吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (1): 83-95.doi: 10.13229/j.cnki.jdxbgxb20190925

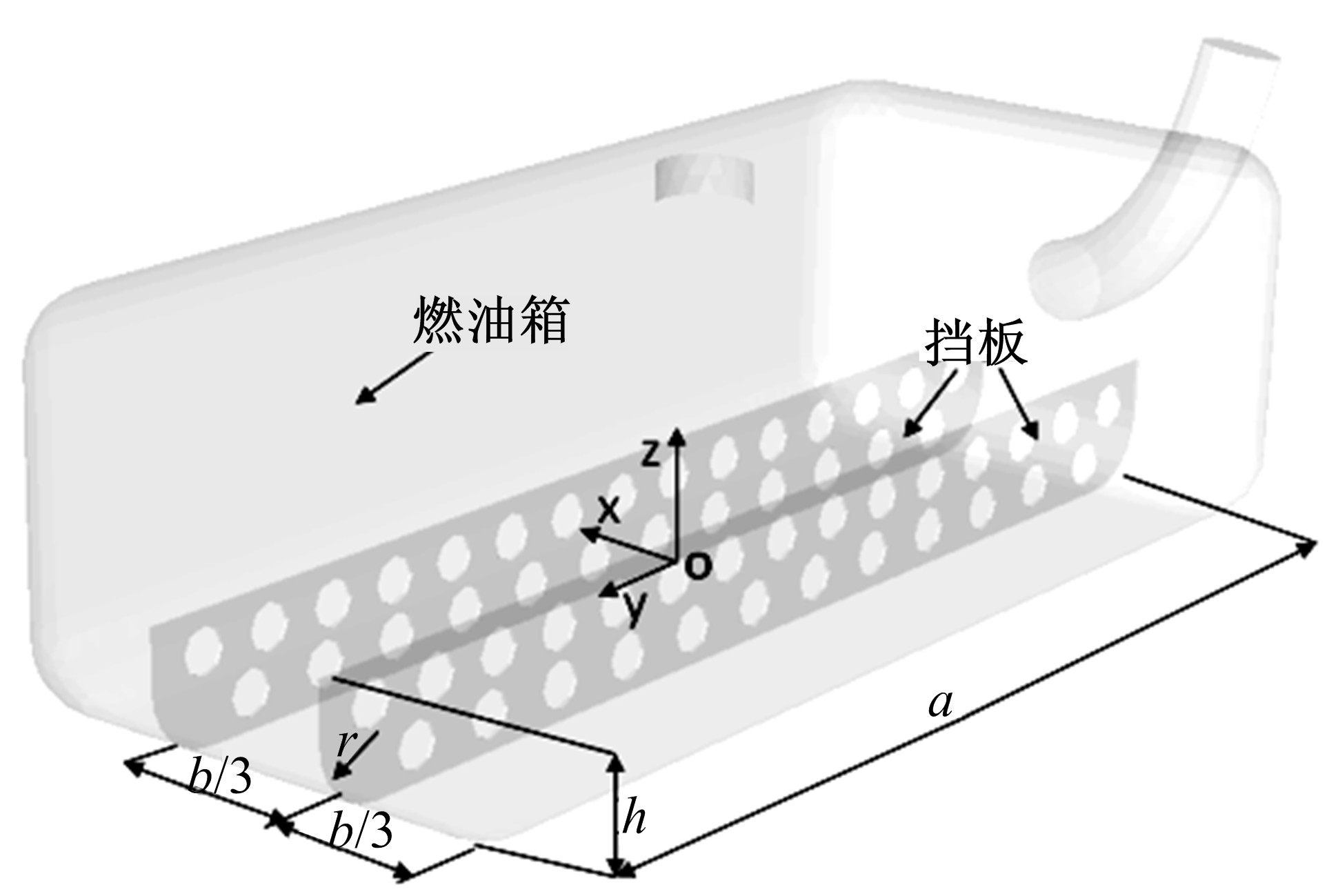

不同挡板结构对油箱内油液晃动特性的数值分析

- 1.江苏大学 汽车与交通工程学院,江苏 镇江 212013

2.内蒙古科技大学 机械工程学院,内蒙古 包头 014010

3.亚普汽车部件股份有限公司,江苏 扬州 225000

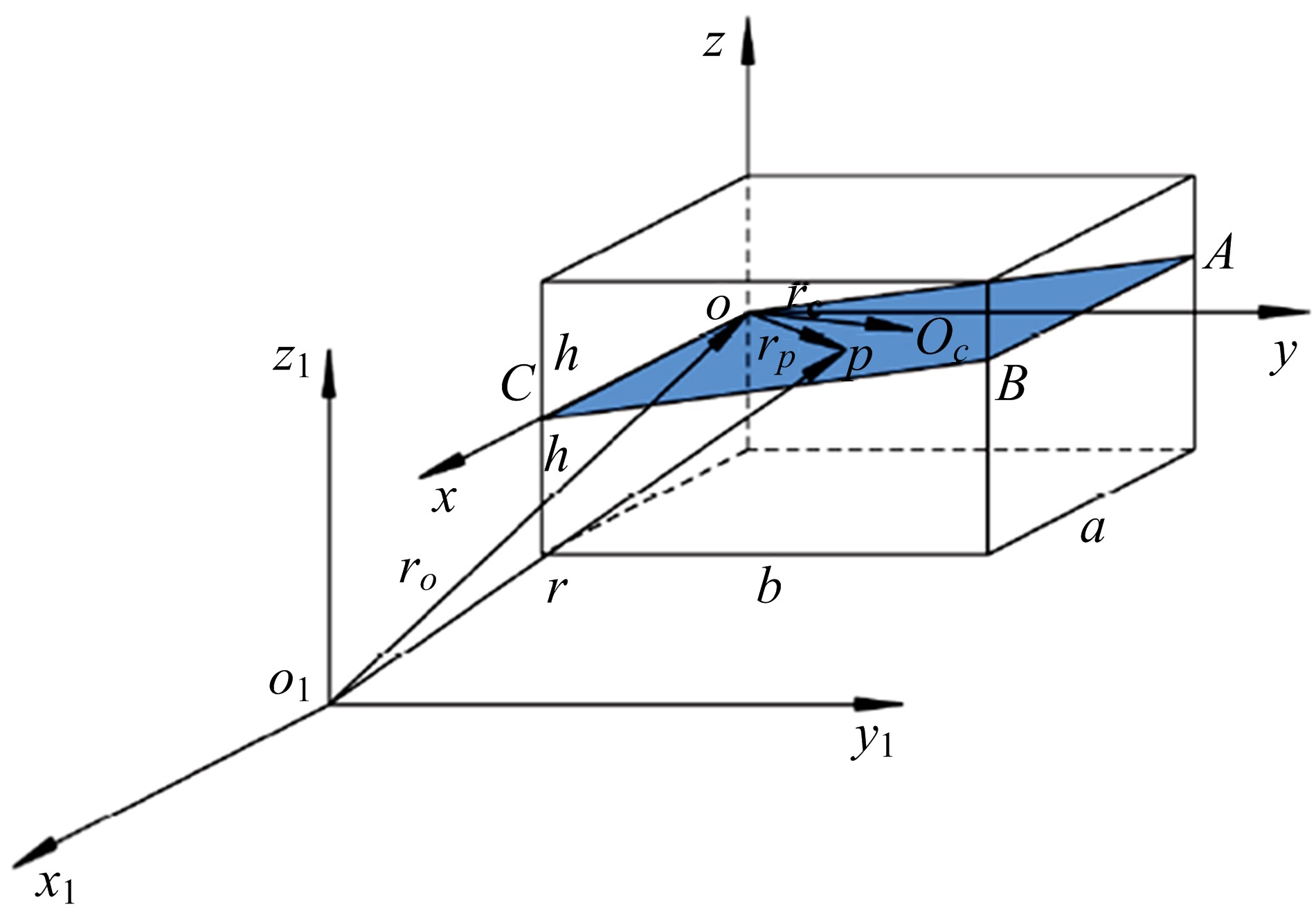

Numerical analysis of oil liquid sloshing characteristics in fuel tank with different baffle structures

En-hui ZHANG1,2( ),Ren HE1(

),Ren HE1( ),Wei-dong SU3

),Wei-dong SU3

- 1.School of Automobile and Traffic Engineering,Jiangsu University,Zhenjiang 212013,China

2.School of Mechanical Engineering,Inner Mongolia University of Science &Technology,Baotou 014010,China

3.Yapp Automotive Parts Co. Ltd. ,Yangzhou 225000,China

摘要:

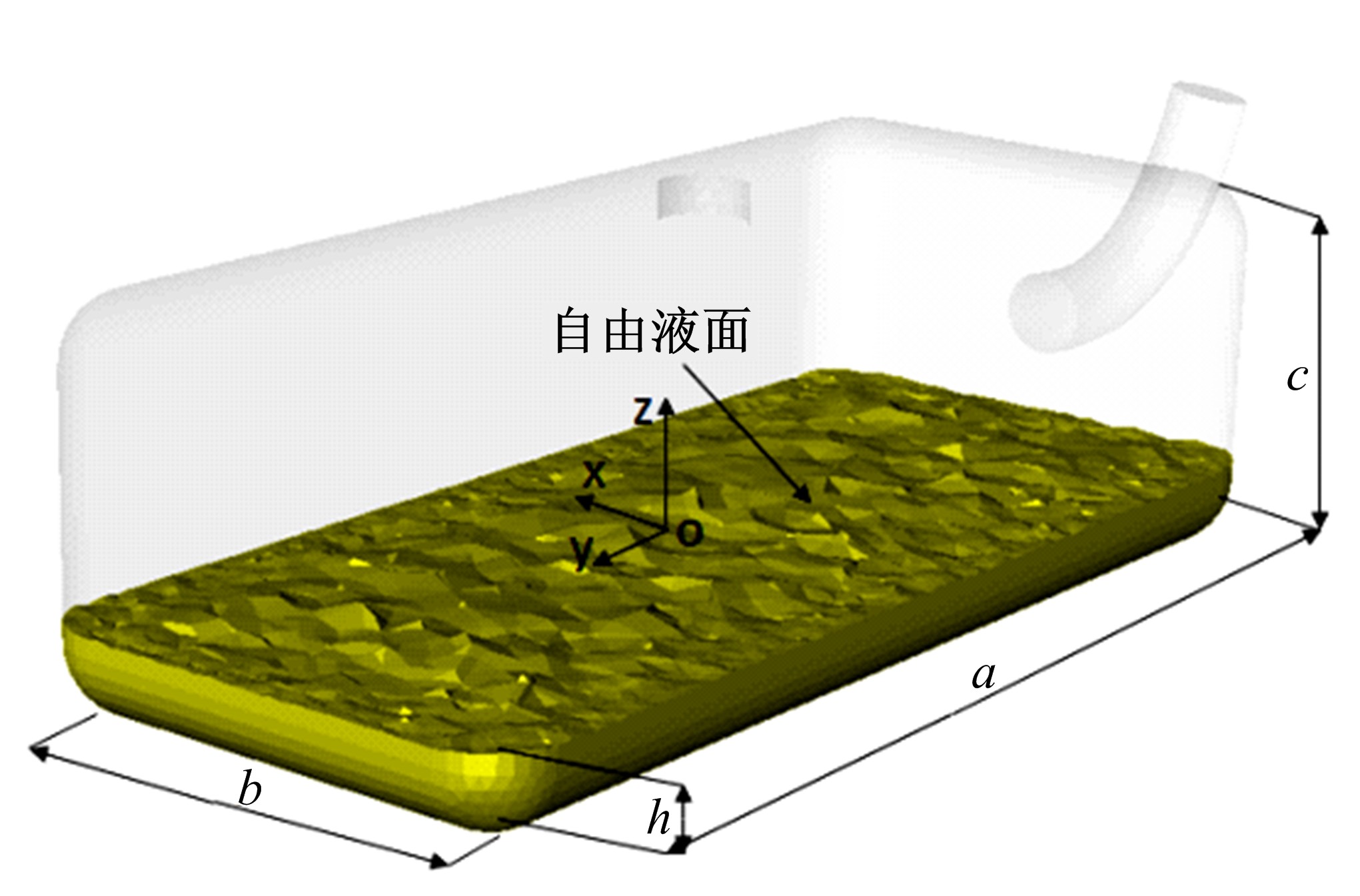

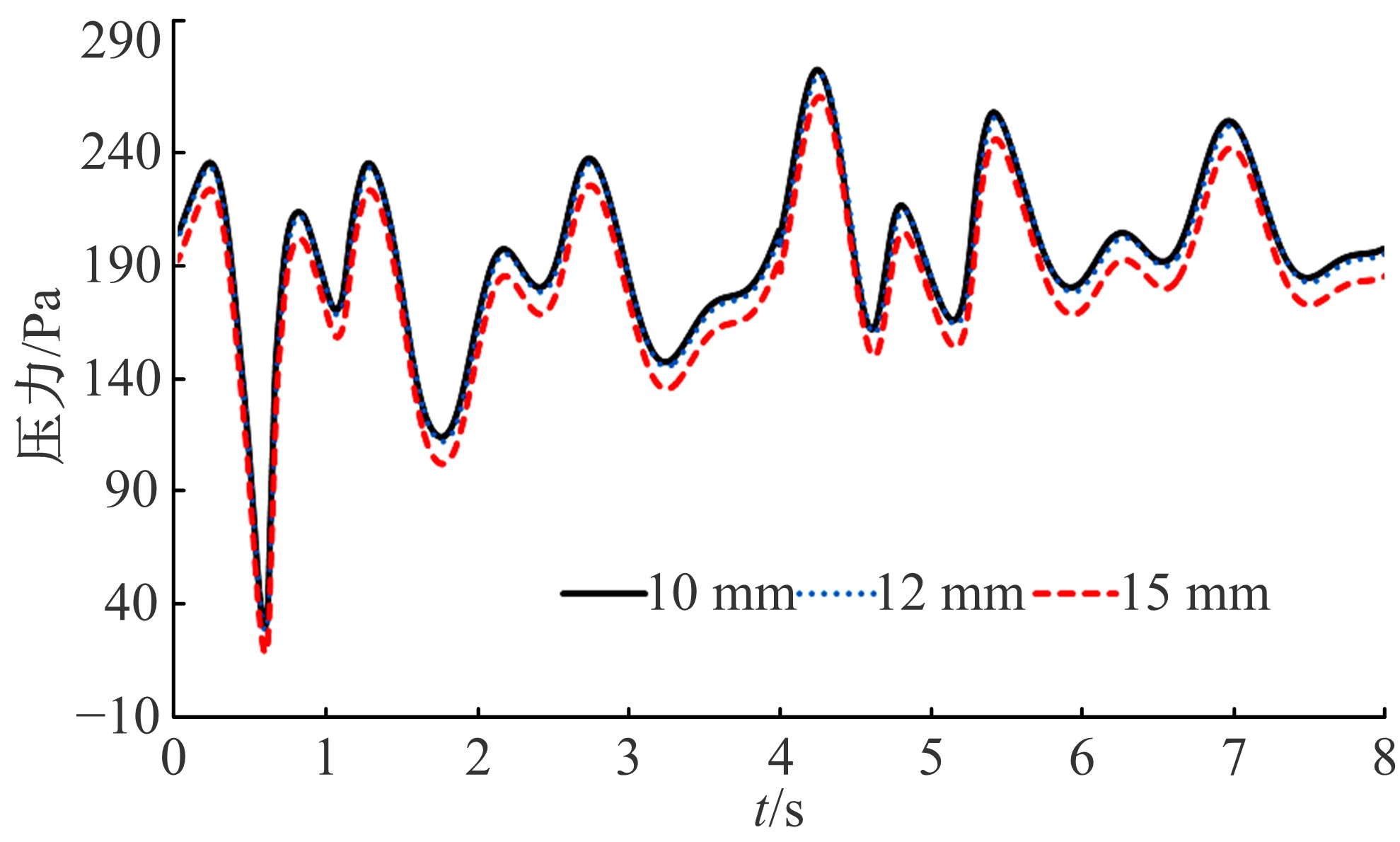

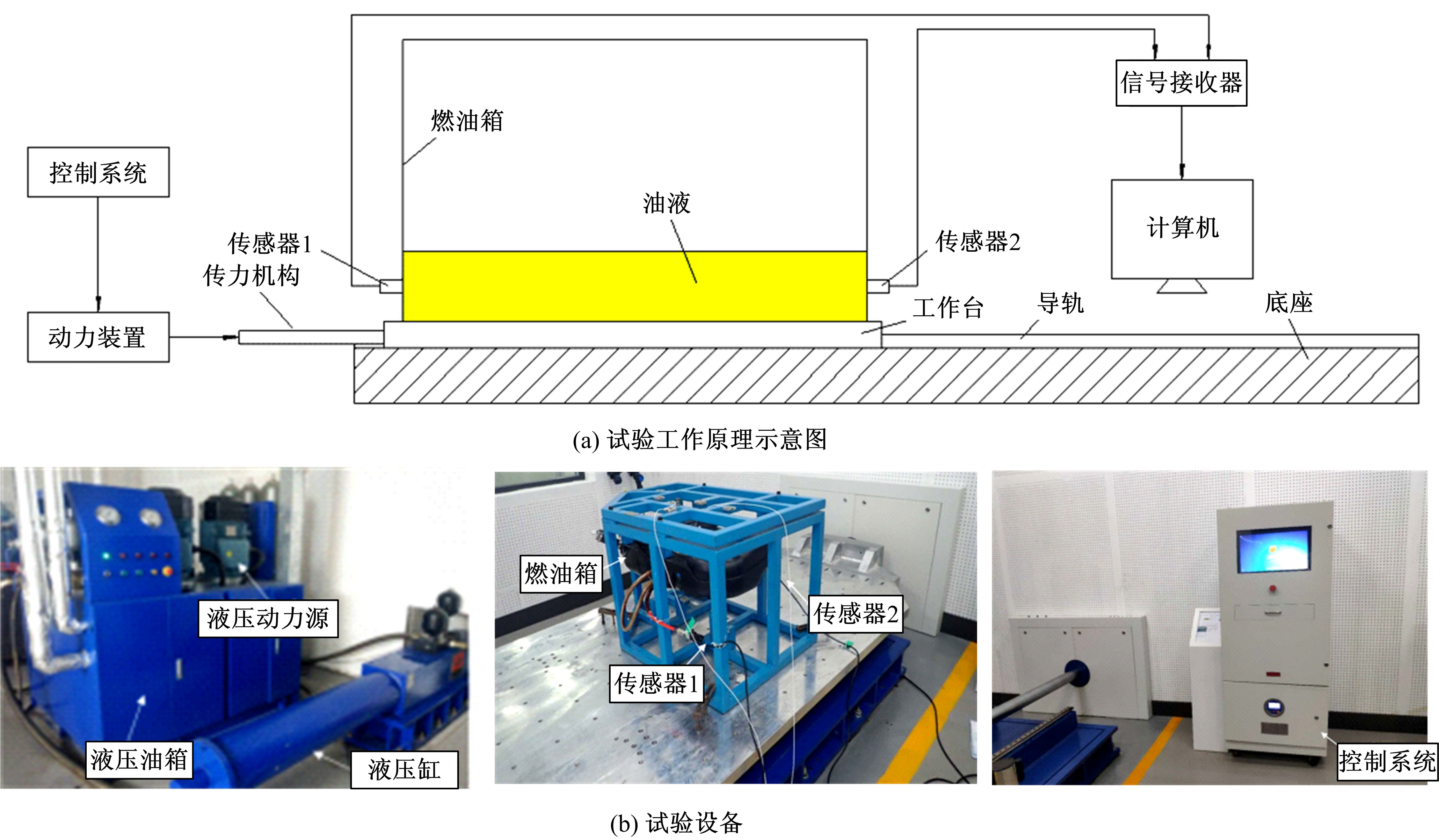

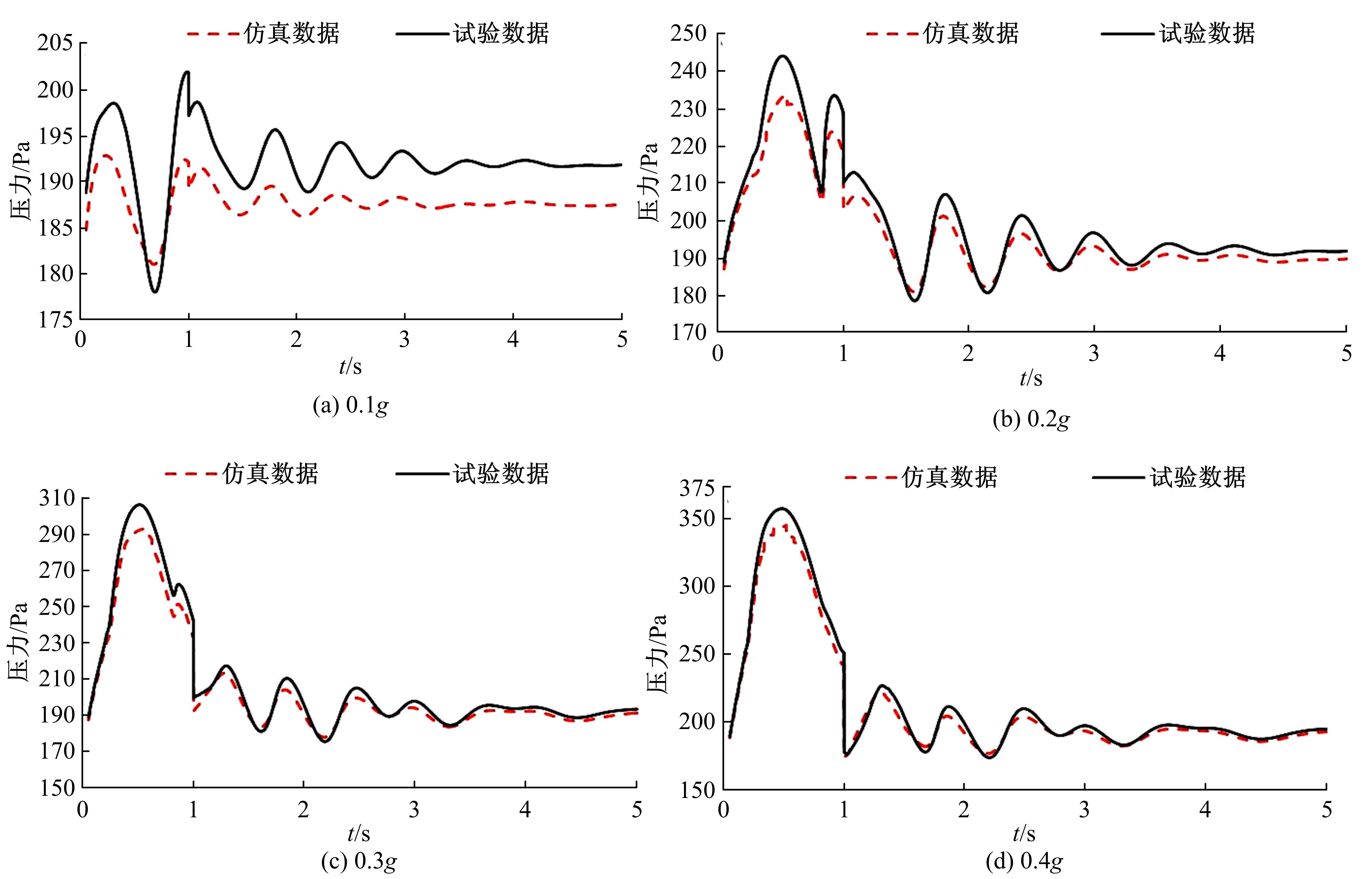

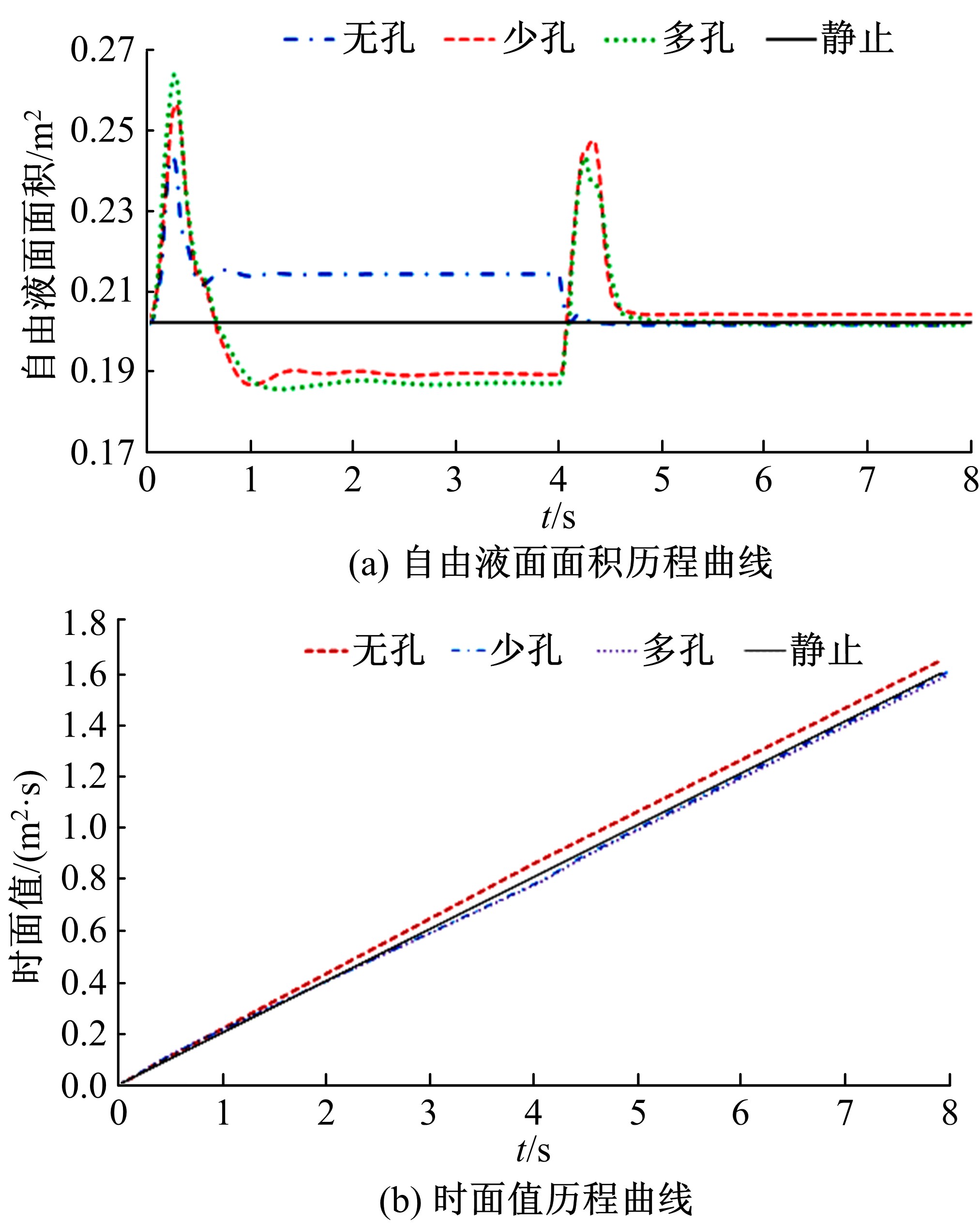

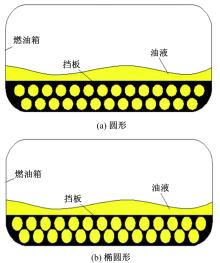

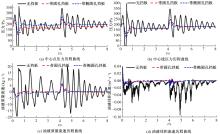

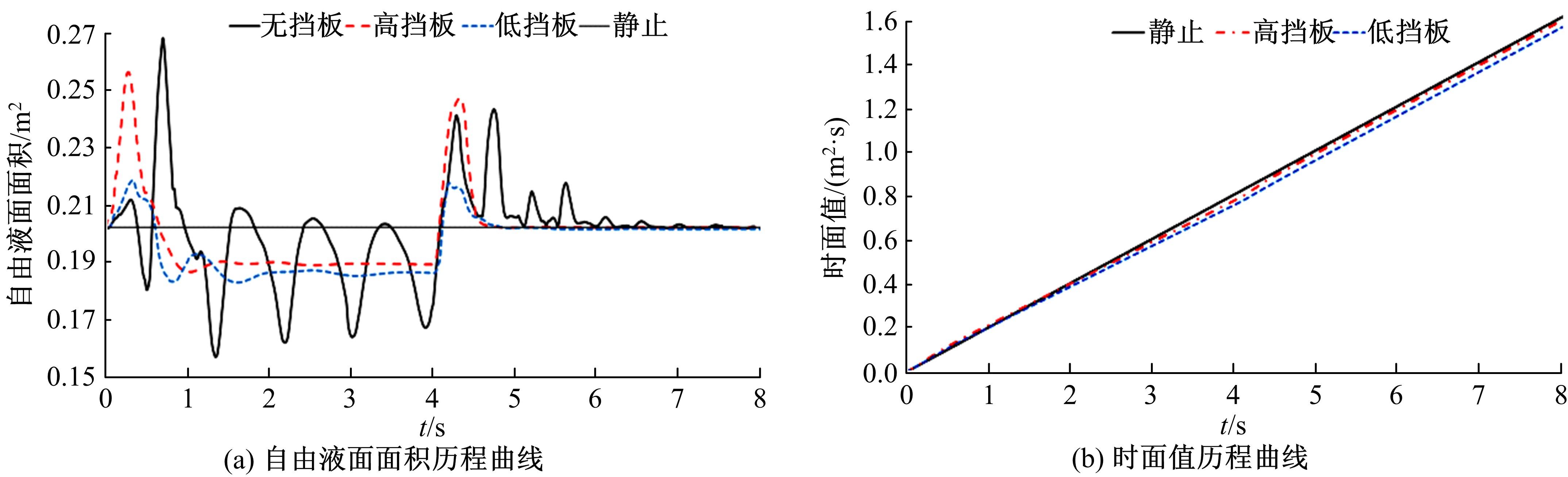

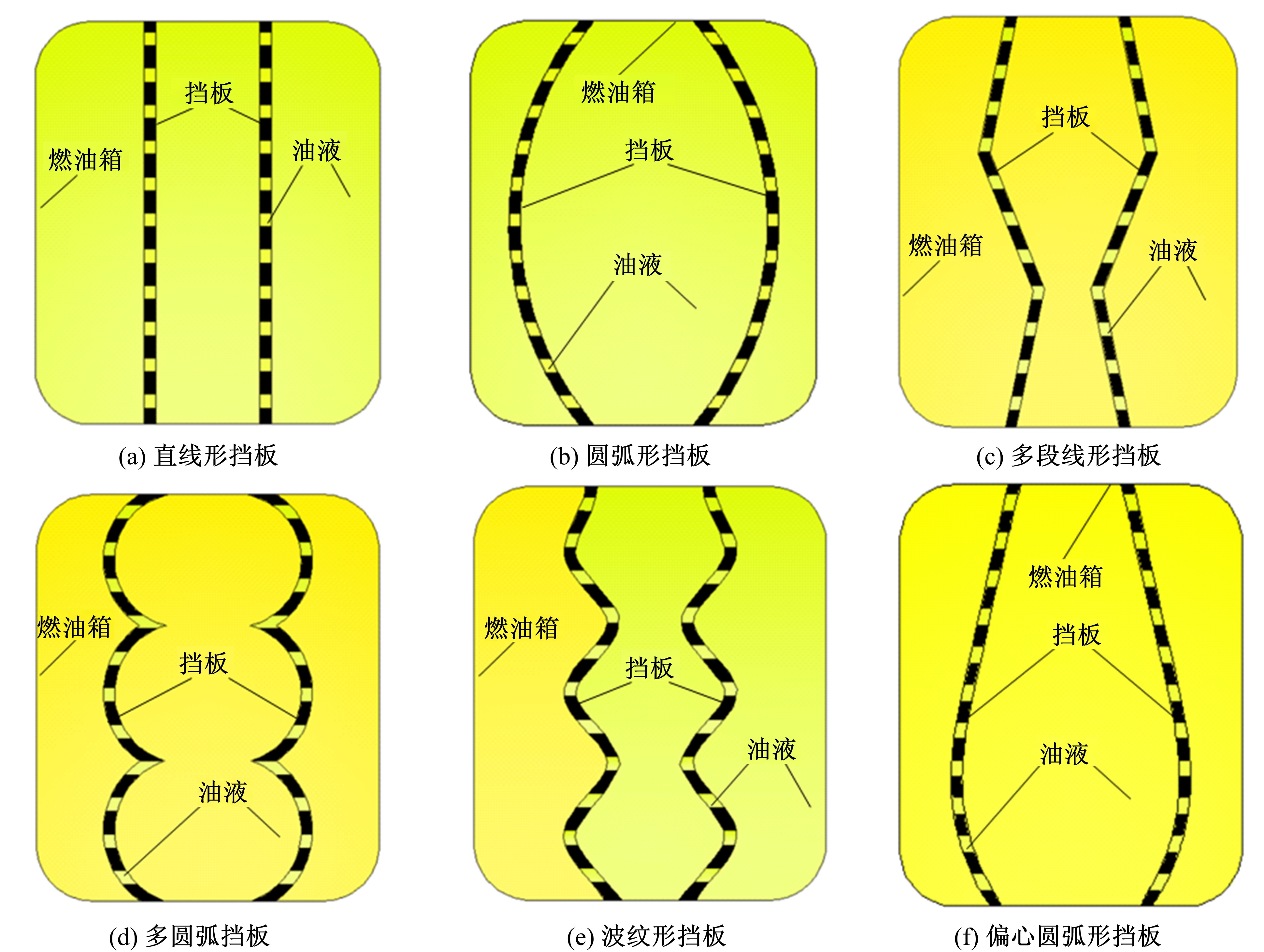

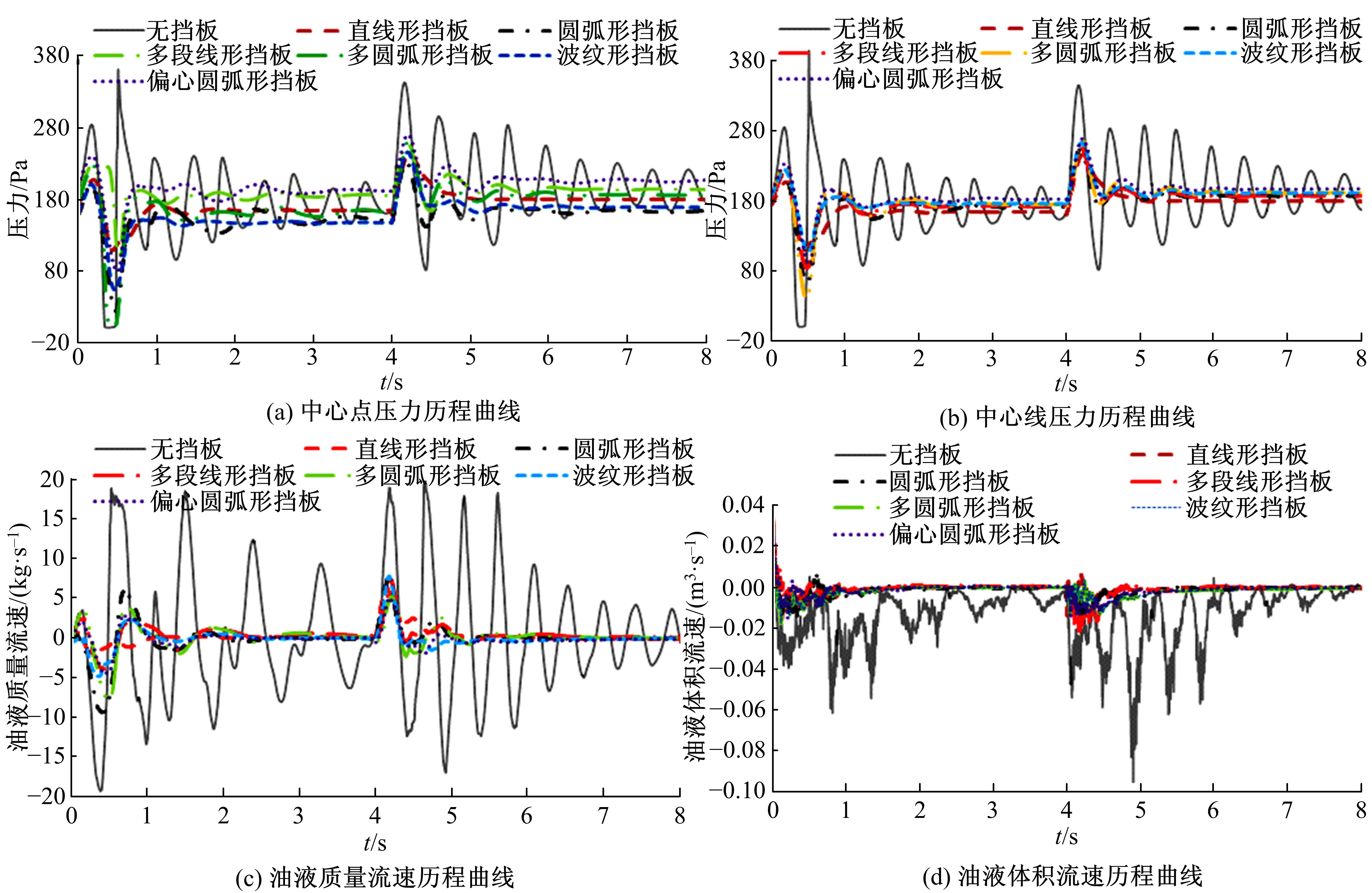

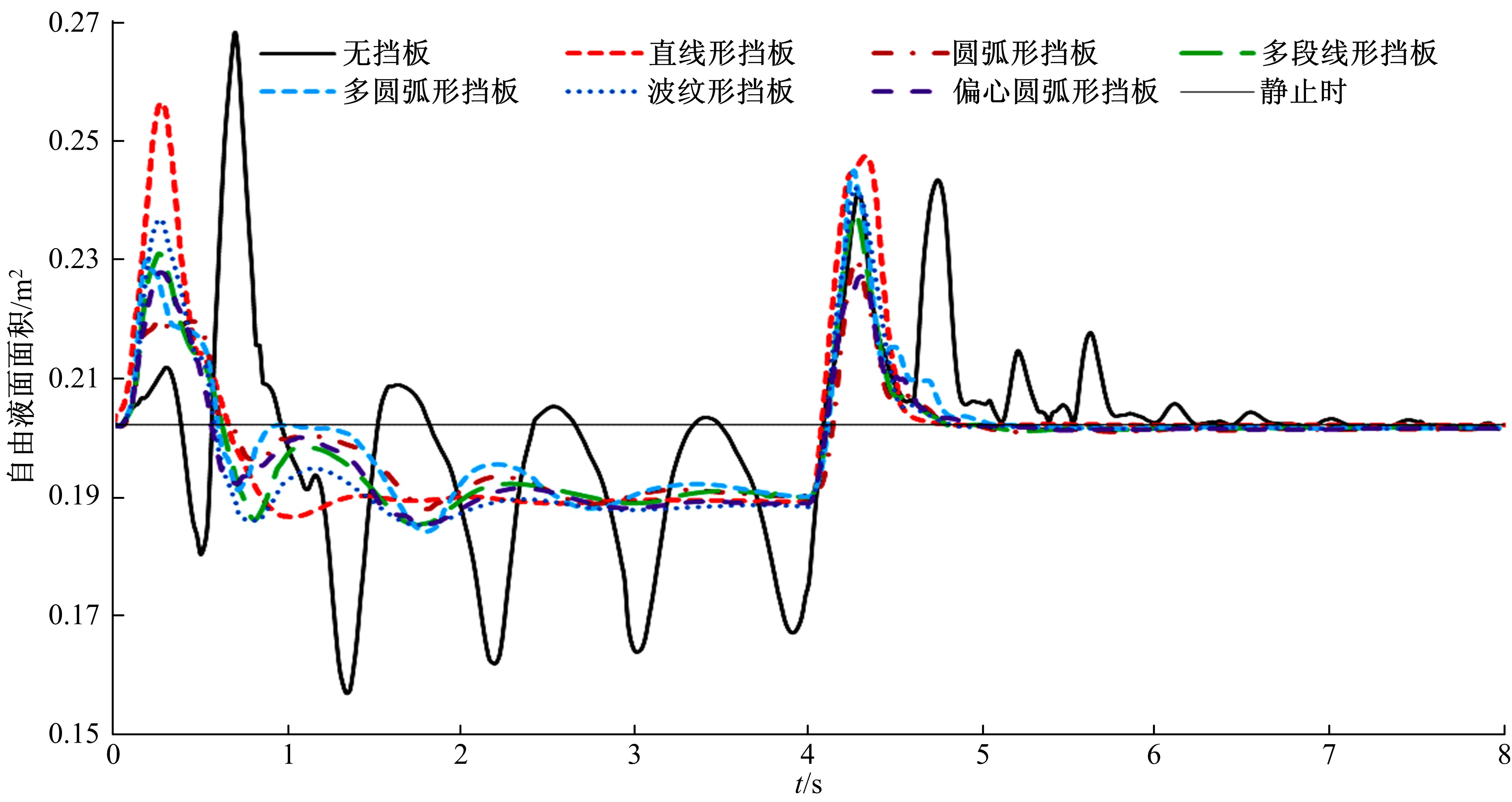

当汽车处于变工况行驶时,油液在油箱内反复晃动会造成晃动噪声、高变速工况下油液供给中断、油气挥发量增加和油箱及其内置件结构损坏等问题产生。为了优化油液防晃结构,创建了充液油箱三维有限元模型,同时验证了仿真参数设置的合理性,并通过试验验证了仿真结果的准确性。利用VOF法,分别模拟了无孔、少孔和多孔挡板、圆孔和椭圆孔挡板、高低挡板和6种不同形状挡板对油液晃动的影响。基于自由液面面积,提出了时面值概念。对比油液晃动参数可知:带少孔、圆孔挡板结构为最优挡板结构,能够有效降低油液晃动压力和时面值;波纹形和直线形挡板分别对油液中心点和中心线晃动压力抑制效果较好,偏心圆弧形挡板作用下油液晃动压力最大;多圆弧形和波纹形挡板作用下时面值分别为最大和最小;挡板明显衰减自由液面面积变化幅度;油液惯性力和重力共同作用有利于时面值的降低。

中图分类号:

- U464.136

| 1 | 费翔. 汽车油箱油液晃动噪声分析技术研究[D]. 上海:上海交通大学机械与动力工程学院, 2014. |

| Fei Xiang. Research on analysis technology of oil sloshing noise in automotive fuel tank[D]. Shanghai: School of Mechanical and Power Engineering, Shanghai Jiaotong University, 2014. | |

| 2 | Wiesche S A D. Noise due to sloshing within automotive fuel tanks[J]. Forsch Im Ingenieurwes, 2005, 70: 13-24. |

| 3 | 田哲文, 谢鑫, 戚叶峰, 等. 基于VOF方法小型赛车燃油晃动数值仿真[J]. 汽车科技, 2016, 43(6): 93-97. |

| Tian Zhe-wen, Xie Xin, Qi Ye-feng, et al. Numerical simulation of small racing car fuel sloshing based on VOF method[J]. Automobile Science & Technology, 2016, 43(6): 93-97. | |

| 4 | Hassanvand A, Hashemabadi S H, Bayat M. Evaluation of gasoline evaporation during the tank splash loading by CFD techniques[J]. International Communications in Heat and Mass Transfer, 2010, 37(7): 907-913. |

| 5 | 张恩慧, 何仁. 汽车油箱中油液晃动影响因素的数值分析[J]. 江苏大学学报:自然科学版, 2018, 39(6): 628-633. |

| Zhang En-hui, He Ren. Numerical analysis of influencing factors on sloshing of oil liquid in automobile fuel tank[J]. Journal of Jiangsu University(Natural Science Edition), 2018, 39(6): 628-633. | |

| 6 | He R, Zhang E, Baowei F. Numerical analysis on the sloshing of free oil liquid surface under the variable conditions of vehicle[J]. Advances in Mechanical Engineering, 2019, 11(2): 1-13. |

| 7 | 陈冬娇. 汽车振动对汽油箱内汽油挥发的影响研究[D]. 武汉: 华中农业大学工学院, 2004. |

| Chen Dong-jiao. The study of automotive vibration on gasoline volatilization in oil tank [D]. Wuhan: College of Technology, Huazhong Agricultura University, 2004. | |

| 8 | Akyildiz H, Unal N E. Sloshing in a three dimensional rectangular tank: numerical simulation and experimental validation[J]. Ocean Engineering, 2006, 33(16): 2135-2149. |

| 9 | Arafa M. Finite element analysis of sloshing in rectangular liquid-filled tanks[J]. Journal of Vibration and Control, 2007, 13(7): 883-903. |

| 10 | 周宏. 液体晃动数值模拟及刚-液耦合动力学研究[D]. 北京:清华大学航天航空学院,2008. |

| Zhou Hong. Study on liquid sloshing simulation and rigid-fluid coupling dynamics[D]. Beijing: School of Aeronautics and Astronautics, Tsinghua University, 2008. | |

| 11 | 董彧. 汽车油箱降噪的稳健设计优化[D]. 上海:上海交通大学机械与动力工程学院, 2011. |

| Dong Yu. Robust design optimization for automotive fuel tank slosh noise depression[D]. Shanghai: School of Mechanical and Power Engineering, Shanghai Jiaotong University, 2011. | |

| 12 | 贾善坡, 许成祥, 谭继可. 矩形容器内液体三维晃动特性研究[J]. 水电能源科学, 2012, 30(1): 142-144, 216. |

| Jia Shan-po, Xu Cheng-xiang, Tan Ji-ke. Characteristic analysis of 3D liquid sloshing in rectangular container[J]. Water Resources and Power, 2012, 30(1): 142-144, 216. | |

| 13 | 宋庆华. 基于Abaqus的油箱晃动噪音模拟[J]. 中国高新技术企业, 2013, 257(14): 58-59. |

| Song Qing-hua. The simulation about sloshing noise of fuel tank based on Abaqus[J]. China High Technology Enterprises, 2013, 257(14): 58-59. | |

| 14 | Thomson M M. Theoretical Hydrodynamics[M]. New York: MacMillan, 1965. |

| [1] | 马芳武,梁鸿宇,王强,蒲永锋. 双材料负泊松比结构的面内冲击动力学性能[J]. 吉林大学学报(工学版), 2021, 51(1): 114-121. |

| [2] | 吴岛,张立斌,张云翔,单洪颖,单红梅. 基于滑移率辨识的汽车制动时序视觉检测方法[J]. 吉林大学学报(工学版), 2021, 51(1): 206-216. |

| [3] | 熊璐,魏琰超,高乐天. 基于惯性测量单元/轮速融合的车辆零速检测方法[J]. 吉林大学学报(工学版), 2021, 51(1): 134-138. |

| [4] | 陈吉清,蓝庆生,兰凤崇,刘照麟. 基于轮胎力预判与拟合的轨迹跟踪控制[J]. 吉林大学学报(工学版), 2020, 50(5): 1565-1573. |

| [5] | 杨志刚,范亚军,夏超,储世俊,单希壮. 基于双稳态尾迹的方背Ahmed模型减阻[J]. 吉林大学学报(工学版), 2020, 50(5): 1635-1644. |

| [6] | 沈哲,王毅刚,杨志刚,贺银芝. 风洞中未知声源漂移误差的逼近修正[J]. 吉林大学学报(工学版), 2020, 50(5): 1584-1589. |

| [7] | 刘钊,程江琳,朱玉田,郑立辉. 轨道车辆垂向振动建模及运动关联分析[J]. 吉林大学学报(工学版), 2020, 50(5): 1600-1607. |

| [8] | 高菲,肖阳,张文华,祁锦轩,李子樵,马骁远. 高温和荷电状态对锂离子电池单体力学响应的耦合影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1574-1583. |

| [9] | 李静,石求军,洪良,刘鹏. 基于车辆状态估计的商用车ESC神经网络滑模控制[J]. 吉林大学学报(工学版), 2020, 50(5): 1545-1555. |

| [10] | 杜常清,曹锡良,何彪,任卫群. 基于混合粒子群算法的双离合变速器参数优化设计[J]. 吉林大学学报(工学版), 2020, 50(5): 1556-1564. |

| [11] | 李银平,靳添絮,刘立. 纯电动铲运机弓网续能系统设计与动态特性仿真[J]. 吉林大学学报(工学版), 2020, 50(2): 454-463. |

| [12] | 赖晨光,王擎宇,胡博,文凯平,陈彦宇. 静气动弹性影响下带小翼汽车尾翼的设计与优化[J]. 吉林大学学报(工学版), 2020, 50(2): 399-407. |

| [13] | 叶辉,刘畅,闫康康. 纤维增强复合材料在汽车覆盖件中的应用[J]. 吉林大学学报(工学版), 2020, 50(2): 417-425. |

| [14] | 陈鑫,王宁,沈传亮,冯晓,杨昌海. 后视镜造型对前侧窗气动噪声的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 426-436. |

| [15] | 李小雨,许男,仇韬,郭孔辉. 各向异性刚度对轮胎力学特性及车辆操纵性的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 389-398. |

|

||