吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (9): 2686-2694.doi: 10.13229/j.cnki.jdxbgxb.20211199

自走式藜麦联合收割机设计及试验

史瑞杰1( ),戴飞1,赵武云1(

),戴飞1,赵武云1( ),杨发荣2,张锋伟1,赵一鸣1,曲浩1,王天福1,郭军海1

),杨发荣2,张锋伟1,赵一鸣1,曲浩1,王天福1,郭军海1

- 1.甘肃农业大学 机电工程学院,兰州 730070

2.甘肃省农业科学院 畜草与绿色农业研究所,兰州 730070

Design and experiments of self⁃propelled quinoa combine harvester

Rui-jie SHI1( ),Fei DAI1,Wu-yun ZHAO1(

),Fei DAI1,Wu-yun ZHAO1( ),Fa-rong YANG2,Feng-wei ZHANG1,Yi-ming ZHAO1,Hao QU1,Tian-fu WANG1,Jun-hai GUO1

),Fa-rong YANG2,Feng-wei ZHANG1,Yi-ming ZHAO1,Hao QU1,Tian-fu WANG1,Jun-hai GUO1

- 1.College of Mechanical and Electrical Engineering,Gansu Agricultural University,Lanzhou 730070,China

2.Livestock Grass and Green Agriculture,Gansu Academy of Agricultural Sciences,Lanzhou 730070,China

摘要:

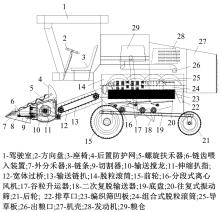

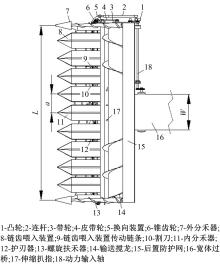

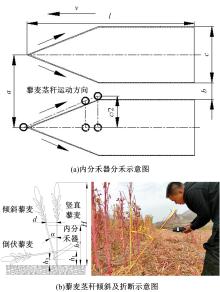

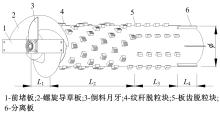

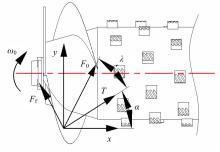

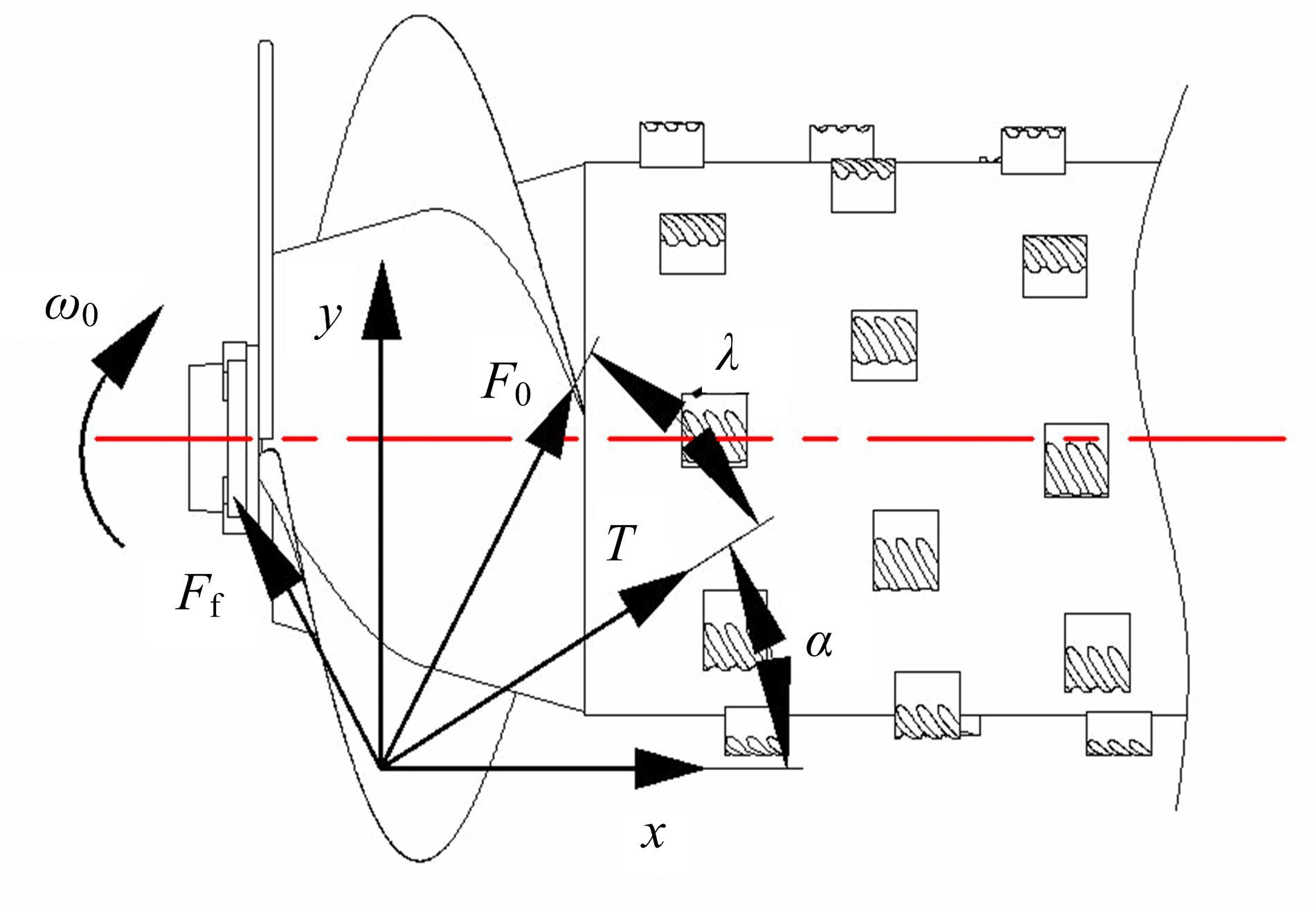

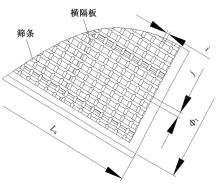

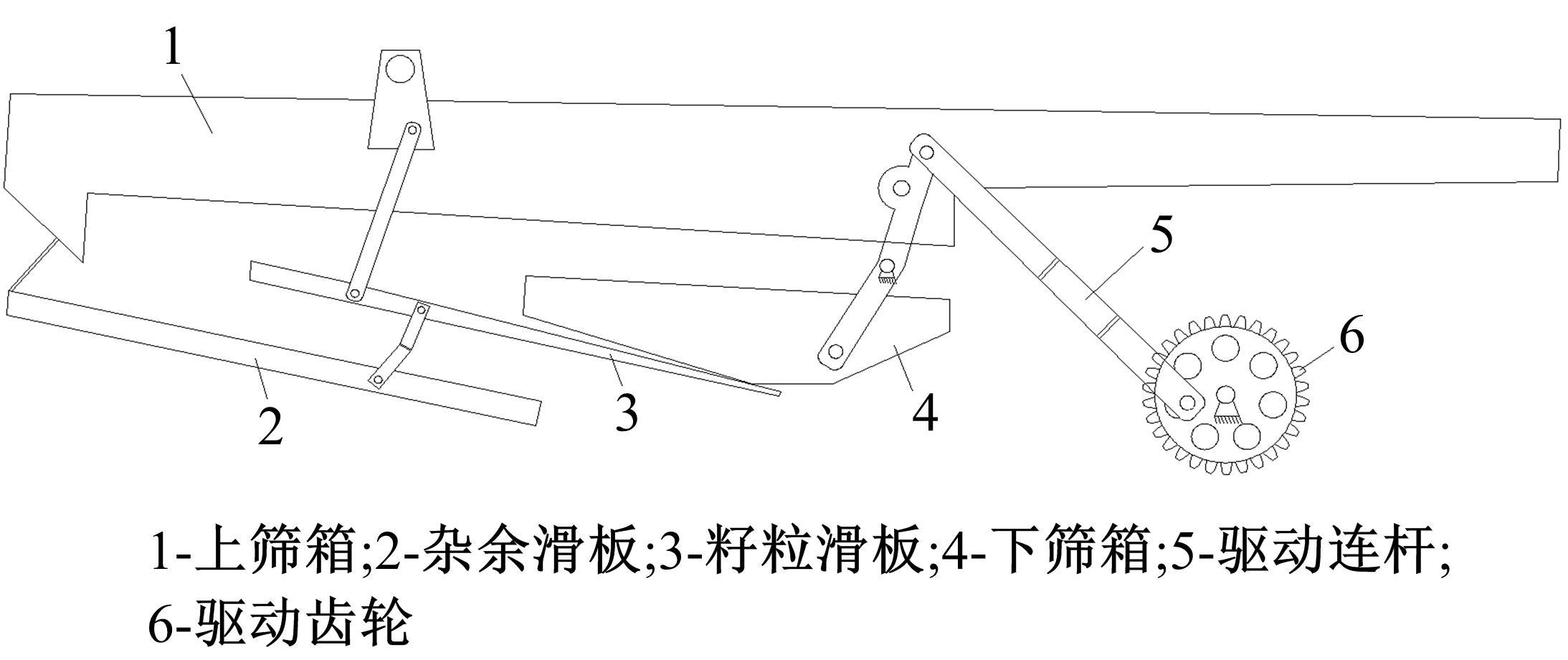

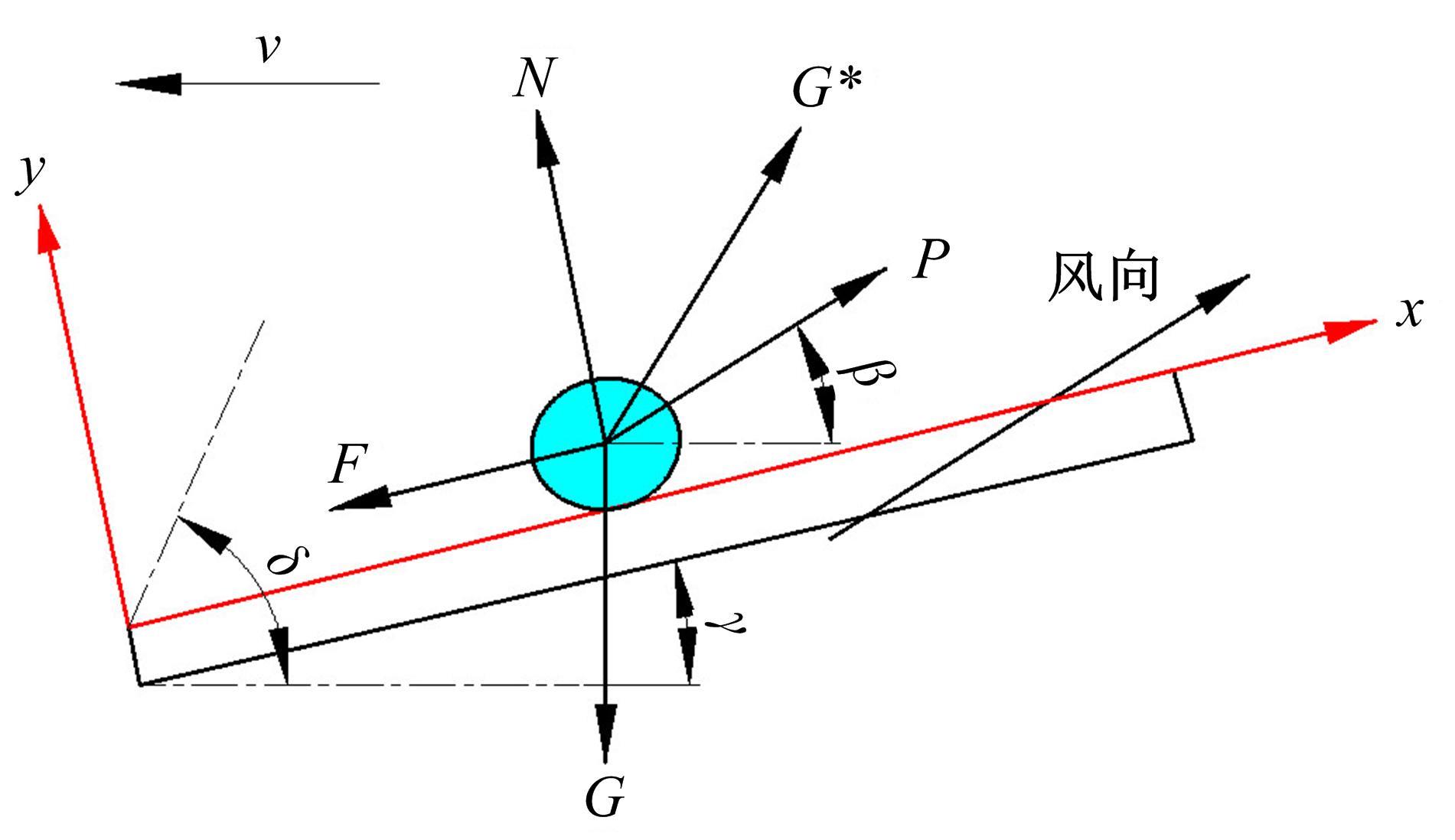

为提高藜麦机械化收获水平,解决普通谷物联合收割机收获时损失大、含杂高、喂入不畅等问题,针对收获期藜麦植株特性设计了一种大型自走式藜麦联合收割机。该机采用扩口式小行距链齿喂入割台、组合式纵轴流脱粒滚筒、专用编织筛凹板、双层往复式异向振动筛等装置,配合宽体过桥、脱粒滚筒无级变速和大脱分空间等设计实现了藜麦的顺畅喂入和高效脱粒分离,对关键部件进行了设计分析,并进行了田间试验。田间试验结果表明:当藜麦籽粒含水率为14.42%时,脱净率为96.83%、含杂率为4.41%、破损率为0.2%、割台损失率为1.14%、夹带损失率为1.73%,清选损失率为1.09%、飞溅损失率为0.16%、总损失率为4.13%;作业期间机具运行平稳,满足藜麦机械化收获要求。本文研究成果可为藜麦联合收割机设计及试验提供一定参考。

中图分类号:

- S225.5

| 1 | Carrasco R R, Espinoza C, Jacobsen S E. Nutritional value and use of the andean crops quinoa (Chenopodium quinoa) and kañiwa (Chenopodium pallidicaule)[J]. Food Reviews International, 2006, 19(1):179-189. |

| 2 | 黄杰, 杨发荣, 李敏权, 等. 13个藜麦材料在甘肃临夏旱作区适应性的初步评价[J]. 草业学报, 2016, 25(3): 191-201. |

| Huang Jie, Yang Fa-rong, Li Min-quan, et al. Preliminary evaluation of adaptability of 13 quinoa varieties in the linxia arid region of gansu province, China[J]. Acta Prataculturae Sinica, 2016, 25(3): 191-201. | |

| 3 | 杨发荣, 黄杰, 魏玉明, 等. 藜麦生物学特性及应用[J]. 草业科学, 2017, 34(3): 607-613. |

| Yang Fa-rong, Huang Jie, Wei Yu-ming, et al. A review of biological characteristics, applications, and culture of chenopodium quinoa [J]. Pratacultural Science, 2017, 34(3): 607-613. | |

| 4 | 袁飞敏, 权有娟, 刘德梅, 等. 藜麦植株形态及花器结构的初步观察[J]. 甘肃农业大学学报, 2018, 53(4): 49-53. |

| Yuan Fei-min, Quan You-juan, Liu De-mei, et al. Primary observation the plant morphologic and floral structure on quiona(Chenopodium quinoa Willd)[J]. Journal of Gansu Agricultural University, 2018, 53(4): 49-53. | |

| 5 | 付丽红, 李晓斌. 基于岭脊分析的藜麦淀粉提取及糊化特性研究[J]. 农业工程学报, 2016, 32(18): 299-306. |

| Fu Li-hong, Li Xiao-bin. Extraction and gelatinization characteristics of chenopodium quinoa willd starch based on ridge analysis[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(18): 299-306. | |

| 6 | Stikic R, Glamoclija D, Demin M, et al. Agronomical and nutritional evaluation of quinoa seeds (Chenopodium quinoa Willd.) as an ingredient in bread formulations[J]. Journal of Cereal Science, 2012, 55(2): 132-138. |

| 7 | González J A, Konishi Y, Bruno M, et al. Interrelationships among seed yield, total protein and amino acid composition of ten quinoa (Chenopodium quinoa) cultivars from two different agroecological regions[J]. Journal of the Science and Food Agriculture, 2012, 92(6): 1222-1229. |

| 8 | 陈庆文, 韩增德, 崔俊伟, 等. 自走式谷物联合收割机发展现状及趋势分析[J]. 中国农业科技导报, 2015, 17(1): 109-114. |

| Cheng Qing-wen, Han Zeng-de, Cui Jun-wei, et al. Development status and trend current situation of self-propelled combine harvester[J]. Journal of Agricultural Science and Technology, 2015, 17(1): 109-114. | |

| 9 | Fu J, Chen Z, Tian L J, et al. Review of grain threshing theory and technology[J]. International Journal of Agricultural and Biological Engineering, 2018, 11(3): 12-20. |

| 10 | 戴飞. 胡麻脱出物分离清选机理与关键技术研究[D]. 兰州:甘肃农业大学机电工程学院,2020. |

| Dai Fei. Study on the separating-cleaning mechanism and key technology of flax threshing material[D]. Lanzhou: College of Mechanical and Electrical Engineering, Gansu Agricultural University, 2020. | |

| 11 | 海梅, 杜文亮, 吴英思, 等. 藜麦脱出物空气动力学特性测试与分析[J]. 农机化研究, 2019, 41(2): 192-195, 215. |

| Mei Hai, Du Wen-liang, Wu Yin-si, et al. Test and analysis of aerodynamics on the quinoa threshed mixture[J]. Journal of Agricultural Mechanization Research, 2019, 41(2): 192-195, 215. | |

| 12 | 吴英思, 郭占斌, 杜文亮, 等. 藜麦脱出物的物料特性研究[J]. 农机化研究, 2017, 39(9): 184-189. |

| Wu Ying-si, Guo Zhan-bin, Du Wen-liang, et al. Study of the material properties on the quinoa threshed mixture[J]. Journal of Agricultural Mechanization Research, 2017, 39(9): 184-189. | |

| 13 | 赵子龙, 郭占斌, 杜文亮, 等. 浸水藜谷的机械特性研究[J]. 农机化研究, 2018, 40(11): 162-165, 170. |

| Zhao Zi-long, Guo Zhan-bin, Du Wen-liang, et al. The study of the mechanical properties of quinoa [J]. Journal of Agricultural Mechanization Research, 2018, 40(11): 162-165, 170. | |

| 14 | 顾建环. 天祝县高原寒旱区藜麦产业全程机械化推广探究[J]. 南方农业, 2020, 14(15):156-157. |

| 15 | 海梅. 藜麦联合收获机脱出物清选试验研究[D]. 呼和浩特: 内蒙古农业大学机电工程学院, 2018. |

| Mei Hai. Experimental study on clearance of quinoa combine harvester[D]. Hohhot: College of Mechanical and Electrical Engineering, Inner Mongolia Agricultural University, 2018. | |

| 16 | 肖正春, 张广伦. 藜麦及其资源开发利用[J]. 中国野生植物资源, 2014, 33(2): 62-66. |

| Xiao Zheng-chun, Zhang Guang-lun. Development and utilization of Chenopodium quinoa willd[J]. Chinese Wild Plant Resources, 2014, 33(2): 62-66. | |

| 17 | 托有德, 朱雪慧. 高原寒旱区藜麦生产机具现状与发展[J]. 农机科技推广, 2020(4):27-29. |

| 18 | 杨科, 刘文瑜, 王旺田, 等. 连作对藜麦生长和生理特性的影响[J]. 江西农业大学学报, 2021, 43(2): 244-252. |

| Yang Ke, Liu Wen-yu, Wang Wang-tian, et al. Effects of continuous cropping on growth and physiological characteristics of quinoa[J]. Acta Agriculturae Universitatis Jiangxiensis, 2021, 43(2):244-252. | |

| 19 | 魏玉明, 黄杰, 顾娴, 等. 藜麦规范化栽培技术规程[J]. 甘肃农业科技, 2015(12):77-80. |

| 20 | 沈宝云, 胡静, 郭谋子, 等. 早熟藜麦新品种条藜2号的选育及栽培技术[J]. 种子, 2019, 38(4): 137-140. |

| Shen Bao-yun, Hu Jing, Guo Mou-zi, et al. Breeding and cultivation techniques of new early maturity variety chenopodium quinoa cv. Tiaoli No.2[J]. Seed, 2019, 38(4): 137-140. | |

| 21 | 王丽娜, 任翠梅, 王明泽, 等. 中国藜麦种质资源分布及研究现状[J]. 黑龙江农业科学, 2020(12): 142-145. |

| Wang Li-na, Ren Cui-mei, Wang Ming-ze, et al. Distribution and research status of quinoa germplasm resources in China[J]. Heilongjiang Agricultural Sciences, 2020(12): 142-145. | |

| 22 | Atul B, Deepak O. Origin of genetic variability and improvement of quinoa(Chenopodium quinoa willd.)[J]. Gene Pool Diversity and Crop Improvement, 2016, 10: 241-270. |

| 23 | 郭建芳, 武小平, 丁健, 等. 矮壮素对藜麦抗倒伏的影响[J]. 山西农业科学, 2020, 48(7): 1019-1021, 1025. |

| Guo Jian-fang, Wu Xiao-ping, Ding Jian, et al. Effect of chlormequat chloride on lodging resistance of quinoa [J]. Journal of Shanxi Agricultural Sciences, 2020, 48(7): 1019-1021, 1025. | |

| 24 | 郭建芳, 武小平, 丁健 [J]. 现代农业科技, 2019(15): 18-19. |

| 25 | 刘巍, 黄小毛, 马丽娜, 等. 油葵联合收获机专用割台设计与试验[J]. 农业机械学报, 2020, 51(8): 83-88, 135. |

| Liu Wei, Huang Xiao-mao, Ma Li-na, et al. Design and experiment of special header of oil sunflower combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(8): 83-88, 135. | |

| 26 | 杜岳峰, 毛恩荣, 朱忠祥, 等. 两行玉米收获机割台设计与试验[J]. 农业机械学报, 2013, 44():22-26. |

| Du Yue-feng, Mao En-rong, Zhu Zhong-xiang, et al. Design and experiment of two-row corn harvester header[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(Sup.2): 22-26. | |

| 27 | 谢里阳. 可靠性设计[M]. 北京: 高等教育出版社, 2013. |

| 28 | 廖庆喜, 徐阳, 袁佳诚, 等. 油菜联合收获机切抛组合式纵轴流脱离装置设计与试验[J]. 农业机械学报, 2019, 50(7):140-150. |

| Liao Qing-xi, Xu Yang, Yuan Jia-cheng, et al. Design and experiment on combined cutting and throwing longitudinal axial flow threshing and separating device of rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(7):140-150. | |

| 29 | 中国农业机械化科学研究院. 农业机械设计手册(下册)[M]. 北京: 中国农业科学技术出版社, 2007. |

| 30 | 戴飞, 付秋峰, 赵武云, 等. 双风道风筛式胡麻脱出物分离清选机设计与试验[J]. 农业机械学报, 2021, 52(4): 117-125, 247. |

| Dai Fei, Fu Qiu-feng, Zhao Wu-yun, et al. Design and test of double duct system of air-screen separating and cleaning machine for flax threshing material[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(4): 117-125, 247. | |

| 31 | 李耀明. 谷物联合收割机的设计与分析[M]. 北京: 机械工业出版社, 2014. |

| 32 | 耿端阳, 牟孝栋, 张国栋, 等. 小麦联合收获机清选机理分析与优化试验[J]. 吉林大学学报:工学版, 2022, 52(1):219-230. |

| Geng Duan-yang, Mu Xiao-dong, Zhang Guo-dong, et al. Analysis and optimization of cleaning mechanism of wheat combine harvester[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(1): 219-230. | |

| 33 | . 收获机械联合收割机试验方法 [S]. |

| 34 | . 计数抽样检测程序 [S]. |

| 35 | . 农业机械试验条件 [S]. |

| 36 | 史瑞杰, 戴飞, 刘小龙, 等. 履带式丘陵山地胡麻联合收割机设计与试验[J]. 农业工程学报, 2021, 37(5):59-67. |

| Shi Rui-jie, Dai Fei, Liu Xiao-long, et al. Design and experiments of crawler-type hilly and mountaineous flax combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(5): 59-67. | |

| 37 | 史瑞杰, 戴飞, 赵武云, 等. 丘陵山地胡麻联合收割机作业参数优化与试验[J]. 吉林大学学报:工学版, 2022, 52(11):2746-2755. |

| Shi Rui-jie, Dai Fei, Zhao Wu-yun, et al. Optimization and experiment of operation parameters of hilly area flax combine harvester[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(11): 2746-2755. |

| [1] | 周鹏飞,陈学庚,蒙贺伟,梁荣庆,张炳成,坎杂. 滚筒式机收膜杂除土装置设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2718-2731. |

| [2] | 刘伟健,罗锡文,曾山,文智强,曾力. 履带式再生稻收获机田间转弯机理和性能试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2695-2705. |

| [3] | 石林榕,赵武云. 西北寒旱农区胡麻滚勺式精量穴播器的设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2706-2717. |

| [4] | 张茂健,金敬福,陈奕颖,陈廷坤. 轮式拖拉机对称结构的振动特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2136-2142. |

| [5] | 耿端阳,纪晓琦,牟孝栋,李华彪,杨昊霖,姚艳春,武继达. 构树收获割台设计与试验[J]. 吉林大学学报(工学版), 2023, 53(7): 2152-2164. |

| [6] | 曹肆林,谢建华,杨豫新,刘永瑞,卢勇涛,孙博. 侧排式棉秸秆还田及残地膜回收联合作业机的设计与试验[J]. 吉林大学学报(工学版), 2023, 53(5): 1514-1528. |

| [7] | 张学军,黄爽,史增录,于永良,周鑫城,靳伟,陈勇,洪佳. 残膜捡拾打包机的设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1220-1230. |

| [8] | 陈永,陈学庚,何浩猛,罗昕,余幸,胡斌. 基于灌溉引水渠介质的膜秆分离装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1245-1256. |

| [9] | 朱光强,李天宇,周福君,王文明. 鲜食玉米仿生摘穗装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1231-1244. |

| [10] | 顿国强,刘文辉,毛宁,吴星澎,纪文义,马洪岩. 交替换岗式大豆小区育种排种器优化设计与试验[J]. 吉林大学学报(工学版), 2023, 53(1): 285-296. |

| [11] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [12] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

| [13] | 高文英,林静,李宝筏,王伟,谷士艳. 秸秆深埋还田机振动特性分析与结构优化[J]. 吉林大学学报(工学版), 2022, 52(4): 970-980. |

| [14] | 刘佳杰,马兰,向伟,颜波,文庆华,吕江南. 4QM-4.0型麻类青饲料联合收获机研制[J]. 吉林大学学报(工学版), 2022, 52(12): 3039-3048. |

| [15] | 史瑞杰,戴飞,赵武云,刘小龙,瞿江飞,张锋伟. 丘陵山地胡麻联合收割机作业参数优化与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2746-2755. |

|