吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (6): 1799-1808.doi: 10.13229/j.cnki.jdxbgxb.20221208

• 交通运输工程·土木工程 • 上一篇

影响智能骨料感知的关键因素及数据分析方法

- 1.东南大学 交通学院,南京 211189

2.滨湖区蠡湖街道办事处,江苏 无锡 214000

Key factors affecting smart aggregate perception and data analysis methods

Ning WANG1( ),Tao MA1,Feng CHEN1(

),Tao MA1,Feng CHEN1( ),Yong-qiang FU2

),Yong-qiang FU2

- 1.School of Transportation,Southeast University,Nanjing 211189,China

2.Lihu Street Office,Binhu District,Wuxi 214000,China

摘要:

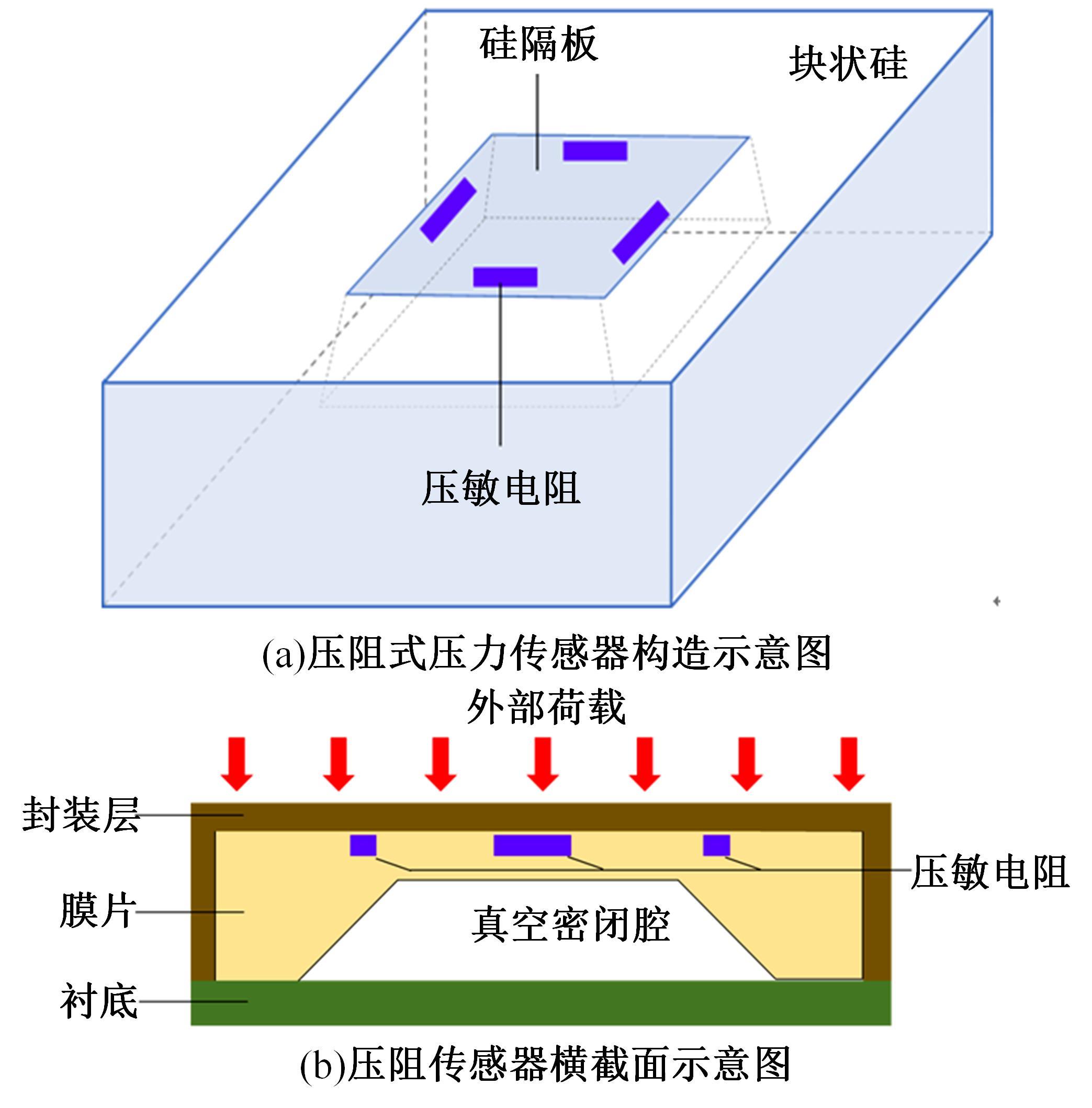

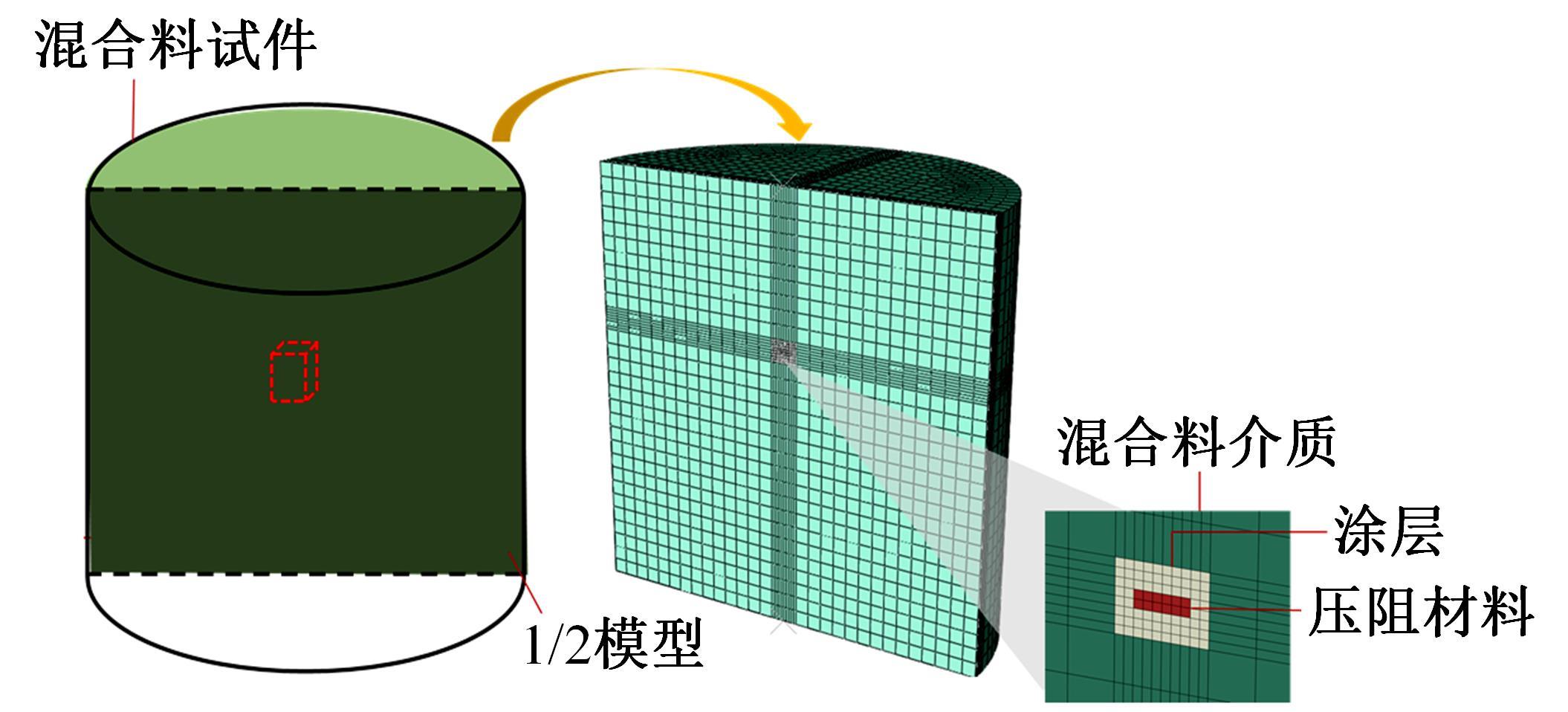

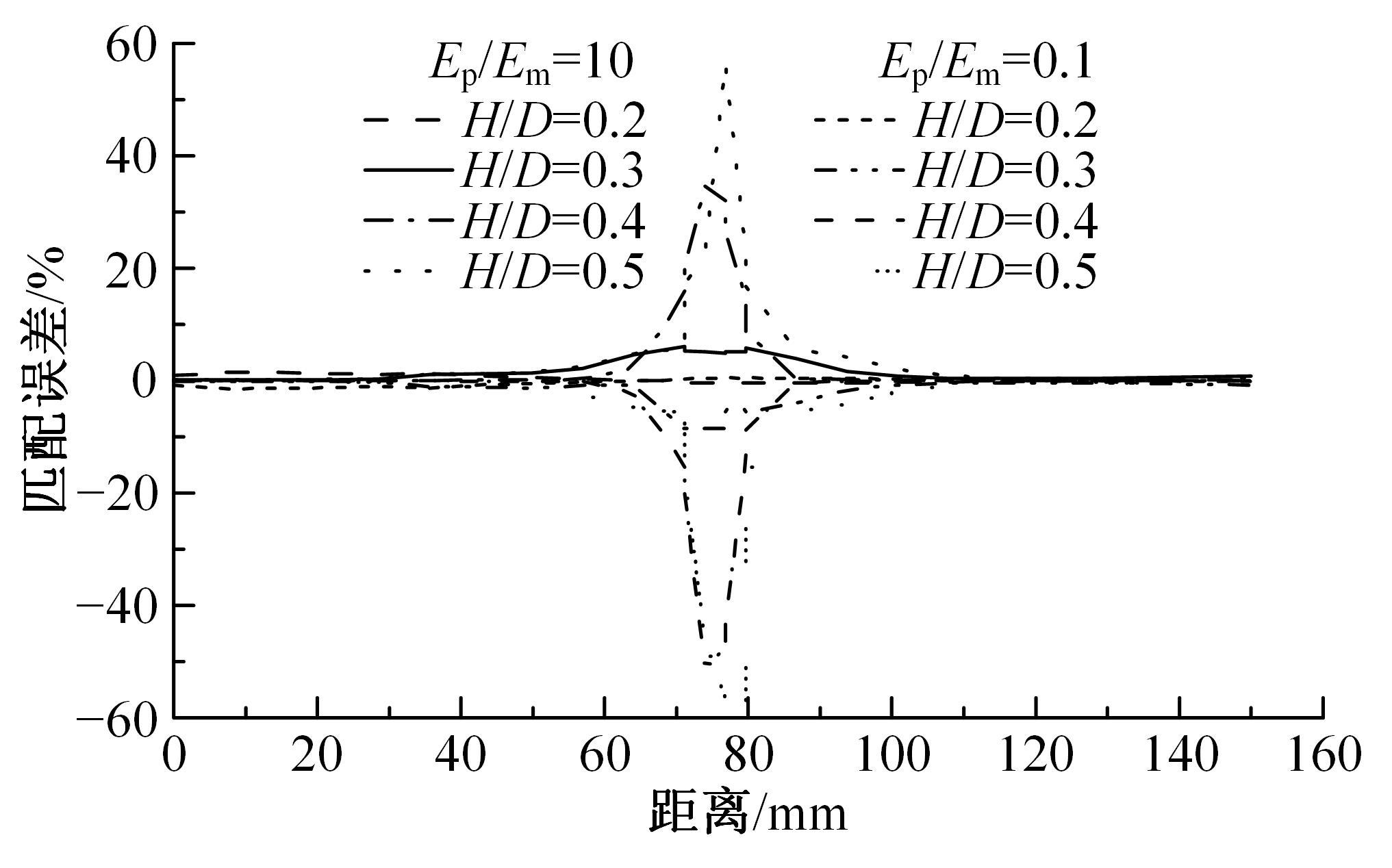

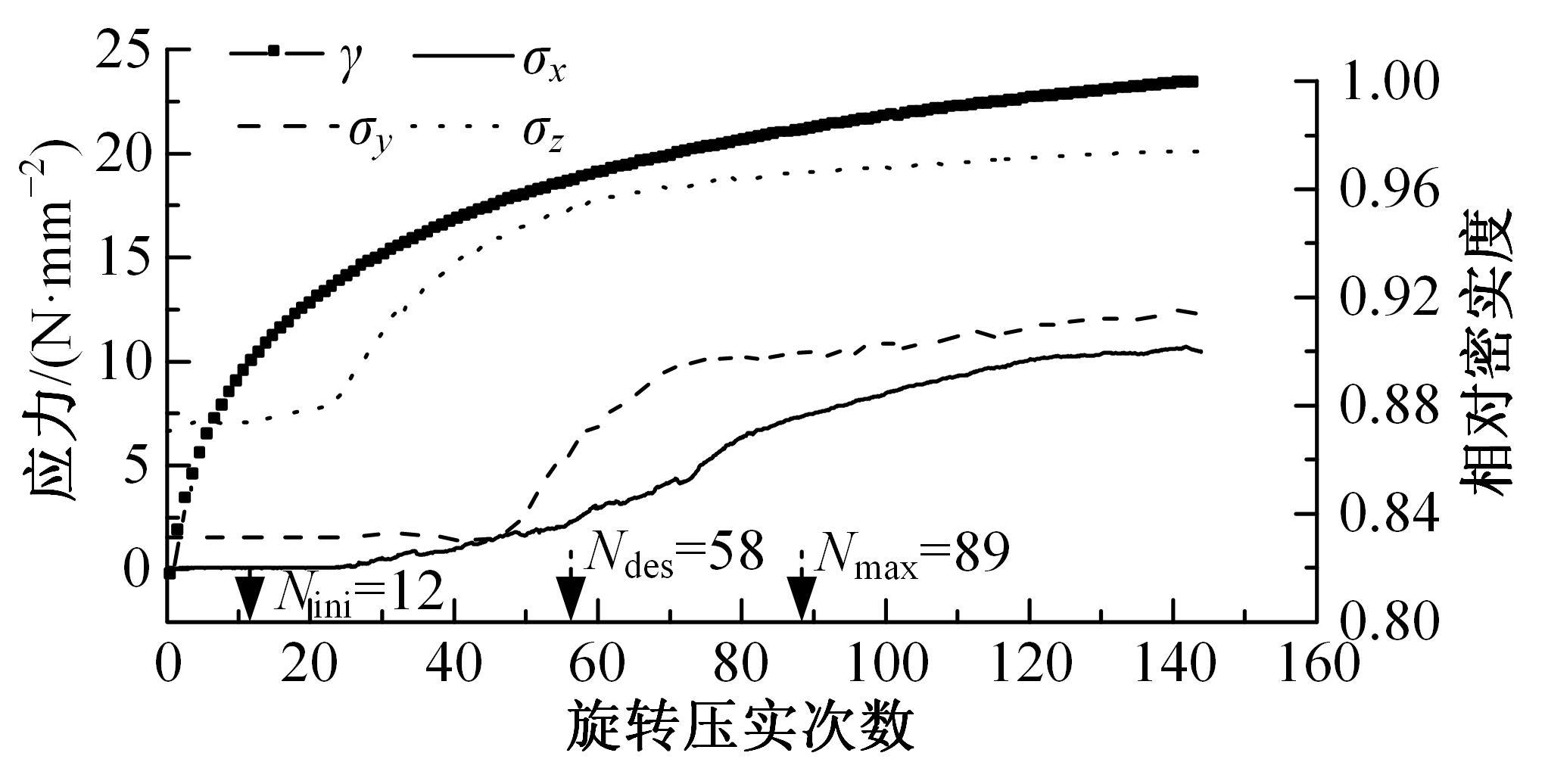

为研究不同荷载作用形式、封装材料和形状特性对智能骨料传感器监测结果的影响,实现基于传感器感知参数对混合料介质物理力学特征的有效评价,对埋入式智能骨料传感器SmartRock的室内二次标定进行了试验,构建了传感器-混合料介质耦合三维有限元数值模型,并开展了基于SmartRock传感器的水泥稳定碎石旋转压实和无侧限抗压强度试验。结果表明:集中荷载作用下的传感器应力响应远大于均布荷载;传感器高度与底面边长的比值H/D<0.3,埋入式传感器封装材料与周围介质模量的比值Ep/Em>5时,匹配误差可保持在较低且稳定的水平;可通过分析SmartRock传感器应力响应的离散系数Sv表征混合料压实度及强度的演化规律。

中图分类号:

- U416.2

| 1 | 《中国公路学报》编辑部. 中国路面工程学术研究综述·2020[J]. 中国公路学报, 2020, 33(10): 1-66. |

| Editorial department of China highway journal of highway and transport. Summary of academic research on pavement engineering in China·2020[J]. China Highway Journal, 2020, 33(10): 1-66. | |

| 2 | 张立祥, 罗强, 张良,等. 土压力传感器在硬土介质中的非线性响应分析[J]. 岩土力学, 2013, 34(12): 3633-3640. |

| Zhang Li-xiang, Luo Qiang, Zhang Liang, et al. Nonlinear response analysis of earth pressure sensor in hard soil[J]. Geotechnical Mechanics, 2013, 34(12): 3633-3640. | |

| 3 | 刘荣梅, 赵振, 白树伟. 埋入式光纤智能复合材料简化界面的应变传递分析[J]. 材料导报, 2021, 35(20): 20161-20165. |

| Liu Rong-mei, Zhao Zhen, Bai Shu-wei. Strain transfer analysis at simplified Interface of embedded optical fiber intelligent composites[J]. Materials Review, 2021, 35(20): 20161-20165. | |

| 4 | Xiang P, Wang H. Optical fibre-based sensors for distributed strain monitoring of asphalt pavements[J]. International Journal of Pavement Engineering, 2018, 19(9): 842-850. |

| 5 | 刘朝晖, 夏红卫, 柳力. 埋入式传感器与沥青混合料的交互影响研究[J]. 长沙理工大学学报:自然科学版, 2021, 18(1): 1-6. |

| Liu Zhao-hui, Xia Hong-wei, Liu Li. Interaction between embedded sensors and asphalt mixture[J]. Journal of Changsha University of Science and Technology (Natural Science Edition), 2021, 18(1): 1-6. | |

| 6 | 谭忆秋, 董泽蛟, 田庚亮, 等. 光纤光栅传感器与沥青混合料协同变形评价方法[J]. 土木建筑与环境工程, 2009, 31(2): 100-104. |

| Tan Yi-qiu, Dong Ze-jiao, Tian Geng-liang, et al. Evaluation method for synergistic deformation of fiber grating sensor and asphalt mixture[J]. Civil Engineering and Environmental Engineering, 2009, 31(2): 100-104. | |

| 7 | 郑钟铭, 国旗, 吴娜,等. 基于波片棱镜组合能量调节的切趾光纤光栅[J]. 吉林大学学报:信息科学版, 2020, 38(5): 523-528. |

| Zheng Zhong-ming, Guo Qi, Wu Na, et al. Fiber bragg grating with cut toe based on waveplate prisms combined energy regulation[J]. Journal of Jilin University(Information Science Edition), 2020, 38(5): 523-528. | |

| 8 | 张浩, 李俊杰, 康飞. 基于压电智能骨料的混凝土梁裂缝损伤监测研究[J]. 振动与冲击, 2021, 40(21): 215-222. |

| Zhang Hao, Li Jun-jie, Kang Fei. Research on crack damage monitoring of concrete beams based on piezoelectric smart aggregate[J]. Vibration and Impact, 2021, 40(21): 215-222. | |

| 9 | 张楠, 霍羽. 煤矿环境下人员移动无线传感器节点协同定位算法[J]. 吉林大学学报:工学版, 2022, 52(5):1168-1173. |

| Zhang Nan, Huo Yu. Collaborative location algorithm of personnel mobile wireless sensor nodes in coal mine environment[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(5):1168-1173. | |

| 10 | Dan H C, Yang D, Liu X, et al. Experimental investigation on dynamic response of asphalt pavement using smartrock sensor under vibrating compaction loading[J]. Construction and Building Materials, 2020, 247: No.118592. |

| 11 | Wang X, Shen S, Huang H, et al. Characterization of particle movement in superpave gyratory compactor at meso-scale using smartrock sensors[J]. Construction and Building Materials, 2018, 175: 206-214. |

| 12 | Wang N, Han T, Cheng H, et al. Monitoring structural health status of asphalt pavement using intelligent sensing technology[J]. Construction and Building Materials, 2022, 352: No. 129025. |

| 13 | 侯爽, 雷晋芳, 欧进萍. 基于压电智能骨料的沥青混凝土路面车辆动态荷载监测[J]. 振动与冲击, 2014, 33(4): 42-47. |

| Hou Shuang, Lei Jin-fang, Jin-ping Ou. Dynamic vehicle load monitoring of asphalt concrete pavements based on piezoelectric smart aggregates[J]. Vibration and Impact, 2014, 33(4): 42-47. | |

| 14 | Asadi P, Mehrabi H, Asadi A, et al. Deep convolutional neural networks for pavement crack detection using an inexpensive global shutter RGB-D sensor and ARM-based single-board computer[J]. Transportation Research Record, 2021, 2675(9): 885-897. |

| 15 | Pan Y, Zhang X, Cervone G, et al. Detection of asphalt pavement potholes and cracks based on the unmanned aerial vehicle multispectral imagery[J]. IEEE Journal of Selected Topics in Applied Earth Observations and Remote Sensing, 2018, 11(10): 3701-3712. |

| 16 | Di Graziano A, Marchetta V, Cafiso S. Structural health monitoring of asphalt pavements using smart sensor networks: a comprehensive review[J]. Journal of Traffic and Transportation Engineering (English Edition), 2020, 7(5): 639-651. |

| 17 | Rys D, Burnos P. Study on the accuracy of axle load spectra used for pavement design[J]. International Journal of Pavement Engineering, 2022, 23(11): 3706-3715. |

| 18 | Al Khateeb L, Tang T, Erkens S, et al. Effect of fiber bragg grating sensors installation on pavement responses[C]∥Advances in Materials and Pavement Performance Prediction, Florida, USA, 2018: 79-82. |

| 19 | Chen C, Chandra S, Han Y, et al. Deep learning-based thermal image analysis for pavement defect detection and classification considering complex pavement conditions[J]. Remote Sensing, 2021, 14(1): 106-123. |

| 20 | Skar A, Levenberg E, Andersen S, et al. Analysis of a moving measurement platform based on line profile sensors for project-level pavement evaluation[J]. Road Materials and Pavement Design, 2021, 22(9): 2069-2085. |

| 21 | Cheng Z, Zhang D, Xie S, et al. Smartrock-based research on gyratory locking point for stone mastic asphalt mixture[J]. Buildings, 2022, 12(2): 97-113. |

| 22 | Wang N, Chen F, Ma T, et al. Compaction performance of cold recycled asphalt mixture using smartrock sensor[J]. Automation in Construction, 2022, 140: No. 104377. |

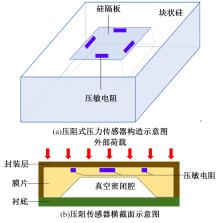

| 23 | 卢鹏. 新型MEMS压阻式压力传感器的设计[D]. 重庆: 电子科技大学机械与电器工程学院,2021. |

| Lu Peng. Design of a new MEMS piezoresistive pressure sensor[D]. Chongqing: School of Mechanical and Electrical Engineering, University of Electronic Science and Technology, 2021. | |

| 24 | 曾辉. 岩土应力传感器匹配系数的等效性和真实性[C]∥水电与矿业工程中的岩石力学问题——中国北方岩石力学与工程应用学术会议文集, 郑州, 中国, 1991: 796-803. |

| 25 | 曾辉, 余尚江. 岩土压力传感器匹配误差的特性[J]. 岩土力学, 2004, 25(12): 2003-2006. |

| Zeng Hui, Yu Shang-jiang. Characterization of matching errors in geotechnical pressure sensors [J]. Geotechnics, 2004, 25(12): 2003-2006. | |

| 26 | 朱元广, 刘泉声, 蒋景东,等. 水泥砂浆体中三向压力传感器的测量特性[J]. 岩石力学与工程学报, 2015, 34(9): 1877-1885. |

| Zhu Yuan-guang, Liu Quan-shing, Jiang Jing-dong, et al. Measurement characteristics of three-way pressure sensors in cement mortar bodies[J]. Journal of Rock Mechanics and Engineering, 2015, 34(9): 1877-1885. | |

| 27 | . 公路工程沥青及沥青混合料试验规程 [S]. |

| 28 | Butcher M. Determining gyratory compaction characteristics using servopac gyratory compactor[J]. Transportation Research Record, 1998, 1630(1): 89-97. |

| [1] | 杨柳,王创业,王梦言,程阳. 设置自动驾驶小客车专用车道的六车道高速公路交通流特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2043-2052. |

| [2] | 周正峰,于晓涛,陶雅乐,郑茂,颜川奇. 基于灰色关联分析的树脂与弹性体高黏沥青高温性能评价[J]. 吉林大学学报(工学版), 2023, 53(7): 2078-2088. |

| [3] | 马涛,马源,黄晓明. 基于多元非线性回归的智能压实关键参数最优解[J]. 吉林大学学报(工学版), 2023, 53(7): 2067-2077. |

| [4] | 黄晓明,赵润民. 道路交通基础设施韧性研究现状及展望[J]. 吉林大学学报(工学版), 2023, 53(6): 1529-1549. |

| [5] | 张哲,付伟,张军辉,黄超. 循环荷载下冻融路基黏土长期塑性行为[J]. 吉林大学学报(工学版), 2023, 53(6): 1790-1798. |

| [6] | 张青霞,侯吉林,安新好,胡晓阳,段忠东. 基于车辆脉冲响应的路面不平度识别方法[J]. 吉林大学学报(工学版), 2023, 53(6): 1765-1772. |

| [7] | 司春棣,崔亚宁,许忠印,凡涛涛. 层间粘结失效后桥面沥青铺装层细观力学行为分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1719-1728. |

| [8] | 李岩,张久鹏,陈子璇,黄果敬,王培. 基于PCA-PSO-SVM的沥青路面使用性能评价[J]. 吉林大学学报(工学版), 2023, 53(6): 1729-1735. |

| [9] | 赵晓康,胡哲,张久鹏,裴建中,石宁. 基于光纤传感技术的路面结冰智能监测研究进展[J]. 吉林大学学报(工学版), 2023, 53(6): 1566-1579. |

| [10] | 惠冰,杨心怡,张乐扬,李扬. 检测车轨迹偏移对沥青路面磨耗计算误差的影响[J]. 吉林大学学报(工学版), 2023, 53(6): 1756-1764. |

| [11] | 李崛,张安顺,张军辉,钱俊峰. 级配碎石基层结构动力响应模型测试及数值分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1782-1789. |

| [12] | 刘状壮,郑文清,郑健,李轶峥,季鹏宇,沙爱民. 基于网格化的路表温度感知技术[J]. 吉林大学学报(工学版), 2023, 53(6): 1746-1755. |

| [13] | 郑睢宁,何锐,路天宇,徐紫祎,陈华鑫. RET/胶粉复合改性沥青制备及其混合料性能评价[J]. 吉林大学学报(工学版), 2023, 53(5): 1381-1389. |

| [14] | 魏海斌,韩栓业,毕海鹏,刘琼辉,马子鹏. 智能感知道路主动除冰雪系统及实验技术[J]. 吉林大学学报(工学版), 2023, 53(5): 1411-1417. |

| [15] | 杨帆,李琛琛,李盛,刘海伦. 温缩作用下双层连续配筋混凝土路面配筋率设计参数对比分析[J]. 吉林大学学报(工学版), 2023, 53(4): 1122-1132. |

|

||