吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (5): 1514-1528.doi: 10.13229/j.cnki.jdxbgxb.20210931

• 农业工程·仿生工程 • 上一篇

侧排式棉秸秆还田及残地膜回收联合作业机的设计与试验

曹肆林1,2( ),谢建华1,3(

),谢建华1,3( ),杨豫新1,刘永瑞2,卢勇涛2,孙博2

),杨豫新1,刘永瑞2,卢勇涛2,孙博2

- 1.新疆农业大学 机电工程学院,乌鲁木齐 830052

2.新疆农垦科学院 机械装备研究所,新疆 石河子 832011

3.新疆智能农业装备重点实验室,乌鲁木齐 830052

Design and experiment of side row cotton straw returning and residual film recovery combined machine

Si-lin CAO1,2( ),Jian-hua XIE1,3(

),Jian-hua XIE1,3( ),Yu-xin YANG1,Yong-rui LIU2,Yong-tao LU2,Bo SUN2

),Yu-xin YANG1,Yong-rui LIU2,Yong-tao LU2,Bo SUN2

- 1.College of Mechanical and Electrical Engineering,Xinjiang Agricultural University,Urumqi 830052,China

2.Mechanical Equipment Research Institute,Xinjiang Academy of Land Reclamation Sciences,Shihezi 832011,China

3.Xinjiang Key Laboratory of Intelligent Agricultural Equipment,Urumqi 830052,China

摘要:

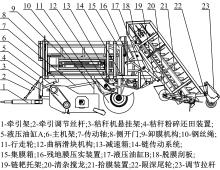

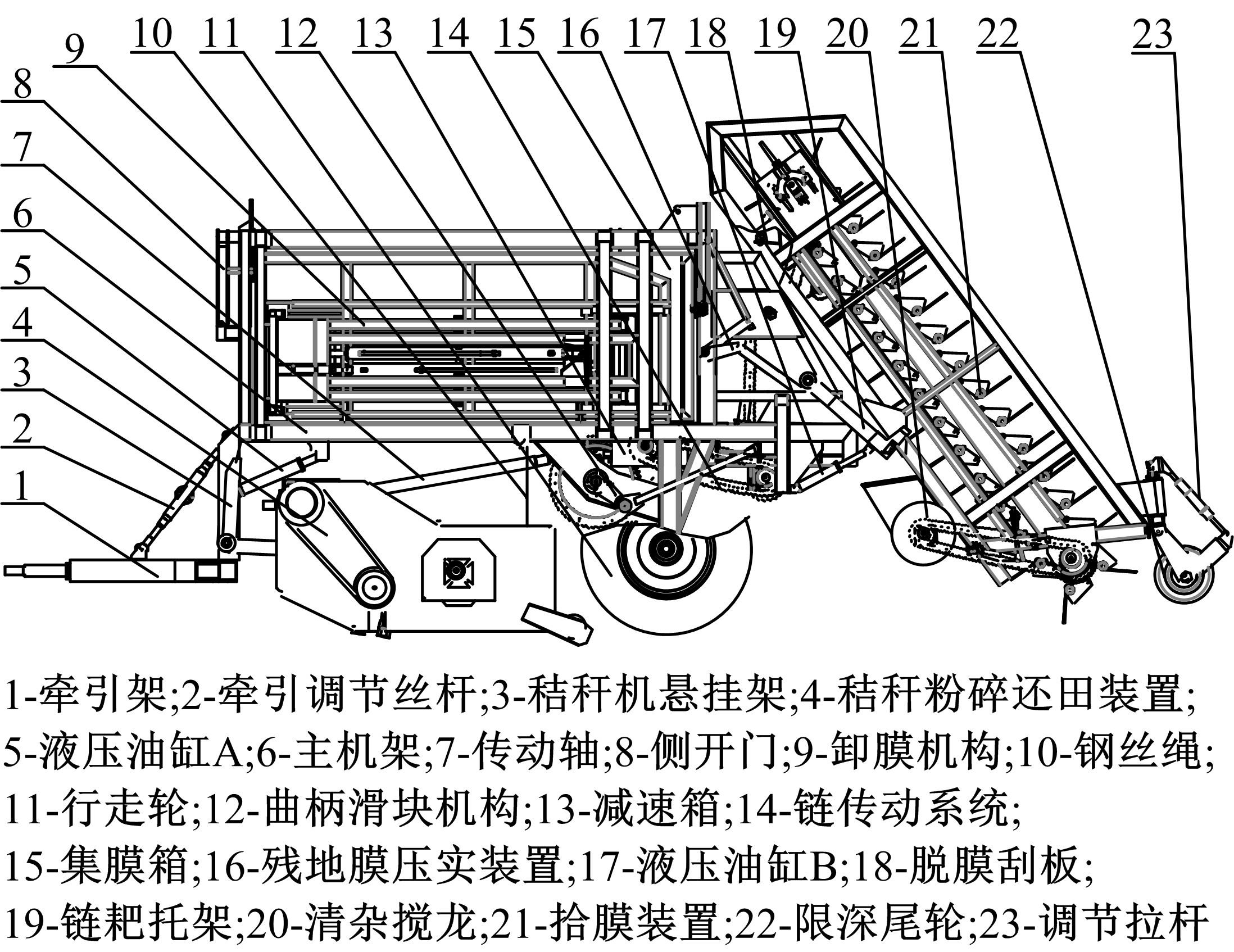

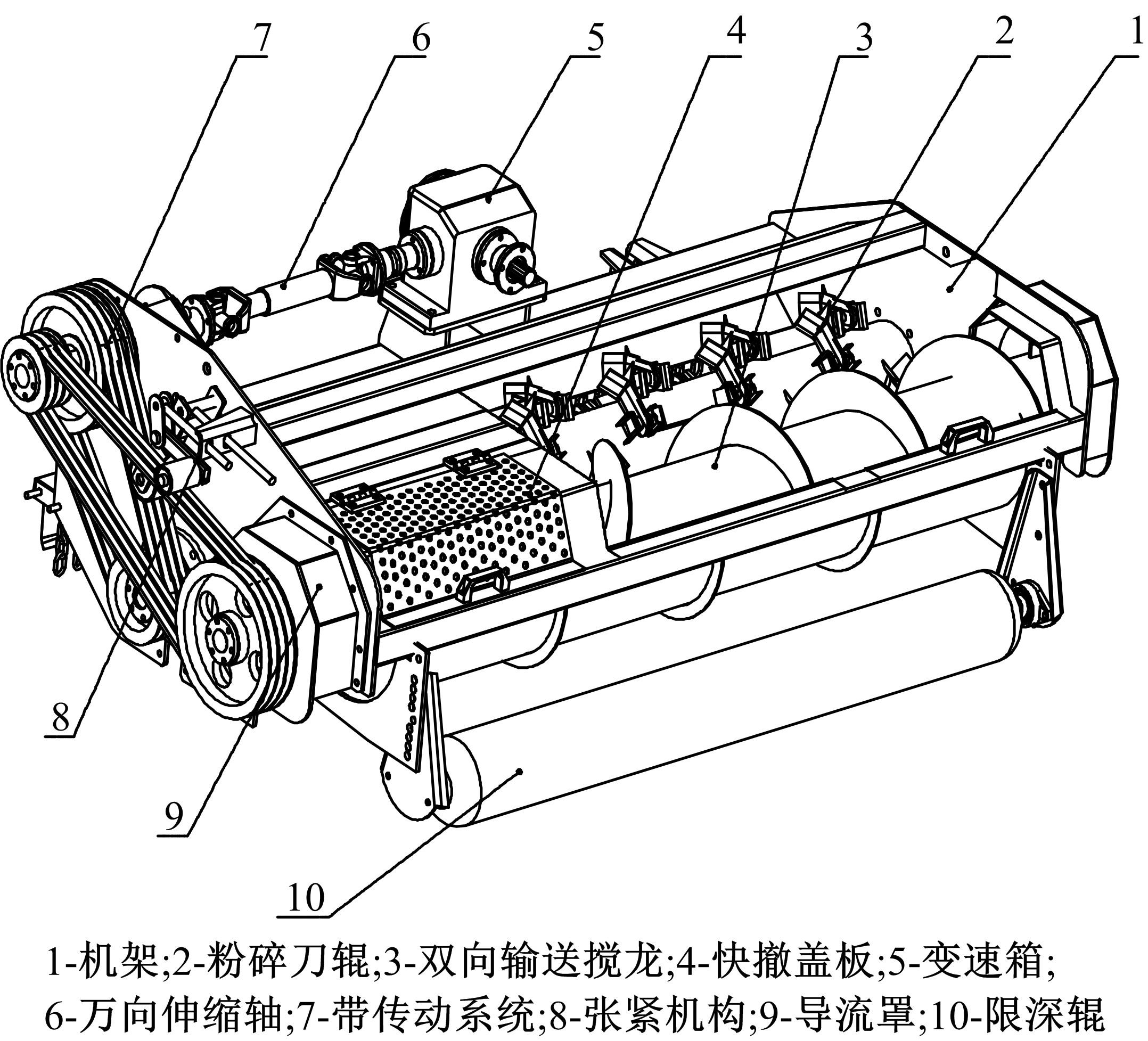

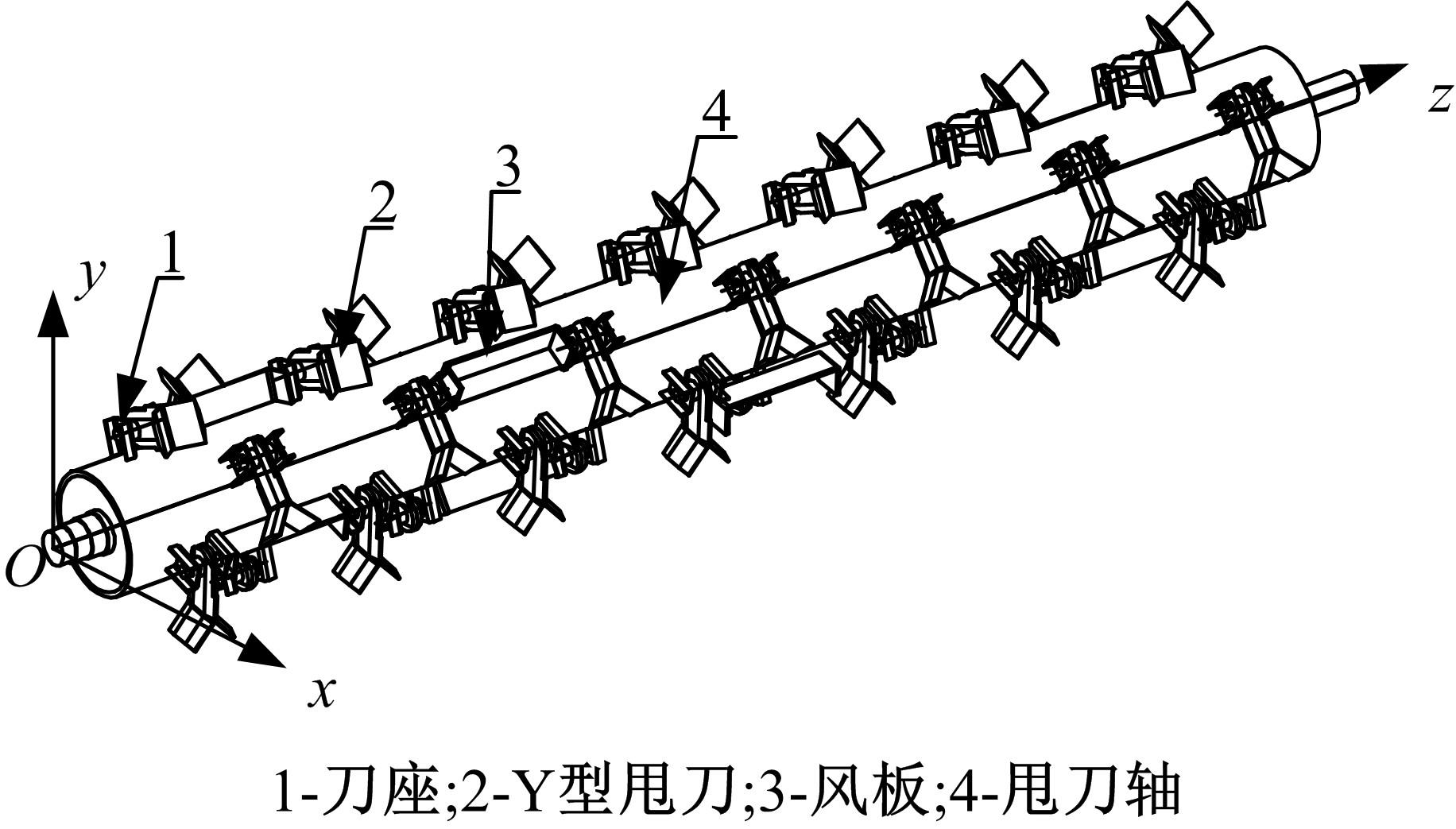

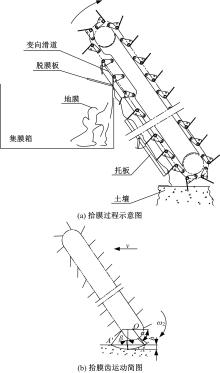

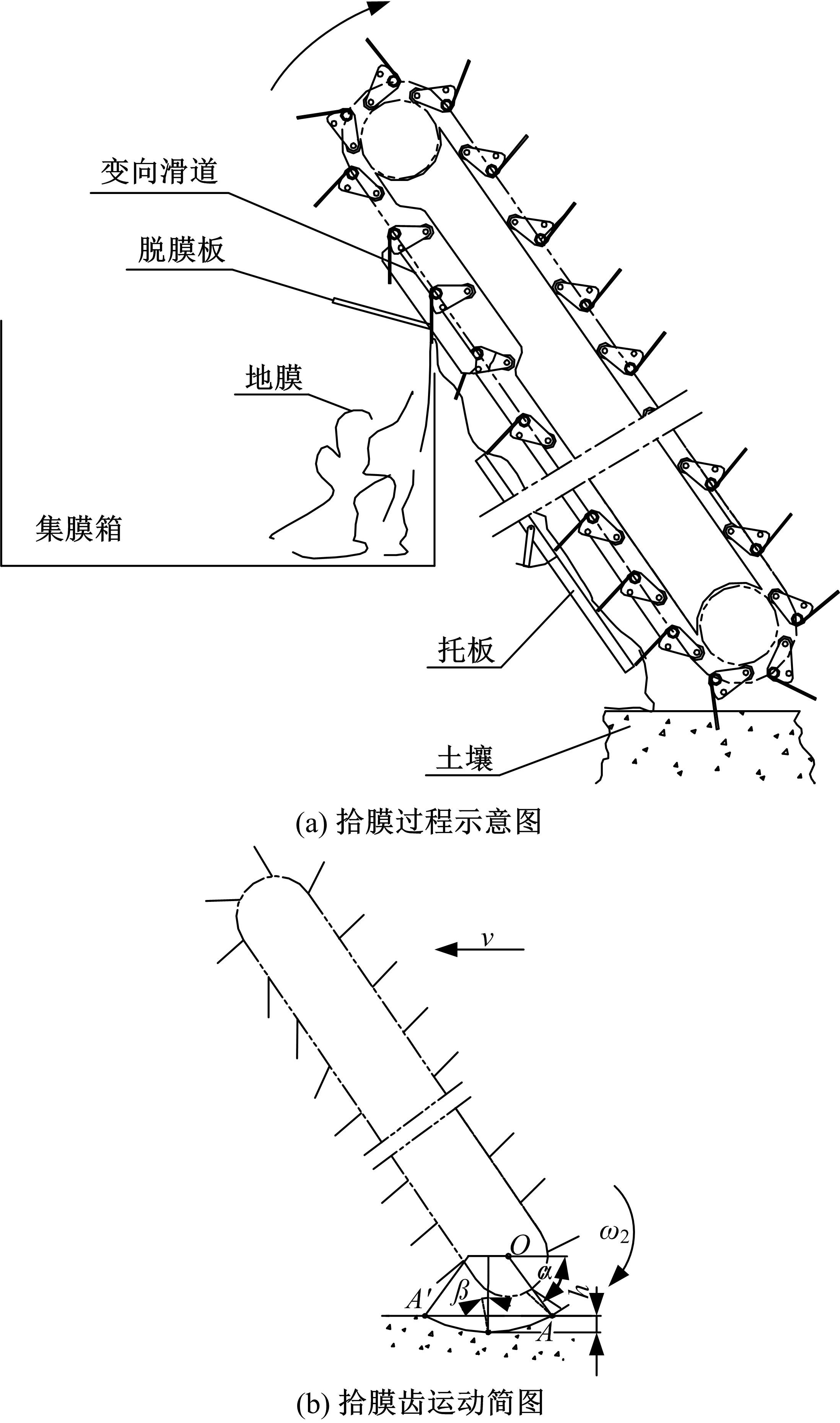

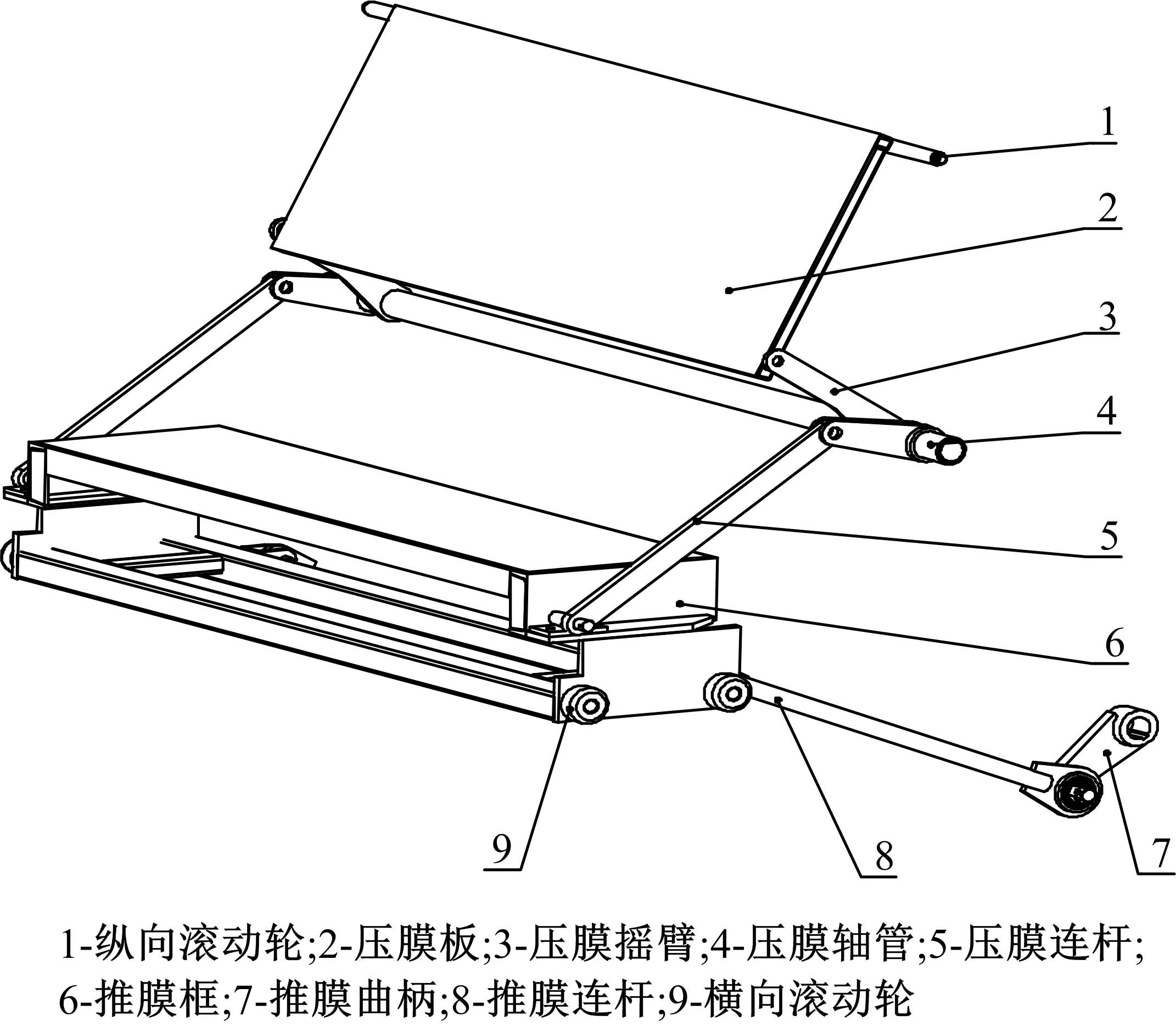

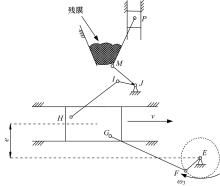

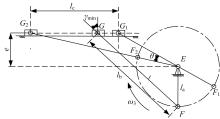

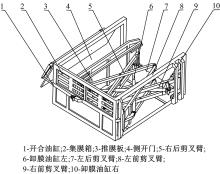

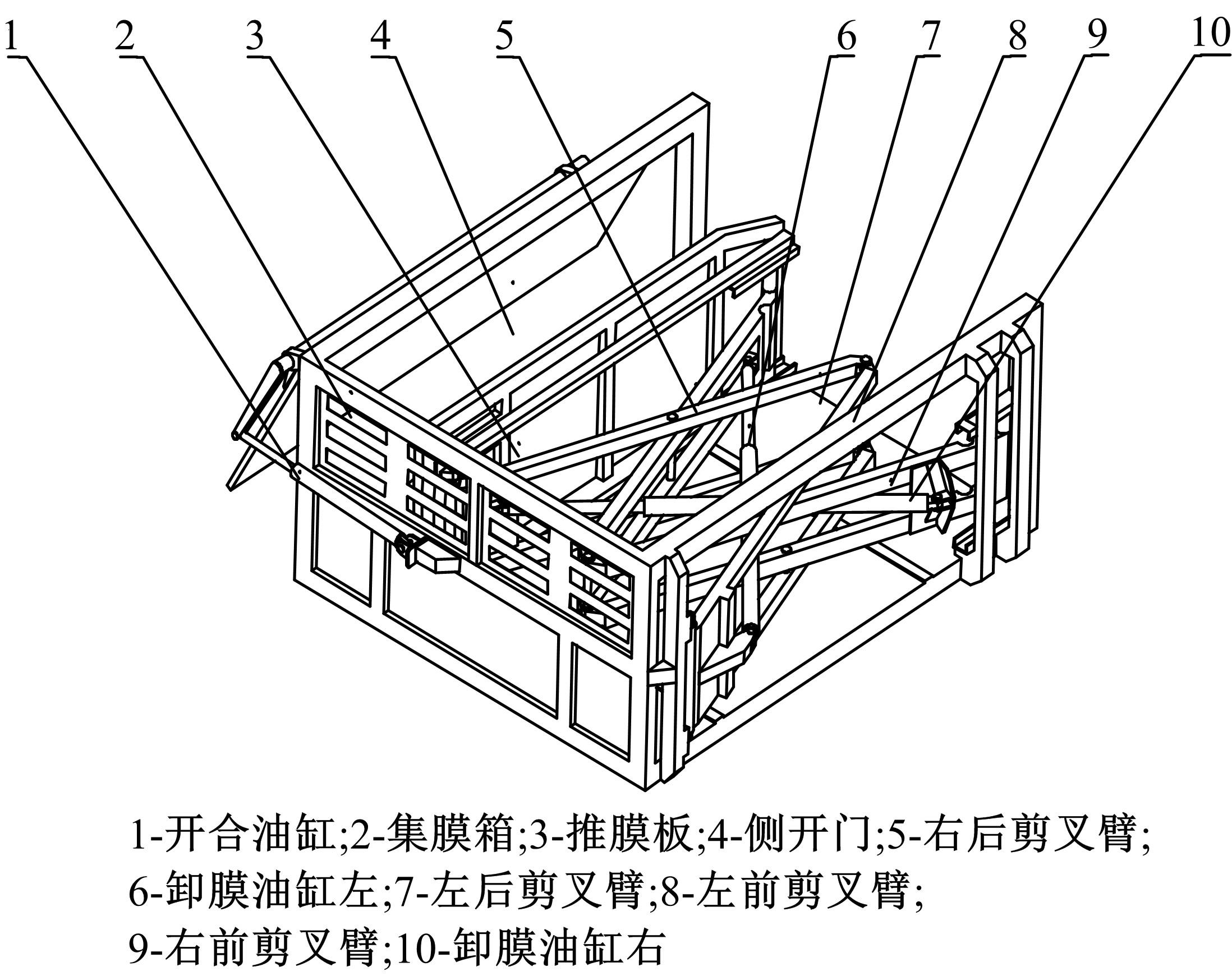

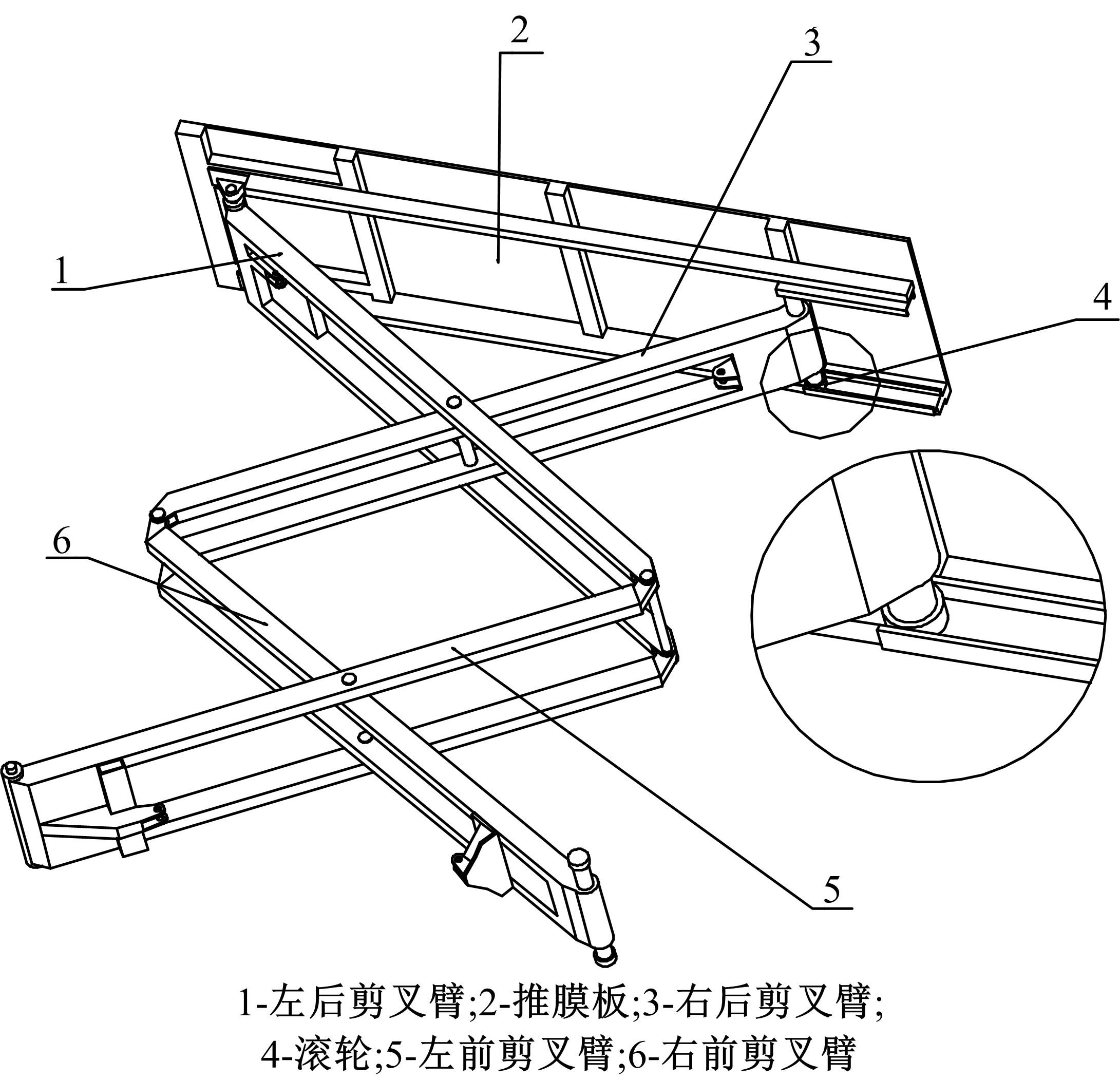

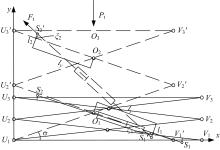

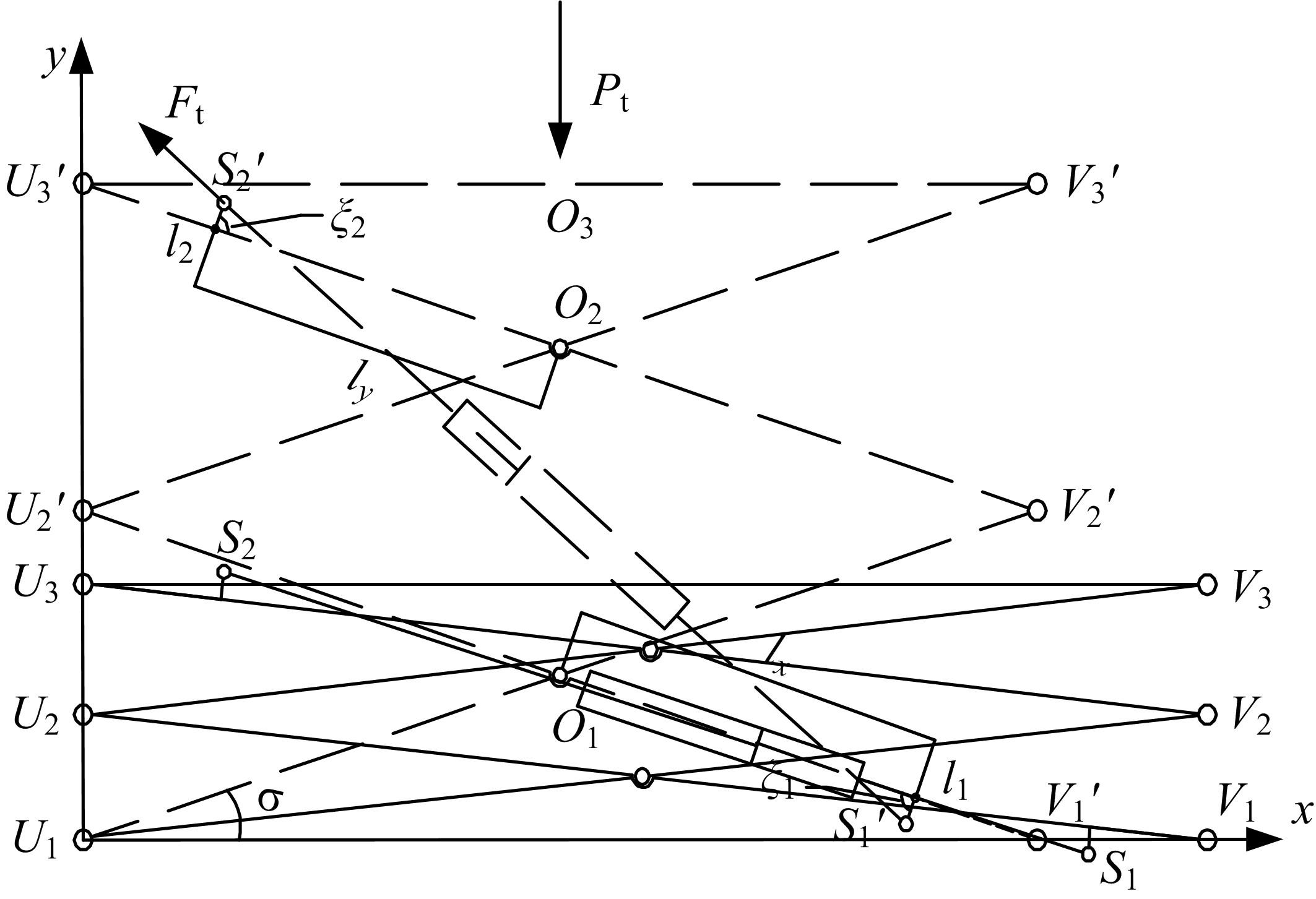

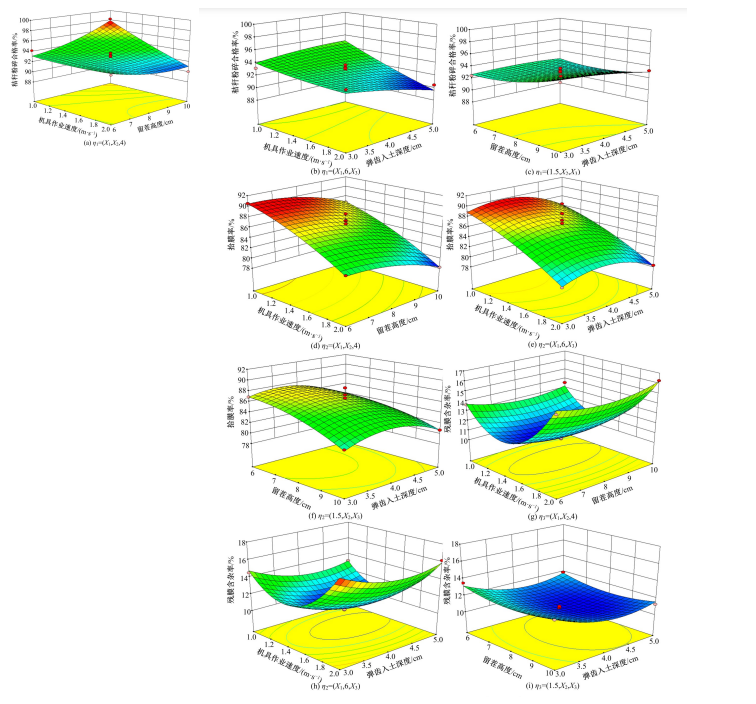

为适应新疆棉区残膜污染治理“遏制增量”的需要,改善秋后残膜回收机存在的功耗高灰尘大、残膜回收率不高、卸膜距离短、膜秆分离效果差等问题,设计了侧排式棉秸秆还田及残地膜回收联合作业机,同时完成棉秸秆粉碎侧向抛洒还田、残地膜捡拾、膜杂分离、收集压缩、卸膜集堆等多项作业。该机具通过螺旋搅龙将粉碎后的棉秸秆输送到膜间交接行;采用限深尾轮随地仿形,确保根茬高度稳定,并实现残膜捡拾弹齿入土深度稳定;运用风力清杂,在捡拾残膜的过程中实现二级清杂,降低回收后残膜的含杂率;通过输送装置对回收后的残膜进行压实,提高装载量。对主要工作部件进行设计和分析,阐明了拾膜、卸膜、残地膜压缩的功能原理,确定了主要部件结构和工作参数。运用Design-Expert软件设计了三因素三水平响应面试验,试验结果表明,机具最佳作业参数如下:机具作业速度为1.09 m/s、留茬高度为9.37 cm、弹齿入土深度为4.07 cm,棉秸秆粉碎合格率、拾膜率和残膜含杂率为96.20%、88.48%、12.00%。以圆整后的作业参数进行了试验验证,试验结果为棉秸秆粉碎合格率94.83%、拾膜率87.26%、残膜含杂率12.23%,试验结果表明:棉秸秆粉碎合格率、拾膜率和残膜含杂率与理论优化值误差分别为1.4%、0.3%和1.9%。研究方法和成果可为相关装备的研究提供参考。

中图分类号:

- S223.5

| 1 | 何文清, 严昌荣, 刘爽, 等.典型棉区地膜应用及污染现状的研究[J].农业环境科学学报, 2009, 28(8): 1618-1622. |

| He Wen-qing, Yan Chang-rong, Liu Shuang, et al. The use of plastic mulch film in typical cotton planting regions and the associated environmental pollution[J]. Journal of Agro-Environment Science, 2009, 28(8): 1618-1622. | |

| 2 | 白云龙, 李晓龙, 张胜, 等.内蒙古地膜残留污染现状及残膜回收利用对策研究[J].中国土壤与肥料, 2015(6): 139-145. |

| Bai Yun-long, Li Xiao-long, Zhang Sheng, et al. Study on the current situation of plastic film residue pollution and the countermeasures for the recovery and utilization of residual film in Inner Mongolia[J]. Soil and Fertilizer Sciences in China, 2015(6): 139-145. | |

| 3 | 李斌, 王吉奎, 蒋蓓.新疆棉区残膜污染及其治理技术[J].农机化研究, 2012, 34(5): 228-232. |

| Li Bin, Wang Ji-kui, Jiang Bei. The ysed plastic film pollution and treatment technology in Xinjiang cotton area[J]. Journal of Agricultural Mechanization Research, 2012, 34(5): 228-232. | |

| 4 | 程宏波, 柴守玺, 陈玉章, 等.西北旱地春小麦不同覆盖措施的温度和产量效应[J].生态学报, 2015, 35(19): 6316-6325. |

| Cheng Hong-bo, Chai Shou-xi, Chen Yu-zhang, et al. Effect of mulching method on soil temperature and grain yield of spring wheat in rainfed agricultural areas of northwestern China[J]. Acta Ecologica Sinica, 2015, 35(19): 6316-6325. | |

| 5 | 严昌荣, 刘恩科, 舒帆, 等.我国地膜覆盖和残留污染特点与防控技术[J].农业资源与环境学报, 2014, 31(2): 95-102. |

| Yan Chang-rong, Liu En-ke, Shu Fan, et al. Review of agricultural plastic mulching and its residual pollution and prevention measures in china[J]. Journal of Agricultural Resources and Environment, 2014, 31(2): 95-102. | |

| 6 | 赵岩, 陈学庚, 温浩军, 等.农田残膜污染治理技术研究现状与展望[J].农业机械学报, 2017, 48(6): 1-14. |

| Zhao Yan, Chen Xue-geng, Wen Hao-jun, et al. Research status and prospect of control technology for residual plastic film pollution in farmland[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(6): 1-14. | |

| 7 | 蒋德莉, 陈学庚, 颜利民, 等.农田残膜资源化利用技术与装备研究[J].中国农机化学报, 2020, 41(1): 179-190. |

| Jiang De-li, Chen Xue-geng, Yan Li-min, et al. Research on technology and equipment for utilization of residual film in farmland[J]. Journal of Chinese Agricultural Mechanization, 2020, 41(1): 179-190. | |

| 8 | 朱金儒, 李文昊, 王振华, 等.覆膜滴灌棉田地膜残留量对棉花生长的影响[J].干旱区研究, 2021, 38(2): 570-579. |

| Zhu Jin-ru, Li Wen-hao, Wang Zhen-hua, et al. Effect of film mulching residue on cotton growth in drip irrigation cotton field[J]. Arid Zone Reserarch, 2021, 38(2): 570-579. | |

| 9 | 梁荣庆, 陈学庚, 张炳成, 等.新疆棉田残膜回收方式及资源化再利用现状问题与对策[J].农业工程学报, 2019, 35(16): 1-13. |

| Liang Rong-qing, Chen Xue-geng, Zhang Bing-cheng, et al. Problems and countermeasure of recycling methods and resource reuse of residual film in cotton fields of Xinjiang[J]. Transactions of the CSAE, 2019, 35(16): 1-13. | |

| 10 | 胡灿, 王旭峰, 陈学庚, 等.新疆农田残膜污染现状及防控策略[J].农业工程学报, 2019, 35(24): 223-234. |

| Hu Can, Wang Xu-feng, Chen Xue-geng, et al. Current situation and control strategies of residual film pollution in xinjiang[J]. Transactions of the CSAE, 2019, 35(24): 223-234. | |

| 11 | 李东, 赵武云, 辛尚龙, 等.农田残膜回收技术研究现状与展望[J].中国农机化学报, 2020, 41(5): 204-209. |

| Li Dong, Zhao Wu-yun, Xin Shang-long, et al. Current situation and prospect of recycling technology of farmland residual film[J]. Transactions of the CSAE, 2020, 41(5): 204-209. | |

| 12 | 史增录, 唐学鹏, 甄军, 等.钉齿式残膜捡拾机构运动仿真分析及性能试验[J].农业工程学报, 2019, 35(4): 64-71. |

| Shi Zeng-lu, Tang Xue-peng, Zhen Jun, et al. Performance test and motion simulation analysis of nail tooth type mechanism for collecting plastic residue [J]. Transactions of the CSAE, 2019, 35(4): 64-71. | |

| 13 | 唐永飞, 赵永满, 王吉奎, 等.夹指链式残膜回收机脱膜装置设计与试验[J].农业工程学报, 2020, 36(13): 11-19. |

| Tang Yong-fei, Zhao Yong-man, Wang Ji-kui, et al. Design and experiment of film removing device for clamping finger-chain type residual film collector[J]. Transactions of the CSAE, 2020, 36(13): 11-19. | |

| 14 | 杨松梅, 陈学庚, 颜利民, 等.残膜回收机带式卷膜装置设计与试验[J].农业机械学报, 2021, 52(2): 135-144. |

| Yang Song-mei, Chen Xue-geng, Yan Li-min, et al. Design and experiment on belt-type curl-up film device for residual plastic film recycling machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(2): 135-144. | |

| 15 | 李景彬, 杨禹锟, 温宝琴, 等.基于根茬检测的秋后残膜回收导航路径提取方法[J].吉林大学学报: 工学版, 2021, 51(4): 1528-1539. |

| Li Jing-bin, Yang Yu-kun, Wen Bao-qin, et al. Method of extraction of navigation path of post-autumn residual film recovery based on stubble detection [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1528-1539. | |

| 16 | 施丽莉, 胡志超, 顾峰玮, 等.耙齿式垄作花生残膜回收机设计及参数优化[J].农业工程学报, 2017, 33(2): 8-15. |

| Shi Li-li, Hu Zhi-chao, Gu Feng-wei, et al. Design on automatic unloading mechanism for teeth type residue plastic film collector[J]. Transactions of the CSAE, 2017, 33(2): 8-15.. | |

| 17 | 于福锋, 李平, 张凤奎, 等.链耙式棉田耕层残膜回收机设计[J].农业工程, 2019, 9(10): 100-104. |

| Yu Fu-feng, Li Ping, Zhang Feng-kui, et al. Design of chain-type cotton field plough layer residual film recovery machine[J]. Agricultural Engineering, 2019, 9(10): 100-104. | |

| 18 | 闫盼盼, 曹肆林, 罗昕, 等.弹齿链耙式播前残膜回收机的设计研究[J].农机化研究, 2016, 38(6): 137-142. |

| Yan Pan-pan, Cao Si-lin, Luo Xin, et al. Research on the spring-tooth-chain-harrow incomplete plastic film recycling machine[J]. Journal of Agricultural Mechanization Research, 2016, 38(6): 137-142. | |

| 19 | 康建明, 彭强吉, 王士国, 等.弹齿式残膜回收机捡拾装置改进设计与试验[J].农业机械学报, 2018, 49(): 295-303. |

| Kang Jian-ming, Peng Qiang-ji, Wang Shi-guo, et al. Improved design and experiment on pickup unit of spring-tooth residual plastic film collector[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(Sup.1): 295-303. | |

| 20 | 王昭宇, 陈学庚, 颜利民, 等.随动式残膜回收机起膜捡拾机构设计与试验[J].农业机械学报, 2021, 52(4): 80-90. |

| Wang Zhao-yu, Chen Xue-geng, Yan Li-min, et al. Design and experiment on collecting and removing device for profile modeling residual plastic film collector[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(4): 80-90. | |

| 21 | 谢建华, 杨豫新, 曹肆林, 等.导向链耙式地表残膜回收机设计与试验[J].农业工程学报, 2020, 36(22): 76-86. |

| Xie Jian-hua, Yang Yu-xin, Cao Si-lin, et al. Design and experiments of rake type surface residual film recycling machine with guide chain[J]. Transactions of the CSAE, 2020, 36(22): 76-86. | |

| 22 | 张慧明, 陈学庚, 颜利民, 等.随动式秸秆还田与残膜回收联合作业机设计与试验[J].农业工程学报, 2019, 35(19): 11-19. |

| Zhang Hui-ming, Chen Xue-geng, Yan Li-min, et al. Design and test of master-slave straw returning and residual film recycling combine machine[J]. Transactions of the CSAE, 2019, 35(19): 11-19. | |

| 23 | . 螺旋输送机 [S]. |

| 24 | 秦宽, 曹成茂, 廖移山, 等.秸秆还田施肥点播机粉碎抛撒装置结构设计与优化[J].农业工程学报, 2020, 36(3): 1-10. |

| Qin Kuan, Cao Cheng-mao, Liao Yi-shan, et al. Design and optimization of crushing and throwing device for straw returning to field and fertilizing hill-seeding machine[J]. Transactions of the CSAE, 2020, 36(3): 1-10. | |

| 25 | 陈兴华, 陈学庚, 李景彬, 等.钉齿滚筒式播前残膜回收装置设计与试验[J].农业工程学报, 2020, 36(2): 30-39. |

| Chen Xing-hua, Chen Xue-geng, Li Jing-bin, et al. Design and test of nail-teeth roller-type residual film recovery device before sowing[J]. Transactions of the CSAE, 2020, 36(2): 30-39. | |

| 26 | 张学军, 黄爽, 史增录, 等.残膜捡拾打包机的设计与试验[J/OL]. [2021-09-15]. |

| 27 | 刘建良, 张具安.双剪叉升降平台结构设计及有限元仿真[J]. 煤炭科学技术, 2018, 46(): 193-195。 |

| Liu Jian-liang, Zhang Ju-an. Finite elements simulation and structural design of scissors elevating platform[J]. Coal Science and Technology, 2018, 46(Sup.1):193-195. | |

| 28 | 残地膜回收机 [S] |

| 29 | 保护性耕作机械 秸秆粉碎还田机 [S] |

| 30 | 张学军, 刘家强, 史增录, 等.残膜回收机逆向膜土分离装置的设计与参数优化[J].农业工程学报, 2019, 35(4): 46-55. |

| Zhang Xue-jun, Liu Jia-qiang, Shi Zeng-lu, et al. Design and parameter optimization of reverse membrane and soilseparation device for residual film recovery machine[J]. Transactions of the CSAE, 2019, 35(4): 46-55. | |

| 31 | 严伟, 胡志超, 吴努, 等.铲筛式残膜回收机输膜机构参数优化与试验[J].农业工程学报, 2017, 33(1): 17-24. |

| Yan Wei, Hu Zhi-chao, Wu Nu, et al. Parameter optimization and experiment of film transmission mechanism of spade screen recovery machine[J]. Transactions of the CSAE, 2017, 33(1): 17-24. | |

| 32 | 施丽莉, 胡志超, 顾峰玮, 等.耙齿式垄作花生残膜回收机设计及参数优化[J].农业工程学报, 2017, 33(2): 8-15. |

| Shi Li-li, Hu Zhi-chao, Gu Feng-wei, et al. Design on automatic unloading mechanism for teeth type residue plastic film collector[J]. Transactions of the CSAE, 2017, 33(2): 8-15. |

| [1] | 张惠,聂志玲,肖宏伟,王聃星. 无人驾驶汽车智能座舱人机交互界面色彩设计[J]. 吉林大学学报(工学版), 2023, 53(5): 1315-1321. |

| [2] | 张学军,黄爽,史增录,于永良,周鑫城,靳伟,陈勇,洪佳. 残膜捡拾打包机的设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1220-1230. |

| [3] | 李本怀,刘艳文,王璐,陈雪乾,左文杰. 吸能与压溃位移约束下的轨道车辆前端结构抗撞性优化[J]. 吉林大学学报(工学版), 2023, 53(4): 982-988. |

| [4] | 陈永,陈学庚,何浩猛,罗昕,余幸,胡斌. 基于灌溉引水渠介质的膜秆分离装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1245-1256. |

| [5] | 金敬福,董新桔,贾志成,王康,贺连彬,邹猛,齐迎春. 板簧式弹性金属车轮胎面弹片结构优化[J]. 吉林大学学报(工学版), 2023, 53(4): 964-972. |

| [6] | 李胜,朱佳,黄德惠,陈存福,费洪庆,丰伟,胡兴军. 空冷中冷器百叶窗翅片结构参数优化[J]. 吉林大学学报(工学版), 2023, 53(4): 998-1006. |

| [7] | 杨帆,李琛琛,李盛,刘海伦. 温缩作用下双层连续配筋混凝土路面配筋率设计参数对比分析[J]. 吉林大学学报(工学版), 2023, 53(4): 1122-1132. |

| [8] | 朱光强,李天宇,周福君,王文明. 鲜食玉米仿生摘穗装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1231-1244. |

| [9] | 杨艳,侍玉青,张晓蓉,罗冠炜. 一类多刚性限幅振动系统的动态稳定性分析[J]. 吉林大学学报(工学版), 2023, 53(2): 364-375. |

| [10] | 刘状壮,张有为,季鹏宇,Abshir Ismail Yusuf,李林,郝亚真. 电热型融雪沥青路面传热特性研究[J]. 吉林大学学报(工学版), 2023, 53(2): 523-530. |

| [11] | 陈凤祥,张俊宇,裴冯来,侯明涛,李其朋,李培庆,王洋洋,张卫东. 质子交换膜燃料电池氢气供应系统的建模及匹配设计[J]. 吉林大学学报(工学版), 2022, 52(9): 1982-1995. |

| [12] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [13] | 杨红波,史文库,陈志勇,郭年程,赵燕燕. 基于某二级减速齿轮系统的齿面修形优化[J]. 吉林大学学报(工学版), 2022, 52(7): 1541-1551. |

| [14] | 罗小博,宋彧,王腾,金子秋,谢国鑫. 新型分形防屈曲支撑参数设计及受力性能[J]. 吉林大学学报(工学版), 2022, 52(7): 1607-1619. |

| [15] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

|

||