吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (11): 3184-3191.doi: 10.13229/j.cnki.jdxbgxb.20230054

• 材料科学与工程 • 上一篇

2024铝合金双轴肩搅拌摩擦焊接头热循环及组织特征

冯家铖1,2( ),宫文彪1,2,3(

),宫文彪1,2,3( ),鞠川4,李于朋1,2,孙雨萌1,2,朱芮1,2

),鞠川4,李于朋1,2,孙雨萌1,2,朱芮1,2

- 1.长春工业大学 先进结构材料教育部重点实验室,长春 130012

2.长春工业大学 材料科学与工程学院,长春 130012

3.吉林省泰浩轨道客车装备有限公司,长春 130500

4.枣庄学院,山东 枣庄 277000

Thermal cycle and microstructures characteristic of bobbin tool friction stir welded 2024 aluminum alloy

Jia-cheng FENG1,2( ),Wen-biao GONG1,2,3(

),Wen-biao GONG1,2,3( ),Chuan JU4,Yu-peng LI1,2,Yu-meng SUN1,2,Rui ZHU1,2

),Chuan JU4,Yu-peng LI1,2,Yu-meng SUN1,2,Rui ZHU1,2

- 1.Key Laboratory of Advanced Structural Materials,Ministry of Education,Changchun University of Technology,Changchun 130012,China

2.School of Materials Science and Engineering,Changchun University of Technology,Changchun 130012,China

3.Jilin Province Taihao Railway Vehicles Facilities Co. ,Ltd. ,Changchun 130500,China

4.Zaozhuang University,Zaozhuang 277000,China

摘要:

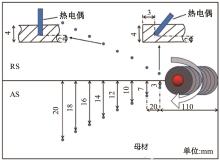

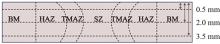

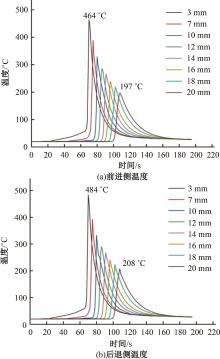

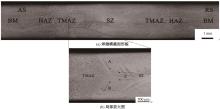

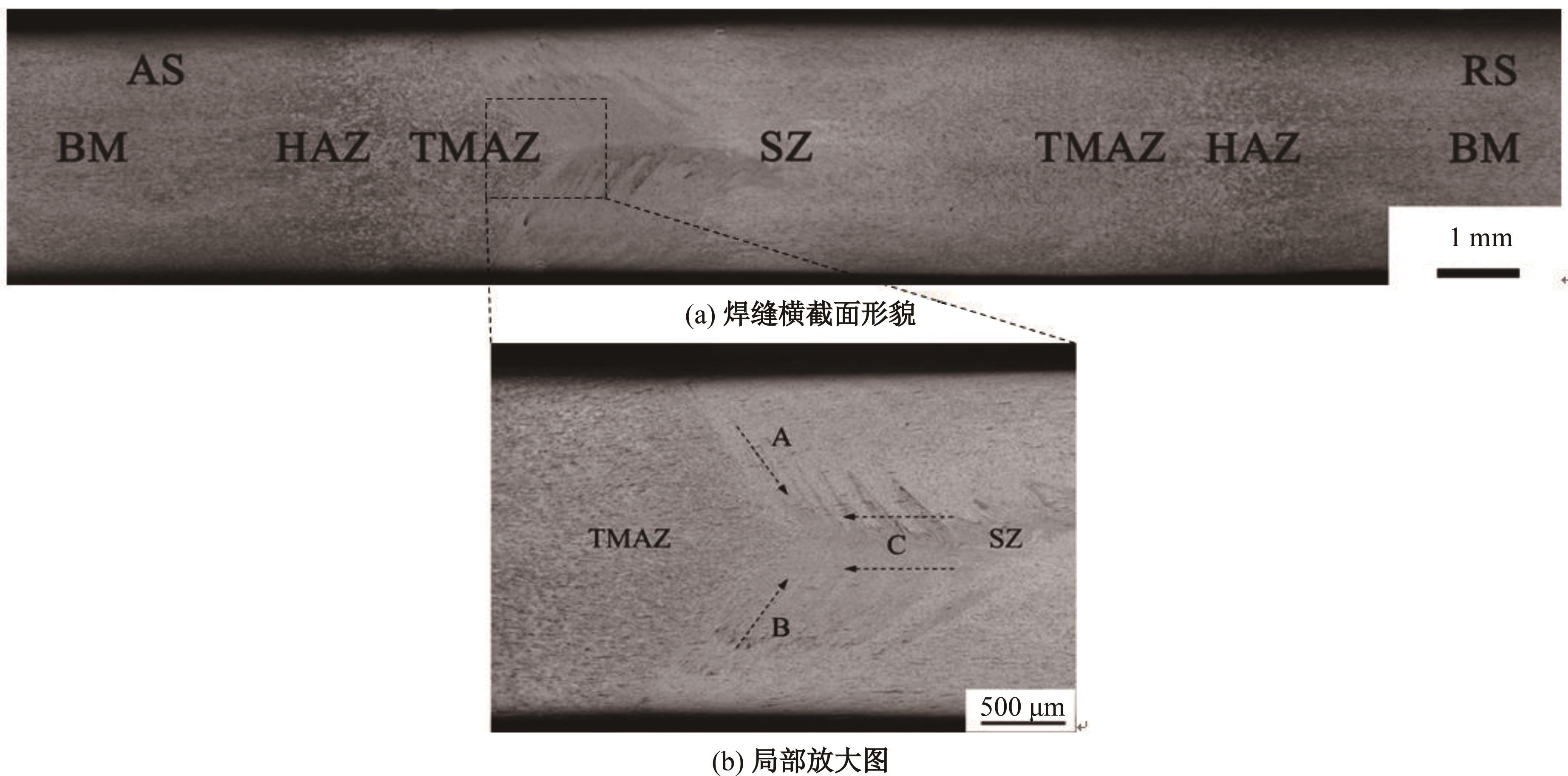

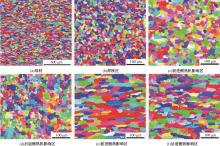

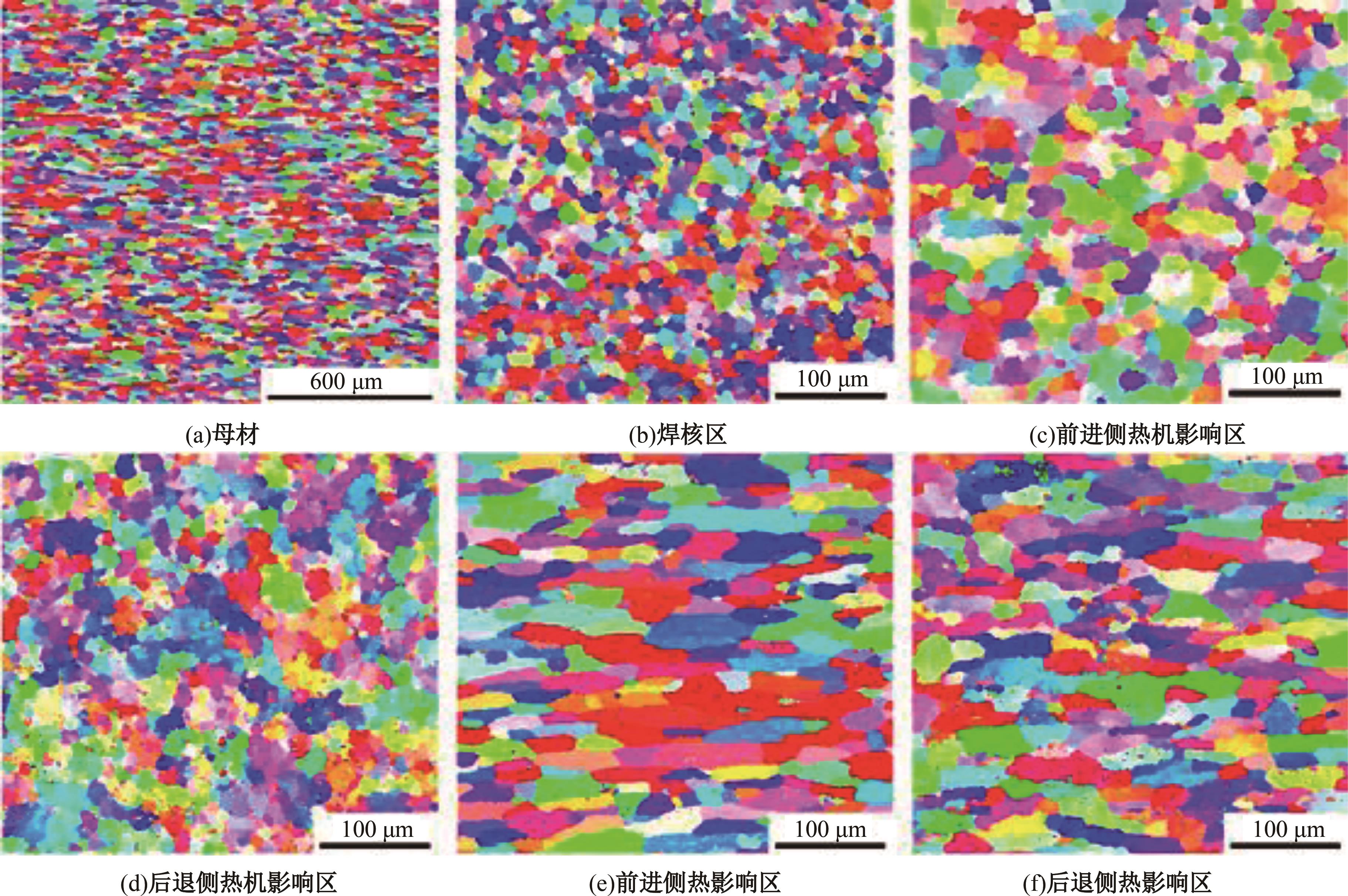

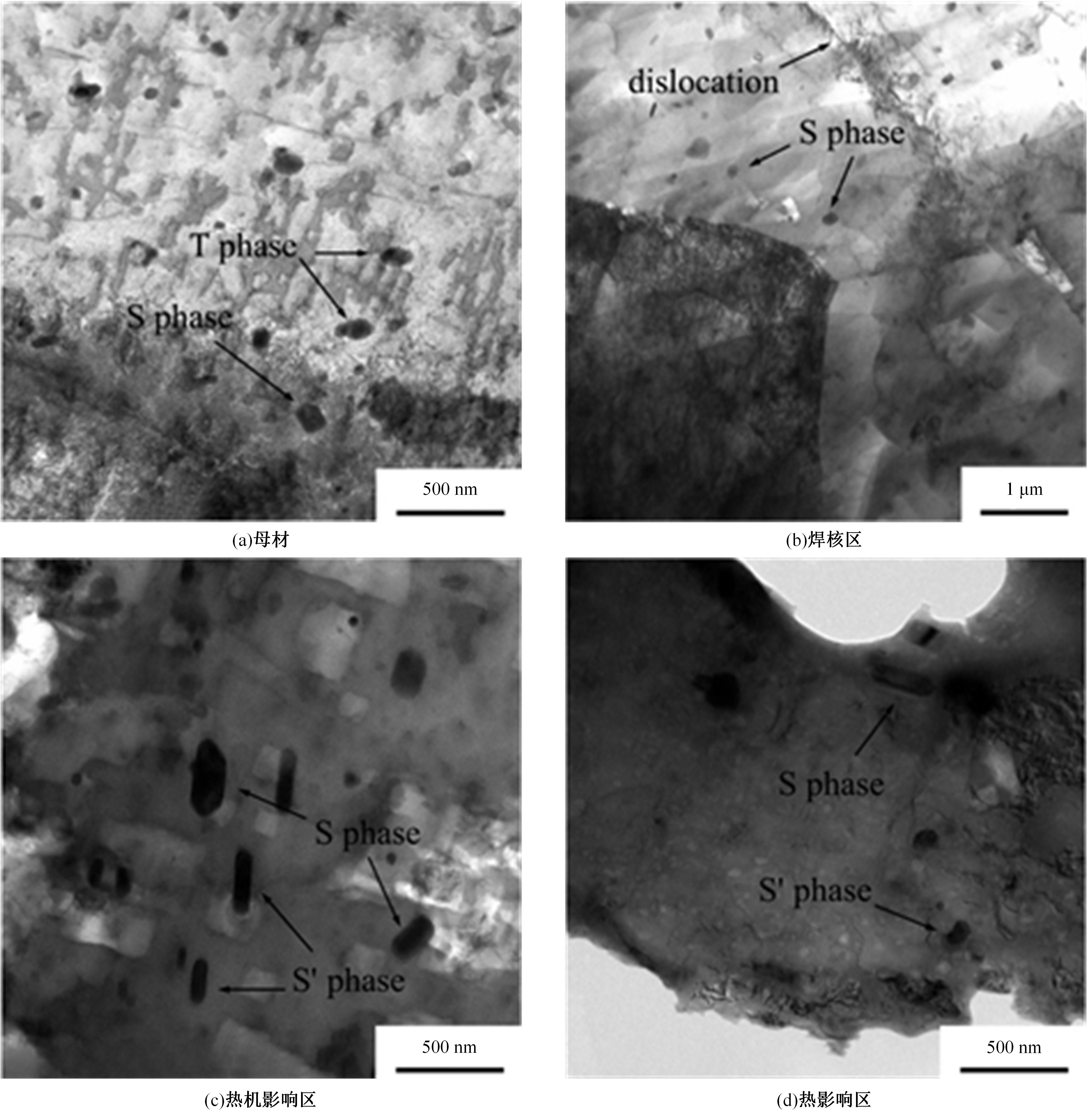

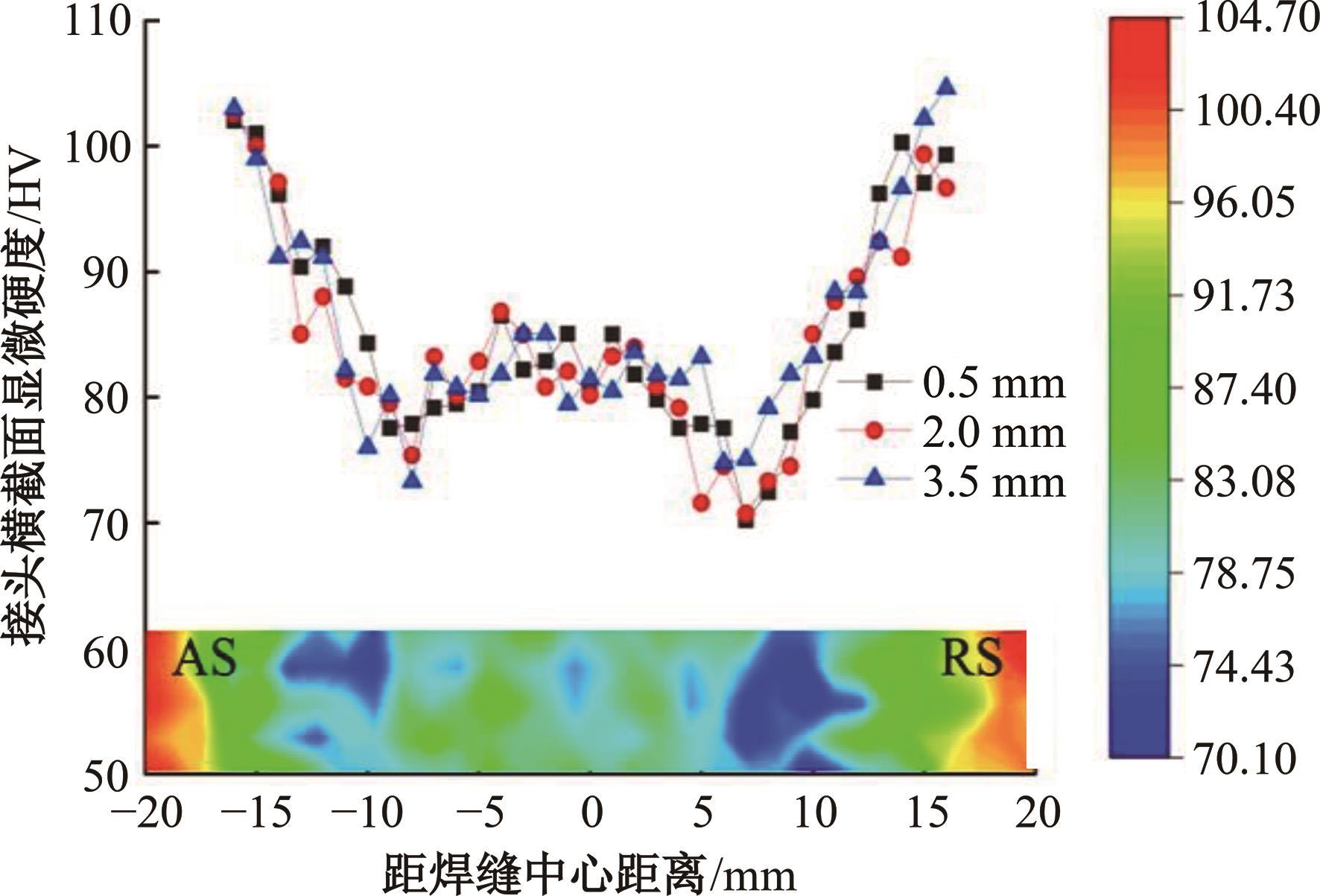

采用双轴肩搅拌摩擦焊(Bobbin tool friction stir welding, BT-FSW)对4 mm厚2024铝合金进行焊接,研究了焊接热循环温度对焊缝组织与性能的影响。结果表明:后退侧峰值温度高于前进侧,温度差约为20 ℃;焊核区平均晶粒尺寸为10.1 μm,后退侧各区域平均晶粒尺寸大于前进侧,小角度晶界占比小于前进侧;焊核区形成了细小的沉淀相S相,热影响区沉淀相数量减少和尺寸的增加导致力学性能下降;接头显微硬度呈“W”型分布,后退侧热机影响区与热影响区交界处硬度值最小,约为72.3 HV。

中图分类号:

- TG453

| 1 | 虞文军, 陈静. 国产2024铝合金不同连接工艺下组织和性能的研究[J]. 应用激光, 2012, 32(6): 31-34. |

| Yu Wen-jun, Chen Jing. Investigation of 2024 Al-alloy welding joint of different welding technology[J]. Applied Laser, 2012, 32(6): 31-34. | |

| 2 | 马小革. AA7050/AA2024异种铝合金搅拌摩擦焊疲劳特性研究[D]. 沈阳: 沈阳航空航天大学航空航天工程学院, 2013. |

| Ma Xiao-ge. Research on fatigue properties of friction stir welding AA7050/AA2024 aluminum alloys[D]. Shenyang: School of Aerospace Engineering, Shenyang Aerospace University, 2013. | |

| 3 | 桂兵, 张栋梁. 中厚板2024铝合金MIG焊工艺研究[J]. 焊接技术, 2018, 47(8): 46-48. |

| Gui Bing, Zhang Dong-liang. Study on MIG welding process of 2024 aluminum alloy for medium thickness plate[J]. Welding Technology, 2018, 47(8): 46-48. | |

| 4 | 郝云飞, 魏瑞刚, 周庆, 等. 焊接热输入对铝合金双轴肩搅拌摩擦焊缝形貌与接头性能的影响[J]. 焊接学报, 2018, 39(2): 84-88. |

| Hao Yun-fei, Wei Rui-gang, Zhou Qing, et al. Effect of heat input on weld morphology and tensile properties of bobbin friction stir welded joints[J]. Transactions of the China Welding Institution, 2018, 39(2): 84-88. | |

| 5 | 张会杰, 王敏, 张骁, 等. 2A14-T6铝合金双轴肩搅拌摩擦焊特征及接头组织性能分析[J]. 焊接学报, 2015, 36(12): 65-68. |

| Zhang Hui-jie, Wang Min, Zhang Xiao, et al. Characteristics and joint microstructure-property analysis of bobbin tool friction stir welding of 2A14-T6 aluminum alloy[J]. Transactions of the China Welding Institution, 2015, 36(12): 65-68. | |

| 6 | Fuse K, Badheka V. Bobbin tool friction stir welding: a review[J]. Science and Technology of Welding & Joining, 2018, 24(4): 277-304. |

| 7 | Wang F F, Li W Y, Shen J J, et al. Effect of tool rotational speed on the microstructure and mechanical properties of bobbin tool friction stir welding of Al-Li alloy[J]. Materials & Design, 2015, 86(5): 933-940. |

| 8 | Xu W F, Luo Y X, Fu M W. Microstructure evolution in the conventional single side and bobbin tool friction stir welding of thick rolled 7085-T7452 aluminum alloy[J]. Materials Characterization, 2018, 138(4): 48-55. |

| 9 | 李敬勇, 周小平, 董春林, 等. 6082铝合金双轴肩搅拌摩擦焊试板温度场研究[J]. 航空材料学报, 2013, 33(5): 36-40. |

| Li Jing-yong, Zhou Xiao-ping, Dong Chun-lin, et al. Temperature fields in 6082 aluminum alloy samples bobbin-tool friction stir welded[J]. Journal of Aeronautical Materials, 2013, 33(5): 36-40. | |

| 10 | 吉华, 邓运来, 邓建峰, 等. 焊接速度对6005A-T6铝合金双轴肩搅拌摩擦焊接头力学性能的影响[J]. 焊接学报, 2019, 40(5): 24-29. |

| Ji Hua, Deng Yun-lai, Deng Jian-feng, et al. Effect of welding speed on mechanical properties of bobbin tool friction stir welded 6005A-T6 aluminum alloy joints[J]. Transactions of the China Welding Institution, 2019, 40(5): 24-29. | |

| 11 | 戴忠晨, 云中煌, 付宁宁, 等. 5 mm厚6005A-T6铝合金双轴肩搅拌摩擦焊接头的组织及性能[J]. 机械工程材料, 2018, 42(2): 69-73. |

| Dai Zhong-chen, Yun Zhong-huang, Fu Ning-ning, et al. Microstructure and properties of bobbin tool friction stir welded joint of 5 mm thick 6005A-T6 aluminum alloy[J]. Materials for Mechanical Engineering, 2018, 42(2): 69-73. | |

| 12 | 王春桂, 赵运强, 董春林, 等. 6063-T6铝合金双轴肩搅拌摩擦焊接头组织及力学性能分析[J]. 焊接学报, 2018, 39(10): 108-112. |

| Wang Chun-gui, Zhao Yun-qiang, Dong Chun-lin, et al. Analysis on microstructure and mechanical properties of 6063-T6 self-reacting friction stir welding[J]. Transactions of the China Welding Institution, 2018, 39(10): 108-112. | |

| 13 | Threadgill P L. Friction stir welding-state of the art[R]. Industrial Member Report, 1999. |

| 14 | Trueba L, Torres M A, Johannes L B, et al. Process optimization in the self-reacting friction stir welding of aluminum 6061-T6[J]. International Journal of Material Forming, 2017, 11(4): 559-570. |

| 15 | 钮旭晶, 侯振国, 鲁二敬, 等. 标动铝合金底板双轴肩搅拌摩擦焊的数值仿真[J]. 轨道交通装备与技术, 2019, 2019(6): 26-30. |

| Niu Xu-jing, Hou Zhen-guo, Lu Er-jing, et al. Numerical simulation of FSW with double probes for base board of standard EMU[J]. Rail Transportation Equipment and Technology, 2019, 2019(6): 26-30. | |

| 16 | 李于朋, 孙大千, 宫文彪. 6082-T6铝合金薄板双轴肩搅拌摩擦焊温度场[J]. 吉林大学学报: 工学版, 2019, 49(3): 836-841. |

| Li Yu-peng, Sun Da-qian, Gong Wen-biao. Temperature fields in bobbin-tool friction stir welding for 6082-T6 aluminum alloy sheet[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(3): 836-841. | |

| 17 | Fuse K, Badheka V. Hybrid self-reacting friction stir welding of AA6061-T6 aluminium alloy with cooling assisted approach[J]. Metals, 2020, 11(1): 11010016. |

| 18 | Ahmed M M Z, Habba M M A, Elsayed M M, et al. Bobbin tool friction stir welding of aluminum thick lap joints: effect of process parameters on temperature distribution and joints' properties[J]. Materials, 2021, 14(16): 14164585. |

| 19 | Wang Z, Zhang B, Zhang Z, et al. Enhanced fatigue properties of 2219 Al alloy joints via bobbin tool friction stir welding[J]. Acta Metallurgica Sinica, 2022, 36: 586-596. |

| 20 | Zhu R, Gong W B, Cui H. Temperature evolution, microstructure, and properties of friction stir welded ultra-thick 6082 aluminum alloy joints[J]. The International Journal of Advanced Manufacturing Technology, 2020, 108(1/2): 331-343. |

| 21 | 刘西畅, 李文亚, 高彦军, 等. 铝合金双轴肩搅拌摩擦焊过程材料流动行为[J]. 焊接学报, 2021, 42(3): 48-56. |

| Liu Xi-chang, Li Wen-ya, Gao Yan-jun, et al. Material flow behavior during bobbin-tool friction stir welding of aluminum alloy[J]. Transactions of the China Welding Institution, 2021, 42(3): 48-56. | |

| 22 | Scialpi A, Filippis D, Cavaliere P. Influence of shoulder geometry on microstructure and mechanical properties of friction stir welded 6082 aluminium alloy[J]. Materials & Design, 2007, 28(4): 1124-1129. |

| 23 | Lin Y C, Xia Y C, Jiang Y Q, et al. Precipitation hardening of 2024-T3 aluminum alloy during creep aging[J]. Materials Science and Engineering, 2013, 565: 420-429. |

| 24 | 吕可欣. 2xxx系铝合金主要强化相的微观结构研究[D]. 上海: 上海交通大学材料科学与工程学院, 2019. |

| Ke-xin Lyu. Study on microstructure of main strengthening phases of 2xxx aluminum alloy[D]. Shanghai: School of Materials Science and Engineering, Shanghai Jiao Tong University, 2019. | |

| 25 | Fu R D, Zhang J F, Li Y J, et al. Effect of welding heat input and post-welding natural aging on hardness of stir zone for friction stir-welded 2024-T3 aluminum alloy thin-sheet[J]. Materials Science and Engineering, 2013, 559: 319-324. |

| [1] | 王磊,刘小鹏,周松,安金岚,张宏杰,丛家慧. 超声滚压对2024铝合金疲劳裂纹扩展行为的影响[J]. 吉林大学学报(工学版), 2024, 54(12): 3486-3495. |

| [2] | 安红萍,武建国. 热变形参数对2.25Cr-lMo-0.25V钢动态再结晶的影响[J]. 吉林大学学报(工学版), 2024, 54(12): 3460-3467. |

| [3] | 吴迪,耿文华,李洪梅,孙大千. 铝/钢等离子弧熔⁃钎焊接头界面电子背散射衍射分析[J]. 吉林大学学报(工学版), 2023, 53(5): 1331-1337. |

| [4] | 卢晓红,乔金辉,周宇,马冲,隋国川,孙卓. 搅拌摩擦焊温度场研究进展[J]. 吉林大学学报(工学版), 2023, 53(1): 1-17. |

| [5] | 庄蔚敏,王恩铭. 随机壁厚三维实体泡沫铝建模及压缩仿真[J]. 吉林大学学报(工学版), 2022, 52(8): 1777-1785. |

| [6] | 王金国,黄恺,闫瑞芳,任帅,王志强,郭劲. 元胞自动机-有限元法模拟碳当量元素对亚共晶球墨铸铁流动性的影响[J]. 吉林大学学报(工学版), 2021, 51(3): 855-865. |

| [7] | 范以撒,那景新,上官林建. 基于剩余强度的高速动车侧窗粘接强度校核方法[J]. 吉林大学学报(工学版), 2021, 51(3): 840-846. |

| [8] | 田银宝,申俊琦,胡绳荪,勾健. EP/EN模数对铝合金VP-CMT焊熔滴过渡及焊道成形的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1663-1668. |

| [9] | 王金国,王志强,任帅,闫瑞芳,黄恺,郭劲. Ti添加量对球墨铸铁组织及力学性能的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1653-1662. |

| [10] | 修文翠,吴化,韩英,刘云旭. 等温热处理温度对超级贝氏体组织与性能的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 520-525. |

| [11] | 宫文彪,朱芮,郄新哲,崔恒,宫明月. 6082铝合金超厚板搅拌摩擦焊接头组织与性能[J]. 吉林大学学报(工学版), 2020, 50(2): 512-519. |

| [12] | 陈学文,王继业,杨喜晴,皇涛,宋克兴. Cr8合金钢热变形行为及位错密度演变规律[J]. 吉林大学学报(工学版), 2020, 50(1): 91-99. |

| [13] | 王金国,任帅,闫瑞芳,黄恺,王志强. TiC颗粒对铸态球墨铸铁组织和力学性能的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 2010-2018. |

| [14] | 徐戊矫,刘承尚,鲁鑫垚. 喷丸处理后6061铝合金工件表面粗糙度的模拟计算及预测[J]. 吉林大学学报(工学版), 2019, 49(4): 1280-1287. |

| [15] | 李于朋,孙大千,宫文彪. 6082⁃T6铝合金薄板双轴肩搅拌摩擦焊温度场[J]. 吉林大学学报(工学版), 2019, 49(3): 836-841. |

|

||