吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (8): 2212-2218.doi: 10.13229/j.cnki.jdxbgxb.20211086

• 车辆工程·机械工程 • 上一篇

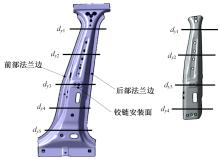

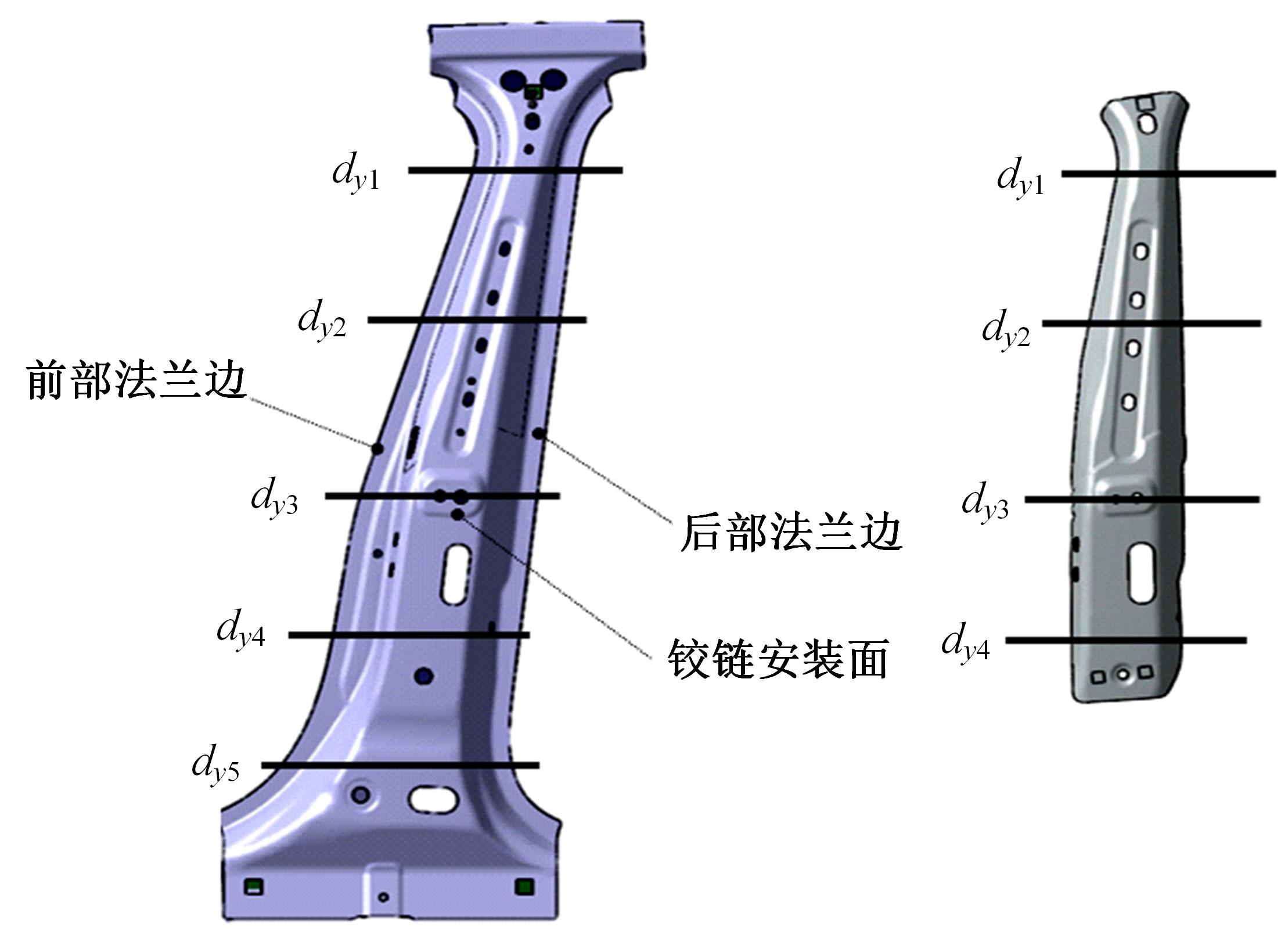

白车身B柱焊接变形模拟及预变形控制方法

- 一汽-大众汽车有限公司 预批量中心,长春 130011

Welding deformation and compensation method of B-pillar in body-in-white

Xiao ZHOU( ),Yi-jie LIANG(

),Yi-jie LIANG( ),Zhong-xuan XI,Yu-tao WANG

),Zhong-xuan XI,Yu-tao WANG

- Vor Serien Center,FAW-Volkswagen Automotive Co. ,Ltd. ,Changchun 130011,China

摘要:

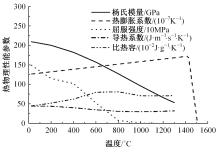

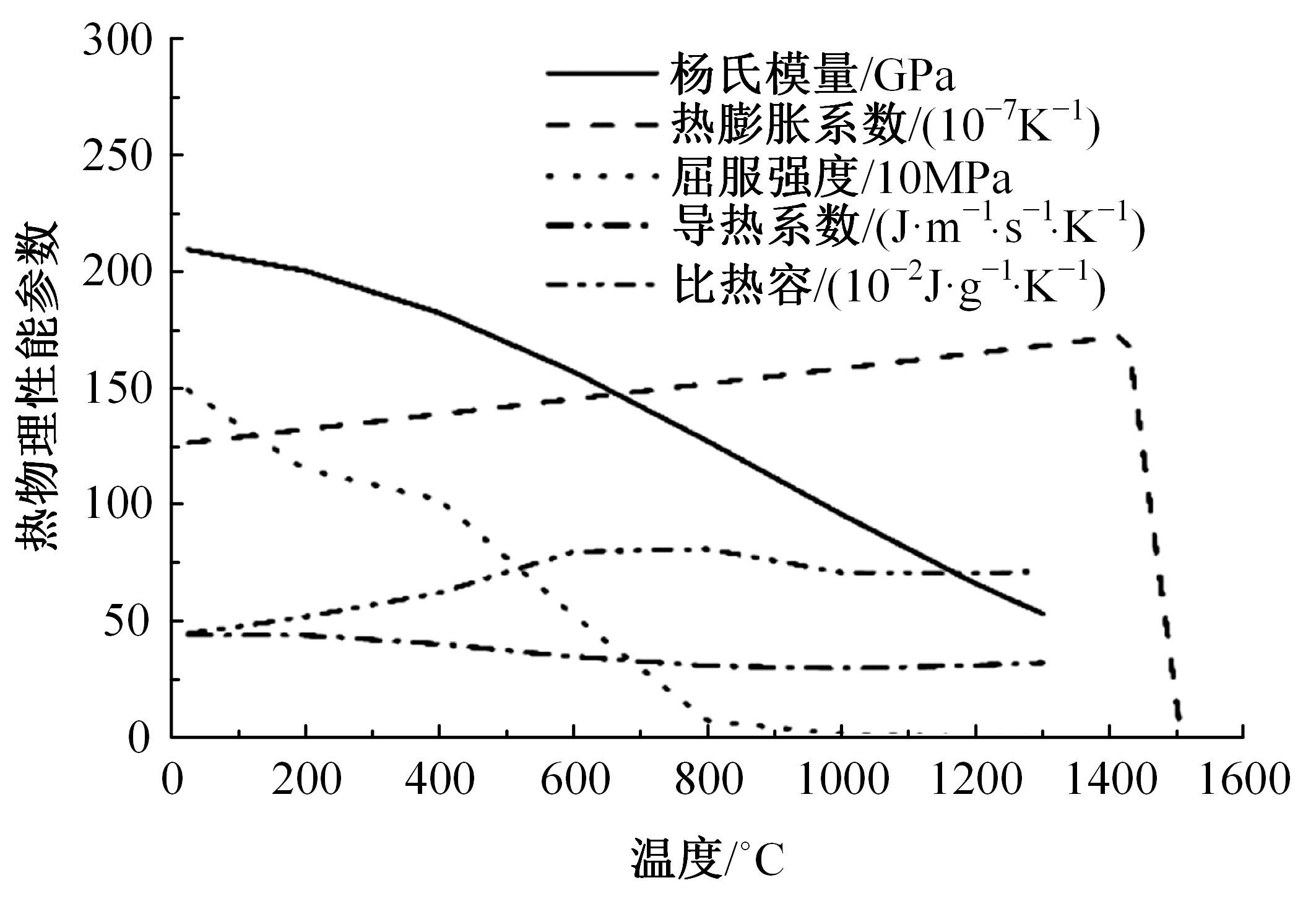

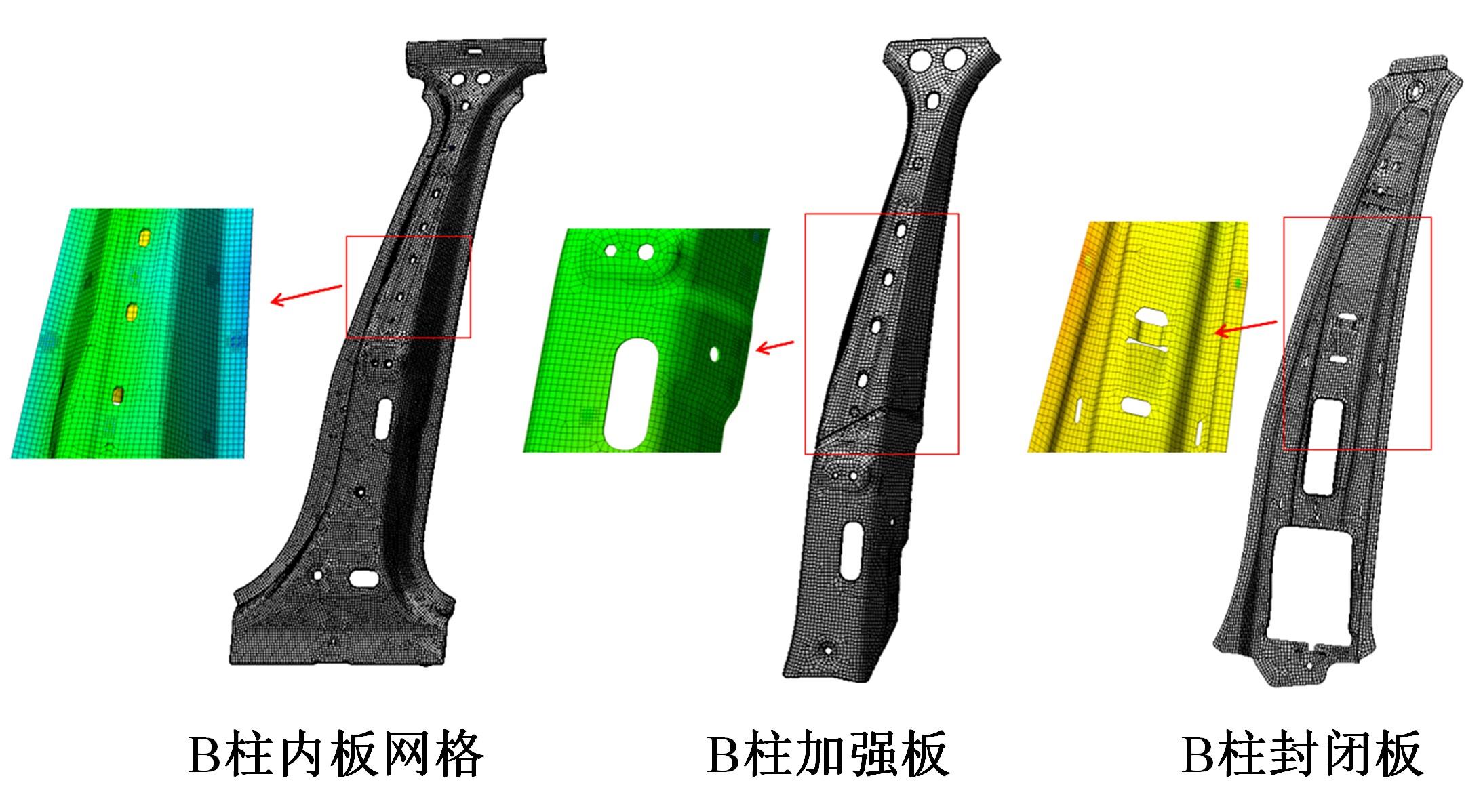

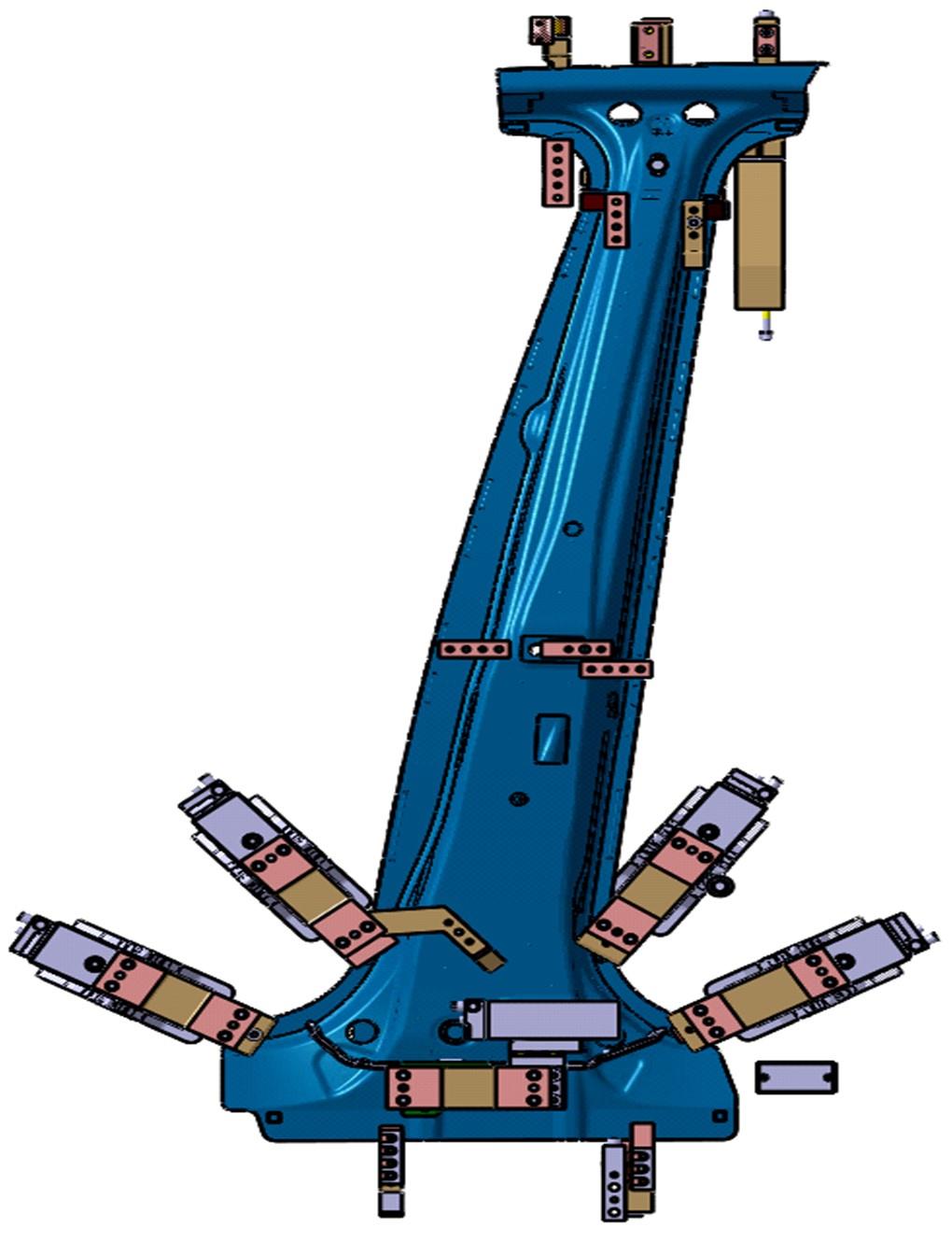

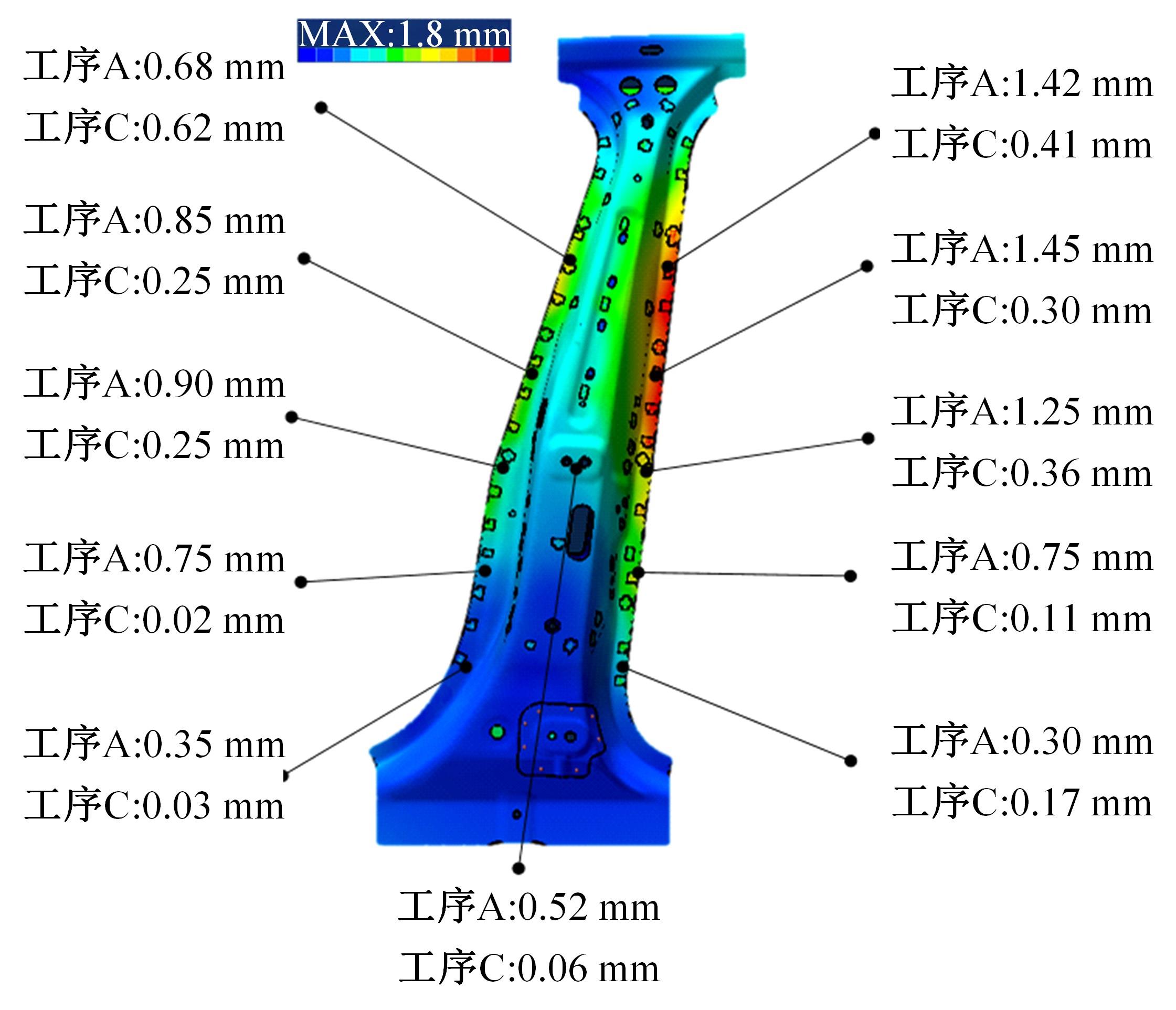

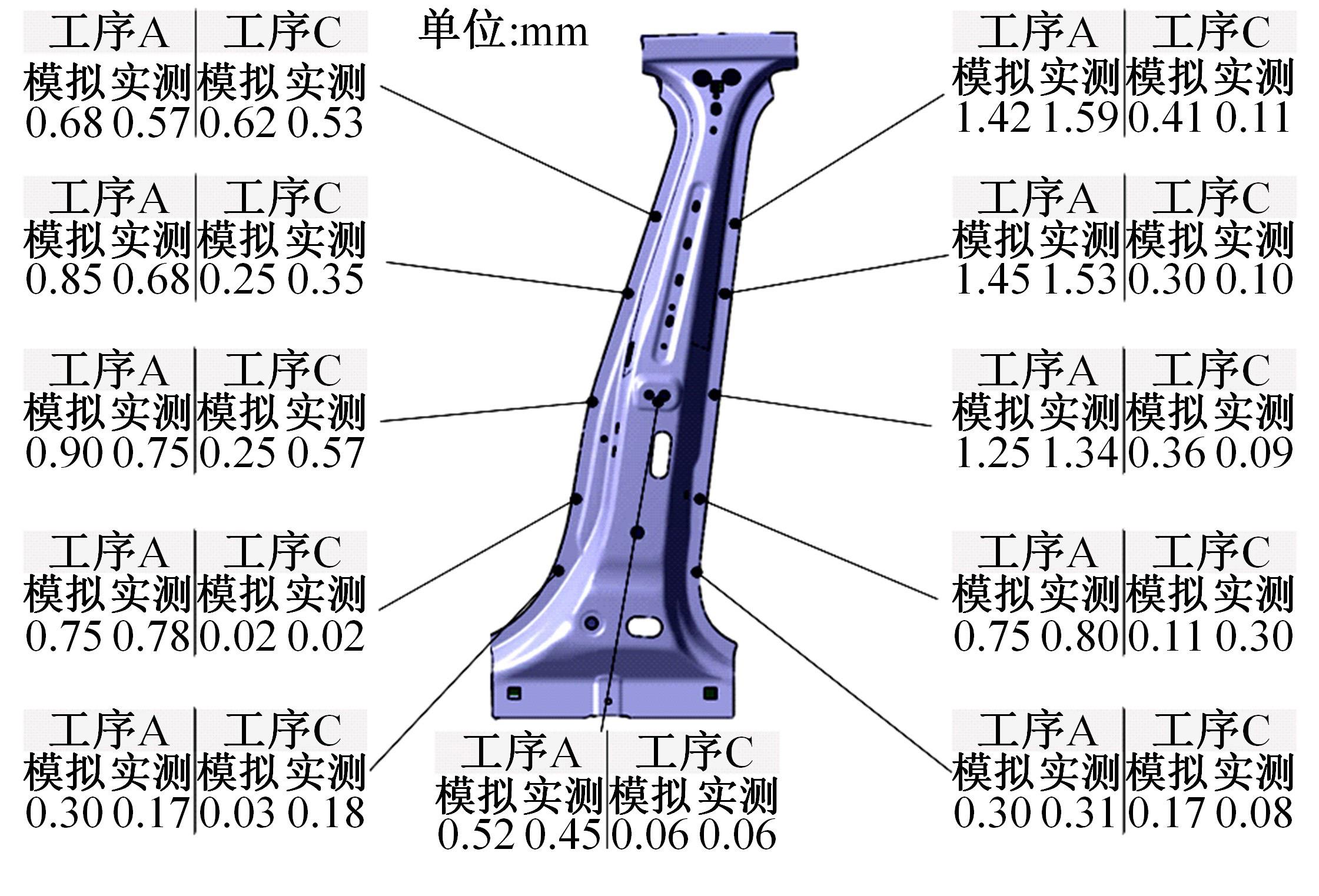

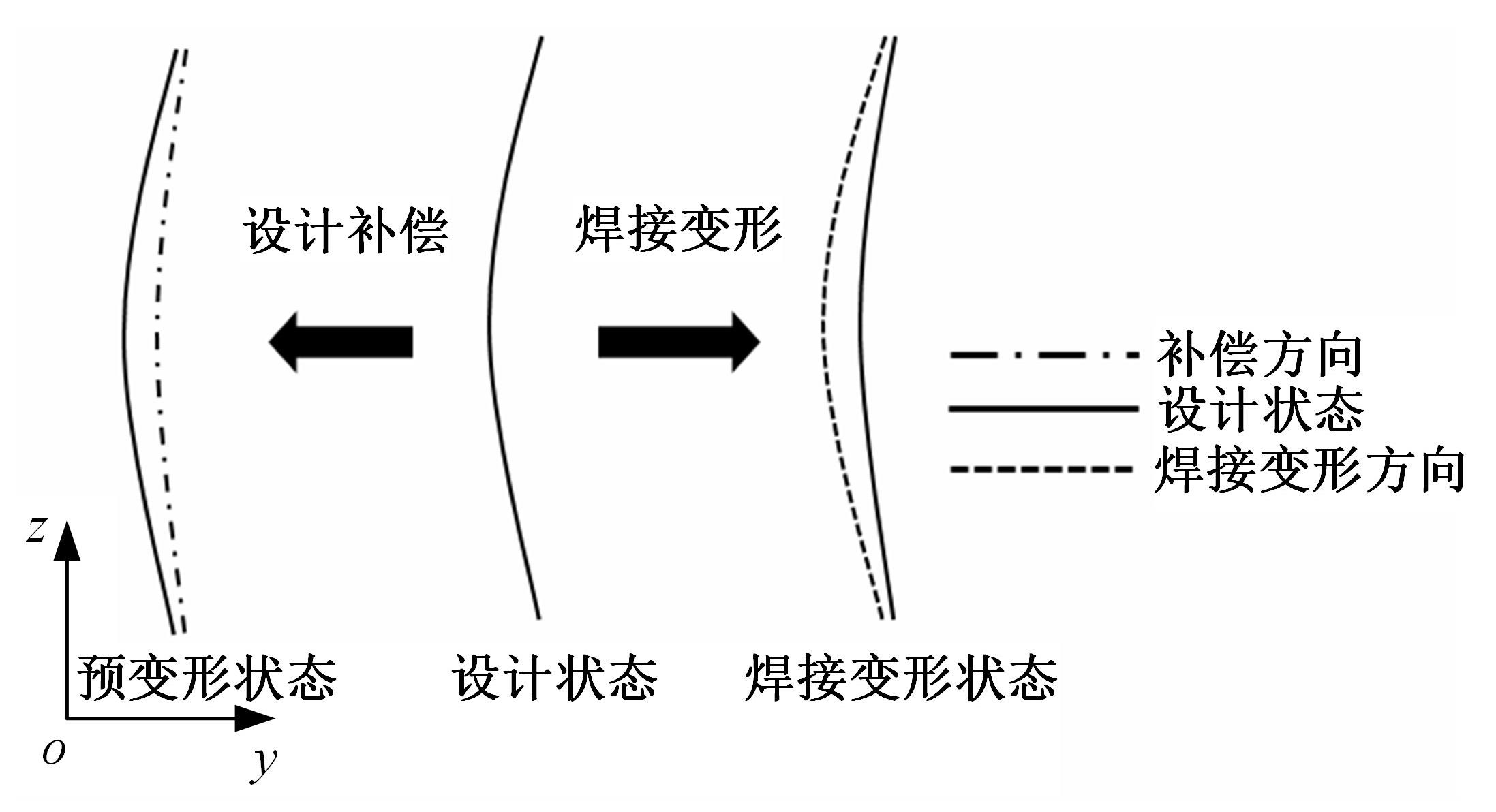

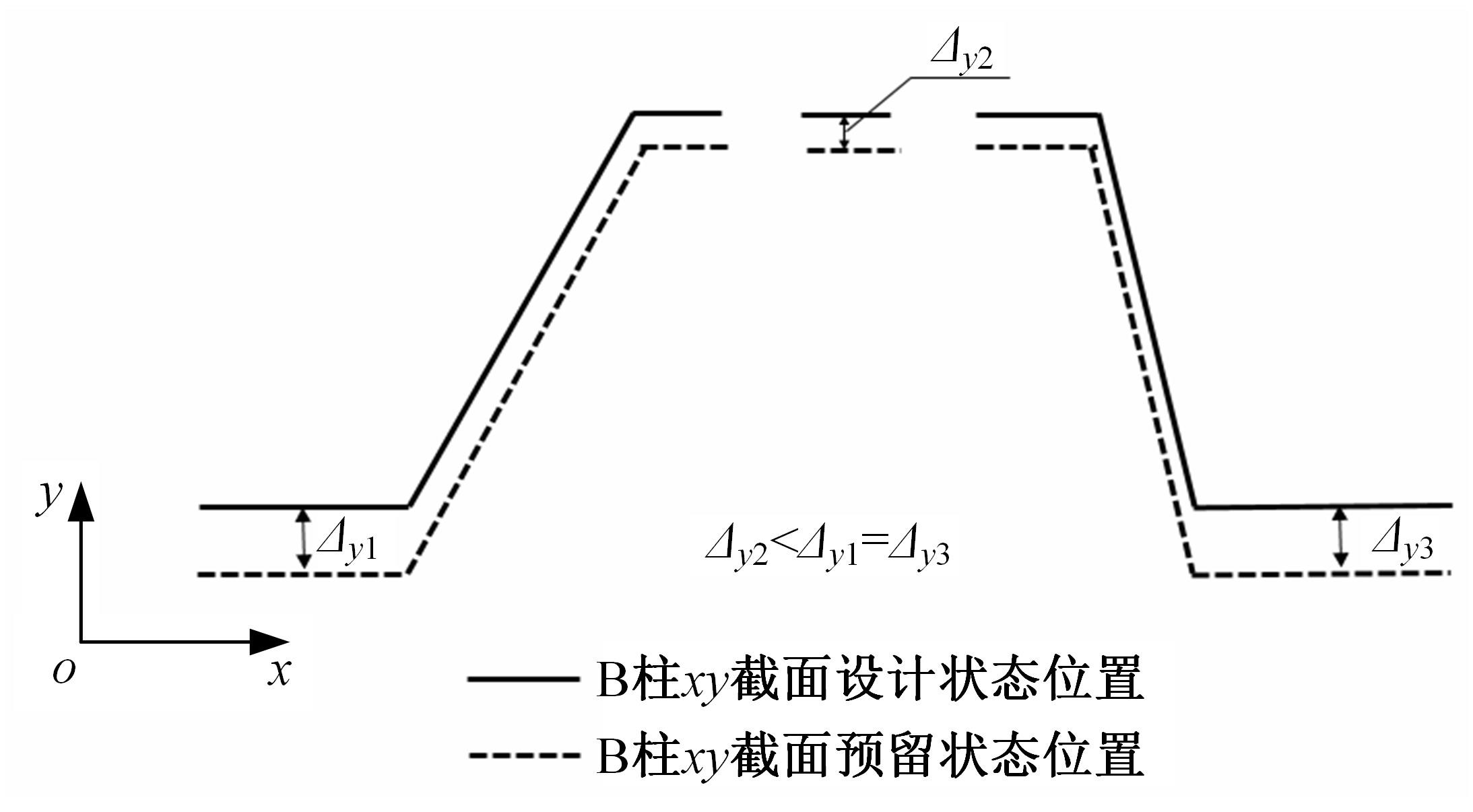

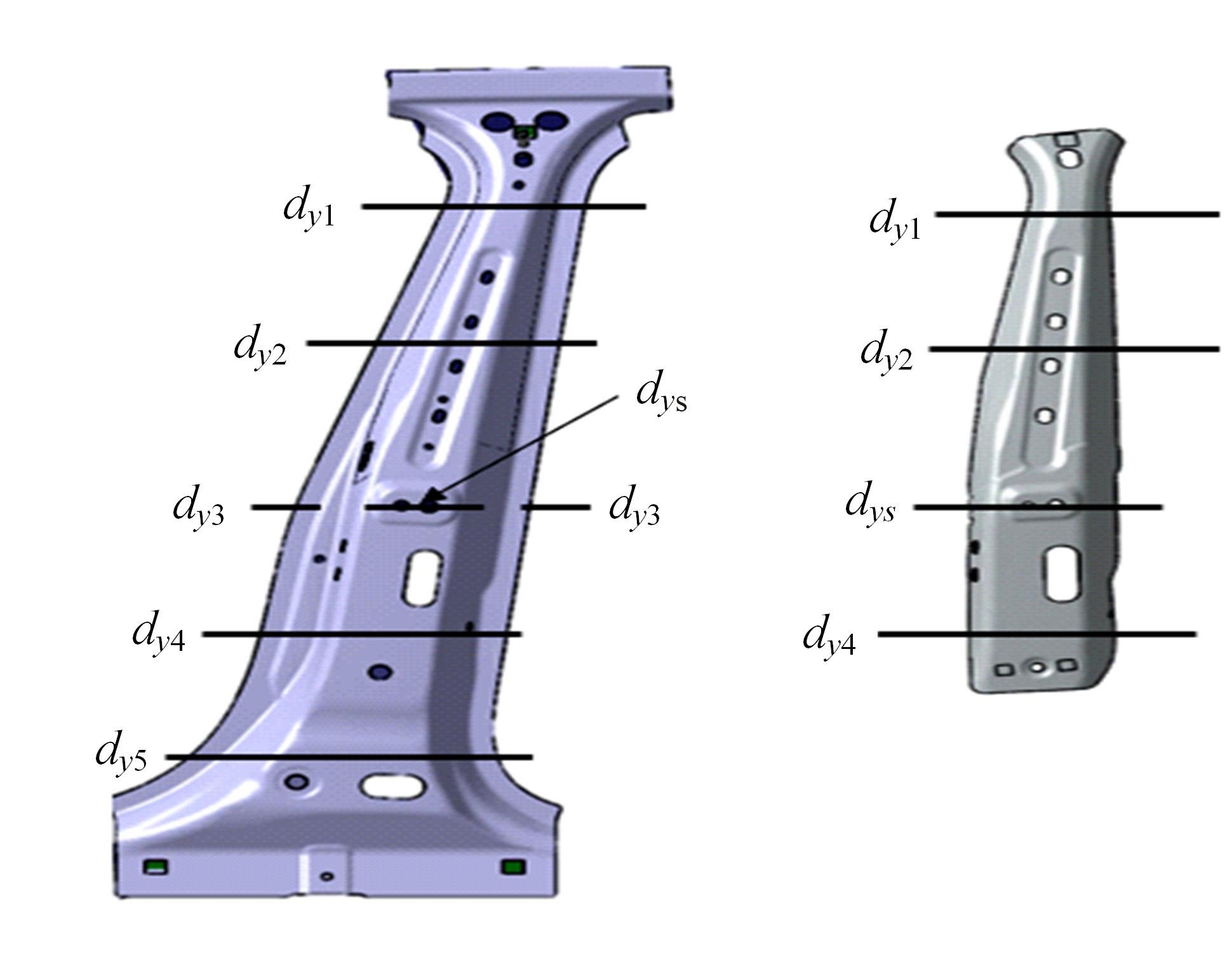

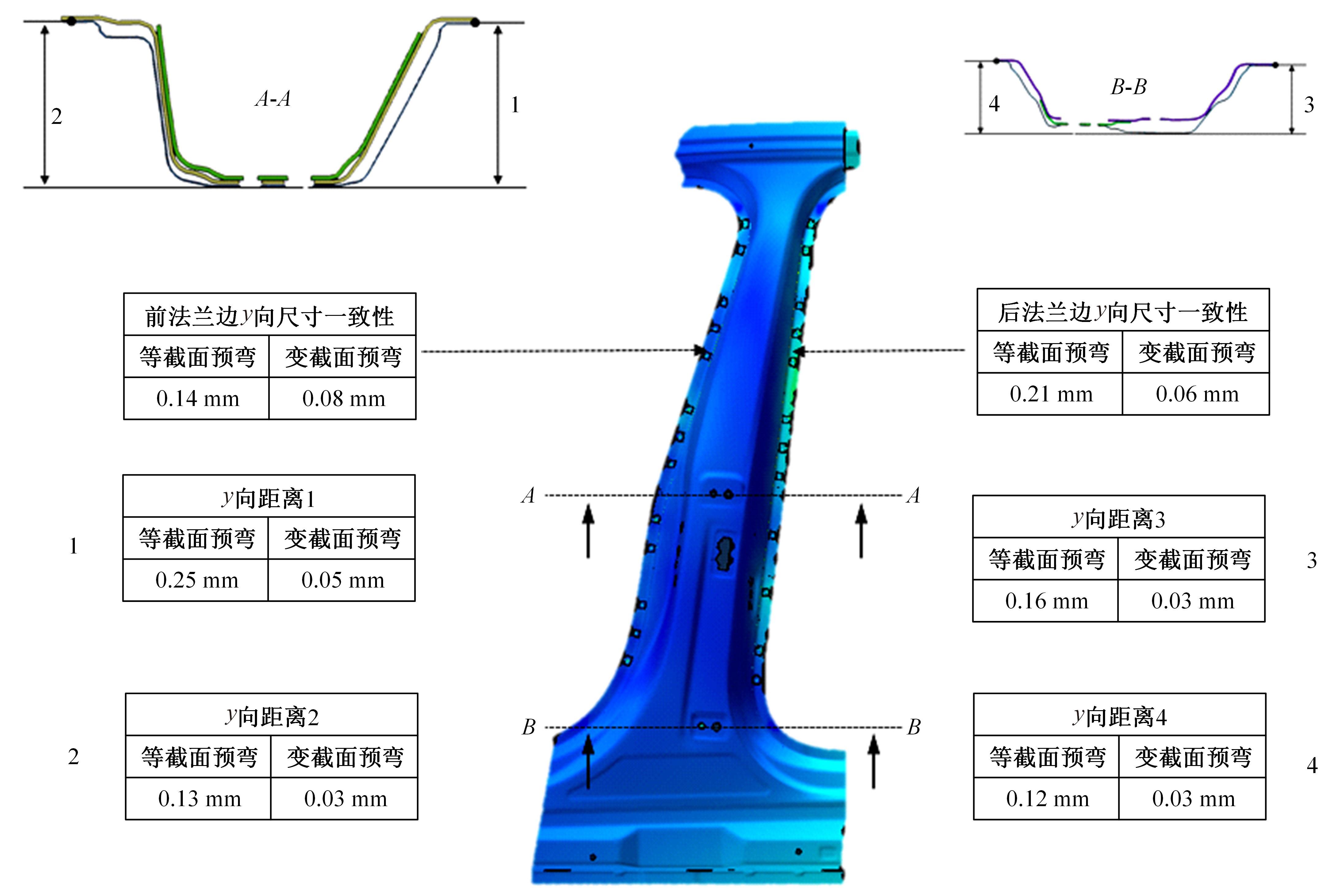

为解决白车身B柱焊接变形带来的整车匹配及功能性问题,基于有限元方法对车身B柱区域焊接过程进行全工序模拟,预测B柱焊接变形量,结合试验及测量的手段对预测精度进行评估,结果表明:基于有限元方法的B柱焊接变形模拟具有良好的预测精度。提出了带补偿的等截面预弯和变截面预弯两种焊接预变形控制方式,通过多目标优化模型计算预变形量,并结合有限元模拟对两种预变形控制方式进行验证,结果表明:采用两种预变形方式进行尺寸控制的零件经过焊接后均可实现精度符合设计要求的车身尺寸,且采用变截面预弯的控制精度优于带补偿的等截面预弯的控制精度。

中图分类号:

- TG404

| 1 | 王庆, 刘钊, 黄平华, 等. 白车身激光焊接过程的变形预测及几何补偿方法[J]. 上海交通大学学报, 2019, 53(1): 62-68. |

| Wang Qing, Liu Zhao, Huang Ping-hua, et al. Distortion prediction and geometry compensation method for laser welding-induced distortion of body-in-white[J]. Journal of Shanghai Jiao Tong University, 2019, 53(1): 62-68. | |

| 2 | 黄平华, 郭志强, 王一栋, 等. 车身B柱零件焊接变形链式仿真的实现及应用[C]∥第十七届中国CAE工程分析技术年会论文集, 海南, 中国, 2021: 328-331. |

| 3 | 董文超, 陆善平, 李殿中. 焊接顺序对大型薄板装甲钢结构焊接变形的影响[J]. 焊接学报, 2015, 36(7): 43-46. |

| Dong Wen-chao, Lu Shan-ping, Li Dian-zhong. Effect of welding sequence on welding distortion of large sized thin aasmor steel structure[J]. Transactions of China Welding Institution, 2015, 36(7): 43-46. | |

| 4 | 卢晶晶, 刑彦锋. 基于SYSWELD薄板焊接变形研究[J]. 热加工工艺, 2016, 45(11): 174-177. |

| Lu Jing-jing, Xing-Yan-feng. Study on welding deformation of thin plate using SYSWELD Software[J]. Hot Working Technology, 2016, 45(11): 174-177. | |

| 5 | 汪文芳. 轿车车身尺寸控制与夹具工艺设计分析[D].武汉: 武汉理工大学汽车工程学院, 2010. |

| Wang Wen-fang. Analysis of car body size control and fixture process design[D]. Wuhan: School of Automotive Engineering, Wuhan University of Technology, 2010. | |

| 6 | 汪建华, 陆皓, 魏良武. 固有应变有限元法预测焊接变形理论及其应用[J]. 焊接学报, 2002,23(6): 36-40. |

| Wang Jian-hua, Lu Hao, Liang-wu Wie. Theory and application of inherent strain finite element method in predicting welding deformation[J]. Transactions of China Welding Institution, 2002,23(6): 36-40. | |

| 7 | 李娅娜. 焊接变形预测与控制的数值方法研究及工程应用[D].大连: 大连交通大学机车车辆工程学院, 2010. |

| Li Ya-na. Research and engineering application on numerical method of welding deformation prediction and control[D]. Dalian: College of Locomotive and Rolling Stovk Engineering, Dalian Jiaotong University, 2010. | |

| 8 | 吴言高, 李午申, 邹宏军, 等. 焊接数值模拟技术发展现状[J]. 焊接学报, 2002, 23(3): 89-92. |

| Wu Yan-gao, Li Wu-shen, Zhou Hong-jun, et al. State-of-the-art of numerical simulation in welding[J]. Transactions of China Welding Institution, 2002, 23(3): 89-92. | |

| 9 | Dean D, Hidekazu M. Numerical simulation of temperature field and residual stress in multi-pass welds in stainless steel pipe and comparison with experimental measurements[J]. Computational Materials Science, 2006, 37(3):269-277. |

| 10 | 赵海燕, 吴骏巍, 陆向明, 等. 基于局部-整体有限元法的薄壁筒焊接变形计算[J]. 清华大学学报:自然科学版, 2017, 57(5): 449-453. |

| Zhao Hai-yan, Wu Jun-wei, Lu Xiang-ming, et al. Calculation of welding deformation of thin-walled tube based on local-global finite element method[J]. Journal of Tsinghua University (Natural Science Edition), 2017, 57(5): 449-453. | |

| 11 | 薛忠明, 顾兰, 张彦华. 激光焊接温度场数值模拟[J]. 焊接学报, 2003, 24(2): 79-82. |

| Xue Zhong-ming, Gu Lan, Zhang Yan-hua. Numerical simulation of temperature field in laser welding[J]. Transactions of China Welding Institution, 2003, 24(2): 79-82. |

| [1] | 陈鑫,张冠宸,赵康明,王佳宁,杨立飞,司徒德蓉. 搭接焊缝对铝合金焊接结构轻量化设计的影响[J]. 吉林大学学报(工学版), 2023, 53(5): 1282-1288. |

| [2] | 龙海波,杨家其,尹靓,赵学彧,向子权. 基于鲁棒优化的不确定需求下应急物资配送多目标决策模型[J]. 吉林大学学报(工学版), 2023, 53(4): 1078-1084. |

| [3] | 何颖,樊俊松,王巍,孙庚,刘衍珩. 无人机空地安全通信与航迹规划的多目标联合优化方法[J]. 吉林大学学报(工学版), 2023, 53(3): 913-922. |

| [4] | 刘汉武,雷雨龙,阴晓峰,付尧,李兴忠. 增程式电动汽车增程器多点控制策略优化[J]. 吉林大学学报(工学版), 2022, 52(8): 1741-1750. |

| [5] | 陈昭明,邹劲松,王伟,石明全. 改进粒子群神经网络融合有限元分析的铸锻双控动态成型多目标优化[J]. 吉林大学学报(工学版), 2022, 52(7): 1524-1533. |

| [6] | 马永杰,陈敏. 基于卡尔曼滤波预测策略的动态多目标优化算法[J]. 吉林大学学报(工学版), 2022, 52(6): 1442-1458. |

| [7] | 姜斌祥,姜彤彤,王永雷. 基于文化遗传算法的毒品检验区块链共识算法优化[J]. 吉林大学学报(工学版), 2022, 52(3): 684-692. |

| [8] | 黄晗,闫庆昊,向枳昕,杨鑫涛,陈金宝,许述财. 基于虾螯的仿生多胞薄壁管耐撞性分析及优化[J]. 吉林大学学报(工学版), 2022, 52(3): 716-724. |

| [9] | 张立杰,阿喜塔,田笑,李稳. 基于Gamma过程的加速退化试验多目标优化设计[J]. 吉林大学学报(工学版), 2022, 52(2): 361-367. |

| [10] | 孙宝凤,任欣欣,郑再思,李国一. 考虑工人负荷的多目标流水车间优化调度[J]. 吉林大学学报(工学版), 2021, 51(3): 900-909. |

| [11] | 周炳海,何朝旭. 基于静态半成套策略的多目标准时化物料配送调度[J]. 吉林大学学报(工学版), 2021, 51(3): 910-916. |

| [12] | 黄继承,沈成,纪爱敏,李显旺,张彬,田昆鹏,刘浩鲁. 工业大麻收割机切割⁃输送关键部件作业参数优化[J]. 吉林大学学报(工学版), 2021, 51(2): 772-780. |

| [13] | 周炳海,吴琼. 基于多目标的机器人装配线平衡算法[J]. 吉林大学学报(工学版), 2021, 51(2): 720-727. |

| [14] | 马芳武,韩丽,吴量,李金杭,杨龙帆. 基于遗传与粒子群算法的隔振平台减振性能优化[J]. 吉林大学学报(工学版), 2020, 50(5): 1608-1616. |

| [15] | 陈学深,陈涛,武涛,马旭,曾令超,陈林涛. 覆草冬种马铃薯收获机稻草分离机构设计与试验[J]. 吉林大学学报(工学版), 2020, 50(2): 749-757. |

|

||