吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (1): 22-43.doi: 10.13229/j.cnki.jdxbgxb.20230651

胶粉改性沥青老化机理及表征评价研究综述

唐乃膨1,2( ),薛晨阳2,刘少鹏3,朱洪洲1,2(

),薛晨阳2,刘少鹏3,朱洪洲1,2( ),李睿1,2

),李睿1,2

- 1.重庆交通大学 交通土建工程材料国家地方联合工程研究中心,重庆 400074

2.重庆交通大学 土木工程学院,重庆 400074

3.交通运输部规划研究院,北京 100028

Review on aging mechanism, characterization and evaluation of crumb rubber modified asphalt

Nai-peng TANG1,2( ),Chen-yang XUE2,Shao-peng LIU3,Hong-zhou ZHU1,2(

),Chen-yang XUE2,Shao-peng LIU3,Hong-zhou ZHU1,2( ),Rui LI1,2

),Rui LI1,2

- 1.National & Local Joint Engineering Research Center for Transportation Civil Engineering Materials,Chongqing Jiaotong University,Chongqing 400074,China

2.School of Civil Engineering,Chongqing Jiaotong University,Chongqing 400074,China

3.Transport Planning and Research Institute,Ministry of Transport,Beijing 100028,China

摘要:

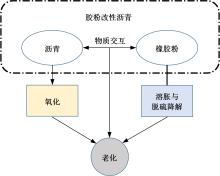

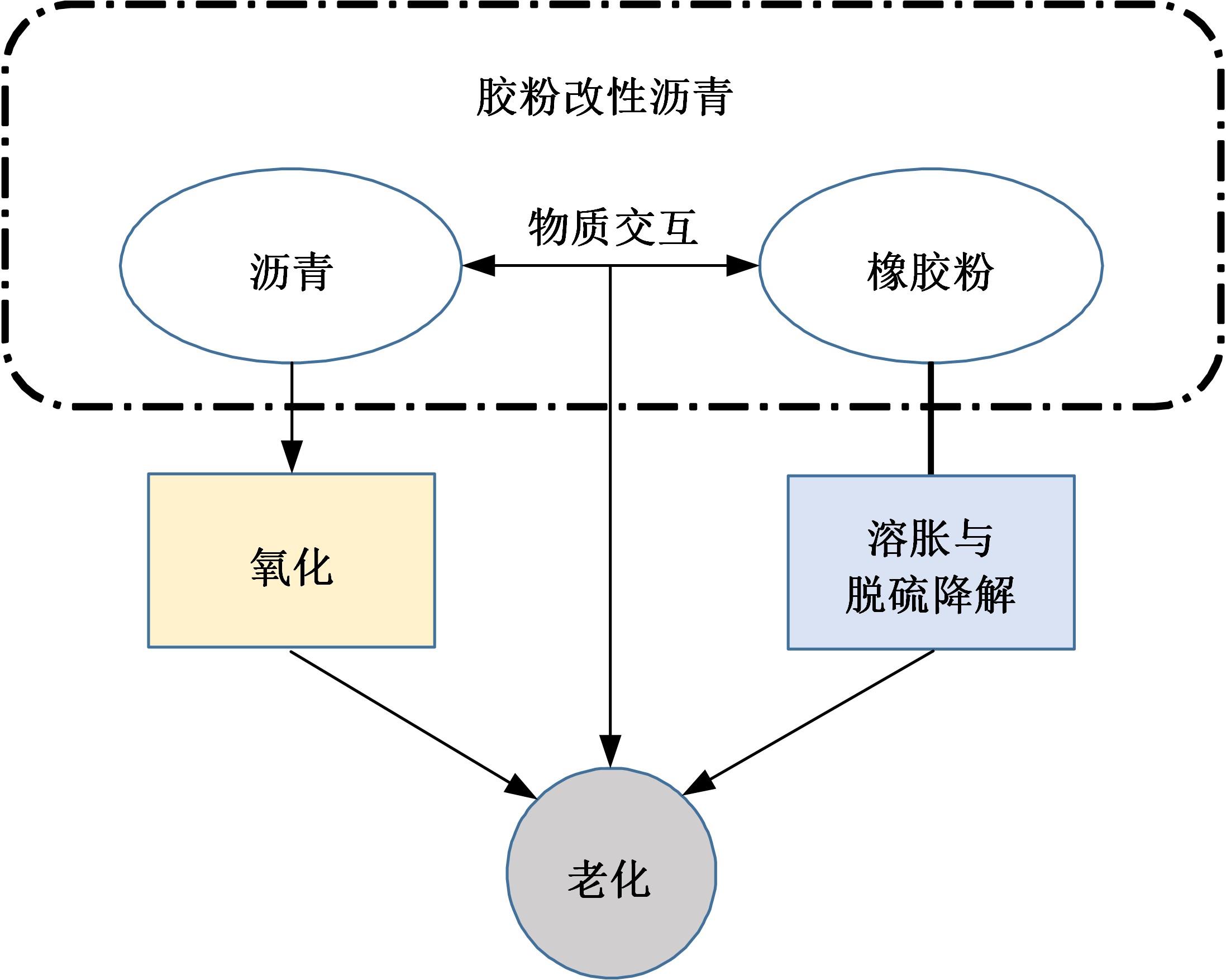

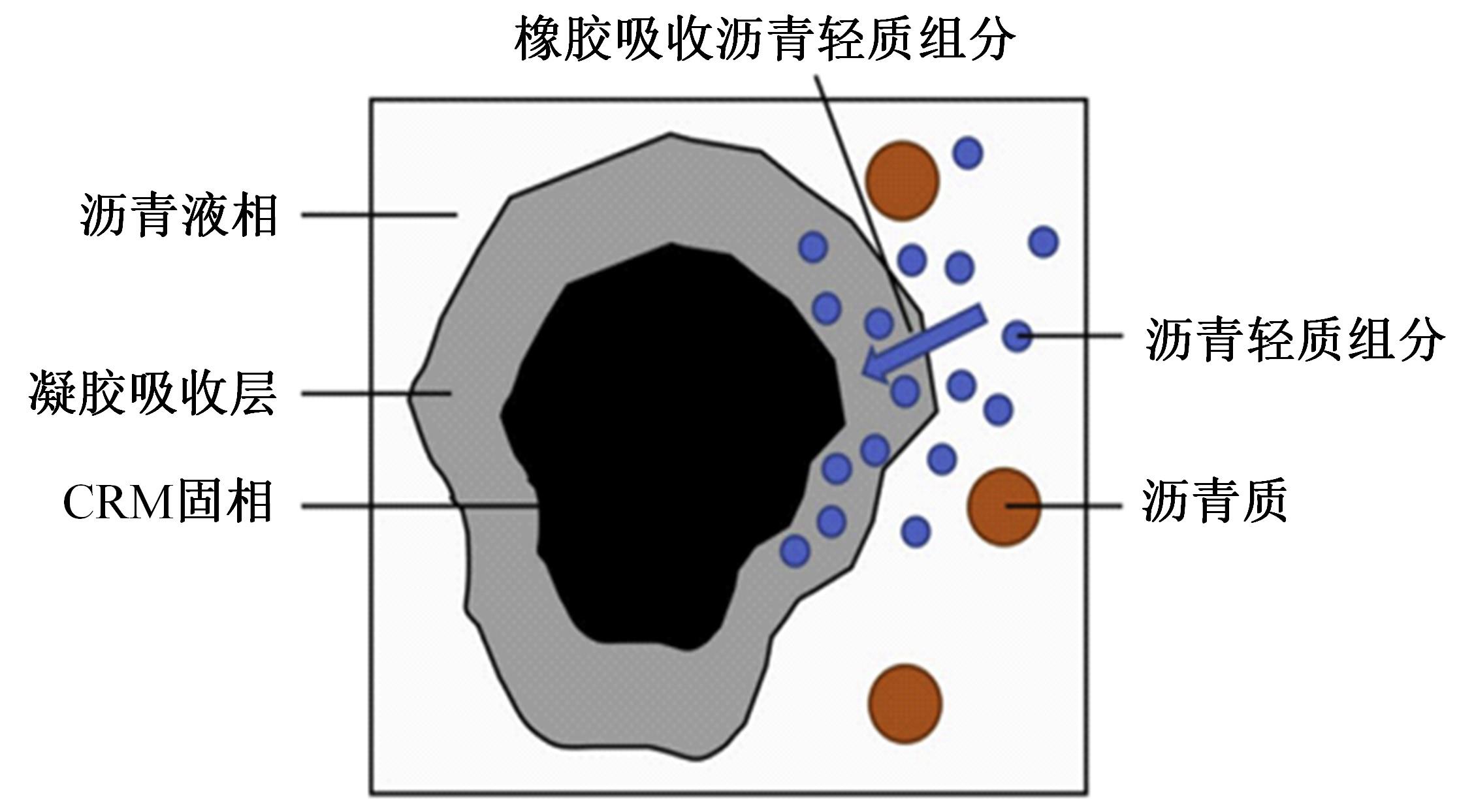

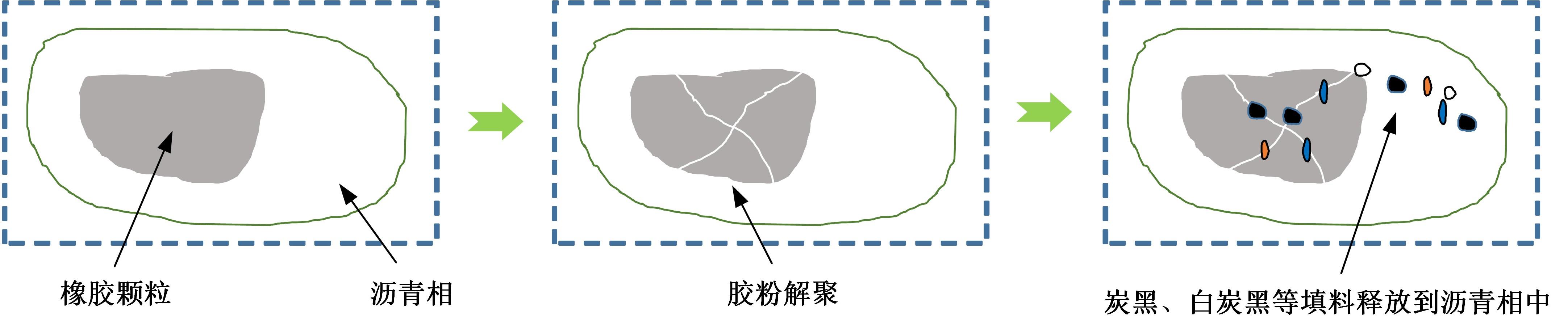

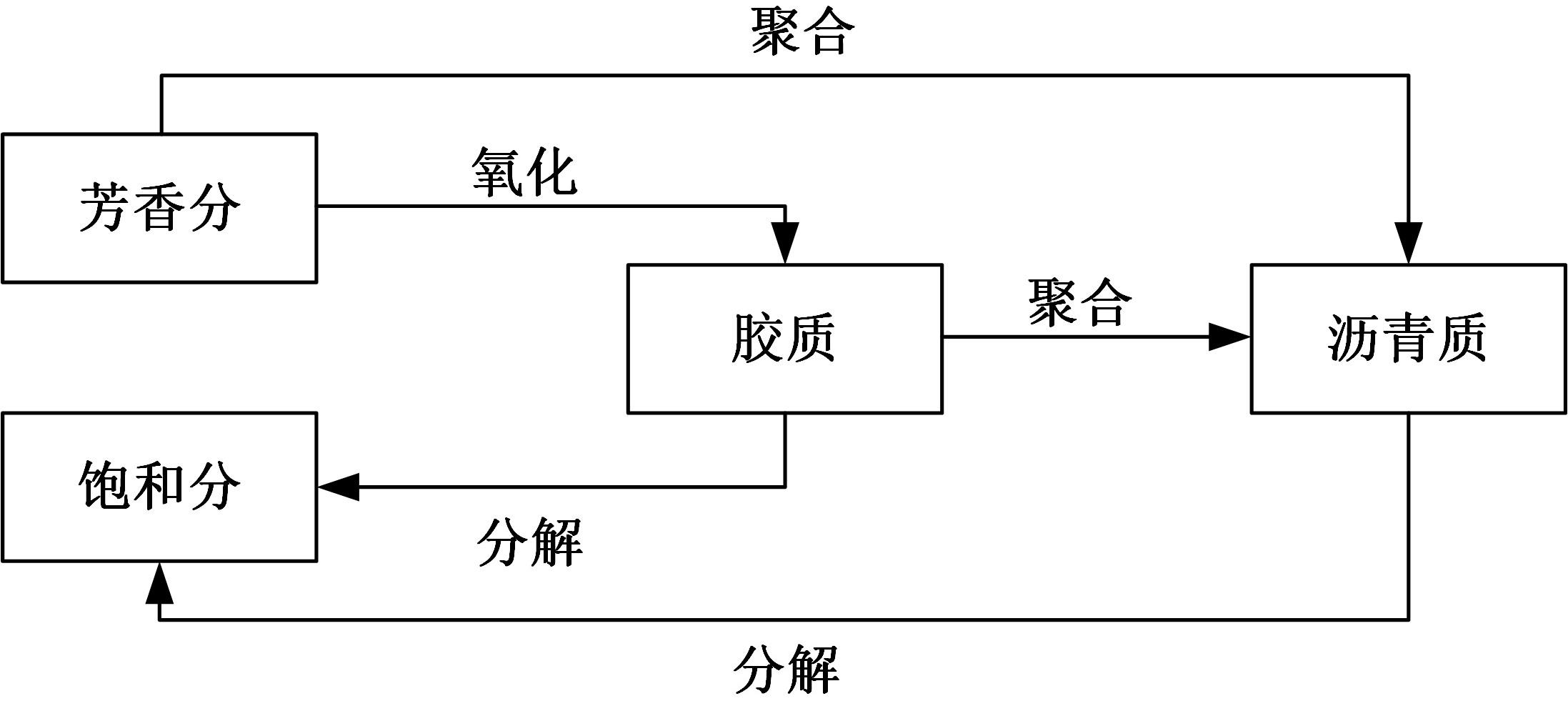

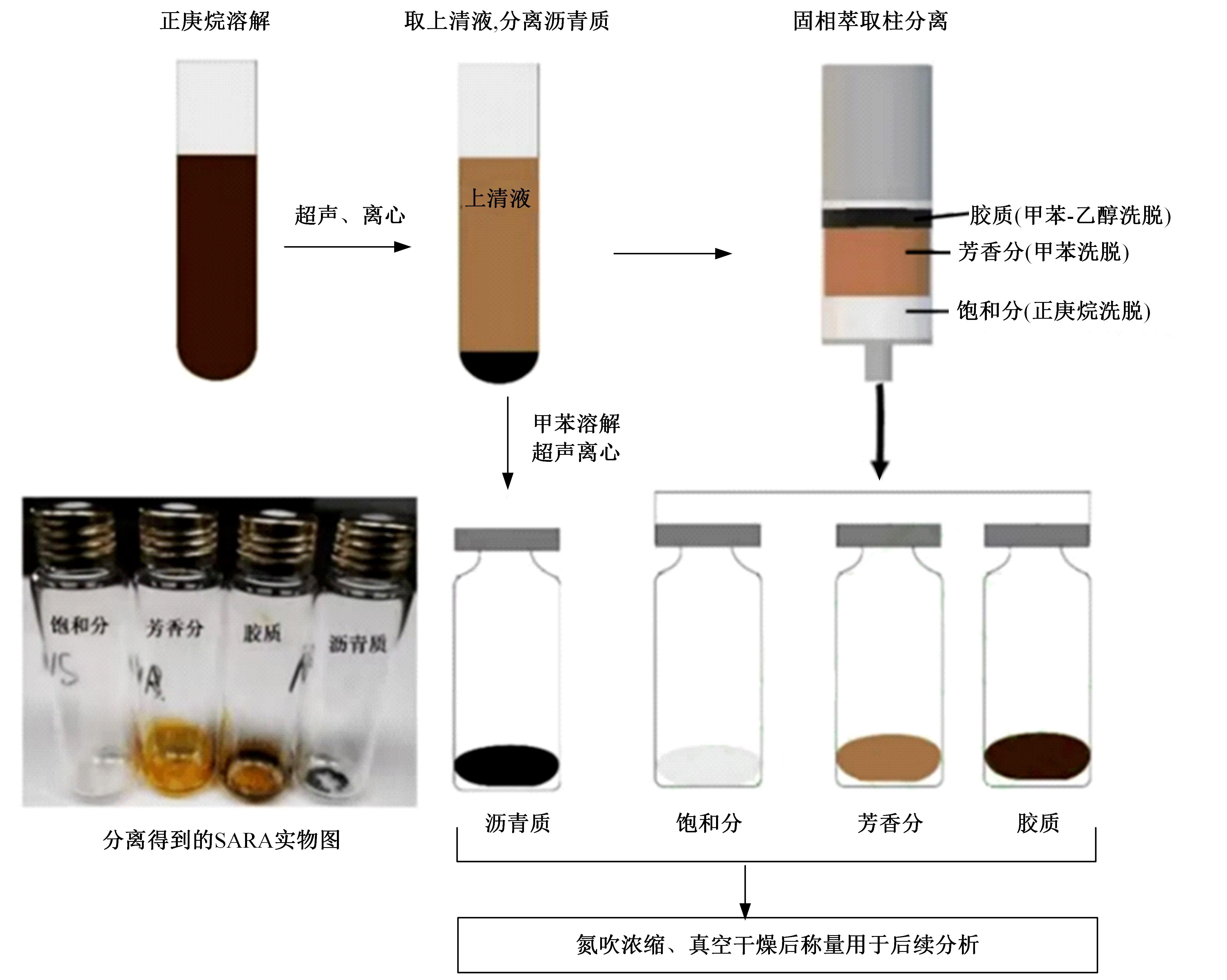

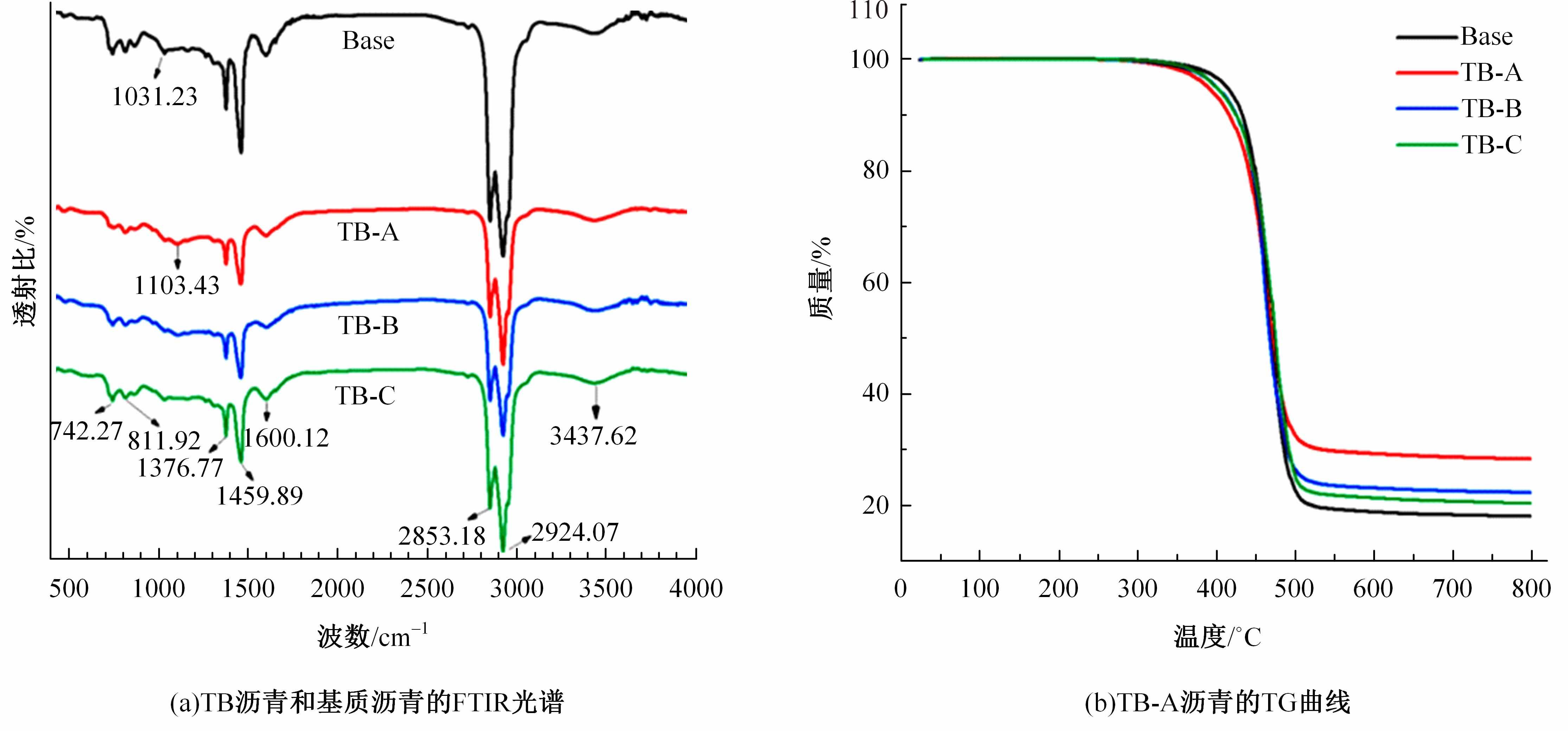

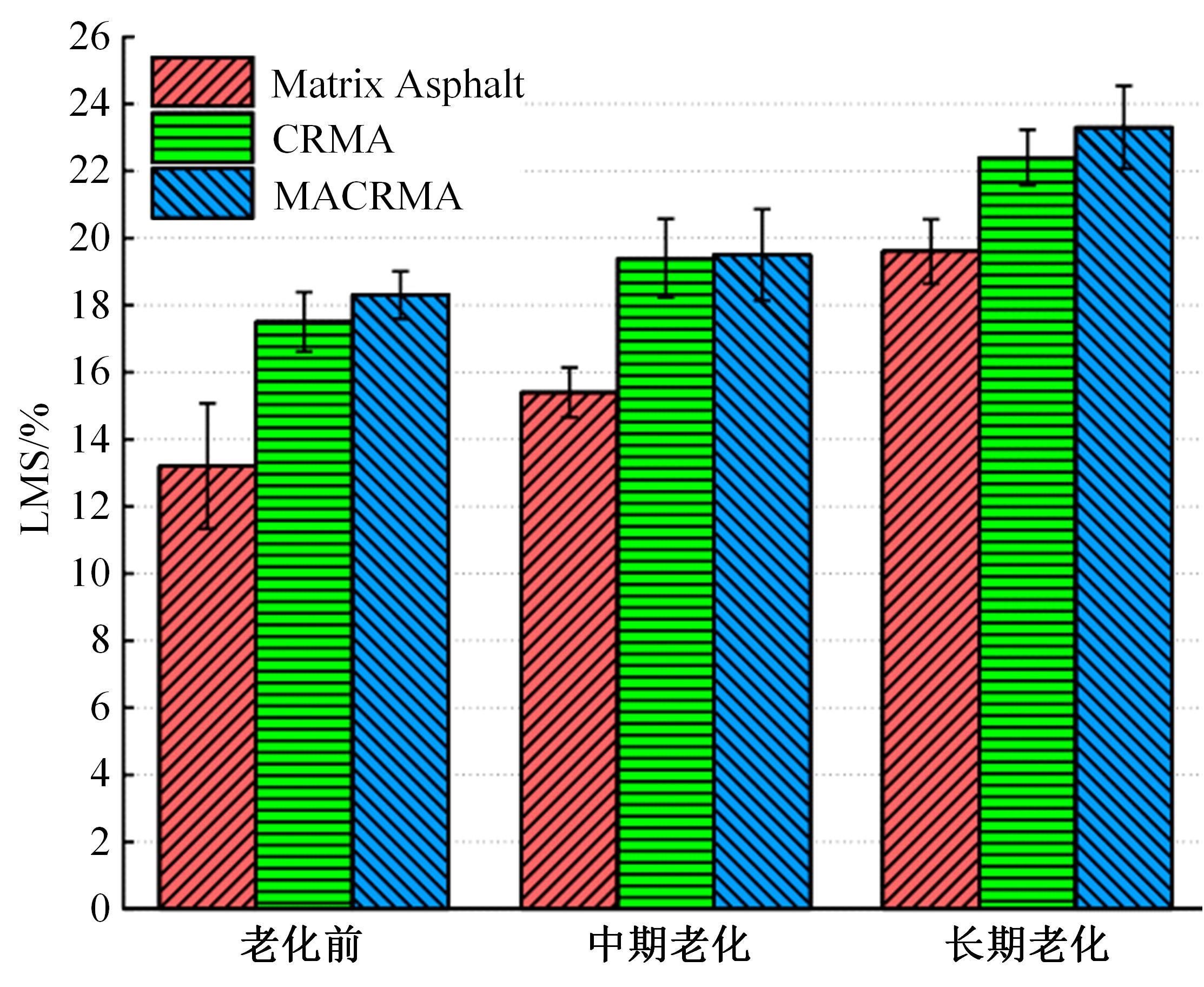

综述了国内外对胶粉改性沥青老化机理、表征及评价的研究现状。胶粉改性沥青的老化过程伴随着胶粉的溶胀、降解反应以及沥青与胶粉之间的物质交互作用;胶粉改性沥青老化行为的表征主要从化学组分、分子结构、分子量、表面形貌入手,并解释其对宏观性能的影响;胶粉改性沥青老化性能评价主要采用黏度、复数模量、低温蠕变劲度、疲劳寿命等流变学指标,且通常与微观表征及化学方法相结合。然而,当前国内外对胶粉改性沥青老化过程中填料迁移行为关注较少,特别是炭黑、白炭黑等填料的作用机理有待进一步挖掘;缺乏胶粉改性沥青多组分老化特征同步表征方法;缺乏统一的老化评价指标,且大多研究在混合料老化性能验证方面存在不足。最后,提出了胶粉改性沥青老化机理及表征评价研究的发展趋势与展望。

中图分类号:

- U414

| 1 | 马涛, 陈葱琳, 张阳, 等. 胶粉应用于沥青改性技术的发展综述[J]. 中国公路学报, 2021, 34 (10): 1-16. |

| Ma Tao, Chen Cong-lin, Zhang Yang, et al. Development of using crumb rubber in asphalt modification: a review[J]. China Journal of Highway and Transport, 2021, 34(10): 1-16. | |

| 2 | Wang T, Xiao F, Zhu X, et al. Energy consumption and environmental impact of rubberized asphalt pavement[J]. Journal of Cleaner Production, 2018, 180:139-158. |

| 3 | Zhou H, Holikatti S, Vacura P. Caltrans use of scrap tires in asphalt rubber products: a comprehensive review[J]. Journal of Traffic and Transportation Engineering(English Edition), 2014, 1(1): 39-48. |

| 4 | 王国清, 曹东伟, 王志斌, 等. 大掺量胶粉改性沥青胶结料流变性能对比研究[J]. 公路交通科技, 2022, 39(7): 7-14, 22. |

| Wang Guo-qing, Cao Dong-wei, Wang Zhi-bin, et al. Comparative study on rheological properties of asphalt binder modified with high content crumb rubber[J]. Journal of Highway and Transportation Research and Development, 2022, 39(7): 7-14, 22. | |

| 5 | Navarro F J, Partal P, Martı́nez-Boza F, et al. Thermo-rheological behaviour and storage stability of ground tire rubber-modified bitumens[J]. Fuel, 2004, 83(14): 2041-2049. |

| 6 | Han L, Zheng M, Wang C. Current status and development of terminal blend tyre rubber modified asphalt[J]. Construction and Building Materials, 2016, 128: 399-409. |

| 7 | 朱洪洲, 苏春力, 唐乃膨, 等. 胶粉改性沥青排放物采样及定量分析方法[J/OL]. 吉林大学学报:工学版, 2023: 1-8. |

| Zhu Hong-zhou, Su Chun-li, Tang Nai-peng, et al. Sampling and quantitative analysismethod of emissions from crumb rubber modified asphalt[J/OL]. Journal of Jilin University(Engineering and Technology Edition), 2023,53: 1-8. | |

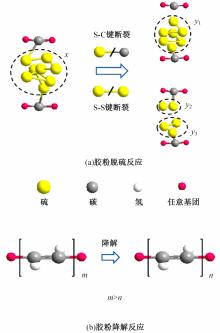

| 8 | 杨毅文, 袁浩, 马涛. 脱硫橡胶沥青溶胀原理及路用性能[J]. 公路交通科技, 2012, 29(2): 35-39. |

| Yang Yi-wen, Yuan Hao, Ma Tao. Swelling principle and pavement performance of desulfurized rubber asphalt[J]. Journal of Highway and Transportation Research Development, 2012, 29(2): 35-39. | |

| 9 | 董瑞琨, 梁文兵, 唐乃膨, 等. 废食用油预脱硫胶粉改性沥青组分与黏弹性研究[J]. 中国公路学报, 2019, 32(4): 226-234. |

| Dong Rui-kun, Liang Wen-bing, Tang Nai-peng, et al. Composition and viscoelasticity of asphalt modified with crumb rubber pre-desulfurized by waste cooking oil[J]. China Journal of Highway and Transport, 2019, 32(4): 226-234. | |

| 10 | 刘文昌, 党涛, 梁慧, 等. 胶粉活化对橡胶沥青性能的影响研究进展[J]. 市政技术, 2022, 40(9): 39-44, 49. |

| Liu Wen-chang, Dang Tao, Liang Hui, et al. Research progress of the effect of rubber powder activation on rubber asphalt properties[J]. Municipal Engineering Technology, 2022, 40(9): 39-44, 49. | |

| 11 | 葛豪. 无机纳米粒子/胶粉复配改性沥青制备与抗老化性能研究[D]. 重庆: 重庆交通大学土木工程学院, 2021. |

| Ge Hao. Study on preparation and aging resistance of asphalt modified by inorganic nanoparticles/rubber powder[D]. Chongqing: School of Civil Engineering, Chongqing Jiaotong University, 2021. | |

| 12 | 李宁, 申爱琴, 周彬, 等. 基于流变和微观分析的PR改性沥青老化性能评价[J]. 材料科学与工程学报, 2019, 37(5): 812-816. |

| Li Ning, Shen Ai-qin, Zhou Bin, et al. Evaluation of aging properties of PR modified asphalt based on rheological and microscopic analysis[J]. Journal of Materials Science and Engineering, 2019, 37(5): 812-816. | |

| 13 | 杨永强, 康秉铎, 郭海东, 等. 活化胶粉/SBS复合改性沥青短期老化性能[J]. 长安大学学报:自然科学版, 2021, 41(5): 23-33. |

| Yang Yong-qiang, Kang Bing-duo, Guo Hai-dong, et al. Short-term aging performance of activated rubber powder/SBS composite modified asphalt[J]. Journal of Chang 'an University(Natural Science Edition), 2021, 41(5): 23-33. | |

| 14 | Yu H, Deng G, Wang D, et al. Warm asphalt rubber: a sustainable way for waste tire rubber recycling[J]. Journal of Central South University, 2020, 27(11):3477-3498. |

| 15 | Wang H, Liu X, Apostolidis P, et al. Review of warm mix rubberized asphalt concrete: towards a sustainable paving technology[J]. Journal of Cleaner Production, 2018, 177(10): 302-314. |

| 16 | 陈启维. 四类温拌橡胶沥青的流变性能研究[J]. 市政技术, 2022, 40(3): 1-6. |

| Chen Qi-wei. Rheological properties of four types of warm-mixed rubber asphalt[J]. Municipal Engineering Technology, 2022, 40(3): 1-6. | |

| 17 | 徐永丽, 杨煦兰, 周吉森, 等. 温拌沥青的沥青烟成分及温拌剂抑烟性能研究[J]. 吉林大学学报:工学版, 2022, 52(12): 1-8. |

| Xu Yong-li, Yang Xu-lan, Zhou Ji-sen, et al. Study on the asphalt fume composition of warm mix asphalt and smoke suppression performance of warm mix agent[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52 (12): 1-8. | |

| 18 | Ma L, Varveri A, Jing R, et al. Comprehensive review on the transport and reaction of oxygen and moisture towards coupled oxidative ageing and moisture damage of bitumen[J]. Construction and Building Materials, 2021, 283:No.122632. |

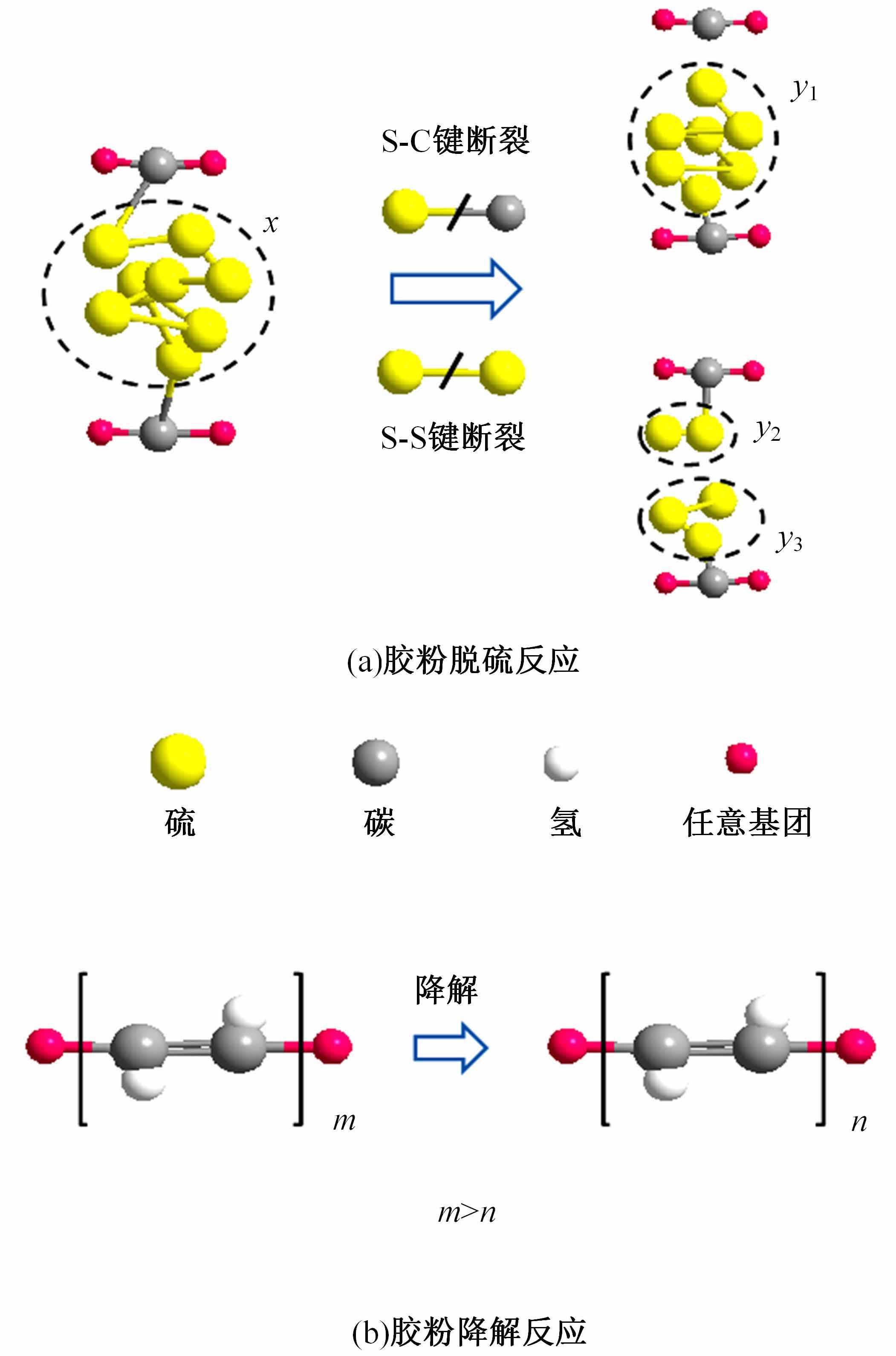

| 19 | 郭猛, 任鑫, 焦峪波, 等. 沥青及沥青混合料老化与抗老化研究综述[J]. 中国公路学报, 2022, 35(4): 41-59. |

| Guo Meng, Ren Xin, Jiao Yu-bo, et al. Review of aging and antiaging of asphalt and asphalt mixtures[J]. China Journal of Highway and Transport, 2022, 35(4): 41-59. | |

| 20 | 洪斌, 陆国阳, 高峻凌, 等. 路用聚氨酯胶结料的抗紫外老化性能[J]. 中国公路学报, 2020, 33(10): 240-253. |

| Hong Bin, Lu Guo-yang, Gao Jun-ling, et al. Anti-ultraviolet aging performance of polyurethane binders used in roads[J]. China Journal of Highway and Transport, 2020, 33(10): 240-253. | |

| 21 | 中国公路学报编辑部. 中国路面工程学术研究综述·2020[J]. 中国公路学报, 2020, 33(10): 1-66. |

| Editorial Department of China Journal of Highway and Transport. Review on China's pavement engineering research: 2020[J]. China Journal of Highway and Transport, 2020, 33(10): 1-66. | |

| 22 | Chang X, Zhang R, Xiao Y, et al. Mapping of publications on asphalt pavement and bitumen materials: A bibliometric review[J]. Construction and Building Materials, 2020, 234: No.117370. |

| 23 | 钱春香, 解建光, 王鸿博. SBS和SEBS改性沥青及混合料抗老化性能[J]. 东南大学学报:自然科学版, 2005, 35(6): 945-949. |

| Qian Chun-xiang, Xie Jian-guang, Wang Hong-bo. Anti-aging capability of SBS and SEBS modified asphalt and mixture[J]. Journal of Southeast University(Natural Science Edition), 2005, 35(6): 945-949. | |

| 24 | 赵可成, 陈宇, 黄考取. 基于核壳结构缓释剂和抗氧化剂的新型复合沥青抗老化剂研究[J]. 材料导报, 2019, 33(): 261-266, 272. |

| Zhao Ke-cheng, Chen Yu, Huang Kao-qu. Development of long-lasting antiaging additives for recycled asphalt binders[J]. Materials Review, 2019, 33(Sup.2): 261-266, 272. | |

| 25 | 张立科, 张玉贞. 加工工艺对沥青高温性能、抗老化性能和感温性能的影响研究[J]. 石油沥青, 2008, 22(6): 37-39. |

| Zhang Li-ke, Zhang Yu-zhen. Study on the influence of processing technology on high temperature, aging resistance and temperature sensing properties of asphalt[J]. Petroleum Pitch, 2008, 22(6): 37-39. | |

| 26 | 王筵铸, 王旭东, 张龙生, 等. 橡胶沥青配伍性及黏附性能研究[J]. 公路交通科技, 2019, 36(3): 34-41. |

| Wang Yan-zhu, Wang Xu-dong, Zhang Long-sheng, et al. Study on compatibility and adhesion property of rubber asphalt[J]. Journal of Highway and Transportation Research Development, 2019, 36(3): 34-41. | |

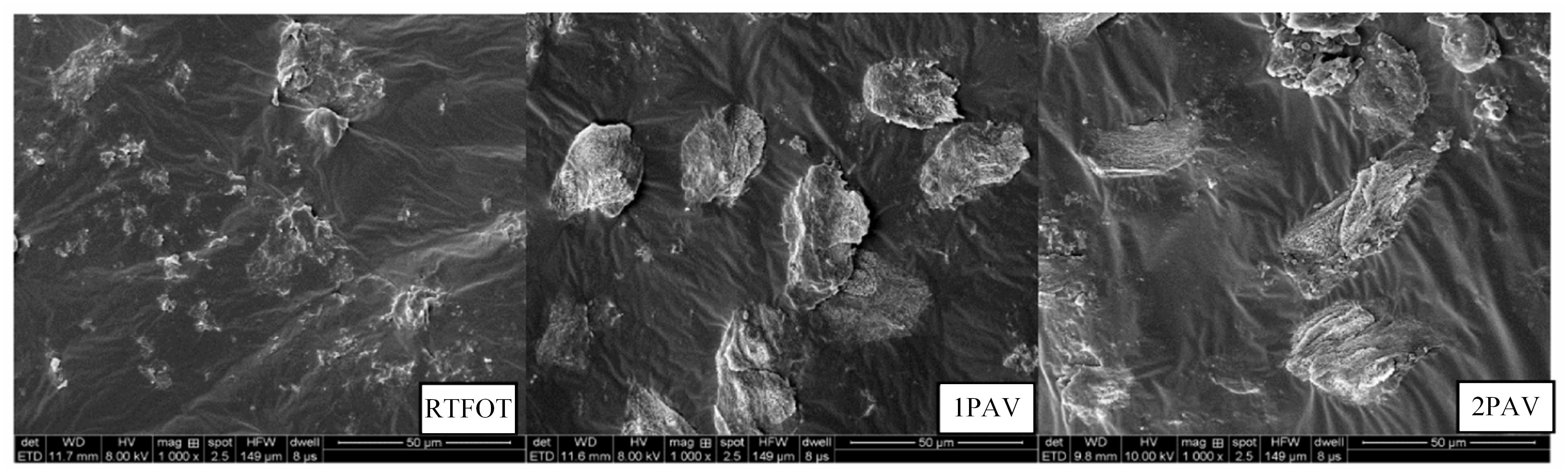

| 27 | Li D, Leng Z, Wang H, et al. Structural and mechanical evolution of the multiphase asphalt rubber during aging based on micromechanical back-calculation and experimental methods[J]. Materials & Design, 2022, 215:No.110421. |

| 28 | Petersen J C. Transportation research circular E-C140: a review of the fundamentals of asphalt oxidation: chemical, physicochemical, physical property, and durability relationships[R]. Washington DC: Transportation Research Board of the National Academies, 2009. |

| 29 | 张丽宏. 橡胶沥青老化微观机理研究[C]∥《环境工程》2018年全国学术年会,中国合肥,2018. |

| Zhang Li-hong. Study on aging microscopic mechanism of rubber modified asphalt[C]∥Environmental Engineering 2018 National Academic Conference, Hefei, China, 2018. | |

| 30 | Wang H, Liu X, Apostolidis P, et al. Numerical investigation of rubber swelling in bitumen[J]. Construction and Building Materials, 2019, 214: 506-515. |

| 31 | Tang N, Lv Q, Huang W, et al. Chemical and rheological evaluation of aging characteristics of terminal blend rubberized asphalt binder[J]. Construction and Building Materials, 2019, 205:87-96. |

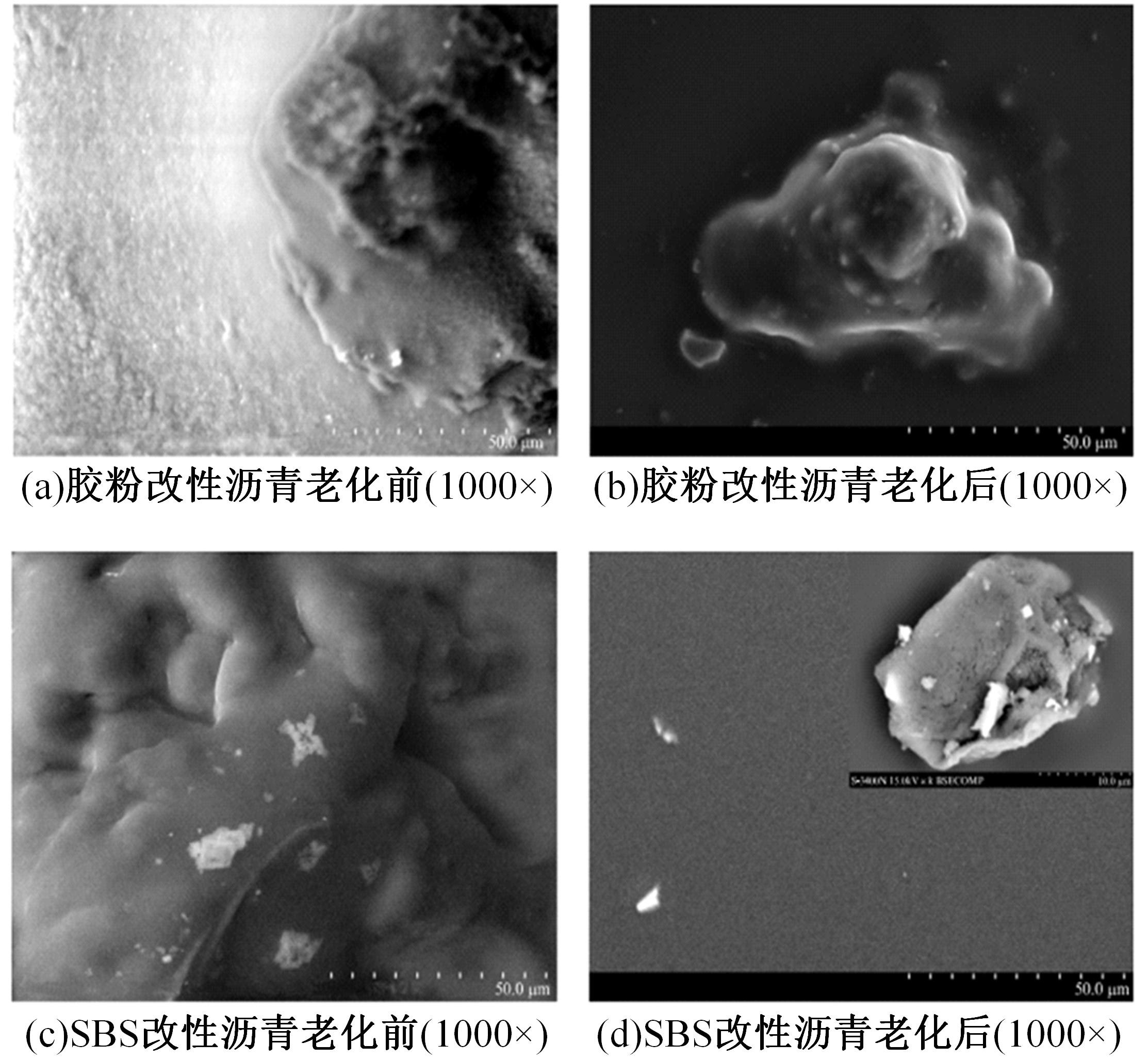

| 32 | 陈峰. 基质沥青和SBS改性沥青老化行为与机理研究[D]. 西安: 长安大学材料学院, 2012. |

| Chen Feng. Aging behavior and mechanism of base asphalt and SBS modified asphalt[D]. Xi'an: School of Materials, Chang 'an University, 2012. | |

| 33 | 陈钦庭, 王志祥. SBS改性沥青老化机理分析[J]. 武汉理工大学学报:交通科学与工程版, 2021, 45(6): 1145-1150. |

| Chen Qin-ting, Wang Zhi-xiang. Analysis of aging mechanism of SBS modified asphalt [J]. Journal of Wuhan University of Technology(Transportation Science & Engineering), 2021, 45(6): 1145-1150. | |

| 34 | 宋家乐, 何璐, 王欣, 等. SBS改性沥青的RTFOT微观老化机理[J]. 公路交通科技, 2020, 37(2): 1-7. |

| Song Jia-le, He Lu, Wang Xin, et al. Microscopic aging mechanism of SBS modified asphalt in RTFOT[J]. Journal of Highway and Transportation Research and Development, 2020, 37(2): 1-7. | |

| 35 | 滕旭秋, 费占黎, 文华, 等. 多因素作用下橡胶沥青老化特性研究[J]. 兰州交通大学学报, 2016, 35(4): 1-5. |

| Teng Xu-qiu, Fei Zhan-li, Wen Hua, et al. Study on aging characteristics of rubber asphalt in consideration of multiple factors[J]. Journal of Lanzhou Jiaotong University, 2016, 35(4): 1-5. | |

| 36 | 何亮, 凌天清, 马育, 等. 橡胶沥青老化性能及特征研究[J]. 建筑材料学报, 2015, 18(4): 565-571. |

| He Liang, Ling Tian-qing, Ma Yu, et al. Research on asphalt rubber aging performance and characteristics[J]. Journal of Building Materials, 2015, 18(4): 565-571. | |

| 37 | Geng J, Chen M, Xia C, et al. Quantitative determination for effective rubber content in aged modified asphalt binder[J]. Journal of Cleaner Production, 2022, 331:No.129978. |

| 38 | 李宁利, 赵新坡, 孙吉书, 等. 橡胶沥青老化机理研究[J]. 公路交通科技, 2015, 32(7): 18-22. |

| Li Ning-li, Zhao Xin-po, Sun Ji-shu, et al. Study on aging mechanism of rubber modified asphalt[J]. Journal of Highway and Transportation Research Development, 2015, 32(7): 18-22. | |

| 39 | 黄明, 汪翔, 黄卫东. 橡胶沥青混合料疲劳性能的自愈合影响因素分析[J]. 中国公路学报, 2013, 26(4): 16-22. |

| Huang Ming, Wang Xiang, Huang Wei-dong. Analysis of influencing factors for self-healing of fatigue performance of asphalt rubber mixture[J]. China Journal of Highway and Transport, 2013, 26(4): 16-22. | |

| 40 | Li D, Leng Z, Zou F, et al. Effects of rubber absorption on the aging resistance of hot and warm asphalt rubber binders prepared with waste tire rubber[J]. Journal of Cleaner Production, 2021, 303:No.127082. |

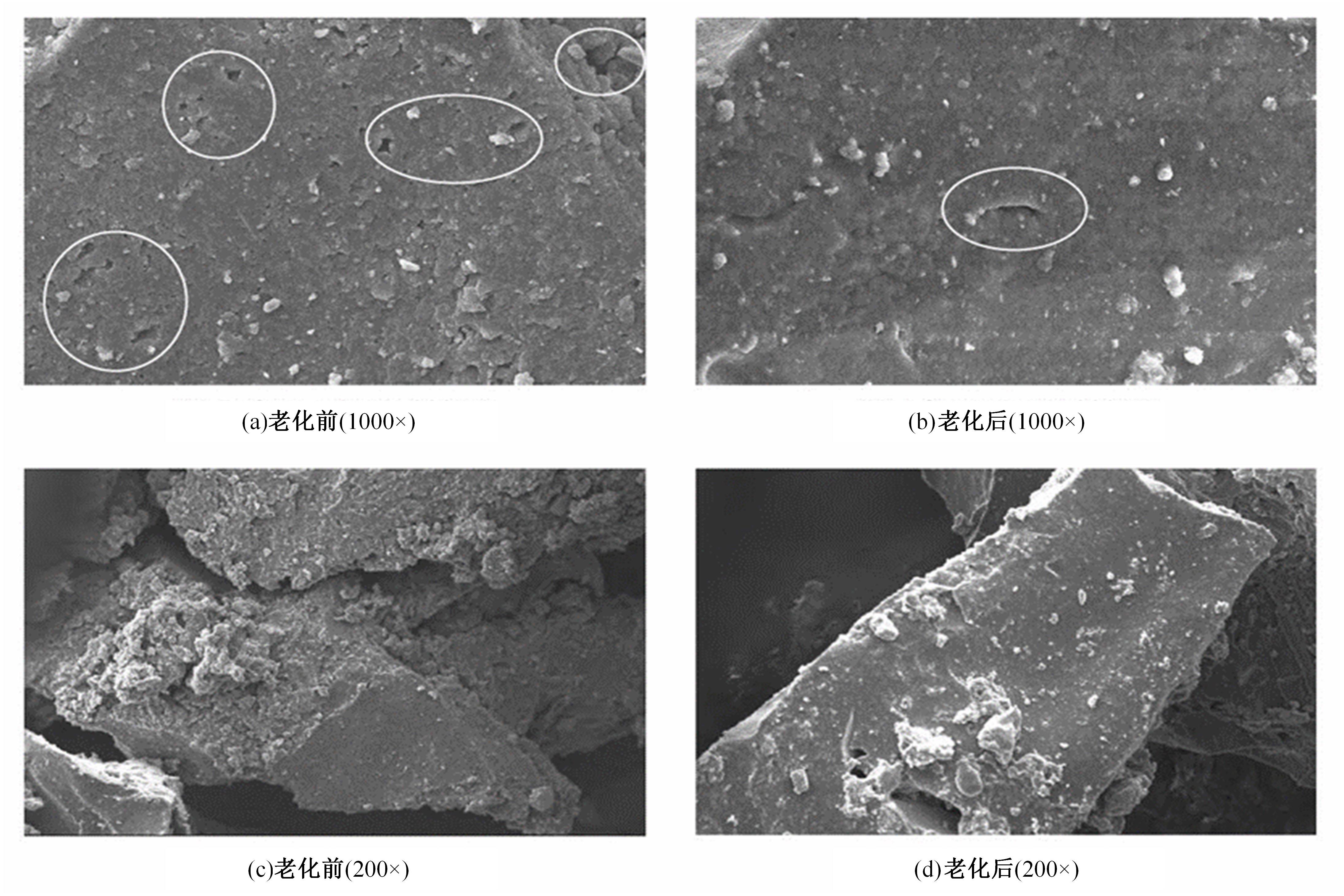

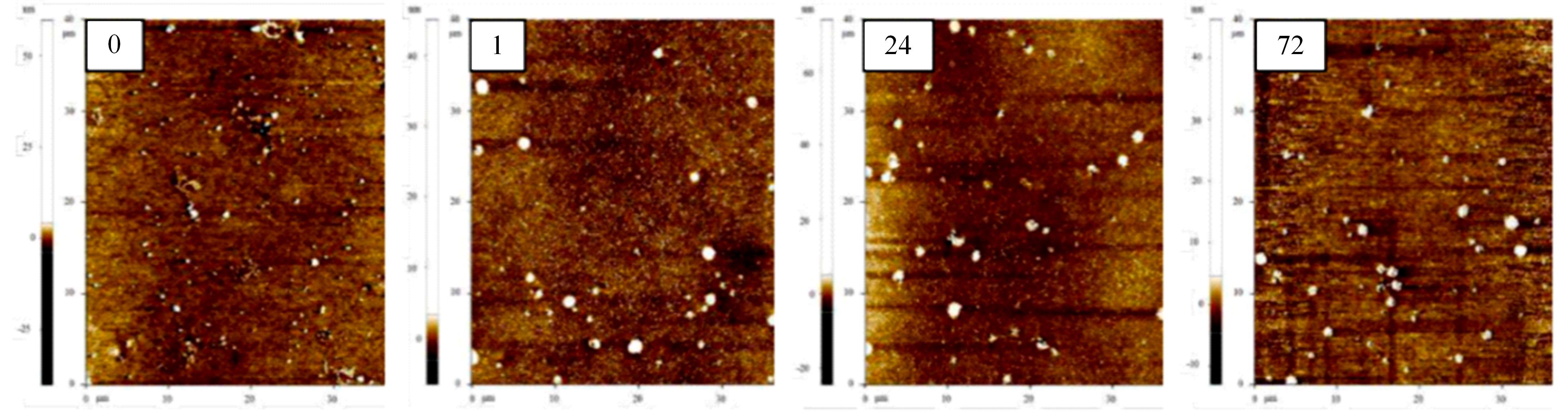

| 41 | 何亮, 马育, 凌天清, 等. 橡胶改性沥青及老化特征微观尺度分析[J]. 功能材料, 2015, 46(21): 21093-21098. |

| He Liang, Ma Yu, Ling Tian-qing, et al. Microscale analysis of asphalt rubber and aging Characteristics[J]. Journal of Functional Materials, 2015, 46(21):21093-21098. | |

| 42 | Amir G, Magdy A, Mohyeldin R. Evaluation of oxidization of crumb rubber-modified asphalt during short-term aging[J]. Transportation Research Record, 2015, 2505:84-91. |

| 43 | Zhang X, Xu C. The mechanism of asphalt modification by crumb rubber[J]. China Petroleum Processing & Petrochemical Technology, 2012, 14(3): 39-43. |

| 44 | Xu G, Kong P, Yu Y, et al. Rheological properties of rubber modified asphalt as function of waste tire rubber reclaiming degree[J]. Journal of Cleaner Production, 2022, 332:No.130113. |

| 45 | Wang S, Wang Q, Li S. Thermooxidative aging mechanism of crumb-rubber-modified asphalt[J]. Journal of Applied Polymer Science, 2016, 133(16): No.43323. |

| 46 | Jiao B, Pan B, Che T. Evaluating impacts of desulfurization and depolymerization on thermodynamics properties of crumb rubber modified asphalt through molecular dynamics simulation[J]. Construction and Building Materials, 2022, 323:No.126360. |

| 47 | Presti D L. Recycled type rubber modified bitumens for road asphalt mixtures: a literature review[J]. Construction & Building Materials, 2013, 49(6): 863-881. |

| 48 | Shatanawi K M, Biro S, Geiger A, et al. Effects of furfural activated crumb rubber on the properties of rubberized asphalt[J]. Construction and Building Materials, 2012, 28(1): 96-103. |

| 49 | Ghavibazoo A. Composition analysis of crumb rubber during interaction with asphalt and effect on properties of binder[J]. International Journal of Pavement Engineering, 2013, 14(5): 517-530. |

| 50 | Ghavibazoo A, Ragab M. Mechanism of crumb rubber modifier dissolution into asphalt matrix and its effect on final physical properties of crumb rubber-modified binder[J]. Journal of the Transportation Research Board, 2013, 2370: 92-101. |

| 51 | 刘延军, 叶志刚, 张玉贞. 橡胶粉改性沥青老化性能研究[J]. 施工技术, 2017, 46(11): 53-56. |

| Liu Yan-jun, Ye Zhi-gang, Zhang Yu-zhen. Study on aging performance of crumb rubber modified asphalt[J]. Municipal Engineering Technology, 2017, 46(11): 53-56. | |

| 52 | Li B, Zhou J, Zhang Z, et al. Effect of short-term aging on asphalt modified using microwave activation crumb rubber[J]. Materials, 2019, 12(7):No.1039. |

| 53 | Dhalaan M A. Characterization and Design of Recycled Asphalt Concrete Mixture Using Indirect Tensile Test Methods[M]. Austin:University of Texas at Austin, 1982. |

| 54 | Ibrahim M R, Katman H Y, Karim M R, et al. A review on the effect of crumb rubber addition to the rheology of crumb rubber modified bitumen[J]. Advances in Materials Science and Engineering, 2013(1):1-8. |

| 55 | 李炜光, 荣丽娟. 陕西常用沥青老化组分变化规律及其影响[J]. 石油沥青, 2012, 26(2): 28-32. |

| Li Wei-guang, Rong Li-juan. Changes of aging components and their effects on asphalt in Shaanxi Province[J]. Petroleum Bitumen, 2012, 26(2): 28-32. | |

| 56 | 刘军, 李和平, 杨彦海, 等. 辽河AH-90~#沥青老化组分变化研究[J]. 沈阳建筑工程学院学报:自然科学版, 2004(2): 127-129. |

| Liu Jun, Li He-ping, Yang Yan-hai, et al. Study on the changes of the aging components of Liaohe AH-90~# asphalt[J]. Journal of Shenyang Institute of Civil Engineering and Architecture(Natural Science Edition), 2004, (2):127-129. | |

| 57 | 常嵘, 王宏鑫. 沥青老化行为与老化机理研究[J]. 中国科技论文, 2020, 15(4): 420-424. |

| Chang Rong, Wang Hong-xin. Research on aging behavior and aging mechanism of asphalt[J]. China Science Paper, 2020, 15(4): 420-424. | |

| 58 | 王宝松, 金峰, 叶奋. 橡胶沥青微观结构热老化机理研究及影响因素分析[J]. 公路交通技术, 2013(6): 29-32. |

| Wang Bao-song, Jin Feng, Ye Fen. Research on thermal aging mechanism of microstructure of rubber asphalt and analysis for influence factors[J]. Technology of Highway and Transport, 2013(6): 29-32. | |

| 59 | Cui Y, Glover C J, Braziunas J, et al. Further exploration of the pavement oxidation model – Diffusion-reaction balance in asphalt[J]. Construction and Building Materials, 2018, 161: 132-140. |

| 60 | Glover C J, Davison R R, Domke C H, et al. Development of a new method for assessing asphalt binder performance durability[R]. Federal Highway Administration Report, 2001. |

| 61 | Wang Q, Li S, Wu X, et al. Weather aging resistance of different rubber modified asphalts[J]. Construction and Building Materials, 2016, 106: 443-448. |

| 62 | Wang S, Huang W, Liu X, et al. Influence of high content crumb rubber and different preparation methods on properties of asphalt under different aging conditions: chemical properties, rheological properties, and fatigue performance[J]. Construction and Building Materials, 2022, 327: No.126937. |

| 63 | 王强. 胶粉改性沥青老化过程中的结构与性能演化[D]. 上海: 上海应用技术学院材料科学与工程学院, 2016. |

| Wang Qiang. Structure and property evolution of crumb rubber modified Asphalt during aging process[D]. Shanghai: School of Materials Science and Engineering, Shanghai Institute of Applied Technology, 2016. | |

| 64 | Qian G, Yang C, Huang H, et al. Resistance to ultraviolet aging of nano-sio2 and rubber powder compound modified asphalt[J]. Materials, 2020, 13(22): No.5067. |

| 65 | 单宝龙, 孙敬军, 高会娟, 等. 四组分分析法研究老化改性沥青[J]. 当代化工, 2013, 42(6): 743-745. |

| Shan Bao-long, Sun Jing-jun, Gao Hui-juan, et al. Study on aging modified asphalt by four-component analysis[J]. Contemporary Chemical Industry, 2013, 42(6): 743-745. | |

| 66 | Gao M, Fan C, Chen X, et al. Study on ultraviolet aging performance of composite modified asphalt based on rheological properties and molecular dynamics simulation[J]. Advances in Materials Science and Engineering, 2022, No.7894190. |

| 67 | Fini E H, Hosseinnezhad S, Oldham D J, et al. Investigating the effectiveness of liquid rubber as a modifier for asphalt binder[J]. Road Materials and Pavement Design, 2016, 17(4): 825-840. |

| 68 | Saha Chowdhury P, Mullapudi R S, Muppireddy A. An investigation on the effect of aging on chemical and mechanical properties of asphalt binders[J]. Journal of Materials in Civil Engineering, 2022, 34(10): No.04022252. |

| 69 | 张洪刚, 谭华, 刘文昌, 等. 基质沥青化学组分对橡胶沥青性能影响的灰关联分析[J]. 公路, 2021, 66(4): 274-281. |

| Zhang Hong-gang, Tan Hua, Liu Wen-chang, et al. Grey relational analysis on asphalt component and rubberized asphalt performance[J]. Highway, 2021, 66(4): 274-281. | |

| 70 | 王珊珊, 郑华宇, 朱建国, 等. 固相萃取结合顶空GC-MS用于沥青老化机理研究[J]. 中国公路学报, 2021, 35(10): 1-18. |

| Wang Shan-shan, Zheng Hua-yu, Zhu Jian-guo, et al. Study on asphalt aging mechanism based on solid phase extraction combined with headspace GC-MS[J]. China Journal of Highway and Transport, 2021, 35(10): 1-18. | |

| 71 | 王强, 袁野, 欧阳春发, 等. 废旧橡胶改性沥青的老化研究现状[J]. 高分子通报, 2015(6): 19-28. |

| Wang Qiang, Yuan Ye, Ouyang Chun-fa, et al. Research status of aging of waste rubber modified asphalt[J]. Polymer Bulletin, 2015(6):19-28. | |

| 72 | Kabir S F, Fini E H. Investigating aging and rejuvenation mechanism of biomodified rubberized bitumen[J]. Journal of Materials in Civil Engineering, 2021, 33(7):No.04021142. |

| 73 | 温丽瑗, 张战军, 林海, 等. 基于正交试验的废轮胎胶粉改性沥青微观特性研究[J]. 合成橡胶工业, 2022, 45(4): 294-298. |

| Wen Li-yuan, Zhang Zhan-jun, Lin Hai, et al. Investigation on microscopic properties of crumb rubber modified asphalt based on orthogonal test[J]. China Synthetic Rubber Industry, 2022, 45(4): 294-298. | |

| 74 | 印佳, 毛雨珺, 李金亮, 等. 橡胶沥青紫外老化过程的探索[J]. 合成材料老化与应用, 2010, 39(3): 18-22. |

| Yin Jia, Mao Yu-jun, Li Jin-liang, et al. Investigation on the UV aging of asphalt rubber[J]. Aging and Application of Synthetic Materials, 2010, 39(3): 18-22. | |

| 75 | Wang H, Liu X, Apostolidis P, et al. Effect of laboratory aging on chemistry and rheology of crumb rubber modified bitumen[J]. Materials and Structures, 2020, 53(2): 1-15. |

| 76 | Wang S, Gao Y, Yan K, et al. Effect of long-term aging on waste tire rubber and amorphous poly alpha olefin compound modified asphalt binder and its mixtures[J]. Construction and Building Materials, 2021, 272: No.121667. |

| 77 | 包得祥, 曹青霞, 张富奎, 等. 石墨烯对橡胶复合改性沥青抗老化性能的影响[J]. 建筑材料学报, 2020, 23(5): 1113-1120. |

| Bao De-xiang, Cao Qing-xia, Zhang Fu-kui, et al. Effect of graphene on anti-aging properties of rubber modified asphalt[J]. Journal of Building Materials, 2020, 23(5): 1113-1120. | |

| 78 | 于江, 赵群, 叶奋, 等. 热老化作用下橡胶改性沥青的低温流变性能[J]. 西南交通大学学报, 2021, 56 (1): 108-115. |

| Yu Jiang, Zhao Qun, Ye Fen, et al. Low temperature rheological performance analysis of rubber modified asphalt under heat aging process[J]. Journal of Southwest Jiaotong University, 2021, 56(1): 108-115. | |

| 79 | 黄小燕, 王岚. 热氧老化作用下温拌胶粉改性沥青微观特性研究[J]. 建筑材料学报, 2020, 23(6): 1450-1457. |

| Huang Xiao-yan, Wang Lan. Investigation on microscale characteristics of warm mix rubber modified asphalt depending on thermal-oxidative aging[J]. Journal of Building Materials, 2020, 23(6): 1450-1457. | |

| 80 | 方彬彬, 叶园园, 李承烈, 等. 不同胶粉改性沥青抗老化性能对比[J]. 中外公路, 2017, 37(4): 285-289. |

| Fang Bin-bin, Ye Yuan-yuan, Li Cheng-lie, et al. Comparison of anti-aging properties of different crumb rubber modified asphalt[J]. Journal of China & Foreign Highway, 2017, 37(4): 285-289. | |

| 81 | Wang L, Li X, Shen J, et al. Aging characterizations of modified asphalt binders based on low field nuclear magnetic resonance (LF-NMR)[J]. Materials, 2022, 15(22):No.8224. |

| 82 | Xie J, Zhang Y, Yang Y. Study on preparation method of terminal blend rubberized asphalt binder[J]. Frontiers in Materials, 2020(7):No. 00279. |

| 83 | Zhou Y, Du L, Liu X, et al. Microscopic performance of modified asphalt based on aging[J]. Construction and Building Materials, 2021, 279: No.122429. |

| 84 | 胡栋梁, 顾兴宇, 孙丽君, 等. 基于量子化学的沥青热老化与紫外老化机理[J]. 交通运输工程学报, 2023, 23(2): 141-152. |

| Hu Dong-liang, Gu Xing-yu, Sun Li-jun, et al. Quantum chemistry—based thermal and UV aging mechanism of asphalt[J]. Journal of Traffic and Transportation Engineering, 2023, 23(2): 141-152. | |

| 85 | Zhang F, Hu C. The research for structural characteristics and modification mechanism of crumb rubber compound modified asphalts[J]. Construction and Building Materials, 2015, 76: 330-342. |

| 86 | 唐乃膨. 溶解性胶粉改性沥青的反应机理与流变性能研究[D]. 上海: 同济大学交通运输工程学院, 2017. |

| Tang Nai-peng. Interaction mechanism and rheological properties of terminal blend rubberized asphalt[D]. Shanghai: School of Transportation Engineering, Tongji University, 2017. | |

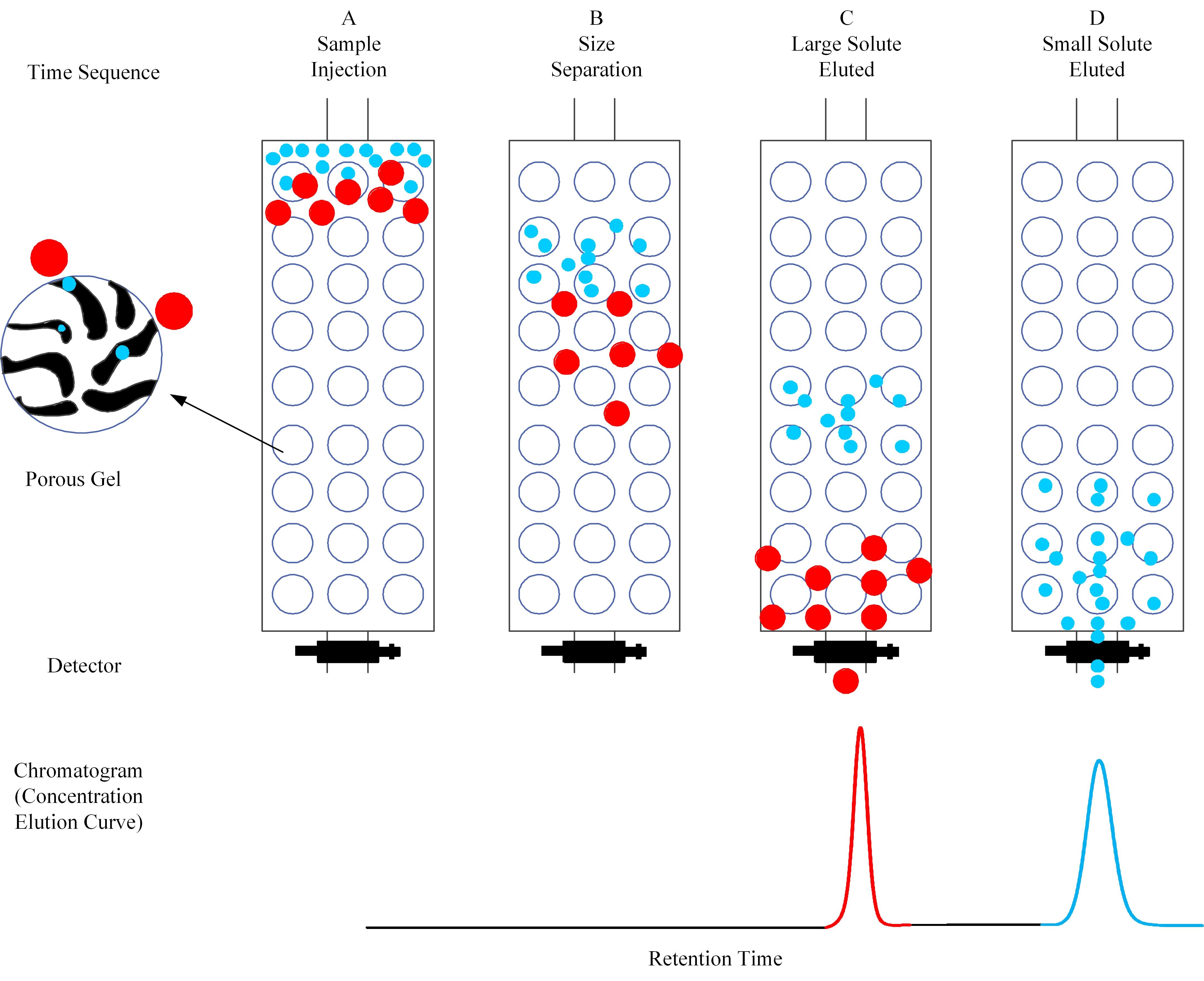

| 87 | 汪大受. 凝胶色谱法[J]. 微生物学通报, 1978(3): 33-43. |

| Wang Da-shou. Gel permeation chromatography[J]. Microbiology China, 1978(3): 33-43. | |

| 88 | Shen J, Amirkhanian S, Xiao F. High-pressure gel permeation chromatography of aging of recycled crumb rubber-modified binders with rejuvenating agents[J]. Journal of the Transportation Research Board, 2006, 1962(1): 21-27. |

| 89 | Zhou T, Zhou J, Li Q, et al. Aging Properties and Mechanism of Microwave-Activated Crumb Rubber Modified Asphalt Binder[J]. Frontiers in Materials, 2020(7): No.603938. |

| 90 | Lee S, Hu J, Kim H, et al. Aging analysis of rubberized asphalt binders and mixes using gel permeation chromatography[J]. Construction and Building Materials, 2011, 25(3): 1485-1490. |

| 91 | Baek S, Kim H, Doh Y, et al. Estimation of high-temperature properties of rubberized asphalt using chromatograph[J]. KSCE Journal of Civil Engineering, 2009, 13(3): 161-167. |

| 92 | Tang N, Dong R. Anti-Aging potential of sulphur in terminal blend rubberized asphalt binder[J]. Construction and Building Materials, 2020, 250:No.118858. |

| 93 | Ye W, Jiang W, Shan J, et al. Research on molecular weight distribution and rheological properties of bitumen during short-term aging[J]. Journal of Materials in Civil Engineering, 2020, 32(3): No.04019377. |

| 94 | 段春婷, 郑冬芳, 刘均庆, 等. 中间相沥青表征研究进展[J]. 新型炭材料, 2018, 33(3): 193-202. |

| Duan Chun-ting, Zheng Dong-fang, Liu Jun-qing, et al. Research progress on the characterization of mesophase pitch[J]. New Carbon Materials, 2018, 33(3): 193-202. | |

| 95 | Xiang Y, Xie Y, Long G, et al. Ultraviolet irradiation of crumb rubber on mechanical performance and mechanism of rubberised asphalt[J]. Road Materials and Pavement Design, 2019, 20(7): 1624-1637. |

| 96 | 王明, 刘黎萍, 吴后选. SBS改性沥青显微相态与宏观性能相关性研究[J]. 建筑材料学报, 2016, 19(1): 119-123, 142. |

| Wang Ming, Liu Li-ping, Wu Hou-xuan. Correlation between Phase Microstructure and Macroscopic Performance of SBS Modified Bitumen[J]. Journal of Building Materials, 2016, 19(1): 119-123, 142. | |

| 97 | 梁庆, 郑云, 张关发, 等. 废机油再生SBS改性沥青性能及再生机理[J]. 科学技术与工程, 2023, 23(2): 777-784. |

| Liang Qing, Zheng Yun, Zhang Guan-fa, et al. Performance and mechanism of styrence-butadiene-styrene (SBS) modified asphalt regenerated from waste engine oil[J]. Science Technology and Engineering, 2023, 23(2): 777-784. | |

| 98 | 蔡斌, 余功新, 李彦伟, 等. 超高掺量胶粉改性沥青性能[J]. 重庆交通大学学报:自然科学版, 2021, 40 (9): 117-123. |

| Cai Bin, Yu Gong-xin, Li Yan-wei, et al. Performance of ultra-high content rubber modified asphalt[J]. Journal of Chongqing Jiaotong University(Natural Sciences), 2021, 40(9): 117-123. | |

| 99 | Chang M, Zhang Y, Pei J, et al. Low-temperature rheological properties and microscopic characterization of asphalt rubbers containing heterogeneous crumb rubbers[J]. Materials, 2020, 13(18): No.4120. |

| 100 | 王岚, 陈刚, 邢永明, 等. 老化对胶粉和SBS改性沥青流变性能的影响[J]. 建筑材料学报, 2015, 18(3): 499-504. |

| Wang Lan, Chen Gang, Xing Yong-ming, et al. Effect of aging on rheological properties of crumb rubber and SBS modified asphalt[J]. Journal of Building Materials, 2015, 18(3): 499-504. | |

| 101 | Dong R, Zhao M, Xia W, et al. Chemical and microscopic investigation of co-pyrolysis of crumb tire rubber with waste cooking oil at mild temperature[J]. Waste Management, 2018, 79: 516-525. |

| 102 | Zadshir M, Ploger D, Yu X K, et al. Chemical, thermophysical, rheological, and microscopic characterisation of rubber modified asphalt binder exposed to UV radiation[J]. Road Materials and Pavement Design, 2020, 21: 123-139. |

| 103 | Ma W, Huang T, Guo S, et al. Atomic force microscope study of the aging/rejuvenating effect on asphalt morphology and adhesion performance[J]. Construction and Building Materials, 2019, 205: 642-655. |

| 104 | 崔亚楠, 于庆年, 韩吉伟, 等. 复杂气候条件下胶粉改性沥青的低温性能[J]. 材料导报, 2018, 32(12): 2078-2084. |

| Cui Ya-nan, Yu Qing-nian, Han Ji-chao, et al. Low temperature performance of rubber-modified asphalt under complex climate[J]. Materials Review, 2018, 32(12): 2078-2084. | |

| 105 | Wang L, Liu Y, Zhang L. Micro/nanoscale study on the effect of aging on the performance of crumb rubber modified asphalt[J]. Mathematical Problems in Engineering, 2020,No:1924349 . |

| 106 | Ren M, Li Y, Cheng P, et al. Effect of modifier on low-temperature reversible aging behavior of asphalt binder and its morphology analysis[J]. Construction and Building Materials, 2022, 351:No.128943. |

| 107 | 丁湛, 王爱波, 栗慧峰, 等. 胶粉颗粒变化对橡胶沥青粘度的影响分析[J]. 应用化工, 2023, 52(2): 350-354. |

| Ding Zhan, Wang Ai-bo, Li Hui-feng, et al. Effect analysis of particle changes of crumb rubber on viscosity of rubber asphalt[J]. Applied Chemical Industry, 2023, 52(2): 350-354. | |

| 108 | 周新星. 高掺量橡胶化生物沥青的相分离机理研究[J]. 公路, 2022, 67(7): 347-353. |

| Zhou Xin-xing. Study on phase separation mechanism of high content rubberized bio-asphalt[J]. Highway, 2022, 67(7): 347-353. | |

| 109 | 丁倩. 基于显微光谱技术的复合纤维成份定性分析方法研究[D]. 上海: 东华大学纺织学院, 2014. |

| Ding Qian. Investigation into the qualitative analysis of composite fiber through the detection of the microscopy spectrometry[D]. Shanghai: Textile College, Donghua University, 2014. | |

| 110 | 周艳明. 红外显微成像结合主成分分析对聚烯烃紫外光氧化的研究[D]. 北京: 北京化工大学理学院, 2010. |

| Zhou Yan-ming. FTIR imaging coupled with principal component analysis for study of photooxidation of polyolefin[D]. Beijing: School of Science, Beijing University of Chemical Technology, 2010. | |

| 111 | 周鑫. 聚合物复合材料相容性的傅立叶变换红外光谱显微成像研究[D]. 北京: 北京化工大学理学院, 2008. |

| Zhou Xin. Miscibility behavior of polymer composites using fourier transform infrared microscopic imaging[D]. Beijing: School of Science, Beijing University of Chemical Technology, 2008. | |

| 112 | Virginie M, Jerome L, Francoise D, et al. Infrared microscopy investigation of oxidation and phase evolution in bitumen modified with polymers[J]. Fuel, 2008, 87: 1270-1280. |

| 113 | Abdelmagid A A A, Feng C. Laboratory evaluation of the effects of short-term aging on high temperature performance of asphalt binder modified with crumb rubber and rice husk ash[J]. Petroleum Science and Technology, 2019, 37(13): 1557-1565. |

| 114 | 张智豪, 李波, 魏永政. 短期老化对胶粉改性沥青高温性能的影响[J]. 现代化工, 2018, 38(9): 105-109. |

| Zhang Zhi-hao, Li Bo, Wei Yong-zheng. Effect of short-term aging on high-temperature properties of crumb rubber modified asphalt[J]. Modern Chemical Industry, 2018, 38(9): 105-109. | |

| 115 | Chen R, Zhu H, Kong L, et al. Stage-aging characteristics and stages division of crumb rubber modified asphalt binder[J]. Construction and Building Materials, 2023, 367: 129712. |

| 116 | 沈燕, 康爱红, 王超, 等. 橡胶沥青混合料中橡胶沥青老化程度的表征[J]. 合成橡胶工业, 2017, 40(6): 467-472. |

| Shen Yan, Kang Ai-hong, Wang Chao, et al. Characterization of aging degree of asphalt rubber in rubber asphalt mixture[J]. China Synthetic Rubber Industry, 2017, 40(6): 467-472. | |

| 117 | Wang S, Huang W, Lin P. Low-temperature and fatigue characteristics of degraded crumb rubber–modified bitumen before and after aging[J]. Journal of Materials in Civil Engineering, 2022, 34(3): No.04021493. |

| 118 | 谭忆秋, 符永康, 纪伦, 等. 橡胶沥青低温评价指标[J]. 哈尔滨工业大学学报, 2016, 48(3): 66-70. |

| Tan Yi-qiu, Fu Yong-kang, Ji Lun, et al. Low-temperature evaluation index of rubber asphalt[J]. Journal of Harbin Institute of Technology, 2016, 48(3): 66-70. | |

| 119 | Wang R, Xu G, Chen X, et al. Evaluation of aging resistance for high-performance crumb tire rubber compound modified asphalt[J]. Construction and Building Materials, 2019, 218: 497-505. |

| 120 | Chen Z, Wang T, Pei J, et al. Low temperature and fatigue characteristics of treated crumb rubber modified asphalt after a long term aging procedure[J]. Journal of Cleaner Production, 2019, 234: 1262-1274. |

| 121 | 肖鹏, 王颖倩, 史杉杉. 橡胶沥青老化特性的线性分析与综合评价[J]. 公路, 2014, 59(11): 170-174. |

| Xiao Peng, Wang Ying-qian, Shi Shan-shan. Study of the adhesiveness between epoxy asphalt and granite aggregate[J]. Highway, 2014, 59(11): 170-174. | |

| 122 | Chipps J F, Davison R R, Glover C J. A model for oxidative aging of rubber-modified asphalts and implications to performance analysis[J]. Energy & Fuels, 2001, 15(3): 637-647. |

| 123 | Ghavibazoo A, Abdelrahman M, Ragab M. Evaluation of oxidization of crumb rubber-modified asphalt during short-term aging[J]. Transportation Research Record, 2015,2505: 84-91. |

| 124 | Yuan D, Jiang W, Xiao J, et al. Assessment of the aging process of finished product-modified asphalt binder and its aging mechanism[J]. Journal of Materials in Civil Engineering, 2022, 34(8): No.04022174. |

| 125 | 肖鹏, 郑佳辉, 丁燕. 基于流变指标的胶粉复合改性沥青热氧老化程度评估[J]. 材料科学与工程学报, 2019, 37(1): 113-118. |

| Xiao Peng, Zheng Jia-hui, Ding Yan. Evaluation of thermal aging degrees of rubber compound modified asphalt based on rheological indices[J]. Chinese Journal of Materials Science and Engineering, 2019, 37(1): 113-118. | |

| 126 | Wang S, Huang W, Kang A. Laboratory evaluation of the properties of high-cured crumb rubber modified asphalt containing sulfur and polymer after the oxidative aging procedure[J]. Construction and Building Materials, 2021, 304: No.124611 . |

| 127 | Wang F, Xiao Y, Cui P, et al. Correlation of asphalt performance indicators and aging degrees: a review[J]. Construction and Building Materials, 2020, 250: No.118824. |

| 128 | 于新, 孙文浩, 罗怡琳, 等. 橡胶沥青温度敏感性评价方法研究[J]. 建筑材料学报, 2013, 16(2): 266-270. |

| Yu Xin, Sun Wen-hao, Luo Yi-lin, et al. Research on the evaluation index of temperature sensitivity of CRMA[J]. Journal of Building Materials, 2013, 16(2): 266-270. | |

| 129 | 张恒龙, 徐国庆, 朱崇政, 等. 长期老化对基质沥青与SBS改性沥青化学组成、形貌及流变性能的影响[J]. 长安大学学报:自然科学版, 2019, 39(2): 10-18. |

| Zhang Heng-long, Xu Guo-qing, Zhu Chong-zheng, et al. Influence of long-term aging on chemical constitution, morphology and rheology of base and SBS modified asphalt[J]. Journal of Chang'an University (Natural Science Edition), 2019, 39(2): 10-18. | |

| 130 | 王明, 刘黎萍. 纳观尺度沥青相态力学特性老化行为[J]. 交通运输工程学报, 2019, 19(6): 1-13. |

| Wang Ming, Liu Li-ping. Aging behaviors of nanoscale mechanical properties of asphalt phases[J]. Journal of Traffic and Transportation Engineering, 2019, 19(6): 1-13. | |

| 131 | 杨震, 张肖宁, 虞将苗, 等. 基质沥青老化前后多尺度特性研究[J]. 建筑材料学报, 2018, 21(3): 420-425. |

| Yang Zhen, Zhang Xiao-ning, Yu Jiang-miao, et al. Study on multi-scale characteristics of matrix asphalt before and after aging[J]. Journal of Building Materials, 2018, 21(3): 420-425. | |

| 132 | 田小革, 郑健龙, 张起森. 老化对沥青结合料粘弹性的影响[J]. 交通运输工程学报, 2004(1): 3-6. |

| Tian Xiao-ge, Zheng Jian-long, Zhang Qi-sen. Effect of aging on viscoelastic performance of asphalt binder[J]. Journal of Traffic and Transportation Engineering, 2004(1): 3-6. | |

| 133 | Li Y, Feng J, Wu S, et al. Review of ultraviolet ageing mechanisms and anti-ageing methods for asphalt binders[J]. Journal of Road Engineering, 2022, 2(2): 137-155. |

| 134 | 汪婷. LDHs对沥青抗老化性能的影响研究[J]. 市政技术, 2021, 39 (12): 124-128. |

| Wang Ting. Effect of LDHs on aging resistance of asphalt[J]. Municipal Engineering Technology, 2021, 39 (12): 124-128. | |

| 135 | 金大勇, 颜川奇, 易宏宇, 等. 老化对改性沥青宽温度域黏弹特性的影响[J]. 建筑材料学报, 2022, 25(12): 1321-1328. |

| Jin Da-yong, Yan Chuan-qi, Yi Hong-yu, et al. Influence of aging on the wide-temperature-range viscoelasticity of modified asphalt[J]. Journal of Building Materials, 2022, 25 (12): 1321-1328. | |

| 136 | 袁朝圣. 热光氧耦合条件下SBS改性沥青老化与评价[D]. 长沙: 长沙理工大学交通运输工程学院, 2021. |

| Yuan Chao-sheng. Aging and evaluation of SBS modified asphalt under thermo-photo-oxygen coupling[D]. Changsha: School of Transportation Engineering, Changsha University of Science and Technology, 2021. | |

| 137 | 白献萍, 钱国平, 韦慧, 等. 紫外线光照辐射的SBS改性沥青老化研究现状[J]. 材料科学与工程学报, 2019, 37(5): 855-859. |

| Bai Xian-ping, Qiang Guo-ping, Wei Hui, et al. Review on SBS modified asphalt aging under ultraviolet light radiation[J]. Chinese Journal of Materials Science and Engineering, 2019, 37(5): 855-859. | |

| 138 | 常琨, 王选仓. SBS改性沥青RTFOT老化黏附性量化评价方法研究[J]. 公路交通科技, 2019, 36(12): 29-36. |

| Chang Kun, Wang Xuan-cang. Study on quantitative evaluation method of adhesion of SBS modified asphalt RTFOT aging[J]. Journal of Highway and Transportation Research and Development, 2019, 36(12): 29-36. | |

| 139 | Diab A, You Z, Li X, et al. Rheological models for non-newtonian viscosity of modified asphalt binders and mastics[J]. Egyptian Journal of Petroleum, 2020, 29(2): 105-112. |

| [1] | 王壮,冯振刚,姚冬冬,崔奇,沈若廷,李新军. 导电沥青混凝土研究进展[J]. 吉林大学学报(工学版), 2024, 54(1): 1-21. |

| [2] | 陈俊,孙振浩,赵成,吴欣怡,王俊鹏. 相变沥青混凝土复合结构降温效果试验分析[J]. 吉林大学学报(工学版), 2024, 54(1): 180-187. |

| [3] | 赵胜前,丛卓红,游庆龙,李源. 沥青-集料黏附和剥落研究进展[J]. 吉林大学学报(工学版), 2023, 53(9): 2437-2464. |

| [4] | 马涛,马源,黄晓明. 基于多元非线性回归的智能压实关键参数最优解[J]. 吉林大学学报(工学版), 2023, 53(7): 2067-2077. |

| [5] | 杨柳,王创业,王梦言,程阳. 设置自动驾驶小客车专用车道的六车道高速公路交通流特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2043-2052. |

| [6] | 周正峰,于晓涛,陶雅乐,郑茂,颜川奇. 基于灰色关联分析的树脂与弹性体高黏沥青高温性能评价[J]. 吉林大学学报(工学版), 2023, 53(7): 2078-2088. |

| [7] | 张青霞,侯吉林,安新好,胡晓阳,段忠东. 基于车辆脉冲响应的路面不平度识别方法[J]. 吉林大学学报(工学版), 2023, 53(6): 1765-1772. |

| [8] | 姜屏,陈业文,陈先华,张伟清,李娜,王伟. 改性石灰土在干湿和冻融循环下的无侧限抗压性能[J]. 吉林大学学报(工学版), 2023, 53(6): 1809-1818. |

| [9] | 江辉,李新,白晓宇. 桥梁抗震结构体系发展述评:从延性到韧性[J]. 吉林大学学报(工学版), 2023, 53(6): 1550-1565. |

| [10] | 司春棣,崔亚宁,许忠印,凡涛涛. 层间粘结失效后桥面沥青铺装层细观力学行为分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1719-1728. |

| [11] | 李岩,张久鹏,陈子璇,黄果敬,王培. 基于PCA-PSO-SVM的沥青路面使用性能评价[J]. 吉林大学学报(工学版), 2023, 53(6): 1729-1735. |

| [12] | 刘状壮,郑文清,郑健,李轶峥,季鹏宇,沙爱民. 基于网格化的路表温度感知技术[J]. 吉林大学学报(工学版), 2023, 53(6): 1746-1755. |

| [13] | 赵晓康,胡哲,张久鹏,裴建中,石宁. 基于光纤传感技术的路面结冰智能监测研究进展[J]. 吉林大学学报(工学版), 2023, 53(6): 1566-1579. |

| [14] | 惠冰,杨心怡,张乐扬,李扬. 检测车轨迹偏移对沥青路面磨耗计算误差的影响[J]. 吉林大学学报(工学版), 2023, 53(6): 1756-1764. |

| [15] | 李崛,张安顺,张军辉,钱俊峰. 级配碎石基层结构动力响应模型测试及数值分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1782-1789. |

|

||