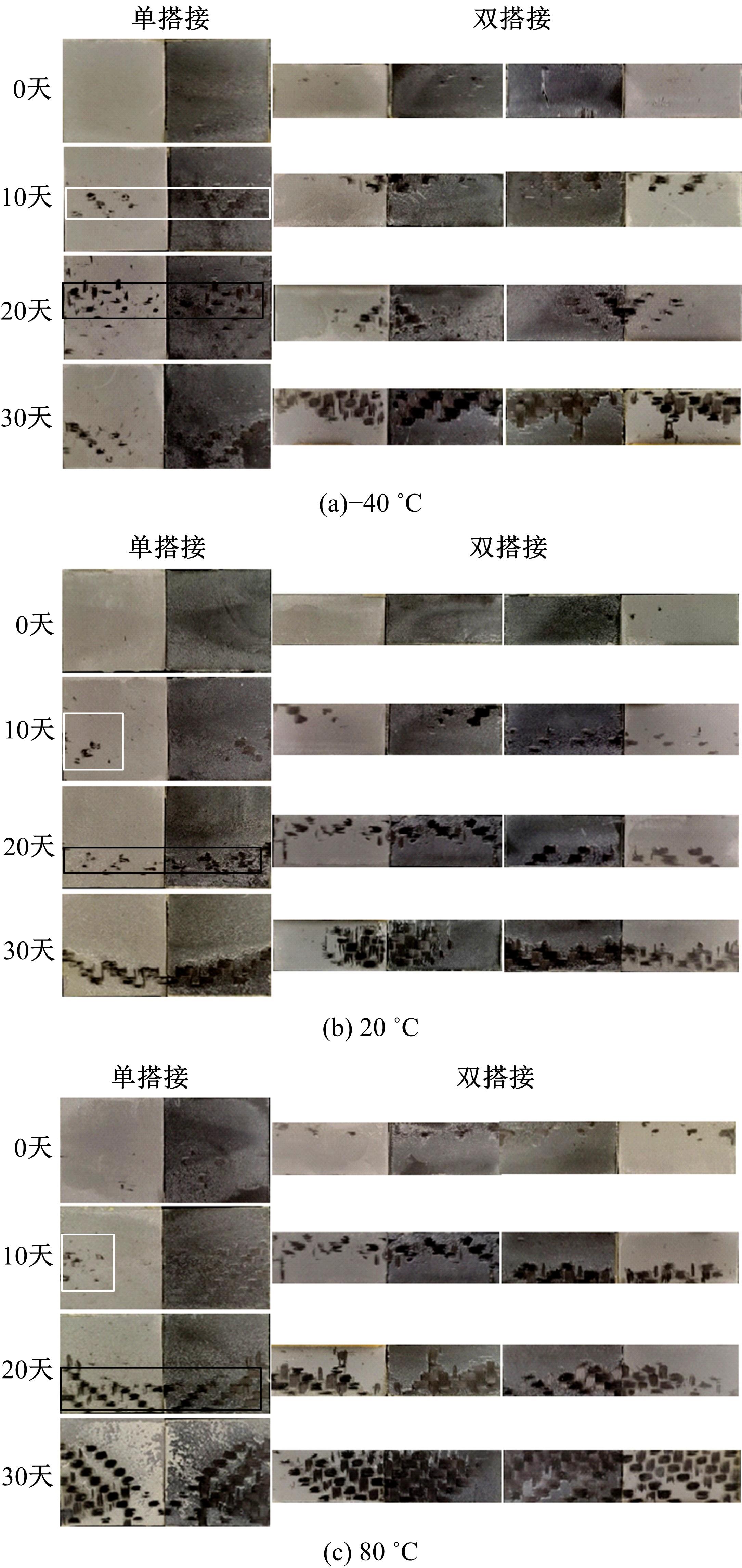

为了对比研究单双搭接接头在高温老化后的失效情况,加工制作了一批Al-CFRP单搭接接头和Al-CFRP-Al双搭接接头。选取80°C高温老化周期0、10、20、30d,并在-40、20、80°C环境下进行准静态拉伸试验,建立一元回归与二元回归模型,分析总结搭接接头失效强度与失效形式变化规律,揭示老化机理。结果表明:老化时间的增加和服役温度的升高都会造成接头失效强度显著下降,服役温度比老化时间对失效强度的影响更大、相关性更高;双搭接接头失效强度明显高于单搭接接头,在工程应用中,在一定条件下可以用双搭接连接来代替单搭接连接以获取更大的承载能力。随着老化时间的增加,搭接接头失效形式从内聚失效变为混合失效并伴随纤维撕裂的出现,老化时间越长,纤维撕裂越明显,通过SEM电镜观察到老化后的CFRP树脂明显减少,CFRP基体与树脂间结合力降低,导致其更容易发生纤维撕裂现象。

中图分类号:

- U463.82

| 1 | , 轻型汽车污染物排放限值及测量方法(中国第六阶段) [S]. |

| 2 | 谭伟, 那景新, 任俊铭, 等. 高低温老化对碳纤维增强复合材料层间力学性能的影响[J]. 吉林大学学报:工学版, 2020, 50(4): 1324-1332. |

| Tan Wei, Na Jing-xin, Ren Jun-ming, et al. Effect of high and low temperature aging on interlaminar mechanical properties of carbon fiber reinforced composites[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(4): 1324-1332. | |

| 3 | Witik R A, Payet J, Michaud V, et al. Assessing the life cycle costs and environmental performance of lightweight materials in automobile applications[J]. Composites Part A: Applied Science and Manufacturing, 2011, 42(11): 1694-1709. |

| 4 | 慕文龙,那景新,谭伟,等.基于FTIR分析的CFRP-铝合金粘接接头剩余强度预测[J].吉林大学学报:工学版, 2021, 51(1): 139-146. |

| Mu Wen-long, Na Jing-xin, Tan Wei, et al. Residual strength prediction of adhesive CFRP-aluminum alloy adhesively bonded joint based on FTIR analysis[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 139-146. | |

| 5 | Liu Q, Lin Y, Zong Z, et al. Lightweight design of carbon twill weave fabric composite body structure for electric vehicle[J]. Composite Structures, 2013, 97: 231-238. |

| 6 | Budhe S, Banea M D, De Barros S, et al. An updated review of adhesively bonded joints in composite materials[J]. International Journal of Adhesion and Adhesives, 2017, 72: 30-42. |

| 7 | Groche P, Wohletz S, Brenneis M, et al. Joining by forming—a review on joint mechanisms, applications and future trends[J]. Journal of Materials Processing Technology, 2014, 214(10): 1972-1994. |

| 8 | Costa M, Viana G, da Silva L F M, et al. Environmental effect on the fatigue degradation of adhesive joints: a review[J]. The Journal of Adhesion, 2017, 93(1/2): 127-146. |

| 9 | 秦国锋,那景新,慕文龙,等.高温老化对CFRP/铝合金粘接接头失效的影响[J]. 吉林大学学报:工学版, 2019, 49(4): 1063-1071. |

| Qin Guo-feng, Na Jing-xin, Mu Wen-long,et al.Degradation failure of adhesively bonded CFRP/ aluminum alloy subjected to high temperature environment[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1063-1071. | |

| 10 | Pecora M, Pannier Y, Lafarie-Frenot M C, et al. Effect of thermo-oxidation on the failure properties of an epoxy resin[J]. Polymer Testing, 2016, 52: 209-217. |

| 11 | Wolfrum J, Eibl S, Lietch L. Rapid evaluation of long-term thermal degradation of carbon fibre epoxy composites [J]. Composites Science and Technology, 2009, 69(3/4): 523-530. |

| 12 | Yao M, Zhu D, Yao Y, et al. Experimental study on basalt FRP/steel single-lap joints under different loading rates and temperatures[J]. Composite Structures, 2016, 145: 68-79. |

| 13 | Qin G F, Na J X, Mu W L, et al. Effect of continuous high temperature exposure on the adhesive strength of epoxy adhesive, CFRP and adhesively bonded CFRP-aluminum alloy joints[J]. Composites Part B:Engineering, 2018, 154: 43-55. |

| 14 | Cassidy P E, Johnson J M, Locke C E. The relationship of glass transition temperature to adhesive strength[J]. The Journal of Adhesion, 1972, 4(3): 183-191. |

| 15 | Zhang Y, Adams R D, da Silva L F M. Effects of curing cycle and thermal history on the glass transition temperature of adhesives[J]. The Journal of Adhesion, 2014, 90(4): 327-345. |

| 16 | Banea M D, de Sousa F S M, da Silva L F M,et al. Effects of temperature and loading rate on the mechanical properties of a high temperature epoxy adhesive[J]. Journal of Adhesion Science and Technology, 2011, 25(18): 2461-2474. |

| 17 | Firmo J P, Roquette M G, Correia J R, et al. Influence of elevated temperatures on epoxy adhesive used in CFRP strengthening systems for civil engineering applications[J]. International Journal of Adhesion and Adhesives, 2019, 93: 102333. |

| 18 | 孙靖先,葛美周,赵香国,等.粘接在轨道交通车辆上的应用进展[J]. 机车车辆工艺, 2020(2): 15-16, 23. |

| Sun Jing-xian, Ge Mei-zhou, Zhao Xiang-guo,et al. Application progress of adhesive bonding in rail transit vehicles[J]. Locomotive & Rolling Stock Technology, 2020(2): 15-16, 23. | |

| 19 | Zamani P, Jaamialahmadi A, da Silva L F M. The influence of GNP and nano-silica additives on fatigue life and crack initiation phase of Al-GFRP bonded lap joints subjected to four-point bending[J]. Composites Part B: Engineering, 2021, 207: 108589. |

| 20 | Lin Y C, Chen X, Zhang H J, et al. Effects of hygrothermal aging on epoxy-based anisotropic conductive film[J]. Materials Letters, 2006, 60(24): 2958-2963. |

| 21 | Lowe A, Fox B, Otieno-Alego V. Interfacial ageing of high temperature carbon/bismaleimide composites[J]. Composites Part A: Applied Science and Manufacturing, 2002, 33(10): 1289-1292. |

| 22 | Skourlis T P, McCullough R L. The effect of temperature on the behavior of the interphase in polymeric composites[J]. Composites Science and Technology, 1993, 49(4): 363-368. |

| 23 | 陈仲堂,赵德平,李彦平.数理统计[M].北京:化学工业出版社, 2014. |

| 24 | Buch X, Shanahan M E R. Influence of the gaseous environment on the thermal degradation of a structural epoxy adhesive[J]. Journal of Applied Polymer Science, 2000, 76(7): 987-992. |

| 25 | Na J, Mu W, Qin G, et al. Effect of temperature on the mechanical properties of adhesively bonded basalt FRP-aluminum alloy joints in the automotive industry [J]. International Journal of Adhesion and Adhesives, 2018, 85: 138-148. |

| 26 | Liu S, Cheng X, Zhang Q, et al. An investigation of hygrothermal effects on adhesive materials and double lap shear joints of CFRP composite laminates[J]. Composites Part B: Engineering, 2016, 91: 431-440. |

| [1] | 王克勇,鲍大同,周苏. 基于数据驱动的车用燃料电池故障在线自适应诊断算法[J]. 吉林大学学报(工学版), 2022, 52(9): 2107-2118. |

| [2] | 曹起铭,闵海涛,孙维毅,于远彬,蒋俊宇. 质子交换膜燃料电池低温启动水热平衡特性[J]. 吉林大学学报(工学版), 2022, 52(9): 2139-2146. |

| [3] | 隗海林,王泽钊,张家祯,刘洋. 基于Avl-Cruise的燃料电池汽车传动比及能量管理策略[J]. 吉林大学学报(工学版), 2022, 52(9): 2119-2129. |

| [4] | 刘岩,丁天威,王宇鹏,都京,赵洪辉. 基于自适应控制的燃料电池发动机热管理策略[J]. 吉林大学学报(工学版), 2022, 52(9): 2168-2174. |

| [5] | 李丞,景浩,胡广地,刘晓东,冯彪. 适用于质子交换膜燃料电池系统的高阶滑模观测器[J]. 吉林大学学报(工学版), 2022, 52(9): 2203-2212. |

| [6] | 张佩,王志伟,杜常清,颜伏伍,卢炽华. 车用质子交换膜燃料电池空气系统过氧比控制方法[J]. 吉林大学学报(工学版), 2022, 52(9): 1996-2003. |

| [7] | 池训逞,侯中军,魏伟,夏增刚,庄琳琳,郭荣. 基于模型的质子交换膜燃料电池系统阳极气体浓度估计技术综述[J]. 吉林大学学报(工学版), 2022, 52(9): 1957-1970. |

| [8] | 裴尧旺,陈凤祥,胡哲,翟双,裴冯来,张卫东,焦杰然. 基于自适应LQR控制的质子交换膜燃料电池热管理系统温度控制[J]. 吉林大学学报(工学版), 2022, 52(9): 2014-2024. |

| [9] | 胡广地,景浩,李丞,冯彪,刘晓东. 基于高阶燃料电池模型的多目标滑模控制[J]. 吉林大学学报(工学版), 2022, 52(9): 2182-2191. |

| [10] | 陈凤祥,伍琪,李元松,莫天德,李煜,黄李平,苏建红,张卫东. 2.5吨燃料电池混合动力叉车匹配、仿真及优化[J]. 吉林大学学报(工学版), 2022, 52(9): 2044-2054. |

| [11] | 武小花,余忠伟,朱张玲,高新梅. 燃料电池公交车模糊能量管理策略[J]. 吉林大学学报(工学版), 2022, 52(9): 2077-2084. |

| [12] | 高青,王浩东,刘玉彬,金石,陈宇. 动力电池应急冷却喷射模式实验分析[J]. 吉林大学学报(工学版), 2022, 52(8): 1733-1740. |

| [13] | 王奎洋,何仁. 基于支持向量机的制动意图识别方法[J]. 吉林大学学报(工学版), 2022, 52(8): 1770-1776. |

| [14] | 王骏骋,吕林峰,李剑敏,任洁雨. 分布驱动电动汽车电液复合制动最优滑模ABS控制[J]. 吉林大学学报(工学版), 2022, 52(8): 1751-1758. |

| [15] | 刘汉武,雷雨龙,阴晓峰,付尧,李兴忠. 增程式电动汽车增程器多点控制策略优化[J]. 吉林大学学报(工学版), 2022, 52(8): 1741-1750. |

|