吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (10): 2234-2243.doi: 10.13229/j.cnki.jdxbgxb20210316

• 车辆工程·机械工程 • 上一篇

针阀运动规律及其对喷嘴内流和喷雾特性影响

- 同济大学 汽车学院,上海 201804

Needle motion and its influence on in-nozzle flow and spray jet characteristics

Wen-bo ZHAO( ),Yu-jie LI,Jun DENG,Li-guang LI,Zhi-jun WU(

),Yu-jie LI,Jun DENG,Li-guang LI,Zhi-jun WU( )

)

- School of Automotive Studies,Tongji University,Shanghai 201804,China

摘要:

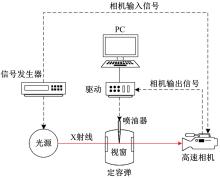

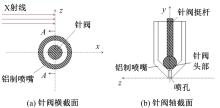

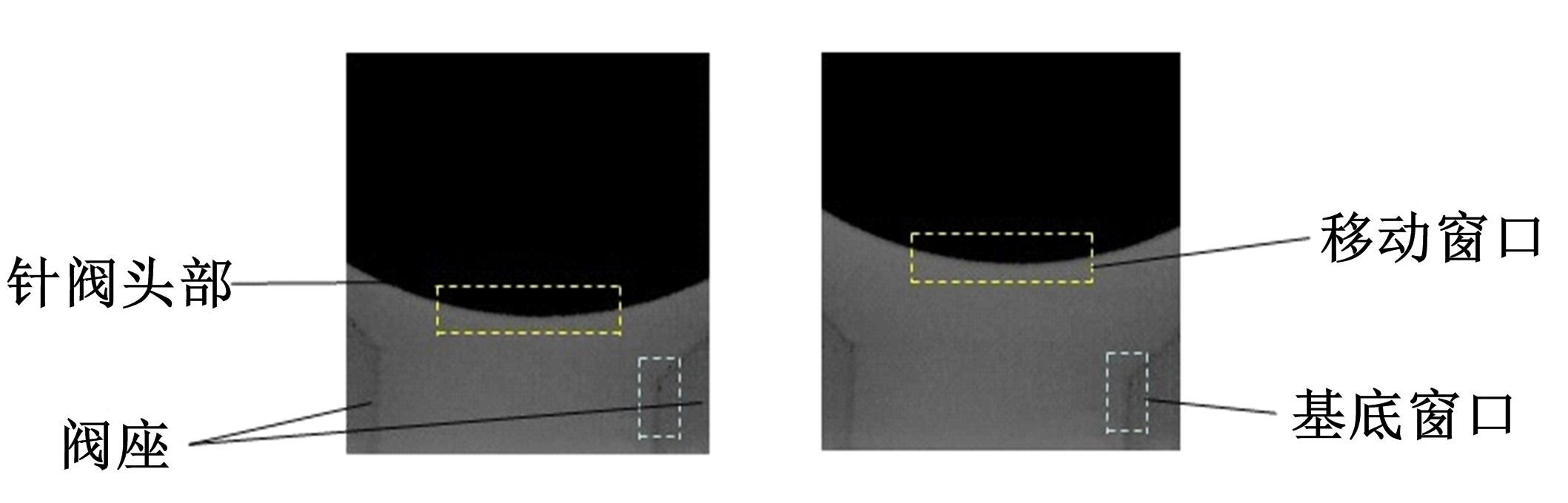

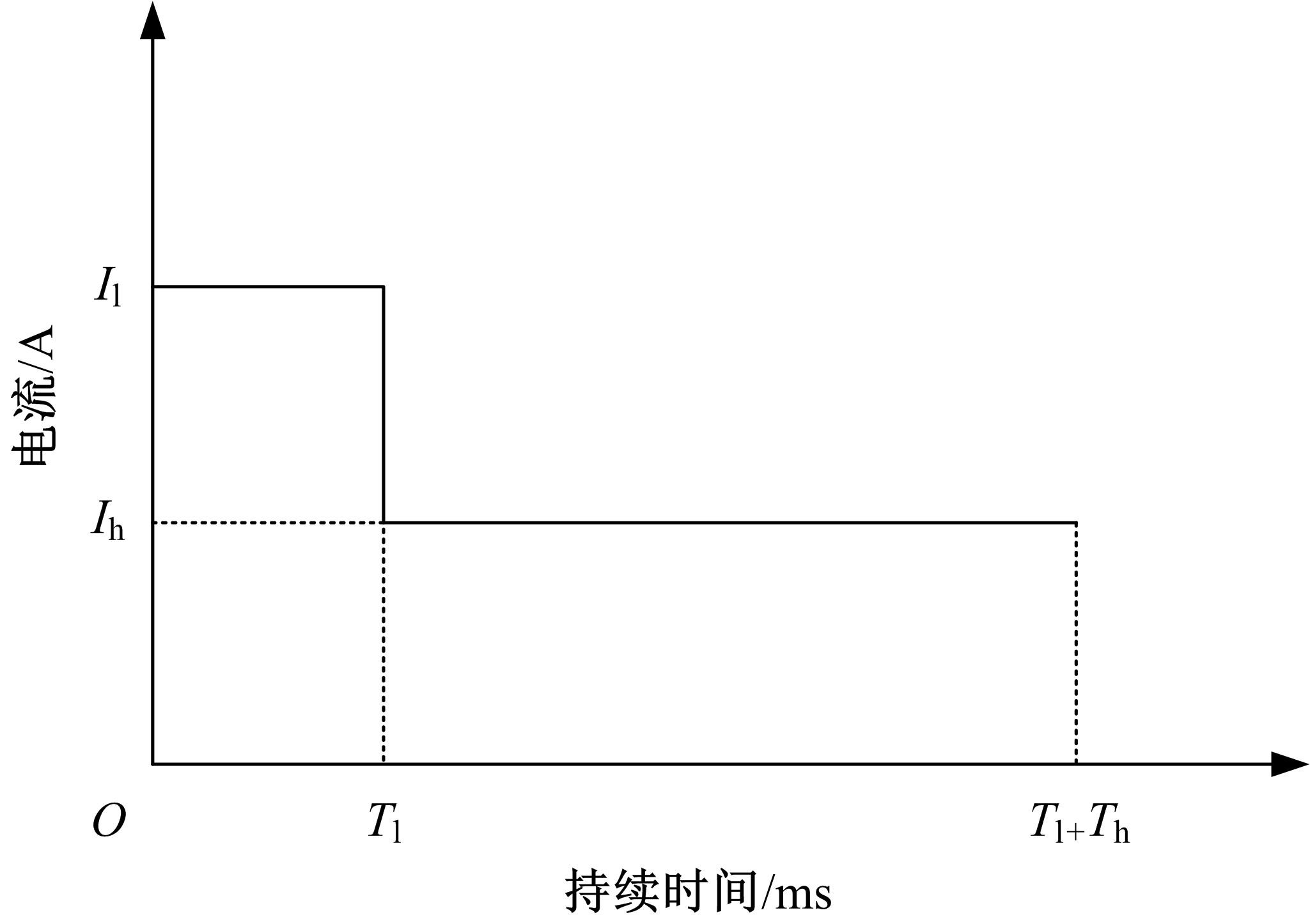

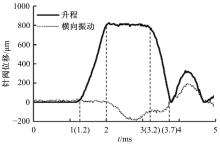

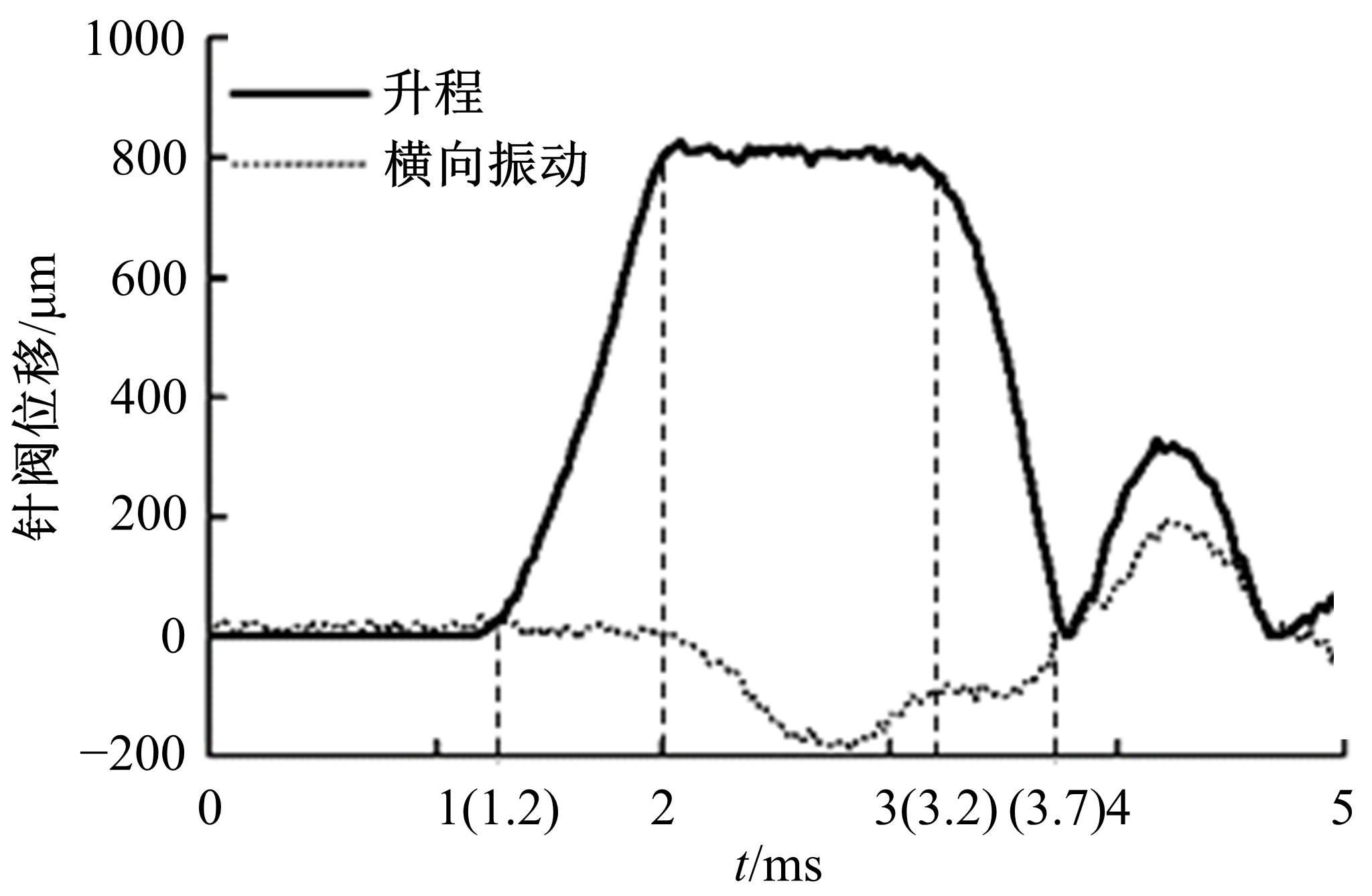

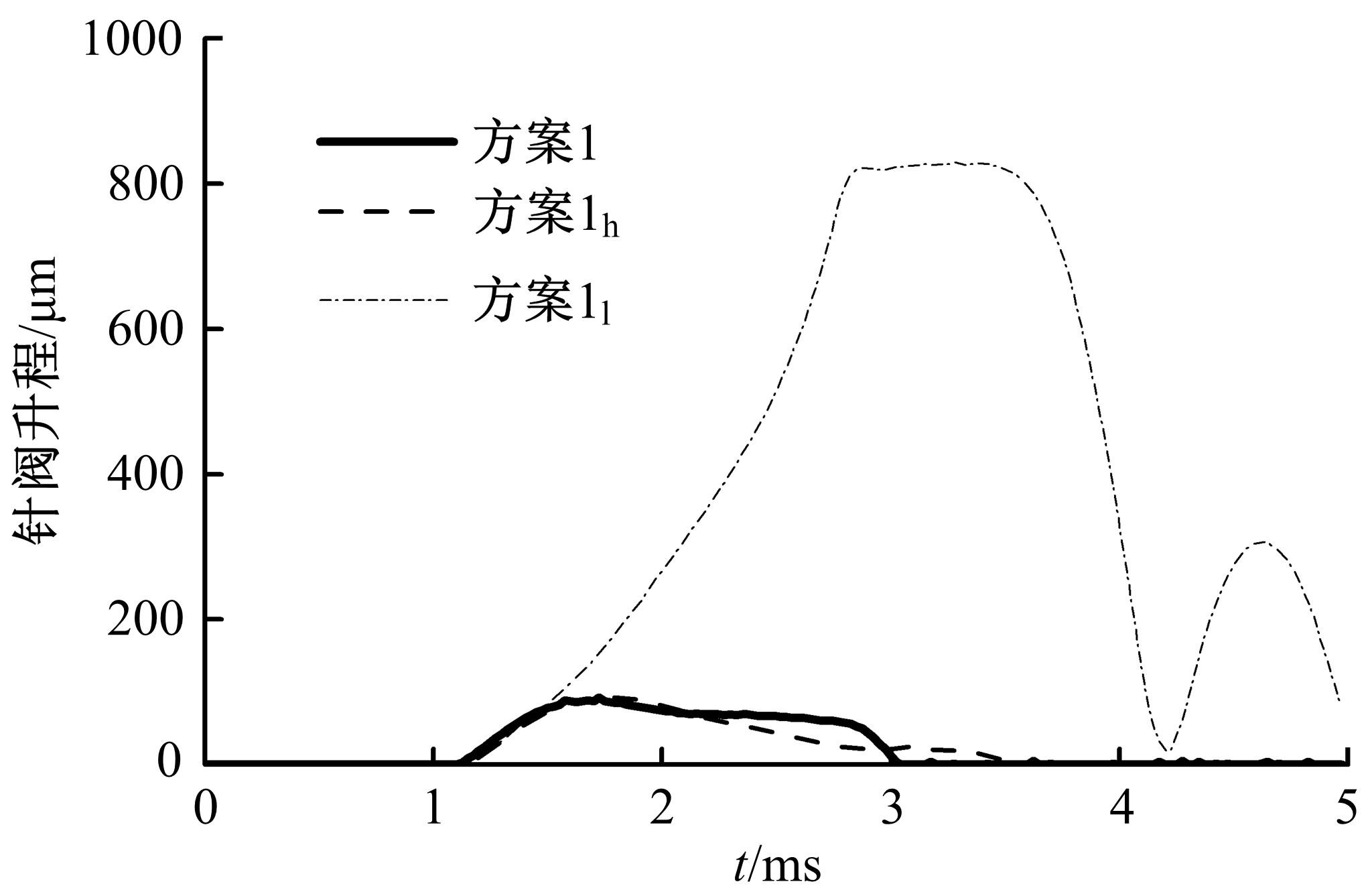

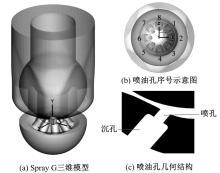

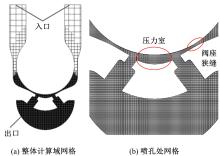

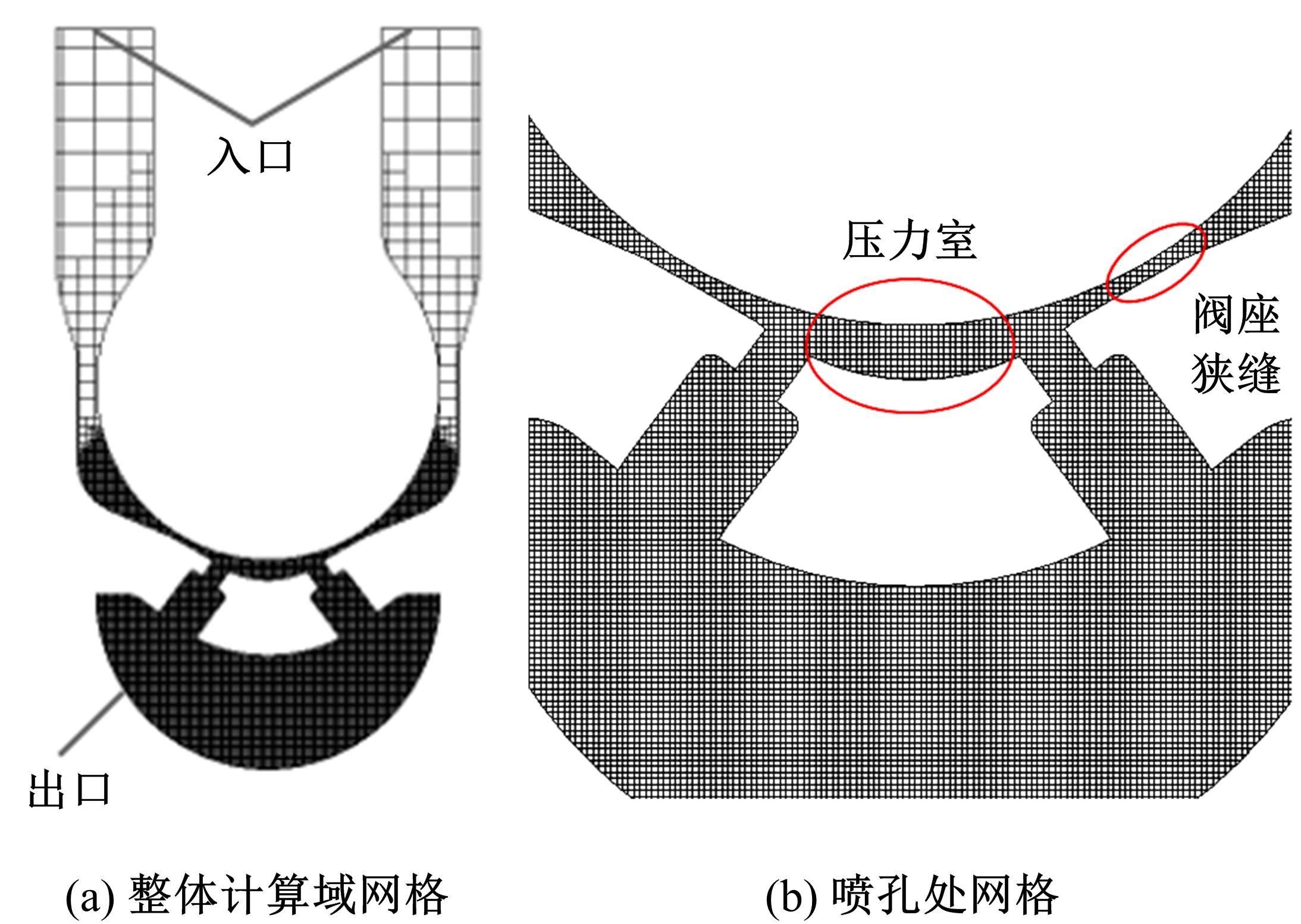

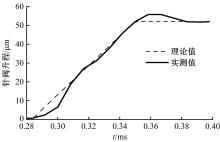

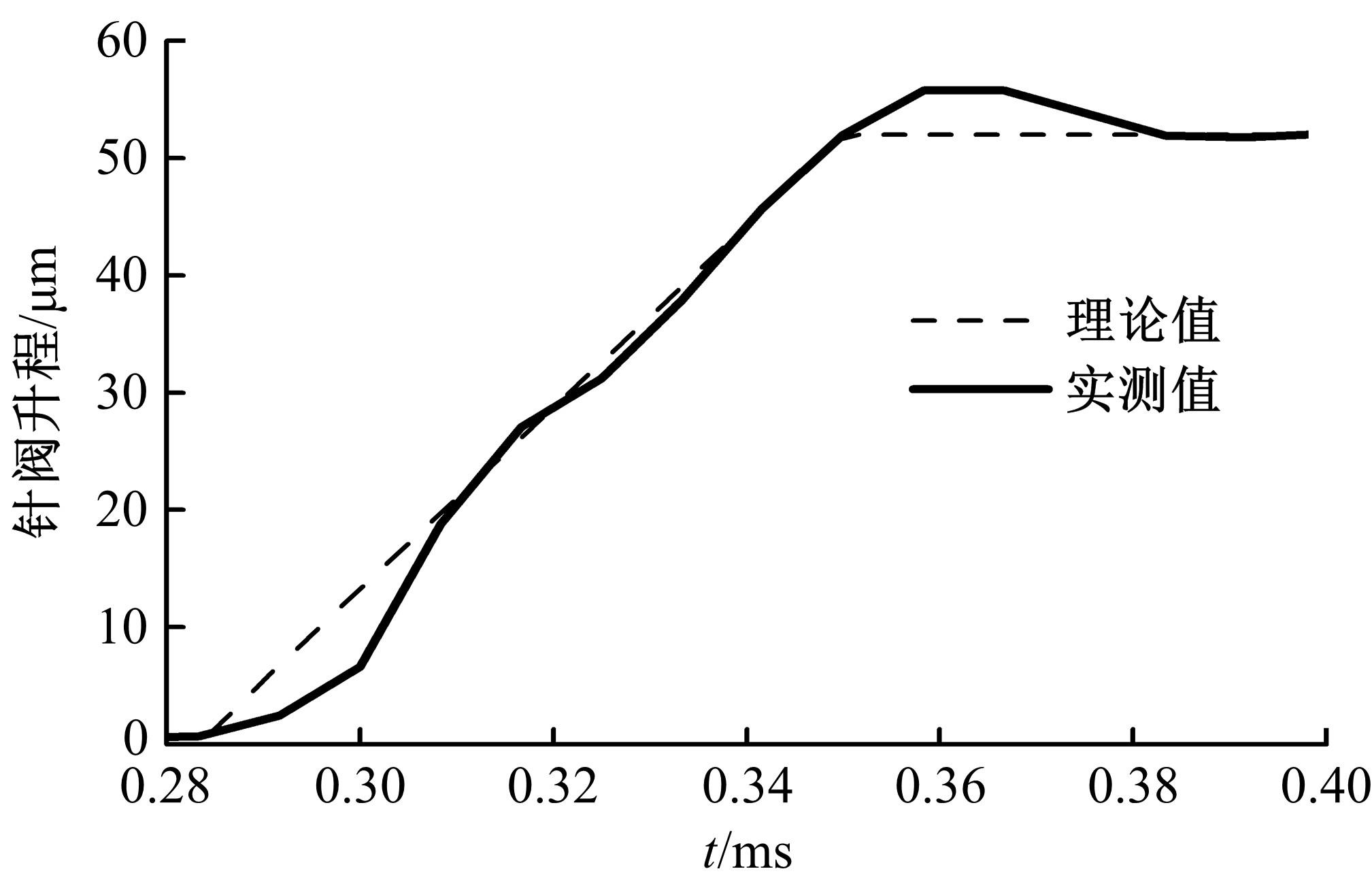

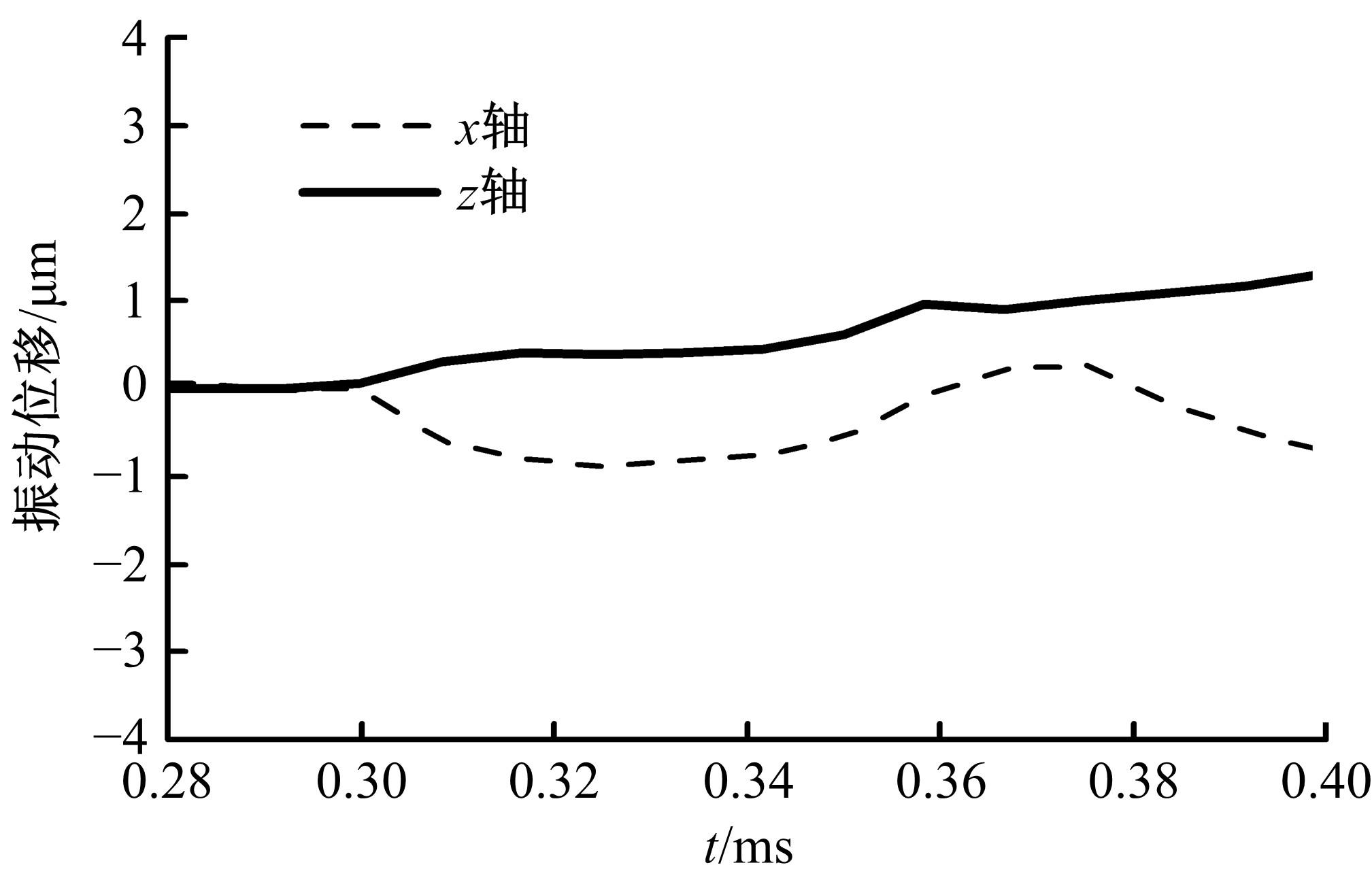

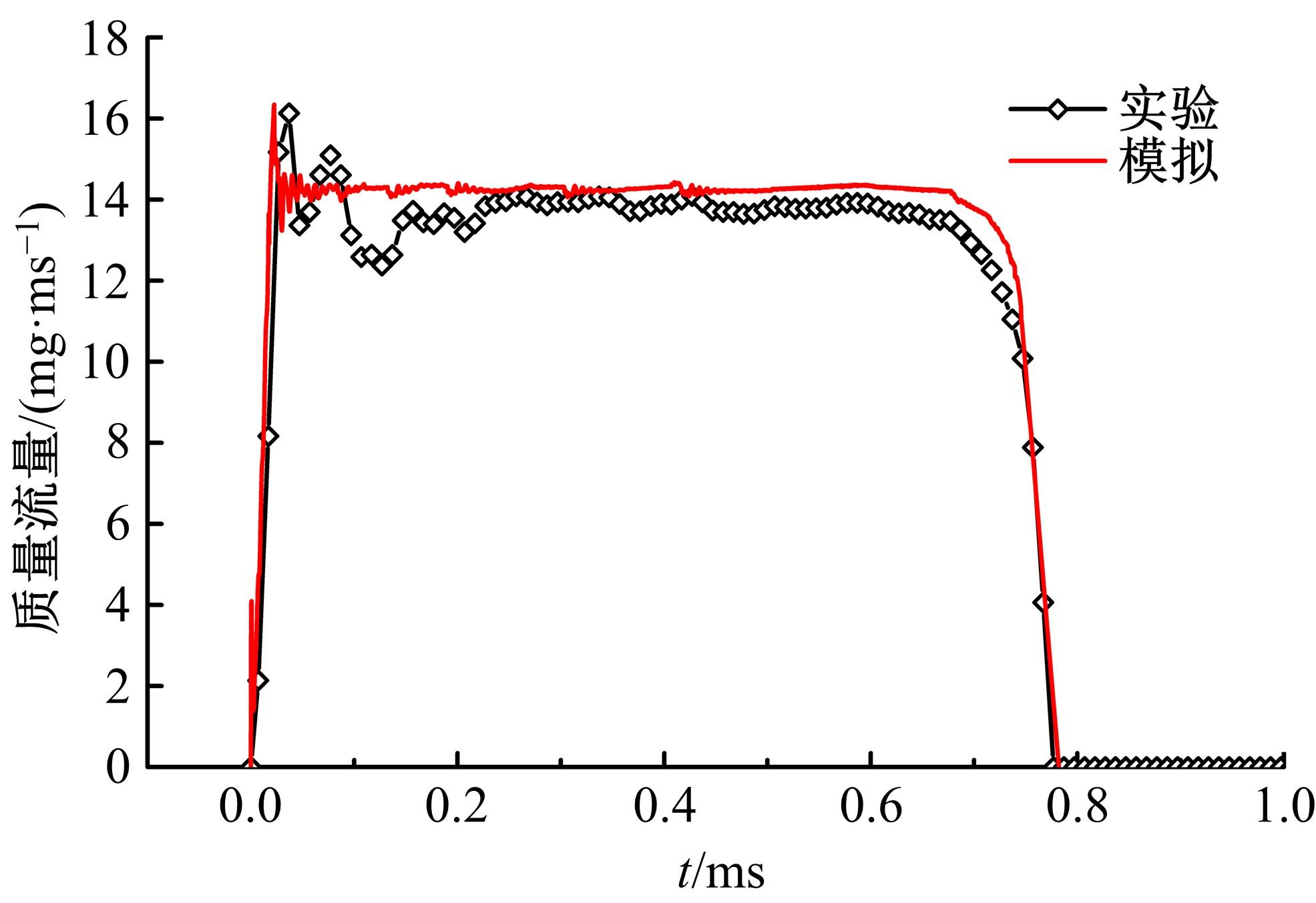

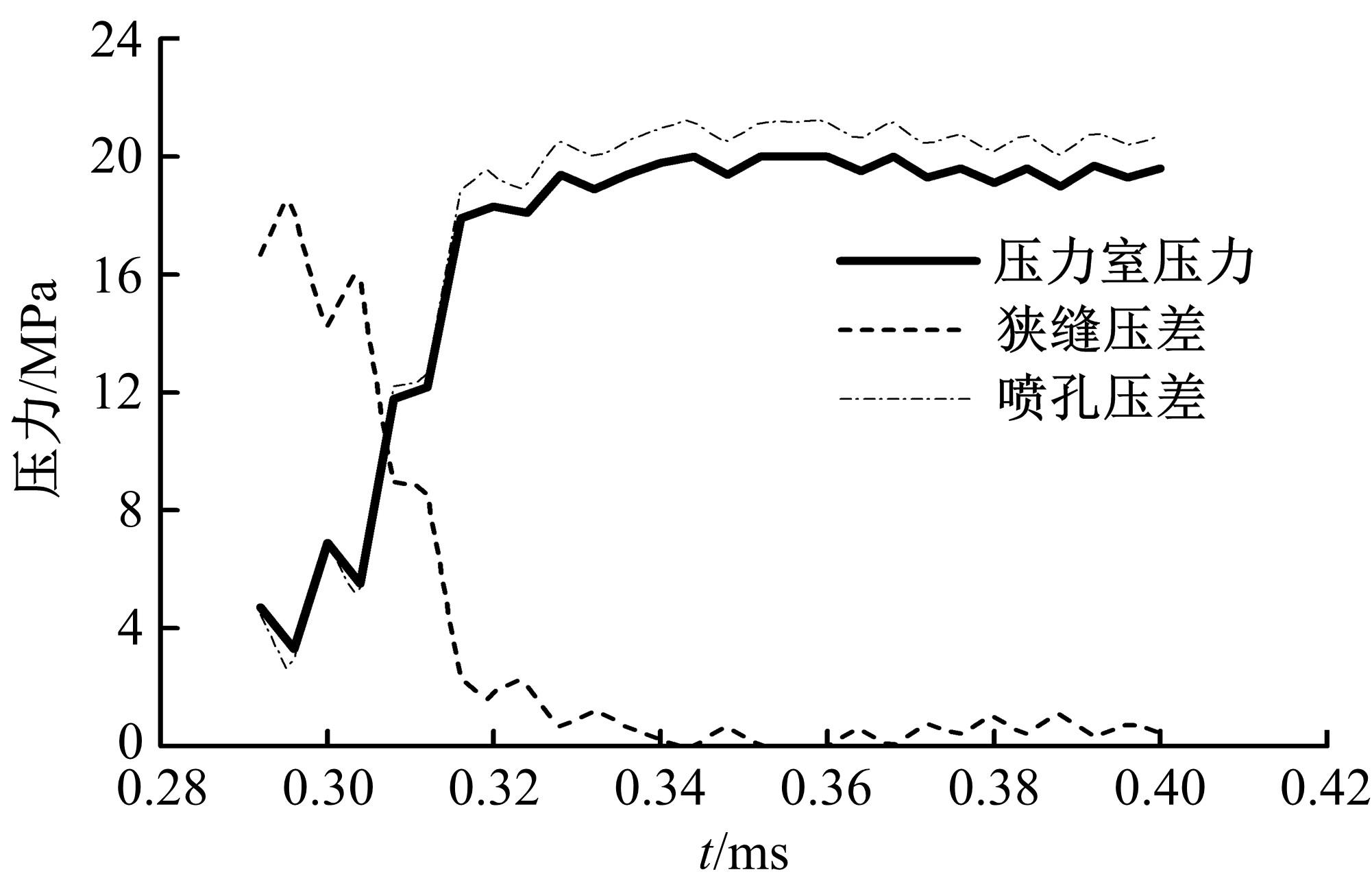

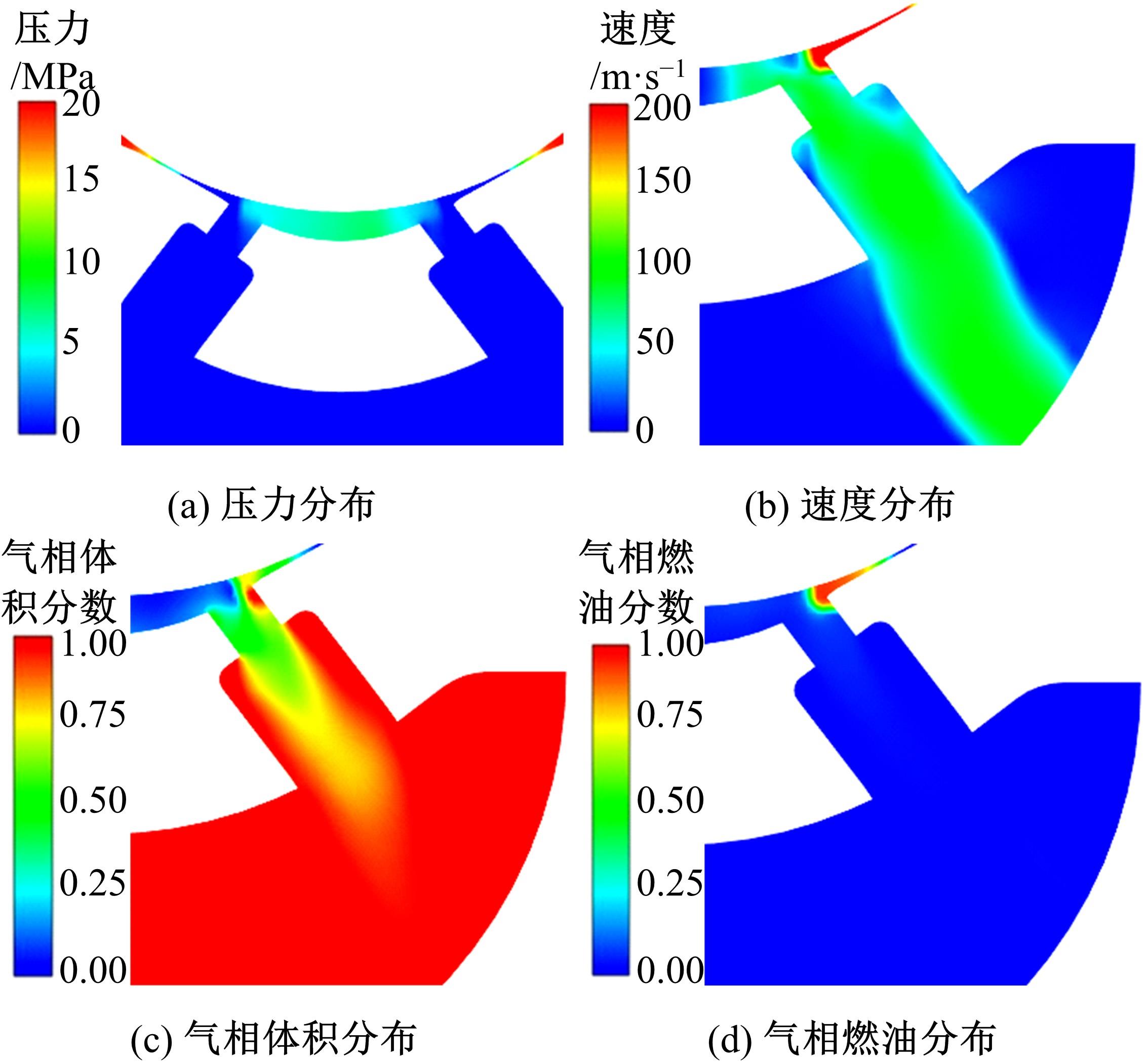

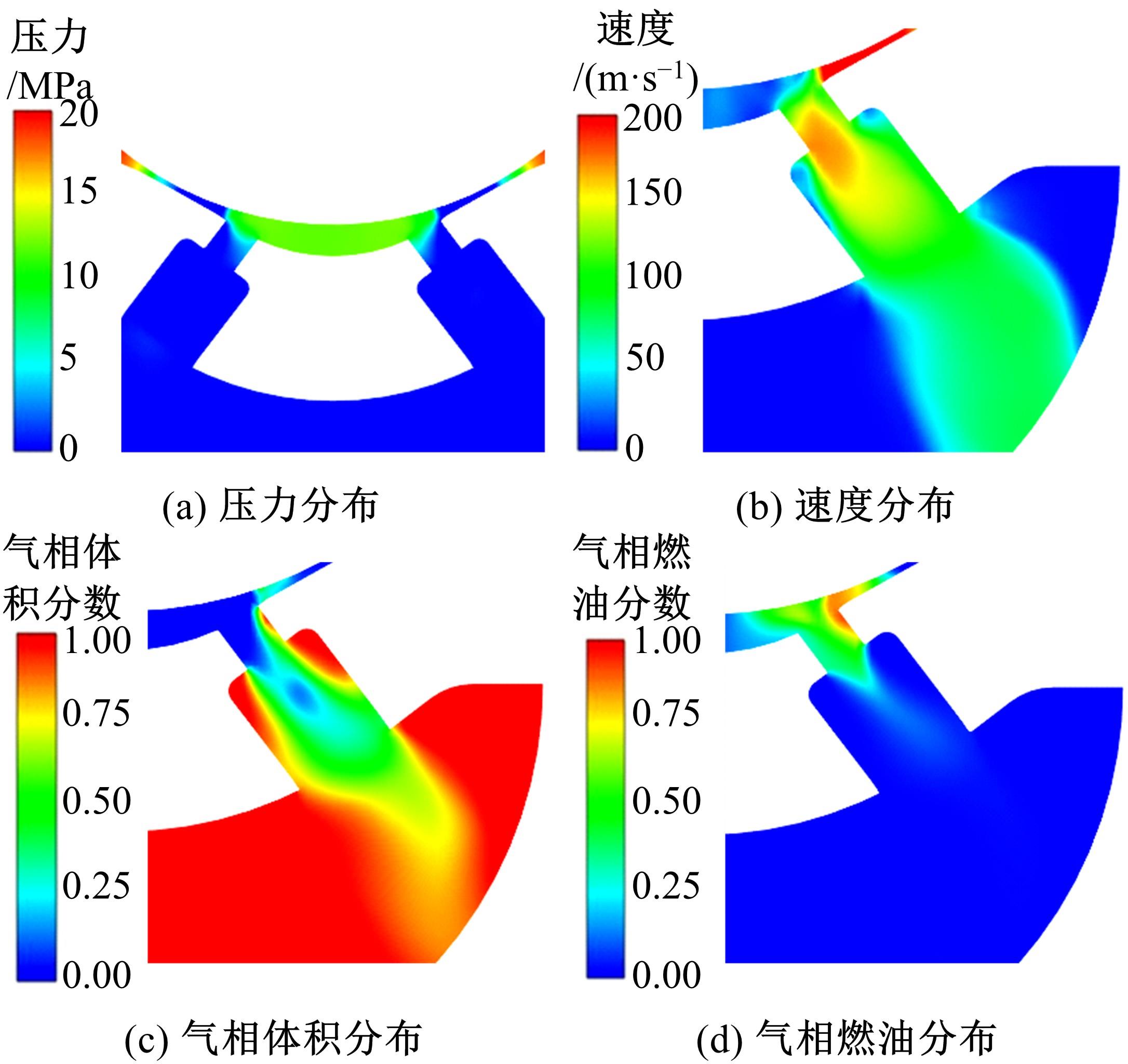

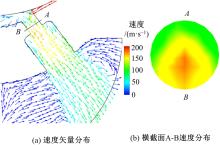

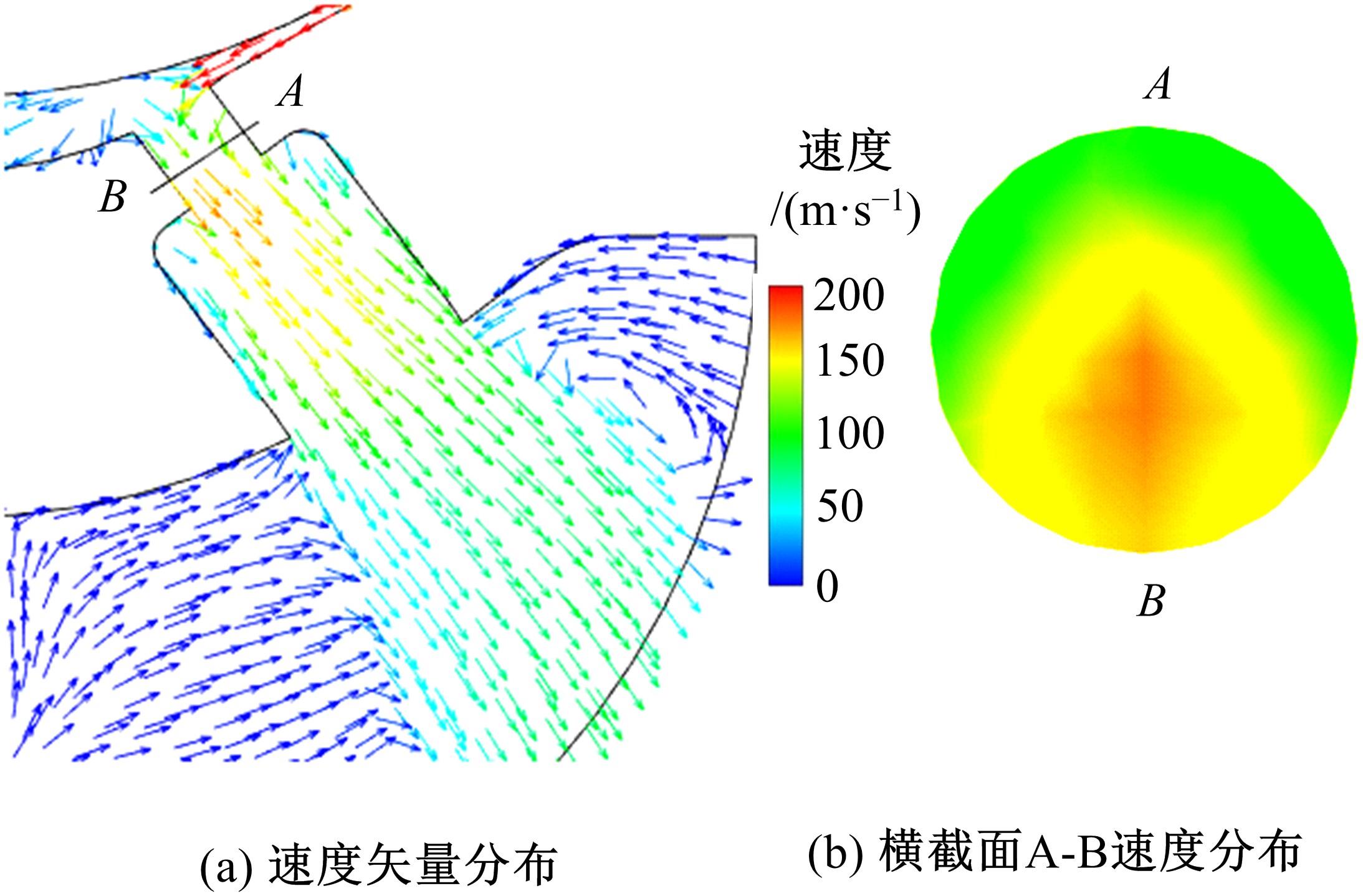

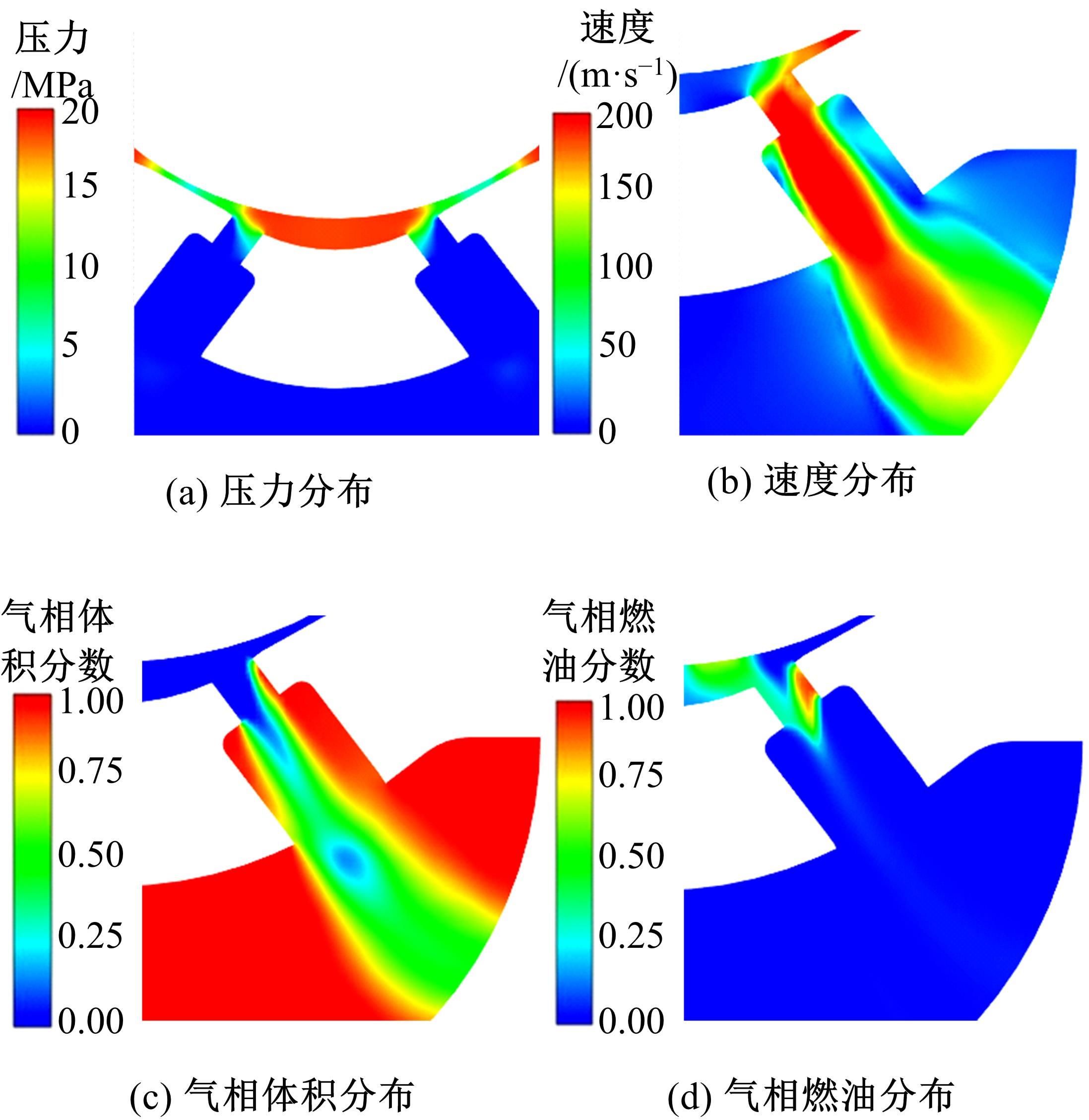

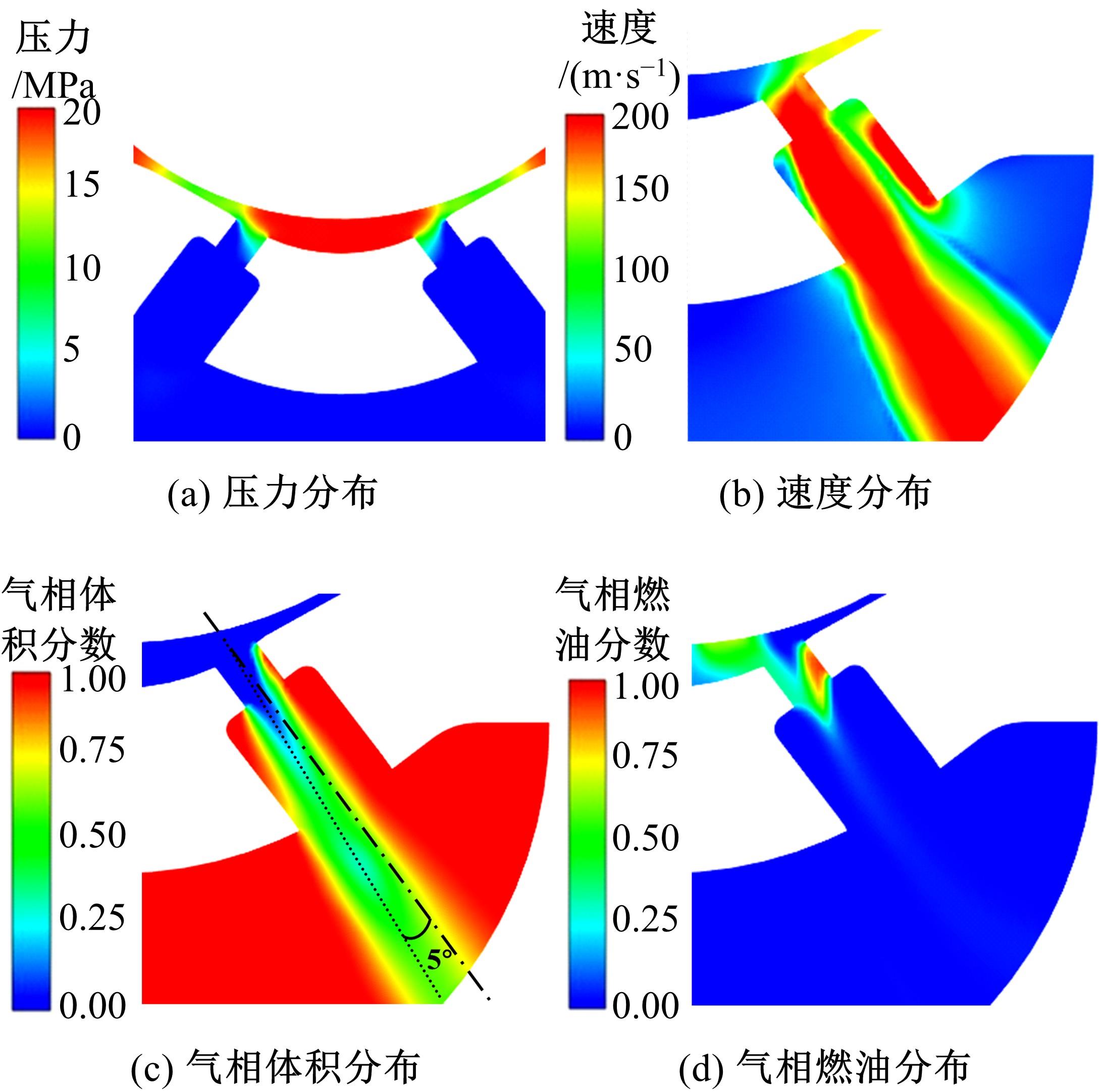

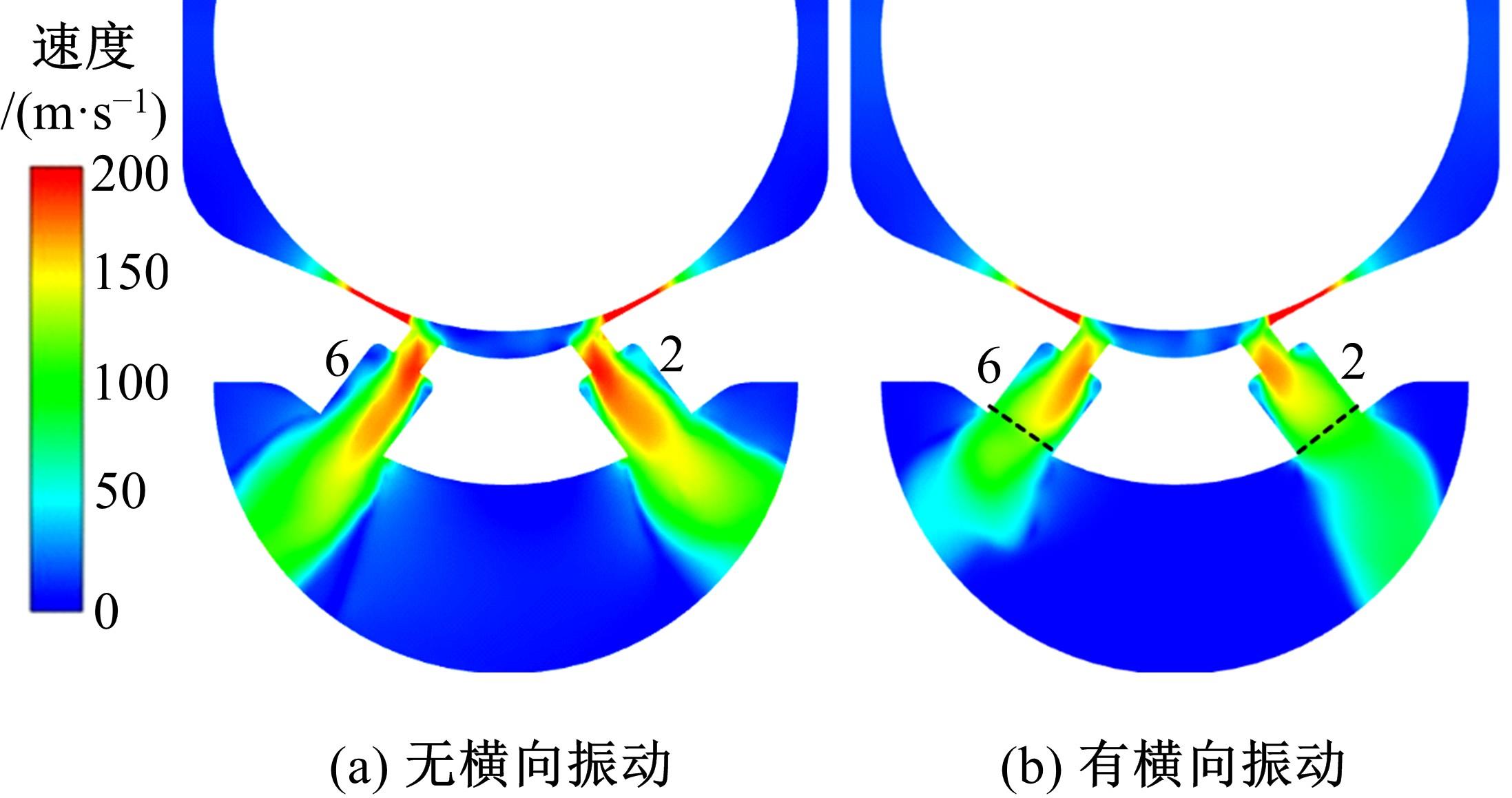

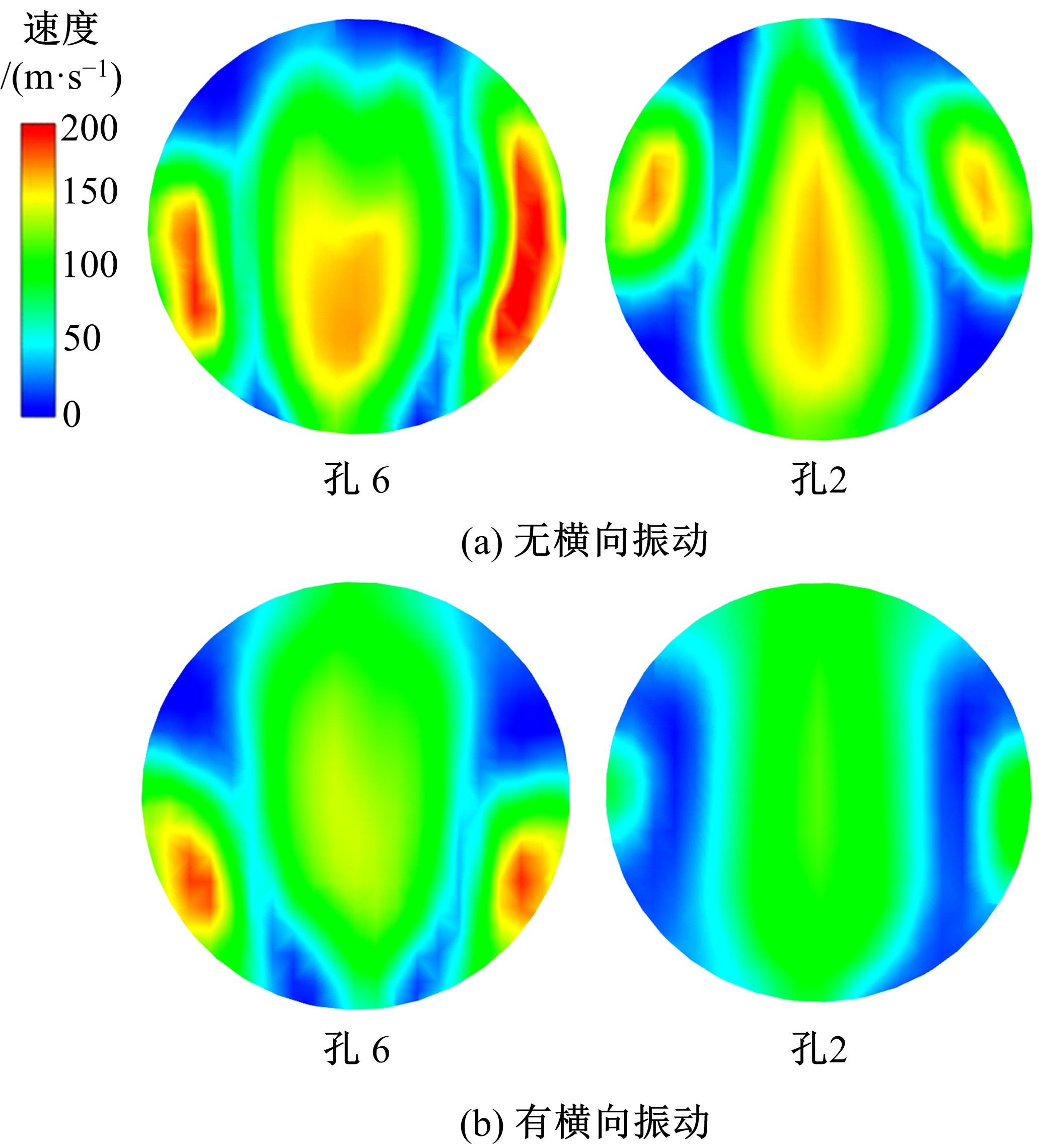

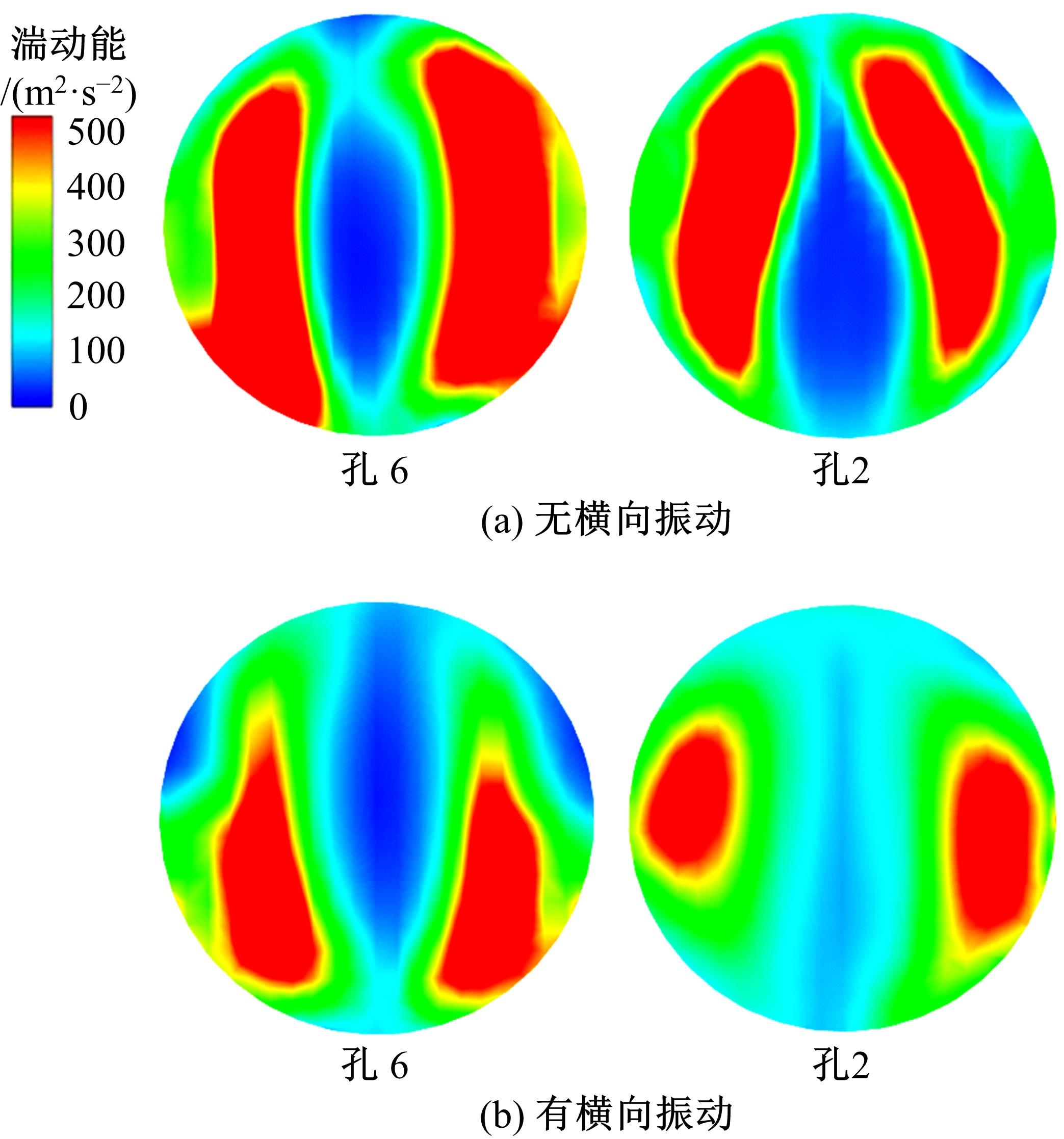

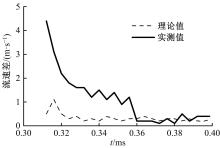

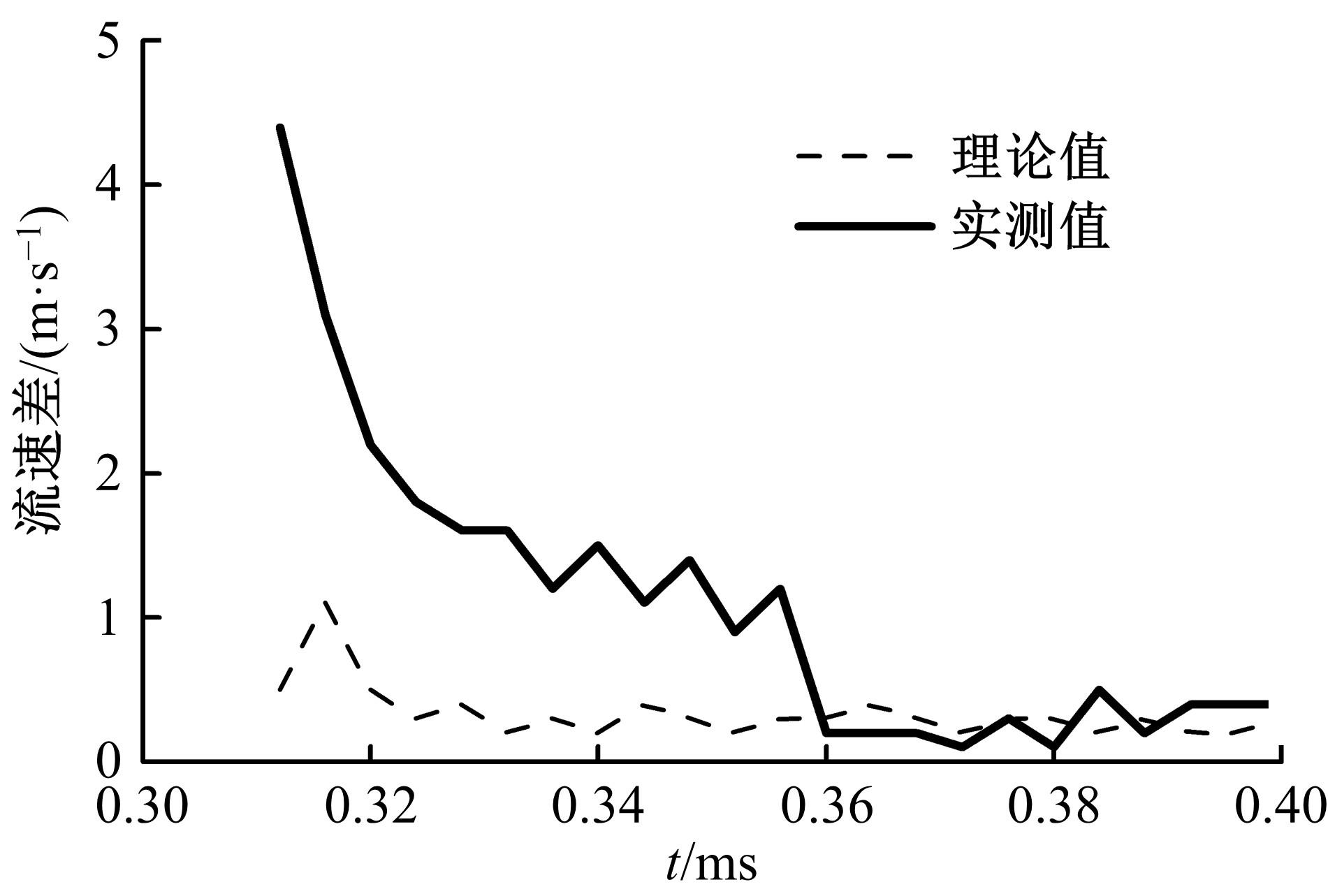

基于超快X射线成像技术研究了GDI喷油器针阀动力学特性和控制电流信号对针阀运动的影响规律。通过仿真计算分析了GDI喷嘴针阀抬升过程对内流空化现象和近场喷雾射流瞬态特性的影响,研究了针阀横向振动对于孔间不均匀性的影响。实验结果表明,针阀组件达到最大限位及落座时会与铁芯和阀座碰撞产生振荡,不利于喷油量的精确控制,减小控制电流能改善喷油控制精度。模拟结果表明,针阀抬升过程中,燃油在喷孔入口上表面产生空化,导致射流喷雾偏离喷孔轴线,最大偏转角可达到5°左右。喷射过程中喷雾油束的偏转会导致喷嘴沉孔出口位置积油,在燃烧的过程中产生积碳,影响发动机的颗粒物排放。在低针阀升程时,针阀横向振动会导致孔间流速不均匀,而随着针阀升程增加,孔间不均匀度显著降低。

中图分类号:

- TK411

| 1 | 姚志良,张明辉,王新彤,等. 中国典型城市机动车排放演变趋势[J]. 中国环境科学, 2012, 32(9): 1565-1573. |

| Yao Zhi-liang, Zhang Ming-hui, Wang Xin-tong, et al. Trends in vehicular emissions in typical cities in China[J]. China Environmental Science, 2012, 32(9): 1565-1573. | |

| 2 | 何志霞,张鑫,陶希成,等. 燃油温度对柴油喷射过程影响的试验[J]. 内燃机学报, 2017, 35(5): 399-405. |

| He Zhi-xia, Zhang Xin, Tao Xi-cheng, et al. Experimental study into effects of fuel temperature on diesel injection process[J]. Transactions of CSICE, 2017, 35(5): 399-405. | |

| 3 | 张正洋,何志霞,郭根苗,等. 柴油机原型喷嘴内瞬态流动的特性试验[J]. 内燃机学报, 2017, 35(2): 136-141. |

| Zhang Zheng-yang, He Zhi-xia, Guo Gen-miao, et al. Experiment of transient cavitating flow in the real-size diesel injector nozzle[J]. Transactions of CSICE, 2017, 35(2): 136-141. | |

| 4 | 黄豪中,史程,张鹏,等. 喷射压力及环境背压对松油-柴油混合燃料喷雾特性的影响[J]. 农业工程学报, 2016, 32(17): 55-61. |

| Huang Hao-zhong, Shi Cheng, Zhang Peng, et al. Effect of injection pressure and ambient pressure on spray characteristics of pine oil-diesel blends[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(17): 55-61. | |

| 5 | 朱希,张振东,程强. GDI多孔喷油器喷雾特性的试验与仿真研究[J]. 内燃机工程, 2015, 36(6): 137-143. |

| Zhu Xi, Zhang Zhen-dong, Cheng Qiang. Numerical simulation and experimental study for spray characteristics of the gasoline direct injection (gdi) multi-hole injector [J]. Chinese Internal Combustion Engine Engineering, 2015, 36(6): 137-143. | |

| 6 | 吴玉强,王谦,高志胜,等. 柴油机喷嘴喷孔非对称结构对近场喷雾特性的影响[J]. 内燃机工程, 2016, 37(6): 170-175. |

| Wu Yu-qiang, Wang Qian, Gao Zhi-sheng, et al. The effect of asymmetric nozzle hole geometry of a diesel nozzle on the near-field spray characteristics [J]. Chinese Internal Combustion Engine Engineering, 2016, 37(6): 170-175. | |

| 7 | Payri R, Viera J P, Gopalakrishnan V, et al. The effect of nozzle geometry over the evaporative spray formation for three different fuels[J]. Fuel, 2017, 188: 645-660. |

| 8 | 施东晓,周禛,郭立新,等. 喷油嘴空穴流动可视化及其对喷雾的影响[J]. 内燃机学报, 2019, 37(1): 54-59. |

| Shi Dong-xiao, Zhou Zhen, Guo Li-xin, et al. Visualization of cavitating flow in diesel injector nozzles and its effects on spray[J]. Transactions of CSICE, 2019, 37(1): 54-59. | |

| 9 | Torelli R, Som S, Pei Y, et al. Influence of fuel properties on internal nozzle flow development in a multi-hole diesel injector[J]. Fuel, 2017, 204: 171-184. |

| 10 | 解方喜,姚卓彤,胡雪松,等. 针阀运动和油压波动对燃油喷雾特性的影响[J]. 吉林大学学报:工学版, 2013, 43(4): 897-902. |

| Xie Fang-xi, Yao Zhuo-tong, Hu Xue-song, et al. Influence of dynamic change of needle and hydraulic pressure in diesel injection nozzle on fuel spray characteristic[J]. Journal of Jilin University (Engineering and Technology Edition), 2013, 43(4): 897-902. | |

| 11 | 何志霞,钟汶君,黄云龙,等. 针阀运动对柴油机喷嘴瞬态流动特性的影响[J]. 内燃机学报, 2012, 30(4): 336-342. |

| He Zhi-xia, Zhong Wen-jun, Huang Yun-long, et al. Investigation of transient behavior of cavitation flow in injector nozzles affected by the needle movement[J]. Transactions of CSICE, 2012, 30(4): 336-342. | |

| 12 | 张现成,许伯彦. 考虑针阀运动的LPG高压旋流喷油器内外流动过程的数值解析[J].内燃机学报, 2013, 31(3): 228-234. |

| Zhang Xian-cheng, Xu Bo-yan. Numerical analysis of internal flow and spray for a lpg high pressure swirl injector with needle movement[J]. Transactions of Csice, 2013, 31(3): 228-234. | |

| 13 | Wang X S, Chen B, Wang R, et al. Experimental study on the relation between internal flow and flashing spray characteristics of R134a using straight tube nozzles[J]. International Journal of Heat and Mass Transfer, 2017, 115(B): 524-536. |

| 14 | 肖体乔,谢红兰,邓彪,等. 上海光源X射线成像及其应用研究进展[J]. 光学学报, 2014, 34(1): 9-23. |

| Xiao Ti-qiao, Xie Hong-lan, Deng Biao, et al. Progresses of X-Ray imaging methodology and its applications at shanghai synchrotron radiation facility[J]. Acta Optica Sinica, 2014, 34(1): 9-23. | |

| 15 | 陈洁. 高分辨率X射线成像技术与应用研究[D]. 合肥:中国科学技术大学核科学技术学院, 2010. |

| Cheng Jie. Research on high resolution X-ray imaging technology and application[D]. Hefei: School of Nuclear Science and Technology, University of Science and Technology of China, 2010. | |

| 16 | 陈荣昌,杜国浩,谢红兰,等. 上海光源X射线成像实验站相位衬度CT初步结果[J]. 核技术, 2009, 32(4): 241-245. |

| Chen Rong-chang, Du Guo-hao, Xie Hong-lan, et al. Preliminary results for X-ray phase contrast micro-tomography on the biomedical imaging beamline at SSRF[J]. Nuclear Techniques, 2009, 32(4): 241-245. | |

| 17 | Shields B, Neroorkar K, and Schmidt D P, et al. Cavitation as rapid flash boiling[C]∥Americas 23rd Annual Conference on Liquid Atomization and Spray Systems, Ventura, USA, 2011: 1-7. |

| 18 | Powell Chris. Measured needle motion (x-ray phase contrast)[EB/OL]. [2021-04-21].. |

| 19 | Parrish Scott. Rate of injection (tube method)[EB/OL]. [2021-04-21].. |

| 20 | Huang W, Moon S, Wang J, et al. Nozzle tip wetting in gasoline direct injection injector and its link with nozzle internal flow[J]. International Journal of Engine Research, 2020, 21(2): 340-351. |

| 21 | Peterson K, Grover R, Mitcham C. Application of optical diagnostics and simulation to fuel injector tip wetting and soot production[C]∥Proceeding of the 11th International Symposium on Combustion Diagnostics, Baden,Germany, 2014: 79-84. |

| 22 | Oude N D, Freeland P, Behringer M, et al. Developing low gasoline particulate emission engines through improved fuel delivery[C]∥SAE Paper, 2014-01-2843. |

| [1] | 金兆辉,谷乐祺,洪伟,解方喜,尤田. 液压可变气门系统压力波动的影响分析[J]. 吉林大学学报(工学版), 2022, 52(4): 773-780. |

| [2] | 张岩,刘玮,张树勇,裴毅强,董蒙蒙,秦静. 二/四冲程可变柴油机燃烧室热负荷的改善[J]. 吉林大学学报(工学版), 2022, 52(3): 504-514. |

| [3] | 赵庆武,程勇,杨雪,王宁. 高重频纳秒脉冲放电点火系统设计[J]. 吉林大学学报(工学版), 2021, 51(2): 414-421. |

| [4] | 李志军,刘浩,张立鹏,李振国,邵元凯,李智洋. 过滤壁结构对颗粒捕集器深床过滤影响的模拟[J]. 吉林大学学报(工学版), 2021, 51(2): 422-434. |

| [5] | 王忠,李游,张美娟,刘帅,李瑞娜,赵怀北. 柴油机排气阶段颗粒碰撞过程动力学特征分析[J]. 吉林大学学报(工学版), 2021, 51(1): 39-48. |

| [6] | 胡云峰,丁一桐,赵志欣,蒋冰晶,高金武. 柴油发动机燃烧过程数据驱动建模与滚动优化控制[J]. 吉林大学学报(工学版), 2021, 51(1): 49-62. |

| [7] | 王建,许鑫,顾晗,张多军,刘胜吉. 基于排气热管理的柴油机氧化催化器升温特性[J]. 吉林大学学报(工学版), 2020, 50(2): 408-416. |

| [8] | 宋昌庆,陈文淼,李君,曲大为,崔昊. 不同当量比下单双点火对天然气燃烧特性的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 1929-1935. |

| [9] | 朱一骁,何小民,金义. 联焰板宽度对单凹腔驻涡燃烧室流线形态的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 1936-1944. |

| [10] | 刘长铖,刘忠长,田径,许允,杨泽宇. 重型增压柴油机燃烧过程中的缸内㶲损失[J]. 吉林大学学报(工学版), 2019, 49(6): 1911-1919. |

| [11] | 胡潇宇,李国祥,白书战,孙柯,李思远. 考虑加热面粗糙度和材料的沸腾换热修正模型[J]. 吉林大学学报(工学版), 2019, 49(6): 1945-1950. |

| [12] | 王德军,吕志超,王启明,张建瑞,丁建楠. 基于EKF及调制傅式级数的缸压辨识[J]. 吉林大学学报(工学版), 2019, 49(4): 1174-1185. |

| [13] | 臧鹏飞,王哲,高洋,孙晨乐. 直线电机/发动机系统稳态运行综合控制策略[J]. 吉林大学学报(工学版), 2019, 49(3): 798-804. |

| [14] | 董伟,宋佰达,邱立涛,孙昊天,孙平,蒲超杰. 直喷汽油机暖机过程中两次喷射比例对燃烧和排放的影响[J]. 吉林大学学报(工学版), 2018, 48(6): 1755-1761. |

| [15] | 李志军, 汪昊, 何丽, 曹丽娟, 张玉池, 赵新顺. 催化型微粒捕集器碳烟分布及其影响因素[J]. 吉林大学学报(工学版), 2018, 48(5): 1466-1474. |

|

||