吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (10): 3038-3044.doi: 10.13229/j.cnki.jdxbgxb.20211359

• 农业工程·仿生工程 • 上一篇

基于虚拟现实的拖拉机变速箱装配系统设计

杨帆1( ),翟志强1(

),翟志强1( ),汪圆圆2,朱忠祥1,杜岳峰1,毛恩荣1

),汪圆圆2,朱忠祥1,杜岳峰1,毛恩荣1

- 1.中国农业大学 工学院,北京 100083

2.北京福田康明斯发动机有限公司,北京 102206

Design of assembly system for tractor transmission based on virtual reality

Fan YANG1( ),Zhi-qiang ZHAI1(

),Zhi-qiang ZHAI1( ),Yuan-yuan WANG2,Zhong-xiang ZHU1,Yue-feng DU1,En-rong MAO1

),Yuan-yuan WANG2,Zhong-xiang ZHU1,Yue-feng DU1,En-rong MAO1

- 1.College of Engineering,China Agricultural University,Beijing 100083,China

2.Beijing Foton Cummins Engine Company,Beijing 102206,China

摘要:

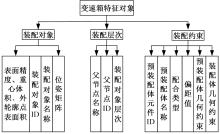

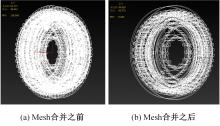

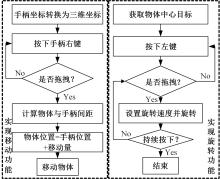

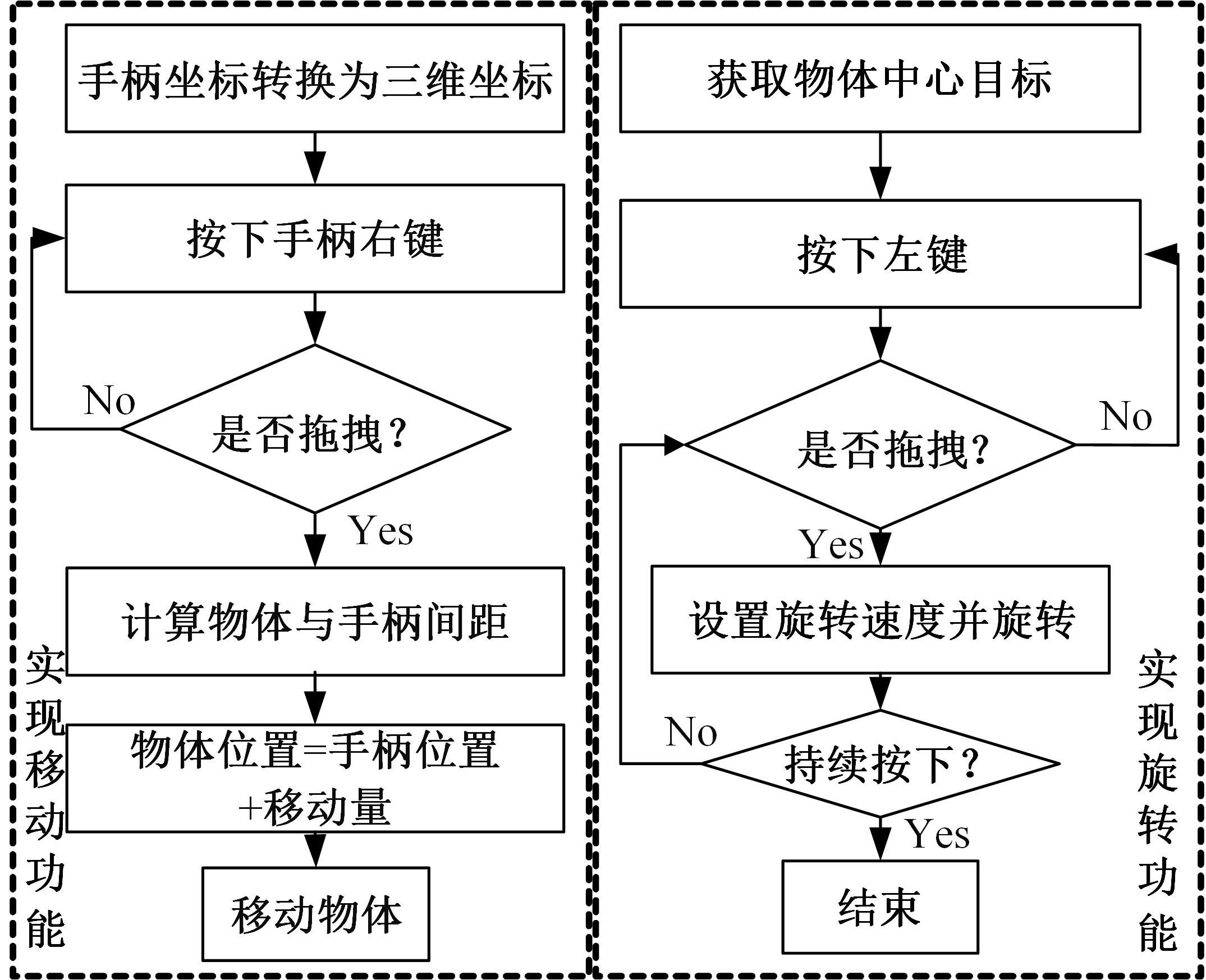

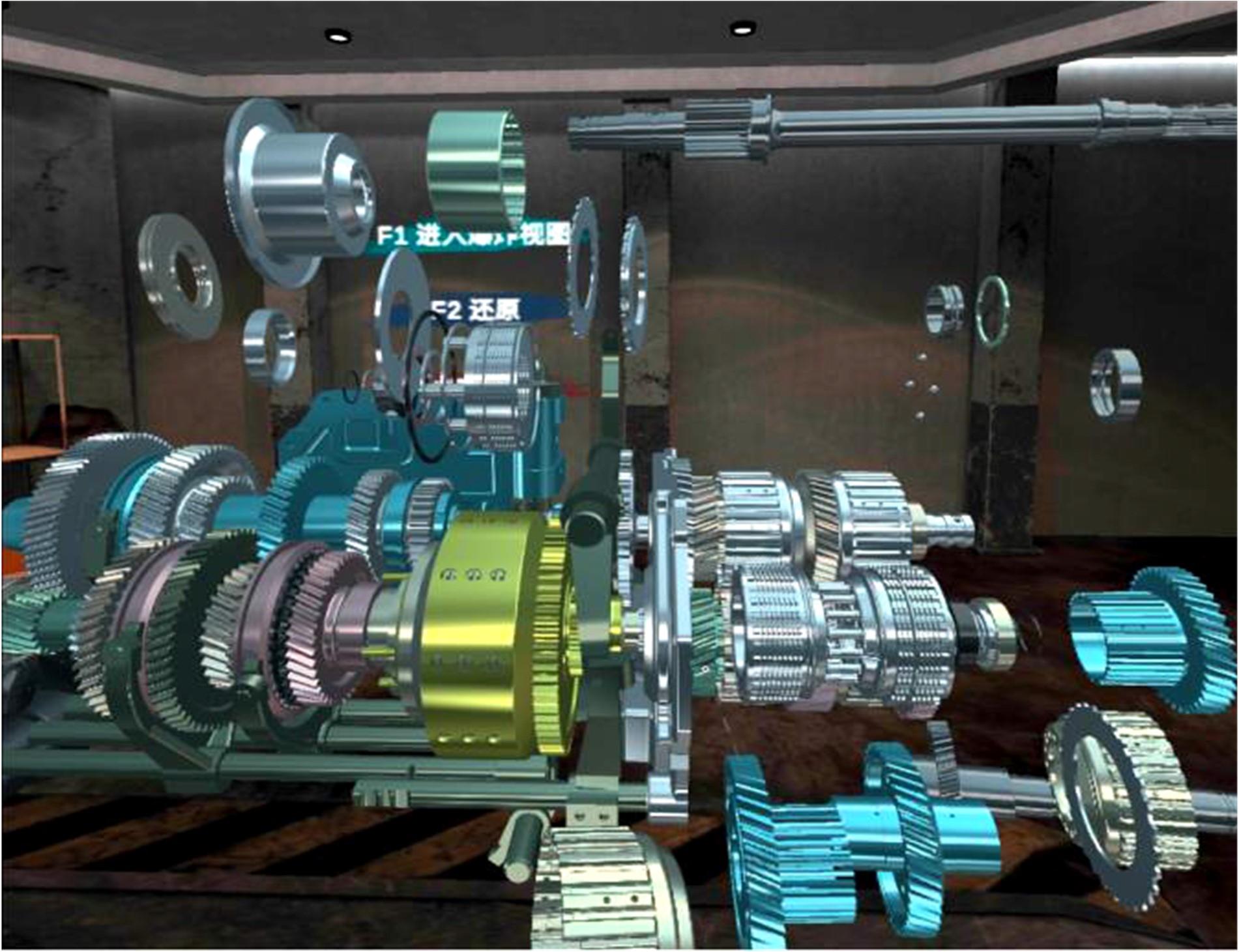

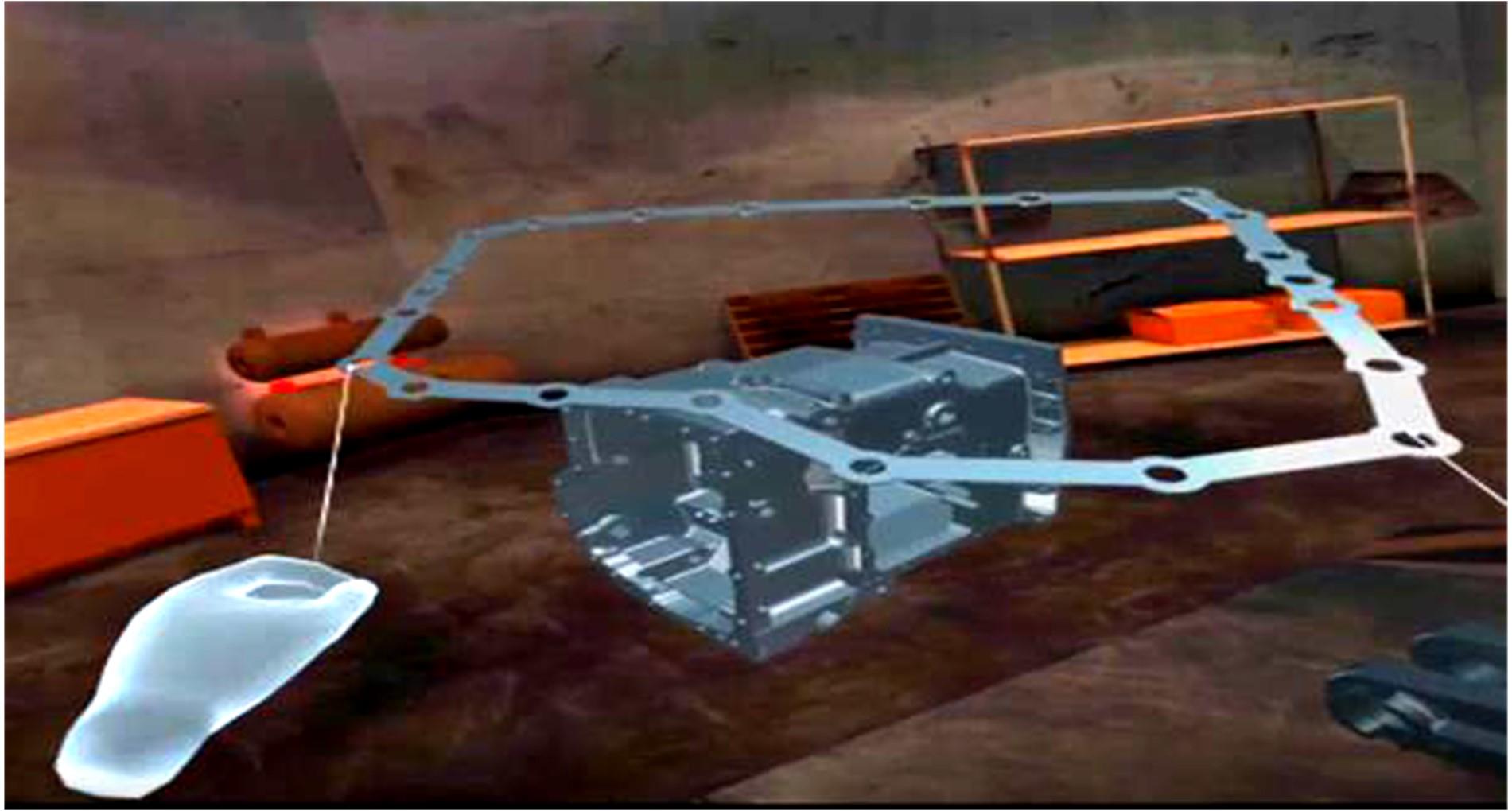

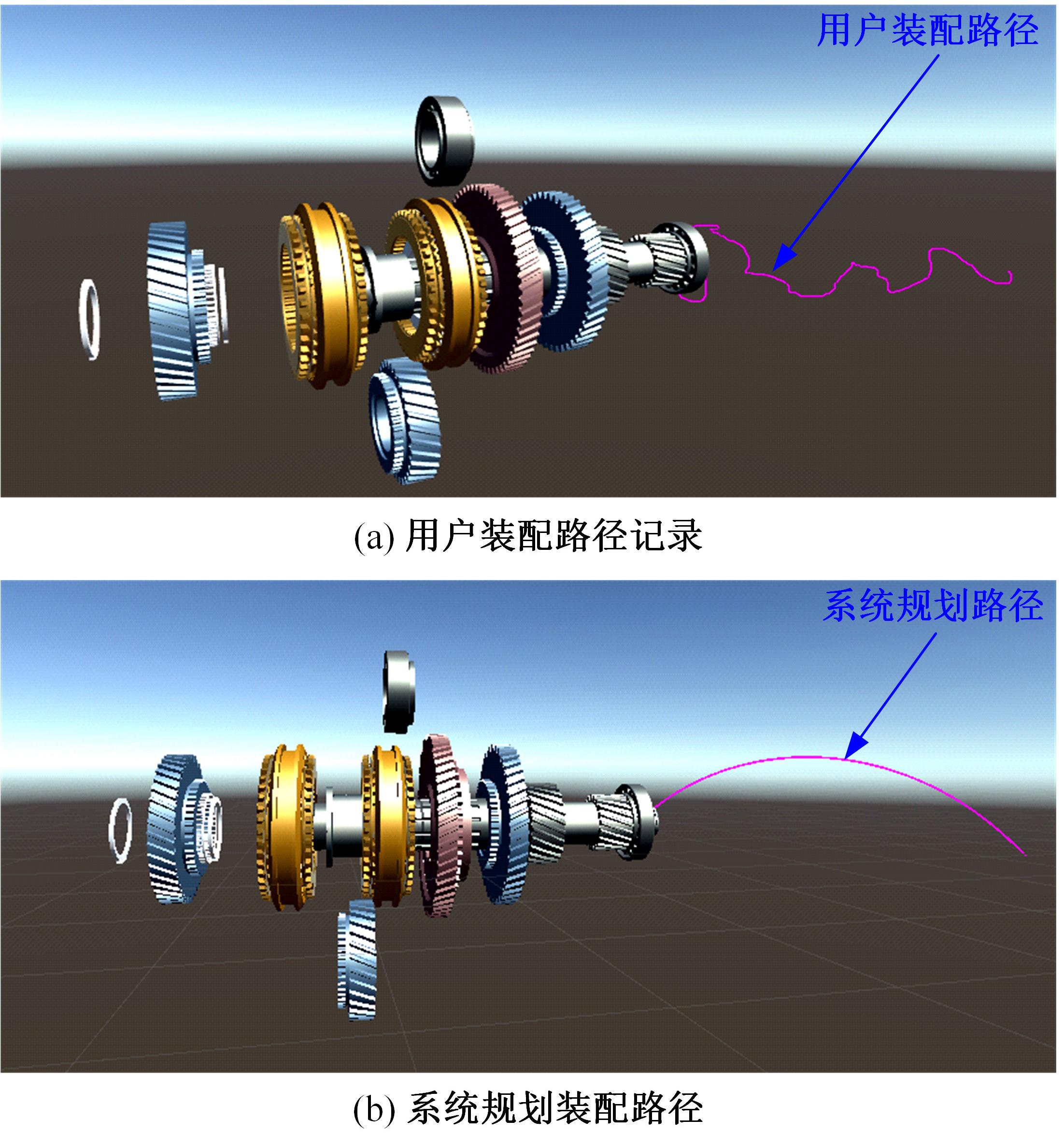

针对拖拉机变速箱装配工艺复杂、成本高、产品开发周期长等问题,研究了基于虚拟现实的拖拉机变速箱虚拟装配技术,开发了具有沉浸感、想象性、交互性等特点的拖拉机变速箱虚拟装配系统。首先,通过研究变速箱虚拟现实模型构建方法,采用模型数据转换的方式从CAD系统提取拖拉机变速箱装配信息,在虚拟装配环境中建立拖拉机变速箱装配信息层次模型,运用Mesh合并、几何元素删减等模型预处理技术获取轻量化虚拟现实模型。其次,基于C#语言在Unity3D环境中开发虚拟装配软件,实现变速箱零部件在虚拟装配环境中的移动、旋转、定位装配、场景漫游、音效播放、零部件名称显示、装配路径规划等功能。最后,以Oculus Quest2头戴显示器为交互设备开展拖拉机变速箱装配试验。试验结果表明:本文开发的变速箱虚拟装备系统运行流畅、模型交互准确、用户操作体验良好,可缩短变速箱虚拟装配周期、降低开发成本。

中图分类号:

- TP391.4

| 1 | 乔玉良. 机械装配工艺的质量问题探讨[J]. 黑龙江科学, 2014, 5(9): 235. |

| Qiao Yu-liang. Discussion on quality problem of mechanical assembly process[J]. Heilongjiang Science, 2014, 5(9): 235. | |

| 2 | 李敏, 韩丰. 虚拟现实技术综述[J]. 软件导刊, 2010, 9(6): 142-144. |

| Li Min, Han Feng. Overview of virtual reality technology[J]. Software Guide, 2010, 9(6): 142-144. | |

| 3 | 赵沁平. 虚拟现实综述[J]. 中国科学, 2009, 39(1): 2-46. |

| Zhao Qin-ping. Overview of virtual reality[J]. Science in China, 2009, 39(1): 2-46. | |

| 4 | 张凤军, 戴国忠, 彭晓兰. 虚拟现实的人机交互综述[J]. 中国科学: 信息科学, 2016, 46(12): 1711-1736. |

| Zhang Feng-jun, Dai Guo-zhong, Peng Xiao-lan. An overview of human-computer interaction in virtual reality[J]. Science China: Information Science, 2016, 46(12): 1711-1736. | |

| 5 | 宁汝新, 郑轶. 虚拟装配技术的研究进展及发展趋势分析[J].中国机械工程, 2005(15): 1398-1404. |

| Ning Ru-xin, Zheng Yi. Research progress and development trend analysis of virtual assembly technology[J]. China Mechanical Engineering, 2005(15): 1398-1404. | |

| 6 | 李建广, 夏平均. 虚拟装配技术研究现状及其发展[J]. 航空制造技术, 2010(3): 34-38. |

| Li Jian-guang, Xia Ping-jun. Research status and development of virtual assembly technology[J]. Aeronautical Manufacturing Technology, 2010(3): 34-38. | |

| 7 | 陈雁飞, 马建民, 高丽. 虚拟现实技术综述[J]. 机械制造与自动化, 2004(5): 5-7. |

| Chen Yan-fei, Ma Jian-min, Gao Li. Review of virtual reality technology[J]. Machine Building & Automation, 2004(5): 5-7. | |

| 8 | Mustufa H, Abidi A, Saber D, et al. Haptics assisted virtual assembly[J]. IFAC PapersOnLine, 2015, 48(3): 100-105. |

| 9 | Gonzalez-Badillo G, Medellin-Castillo H I, Lim T. Development of a haptic virtual reality system for assembly planning and evaluation[J]. Procedia Technology, 2013, 7: 265-272. |

| 10 | 甘豪. 四挡变速器虚拟装配平台的构建[J]. 装备机械, 2019(4): 35-38. |

| Gan Hao. Construction of virtual assembly platform for four-speed transmission[J]. Equipment Machinery, 2019(4): 35-38. | |

| 11 | 杨锟, 刘继红. 面向虚拟装配的装配建模技术[J]. 机械科学与技术, 2001(2): 305-308. |

| Yang Kun, Liu Ji-hong. Assembly modeling technology for virtual assembly[J]. Mechanical Science and Technology for Aerospace Engineering, 2001(2): 305-308. | |

| 12 | 刘文剑, 金天国. 产品自顶向下设计的研究现状及发展方向[J]. 计算机集成制造系统, 2002(1): 1-7. |

| Liu Wen-jian, Jin Tian-guo. Research status and development direction of top-down product design[J]. Computer Integrated Manufacturing Systems, 2002 (1): 1-7. | |

| 13 | 刘振宇, 谭建荣, 张树有. 面向虚拟装配的产品层次信息表达研究[J]. 计算机辅助设计与图形学学报, 2001, (3): 223-228. |

| Liu Zhen-yu, Tan Jian-rong, Zhang Shu-you. The multi level representation of production information for virtual assembly[J]. Journal of Computer-Aided Design & Computer Graphics, 2001(3): 223-228. | |

| 14 | 冯文雯, 陈珝玥, 余虹亮, 等. 基于约束Delaunay三角形多视3D重建[J]. 计算机应用与软件, 2017, 34(7): 120-124. |

| Feng Wen-wen, Chen Yu-yue, Yu Hong-liang, et al. Multi-view 3D reconstruction of delaunay triangle based on constraint[J]. Computer Applications and Software,2017, 34(7): 120-124. | |

| 15 | 胡海鹤. 三维网格模型简化技术研究[D]. 洛阳: 河南科技大学, 2007. |

| Hu Hai-he. Research on simplification technology of 3D model grid[D]. Luoyang: Henan University of Science and Technology, 2007. | |

| 16 | 干智峰. 基于AABB包围盒的双机械臂避碰技术的研究[J]. 科技视界, 2020(17): 95-98. |

| Gan Zhi-feng. Research on collision avoidance technology of double manipulator based on AABB bounding box[J]. Science and Technology Vision, 2020(17): 95-98. | |

| 17 | 马登武, 叶文,李瑛. 基于包围盒的碰撞检测算法综述[J]. 系统仿真学报, 2006(4): 1058-1061, 1064. |

| Ma Deng-wu, Ye Wen, Li Ying. Survey of Box-based algorithms for collision detection[J]. Journal of System Simulation, 2006(4): 1058-1061, 1064. | |

| 18 | 郑轶, 宁汝新, 刘检华, 等. 交互式虚拟装配路径规划及优选方法研究[J]. 中国机械工程, 2006(11): 1153-1156. |

| Zheng Yi, Ning Ru-xin, Liu Jian-hua, et al. Researchon interactive virtual assembly path planning and optimization method[J]. China Mechanical Engineering, 2006(11): 1153-1156. |

| [1] | 陈兆玮,蒲前华. 弹性车轮对大跨斜拉桥车桥耦合振动的抑制特性[J]. 吉林大学学报(工学版), 2023, 53(9): 2519-2532. |

| [2] | 刘平义,李晓婷,高偌霖,李海涛,魏文军,王亚. 车辆侧倾驱动机构设计与试验[J]. 吉林大学学报(工学版), 2023, 53(8): 2185-2192. |

| [3] | 黄学劲,钟锦星,路京雨,赵霁,肖伟,袁新枚. 基于用户画像的电动汽车充电负荷预测方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2193-2200. |

| [4] | 张树培,夏明悦,张玮,陈钊,陈义祥. 考虑非线性刚度的间隙球铰碰撞动力学建模与仿真[J]. 吉林大学学报(工学版), 2023, 53(8): 2227-2235. |

| [5] | 陈辉,邵亚军. 基于惯性基准多传感器耦合的路面谱测量方法[J]. 吉林大学学报(工学版), 2023, 53(8): 2254-2262. |

| [6] | 陈磊,王杨,董志圣,宋亚奇. 一种基于转向意图的车辆敏捷性控制策略[J]. 吉林大学学报(工学版), 2023, 53(5): 1257-1263. |

| [7] | 陈鑫,张冠宸,赵康明,王佳宁,杨立飞,司徒德蓉. 搭接焊缝对铝合金焊接结构轻量化设计的影响[J]. 吉林大学学报(工学版), 2023, 53(5): 1282-1288. |

| [8] | 张勇,毛凤朝,刘水长,王青妤,潘神功,曾广胜. 基于Laplacian算法的汽车外流场畸变网格优化[J]. 吉林大学学报(工学版), 2023, 53(5): 1289-1296. |

| [9] | 汪少华,储堃,施德华,殷春芳,李春. 基于有限时间扩张状态观测的HEV鲁棒复合协调控制[J]. 吉林大学学报(工学版), 2023, 53(5): 1272-1281. |

| [10] | 尹燕莉,黄学江,潘小亮,王利团,詹森,张鑫新. 基于PID与Q⁃Learning的混合动力汽车队列分层控制[J]. 吉林大学学报(工学版), 2023, 53(5): 1481-1489. |

| [11] | 于贵申,陈鑫,武子涛,陈轶雄,张冠宸. AA6061⁃T6铝薄板无针搅拌摩擦点焊接头结构及性能分析[J]. 吉林大学学报(工学版), 2023, 53(5): 1338-1344. |

| [12] | 田彦涛,黄兴,卢辉遒,王凯歌,许富强. 基于注意力与深度交互的周车多模态行为轨迹预测[J]. 吉林大学学报(工学版), 2023, 53(5): 1474-1480. |

| [13] | 杨红波,史文库,陈志勇,郭年程,赵燕燕. 基于NSGA⁃II的斜齿轮宏观参数多目标优化[J]. 吉林大学学报(工学版), 2023, 53(4): 1007-1018. |

| [14] | 赵睿,李云,胡宏宇,高镇海. 基于V2I通信的交叉口车辆碰撞预警方法[J]. 吉林大学学报(工学版), 2023, 53(4): 1019-1029. |

| [15] | 陈小波,陈玲. 定位噪声统计特性未知的变分贝叶斯协同目标跟踪[J]. 吉林大学学报(工学版), 2023, 53(4): 1030-1039. |

|

||