吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (12): 3305-3313.doi: 10.13229/j.cnki.jdxbgxb.20220093

• 车辆工程·机械工程 •

包括面内动态特性的UniTire轮胎模型

- 吉林大学 汽车仿真与控制国家重点实验室,长春 130022

UniTire tire model including in⁃plane dynamic characteristics

Kong-hui GUO( ),Shi-qing HUANG,Hai-dong WU(

),Shi-qing HUANG,Hai-dong WU( ),Dang LU

),Dang LU

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

摘要:

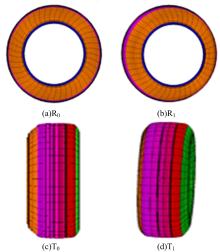

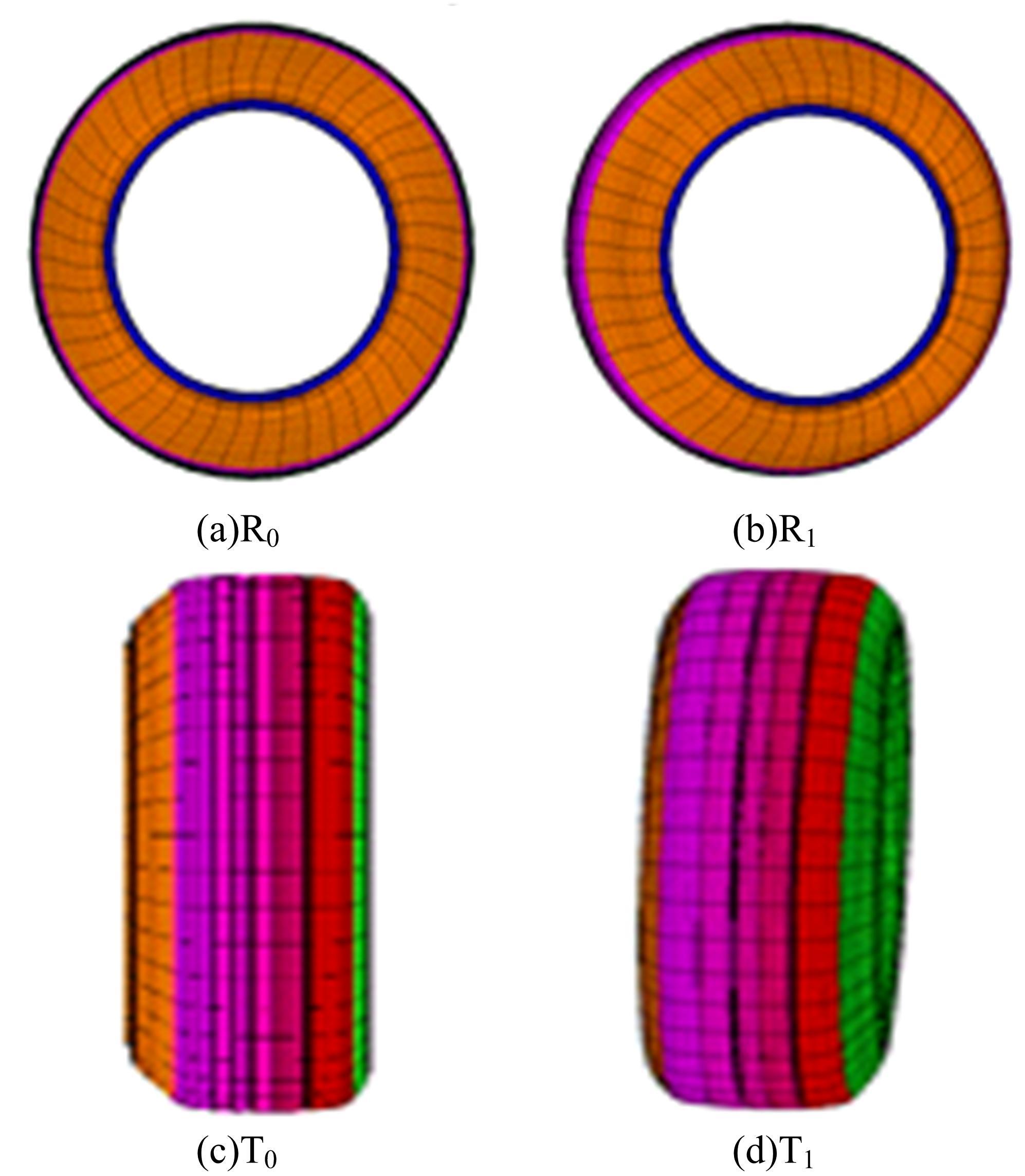

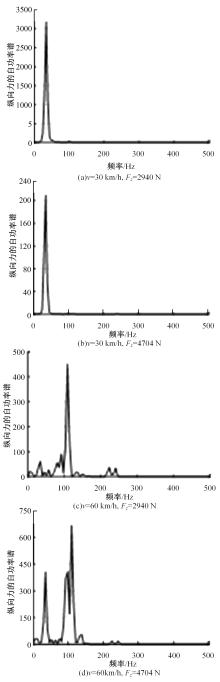

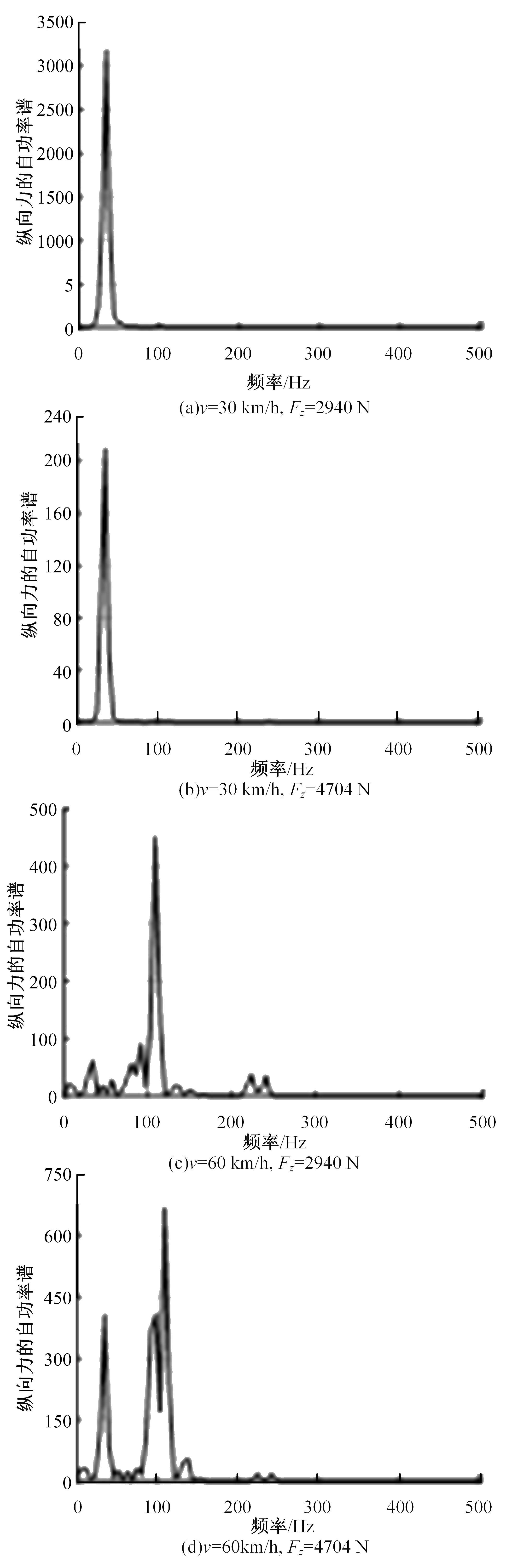

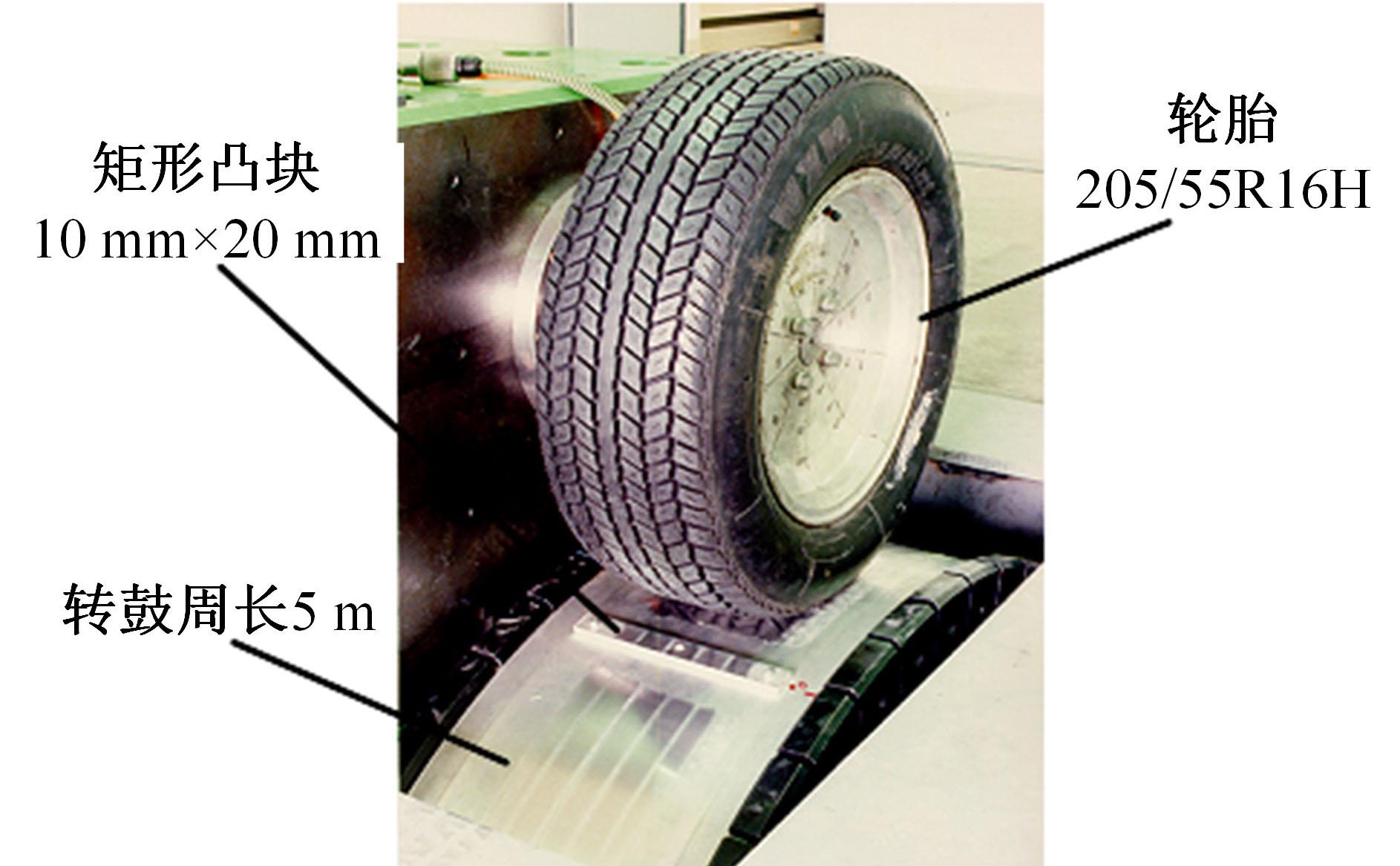

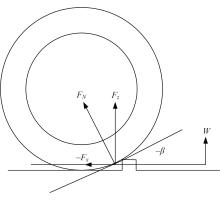

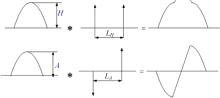

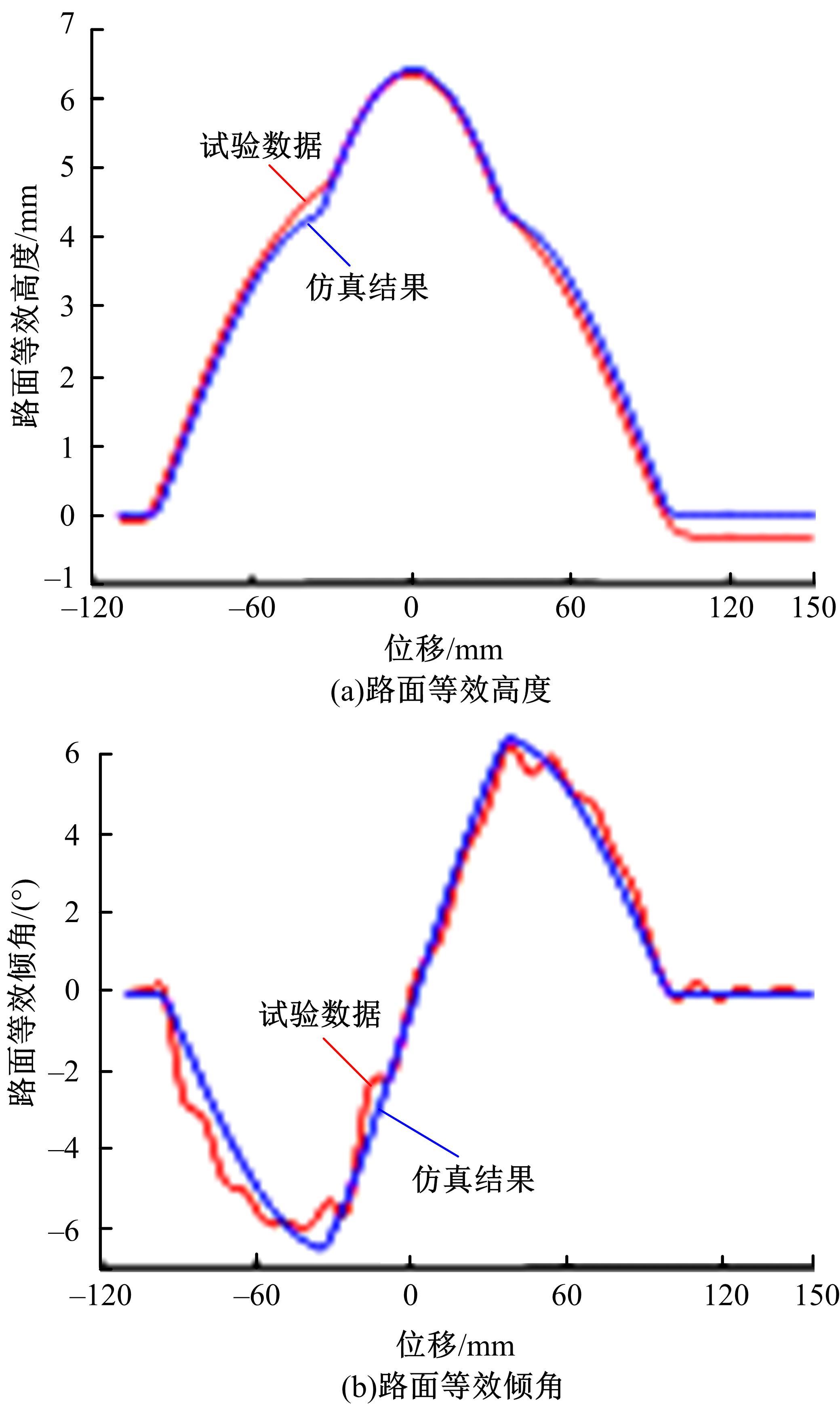

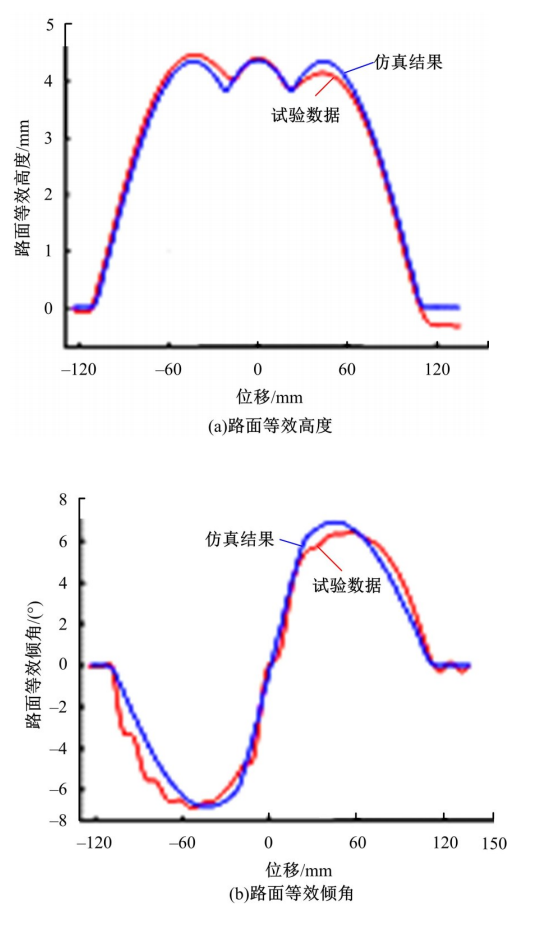

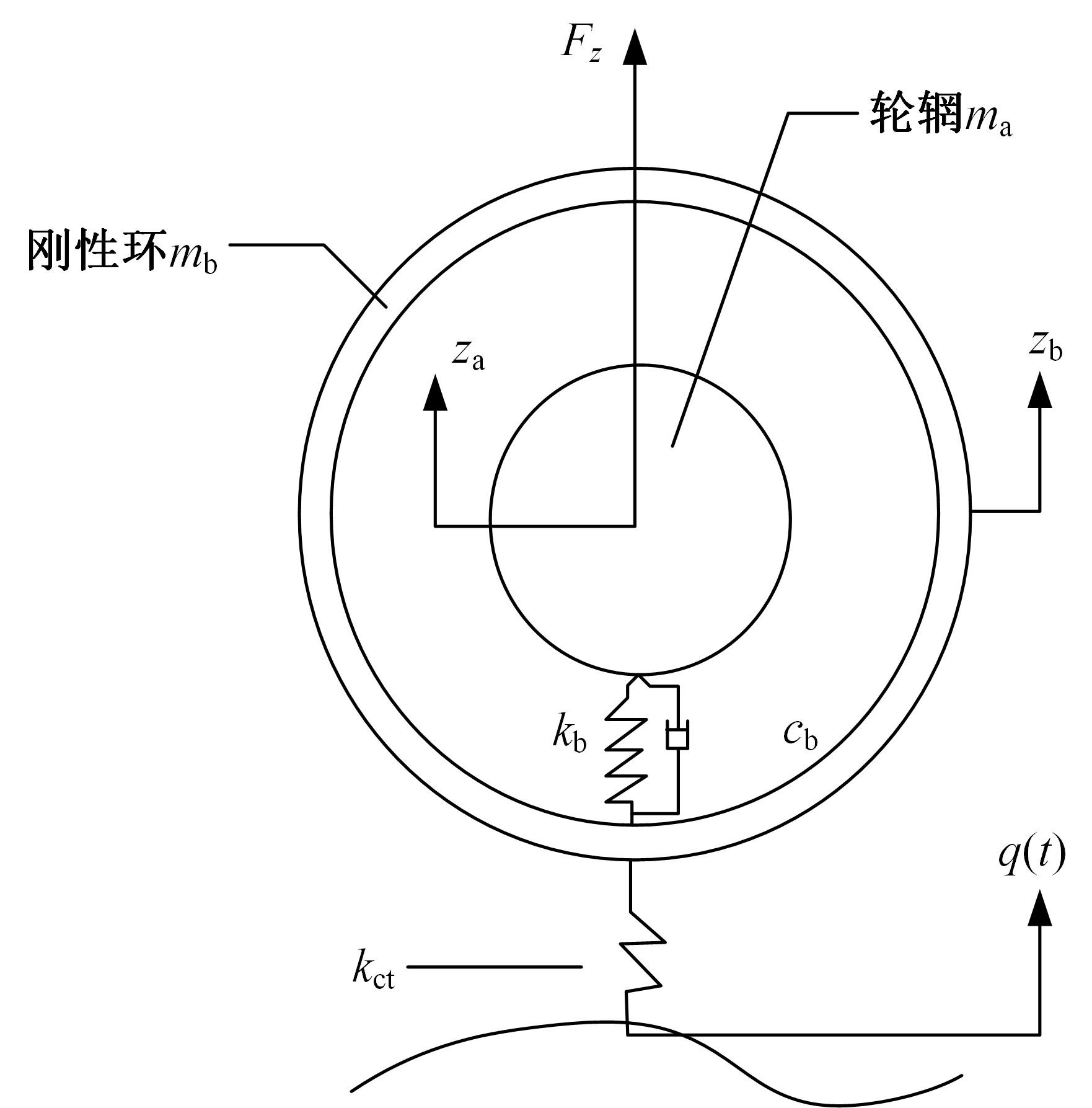

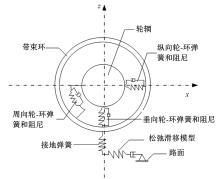

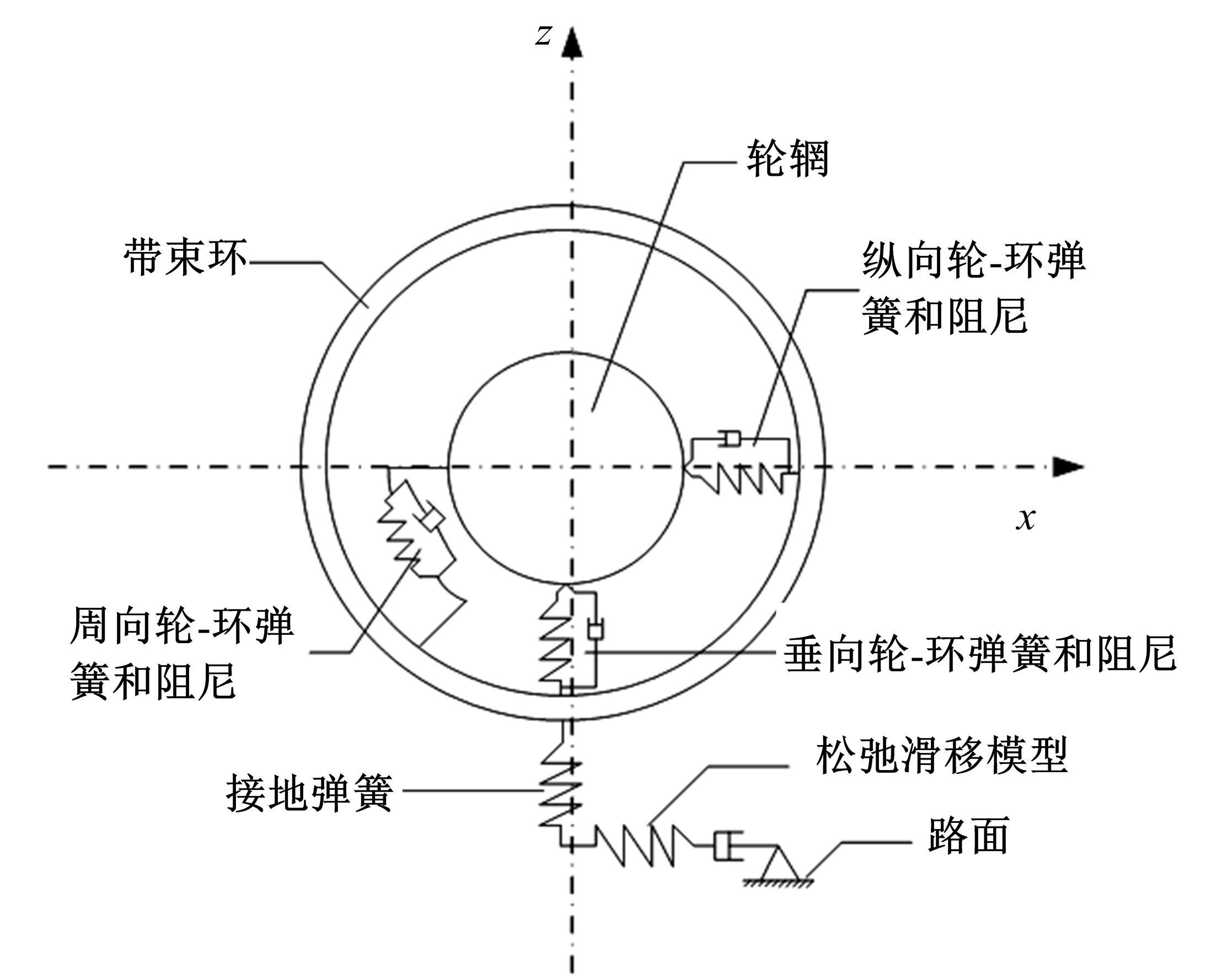

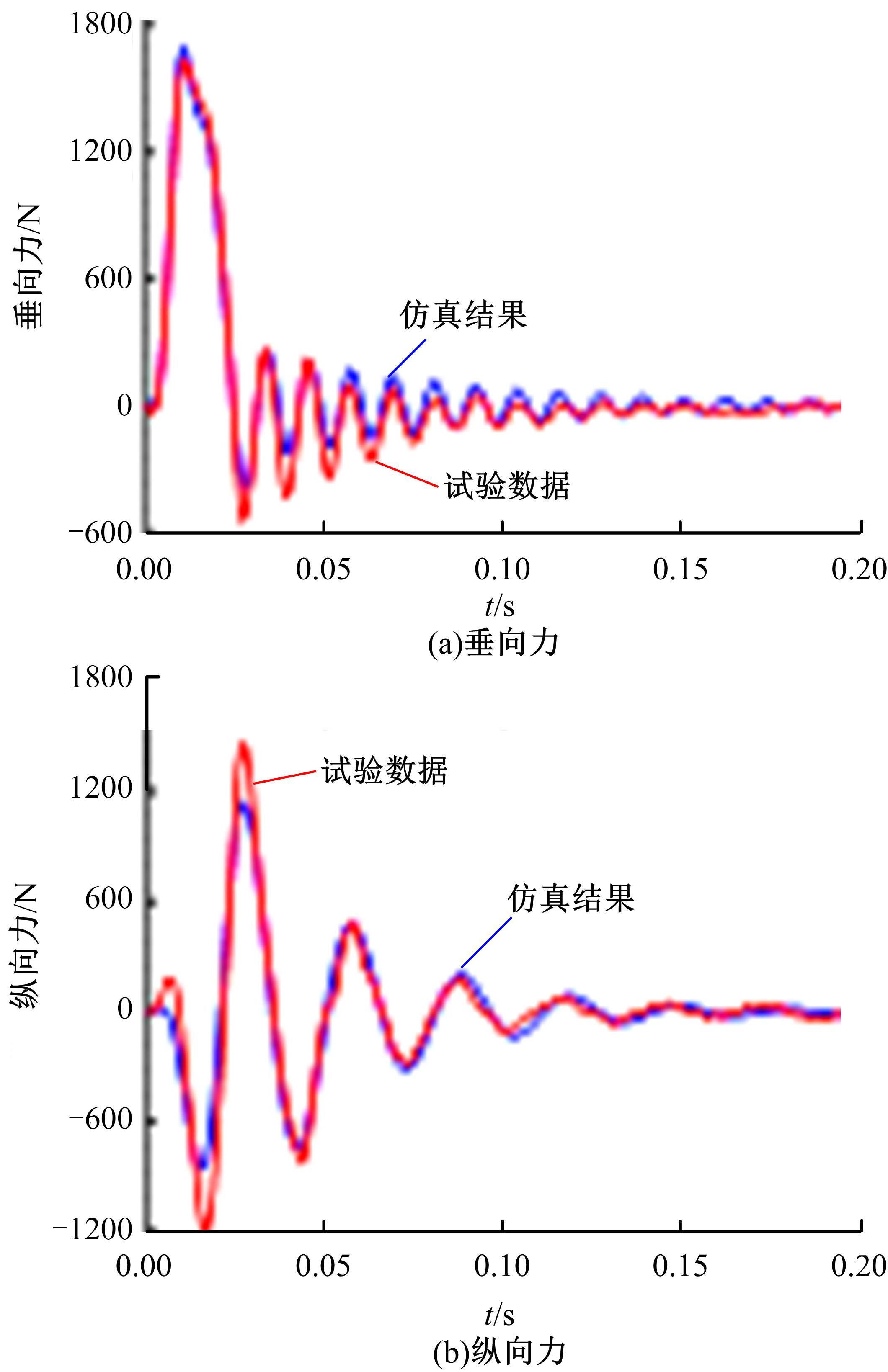

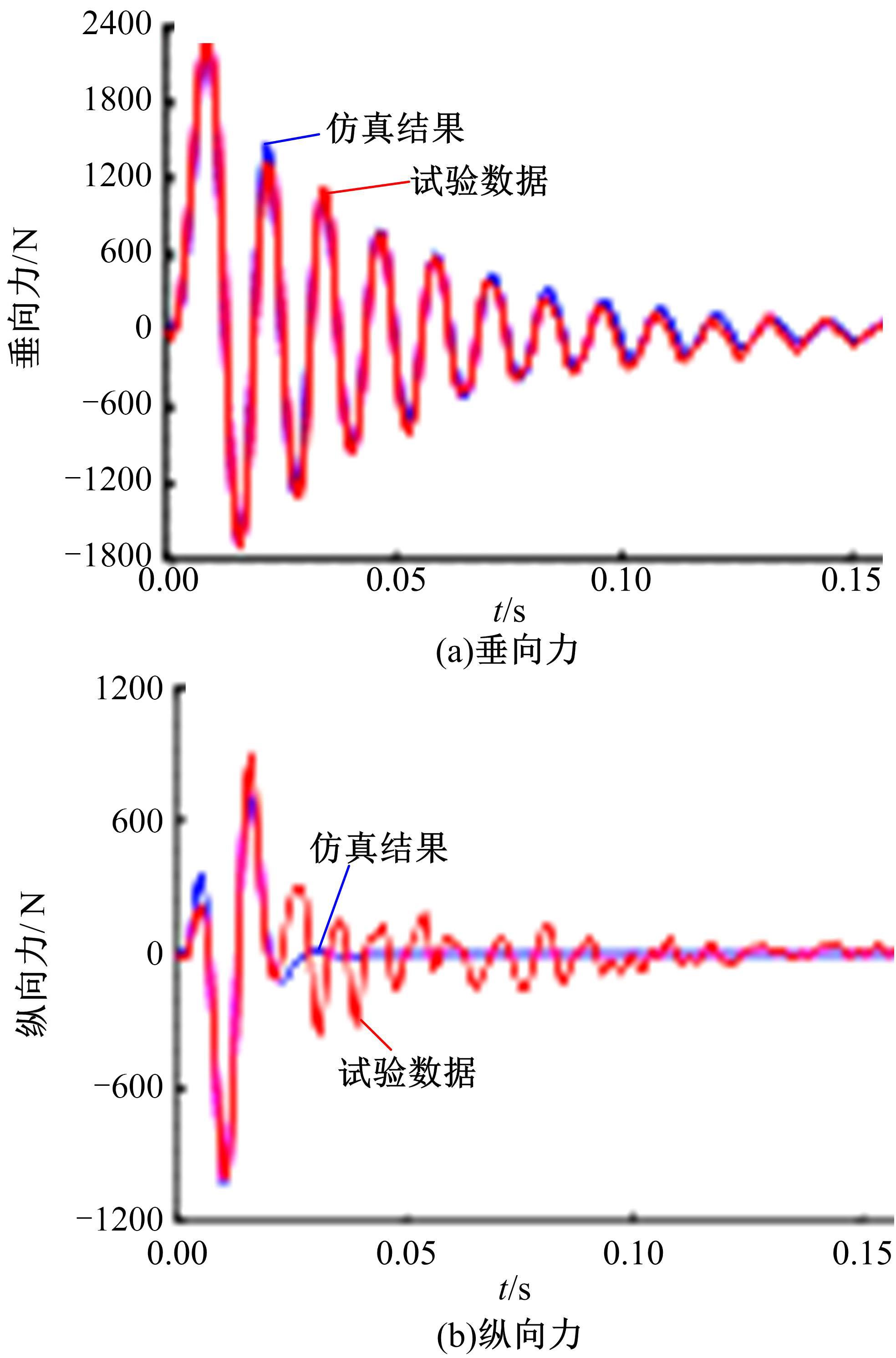

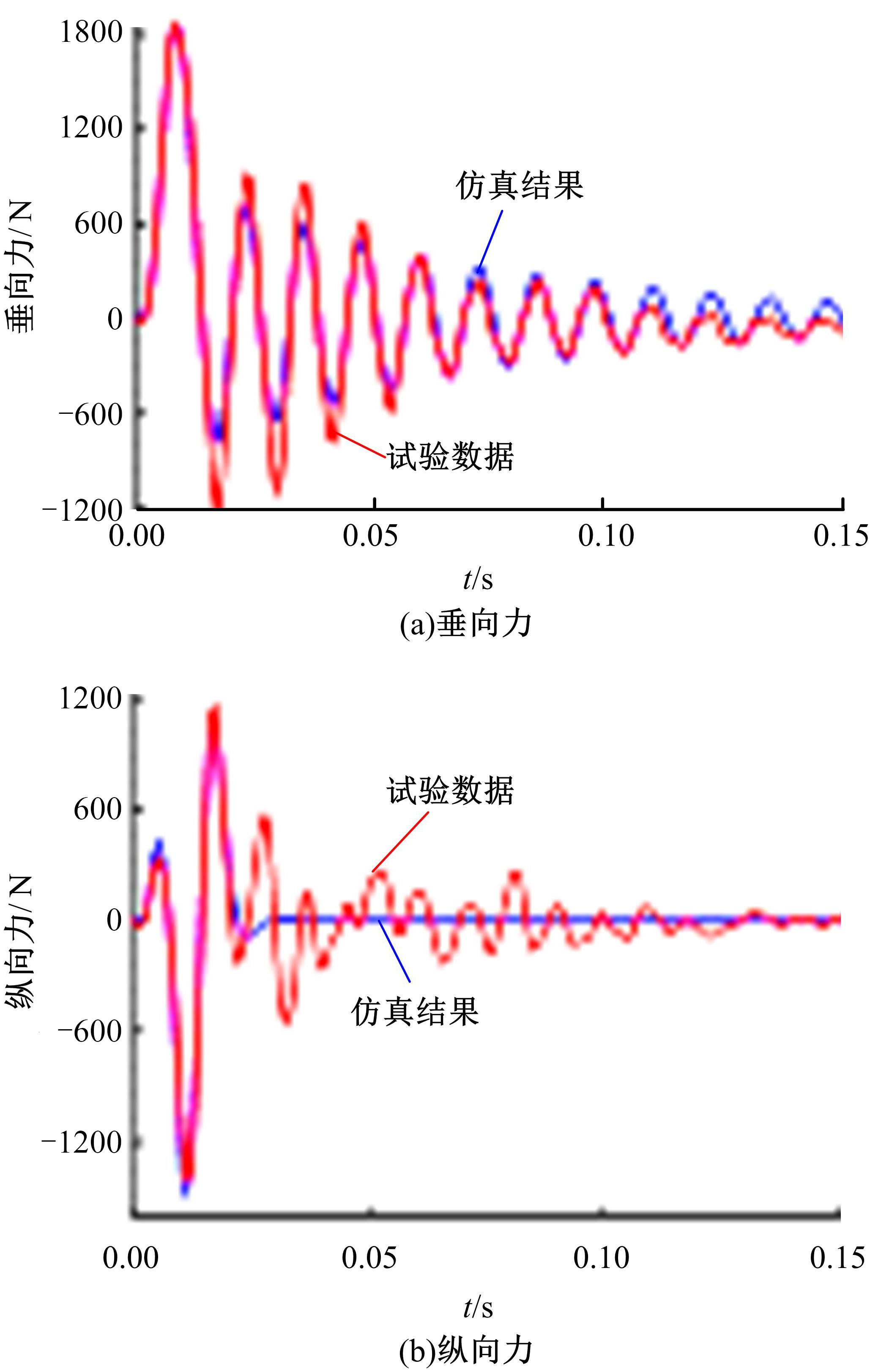

将轮胎低频操稳模型与高频耐久模型进行统一,提出了包括面内动态特性的UniTire 轮胎模型。稳态UniTire是轮胎动态系统的零频输出,当轮胎运动输入信号频率无限大时,轮心力的输出为零,以此为边界条件,建立了轮胎动态系统的传递特性。考虑到整车虚拟试验场仿真中轮心的载荷历程主要受轮胎刚性环模态影响,即平面内频率小于100 Hz,平面外小于60 Hz,更高的频率成分对轮心的载荷分析贡献不大,故建立了满足边界条件的二阶传递模型。本文模型不追求特定输入下轮胎输出的精确数值,模型参数少、容易辨识,满足频域边界条件,体现了主要频带信号的传递特性。最后,利用典型轮胎动态试验数据进行轮胎模型参数辨识和试验验证。结果表明,本文模型能够准确地表达轮胎面内动态特性。

中图分类号:

- U463.34

| 1 | Pacejka H B. Tyre and Vehicle Dynamics[M]. Oxford: Butterworth-Heinemann, 2002. |

| 2 | Gipser M. FTire-the tire simulation model for all applications related to vehicle dynamics[J]. Vehicle System Dynamics, 2007, 45(Sup.1): 139-151. |

| 3 | Gipser M. FTire and puzzling tyre physics: teacher, not student[J]. Vehicle System Dynamics, 2016, 54(4): 448-462. |

| 4 | Gallrein A, Bäcker M. CDTire:a tire model for comfort and durability applications[J]. Vehicle System Dynamics, 2007, 45(Sup.1): 69-77. |

| 5 | Backer M, Gallrein A, Noise Roller M., vibration, harshness model of a rotating tyre[J]. Vehicle System Dynamics, 2016, 54(4): 474-491. |

| 6 | Gallrein A, Bäcker M, Gizatullin A. Structural MBD tire models: closing the gap to structural analysis-history and future of parameter identification[C]∥SAE Paper, 2013-01-0630. |

| 7 | Oertel C. On modeling contact and friction calculation of tyre response on uneven roads[J]. Vehicle System Dynamics,1997, 27(Sup.1): 289-302. |

| 8 | Oertel C, Fandre A. Tire model RMOD-K 7 and misuse load cases[C]∥SAE Paper, 2009-01-0582. |

| 9 | Guan Di-hua, Fan Cheng-jian. Tire modeling for vertical properties including enveloping properties using experimental modal parameters[J]. Vehicle System Dynamics, 2003, 40(6): 419-433. |

| 10 | 危银涛, 冯希金, 冯启章, 等. 轮胎动态模型研究的进展[J]. 汽车安全与节能学报, 2014, 5(4): 311-323. |

| Wei Yin-tao, Feng Xi-jin, Feng Qi-zhang, et al. State of art for tire dynamical model research[J]. Journal of Automotive Safety and Energy, 2014, 5(4): 311-323. | |

| 11 | 吴海东. 不平路面中频激励轮胎动态特性研究[D]. 长春: 吉林大学汽车工程学院,2007. |

| Wu Hai-dong, study of tire dynamic properties under uneven road and medium frequency excitation[D]. Changchun: College of Automotive Engineering, Jilin University, 2007. | |

| 12 | Wu Hai-dong, Guo Kong-hui, Xu Hai-bin. Dynamic tire model used in advanced chassis control[C]∥2011 International Conference on Electric Information and Control Engineering: International Workshop of Automobile, Power and Energy Engineering, Wuhan, China, 2011: 4957-4961. |

| 13 | Liu Z H, Gao Q H. In-plane vibration response of time and frequency domain with rigid-elastic coupled tire model with continuous sidewall[J].Proceedings of the Institution of Mechanical Engineers,Part K:Journal of Multi-body Dynamics, 2018, 232(4) :429-445. |

| 14 | Guo K H, Lu D, Chen S, et al. The UniTire model: a nonlinear and non-steady-state tyre model for vehicle dynamics simulation[J]. Vehicle System Dynamics, 2005, 43(Sup.1): 341-358. |

| 15 | Lugner P, Plöchl M. Specifications of the test procedures[J]. Vehicle System Dynamics, 2007, 45(Sup.1): 21-28. |

| 16 | Bandel P, Monguzzi C. Simulation model of the dynamic behavior of a tire running over an obstacle[J]. Tire Science and Technology, 1988, 16(2): 62-77. |

| [1] | 王佳怡,刘昕晖,王展,陈晋市,韩亚方,王禹琪. 基于AMESim的恒流量控制阀流量特性分析[J]. 吉林大学学报(工学版), 2023, 53(9): 2499-2507. |

| [2] | 陈兆玮,蒲前华. 弹性车轮对大跨斜拉桥车桥耦合振动的抑制特性[J]. 吉林大学学报(工学版), 2023, 53(9): 2519-2532. |

| [3] | 刘平义,李晓婷,高偌霖,李海涛,魏文军,王亚. 车辆侧倾驱动机构设计与试验[J]. 吉林大学学报(工学版), 2023, 53(8): 2185-2192. |

| [4] | 黄学劲,钟锦星,路京雨,赵霁,肖伟,袁新枚. 基于用户画像的电动汽车充电负荷预测方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2193-2200. |

| [5] | 张树培,夏明悦,张玮,陈钊,陈义祥. 考虑非线性刚度的间隙球铰碰撞动力学建模与仿真[J]. 吉林大学学报(工学版), 2023, 53(8): 2227-2235. |

| [6] | 陈辉,邵亚军. 基于惯性基准多传感器耦合的路面谱测量方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2254-2262. |

| [7] | 陈磊,王杨,董志圣,宋亚奇. 一种基于转向意图的车辆敏捷性控制策略[J]. 吉林大学学报(工学版), 2023, 53(5): 1257-1263. |

| [8] | 陈鑫,张冠宸,赵康明,王佳宁,杨立飞,司徒德蓉. 搭接焊缝对铝合金焊接结构轻量化设计的影响[J]. 吉林大学学报(工学版), 2023, 53(5): 1282-1288. |

| [9] | 张勇,毛凤朝,刘水长,王青妤,潘神功,曾广胜. 基于Laplacian算法的汽车外流场畸变网格优化[J]. 吉林大学学报(工学版), 2023, 53(5): 1289-1296. |

| [10] | 汪少华,储堃,施德华,殷春芳,李春. 基于有限时间扩张状态观测的HEV鲁棒复合协调控制[J]. 吉林大学学报(工学版), 2023, 53(5): 1272-1281. |

| [11] | 尹燕莉,黄学江,潘小亮,王利团,詹森,张鑫新. 基于PID与Q⁃Learning的混合动力汽车队列分层控制[J]. 吉林大学学报(工学版), 2023, 53(5): 1481-1489. |

| [12] | 于贵申,陈鑫,武子涛,陈轶雄,张冠宸. AA6061⁃T6铝薄板无针搅拌摩擦点焊接头结构及性能分析[J]. 吉林大学学报(工学版), 2023, 53(5): 1338-1344. |

| [13] | 田彦涛,黄兴,卢辉遒,王凯歌,许富强. 基于注意力与深度交互的周车多模态行为轨迹预测[J]. 吉林大学学报(工学版), 2023, 53(5): 1474-1480. |

| [14] | 杨红波,史文库,陈志勇,郭年程,赵燕燕. 基于NSGA⁃II的斜齿轮宏观参数多目标优化[J]. 吉林大学学报(工学版), 2023, 53(4): 1007-1018. |

| [15] | 赵睿,李云,胡宏宇,高镇海. 基于V2I通信的交叉口车辆碰撞预警方法[J]. 吉林大学学报(工学版), 2023, 53(4): 1019-1029. |

|

||