吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (1): 210-219.doi: 10.13229/j.cnki.jdxbgxb20210516

• 交通运输工程·土木工程 • 上一篇

动静水环境作用下级配离析对沥青混合料水损害的影响评价

陈栩1,2( ),曹超飞1,2,尚静1,2,黄明星1,3,艾长发1,2,任东亚1,2(

),曹超飞1,2,尚静1,2,黄明星1,3,艾长发1,2,任东亚1,2( )

)

- 1.西南交通大学 土木工程学院,成都 610031

2.道路工程四川省重点实验室,成都 610031

3.四川遂广遂西高速公路有限责任公司,四川 遂宁 629000

Evaluation of influence of gradation segregation on pavement moisture damage under action of dynamic and static water environment

Xu CHEN1,2( ),Chao-fei CAO1,2,Jing SHANG1,2,Ming-xing HUANG1,3,Chang-fa AI1,2,Dong-ya Ren1,2(

),Chao-fei CAO1,2,Jing SHANG1,2,Ming-xing HUANG1,3,Chang-fa AI1,2,Dong-ya Ren1,2( )

)

- 1.School of Civil Engineering,Southwest Jiaotong University,Chengdu 610031,China

2.Highway Engineering Key Laboratory of Sichuan Province,Chengdu 610031,China

3.Sichuan Suiguangsuixi Expressway Co. ,Ltd. ,Suining 629000,China

摘要:

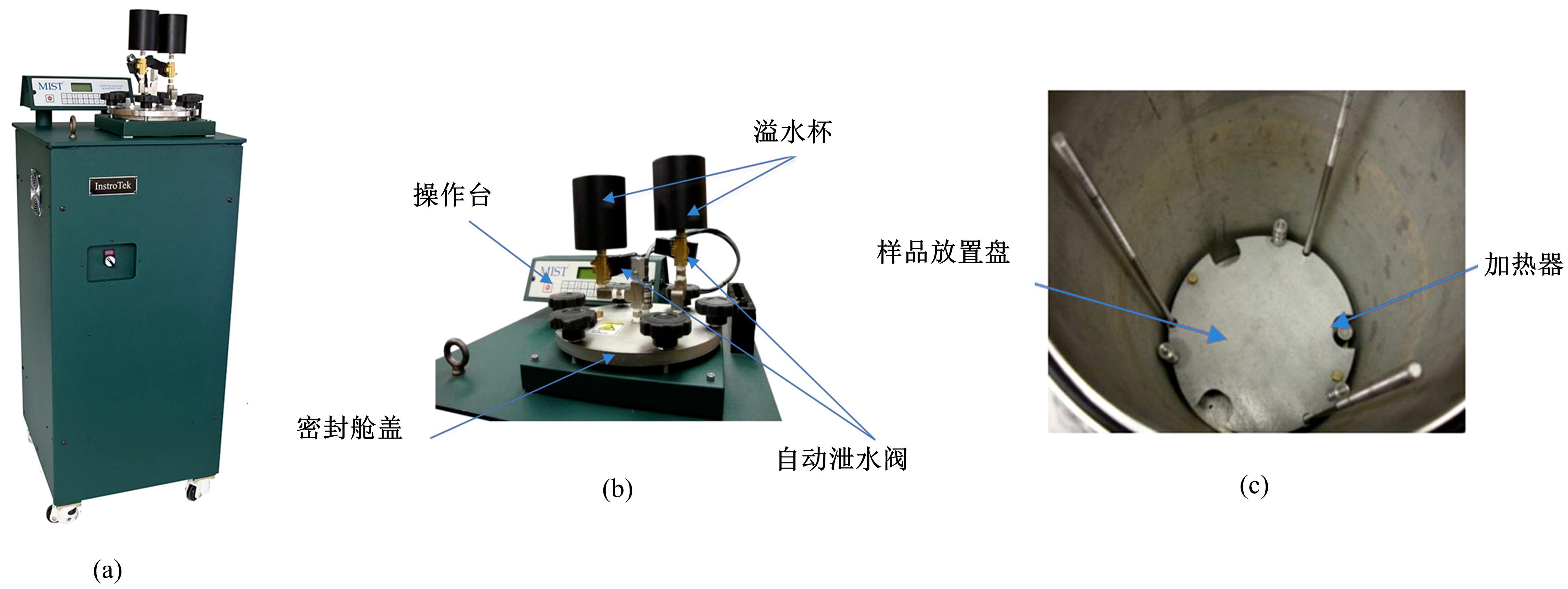

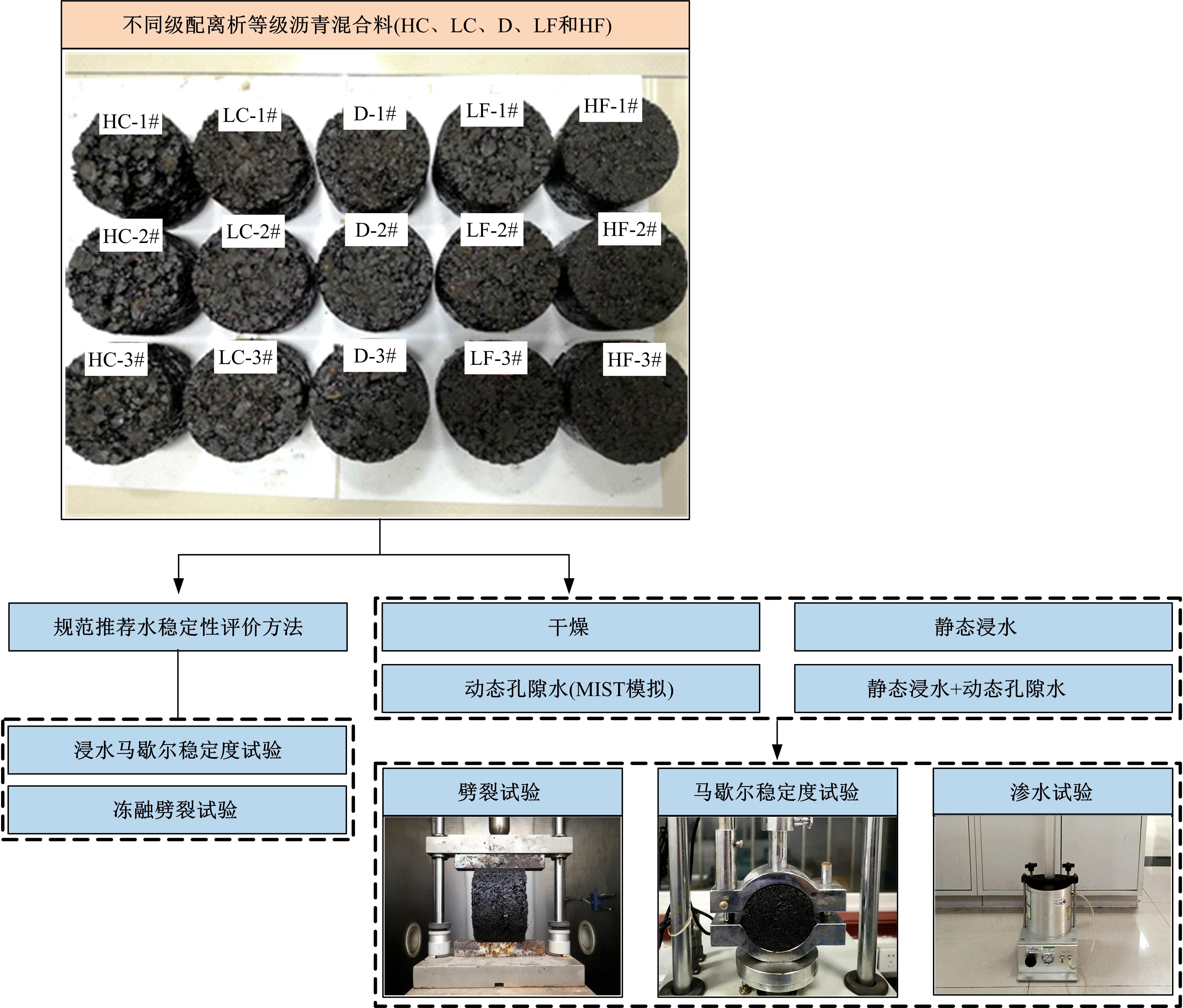

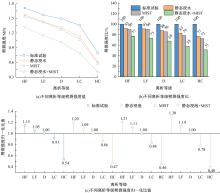

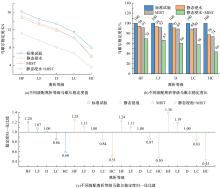

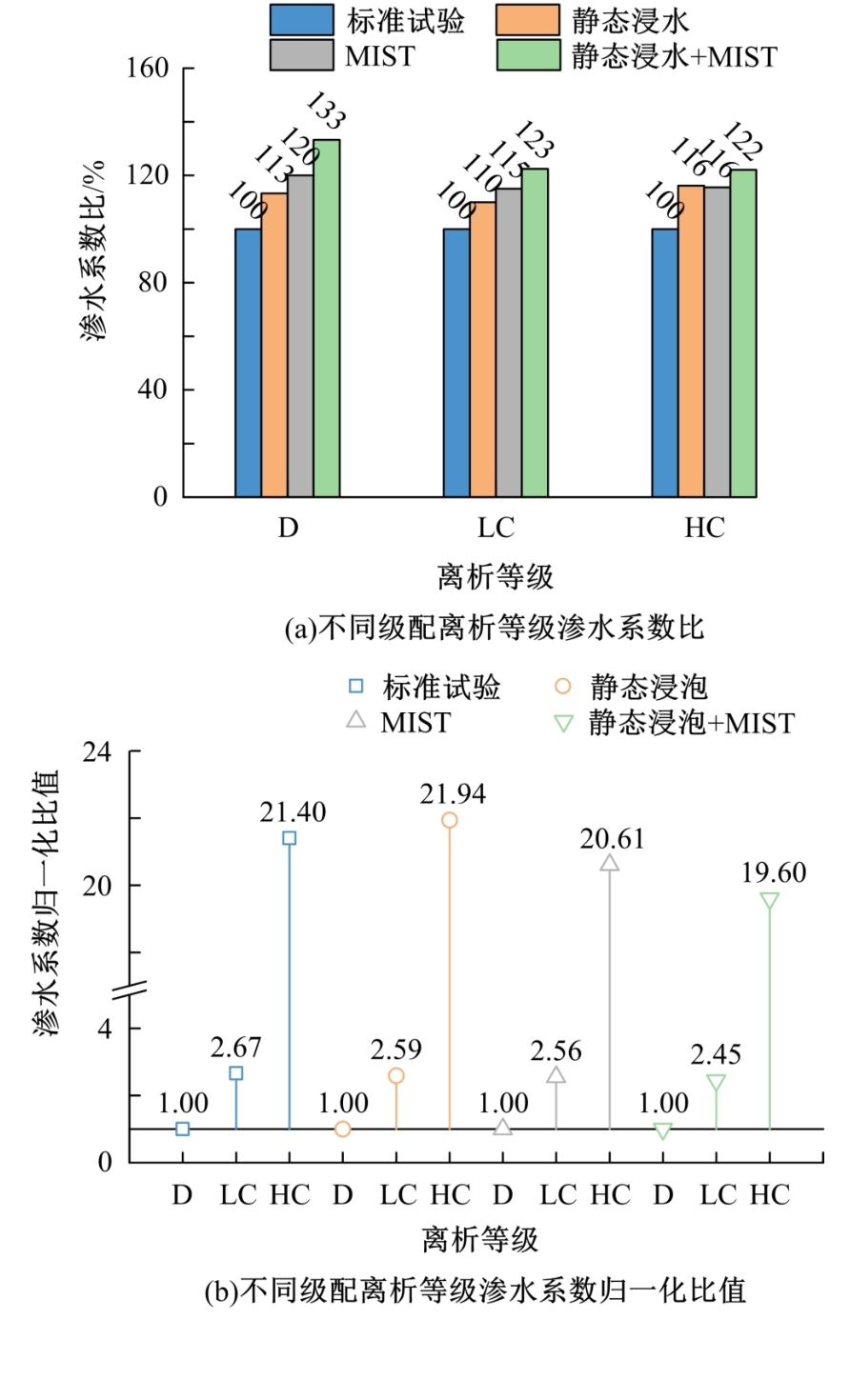

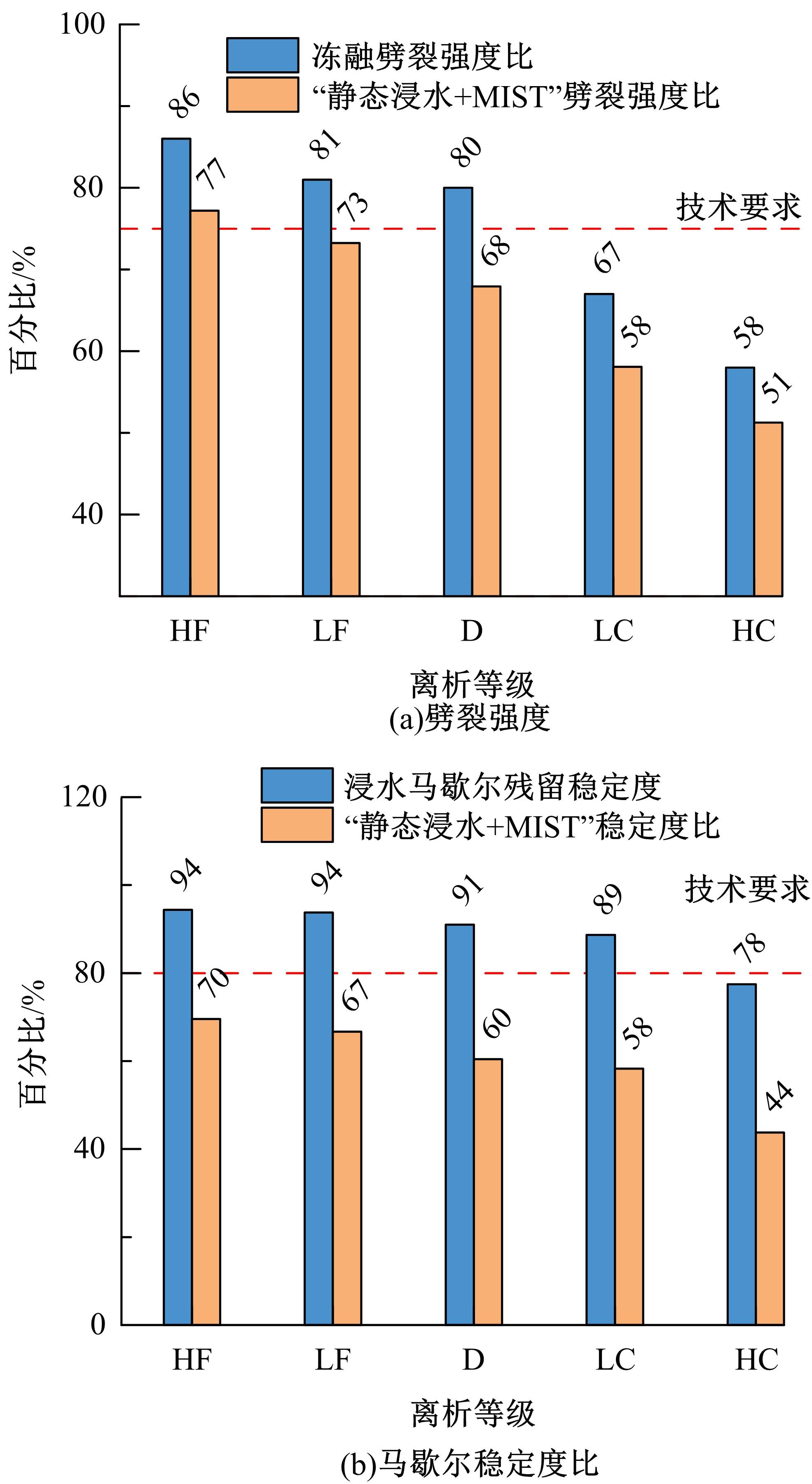

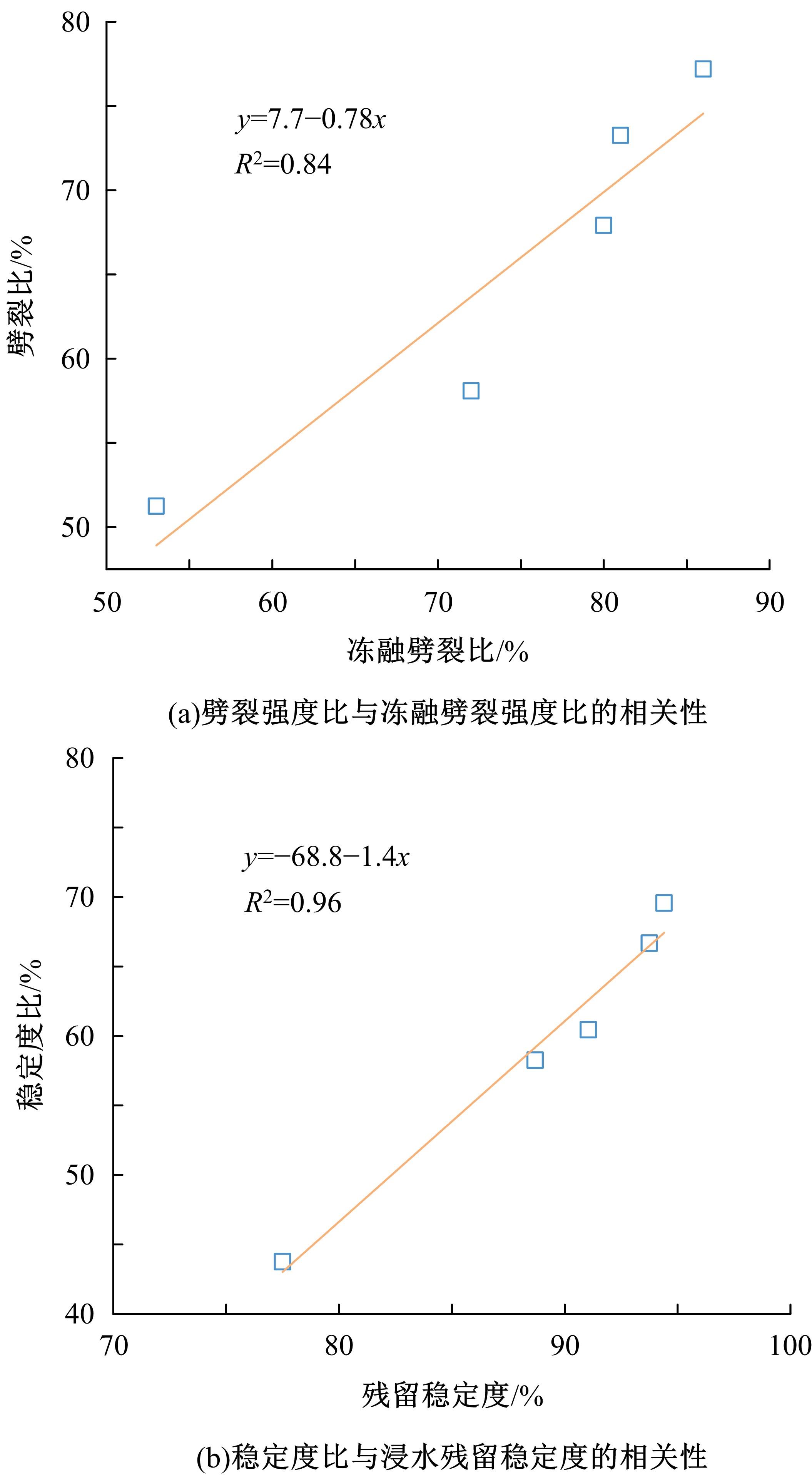

针对现有级配离析对沥青混合料抗水损害性能影响研究的不足,基于水敏感性测试仪(MIST)研究了多种水环境作用和不同离析程度对沥青混合料抗水损性能的影响。试验结果表明:水环境作用对劈裂强度和马歇尔稳定度值的削弱大小顺序为“静态浸水+MIST(长期+短期作用)”>“MIST(短期作用)”>“静态浸水(长期作用)”;出现级配离析后,劈裂强度和马歇尔稳定度值大小顺序为HC(粗集料重度离析)

中图分类号:

- U414

| 1 | 沙庆林. 高速公路沥青路面早期破坏现象及预防[M]. 北京:人民交通出版社 2001. |

| 2 | 沈金安. 沥青及沥青混合料路用性能[M]. 北京:人民交通出版社 2011. |

| 3 | Htet Y Z M. An assessment of moisture induced damage in asphalt pavements[D]. Worcester: Worcester Polytechnic Institute, 2015. |

| 4 | 沈金安,李福普,陈景. 高速公路沥青路面早期损坏分析与防治对策[M]. 北京:人民交通出版社 2004. |

| 5 | 姜旺恒. 沥青路面水损坏机理及动水压力试验应用研究[D]. 广州: 华南理工大学交通学院, 2008. |

| Jiang Wang-heng. Research on water damage mechanism of asphalt pavement and application of hydrodynamic pressure test[D]. Guangzhou: College of Transportation, South China University of Technology, 2008. | |

| 6 | Byzyka J, Rahman M, Chamberlain D A. Thermal segregation of asphalt material in road repair[J]. Journal of Traffic & Transportation Engineering, 2017,4(4):360-371. |

| 7 | 王文涛. 多因素耦合动态孔隙水压力对沥青路面破坏的影响研究[D]. 北京: 北京科技大学材料科学与工程学院, 2020. |

| Wang Wen-tao. Study on the influence of multi-factor coupling dynamic pore water pressure on the failure of asphalt pavement[D]. Beijing: College of Materials Sciences and Engineering, University of Science and Technology Beijing, 2020. | |

| 8 | Wang W, Wang L, Xiong H, et al. A review and perspective for research on moisture damage in asphalt pavement induced by dynamic pore water pressure[J]. Construction and Building Materials, 2019, 204: 631-642. |

| 9 | Mallick R B, Gould J S, Bhattacharjee S, et al. Development of a rational procedure for evaluation of moisture susceptibility of asphalt paving mixes[J]. Asphalt Paving Technology 2003,72:424-462. |

| 10 | 谭忆秋,李晓琳,胡斌. 动水作用对沥青混合料低温抗裂性的影响[J]. 哈尔滨工业大学学报, 2010, 42(1): 119-122. |

| Tan Yi-qiu, Li Xiao-lin, Hu Bin. Effect of hydrodynamic action on crack resistance of asphalt mixture at low temperature[J]. Journal of Harbin Institute of Technology, 2010 42(1): 119-122. | |

| 11 | 潘宝峰. 动水压力作用下路面材料损伤的评价方法研究[D].大连:大连理工大学交通运输学院,2010. |

| Pan Bao-feng. Study on evaluation method of pavement material damage under hydrodynamic pressure[D]. Dalian: College of Traffic and Transportation, Dalian University of Technology, 2010. | |

| 12 | 2013―. Standard practice for moisture conditioning compacted asphalt mixture specimens by using hydrostatic pore pressure [S]. |

| 13 | Lacroix A, Regimand A, James L. Proposed approach for evaluation of cohesive and adhesive properties of asphalt mixtures for determination of moisture sensitivity[J]. Transportation Research Record Journal of the Transportation Research Board, 2016, 2575: 61-69. |

| 14 | Varveri A, Avgerinopoulos S, Scarpas A. experimental evaluation of long- and short-term moisture damage characteristics of asphalt mixtures[J]. Road Materials & Pavement Design, 2016, 17(1): 168-186. |

| 15 | 李立寒,麻旭荣. 级配离析沥青混合料性能的试验研究[J]. 同济大学学报:自然科学版, 2007, 35(12): 1622-1626. |

| Li Li-han, Ma Xu-rong. Experimental study on the performance of graded segregated asphalt mixture[J]. Journal of Tongji University (Natural Science Edition), 2007,35(12): 1622-1626. | |

| 16 | Chen X, Ai C, Du J, et al. Effect of gradation segregation on low-temperature crack resistance of asphalt pavement using 3D DEM[J]. Construction and Building Materials, 2021, 274(3):No.122060. |

| 17 | Li J, Liu G, Yang T, et al. Research on relationships among different distress types of asphalt pavements with semi-rigid bases in china using association rule mining: a statistical point of view[J]. Advances in Civil Engineering, 2019, 2019: 1-15. |

| 18 | Mannan U A, Ahmad M, Tarefder R A. Influence of moisture conditioning on healing of asphalt binders[J]. Construction & Building Materials, 2017, 146(8): 360-369. |

| 19 | Stroup-Gardiner M, Brown E R. Segregation in hot-mix asphalt pavements[J]. Caring national association for home care magazine, 2000. |

| 20 | .公路沥青路面施工技术规范 [S]. |

| 21 | 孙立军. 沥青路面结构行为理论[M]. 北京:人民交通出版社 2005. |

| 22 | 沈金安.关于沥青混合料的均匀性和离析问题[J].公路交通科技,2001(6):20-24. |

| Shen Jin-an. On uniformity and segregation of asphalt mixture [J]. Highway traffic science and technology, 2001(6):20-24. | |

| 23 | Florida D. Florida method of test for measurement of water permeability of compacted asphalt paving mixtures[J]. FM5-565, Dept of Transportation, Tallahassee, 2004. |

| 24 | .公路工程沥青及沥青混合料试验规程 [S]. |

| 25 | .公路沥青路面设计规范 [S]. |

| [1] | 杨柳,王创业,王梦言,程阳. 设置自动驾驶小客车专用车道的六车道高速公路交通流特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2043-2052. |

| [2] | 周正峰,于晓涛,陶雅乐,郑茂,颜川奇. 基于灰色关联分析的树脂与弹性体高黏沥青高温性能评价[J]. 吉林大学学报(工学版), 2023, 53(7): 2078-2088. |

| [3] | 马涛,马源,黄晓明. 基于多元非线性回归的智能压实关键参数最优解[J]. 吉林大学学报(工学版), 2023, 53(7): 2067-2077. |

| [4] | 魏海斌,韩栓业,毕海鹏,刘琼辉,马子鹏. 智能感知道路主动除冰雪系统及实验技术[J]. 吉林大学学报(工学版), 2023, 53(5): 1411-1417. |

| [5] | 郑睢宁,何锐,路天宇,徐紫祎,陈华鑫. RET/胶粉复合改性沥青制备及其混合料性能评价[J]. 吉林大学学报(工学版), 2023, 53(5): 1381-1389. |

| [6] | 关博文,邸文锦,王发平,吴佳育,张硕文,贾治勋. 干湿循环与交变荷载作用下混凝土硫酸盐侵蚀损伤[J]. 吉林大学学报(工学版), 2023, 53(4): 1112-1121. |

| [7] | 杨帆,李琛琛,李盛,刘海伦. 温缩作用下双层连续配筋混凝土路面配筋率设计参数对比分析[J]. 吉林大学学报(工学版), 2023, 53(4): 1122-1132. |

| [8] | 魏海斌,马子鹏,毕海鹏,刘汉涛,韩栓业. 基于力学响应分析方法的导电橡胶复合路面铺装技术[J]. 吉林大学学报(工学版), 2023, 53(2): 531-537. |

| [9] | 刘状壮,张有为,季鹏宇,Abshir Ismail Yusuf,李林,郝亚真. 电热型融雪沥青路面传热特性研究[J]. 吉林大学学报(工学版), 2023, 53(2): 523-530. |

| [10] | 时爽,林岚钦,马涛,顾临皓,张燕宁. 基于分子动力学的生物质透层油稳定性[J]. 吉林大学学报(工学版), 2023, 53(1): 197-209. |

| [11] | 彭勇,章秀芳,郭泽宇,陆学元,李彦伟. 离散元法分析集料接触特性对沥青混合料剪切疲劳寿命的影响[J]. 吉林大学学报(工学版), 2023, 53(1): 178-187. |

| [12] | 孙雅珍,郑直,黄伟明,王金昌. 基于状态空间法的含裂缝水泥路面结构分析[J]. 吉林大学学报(工学版), 2023, 53(1): 188-196. |

| [13] | 时成林,王勇,吴春利,宋文祝. 路堤挡土墙主动土压力计算方法修正[J]. 吉林大学学报(工学版), 2022, 52(6): 1394-1403. |

| [14] | 郭庆林,刘强,吴春利,李黎丽,李懿明,刘富春. 导电沥青及混合料裂缝局部温度场及愈合效果[J]. 吉林大学学报(工学版), 2022, 52(6): 1386-1393. |

| [15] | 姚玉权,仰建岗,高杰,宋亮. 基于性能-费用模型的厂拌再生沥青混合料优化设计[J]. 吉林大学学报(工学版), 2022, 52(3): 585-595. |

|

||