吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (8): 1733-1740.doi: 10.13229/j.cnki.jdxbgxb20210213

• 车辆工程·机械工程 •

动力电池应急冷却喷射模式实验分析

- 1.吉林大学 汽车仿真与控制国家重点实验室,长春 130022

2.吉林大学 汽车工程学院,长春 130022

Experimental analysis on spray mode of power battery emergency cooling

Qing GAO1,2( ),Hao-dong WANG2,Yu-bin LIU1,2,Shi JIN2,Yu CHEN2

),Hao-dong WANG2,Yu-bin LIU1,2,Shi JIN2,Yu CHEN2

- 1.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

2.College of Automotive Engineering,Jilin University,Changchun 130022,China

摘要:

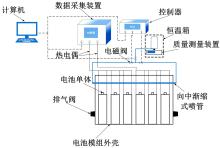

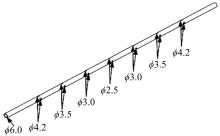

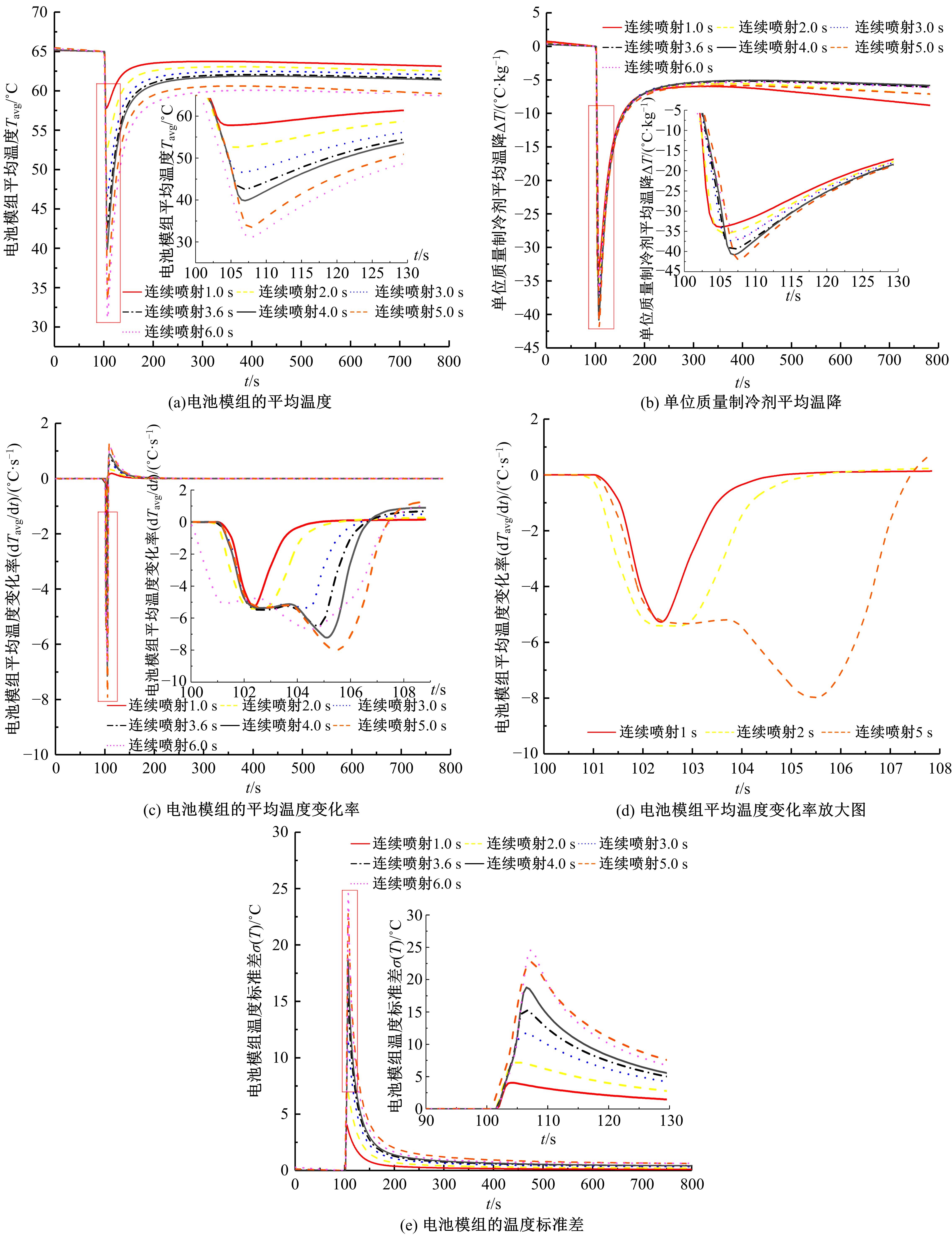

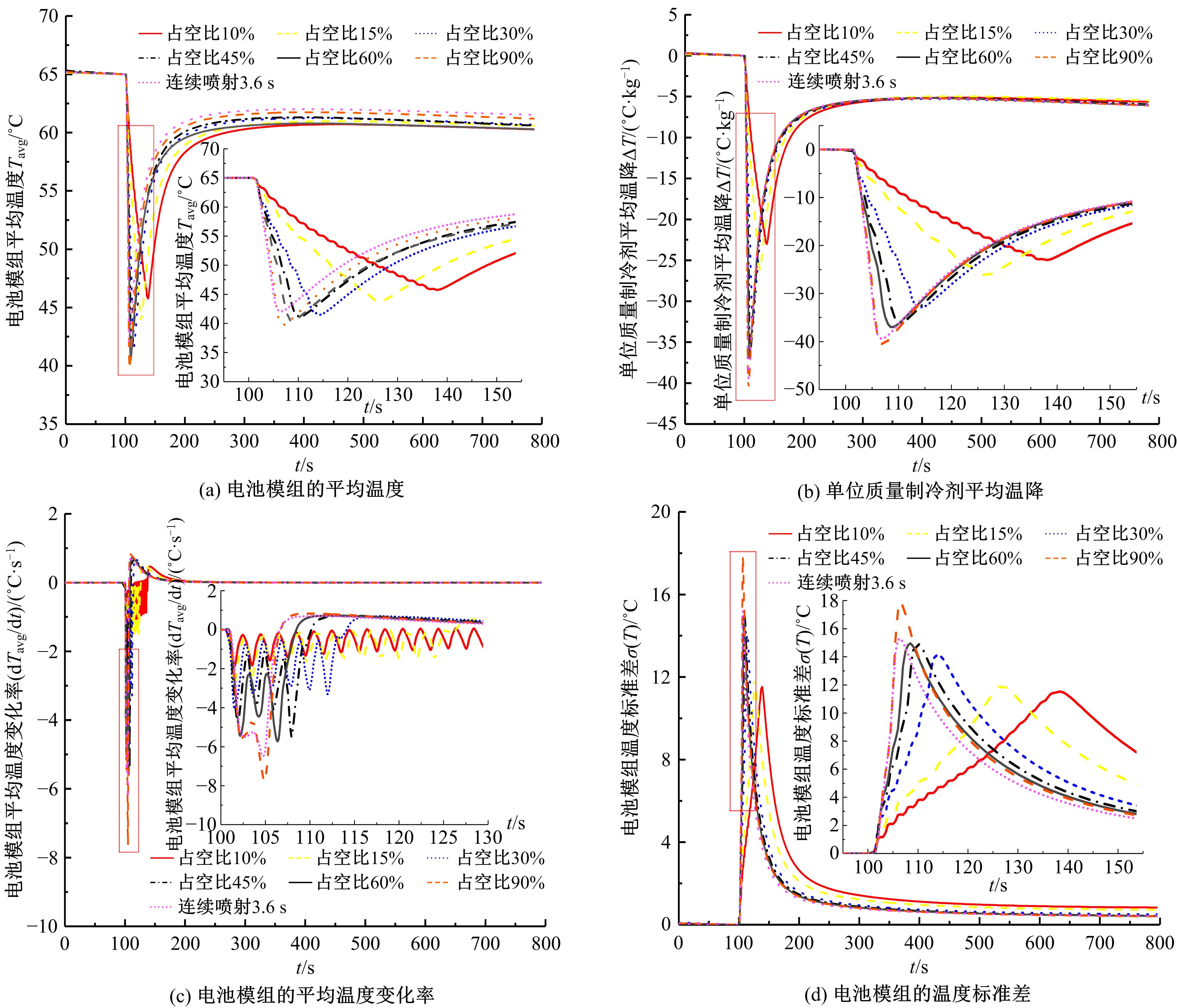

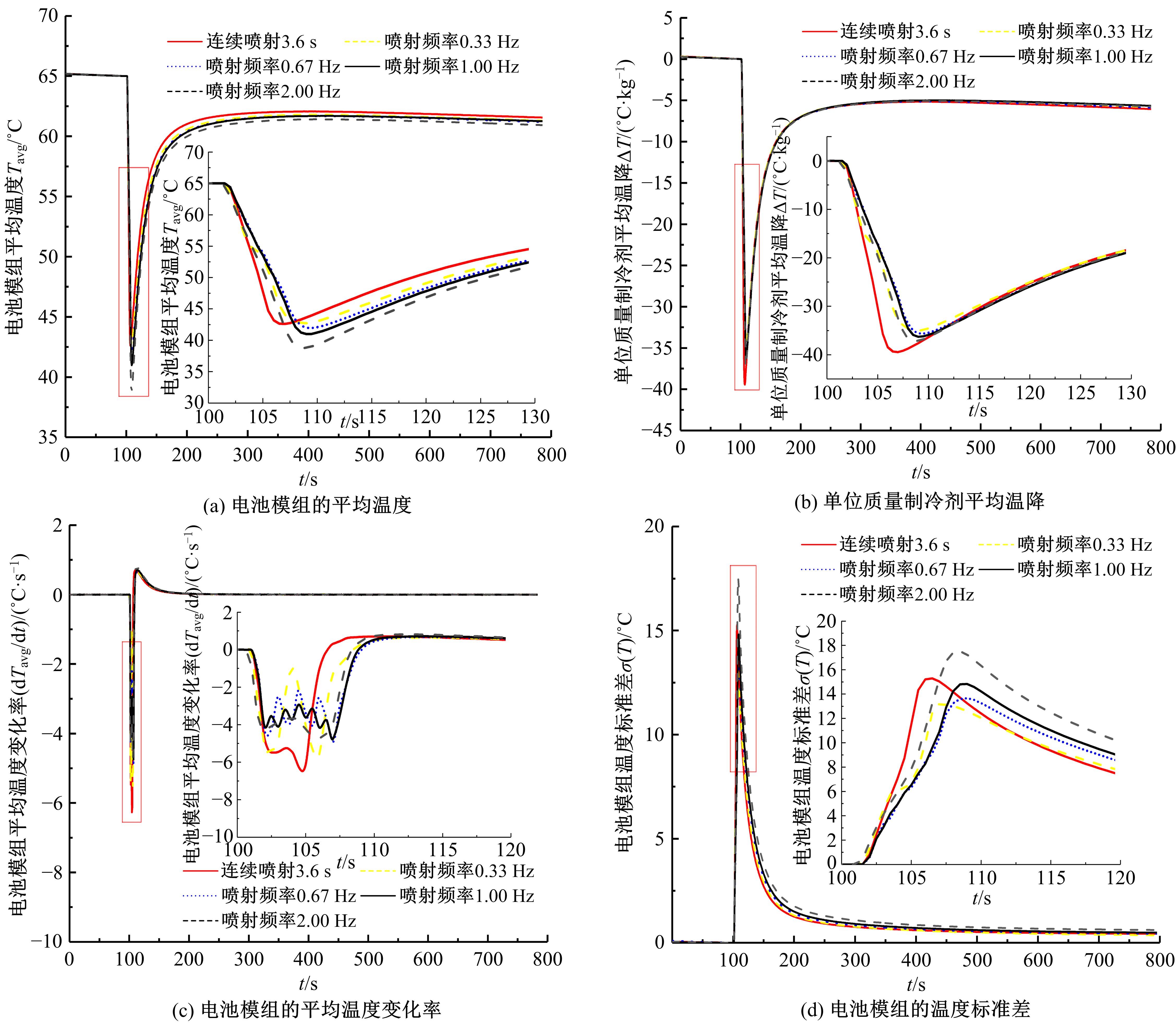

针对电动汽车行驶过程中动力电池的热失控问题,提出一种动力电池应急热管理系统,将高压液态制冷剂直接喷射至电池表面,对过热电池进行应急管控。搭建试验台并进行实验,分析喷射时长、喷射占空比和喷射频率对系统冷却效果的影响。实验结果表明:连续喷射5 s时,单位质量制冷剂平均温降远低于连续喷射6 s,可达-41.94 ℃/kg,制冷剂利用效率有所提升;当脉冲喷射占空比为90%时,系统的冷却效果和对制冷剂的利用效率均超过相同实验条件下的连续喷射,系统冷却能力提升可达10%;当脉冲喷射喷射频率为2 Hz时,系统冷却能力超过相同实验条件下的连续喷射,冷却能力提升达19.4%。

中图分类号:

- U469

| 1 | Yan W, Gao Q, Wang G, et al. A review on research status and key technologies of battery thermal management and its enhanced safety[J]. International Journal of Energy Research, 2018, 42: 4008-4033. |

| 2 | Yang W, Zhou F, Zhou H, et al. Thermal performance of axial air cooling system with bionic surface structure for cylindrical lithium-ion battery module[J]. International Journal of Heat and Mass Transfer, 2020, 161: 120307. |

| 3 | Mohammadian S K, Rassoulinejad-Mousavi S M, Zhang Y. Thermal management improvement of an air-cooled high-power lithium-ion battery by embedding metal foam[J]. Journal of Power Sources, 2015, 296: 305-313. |

| 4 | Zhang F, Lin A, Wang P, et al. Optimization design of a parallel air-cooled battery thermal management system with spoilers[J]. Applied Thermal Engineering, 2021, 182: 116062. |

| 5 | 张天时, 宋东鉴, 高青, 等. 电动汽车动力电池液体冷却系统构建及其工作过程仿真[J]. 吉林大学学报:工学版, 2018, 48(2): 387-397. |

| Zhang Tian-shi, Song Dong-jian, Gao Qing, et al. Construction of power battery liquid cooling system for electric vehicle and simulation of its working process[J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(2): 387-397. | |

| 6 | 鲁佳佳. 纯电动车动力电池包液冷散热特性仿真分析 [D]. 成都: 电子科技大学机械工程学院, 2018. |

| Lu Jia-jia. The research and simulation analysis of heat dissipation with liquid cooling for the power battery pack of pure electric vehicles[D]. Chengdu:School of Mechatronics and Electrical Engineering, University of Electronic Science and Technology, 2018. | |

| 7 | 张天时, 宋东鉴, 高青, 等. 动力电池组扁管束液流热管理增效[J]. 吉林大学学报: 工学版, 2017, 47(4): 1032-1039. |

| Zhang Tian-shi, Song Dong-jian, Gao Qing, et al. Promotive effect on thermal management of power battery pack with liquid flow and flat tube bank[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(4): 1032-1039. | |

| 8 | Weng J, He Y, Ouyang D, et al. Thermal performance of PCM and branch-structured fins for cylindrical power battery in a high-temperature environment[J]. Energy Conversion and Management, 2019, 200: 112106. |

| 9 | Zou D, Ma X, Liu X, et al. Thermal performance enhancement of composite phase change materials(PCM) using graphene and carbon nanotubes as additives for the potential application in lithium-ion power battery[J]. International Journal of Heat and Mass Transfer, 2018, 120: 33-41. |

| 10 | Zou D, Liu X, He R, et al. Preparation of a novel composite phase change material(PCM) and its locally enhanced heat transfer for power battery module[J]. Energy Conversion and Management, 2019, 180: 1196-1202. |

| 11 | Wang Y, Wu J. Thermal performance predictions for an HFE-7000 direct flow boiling cooled battery thermal management system for electric vehicles[J]. Energy Conversion and Management, 2020, 207: 112569. |

| 12 | Hong S H, Dong S J, Park S, et al. Thermal performance of direct two-phase refrigerant cooling for lithium-ion batteries in electric vehicles[J]. Applied Thermal Engineering, 2020, 173: 115213. |

| 13 | He Z, Yan Y, Zhang Z. Thermal management and temperature uniformity enhancement of electronic devices by micro heat sinks: a review[J]. Energy, 2020, 216: 119223. |

| 14 | Kim J. Spray cooling heat transfer: the state of the art[J]. International Journal of Heat and Fluid Flow, 2007, 28(4): 753-767. |

| 15 | Wang J, Guo W, Xiong K, et al. Review of aerospace-oriented spray cooling technology[J]. Progress in Aerospace Sciences, 2020, 116: 100635. |

| 16 | 周华琴. 热表面脉冲式喷雾冷却的实验研究[D]. 天津: 天津大学机械工程学院, 2007. |

| Zhou Hua-qin. Experimental investigation of pulsed spray cooling on a hot surface[D]. Tianjin: College of Mechanical Engineering, Tianjin University, 2007. | |

| 17 | Gao Q, Liu Y, Wang G, et al. An experimental investigation of refrigerant emergency spray on cooling and oxygen suppression for overheating power battery[J]. Journal of Power Sources, 2019, 415: 33-43. |

| 18 | 刘媛. 间歇式喷雾冷却高热流表面机理研究[D]. 天津: 天津大学机械工程学院, 2008. |

| Liu Yuan. Experimental investigation of pulsed spray cooling on a hot surface[D]. Tianjin: College of Mechanical Engineering, Tianjin University, 2008. | |

| 19 | Liu Y, Gao Q, Wang G, et al. Experimental study on active control of refrigerant emergency spray cooling of thermal abnormal power battery[J]. Applied Thermal Engineering, 2021, 182: 116172. |

| 20 | Prada E, Domenico D D, Creff Y, et al. A coupled OD electrochemical ageing & electro-thermal Li-ion modeling approach for HEV/PHEV[C]∥IEEE Vehicle Power and Propulsion Conference, Olaize, France, 2011: 1-8. |

| [1] | 聂光明,谢波,田彦涛. 基于Frenet框架的协同自适应巡航控制算法设计[J]. 吉林大学学报(工学版), 2022, 52(7): 1687-1695. |

| [2] | 杨红波,史文库,陈志勇,郭年程,赵燕燕. 基于某二级减速齿轮系统的齿面修形优化[J]. 吉林大学学报(工学版), 2022, 52(7): 1541-1551. |

| [3] | 张家旭,郭崇,王晨,赵健,王欣志. 基于半实物仿真平台的自动泊车系统性能评价[J]. 吉林大学学报(工学版), 2022, 52(7): 1552-1560. |

| [4] | 郝帅,程川泰,王军年,张君媛,俞有. 运动型SUV驾驶室布置人机优化设计与测试评价[J]. 吉林大学学报(工学版), 2022, 52(7): 1477-1488. |

| [5] | 华琛,牛润新,余彪. 地面车辆机动性评估方法与应用[J]. 吉林大学学报(工学版), 2022, 52(6): 1229-1244. |

| [6] | 李雄,兰凤崇,陈吉清,童芳. Hybird III假人模型与CHUBM人体生物力学模型的正碰损伤对比[J]. 吉林大学学报(工学版), 2022, 52(6): 1264-1272. |

| [7] | 刘兴涛,刘晓剑,武骥,何耀,刘新天. 基于曲线压缩和极限梯度提升算法的锂离子电池健康状态估计[J]. 吉林大学学报(工学版), 2022, 52(6): 1273-1280. |

| [8] | 张英朝,李昀航,郭子瑜,王国华,张喆,苏畅. 长头重型卡车气动减阻优化[J]. 吉林大学学报(工学版), 2022, 52(4): 745-753. |

| [9] | 史文库,张曙光,张友坤,陈志勇,江逸飞,林彬斌. 基于改进海鸥算法的磁流变减振器模型辨识[J]. 吉林大学学报(工学版), 2022, 52(4): 764-772. |

| [10] | 庄蔚敏,陈沈,吴迪. 碳纤维增强复合材料包裹强化形式对钢管横向冲击性能的影响[J]. 吉林大学学报(工学版), 2022, 52(4): 819-828. |

| [11] | 李杰,陈涛,郭文翠,赵旗. 汽车非平稳随机振动空间域虚拟激励法及应用[J]. 吉林大学学报(工学版), 2022, 52(4): 738-744. |

| [12] | 李伟,宋海生,陆浩宇,史文库,王强,王晓俊. 复合材料板簧迟滞特性线性辨识方法[J]. 吉林大学学报(工学版), 2022, 52(4): 829-836. |

| [13] | 段亮,宋春元,刘超,魏苇,吕成吉. 基于机器学习的高速列车轴承温度状态识别[J]. 吉林大学学报(工学版), 2022, 52(1): 53-62. |

| [14] | 庄蔚敏,陈沈,王楠. 温度对车身钢铝胶铆连接结构热应力变化的影响[J]. 吉林大学学报(工学版), 2022, 52(1): 70-78. |

| [15] | 陈剑斌,周宋泽,费峰永,陈永龙,凌国平. 过盈量及滚花方式对装配式凸轮轴压装失效的影响[J]. 吉林大学学报(工学版), 2021, 51(6): 1959-1966. |

|

||