吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (10): 2870-2883.doi: 10.13229/j.cnki.jdxbgxb.20221556

• 交通运输工程·土木工程 • 上一篇

压型钢板-混凝土组合桥面板极限承载力试验

- 同济大学 土木工程学院,上海 200092

Experiment on load capacity of profiled steel sheeting-concrete composite bridge decks

Xie-li ZHANG( ),Chong WU,Qing-tian SU

),Chong WU,Qing-tian SU

- College of Civil Engineering,Tongji University,Shanghai 200092,China

摘要:

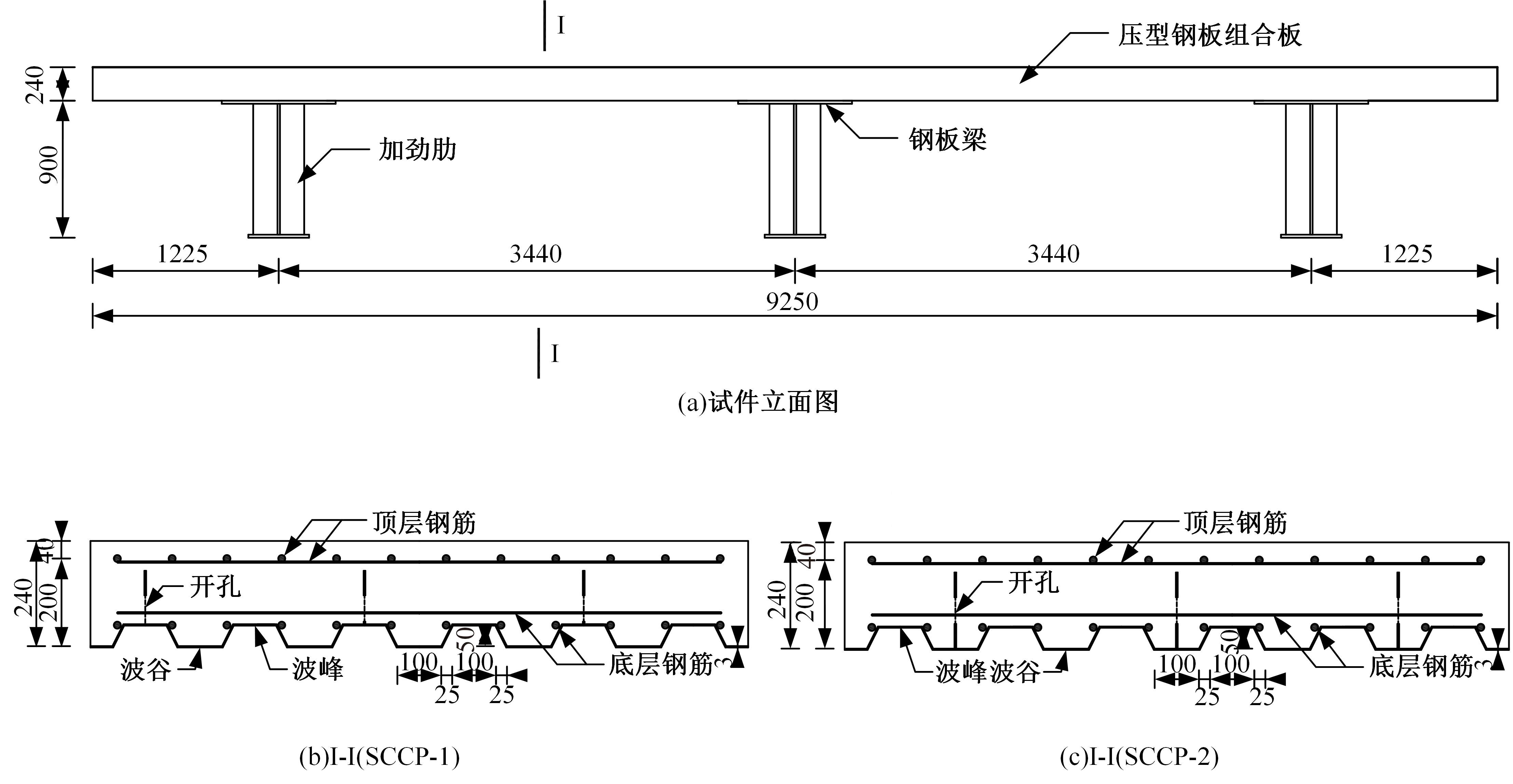

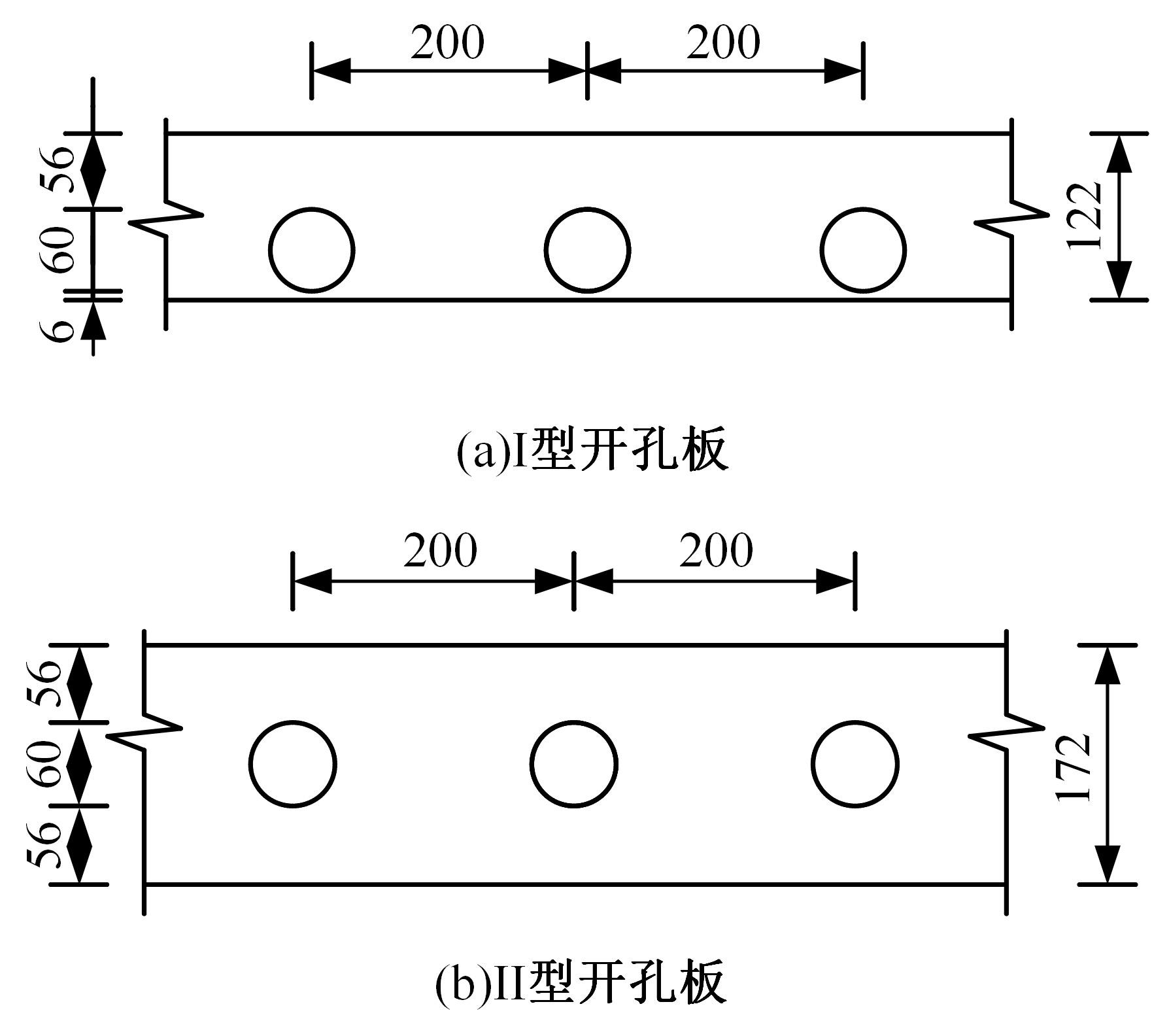

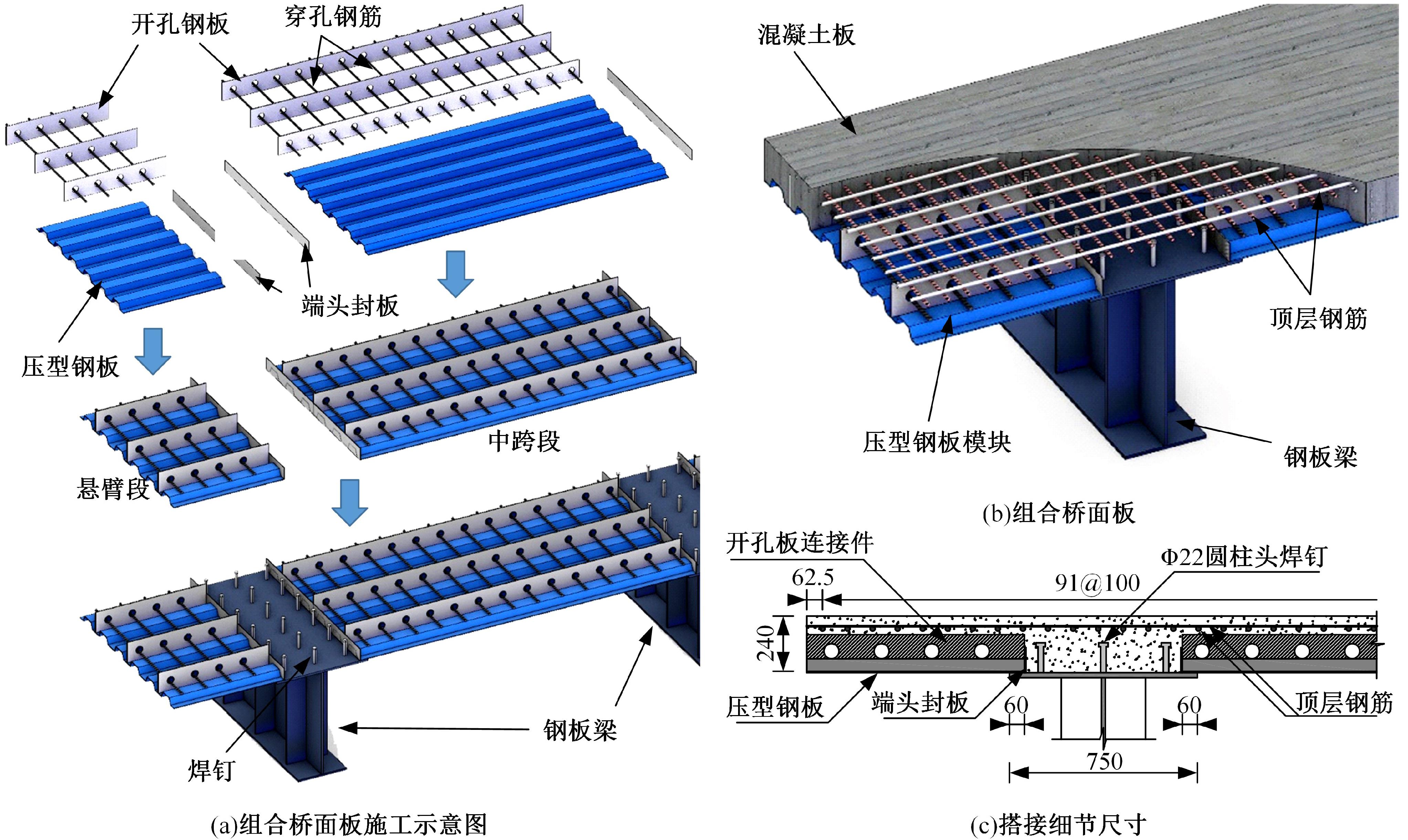

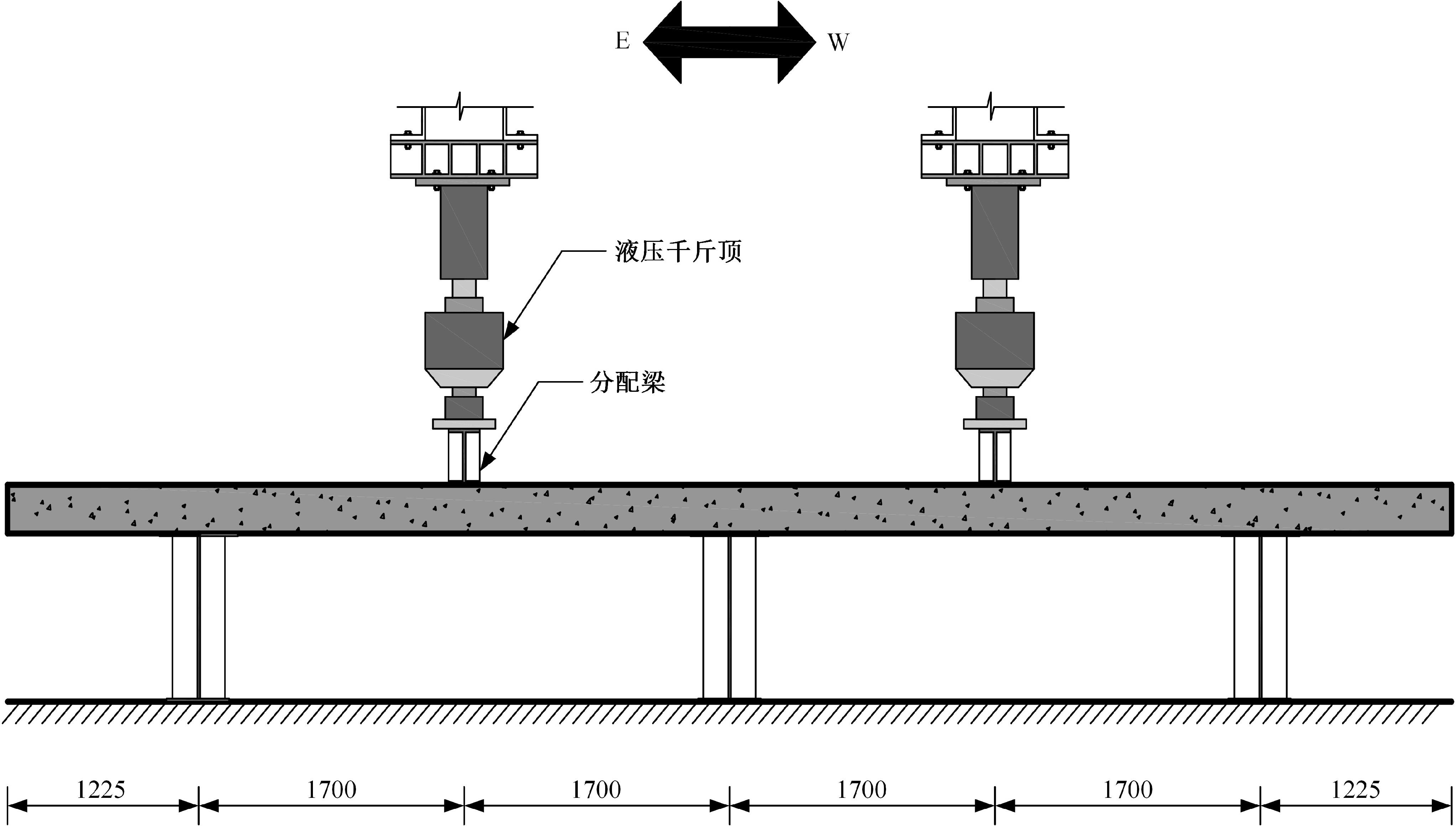

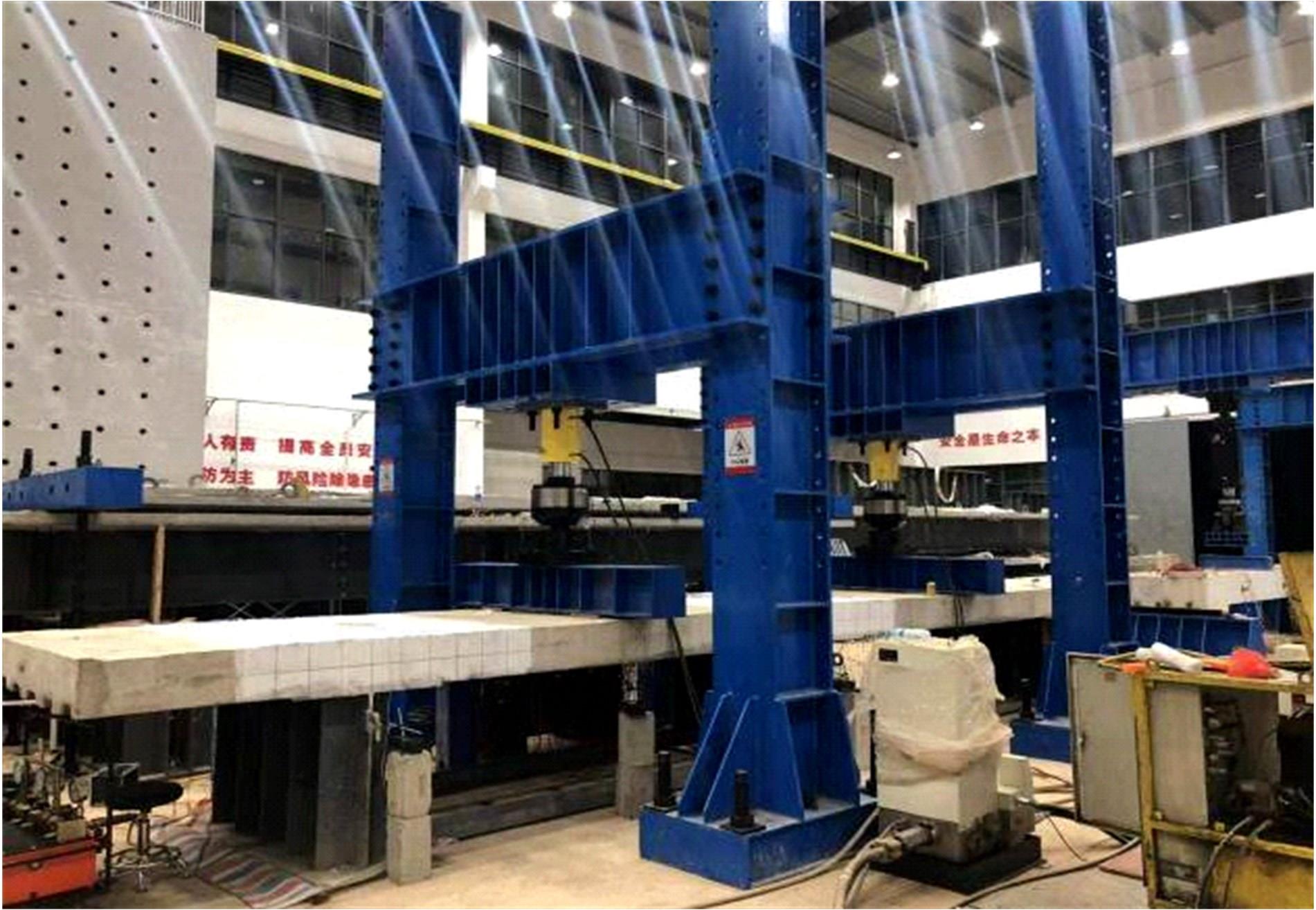

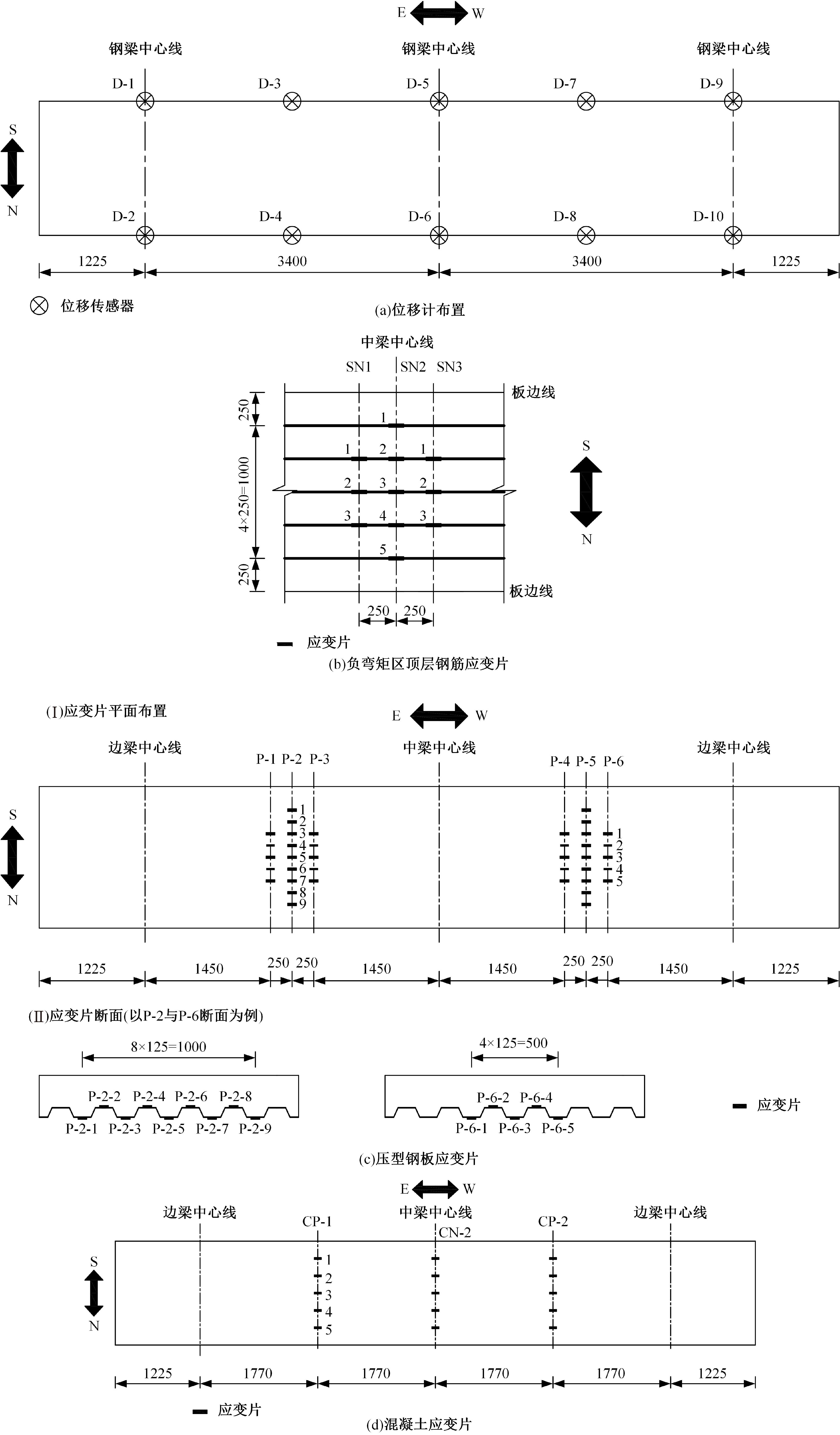

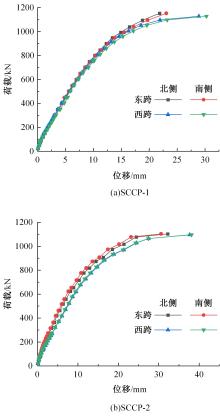

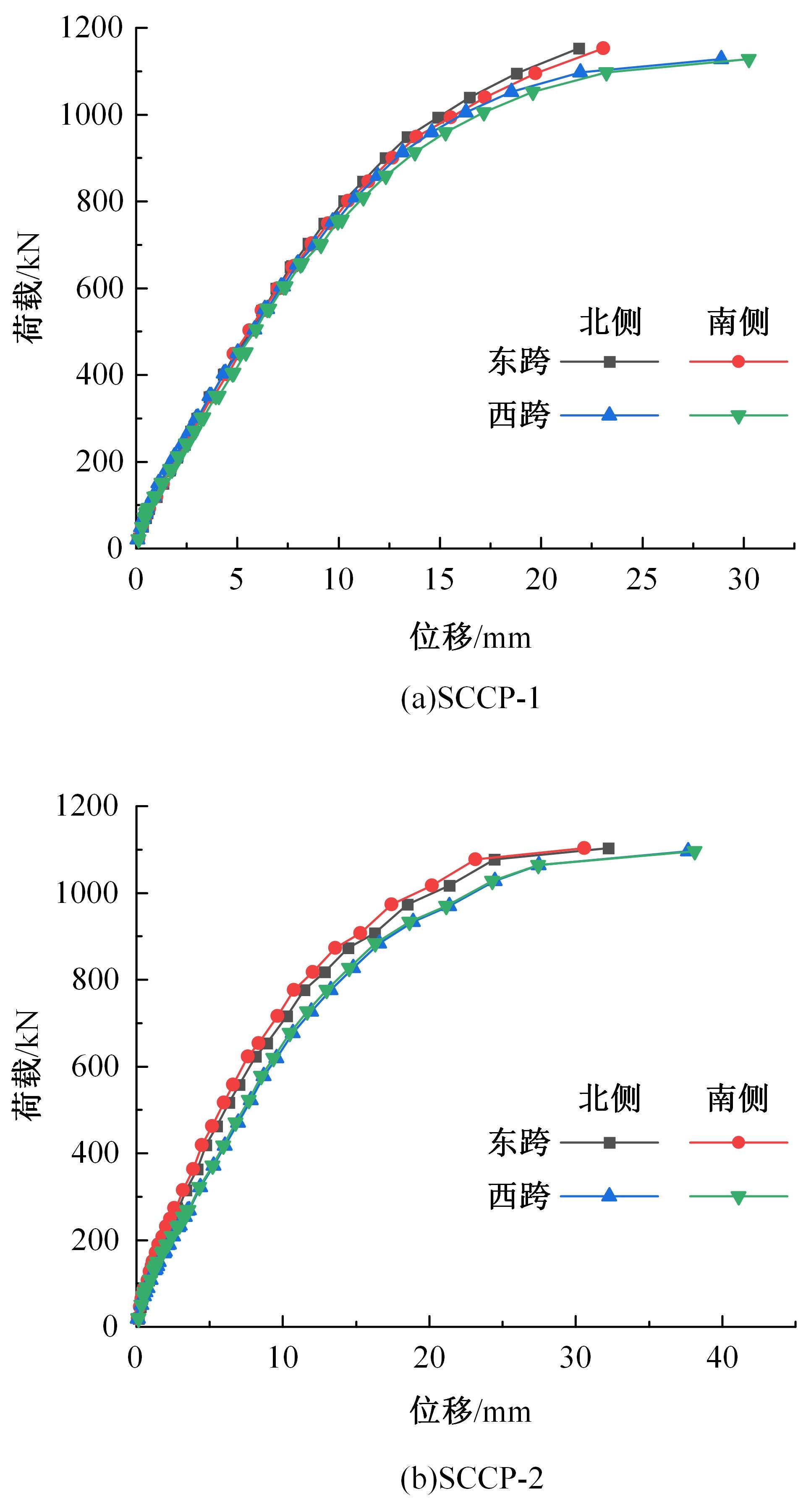

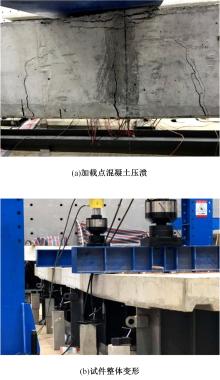

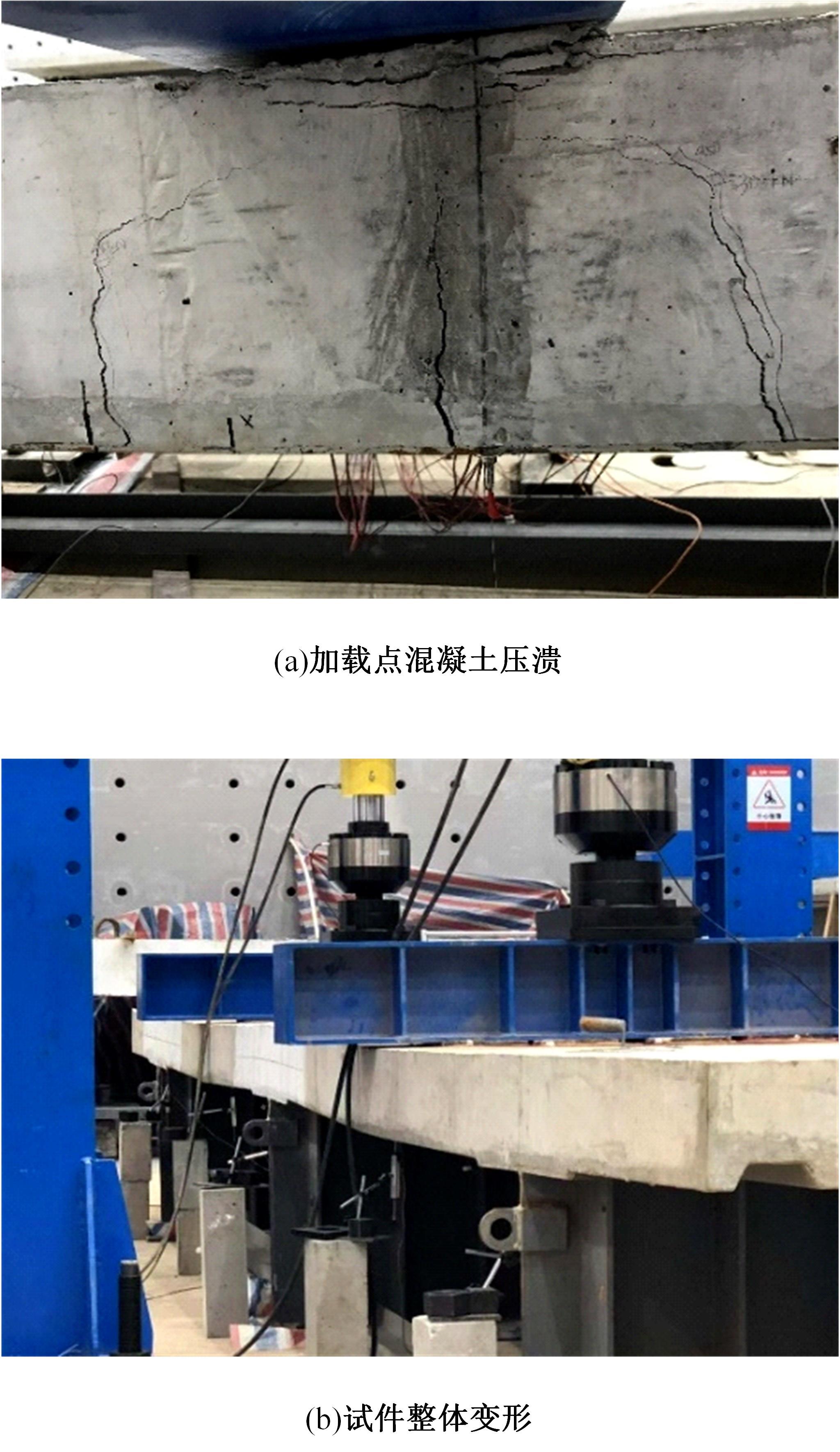

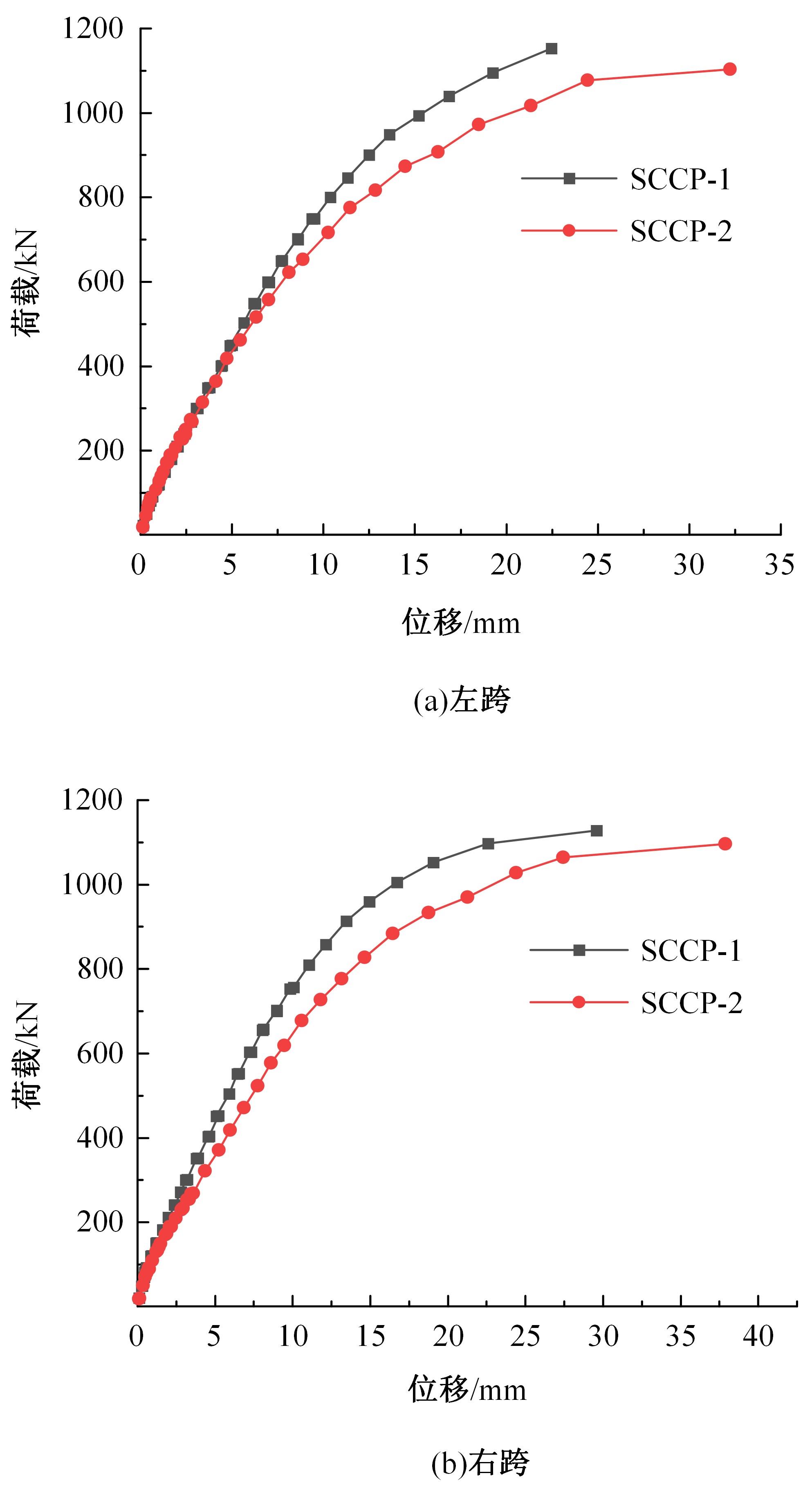

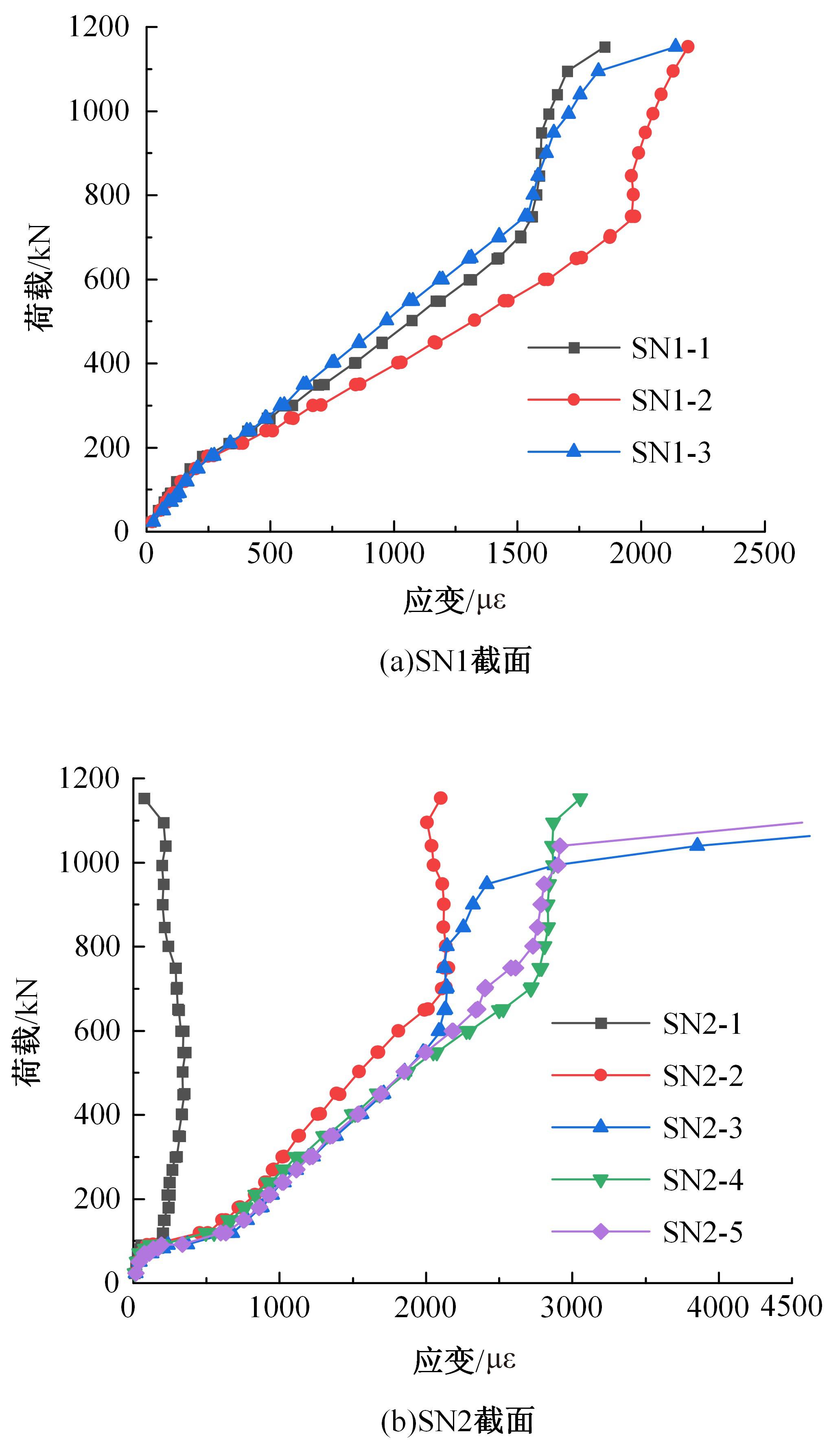

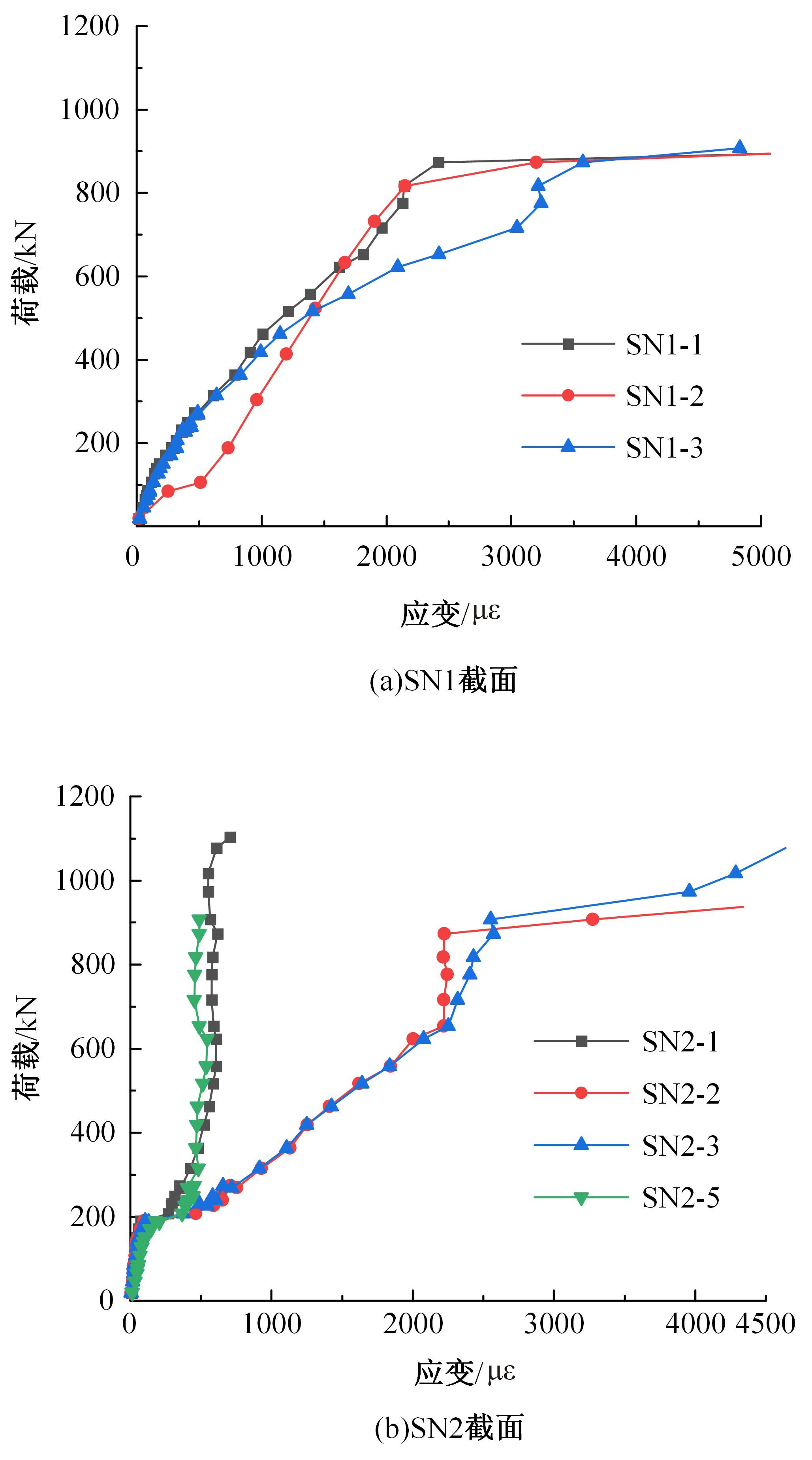

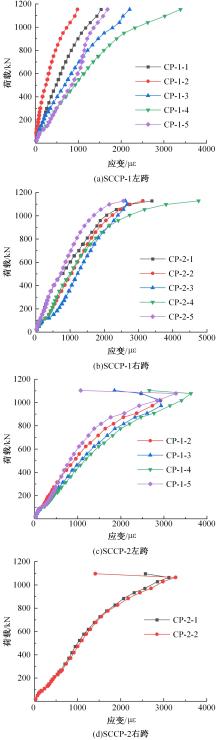

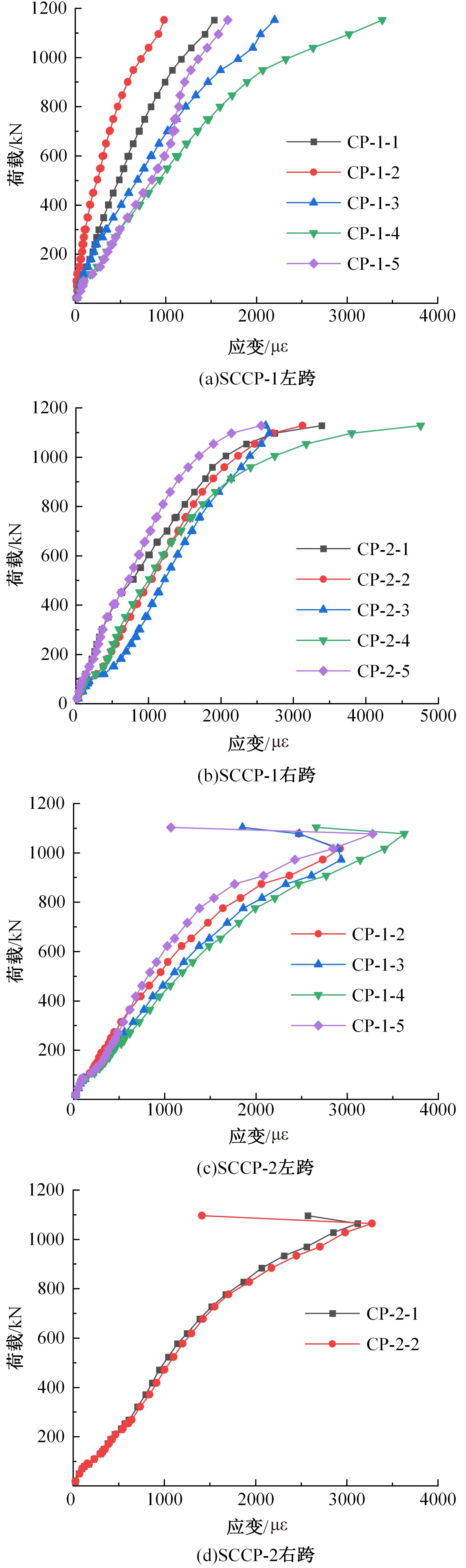

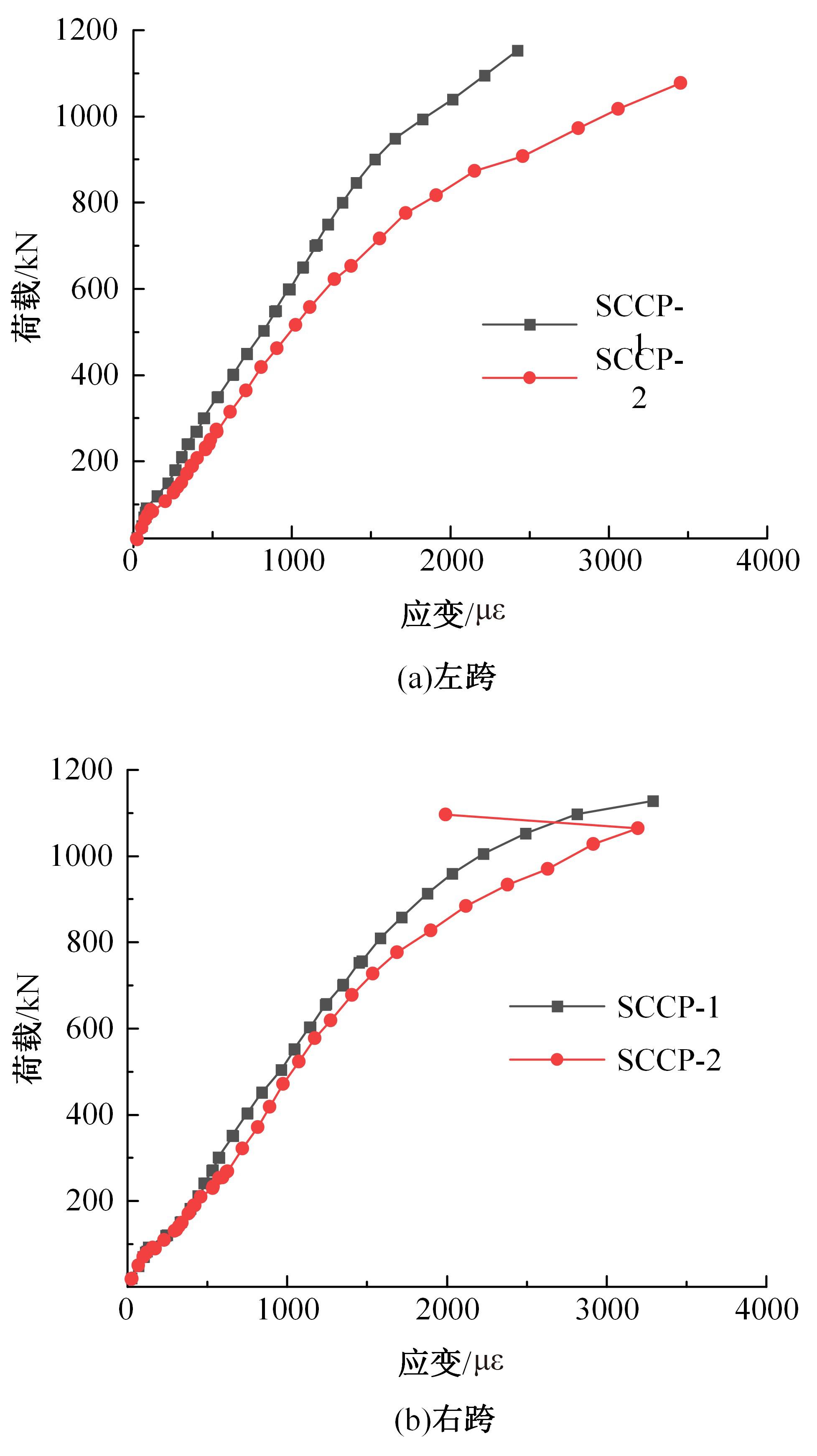

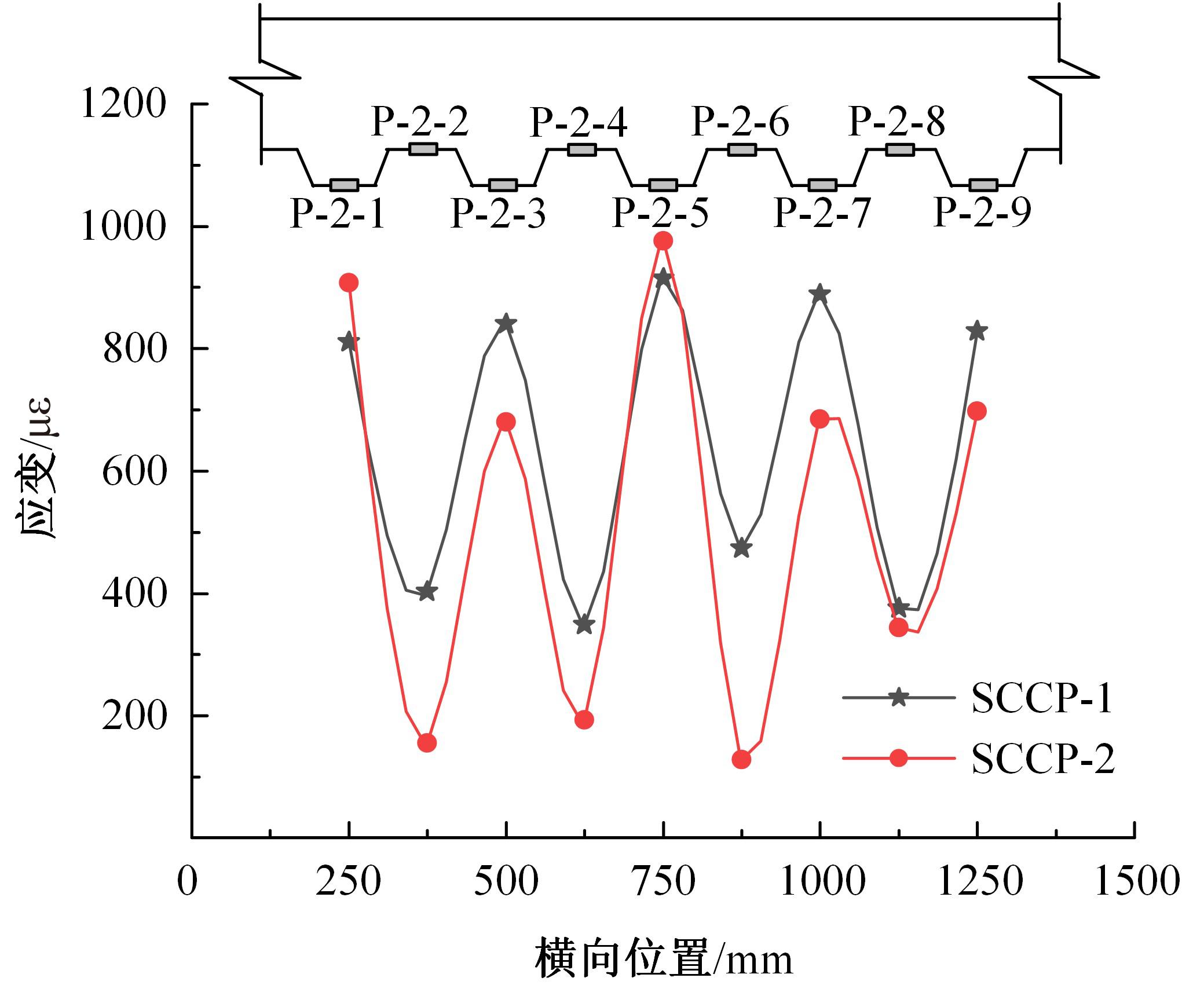

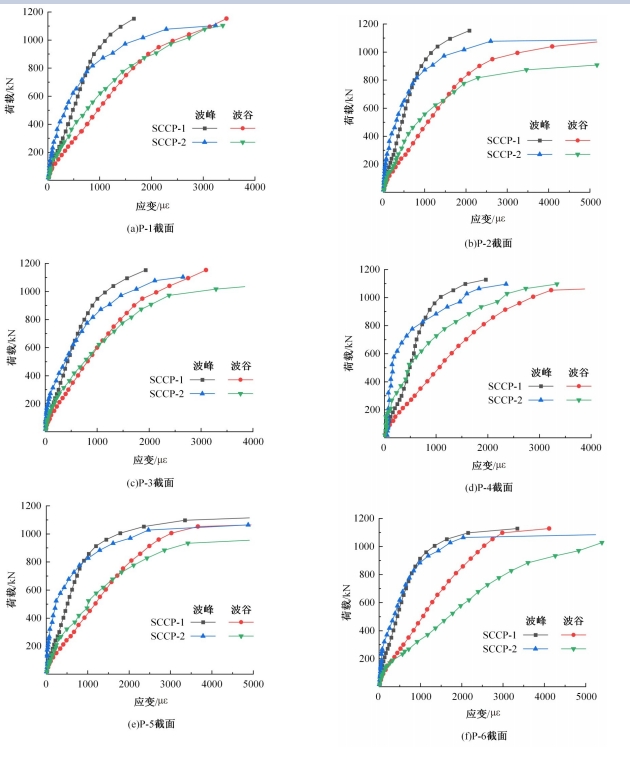

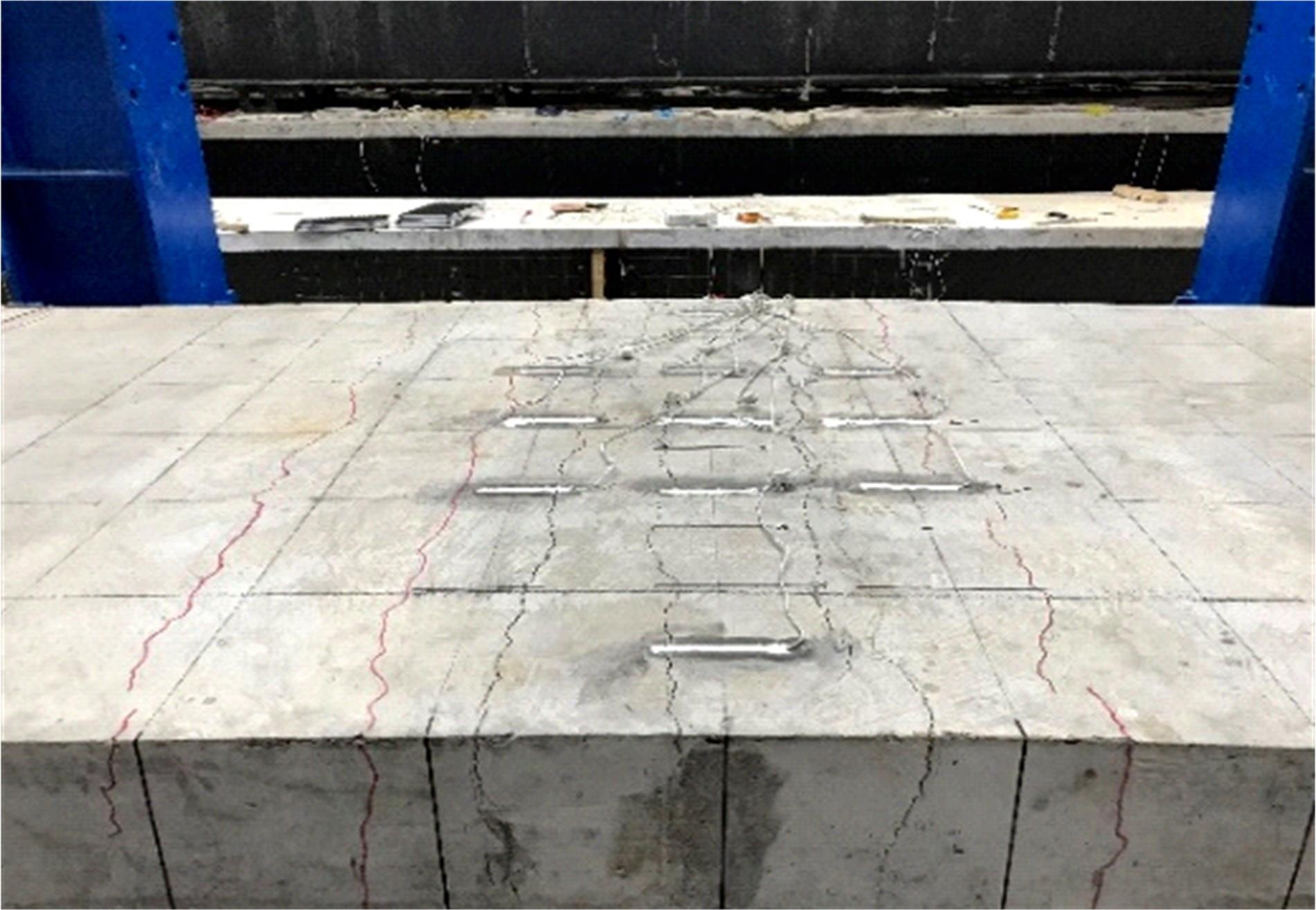

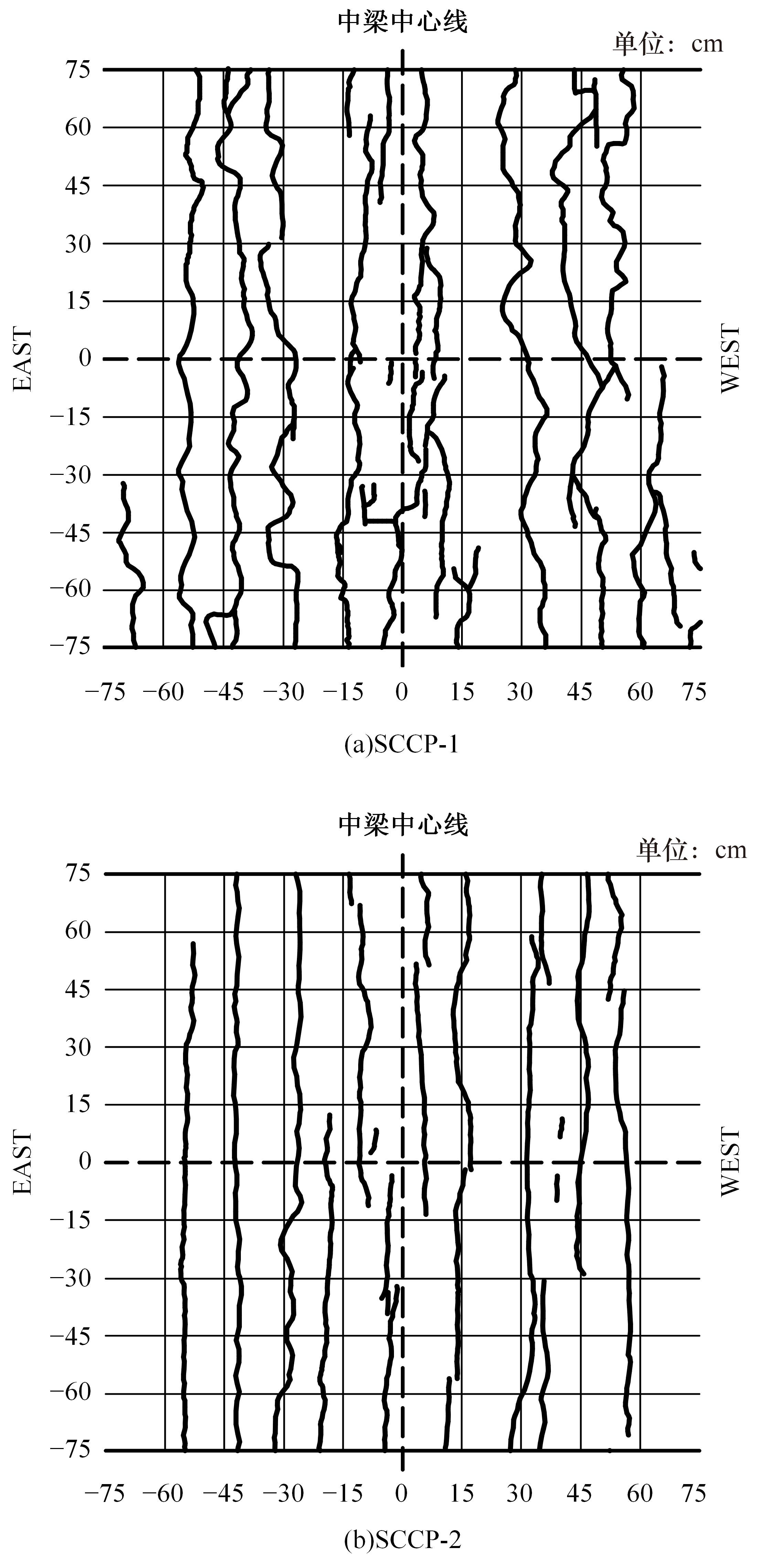

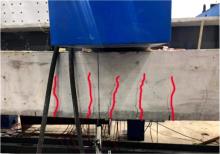

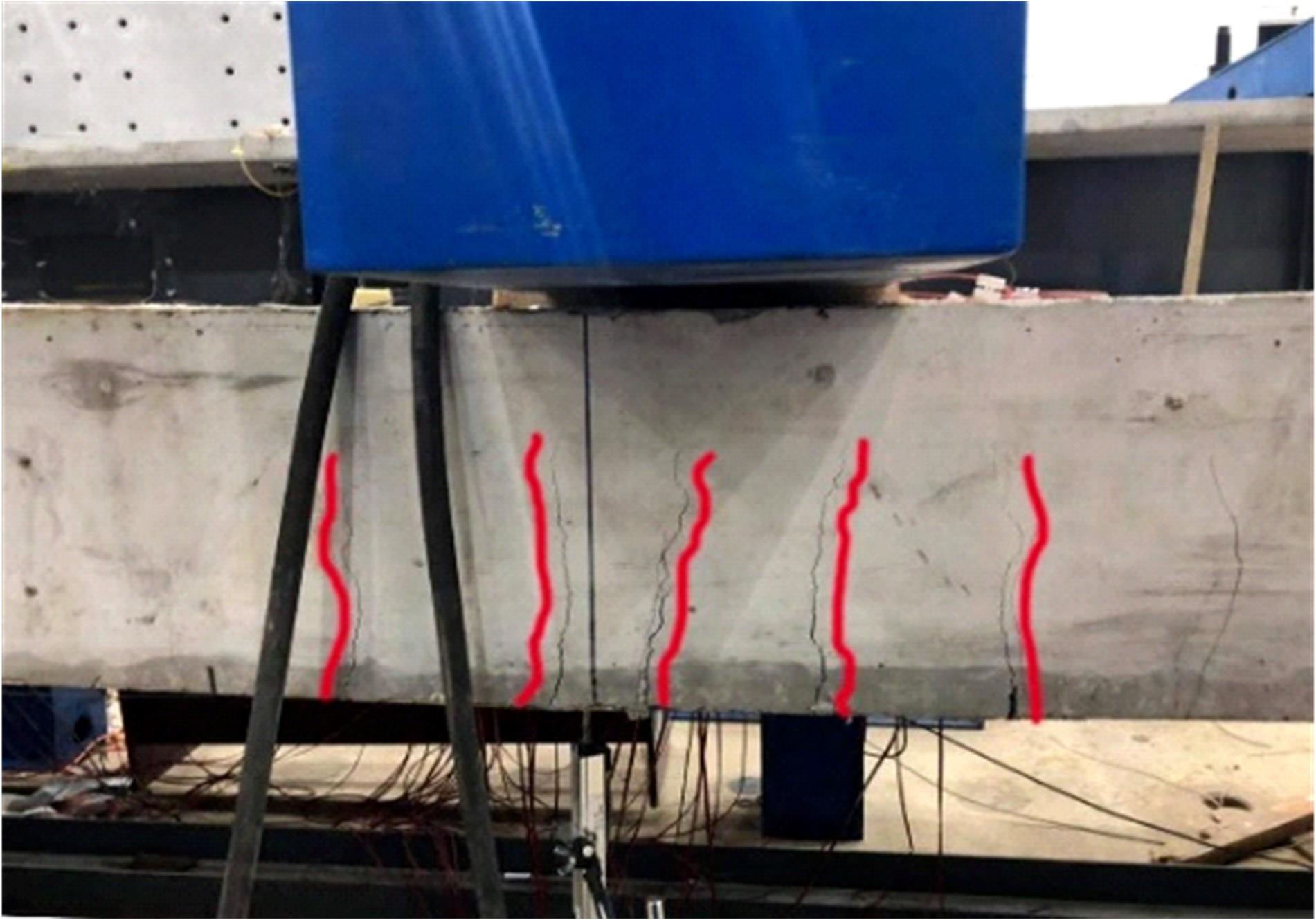

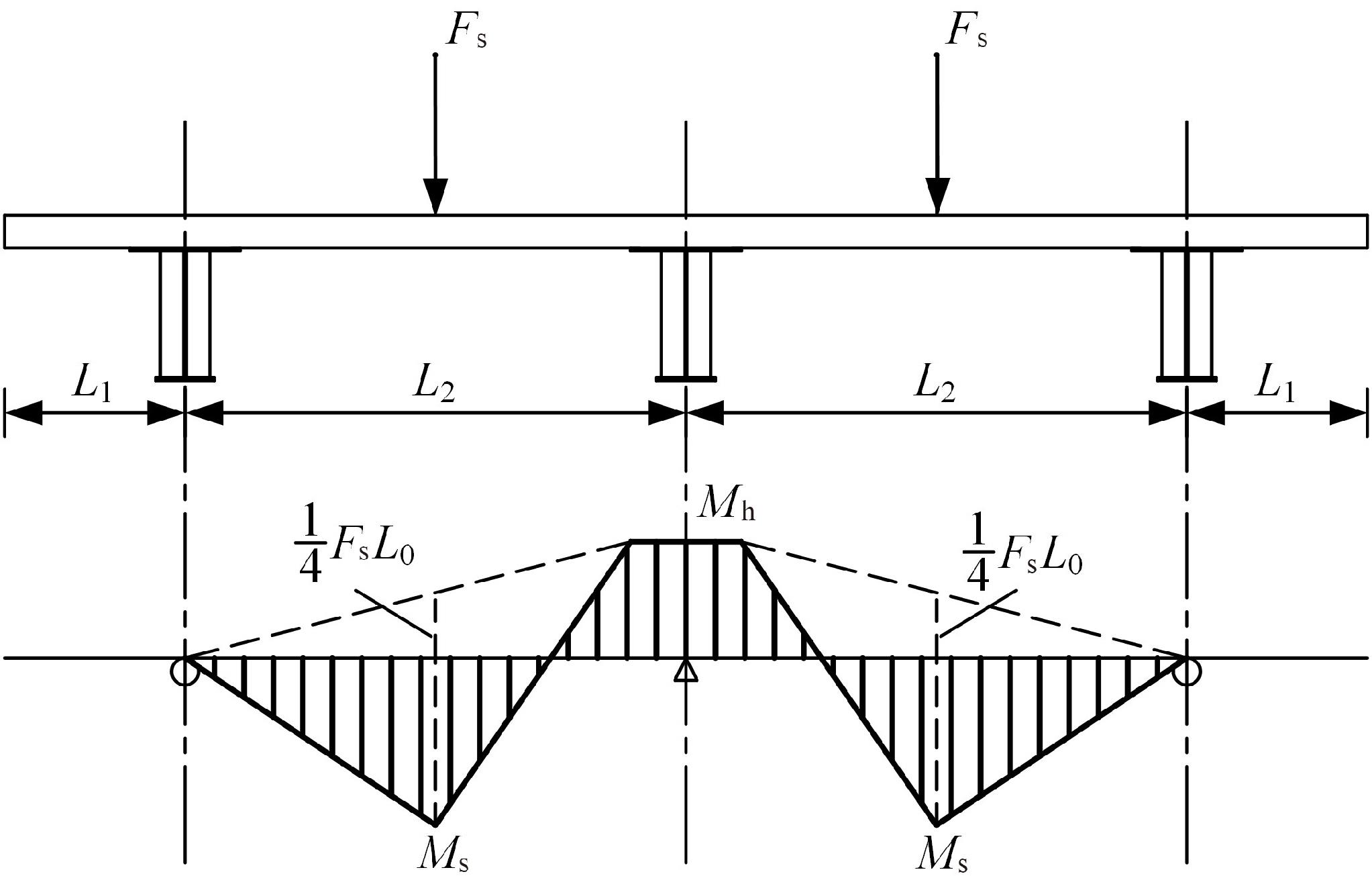

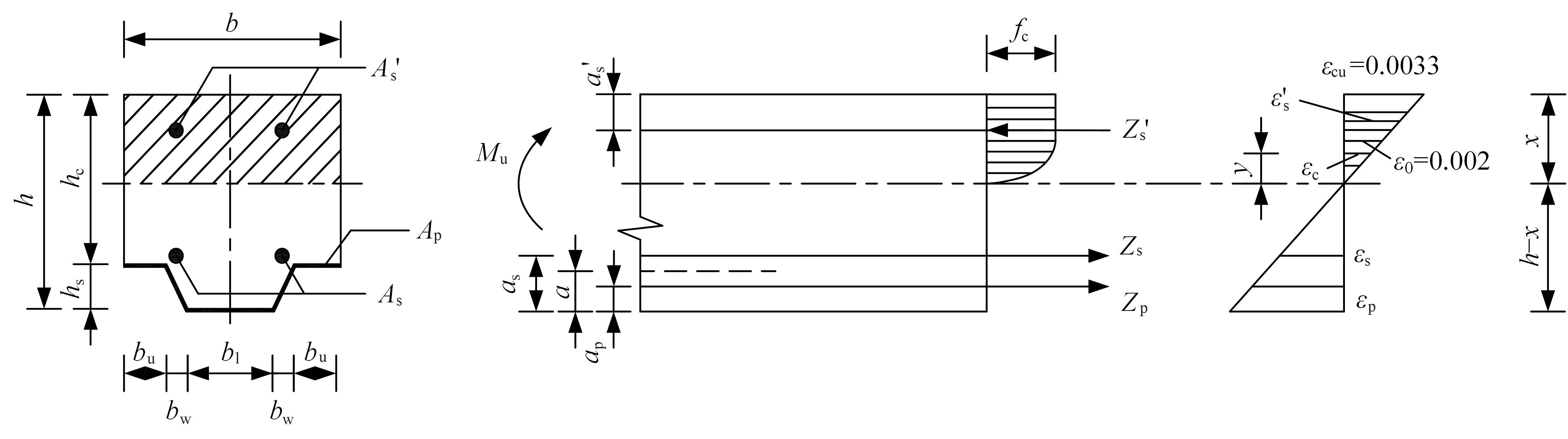

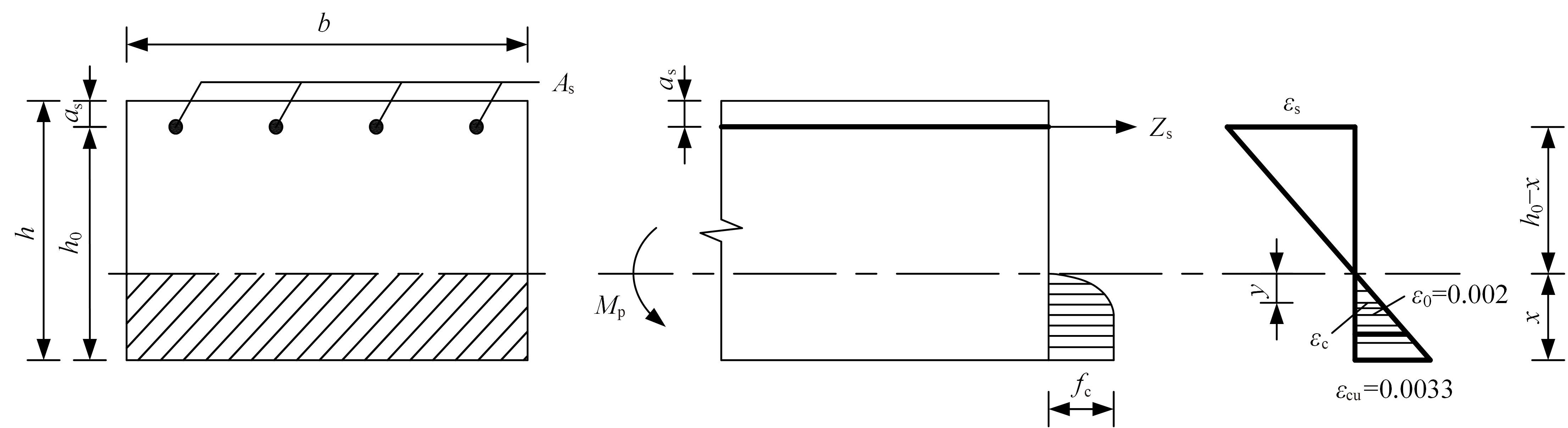

本文提出了一种适用于中小跨径钢板梁桥的压型钢板-混凝土组合板桥面板结构,对2块压型钢板-混凝土组合桥面板试件进行了两跨跨中对称加载试验,考察了连续组合桥面板的跨中挠度、混凝土和钢筋应变、负弯矩区混凝土裂缝的分布范围和裂缝宽度,得到了组合桥面板的破坏形态与极限承载力。组合桥面板试件长9.25 m,宽1.5 m,压型钢板厚3 mm,混凝土板厚24 cm,两试件除PBL连接件布置位置不同(压型钢板的波峰或波谷)外,其余构造、尺寸相同。试验结果表明:组合桥面板试件的极限承载力分别为1 128.5 kN与1 095.7 kN,破坏形态均为弯曲破坏;PBL连接件布置在压型钢板波峰位置可使组合桥面板具有更大的抗弯刚度;组合桥面板的支点位置存在较大范围的负弯矩区,裂缝的分布范围约为2倍顶板宽度,在设计时应引起注意;按塑性理论计算连续组合桥面板的极限承载力与试验结果吻合较好。

中图分类号:

- TU398

| 1 | 聂建国, 樊健生. 广义组合结构及其发展展望[J]. 建筑结构学报, 2006, 27(6): 1-8 |

| Nie Jian-guo, Fan Jian-sheng. The development and prospect of generalized composite structures[J]. Journal of Building Structures, 2006, 27(6): 1-8. | |

| 2 | 陈世鸣. 钢-混凝土组合结构[M]. 北京: 中国建筑工业出版社, 2013. |

| 3 | Porter M L, Ekberg C E. Design recommendations for steel deck floor slabs[J]. J Struct Div, 1976, 102(11): 2121-2136. |

| 4 | Patrick M. A new partial shear connection strength model for composite slabs[J]. Journal of the Australia Institute of Steel Construction, 1990, 24: 2-17. |

| 5 | Daniels B J, Crisinel M. Composite slab behavior and strength analysis, part I: Calculation procedure[J]. J Struct Eng, 1993, 119(1): 16-35. |

| 6 | Daniels B J, Crisinel M. Composite slab behavior and strength analysis, part Ⅱ: comparisons with test results and parametric analysis[J]. J Struct Eng, 1993, 119(1): 39-49. |

| 7 | Chen S. Load carrying capacity of composite slabs with various end constraints[J]. J Constr Steel Res, 2003, 59(3): 385-403. |

| 8 | Abdullah R, Samuel Easterling W. Determination of composite slab strength using a new elemental test method[J]. J Struct Eng, 2007, 133(9): 1268-1277. |

| 9 | Abdullah R, Amuel Easterling W. New evaluation and modeling procedure for horizontal shear bond in composite slabs[J]. J Constr Steel Res, 2009, 65(4): 891-899. |

| 10 | Fauchart J, Sfintesco D. The development and use of the Robinson composite deck in France[R]. IABSE Reports of the Working Commissions, 1968:155-164. |

| 11 | Sonoda K, Horikawa T, Kitoh H, et al. Shearing force on studs and punching shear load of a steel plate and concrete composite slab[J]. Doboku Gakkai Ronbunshu, 1989, 1989(404): 249-258. |

| 12 | Sonoda K, Kitoh H. Ultimate loading capacities and failure modes of steel plate and concrete composite slabs[J]. Doboku Gakkai Ronbunshu, 1993(471): 85-94. |

| 13 | Fujiyama C, Sakurai N, Maekawa K. Fatigue failure mode of steel-concrete composite bridge deck depending on interface property and shear connector profiles[J]. Journal of Japan Society of Civil Engineers, 2011, 67(1): 193-206. |

| 14 | Fujiyama C, Sakurai N, Maekawa K. Failure mode of steel-concrete composite bridge deck depending on shear connector profiles[J]. Journal of Japan Society of Civil Engineers, 2012, 68(1) :1-15. |

| 15 | 杨勇, 祝刚, 周丕健,等. 钢板-混凝土组合桥面板受力性能与设计方法研究[J]. 土木工程学报, 2009. 42(12): 135-141. |

| Yang Yong, Zhu Gang, Zhou Pi-jian,et al. Experimental study on the mechanical behavior and design method of plain steel-plated and concrete composite bridge decks[J]. China Civil Engineering Journal, 2009,42(12): 135-141. | |

| 16 | 徐宙元. 带开孔钢板剪力连接件的钢-混凝土组合桥面板试验研究与理论分析[D]. 成都:西南交通大学土木工程学院, 2013. |

| Xu Zhou-yuan. Experimental study and theory analysis of steel-concrete composite bridge deck with PBL connectors[D]. Chengdu: College of Civil Engineering, Southwest Jiaotong University, 2013. | |

| 17 | Kim H Y, Jeong Y J, et al. Steel-concrete composite deck for PSC girder bridge[J]. KSCE Journal of Civil Engineering, 2005, 9(5): 385-390. |

| 18 | Jeong Y J, Kim H Y, Koo H B. Longitudinal shear resistance of steel-concrete composite slabs with perfobond shear connectors[J]. J Constr Steel Res, 2009, 65(1): 81-88. |

| 19 | . 公路钢筋混凝土及预应力混凝土桥涵设计规范 [S]. |

| [1] | 孙永新,蔺鹏臻,杨子江,冀伟. 考虑黏结-滑移效应的UHPC梁裂缝宽度计算方法[J]. 吉林大学学报(工学版), 2024, 54(9): 2600-2608. |

| [2] | 薛宇欣,周勇军,王业路,范凯翔,赵煜. 基于悬锤系统的简支梁桥冲击系数测试方法适用性[J]. 吉林大学学报(工学版), 2024, 54(9): 2557-2567. |

| [3] | 郭雪莲,韩万水,王涛,周恺,张修石,张书颖. 大件车通行弯桥抗倾覆稳定安全系数评估方法[J]. 吉林大学学报(工学版), 2024, 54(8): 2229-2237. |

| [4] | 肖林,魏欢博,卫星,康志锐. 钢混组合梁栓钉锈胀下混凝土板开裂行为数值分析[J]. 吉林大学学报(工学版), 2024, 54(7): 1958-1965. |

| [5] | 高欣,何舰,兰春光,王泽强. 斜撑布设方案对高支模抗倒塌性能的影响[J]. 吉林大学学报(工学版), 2024, 54(6): 1657-1664. |

| [6] | 张春雷,邵长宇,苏庆田,戴昌源. 球扁钢肋钢纤维混凝土组合桥面板正弯矩受力性能试验[J]. 吉林大学学报(工学版), 2024, 54(6): 1634-1642. |

| [7] | 何华飞,李兆平,符瑞安,马绍麟,黄明利. 考虑地层约束效应的预制侧墙节点抗震性能试验[J]. 吉林大学学报(工学版), 2024, 54(6): 1601-1611. |

| [8] | 张彦玲,贾云飞,贾晓远,郑旺,李运生. 装配式小箱梁桥内力横向分布系数建议公式[J]. 吉林大学学报(工学版), 2024, 54(6): 1688-1700. |

| [9] | 黄汉辉,陈康明,吴庆雄. 钢管混凝土桁式弦杆组合连续梁抗弯性能[J]. 吉林大学学报(工学版), 2024, 54(6): 1665-1676. |

| [10] | 邵长江,崔皓蒙,漆启明,庄卫林. 近断层大跨RC轻柔拱桥纵向阻尼器减震研究[J]. 吉林大学学报(工学版), 2024, 54(5): 1355-1367. |

| [11] | 赵秋,陈鹏,赵煜炜,余澳. 台后设置拱形结构的无缝桥梁整体受力性能[J]. 吉林大学学报(工学版), 2024, 54(4): 1016-1027. |

| [12] | 张洪,朱志伟,胡天宇,龚燕峰,周建庭. 基于改进YOLOv5s的桥梁螺栓缺陷识别方法[J]. 吉林大学学报(工学版), 2024, 54(3): 749-760. |

| [13] | 韩智强,谢刚,卓亚娟,骆佐龙,李华腾. 基于车轮-桥面相干激励的大跨连续梁桥振动响应[J]. 吉林大学学报(工学版), 2024, 54(2): 436-444. |

| [14] | 杨国俊,齐亚辉,石秀名. 基于数字图像技术的桥梁裂缝检测综述[J]. 吉林大学学报(工学版), 2024, 54(2): 313-332. |

| [15] | 谭国金,欧吉,艾永明,杨润超. 基于改进DeepLabv3+模型的桥梁裂缝图像分割方法[J]. 吉林大学学报(工学版), 2024, 54(1): 173-179. |

|

||