Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (1): 294-312.doi: 10.13229/j.cnki.jdxbgxb.20220298

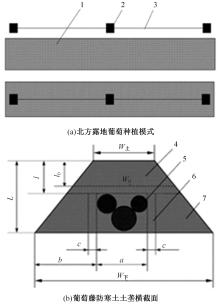

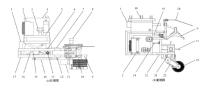

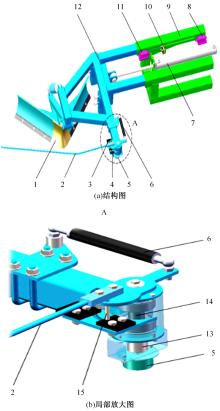

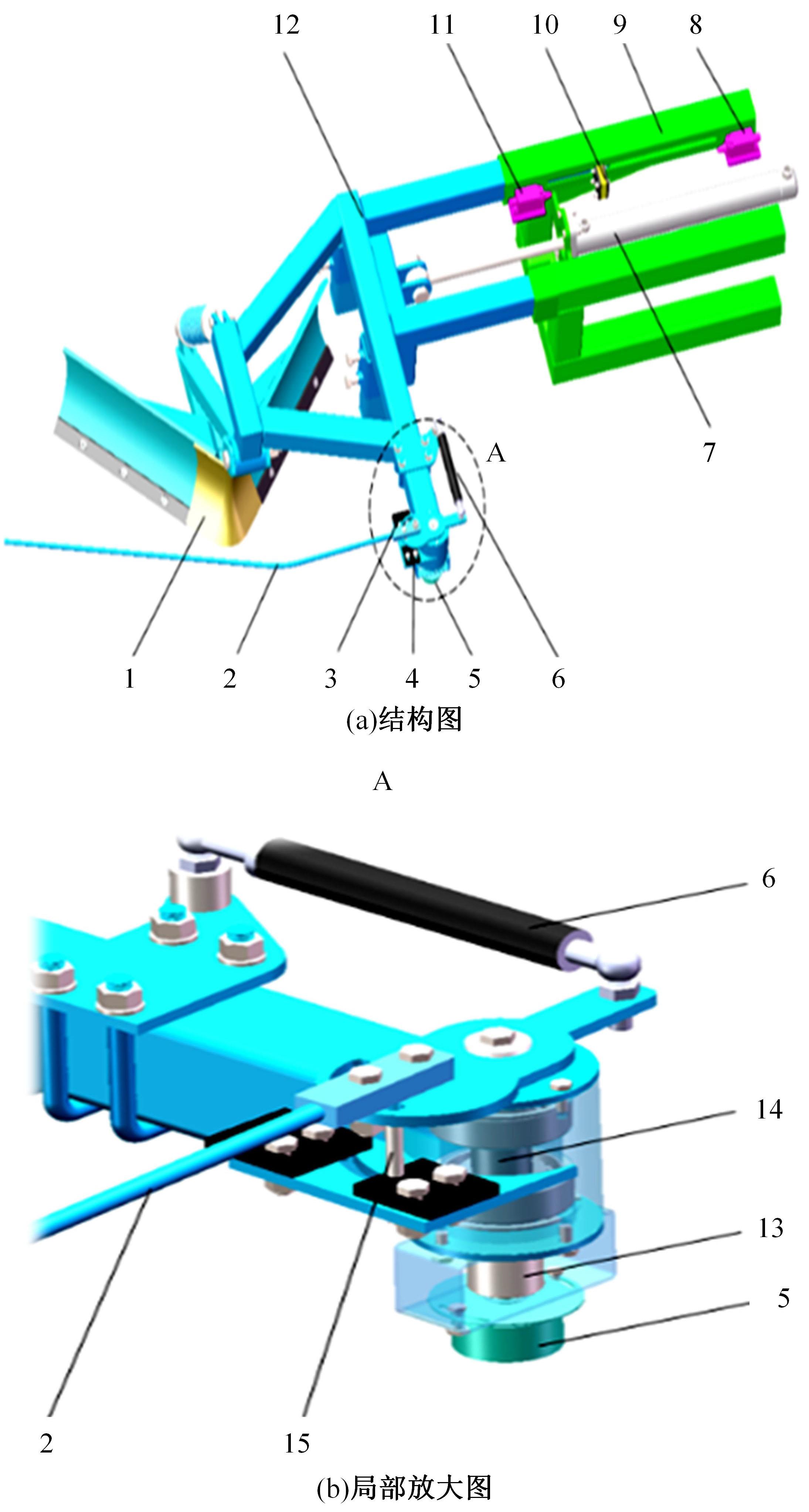

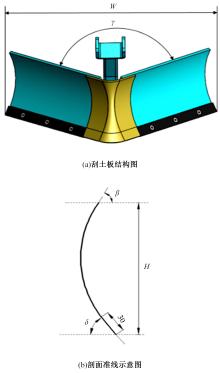

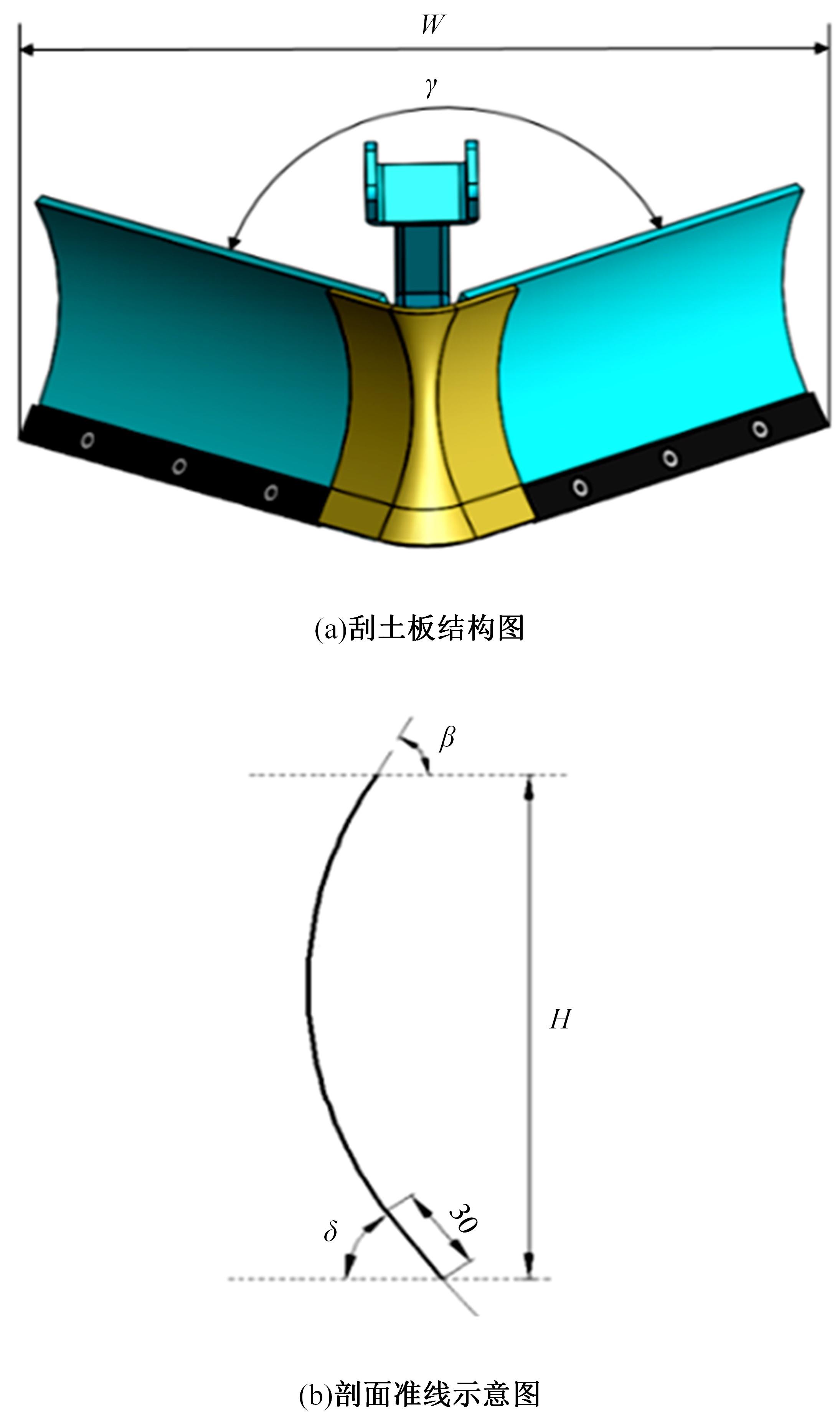

Design and experiment of grapevine cold⁃proof soil cleaner with combined scraping and brushing

Shuai MA1( ),Li-ming XU1(

),Li-ming XU1( ),Shu-cai XU2,Cong NIU1,Cheng-gong YAN1,Hao-chao TAN1

),Shu-cai XU2,Cong NIU1,Cheng-gong YAN1,Hao-chao TAN1

- 1.College of Engineering,China Agricultural University,Beijing 100083,China

2.State Key Laboratory of Automotive Safety and Energy,Tsinghua University,Beijing 100084,China

CLC Number:

- S224.9

| 1 | Wang J, Zhang X Y, Su L, et al. Global warming effects on climate zones for wine grape in Ningxia region, China [J]. Theoretical and Applied Climatology, 2020, 140(4): 1527-1536. |

| 2 | 马帅,徐丽明,袁全春,等. 葡萄机械化清土的发展现状与解决对策[J]. 农机化研究, 2020, 42(7): 1-8. |

| Ma Shuai, Xu Li-ming, Yuan Quan-chun, et al. Development status and countermeasures of grape mechanized soil clearing[J]. Journal of Agricultural Mechanization Research, 2020, 42(7): 1-8. | |

| 3 | 刘松. 圆锥螺旋式入春葡萄挖藤机设计与试验研究[D]. 乌鲁木齐:新疆农业大学, 2014. |

| Liu Song. Design and experiment study of conical spiral manner of grape vines in the spring digging machine[D]. Urumqi: Xinjiang Agricultural University, 2014. | |

| 4 | 亓桂梅,李旋,赵艳侠,等. 2017年世界葡萄及葡萄酒生产及流通概况[J]. 中外葡萄与葡萄酒, 2018(1): 68-74. |

| Qi Gui-mei, Li Xuan, Zhao Yan-xia, et al. Production and circulation of grape and its products in the world in 2017[J]. Sino-Overseas Grapevine & Wine, 2018(1): 68-74. | |

| 5 | 袁全春,徐丽明,马帅,等. 我国北方葡萄冬季埋土和春季清土作业的机械化现状与思考[J]. 中外葡萄与葡萄酒, 2017(6): 66-67. |

| Yuan Quan-chun, Xu Li-ming, Ma Shuai, et al. Current status and considerations on mechanization of winter burying and spring cleaning operations for grapes in northern China[J]. Sino-Overseas Grapevine & Wine, 2017(6): 66-67. | |

| 6 | 徐丽明,邢洁洁,李世军,等. 国外葡萄生产机械化发展和对我国现状的思考[J]. 河北林业科技, 2014(5): 124-128. |

| Xu Li-ming, Xing Jie-jie, Li Shi-jun, et al. Development of mechanization of grape production abroad and reflections on China's current situation[J]. Journal of Hebei Forestry Science and Technology, 2014(5): 124-128. | |

| 7 | 周伟斌. 葡萄起藤机的设计[D]. 银川: 宁夏大学机械工程学院, 2017. |

| Zhou Wei-bin. Design of grape vine digging machine[D]. Yinchuan: School of Mechanical Engineering,Ningxia University, 2017. | |

| 8 | Bisaglia C, Romano E. Utilization of vineyard prunings: A new mechanization system from residues harvest to CHIPS production[J]. Biomass & Bioenergy, 2018, 115: 136-142. |

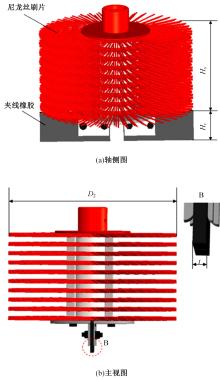

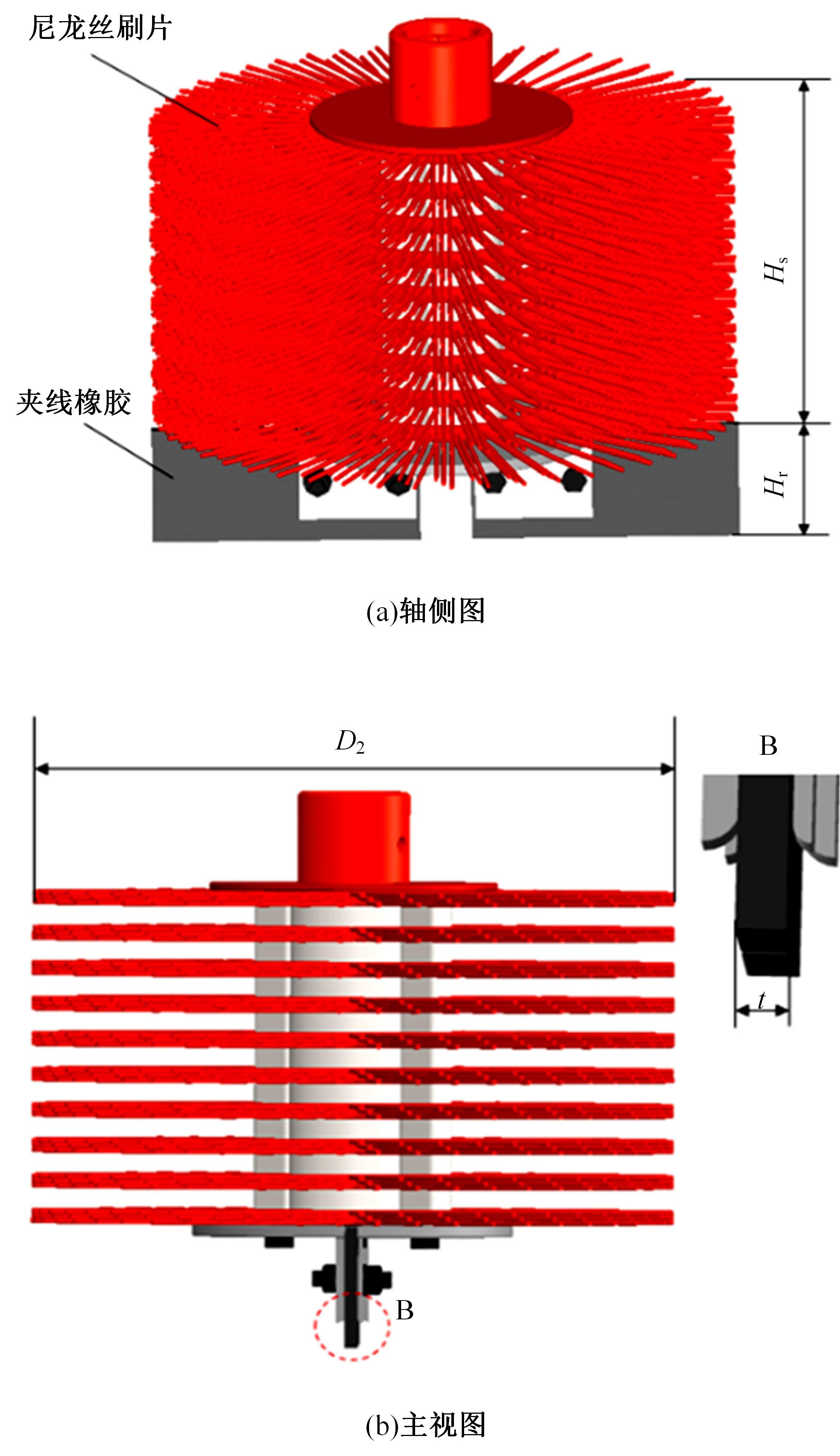

| 9 | 曾鉴. 气吹梳刷组合式葡萄防寒土清除机的设计与试验[D]. 北京: 中国农业大学工学院, 2020. |

| Zeng Jian. Design and experiment of combined air-blown and brush grape cold-proof soil remover[D]. Beijing: College of Engineering, China Agricultural University, 2020. | |

| 10 | 杜光雨. 风力吹送式酿酒葡萄清土机设计及试验研究[D]. 镇江:江苏大学农业工程学院, 2020. |

| Du Guang-yu, Design and experimental study of wine grape covering soil clearing machine with wind blowing [D]. Zhenjiang: College of Agricultural Engineering, Jiangsu University, 2020. | |

| 11 | 曾保宁,田志道,赵润良. 葡萄起藤机的设计与研制[J]. 中国农机化学报, 2013(6): 230-232. |

| Zeng Bao-ning, Tian Zhi-dao, Zhao Run-liang. Design and development of grape vine machine[J]. Journal of Chinese Agricultural Mechanization, 2013(6): 230-232. | |

| 12 | 陈智, 万平, 杨术明, 等. 葡萄藤起藤自动除土机[P]. 中国: CN205755312U. 2016-12-07. |

| 13 | 李法键. 葡萄园防寒土清除机关键部件设计与分析[D]. 秦皇岛: 河北科技师范学院机电工程学院, 2019. |

| Li Fa-jian. Design and analysis on key components of vineyard cold soil removal machine [D]. Qinhuangdao: College of Agricultural Engineering, Hebei Normal University of Science & Technology, 2019. | |

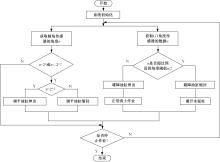

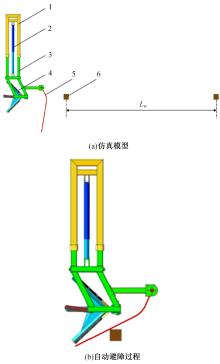

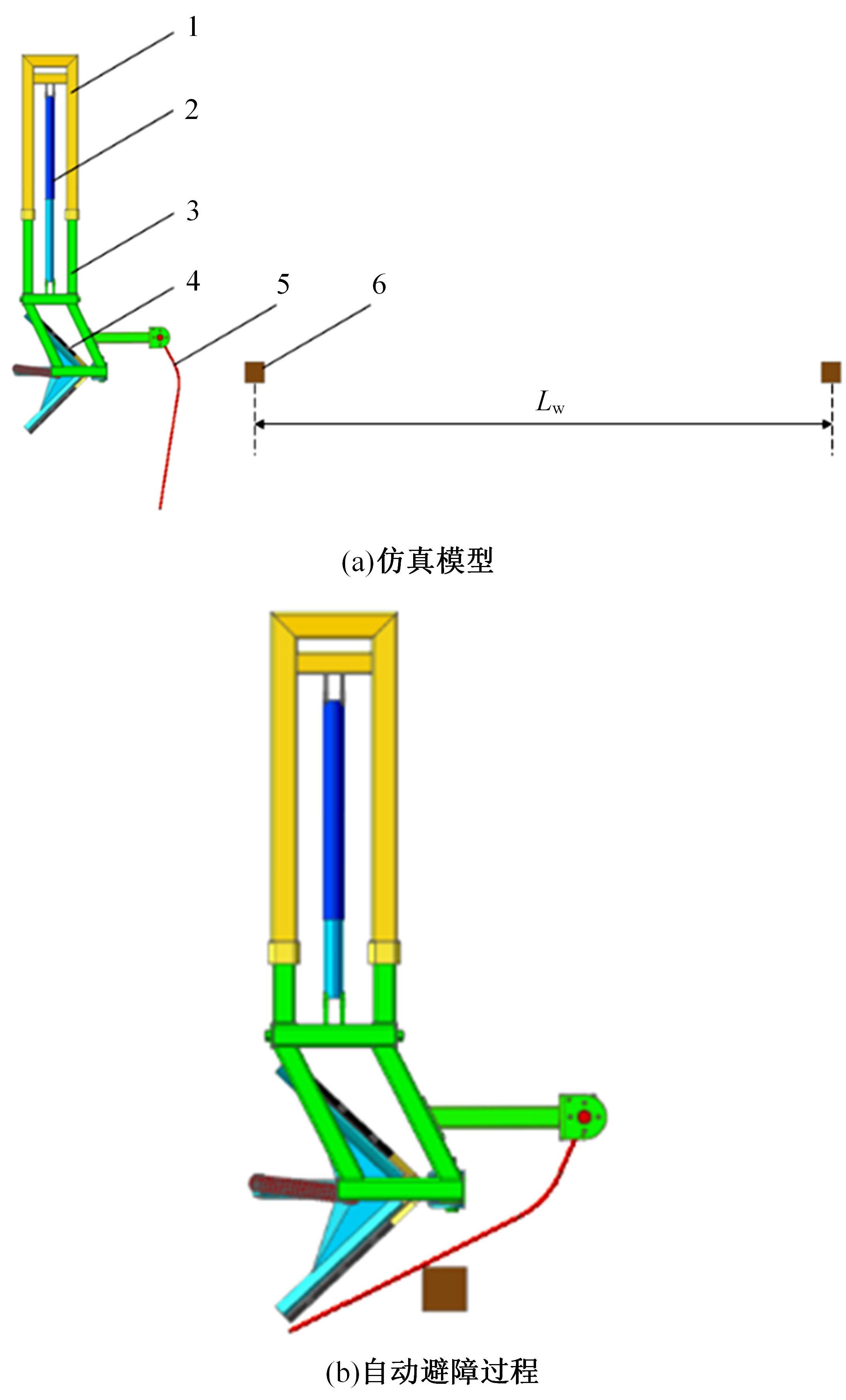

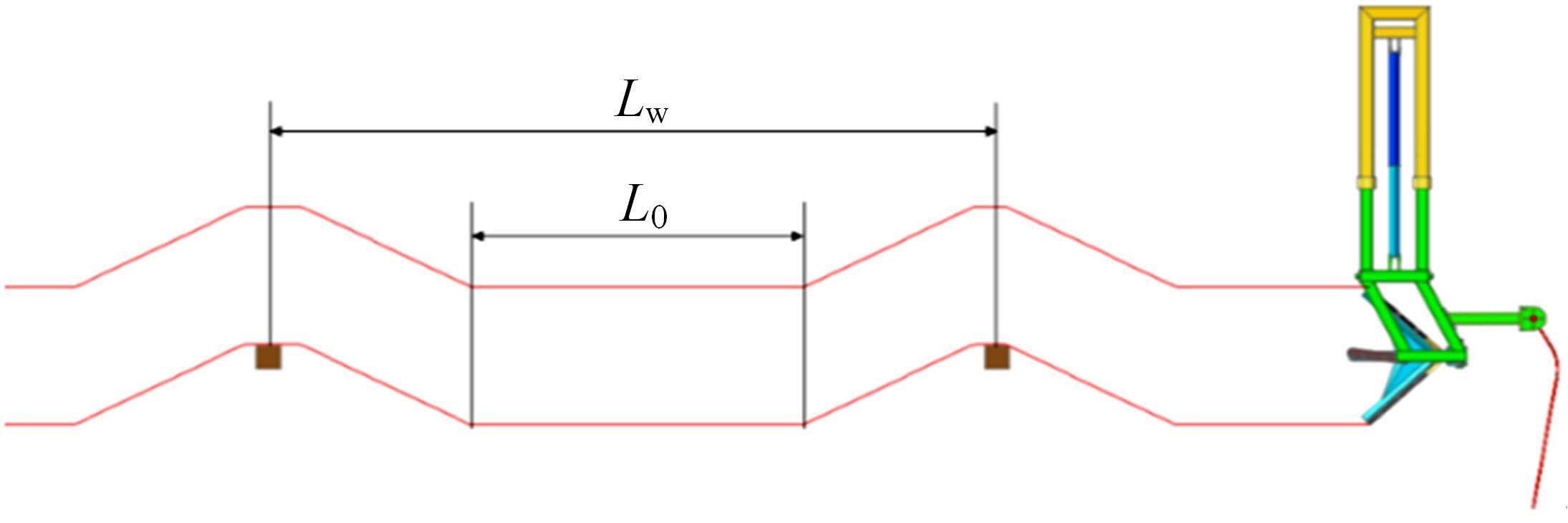

| 14 | 刘芳建,刘忠军,王锦江,等. 自动避障葡萄藤扒土机的设计与试验研究[J]. 农机化研究, 2018(4): 87-90. |

| Liu Fang-jian, Liu Zhong-jun, Wang Jin-jiang, et al. Design and experimental study of automatic obstacle-avoid digging machine for grape wine[J]. Journal of Agricultural Mechanization Research, 2018(4): 87-90. | |

| 15 | 王文斌. 葡萄清土开沟机设计研究[D]. 北京: 中国农业大学工学院, 2015. |

| Wang Wen-bin. Research & design of grape vines digger[D]. Beijing: College of Engineering, China Agricultural University, 2015. | |

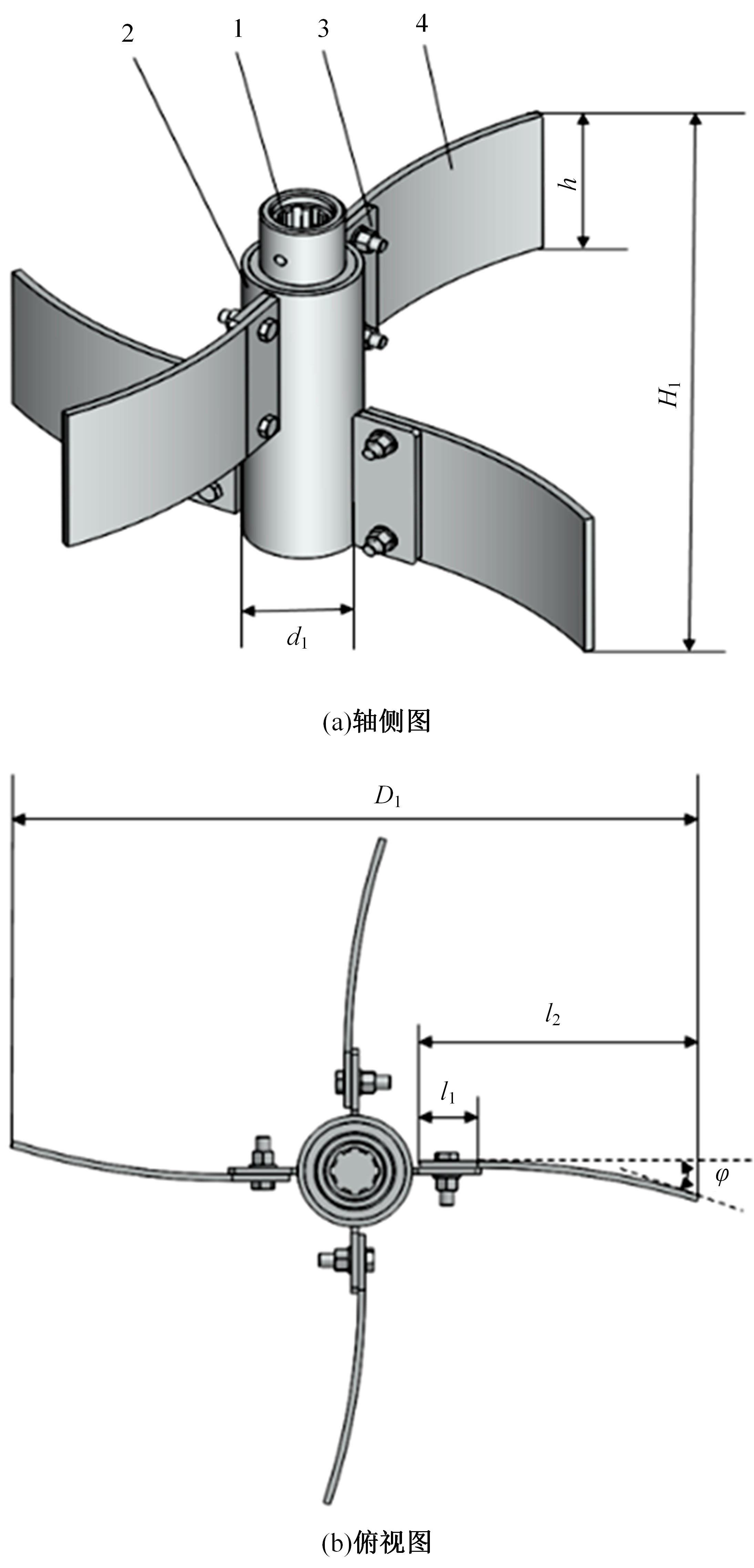

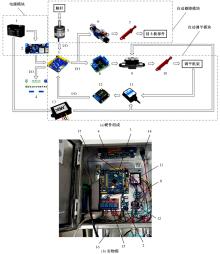

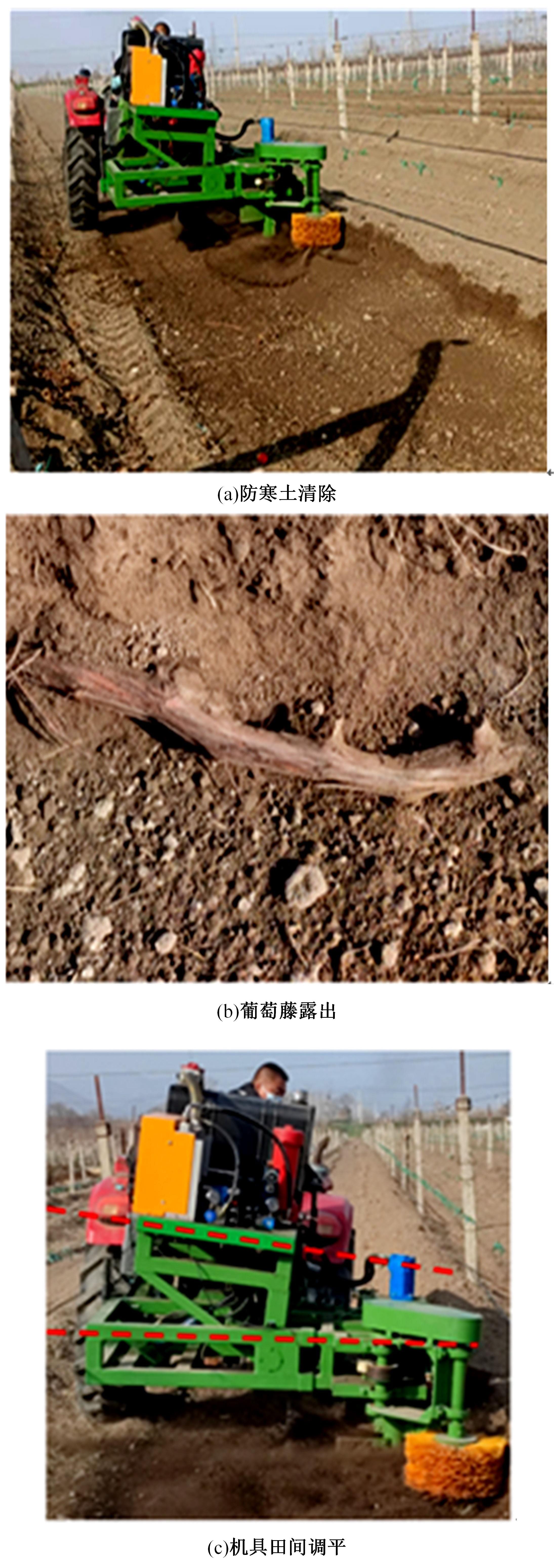

| 16 | 马帅,徐丽明,邢洁洁,等. 叶轮旋转式葡萄藤埋土单边清除机研制[J]. 农业工程学报, 2018, 34(23): 1-10. |

| Ma Shuai, Xu Li-ming, Xing Jie-jie, et al. Development of unilateral cleaning machine for grapevine buried by soil with rotary Impeller[J]. Transactions of the CSAE, 2018, 34(23): 1-10. | |

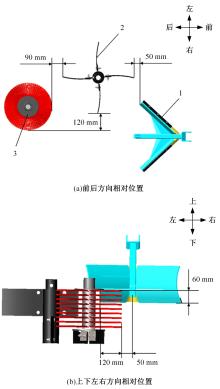

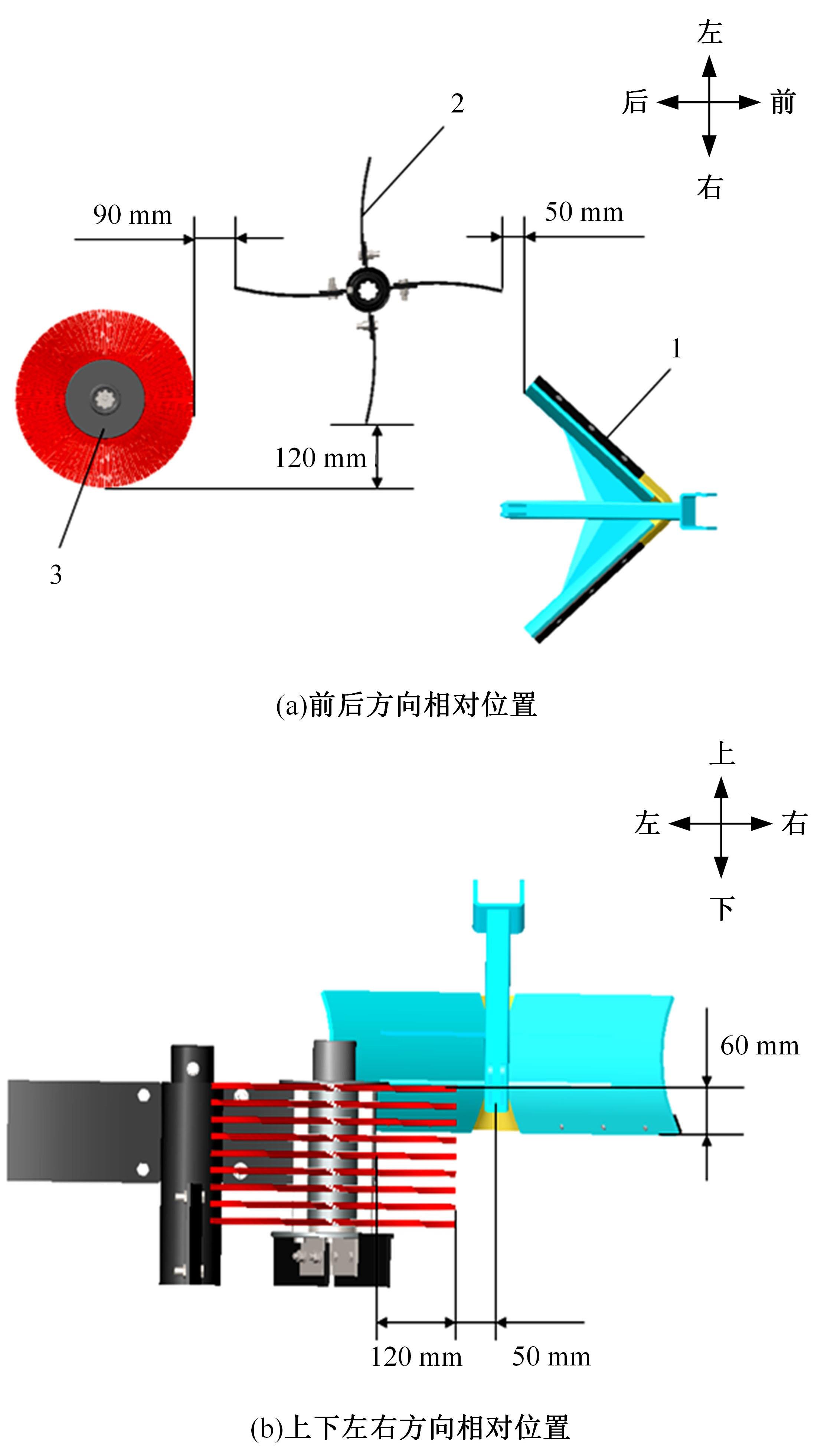

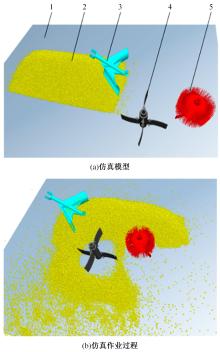

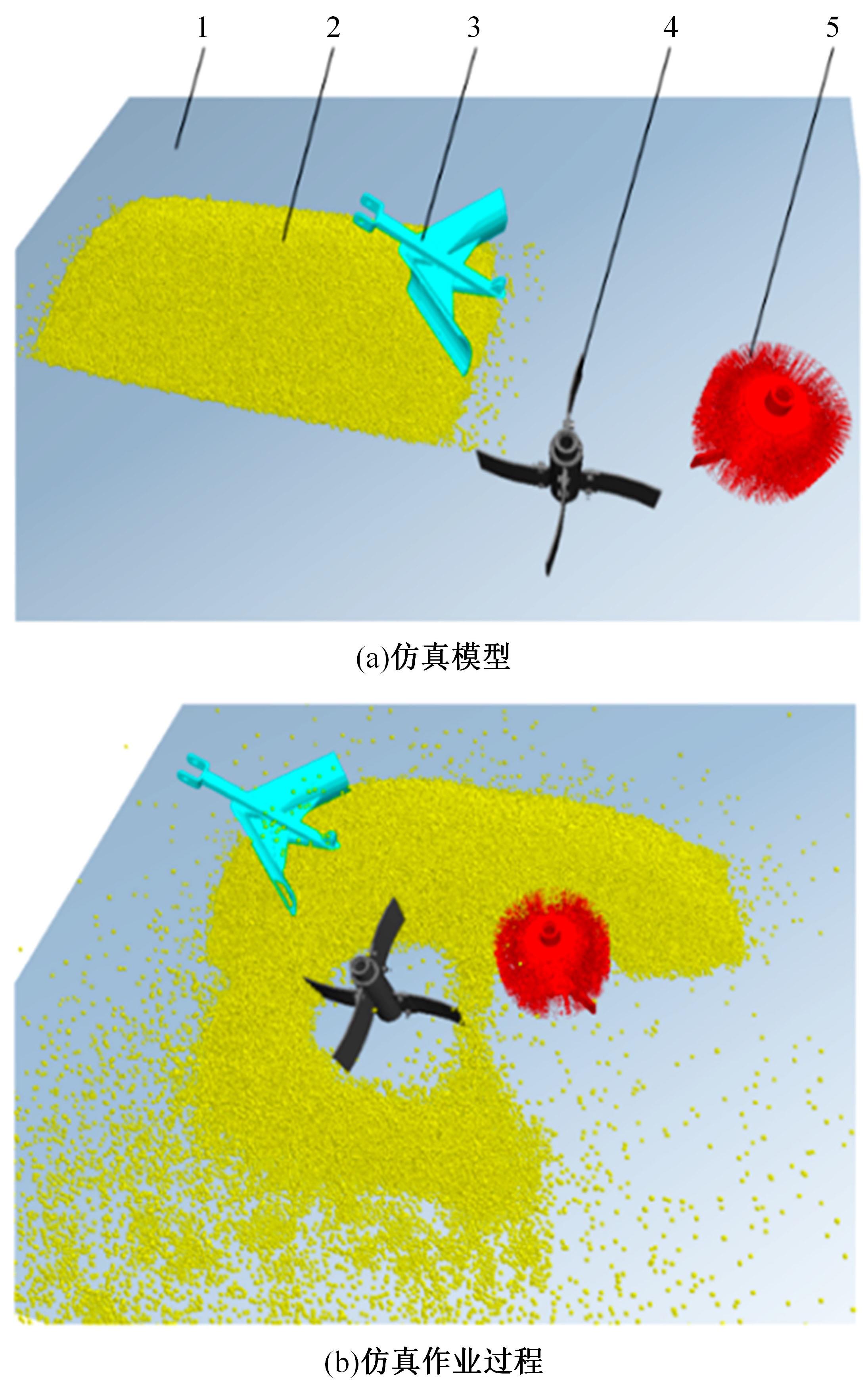

| 17 | Ma Shuai, Niu Cong, Yan Cheng-gong, et al. Soil cleaning effect and parameters optimization of the scraper for grapevine cold-proof soil investigated by DEM simulation [J]. Biosystems Engineering,2021, 210: 156-170. |

| 18 | Coetzee C J, Lombard S G. Discrete element method modelling of a centrifugal fertiliser spreader[J]. Biosystems Engineering, 2011, 109(4): 308-325. |

| 19 | Ding S, Bai L, Yao Y, et al. Discrete element modelling (DEM) of fertilizer dual-banding with adjustable rates[J]. Computers and Electronics in Agriculture, 2018, 152: 32-39. |

| 20 | 胡永光,杨叶成,肖宏儒,等. 茶园施肥机离心撒肥过程仿真与参数优化[J]. 农业机械学报, 2016, 47(5): 77-82. |

| Hu Yong-guang, Yang Ye-cheng, Xiao Hong-ru, et al. Simulation and parameter optimization of centrifugal fertilizer spreader for tea plants[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(5): 77-82. | |

| 21 | Van L P, Tijskens E, Dintwa E, et al. A discrete element model for simulation of a spinning disc fertilizer spreader I. Single particle simulations[J]. Powder Technology, 2006, 170(2):71-85. |

| 22 | 吕金庆,孙贺,兑瀚,等. 锥形撒肥圆盘中肥料颗粒运动模型优化与试验[J]. 农业机械学报, 2018, 49(6): 85-91. |

| Lv Jin-qing, Sun He, Han Dui, et al. Optimization and experiment of fertilizer particle motion model in conical spreading disk[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(6): 85-91. | |

| 23 | 马帅,徐丽明,牛丛,等. 分层交错式葡萄防寒土弧形清土叶轮的设计与试验[J]. 农业工程学报, 2021, 37(10): 1-9. |

| Ma Shuai, Xu Li-ming, Niu Cong, et al. A facile arc impeller with layered-staggered structure to clean cold-proof soil on grapes[J]. Transactions of the CSAE, 2021, 37(10): 1-9. | |

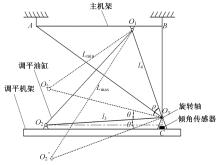

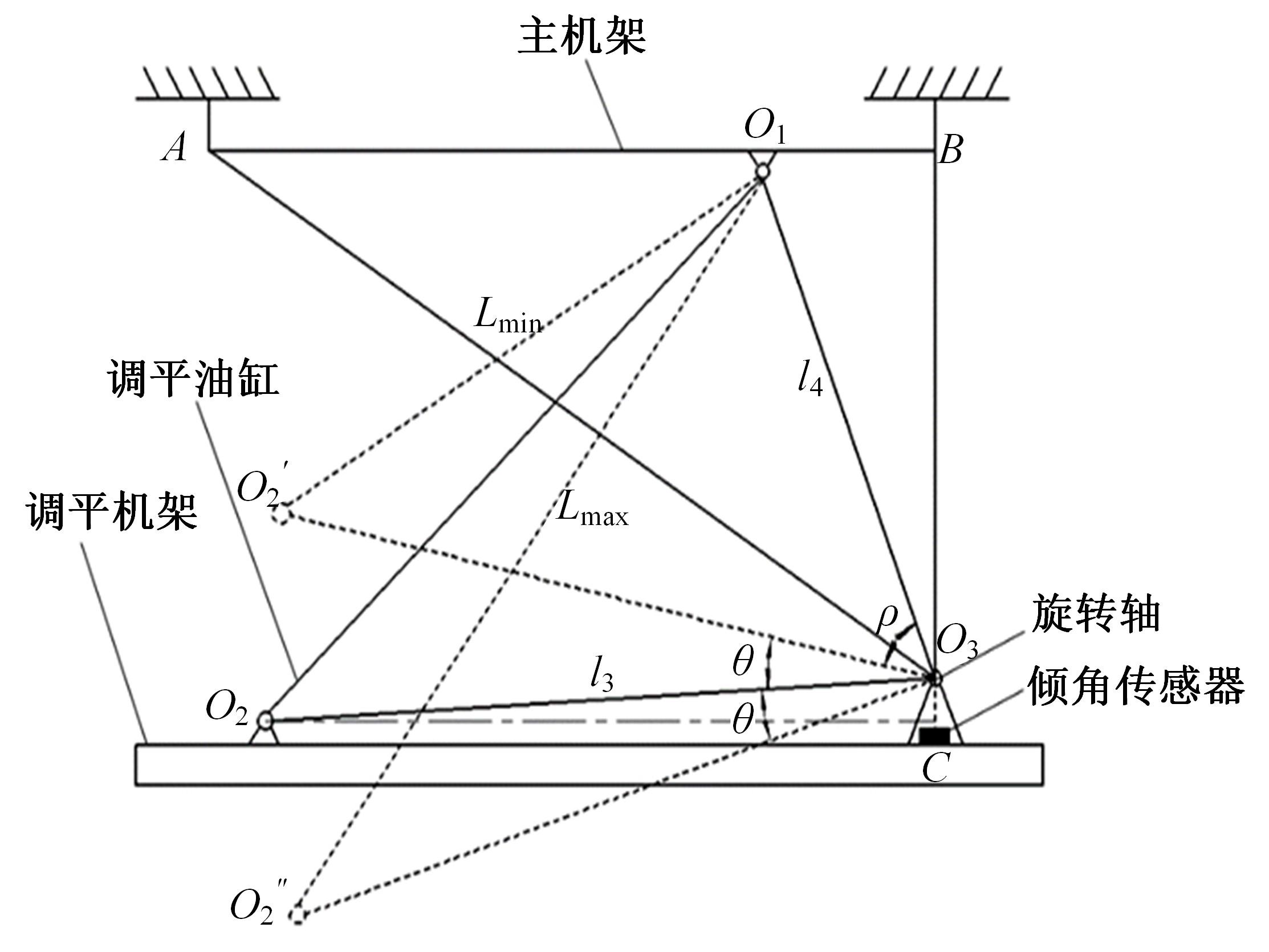

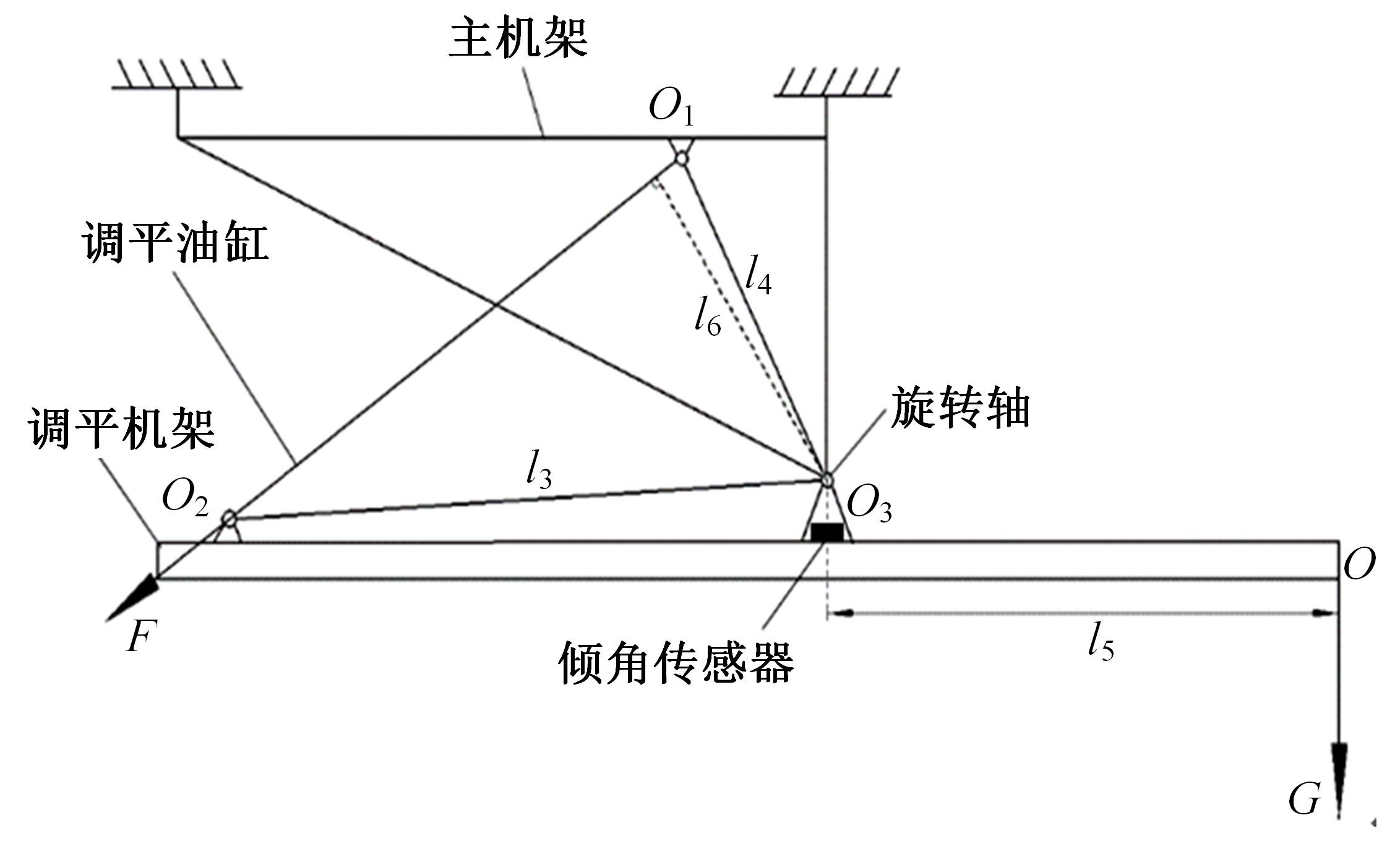

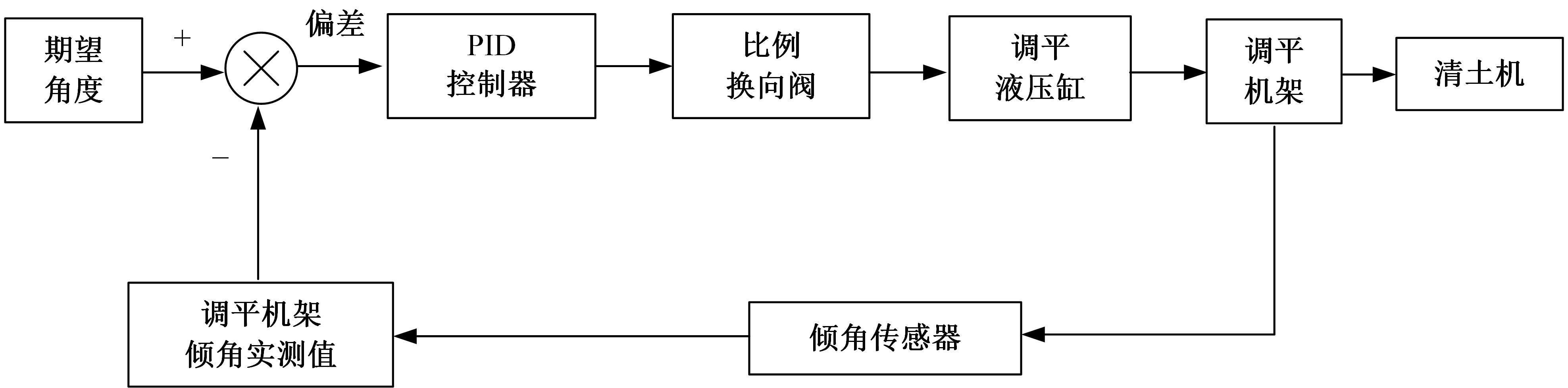

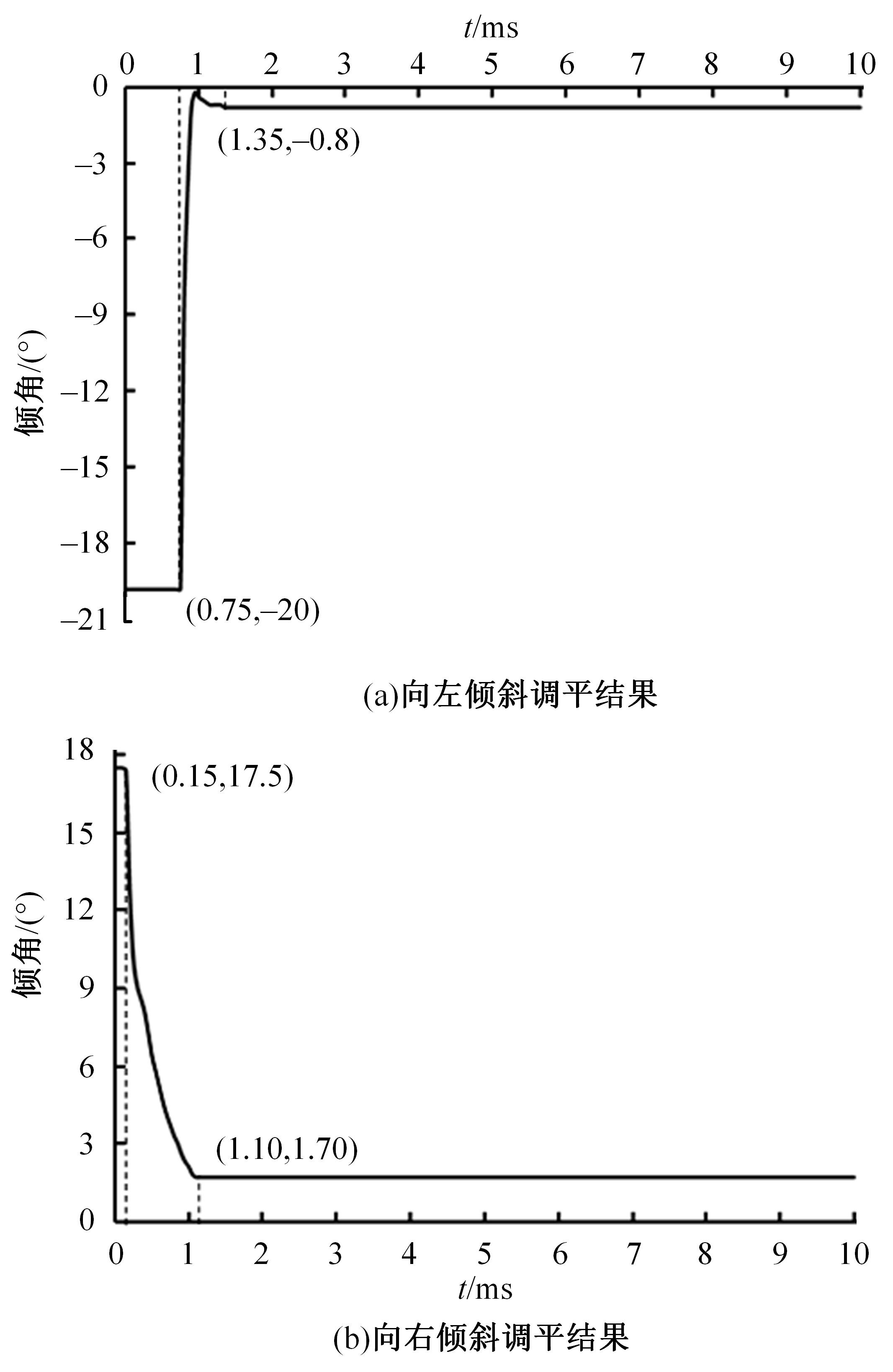

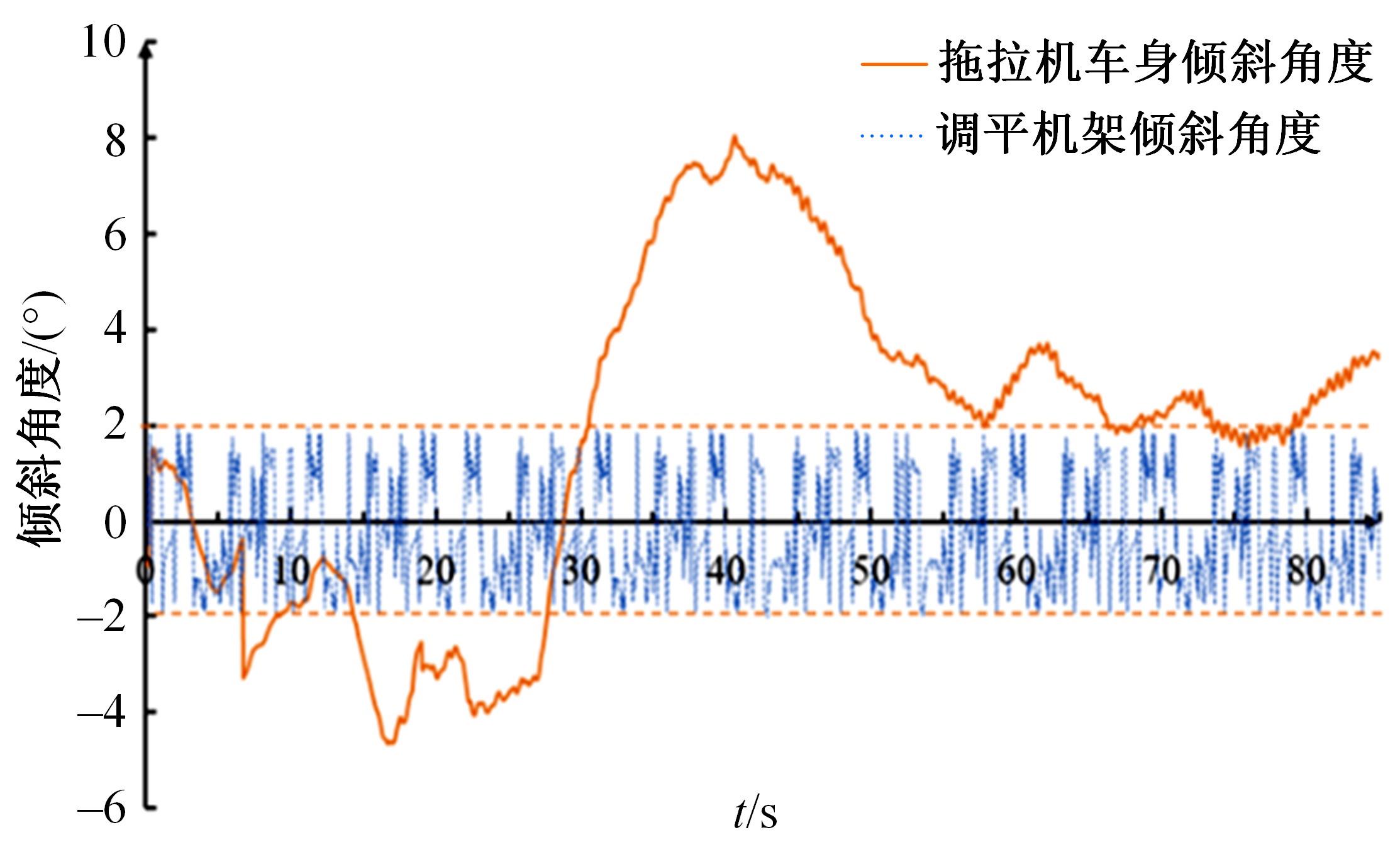

| 24 | 孙永佳,周军,李学强,等. 马铃薯联合收获机车身调平系统设计与试验[J]. 农业机械学报, 2020, 51(): 298-306. |

| Sun Yong-jia, Zhou Jun, Li Xue-qiang, et al. Design and experiment of body leveling system for potato combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(Sup.): 298-306. | |

| 25 | 董伟亮. 液压设计手册[M]. 北京: 机械工业出版社, 2005. |

| 26 | 周浩,胡炼,罗锡文,等. 旋耕机自动调平系统设计与试验[J]. 农业机械学报, 2016, 47(): 117-123. |

| Zhou Hao, Hu Lian, Luo Xi-wen, et al. Design and experiment on auto leveling system of rotary tiller [J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(Sup.): 117-123. | |

| 27 | 潘杰,陈凡,胡建平,等. 基于EDEM-RecurDyn的指夹式取苗爪仿真优化设计[J]. 农业机械学报, 2023,53(5):75-85, 301. |

| Pan Jie, Chen Fan, Hu Jian-ping, et al. Simulation and optimization design of finger-clamping seedling picking claw based on EDEM-RecurDyn[J]. Transactions of the Chinese Society for Agricultural Machinery, 2023,53(5):75-85, 301. | |

| 28 | 王少杰, 殷月, 余圣锋, 等. 基于RecurDyn-EDEM的装载机耦合动力学仿真分析[J]. 机械设计, 2021,38(11):1-6. |

| Wang Shao-jie, Yin Yue, Yu Sheng-feng, et al. Dynamic analysis on loader coupling based on RecurDyn-EDEM[J]. Journal of Machine Design, 2021, 38(11):1-6. | |

| 29 | 于畅畅,徐丽明,王庆杰,等. 篱架式栽培葡萄双边作业株间自动避障除草机设计与试验[J]. 农业工程学报, 2019, 35(5): 1-9. |

| Yu Chang-chang, Xu Li-ming, Wang Qing-jie, et al. Design and experiment of bilateral operation intra-row auto obstacle avoidance weeder for trellis cultivated grape[J]. Transactions of the CSAE, 2019, 35(5): 1-9. | |

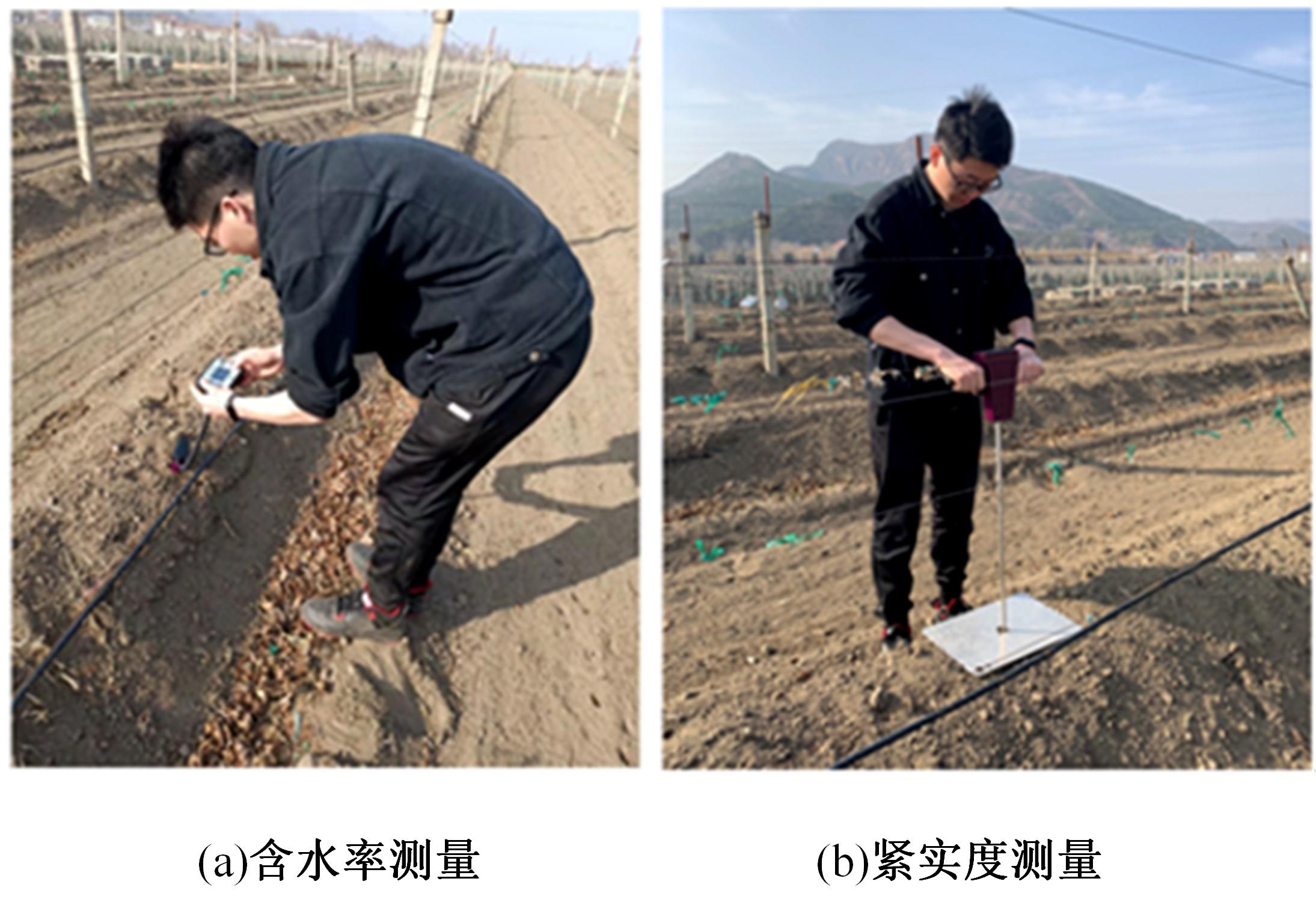

| 30 | 马帅,徐丽明,袁全春,等. 葡萄藤防寒土与清土部件相互作用的离散元仿真参数标定[J]. 农业工程学报, 2020, 36(1): 40-49. |

| Ma Shuai, Xu Li-ming, Yuan Quan-chun, et al. Calibration of discrete element simulation parameters of grapevine antifreezing soil and its interaction with soil-cleaning components[J]. Transactions of the CSAE, 2020, 36(1): 40-49. |

| [1] | Peng-fei ZHOU,Xue-geng CHEN,He-wei MENG,Rong-qing LIANG,Bing-cheng ZHANG,Za KAN. Design and experiment of trommel with function of separating soil from residual film mixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2718-2731. |

| [2] | Wei-jian LIU,Xi-wen LUO,Shan ZENG,Zhi-qiang WEN,Li ZENG. Field turning mechanism and performance test of crawler reclaimed rice harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2695-2705. |

| [3] | Duan-yang GENG,Xiao-qi JI,Xiao-dong MOU,Hua-biao LI,Hao-lin YANG,Yan-chun YAO,Ji-da WU. Design and experiment of harvesting and cutting table of Broussonetia papyrifera [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2152-2164. |

| [4] | Mao-jian ZHANG,Jing-fu JIN,Yi-ying CHEN,Ting-kun CHEN. Vibration symmetry characteristics of wheeled tractor structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2136-2142. |

| [5] | Guang-qiang ZHU,Tian-yu LI,Fu-jun ZHOU,Wen-ming WANG. Design and experiment of bionic ear picking device for fresh corn [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1231-1244. |

| [6] | Guo-qiang DUN,Wen-hui LIU,Ning MAO,Xing-peng WU,Wen-yi JI,Hong-yan MA. Optimization design and experiment of alternate post changing seed metering device for soybean plot breeding [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 285-296. |

| [7] | Shan ZENG,Deng-pan HUANG,Wen-wu YANG,Wei-jian LIU,Zhi-qiang WEN,Li ZENG. Design and test of the chassis of triangular crawler reclaiming rice harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1943-1950. |

| [8] | Guo-liang WEI,Qing-song ZHANG,Biao WANG,Kun HE,Qing-xi LIAO. Analysis and experiment on parameters of plough body of rapeseed direct seeder [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1709-1718. |

| [9] | Wen-ying GAO,Jing LIN,Bao-fa LI,Wei WANG,Shi-yan GU. Vibration characteristics analysis and structural optimization of straw deep bury and returning machine [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 970-980. |

| [10] | Jia-jie LIU,Lan MA,Wei XIANG,Bo YAN,Qing-hua WEN,Jiang-nan LYU. Design of 4QM⁃4.0 fibre crops green fodder combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(12): 3039-3048. |

| [11] | Bai-gong ZENG,Kui-liang LI,Jin YE,Li-li REN,Jaloliddin Rashidov,Ming ZHANG. Design and experiment of harvesting device for industrialized production line of Shanghaiqing [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2756-2764. |

| [12] | Xing-yu WAN,Qing-xi LIAO,Ya-jun JIANG,Yi-yin SHAN,Yu ZHOU,Yi-tao LIAO. Discrete element simulation and experiment of mechanized harve- sting and chopping process for fodder rape crop harvest [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2735-2745. |

| [13] | Guang-qiang ZHU,Tian-yu LI,Fu-jun ZHOU. Design and experiment of flexible clamping and conveying device for bionic ear picking of fresh corn [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2486-2500. |

| [14] | Rong-qing LIANG,Bo ZHONG,He-wei MENG,Zhi-min SUN,Za KAN. Design of 4QJ⁃3 type pickup header of silage oat [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1887-1896. |

| [15] | Jia-cheng YUAN,Chang WANG,Kun HE,Xing-yu WAN,Qing-xi LIAO. Effect of components mass ratio under sieve on cleaning system performance for rape combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1897-1907. |

|

||