吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (1): 285-296.doi: 10.13229/j.cnki.jdxbgxb20210570

• 农业工程·仿生工程 • 上一篇

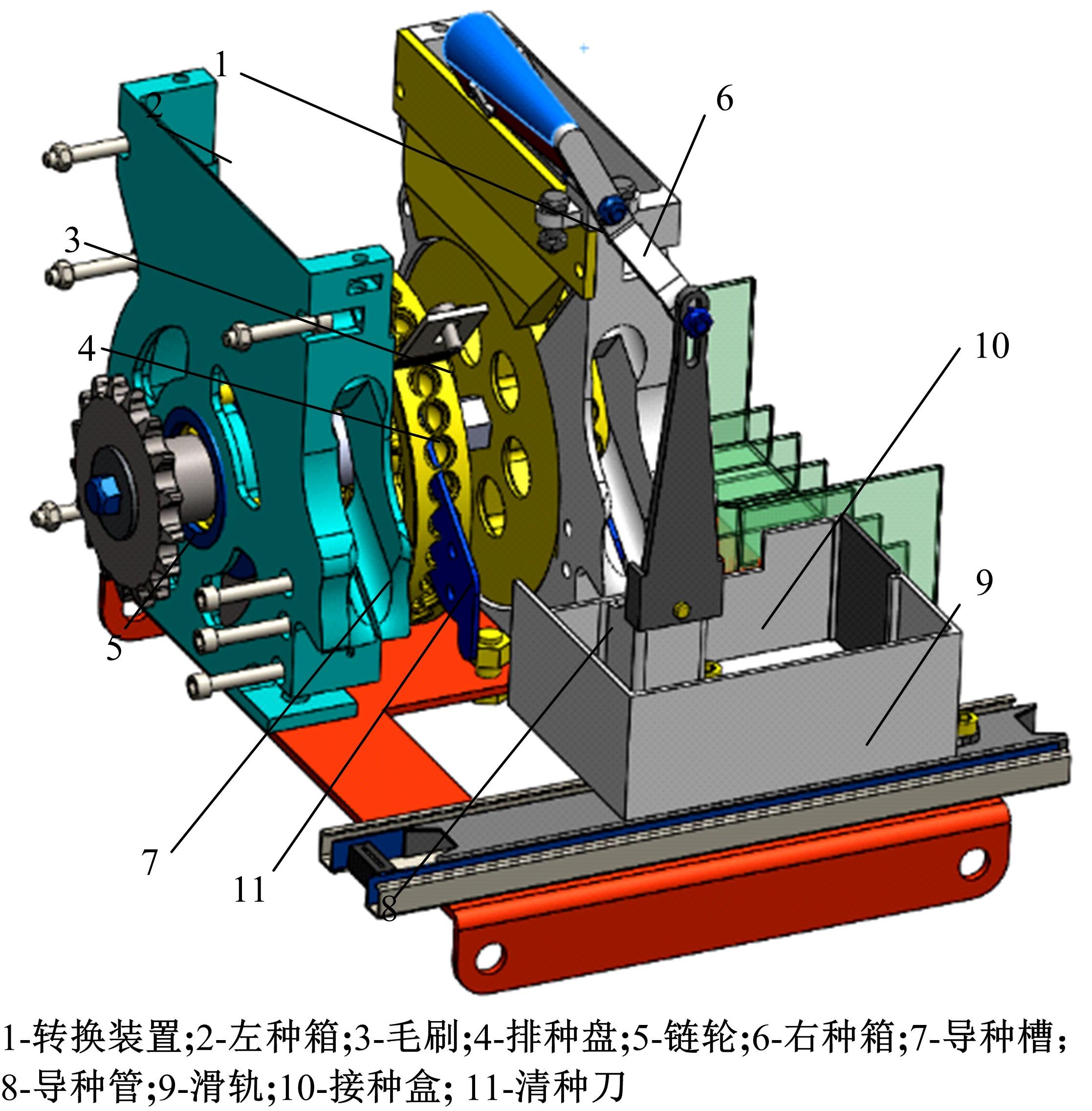

交替换岗式大豆小区育种排种器优化设计与试验

顿国强1( ),刘文辉1,毛宁1,吴星澎1,纪文义2,马洪岩3

),刘文辉1,毛宁1,吴星澎1,纪文义2,马洪岩3

- 1.东北林业大学 机电工程学院,哈尔滨 150040

2.东北农业大学 工程学院,哈尔滨 150030

3.黑龙江睿龙创新科技有限责任公司,哈尔滨 150050

Optimization design and experiment of alternate post changing seed metering device for soybean plot breeding

Guo-qiang DUN1( ),Wen-hui LIU1,Ning MAO1,Xing-peng WU1,Wen-yi JI2,Hong-yan MA3

),Wen-hui LIU1,Ning MAO1,Xing-peng WU1,Wen-yi JI2,Hong-yan MA3

- 1.College of Mechanical and Electrical Engineering,Northeast Forestry University,Harbin 150040,China

2.College of Engineering,Northeast Agricultural University,Harbin 150030,China

3.Heilongjiang Ruilong Innovation Technology Co. ,Ltd. ,Harbin 150050,China

摘要:

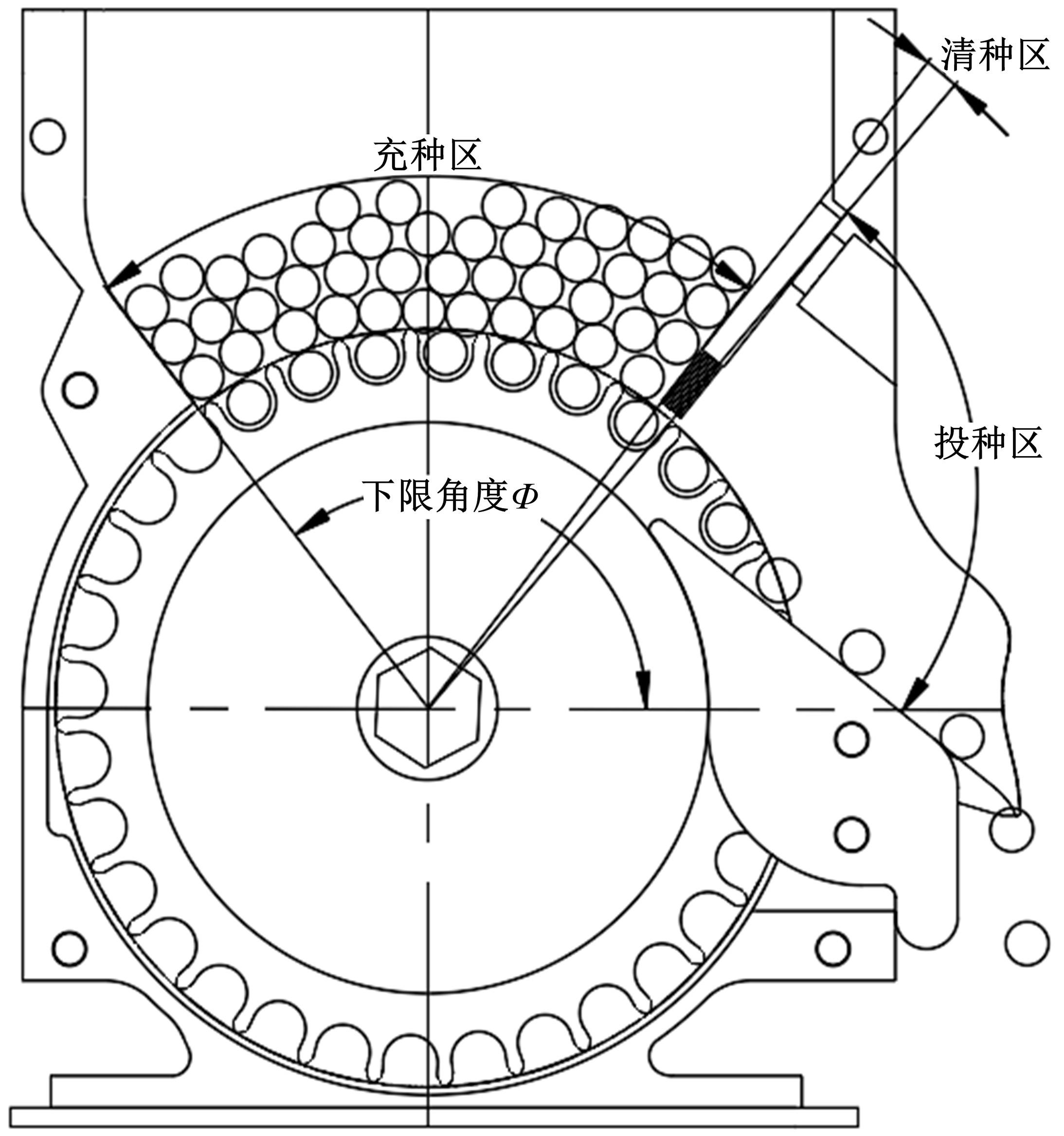

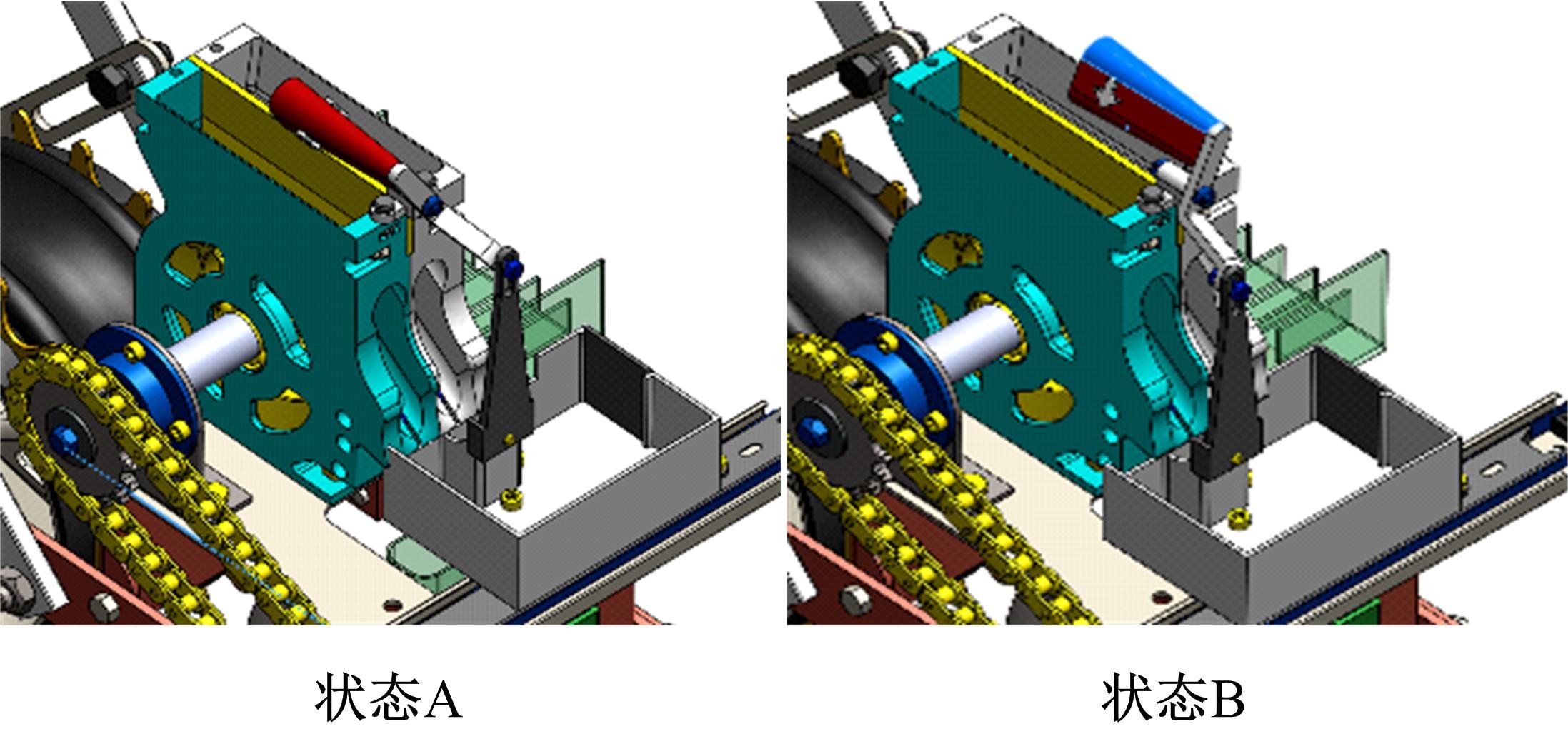

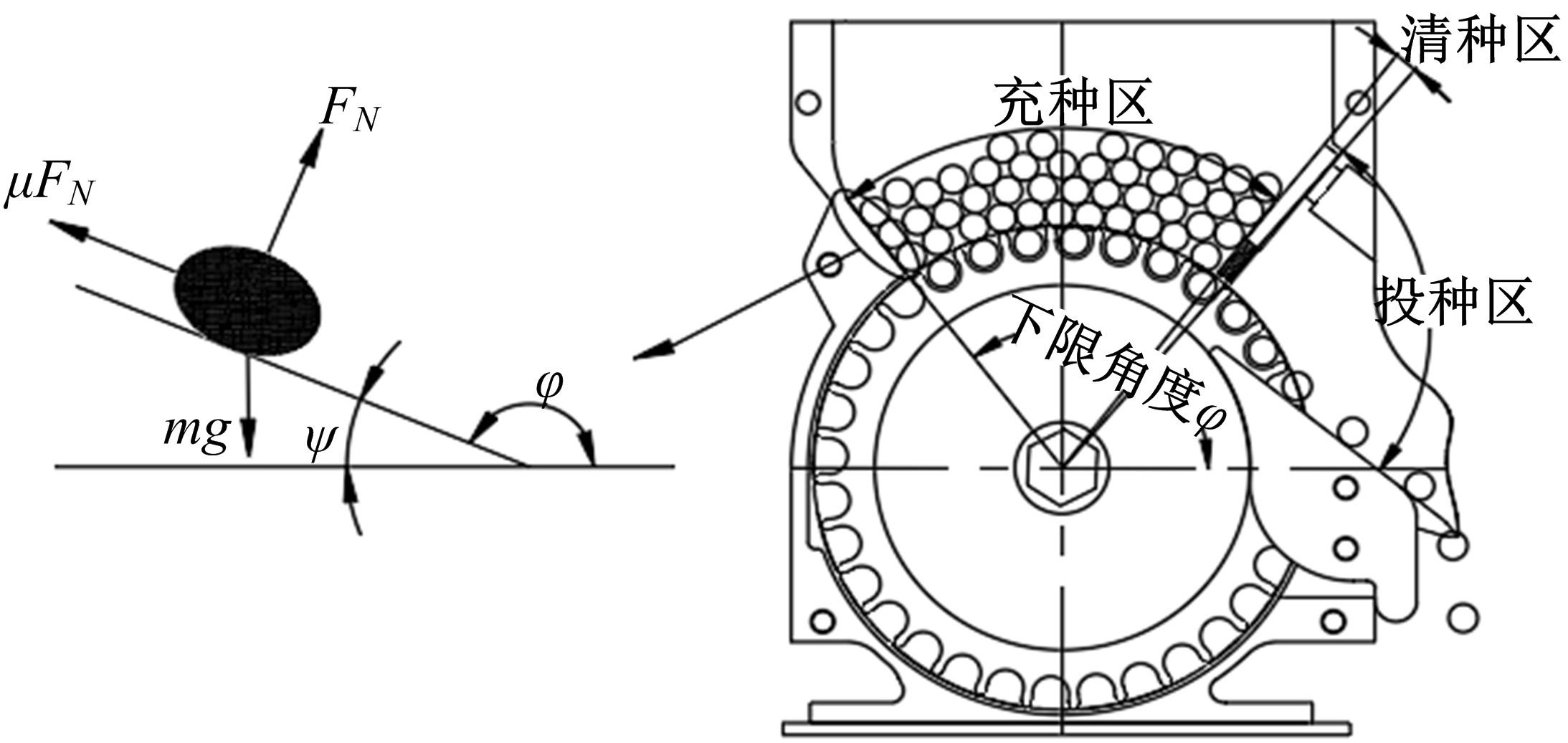

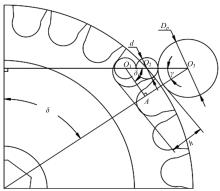

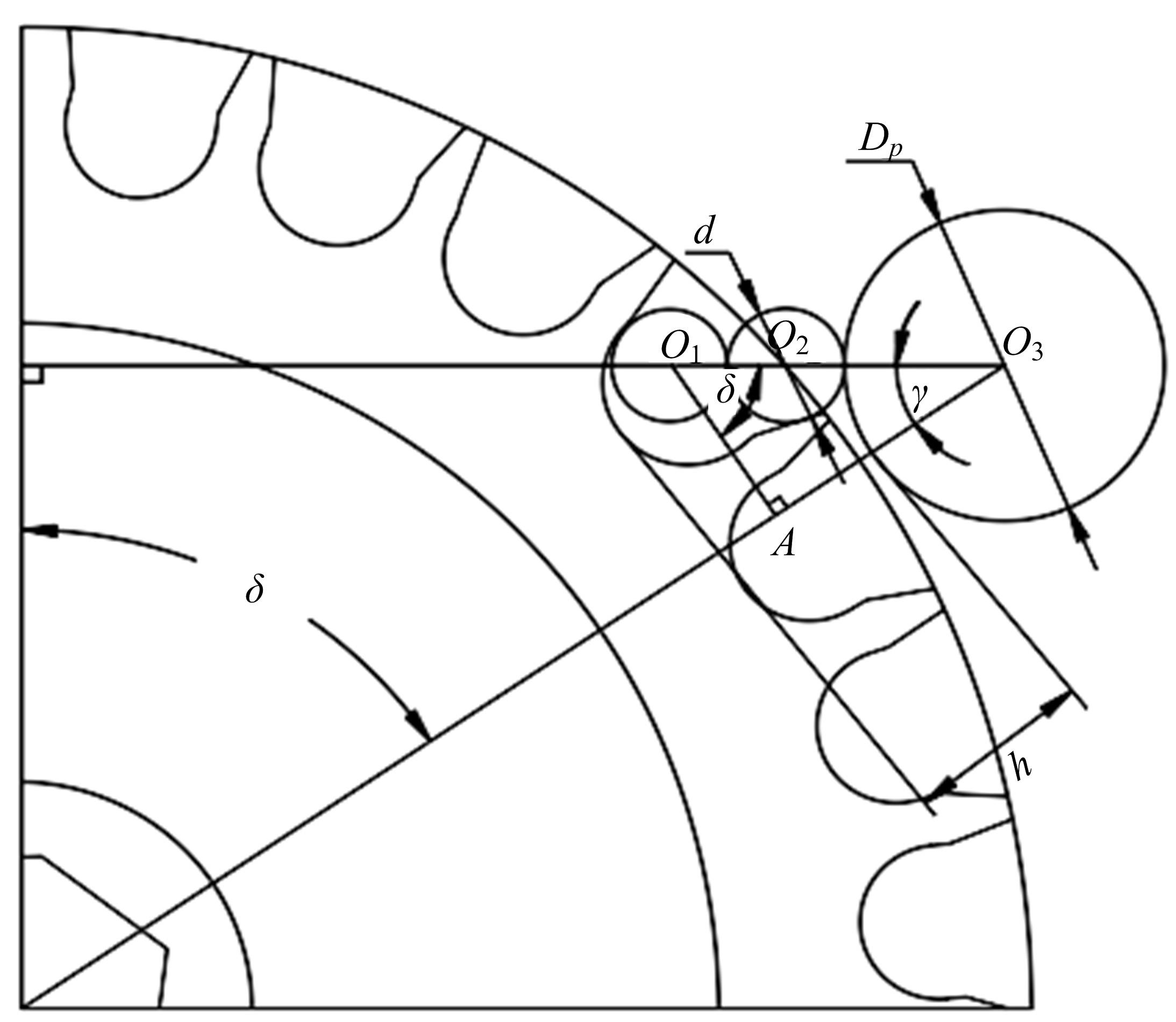

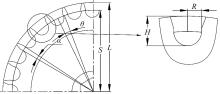

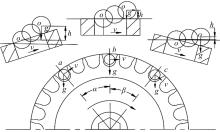

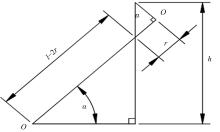

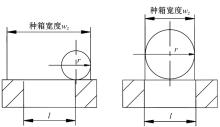

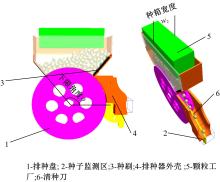

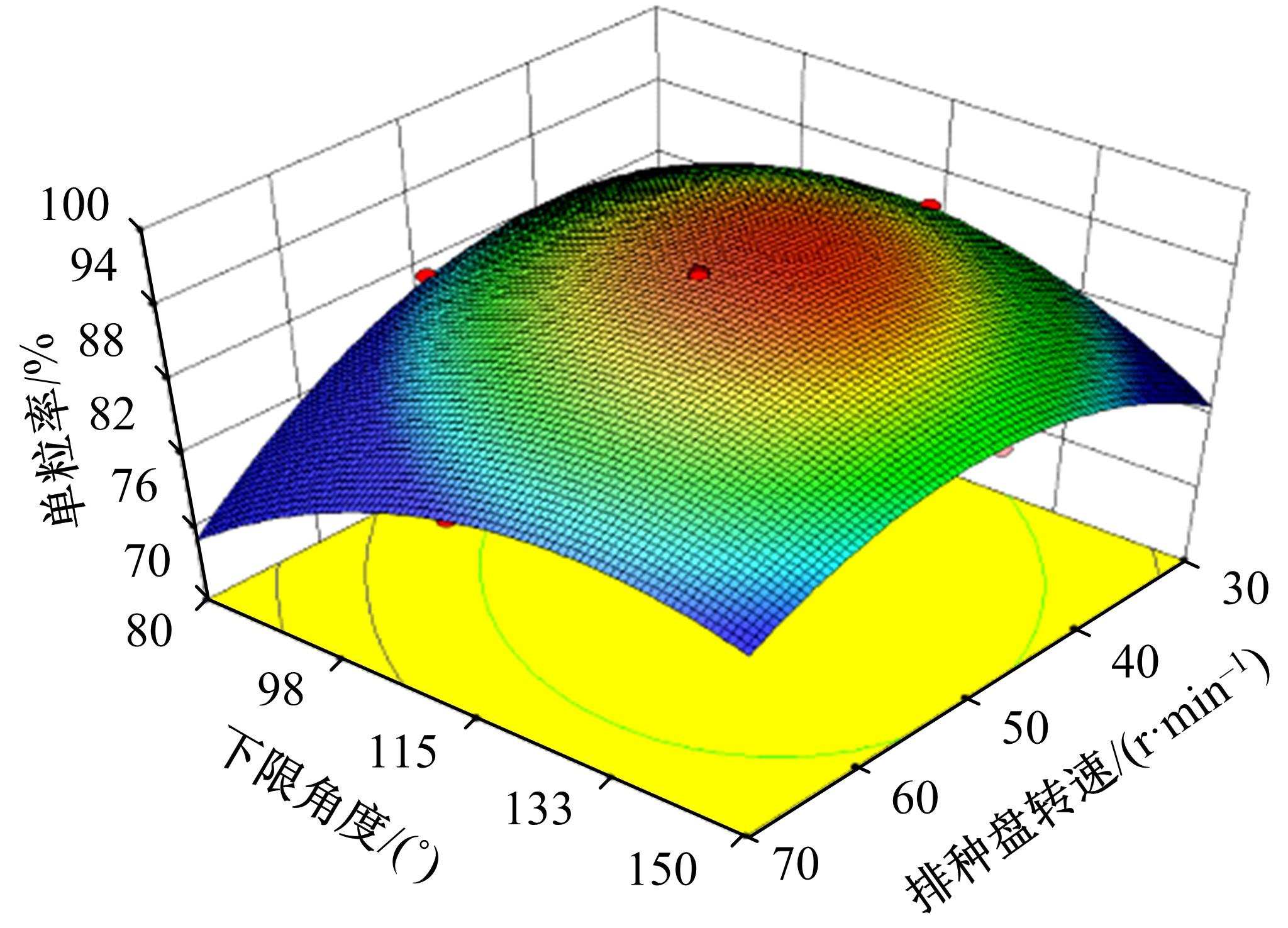

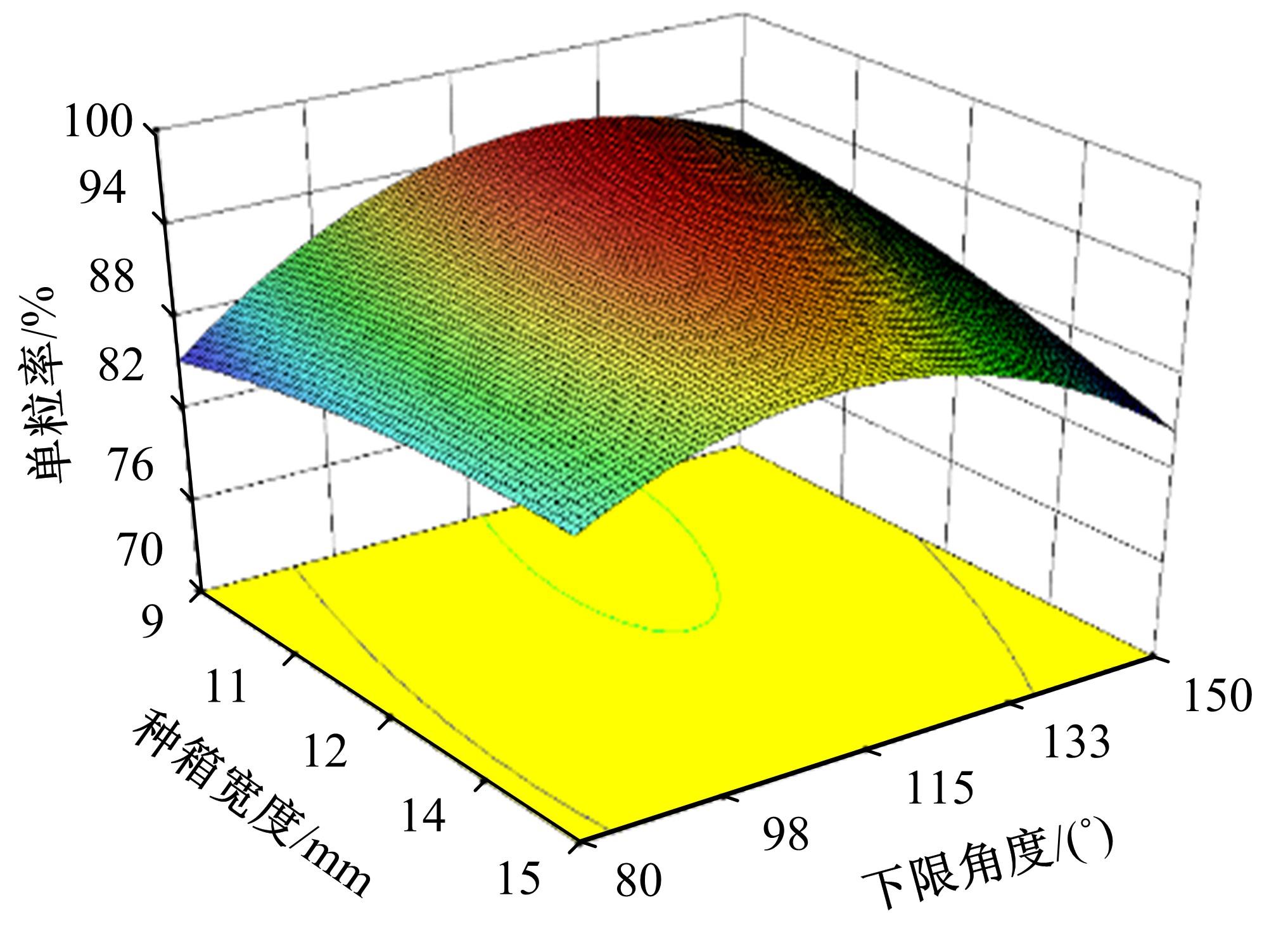

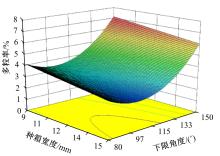

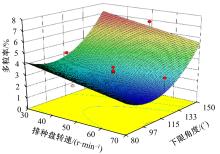

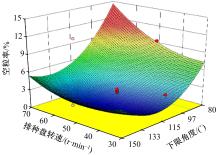

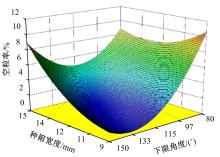

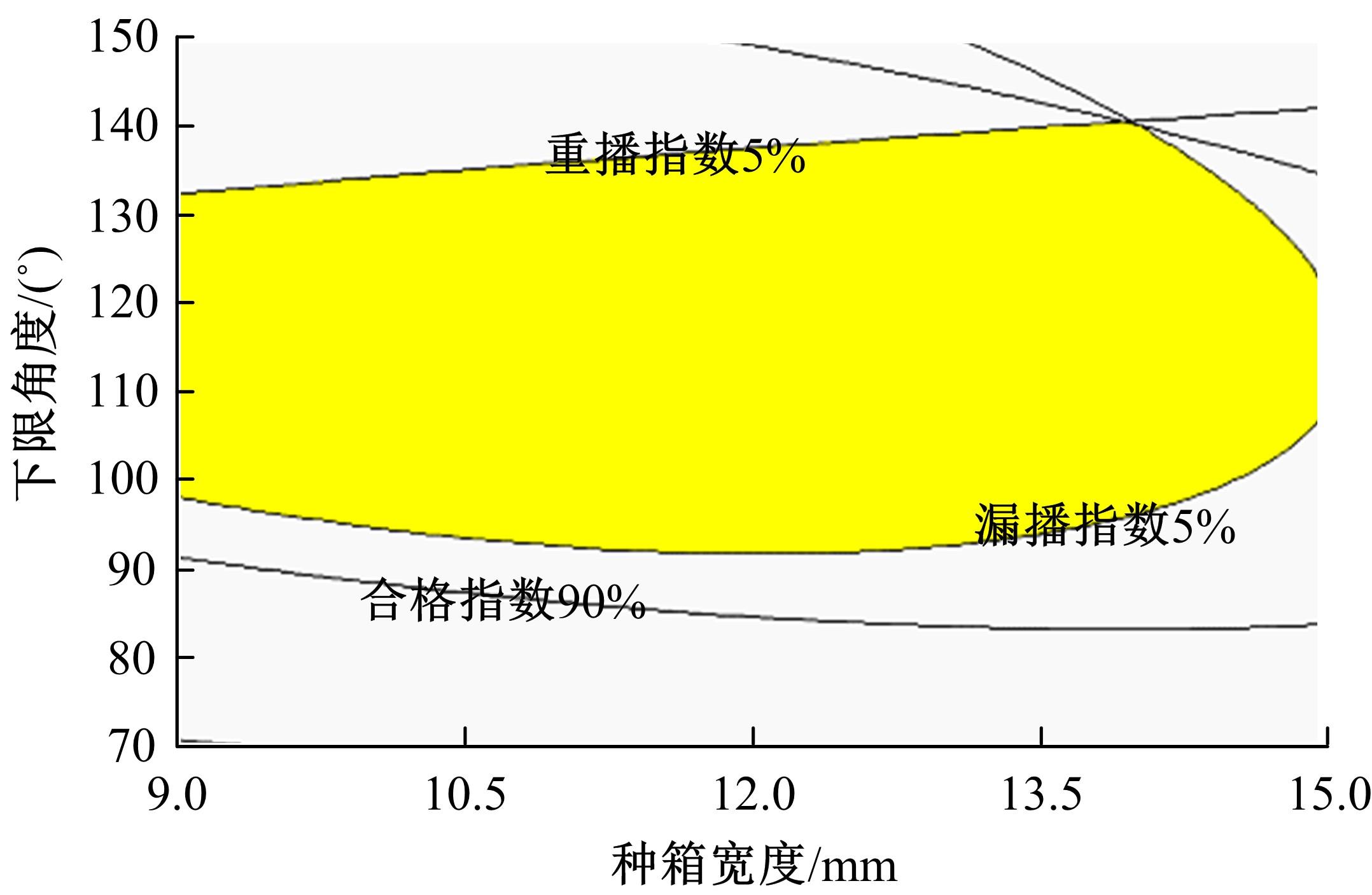

针对大豆小区育种清换种复杂的问题,设计了交替换岗大豆小区育种排种器。采用双排种盘交替作业完成清换种作业,采用离散元软件模拟了不同结构尺寸的排种器的投种、清种工作过程,以排种盘转速、下限角度、种箱宽度为试验因素,以单粒率、多粒率、空粒率为试验指标,采用3因素5水平二次回归正交旋转组合设计试验方法进行试验。试验结果表明:对单粒率,排种盘转速、下限角度、种箱宽度影响为极显著(P<0.01);对多粒率,排种盘转速、下限角度影响为极显著(P<0.01),种箱宽度为显著(P<0.05);对空粒率,排种盘转速、下限角度、种箱宽度影响为极显著(P<0.01)。当排种盘转速为45 r/min时,种箱宽度在9~15 mm,下限角度在92°~140°之间,可获得合格指数大于90%,重播指数小于5%,漏播指数小于5%。在最优组合参数下,制作排种器并进行田间试验,结果表明:仿真结果与理论结果基本吻合,该排种器清换种简洁高效,种子无残留,有效解决了清换种复杂的问题。

中图分类号:

- S223.2

| 1 | 倪坤晓, 何安华. 中国粮食供需形势分析[J]. 世界农业, 2021(2): 10-18. |

| Ni Kun-xiao, He An-hua. Analysis on the situation of grain supply and demand in China[J]. World Agriculture, 2021(2): 10-18. | |

| 2 | 袁承程, 张定祥, 刘黎明, 等. 近10年中国耕地变化的区域特征及演变态势[J]. 农业工程学报, 2021, 37(1): 267-278. |

| Yuan Cheng-cheng, Zhang Ding-xiang, Liu Li-ming, et al. Regional characteristics and spatial-temporal distribution of cultivated land change in China during 2009-2018[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(1): 267-278. | |

| 3 | 刘曙光, 尚书旗, 杨然兵, 等. 小区播种机的发展分析[J]. 农机化研究, 2011, 33(3): 237-241. |

| Liu Shu-guang, Shang Shu-qi, Yang Ran-bing, et al. Development analysis of community planter [J]. Journal of Agricultural Mechanization Research, 2011, 33(3): 237-241. | |

| 4 | 连政国, 王建刚, 杨兆慧, 等. 小区育种机械化在中国的发展[J]. 农业工程学报, 2012, 28(10): 140-144. |

| Lian Zheng-guo, Wang Jian-gang, Yang Zhao-hui, et al. Development of plot-sowing mechanization in China[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(10): 140-144. | |

| 5 | 尚书旗,杨然兵,殷元元,等. 国际田间试验机械的发展现状及展望[J]. 农业工程学报, 2010, 26(): 5-8. |

| Shang Shu-qi, Yang Ran-bing, Yin Yuan-yuan, et al. Current situation and development trend of mechanization of field experiments[J]. Transactions of the Chinese Society of Agricultural Engineering, 2010, 26(Sup.1): 5-8. | |

| 6 | 杨薇, 李建东, 方宪法, 等. 玉米育种播种机械化国内外现状及发展趋势[J]. 农业工程, 2018, 8(6): 9-15. |

| Yang Wei, Li Jian-dong, Fang Xian-fa, et al. Domestic and foreign current situation and development trend of seeding mechanization in maize breeding[J]. Agricultural Engineering, 2018, 8(6): 9-15. | |

| 7 | Lian Zheng-guo, Wang Jian-gang, Yang Zhao-hui, et al. Development of plot-sowing mechanization in China[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(Sup.2): 140-145. |

| 8 | 周家鹏, 王延耀. 小区播种机净种系统的研究[J]. 农机化研究, 2016, 38(10): 109-113. |

| Zhou Jia-peng, Wang Yan-yao. Plot seeder seed-clearing system research[J]. Journal of Agricultural Mechanization Research, 2016, 38(10): 109-113. | |

| 9 | 姜峰. 机动式大豆育种精密播种机的研究[D]. 哈尔滨:东北农业大学工程学院, 2012. |

| Jiang Feng. Study on motorized precision planter for soybean breeding [J]. Harbin:College of Engineering,Northeast Agricultural University, 2012. | |

| 10 | 谷金龙, 陈海涛, 顿国强. 2BXJ-4(A)型大豆小区育种精 量播种机的设计与试验研究[J]. 大豆科学, 2014, 33(5): 742-747. |

| Gu Jin-long, Chen Hai-tao, Guo-qiang Dun. Design and experimental study on 2BXJ-4(A) precision seeder for soybean breeding in plot[J]. Soybean science, 2014, 33(5): 742-747. | |

| 11 | 黄珊珊, 陈海涛, 王业成. 插装式大豆小区播种机排种系统预充种清种机构的设计[J]. 大豆科学, 2017, 36(4): 626-631. |

| Huang Shan-shan, Chen Hai-tao, Wang Ye-cheng, et al. Design of pre filling and cleaning mechanism for seed metering system of plug in soybean plot planter [J]. Soybean Science, 2017, 36 (4): 626-631. | |

| 12 | 陈海涛, 王洪飞, 王业成. 三叶式自动清换种大豆育种气吸排种器设计与试验[J]. 农业机械学报, 2020, 51(12): 75-85. |

| Chen Hai-tao, Wang Hong-fei, Wang Ye-cheng, et al. Design and experiment of three-leaf type air-suction seed meter with automatic clear and replace seeds features for soybean plot test[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(12): 75-85. | |

| 13 | 孙殿君, 蒋洪蔚, 胡国华. 大豆垄上三行“大垄密”栽培技术[J]. 大豆科技, 2014, 22(1): 20-24. |

| Sun Dian-jun, Jiang Hong-wei, Hu Guo-hua. Cultivation technique of "wide ridge dense planting"in soybean[J]. Soybean Science and Technology, 2014, 22(1): 20-24. | |

| 14 | 蔡婧驰,张涛,邓宝英,等.自走式小区精量播种机在小麦育种中的使用总结[J]. 农业与技术, 2019, 39(1): 80-83. |

| Cai Jing-chi, Zhang Tao, Deng Bao-ying, et al. Application summary of self-propelled plot precision planter in wheat breeding[J]. Agriculture and Technology, 2019, 39(1): 80-83. | |

| 15 | 张波屏. 播种机械设计原理[M]. 北京:机械工业出版社, 1982: 283-291. |

| 16 | Ess D R, Hawkins S E, Young J C, et al. Evaluation of the performance of a belt metering system for soybeans planted with a grain drill[J]. Applied Engineering in Agriculture, 2005, 21(6): 965-969. |

| 17 | 杨薇, 方宪法, 李建东, 等. 种腔自净型气吸式玉米小区精量排种器设计与试验[J]. 农业机械学报, 2019, 50(6): 64-73. |

| Yang Wei, Fang Xian-fa, Li Jian-dong, et al. Design and experiment of air-suction precision seed meter with self-clearing seed chamber for corn plot test[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019,50(6):64-73. | |

| 18 | Xu Tian-yue, Yu Jian-qun, Yu Ya-jun, et al. A modelling and verification approach for soybean seed particles using the discrete element method[J]. Advanced Powder Technology, 2018, 29: 3274-3290. |

| 19 | Cay Anil, Kocabiyik Habib, May Sahin. Development of an electro-mechanic control system for seed-metering unit of single seed corn planters part II: field performance[J]. Computers and Electronics in Agriculture, 2018 (145):11⁃17. |

| 20 | 施伟, 李哲, 姚应方, 等. 基于EDEM的内充式花生排种器排种性能仿真研究[J]. 农机化研究, 2021, 43(5): 183-189. |

| Shi Wei, Li Zhe, Yao Ying-fang, et al. Simulation study on seeding performance of inner-filling peanut seed-metering device based on EDEM[J]. Journal of Agricultural Mechanization Research, 2021, 43(5): 183-189. | |

| 21 | 徐浩, 陶栋材, 陶韵晖, 等. 基于EDEM的水稻槽轮排种器排种仿真与试验研究[J]. 中国农业科技导报, 2018, 20(3): 64-70. |

| Xu Hao, Tao Dong-cai, Tao Yun-hui, et al. Simulation and experimental research on rice seed metering device based on EDEM[J]. Journal of Agricultural Science and Technology, 2018, 20(3): 64-70. | |

| 22 | 顿国强, 于春玲, 杨永振, 等. 大豆育种排种盘型孔参数仿真优化与试验[J]. 农业工程学报, 2019, 35(19): 62-73. |

| Guo-qiang Dun, Yu Chun-ling, Yang Yong-zhen, et al. Parameter simulation optimization and experiment of seed plate type hole for soybean breeding[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(19): 62-73. | |

| 23 | 许健, 蔡宗寿, 甘义权, 等. 基于EDEM的倾斜圆盘勺式大豆排种器清种过程优化研究[J]. 东北农业大学学报, 2018, 49(10): 79-88. |

| Xu Jian, Cai Zong-shou, Gan Yi-quan, et al. Optimization study on seed clearing process for declined disc-scooptype soybean seed metering device based on EDEM[J]. Journal of Northeast Agricultural University, 2018, 49(10): 79-88. | |

| 24 | 王琛, 刘扬, 段俊兆, 等. 育种试验小区播种机排种器性能及应用分析[J]. 农业机械, 2012(28): 124-126. |

| Wang Chen, Liu Yang, Duan Jun-zhao. Performance and application analysis of seed metering device of planter in breeding experimental plot[J]. Agricultural Machinery, 2012(28): 124-126. | |

| 25 | 陆伟安, 黄世明, 冯天玉, 等. 型孔式排种器的设计与试验[J]. 湖北农业科学,2020, 59(16): 149-152. |

| Lu Wei-an, Huang Shi-ming, Feng Tian-yu, et al. Design and test of hole-type seed meter[J]. Hubei Agricultural Sciences, 2020, 59(16): 149-152. | |

| 26 | Yazgi Arzu, Degirmencioglu Adnan. Measurement of seed spacing uniformity performance of a precision metering unit as function of the number of holes on vacuum plate[J]. Measurement,2014,56:128⁃135. |

| 27 | 史嵩, 张东兴, 杨丽, 等.基于EDEM软件的气压组合孔式排种器充种性能模拟与验证[J]. 农业工程学报, 2015, 31(3): 62-69. |

| Shi Song, Zhang Dong-xing, Yang Li, et al. Simulation and verification of seed-filling performance of pneumatic-combined holes maize precision seed-metering device based on EDEM[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(3):62-69. | |

| 28 | 潘丽军. 试验设计与数据处理[M]. 南京:东南大学出版社, 2008. |

| 29 | 徐中儒. 回归分析与试验设计[M]. 北京:中国农业出版社, 1998. |

| 30 | 任露泉. 试验优化设计与分析[M]. 2版. 北京:高等教育出版社, 2003. |

| 31 | .中耕作物精密播种机产品质量分等 [S]. |

| 32 | . 单粒(精密)播种机试验方法 [S]. |

| [1] | 张茂健,金敬福,陈奕颖,陈廷坤. 轮式拖拉机对称结构的振动特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2136-2142. |

| [2] | 朱光强,李天宇,周福君,王文明. 鲜食玉米仿生摘穗装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1231-1244. |

| [3] | 彭勇,章秀芳,郭泽宇,陆学元,李彦伟. 离散元法分析集料接触特性对沥青混合料剪切疲劳寿命的影响[J]. 吉林大学学报(工学版), 2023, 53(1): 178-187. |

| [4] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [5] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

| [6] | 高文英,林静,李宝筏,王伟,谷士艳. 秸秆深埋还田机振动特性分析与结构优化[J]. 吉林大学学报(工学版), 2022, 52(4): 970-980. |

| [7] | 王同建,杨书伟,谭晓丹,陈晋市,刘同文,职振领. 基于DEM⁃MBD联合仿真的液压挖掘机作业性能分析[J]. 吉林大学学报(工学版), 2022, 52(4): 811-818. |

| [8] | 耿端阳,孙延成,牟孝栋,张国栋,姜慧新,朱俊科. 基于差速辊的青贮玉米籽粒破碎仿真试验及优化[J]. 吉林大学学报(工学版), 2022, 52(3): 693-702. |

| [9] | 刘佳杰,马兰,向伟,颜波,文庆华,吕江南. 4QM-4.0型麻类青饲料联合收获机研制[J]. 吉林大学学报(工学版), 2022, 52(12): 3039-3048. |

| [10] | 曾百功,黎奎良,叶进,任丽丽,Rashidov Jaloliddin,张明. 工厂化上海青流水线收割装置的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2756-2764. |

| [11] | 万星宇,廖庆喜,蒋亚军,单伊尹,周宇,廖宜涛. 饲用油菜机械化收获切碎过程离散元仿真与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2735-2745. |

| [12] | 朱光强,李天宇,周福君. 鲜食玉米仿生摘穗柔性夹持输送装置设计与试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2486-2500. |

| [13] | 钟昌均,王忠彬,柳晨阳. 悬索桥主索鞍承载力影响因素及结构优化[J]. 吉林大学学报(工学版), 2021, 51(6): 2068-2078. |

| [14] | 梁荣庆,钟波,蒙贺伟,孙志民,坎杂. 4QJ⁃3型青贮燕麦捡拾割台的研制[J]. 吉林大学学报(工学版), 2021, 51(5): 1887-1896. |

| [15] | 袁佳诚,王昌,何坤,万星宇,廖庆喜. 油菜联合收获机筛下物组分质量比对清选性能的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1897-1907. |

|

||