吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (3): 650-656.doi: 10.13229/j.cnki.jdxbgxb.20220474

• 车辆工程·机械工程 • 上一篇

转向架用SMA490BW钢不同焊接区域裂纹扩展速率

- 1.沈阳航空航天大学 航空制造工艺数字化国防重点学科实验室,沈阳 110136

2.沈阳航空航天大学 机电工程学院,沈阳 110136

3.沈阳飞机工业(集团)有限公司,沈阳 110034

Crack growth rate of SMA490BW steel in different welding areas for bogie

Li HUI1( ),Lei JIN2,Wan-wan SONG3,Song ZHOU2(

),Lei JIN2,Wan-wan SONG3,Song ZHOU2( ),Jin-lan AN1

),Jin-lan AN1

- 1.Key Laboratory of Fundamental Science for National Defense of Aeronautical Digital Manufacturing Process,Shenyang Aerospace University,Shenyang 110136,China

2.School of Mechanical and Electrical Engineering,Shenyang Aerospace University,Shenyang 110136,China

3.Shenyang Aircraft Corporation,Shenyang 110034,China

摘要:

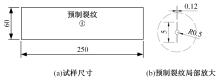

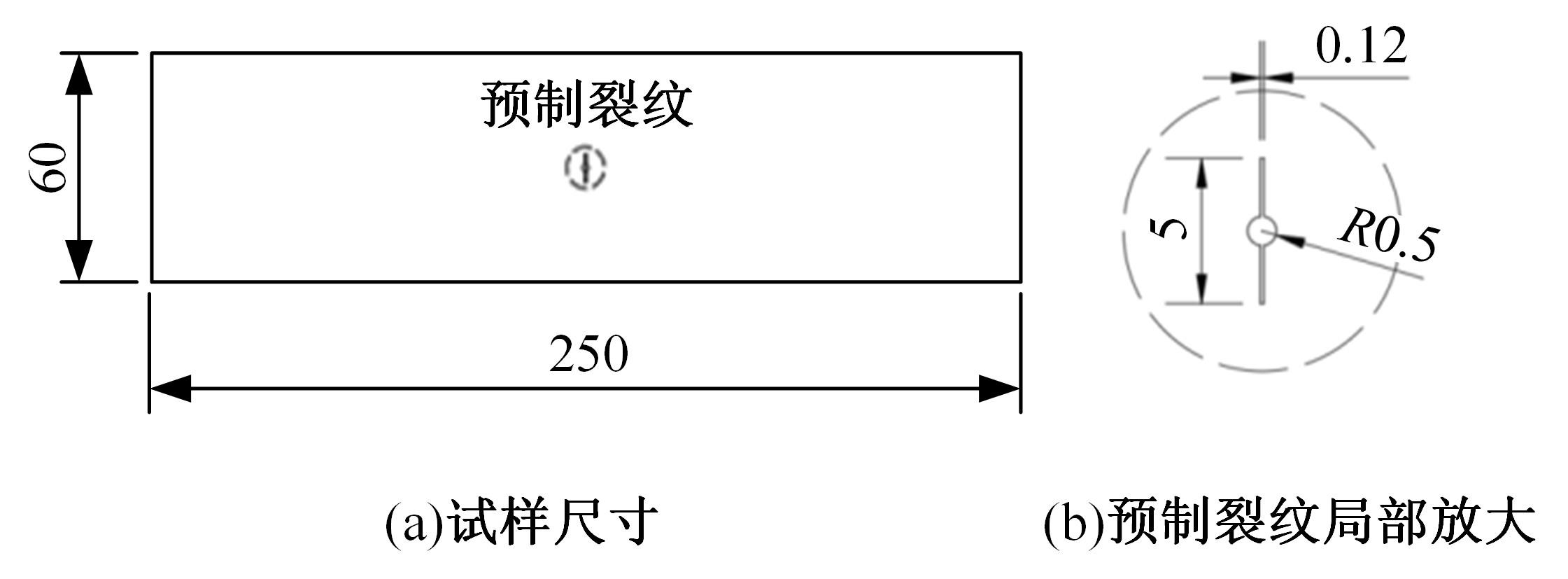

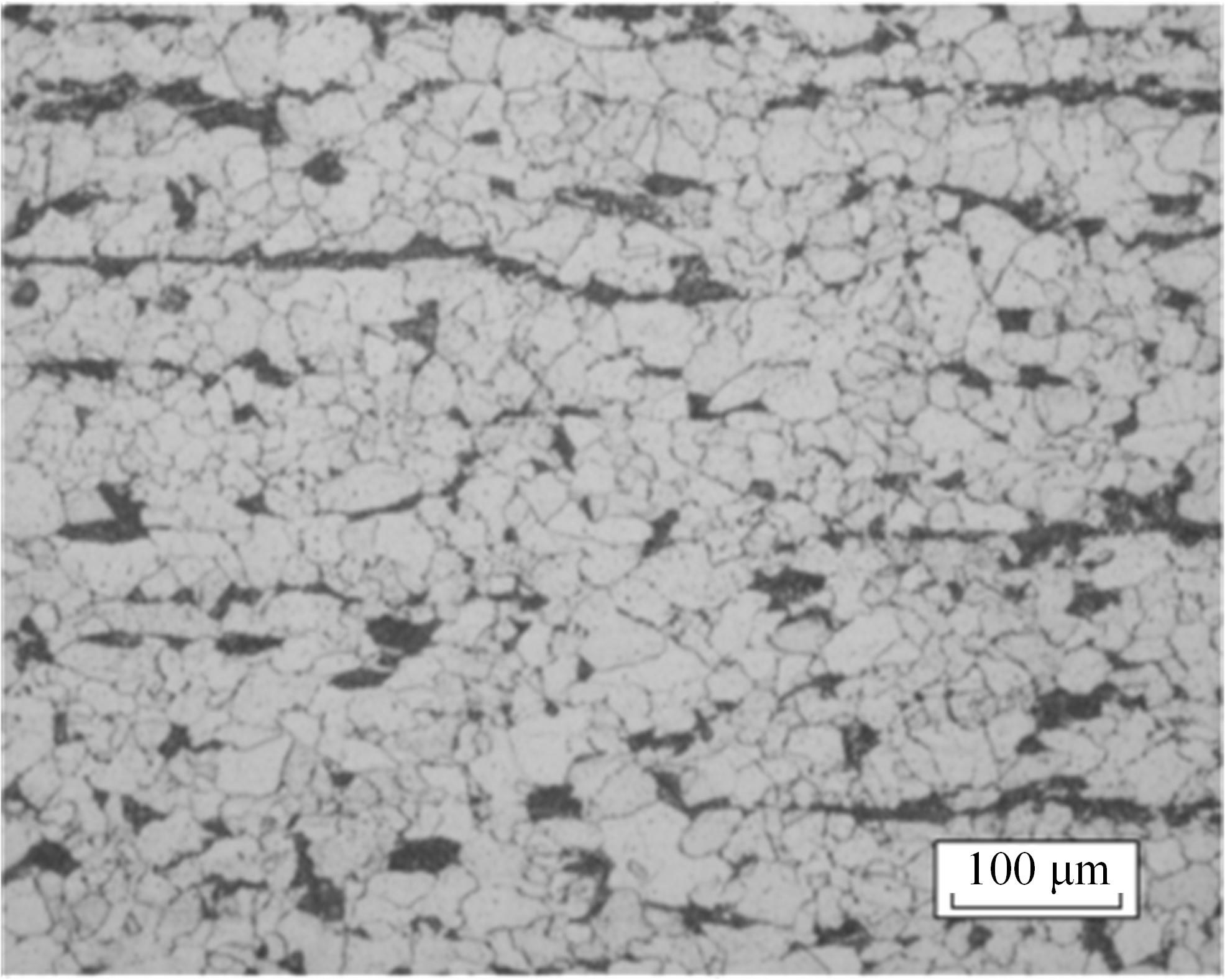

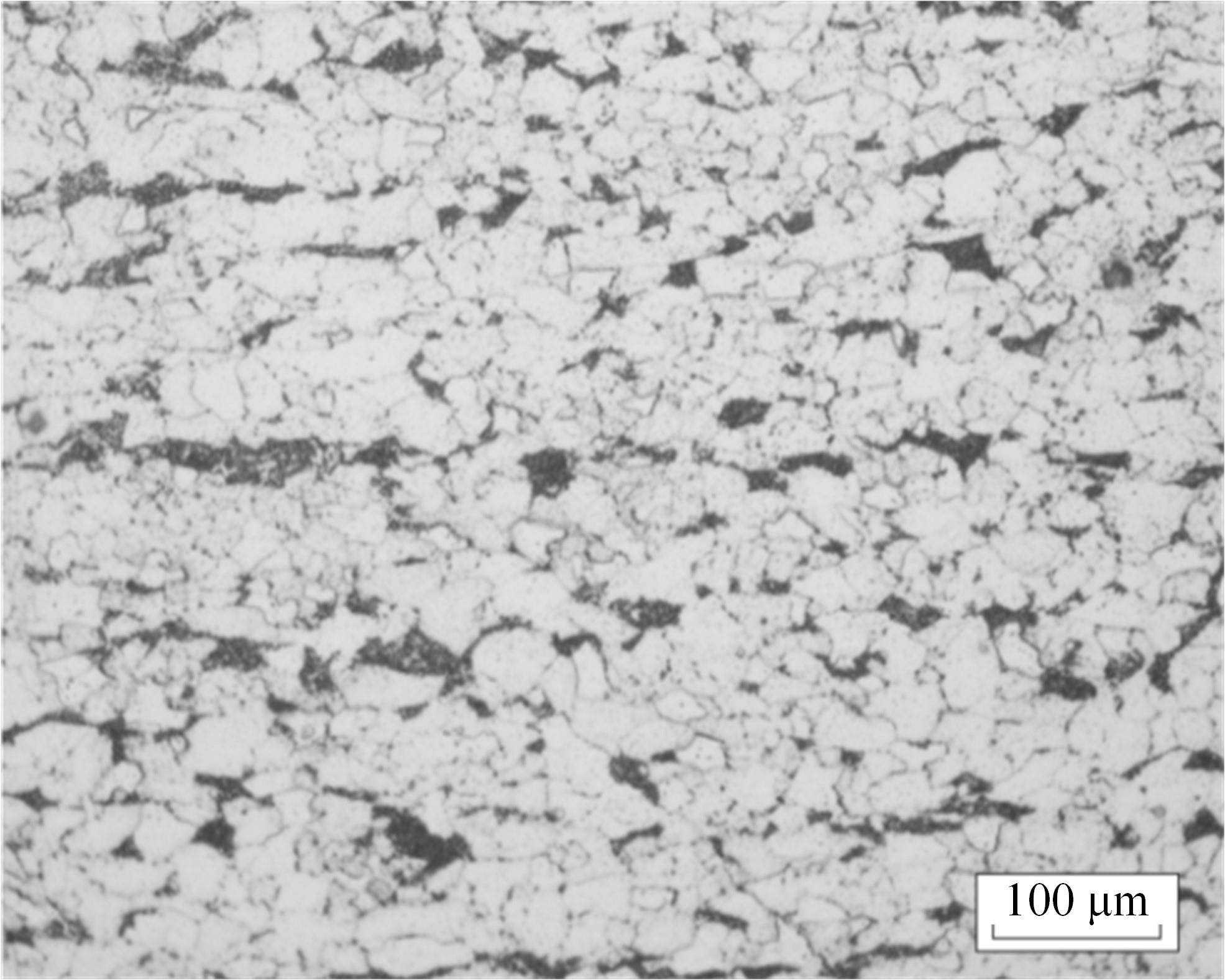

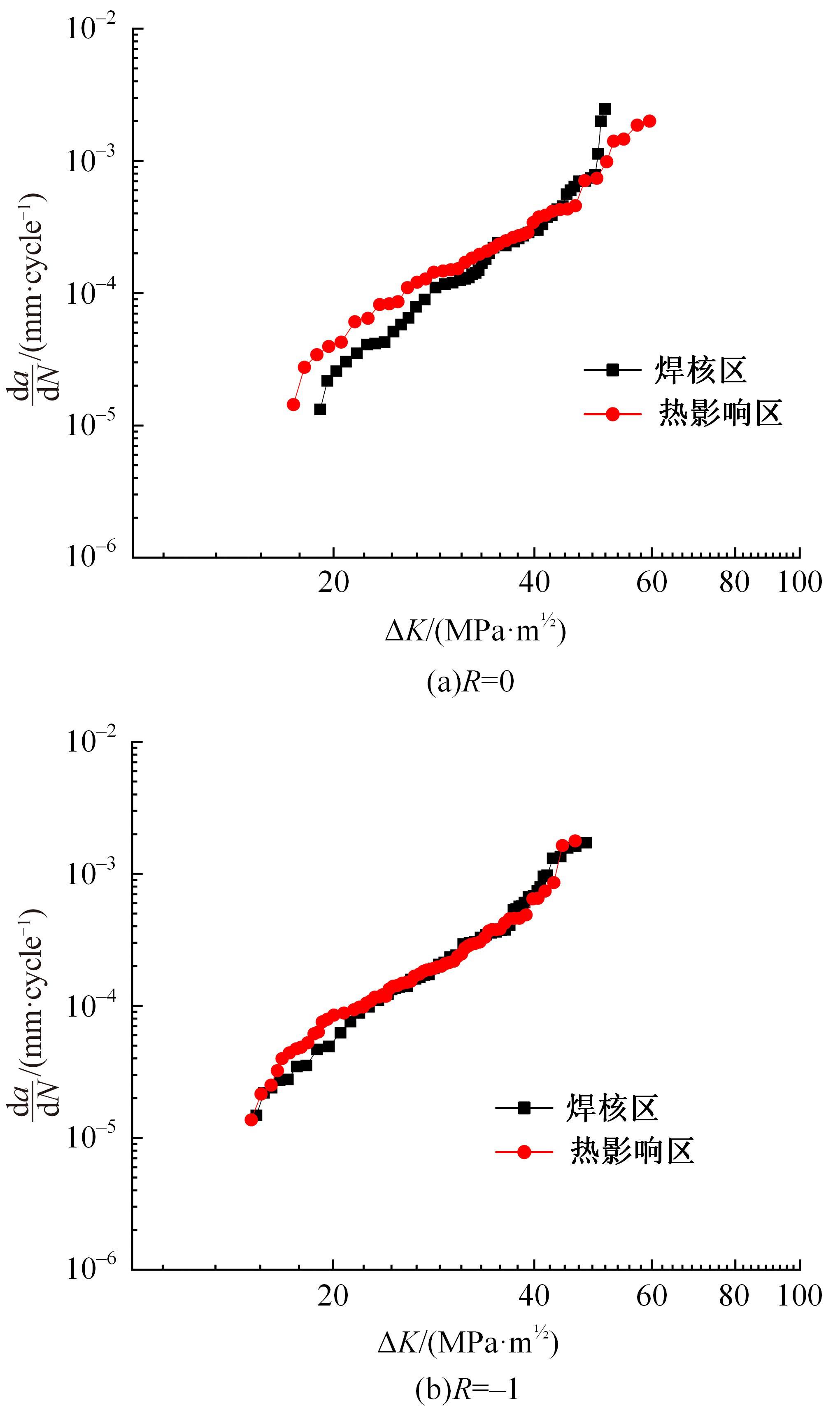

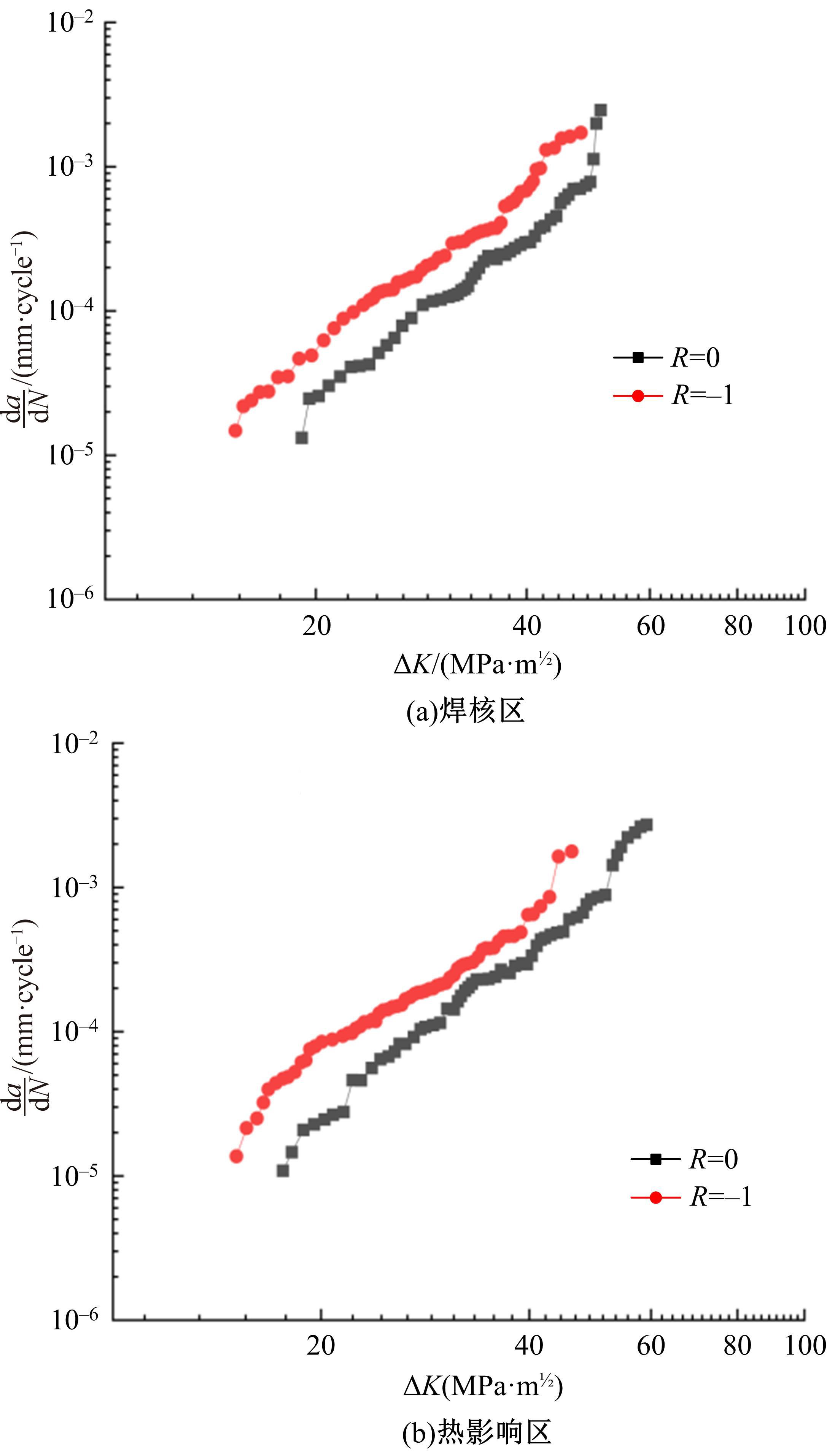

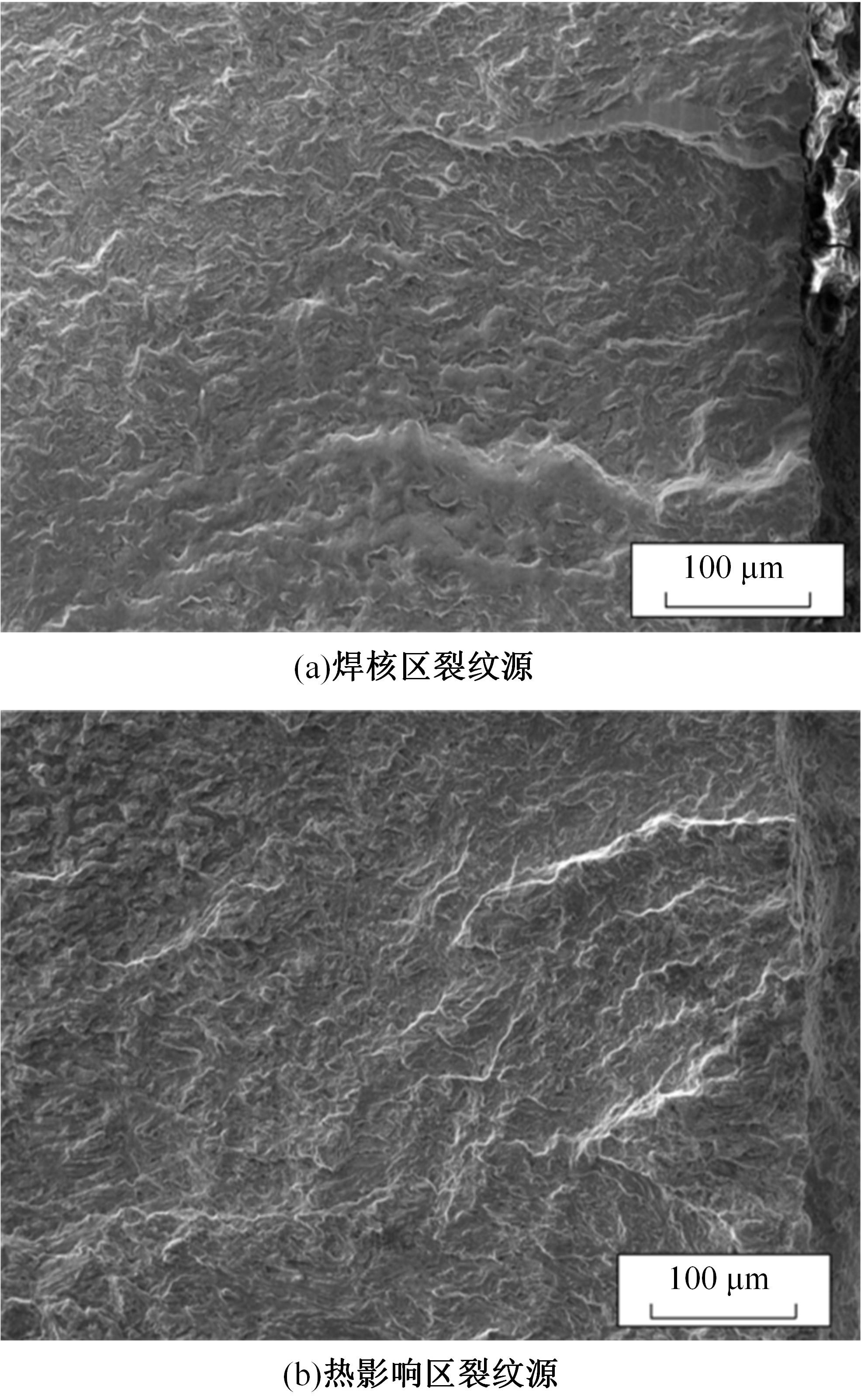

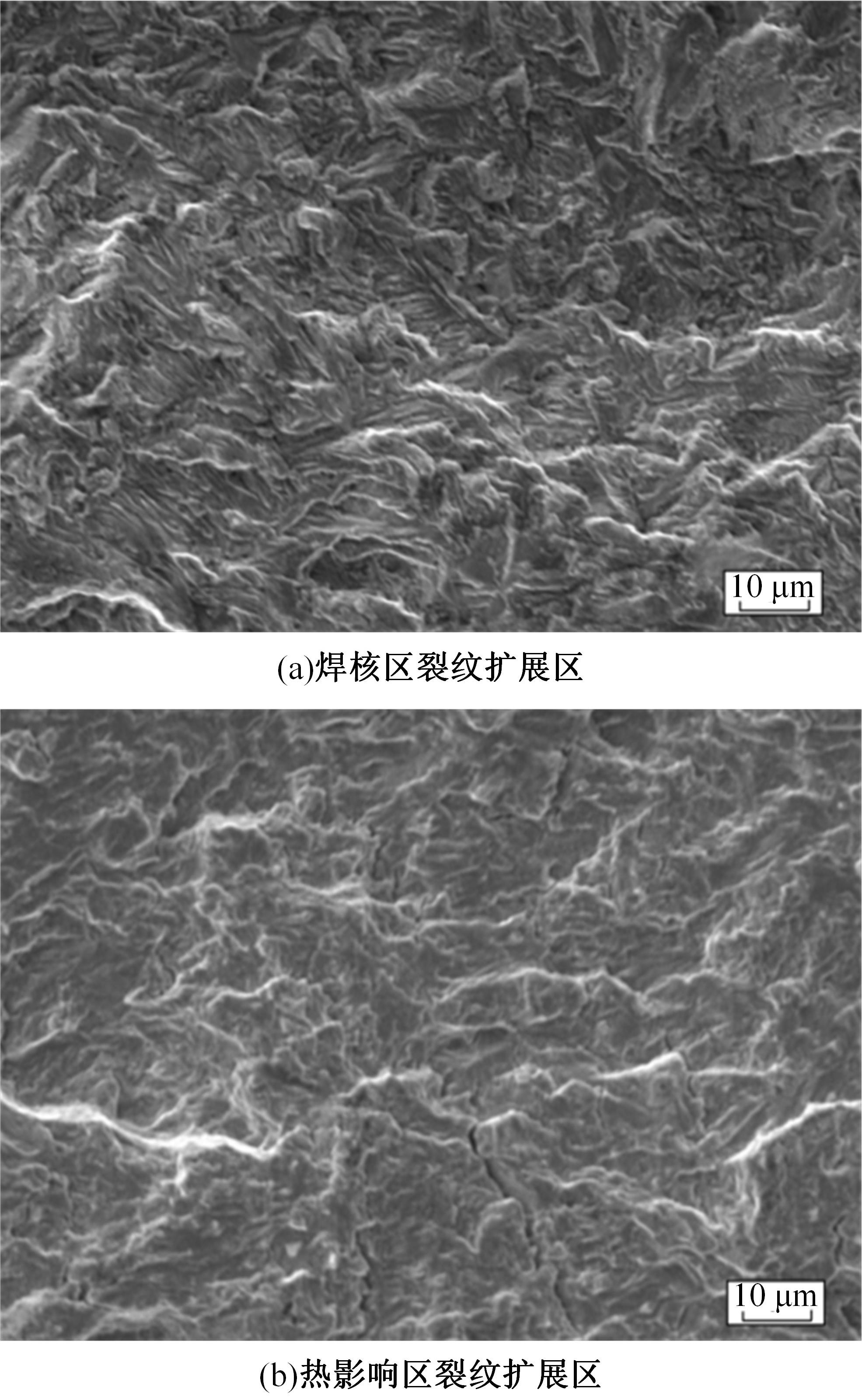

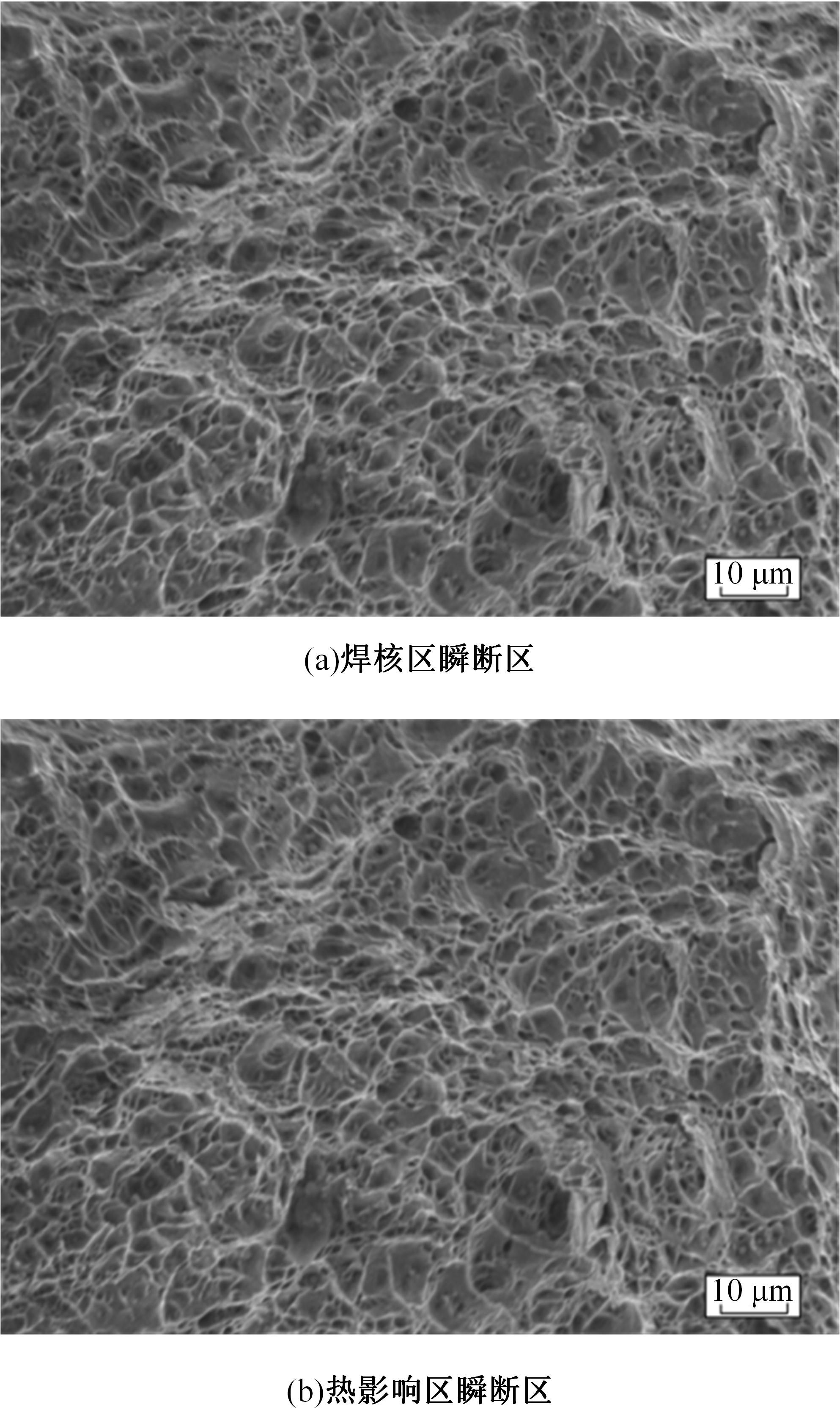

研究了高速列车转向架用SMA490BW钢对接焊在不同应力比和不同焊接区域下的裂纹扩展速率,分析了SMA490BW钢焊接接头不同焊接区域和不同应力比下的疲劳裂纹扩展行为。结果表明:在相同应力比下,SMA490BW钢不同焊接区域(焊核区、热影响区)对裂纹扩展速率的影响不大;应力比对裂纹扩展速率的影响较大;在相同应力强度因子下,应力比R=-1时的裂纹扩展速率明显高于R=0时的裂纹扩展速率;应力比对Paris公式里的c参数的影响较大,对m参数的影响较小。

中图分类号:

- TG405

| 1 | 吕文阁. 基于疲劳短裂纹行为的疲劳寿命估算要疲劳与断裂[M]. 北京: 气象工业出版社, 2002. |

| 2 | Hariharan K, Prakash R V, Sathya P M. Weighted error criterion to evaluate strain-fatigue life prediction methods[J]. International Journal of Fatigue, 2011, 33(5): 727-734. |

| 3 | 杨新华,陈传尧. 疲劳与断裂[M]. 武汉: 华中科技大学出版社, 2018. |

| 4 | 何柏林, 叶斌, 邓海鹏, 等. 转向架用SMA490BW钢焊接接头超高周疲劳性能[J]. 焊接学报, 2019, 40(2): 31-37, 162. |

| He Bo-lin, Ye Bin, Deng Hai-peng, et al. Very high cycle fatigue properties of SMA490BW steel welded joints for train bogie[J]. Transactions of the China Welding Institution, 2019, 40(2): 31-37, 162. | |

| 5 | 李余江, 史春元, 胡文浩, 等. 焊后处理对转向架SMA490BW钢焊接接头疲劳性能的影响[J]. 焊接技术, 2016, 45(11): 79-83. |

| Li Yu-jiang, Shi Chun-yuan, Hu Wen-hao, et al. Influence of post-weld treatment on fatigue properties of welded joints of bogie SMA490BW steel[J]. Welding Technology,2016, 45(11): 79-83. | |

| 6 | 王志杰,齐芳娟,林松,等.焊补对SMA490BW焊接接头疲劳性能的影响[J]. 焊接学报, 2015, 36(5): 109-112, 118. |

| Wang Zhi-jie, Qi Fang-juan, Lin Song, et al. Effect of repair welding on fatigue properties of SMA490BWsteel welded joints[J]. Transactions of the China Welding Institution, 2015, 36(5): 109-112, 118. | |

| 7 | 张成竹, 陈辉, 蔡创, 等. 激光清洗对SMA490BW钢接头表面应力及腐蚀的影响[J]. 焊接学报,2020, 41(11): 89-96, 102. |

| Zhang Cheng-zhu, Chen Hui, Cai Chuang, et al. Effect of laser cleaning on surface stress and corrosion of SMA490BW steel welded joint[J]. Transactions of the China Welding Institution, 2020, 41(11): 89-96, 102. | |

| 8 | 罗开玉, 邢月华, 柴卿锋, 等. 激光冲击强化对2Cr13不锈钢腐蚀疲劳性能的影响[J]. 吉林大学学报: 工学版, 2019, 49(3): 850-858. |

| Luo Kai-yu, Xing Yue-hua, Chai Qing-feng, et al. Effects of laser shock peening on corrosion fatigue behaviour of 2Cr13 stainless steel[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(3): 850-858. | |

| 9 | 谢旭, 吴向阳, 张志毅, 等. 焊接工艺对SMA490BW耐候钢接头腐蚀行为的影响[J]. 表面技术, 2018, 47(10): 256-261. |

| Xie Xu, Wu Xiang-yang, Zhang Zhi-yi, et al. Effects of welding processes on corrosion behavior of SMA490BW weathering steel joints[J]. Surface Technology, 2018, 47(10): 256-261. | |

| 10 | 崔坤强, 吴向阳, 张志毅, 等. SMA490BW耐候钢及其焊接接头的盐雾腐蚀行为[J].热加工工艺,2018,47(13):68-71. |

| Cui Kun-qiang, Wu Xiang-yang, Zhang Zhi-yi, et al. Salt fog corrosion behavior of SMA490BW weathering steel and its welded joints[J]. Hot Working Technology, 2018, 47(13): 68-71. | |

| 11 | 许良, 黄国栋, 回丽, 等. 转向架用SMA490BW钢的疲劳裂纹扩展行为研究[J]. 热加工工艺, 2022(10): 1-5. |

| Xu Liang, Huang Guo-dong, Hui Li, et al. Research on fatigue crack propagation behavior of SMA490BW steel for bogie[J]. Hot Working Technology, 2022(10): 1-5. | |

| 12 | Paris P C, Erdogan F. A critical analysis of crack propagation laws[J]. Journal of Basic Engineering, ASME, 1963, 84(4): 528-534. |

| 13 | Paris P C, Gomez M P, Anderson W P. A Rational analytic theory of fatigue[J]. The Trend in Engineering, 1961, 13(1): 9-14. |

| 14 | 韦龙, 王时越, 刘国寿, 等. 不同应力比下ADB610钢疲劳裂纹扩展速率的试验研究[J]. 机械强度, 2016, 38(1): 64-68. |

| Wei Long, Wang Shi-yue, Liu Guo-shou, et al. Experiment study on crack growth rate of ADB610 steel under different stress ratios[J]. Journal of Mechanical Strength, 2016, 38(1): 64-68. | |

| 15 | Elber W. Fatigue crack closure under cyclic tension[J]. Engineering Fracture Mechanics, 1971, 2: 37-45. |

| 16 | Ismonov S, Daniewicz S R. Simulation and comparison of several crack closure assessment methodologies using three-dimensional finite element analysis[J]. International Journal of Fatigue, 2010, 32(8): 1322-1329. |

| [1] | 杨志军,张驰,黄观新. 基于浮动坐标法的刚柔耦合定位平台力学模型[J]. 吉林大学学报(工学版), 2024, 54(2): 385-393. |

| [2] | 石林榕,赵武云. 西北寒旱农区胡麻滚勺式精量穴播器的设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2706-2717. |

| [3] | 柴博森,王广义,闫东,朱国仁,张进,吕恒升. 液力变矩器空化数值模拟及对性能的影响[J]. 吉林大学学报(工学版), 2023, 53(8): 2236-2244. |

| [4] | 陈贵升,罗国焱,李靓雪,黄震,李一. 柴油机颗粒捕集器孔道流场及其高原环境下噪声特性分析[J]. 吉林大学学报(工学版), 2023, 53(7): 1892-1901. |

| [5] | 陈国辉,徐业银,焦映厚. 考虑偏转的斜齿轮啮合刚度及其振动分析[J]. 吉林大学学报(工学版), 2023, 53(7): 1902-1910. |

| [6] | 于立娟,安阳,何佳龙,李国发,王升旭. 机电装备载荷谱外推技术研究进展及发展趋势[J]. 吉林大学学报(工学版), 2023, 53(4): 941-953. |

| [7] | 王建,于威,王斌. 高原状态下甲醇替代率对柴油机燃烧与排放的影响[J]. 吉林大学学报(工学版), 2023, 53(4): 954-963. |

| [8] | 李胜,朱佳,黄德惠,陈存福,费洪庆,丰伟,胡兴军. 空冷中冷器百叶窗翅片结构参数优化[J]. 吉林大学学报(工学版), 2023, 53(4): 998-1006. |

| [9] | 柴博森,闫东,王广义,左文杰. 制动工况桃腔偶合器三维涡特征分析及仿真评价[J]. 吉林大学学报(工学版), 2023, 53(11): 3045-3055. |

| [10] | 朱凌,王秋成. 空间几何约束下新能源汽车驱动系统协调控制方法[J]. 吉林大学学报(工学版), 2022, 52(7): 1509-1514. |

| [11] | 金兆辉,谷乐祺,洪伟,解方喜,尤田. 液压可变气门系统压力波动的影响分析[J]. 吉林大学学报(工学版), 2022, 52(4): 773-780. |

| [12] | 张岩,刘玮,张树勇,裴毅强,董蒙蒙,秦静. 二/四冲程可变柴油机燃烧室热负荷的改善[J]. 吉林大学学报(工学版), 2022, 52(3): 504-514. |

| [13] | 李国发,王彦博,何佳龙,王继利. 机电装备健康状态评估研究进展及发展趋势[J]. 吉林大学学报(工学版), 2022, 52(2): 267-279. |

| [14] | 王磊,黄秉汉,丛家慧,回丽,周松,徐永臻. 超声冲击对搅拌摩擦焊缝疲劳性能的影响[J]. 吉林大学学报(工学版), 2022, 52(11): 2542-2548. |

| [15] | 赵文伯,李玉洁,邓俊,李理光,吴志军. 针阀运动规律及其对喷嘴内流和喷雾特性影响[J]. 吉林大学学报(工学版), 2022, 52(10): 2234-2243. |

|

||