吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (4): 773-780.doi: 10.13229/j.cnki.jdxbgxb20200895

• 车辆工程·机械工程 • 上一篇

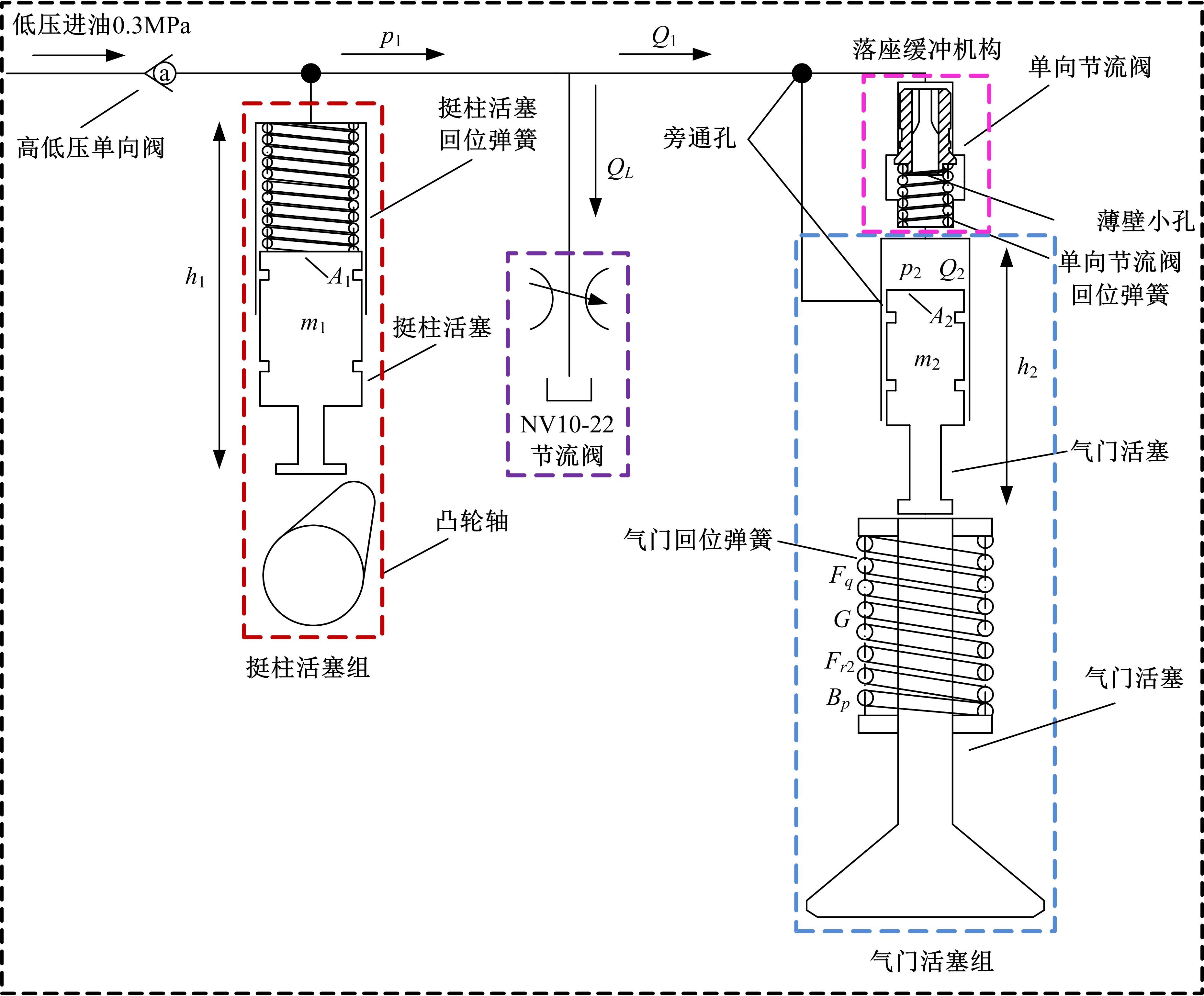

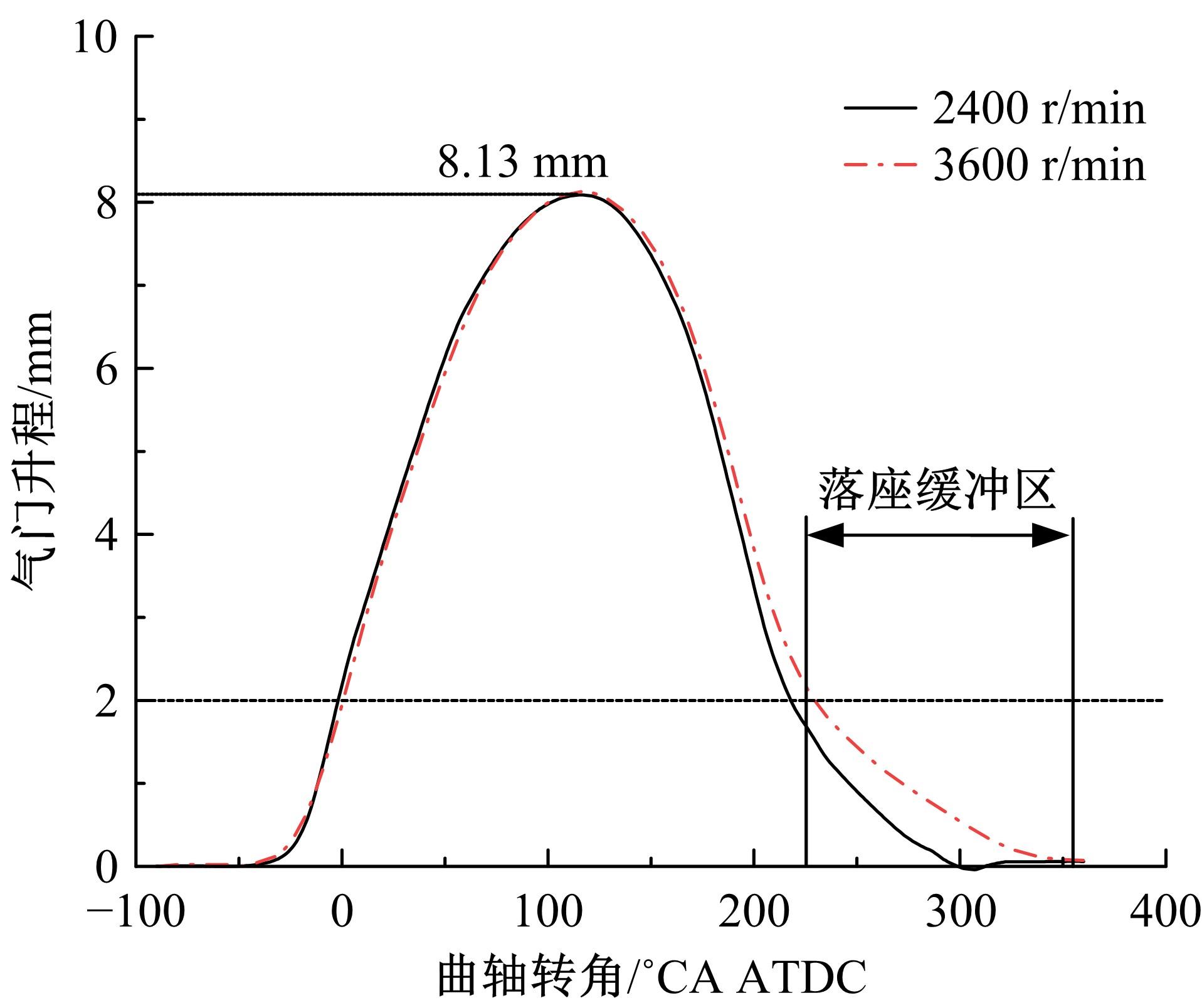

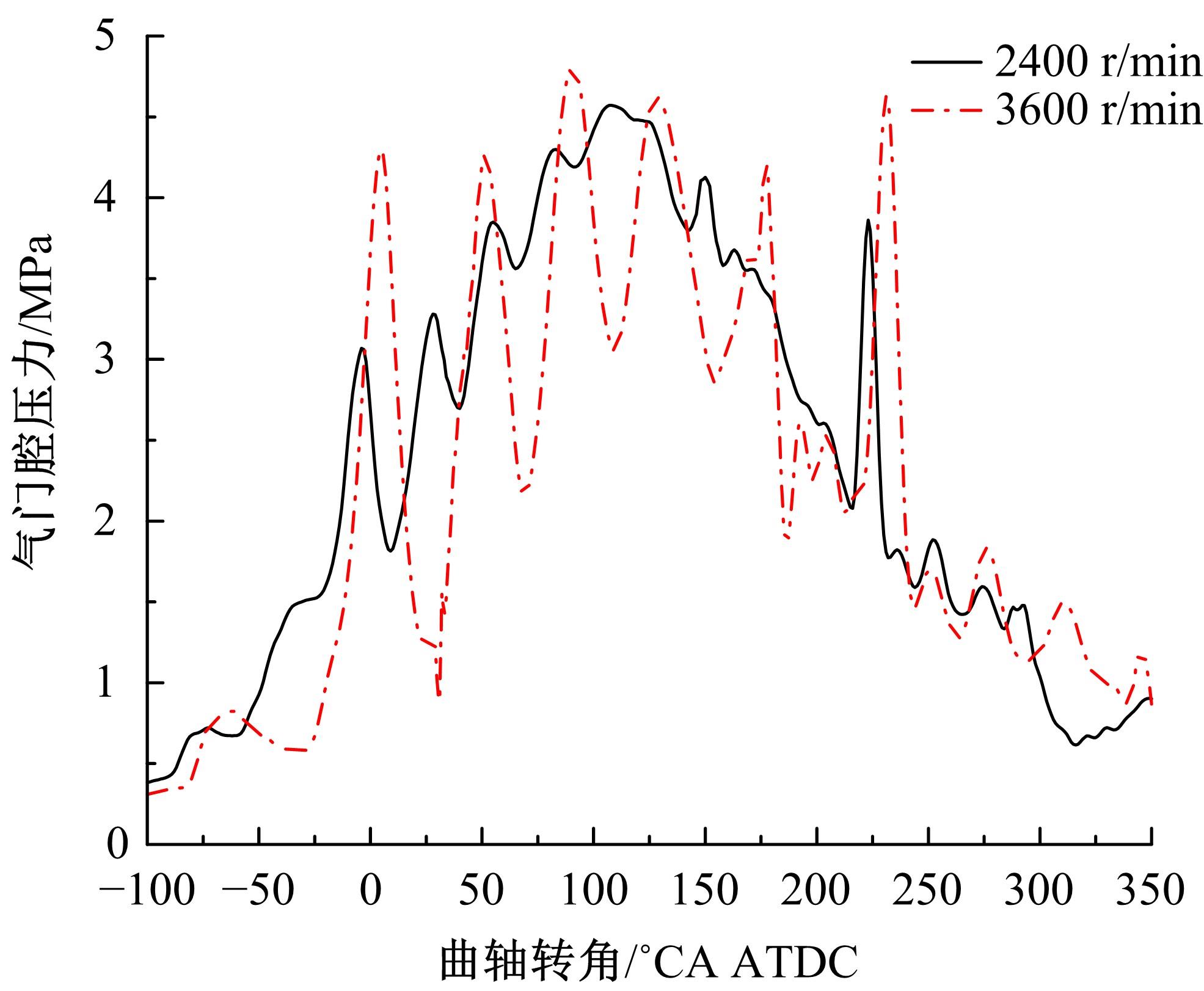

液压可变气门系统压力波动的影响分析

- 1.吉林大学 汽车仿真与控制国家重点实验室,长春 130022

2.长春职业技术学院 工程技术分院,长春 130033

Analysis on pressure fluctuation of hydraulic variable valve actuation

Zhao-hui JIN1( ),Le-qi GU1,Wei HONG1,Fang-xi XIE1(

),Le-qi GU1,Wei HONG1,Fang-xi XIE1( ),Tian YOU2

),Tian YOU2

- 1.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

2.Engineering Branch,Changchun University of Technology,Changchun 130033,China

摘要:

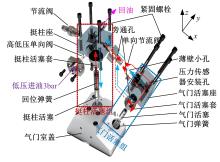

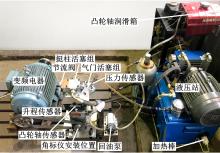

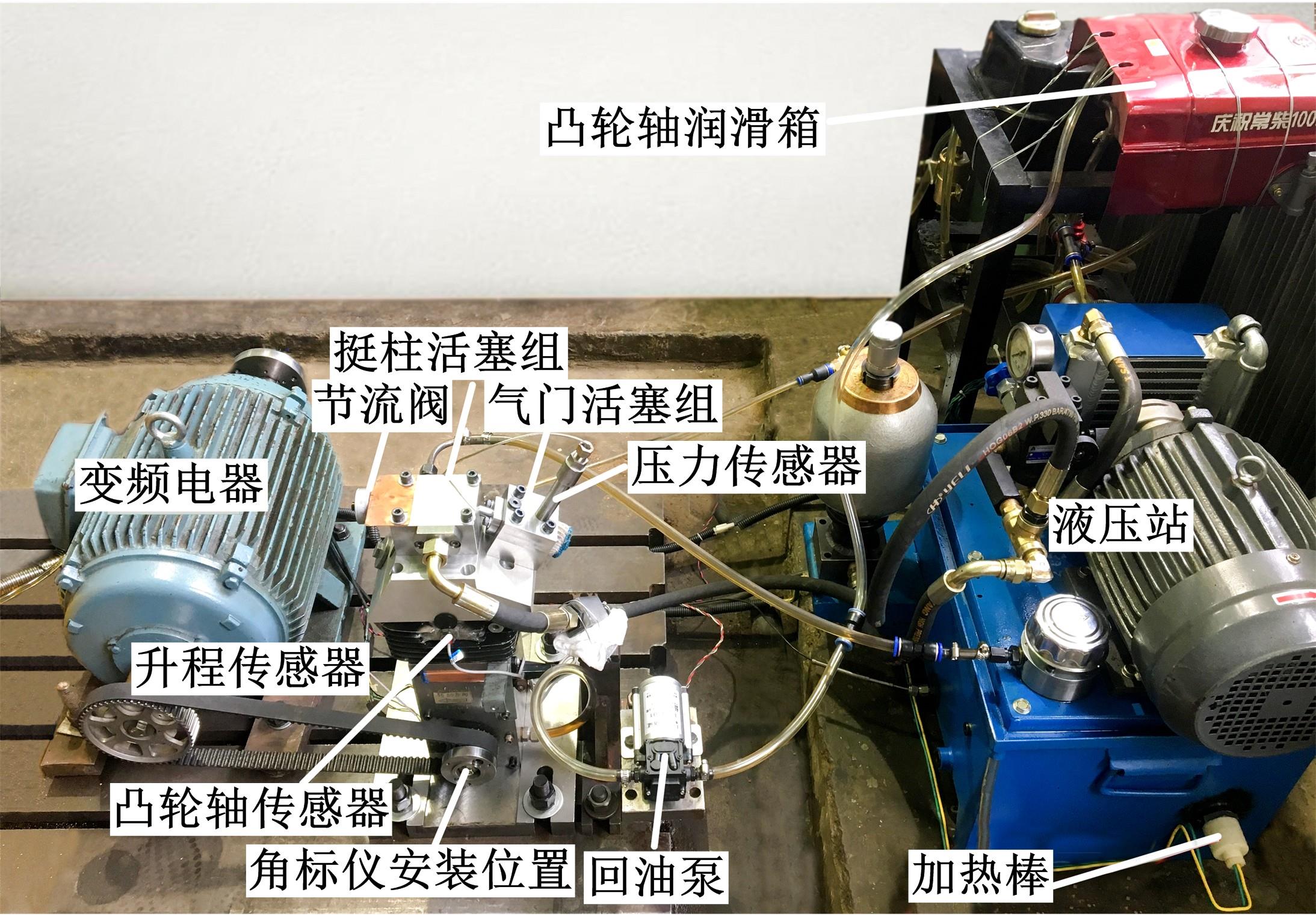

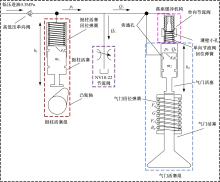

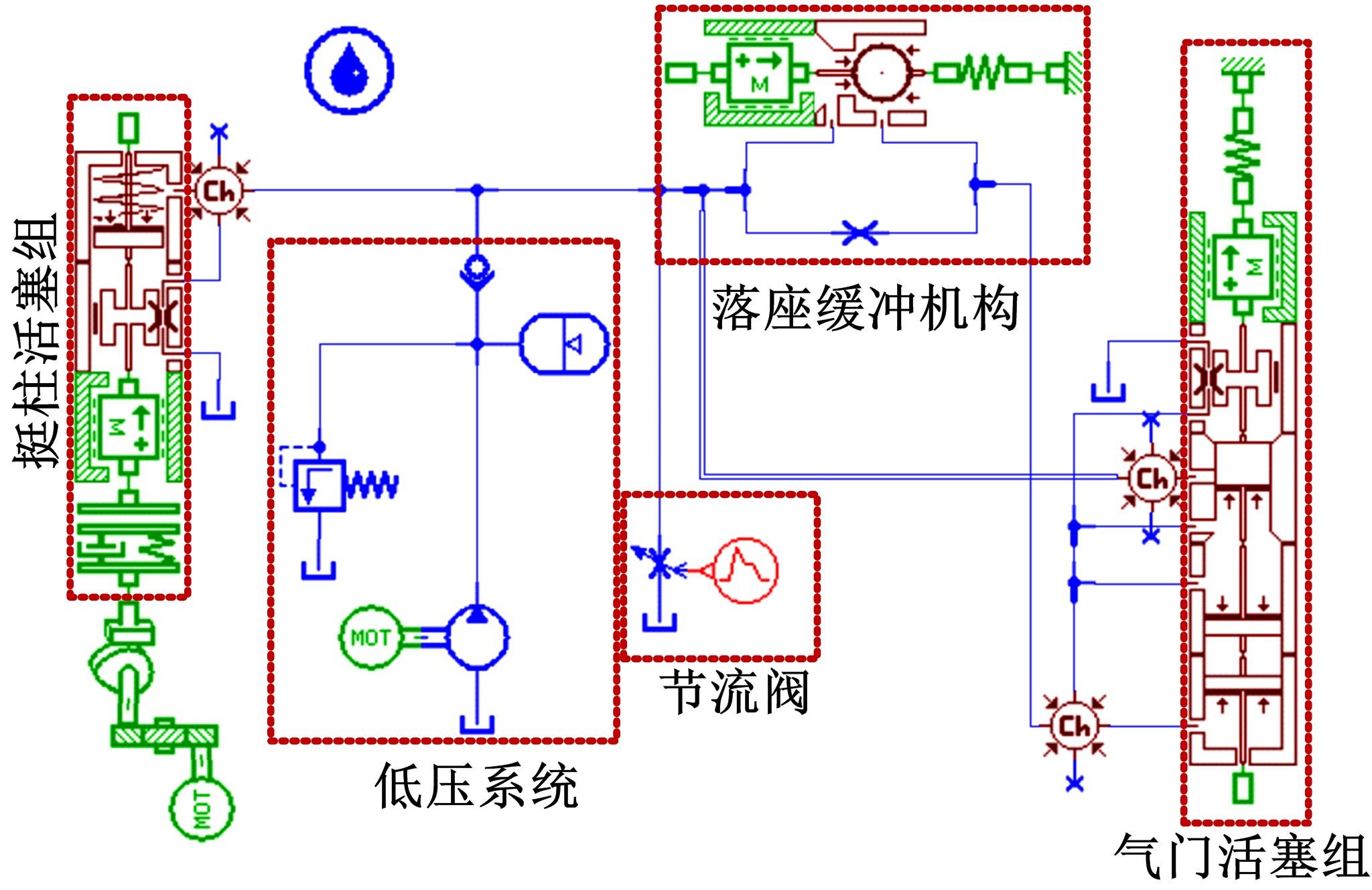

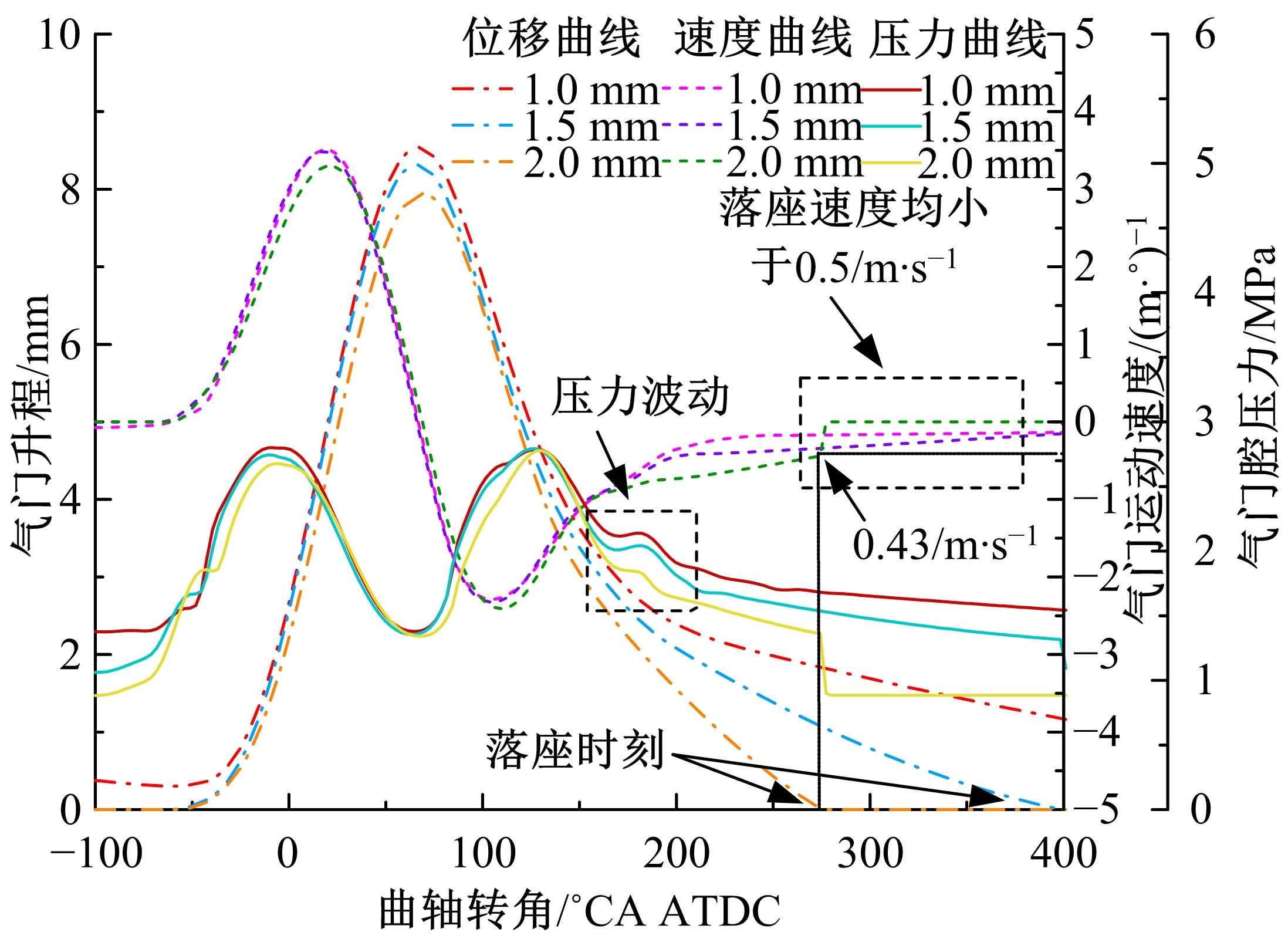

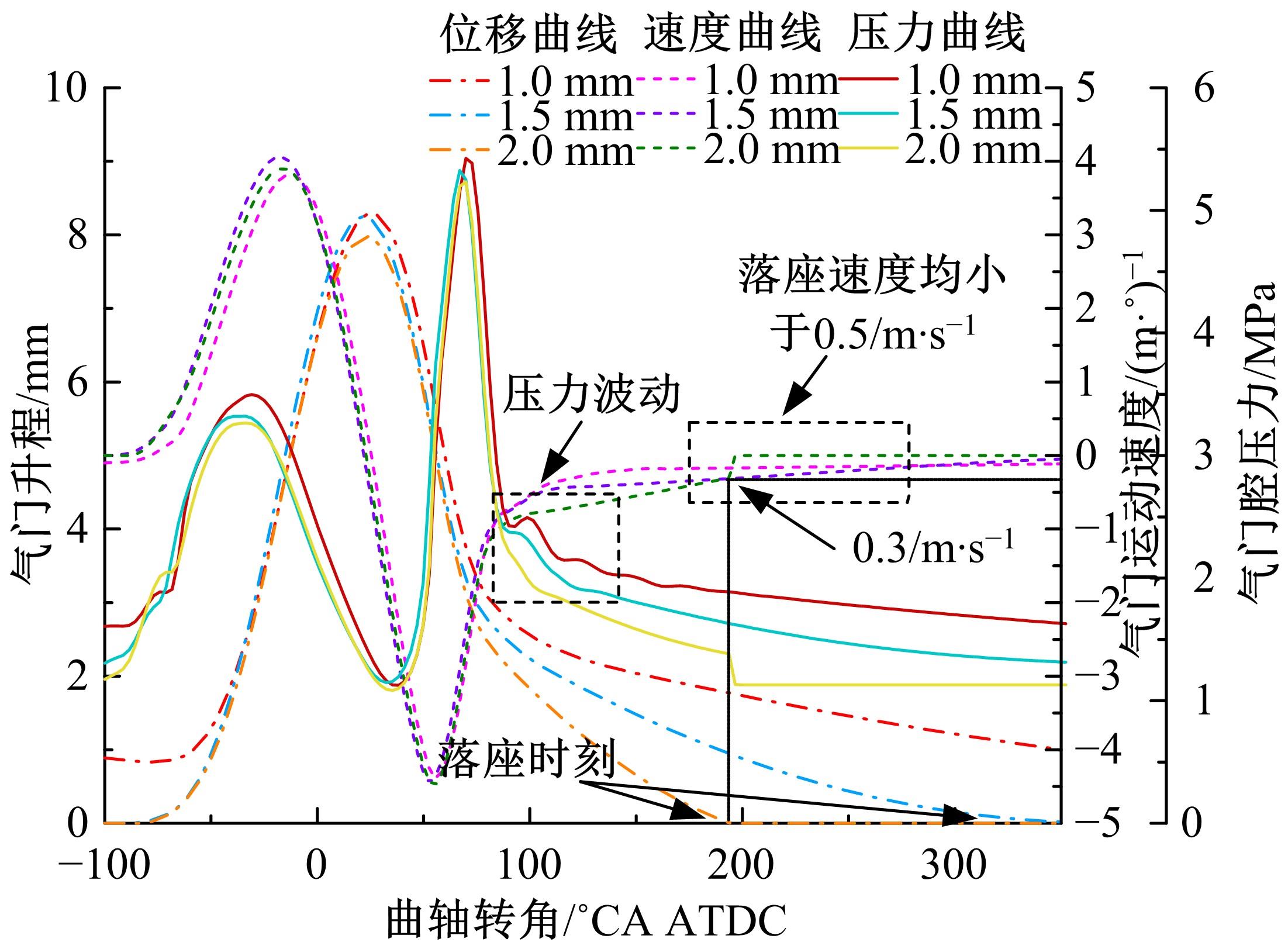

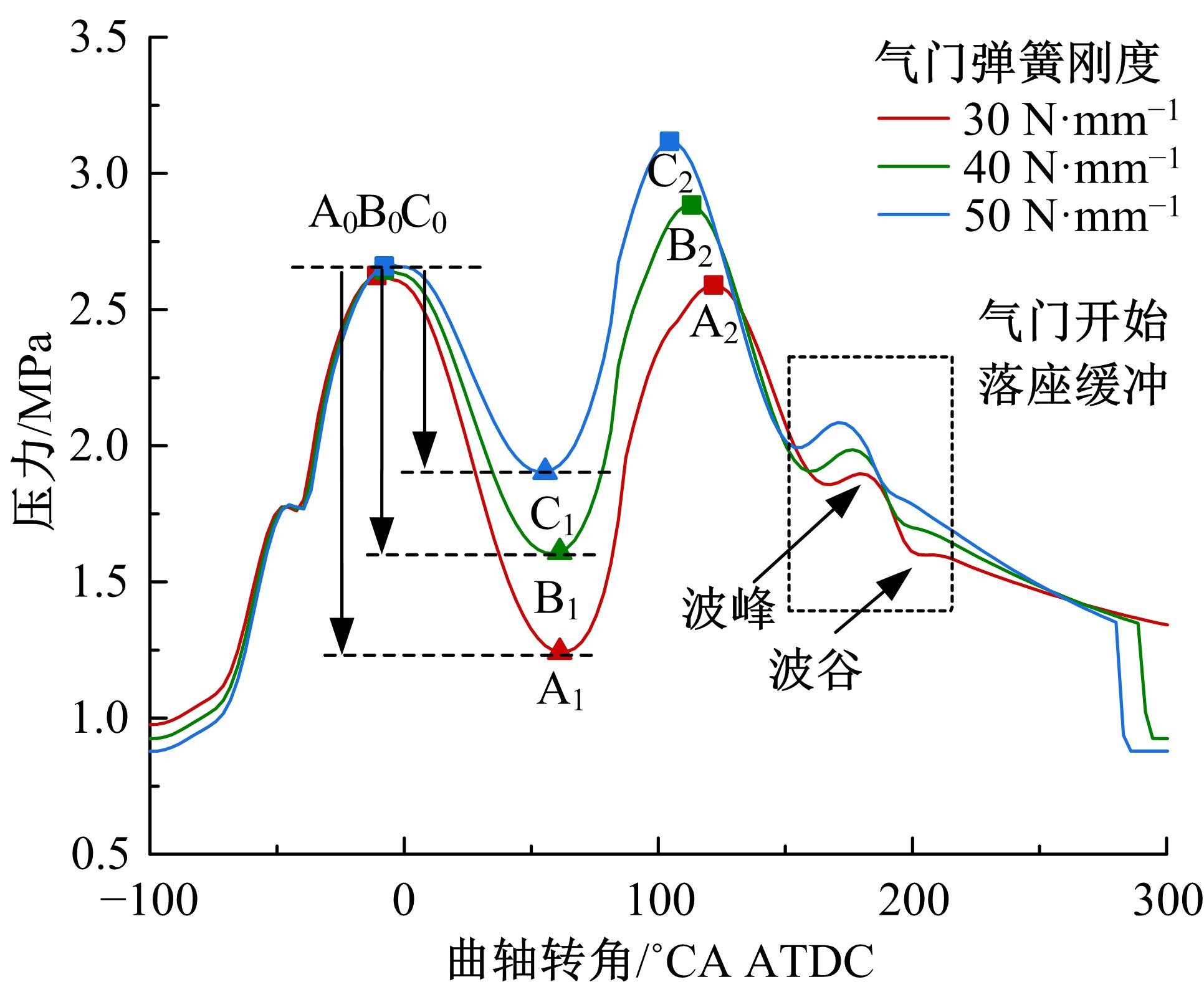

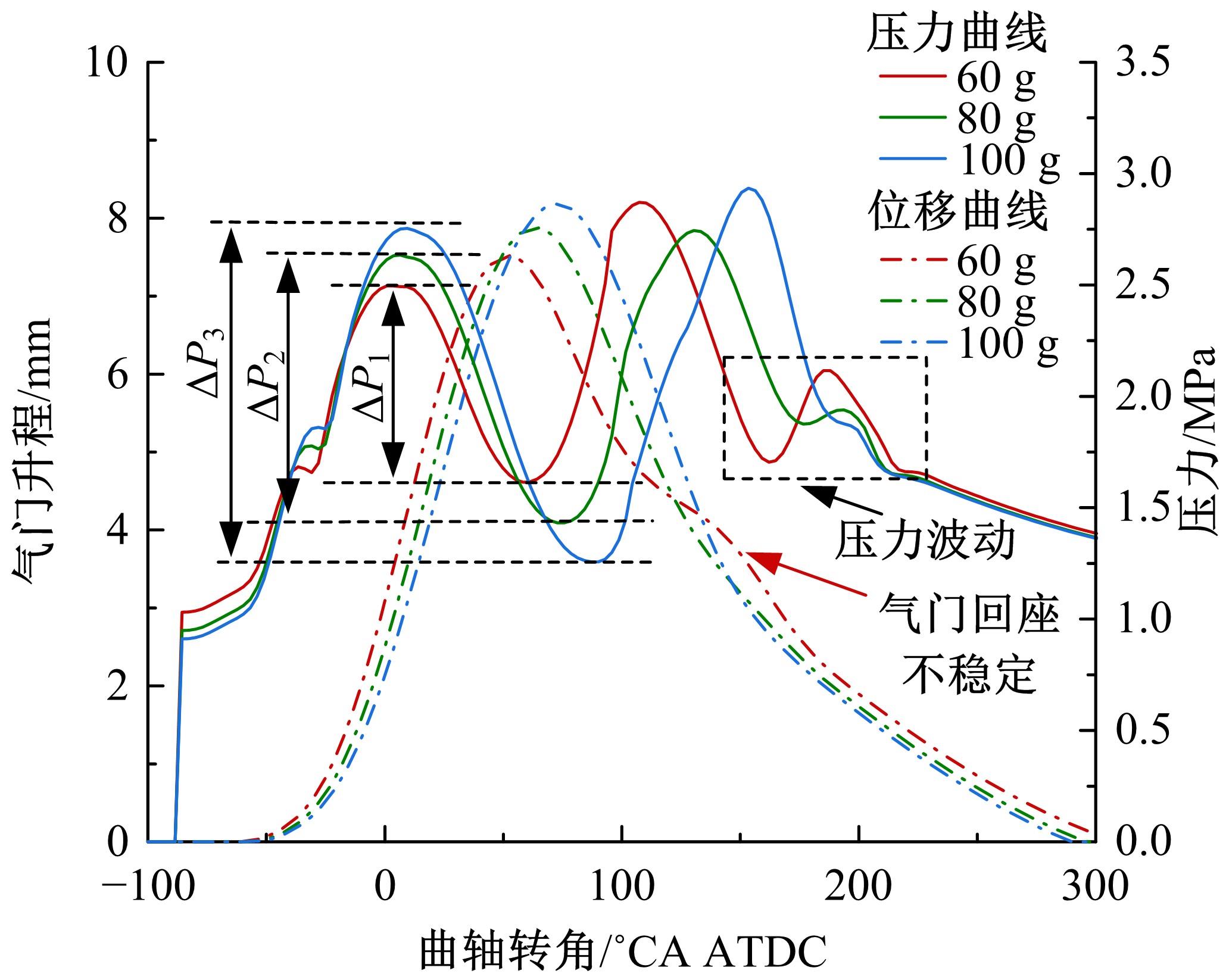

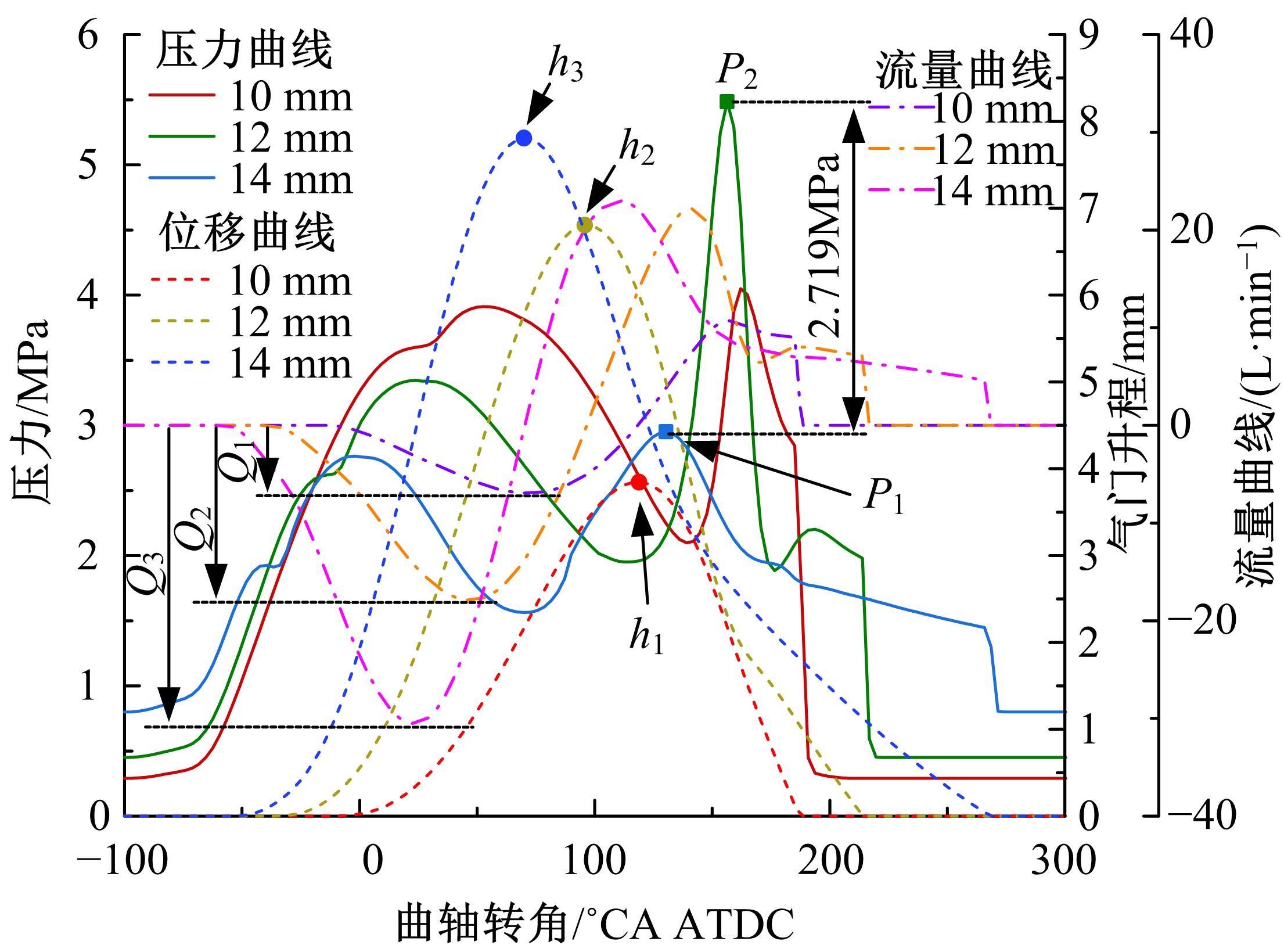

针对液压可变气门机构实际运行中系统会产生压力波动,影响可变气门机构的工作性能这一问题,分析了压力波动产生的原因,并采取了有效措施减小压力波动。通过试验及AMESim仿真探究了气门弹簧刚度、气门活塞质量、节流孔径大小等关键参数对系统压力波动的影响。研究表明:当气门落座速度小于0.5 m

中图分类号:

- TK417

| 1 | Tong S, Li X, Liu S, et al. Effect of two-stage valve lift for fuel economy and performance on a PFI gasoline engine[C]∥SAE Paper, 2014-01-2874. |

| 2 | Xu J T, Chang S Q, Fan X Y, et al. Effects of electromagnetic intake valve train on gasoline engine intake charging[J]. Applied Thermal Engineering, 2016, 96: 708-715. |

| 3 | Knop V, Mattioli L. An analysis of limits for part load efficiency improvement with VVA devices[J]. Energy Conversion and Management, 2015, 105: 1006-1016. |

| 4 | Liang L, Luo X H, Liu Y S, et al. A numerical investigation in effects of inlet pressure fluctuations on the flow and cavitation characteristics inside water hydraulic poppet valves[J]. International Journal of Heat and Mass Transfer, 2016, 103: 684-700. |

| 5 | Lu X X, Wang D M, Shen W, et al. Experimental investigation of the propagation characteristics of an interface wave in a jet pump under cavitation condition[J]. Experimental Thermal and Fluid Science, 2015, 63: 74-83. |

| 6 | 陈飞. 全可变液压气门系统的建模仿真与试验研究[D]. 济南: 山东大学机械工程学院, 2018. |

| Chen Fei. Simulation and experiment research of a fully variable hydraulic valve system[D], Jinan: College of Mechanical Engineering, Shandong University, 2018. | |

| 7 | 韩志强,胡明艳,赵家辉,等. 电液可变气门系统液压油路瞬时压力的分析[J]. 内燃机工程, 2019, 40(2): 82-91. |

| Han Zhi-qiang, Hu Ming-yan, Zhao Jia-hui, et al. Analysis of instantaneous pressure of hydraulic circuit in electro-hydraulic variable valve timing system[J]. Chinese Internal Combustion Engine Engineering, 2019, 40(2): 82-91. | |

| 8 | 谢宗法, 秦磊, 王志明, 等. 全可变气门机构中的液压压力波动现象[J]. 内燃机学报, 2011, 29(5): 455-460. |

| Xie Zong-fa, Qin Lei, Wang Zhi-ming, et al. Hydraulic pressure fluctuation in fully variable valve train[J]. Transactions of CSICE, 2011, 29(5): 455-460. | |

| 9 | 钟兵, 洪伟, 杨国志, 等. 液压可变气门机构压力波动及动作循环变动[J]. 吉林大学学报: 工学版, 2020, 50 (3): 796 - 803. |

| Zhong Bing, Hong Wei, Yang Guo-zhi, et al. Pressure fluctuation and cyclic variation of movement of hydraulic variable valve mechanism[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(3): 796- 803. | |

| 10 | 钟兵, 洪伟, 金兆辉, 等. 进气门早关液压可变气门机构运动特性[J]. 吉林大学学报: 工学版, 2018, 48(3): 727-734. |

| Zhong Bing, Hong Wei, Jin Zhao-hui, et al. Movement characteristics of hydraulic variable valve train with early intake valve closing[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(3): 727-734. | |

| 11 | 解方喜, 钟兵, 杨国志, 等. 凸轮驱动式液压可变气门机构设计及运动特性[J]. 汽车工程, 2020, 42(3): 307-314. |

| Xie Fang-xi, Zhong Bing, Yang Guo-zhi, et al. Design and motion characteristics of cam-driven hydraulic variable valve mechanism[J]. Automotive Engineering, 2020, 42(3): 307-314. | |

| 12 | Jin Z H, Hong W, You T, et al. Effect of multi-factor coupling on the movement characteristics of the hydraulic variable valve actuation[J]. Energies, 2020, 13(11): 2870. |

| 13 | ZlobinA V, Tarasevich S É. Hydraulic resistance of pipes with uniform continuous roughness of varying profile[J]. Journal of Engineering Physics and Thermophysics, 2020, 93(3): 725-732. |

| 14 | Boretti Alberto. Use of variable valve actuation to control the load in a direct injection, turbocharged, spark-ignition engine[C]∥SAE Paper, 2010-01-2225. |

| 15 | 宋佳彬. 变刚度气门弹簧设计方法研究[D]. 长春:吉林大学汽车工程学院, 2018. |

| Song Jia-bin. Research on design method of variable stiffness valve spring[D]. Changchun: College of Automotive Engineering, Jilin University, 2018. |

| [1] | 张岩,刘玮,张树勇,裴毅强,董蒙蒙,秦静. 二/四冲程可变柴油机燃烧室热负荷的改善[J]. 吉林大学学报(工学版), 2022, 52(3): 504-514. |

| [2] | 赵庆武,程勇,杨雪,王宁. 高重频纳秒脉冲放电点火系统设计[J]. 吉林大学学报(工学版), 2021, 51(2): 414-421. |

| [3] | 李志军,刘浩,张立鹏,李振国,邵元凯,李智洋. 过滤壁结构对颗粒捕集器深床过滤影响的模拟[J]. 吉林大学学报(工学版), 2021, 51(2): 422-434. |

| [4] | 王忠,李游,张美娟,刘帅,李瑞娜,赵怀北. 柴油机排气阶段颗粒碰撞过程动力学特征分析[J]. 吉林大学学报(工学版), 2021, 51(1): 39-48. |

| [5] | 胡云峰,丁一桐,赵志欣,蒋冰晶,高金武. 柴油发动机燃烧过程数据驱动建模与滚动优化控制[J]. 吉林大学学报(工学版), 2021, 51(1): 49-62. |

| [6] | 王建,许鑫,顾晗,张多军,刘胜吉. 基于排气热管理的柴油机氧化催化器升温特性[J]. 吉林大学学报(工学版), 2020, 50(2): 408-416. |

| [7] | 宋昌庆,陈文淼,李君,曲大为,崔昊. 不同当量比下单双点火对天然气燃烧特性的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 1929-1935. |

| [8] | 朱一骁,何小民,金义. 联焰板宽度对单凹腔驻涡燃烧室流线形态的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 1936-1944. |

| [9] | 刘长铖,刘忠长,田径,许允,杨泽宇. 重型增压柴油机燃烧过程中的缸内㶲损失[J]. 吉林大学学报(工学版), 2019, 49(6): 1911-1919. |

| [10] | 胡潇宇,李国祥,白书战,孙柯,李思远. 考虑加热面粗糙度和材料的沸腾换热修正模型[J]. 吉林大学学报(工学版), 2019, 49(6): 1945-1950. |

| [11] | 王德军,吕志超,王启明,张建瑞,丁建楠. 基于EKF及调制傅式级数的缸压辨识[J]. 吉林大学学报(工学版), 2019, 49(4): 1174-1185. |

| [12] | 臧鹏飞,王哲,高洋,孙晨乐. 直线电机/发动机系统稳态运行综合控制策略[J]. 吉林大学学报(工学版), 2019, 49(3): 798-804. |

| [13] | 董伟,宋佰达,邱立涛,孙昊天,孙平,蒲超杰. 直喷汽油机暖机过程中两次喷射比例对燃烧和排放的影响[J]. 吉林大学学报(工学版), 2018, 48(6): 1755-1761. |

| [14] | 李志军, 汪昊, 何丽, 曹丽娟, 张玉池, 赵新顺. 催化型微粒捕集器碳烟分布及其影响因素[J]. 吉林大学学报(工学版), 2018, 48(5): 1466-1474. |

| [15] | 林学东, 江涛, 许涛, 李德刚, 郭亮. 高压共轨柴油机起动工况高压泵控制策略[J]. 吉林大学学报(工学版), 2018, 48(5): 1436-1443. |

|

||