吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (3): 504-514.doi: 10.13229/j.cnki.jdxbgxb20200857

• 车辆工程·机械工程 • 上一篇

二/四冲程可变柴油机燃烧室热负荷的改善

张岩1( ),刘玮1,张树勇1,裴毅强2(

),刘玮1,张树勇1,裴毅强2( ),董蒙蒙2,秦静2,3

),董蒙蒙2,秦静2,3

- 1.中国北方发动机研究所 柴油机增压技术重点实验室,天津 300072

2.天津大学 内燃机燃烧学国家重点实验室,天津 300072

3.天津大学 内燃机研究所,天津 300072

Optimization on thermal load of combustion chamber on two/four⁃stroke switchable diesel engine

Yan ZHANG1( ),Wei LIU1,Shu-yong ZHANG1,Yi-qiang PEI2(

),Wei LIU1,Shu-yong ZHANG1,Yi-qiang PEI2( ),Meng-meng DONG2,Jing QIN2,3

),Meng-meng DONG2,Jing QIN2,3

- 1.National Key Laboratory of Diesel Engine Turbocharging,China North Engine Research Institute,Tianjin 300072,China

2.State Key Laboratory of Engines,Tianjin University,Tianjin 300072,China

3.Internal Combustion Engine Research Institute,Tianjin University,Tianjin 300072,China

摘要:

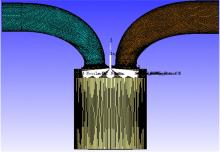

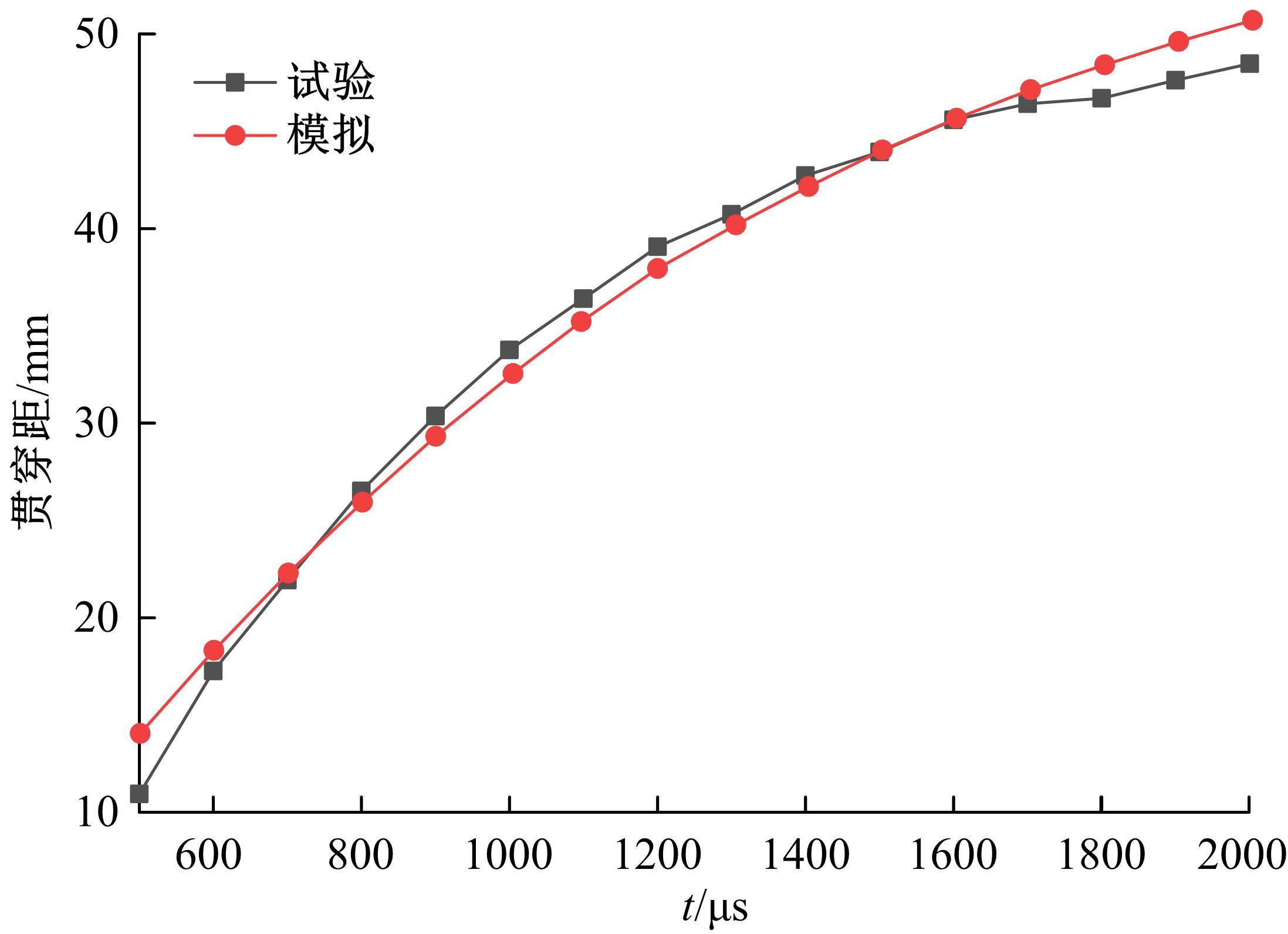

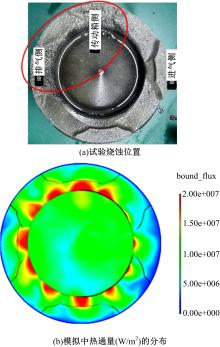

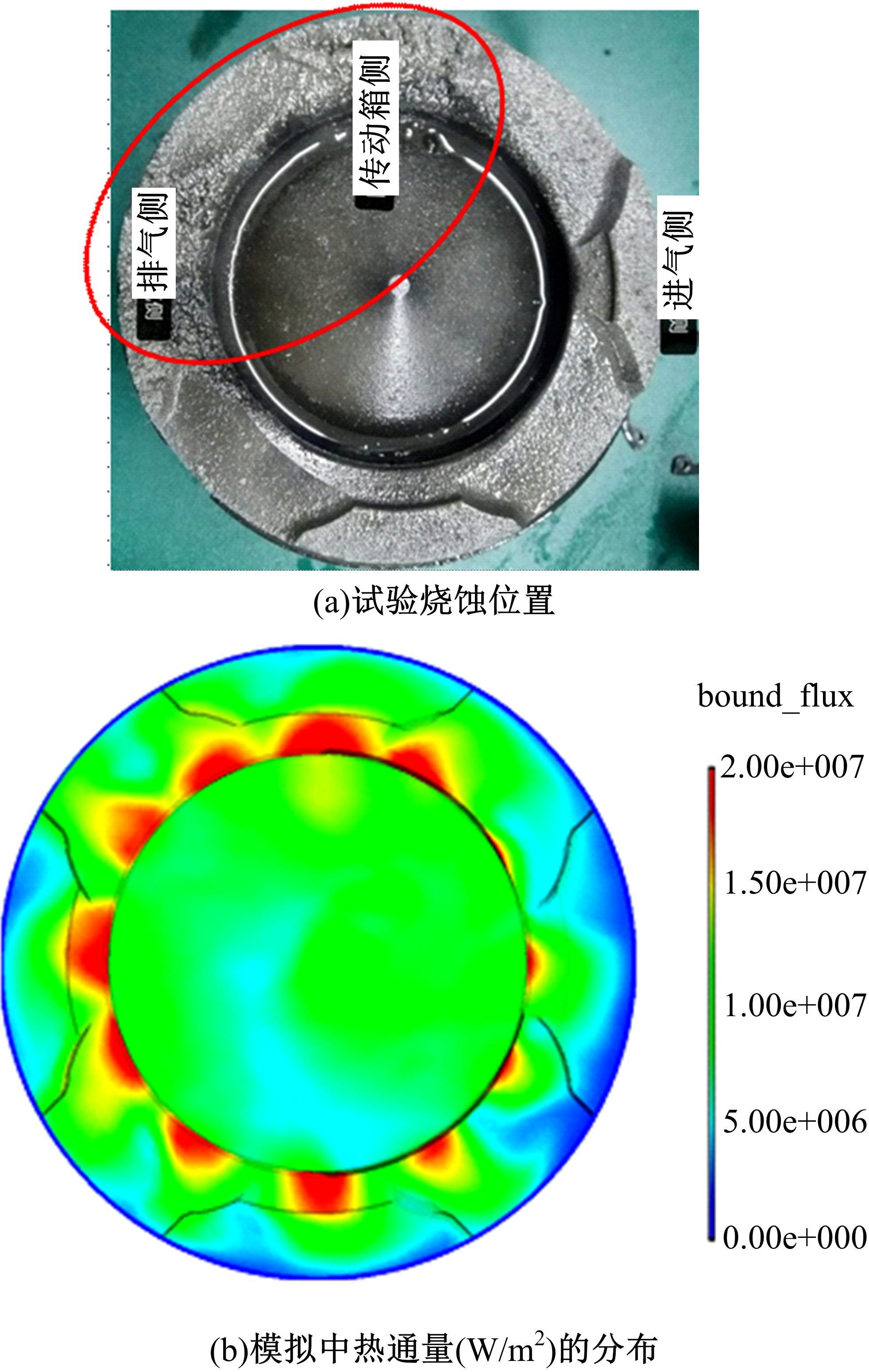

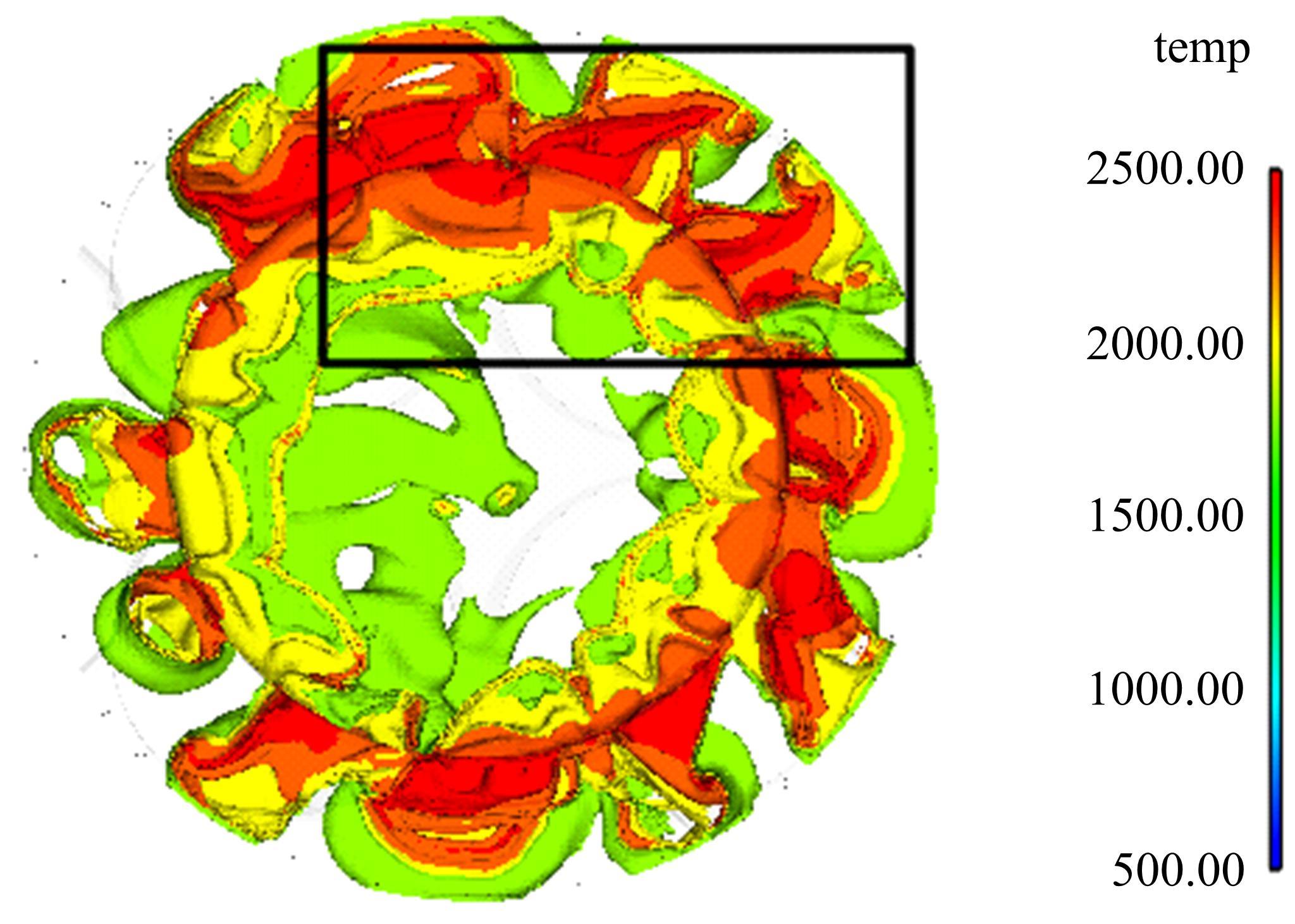

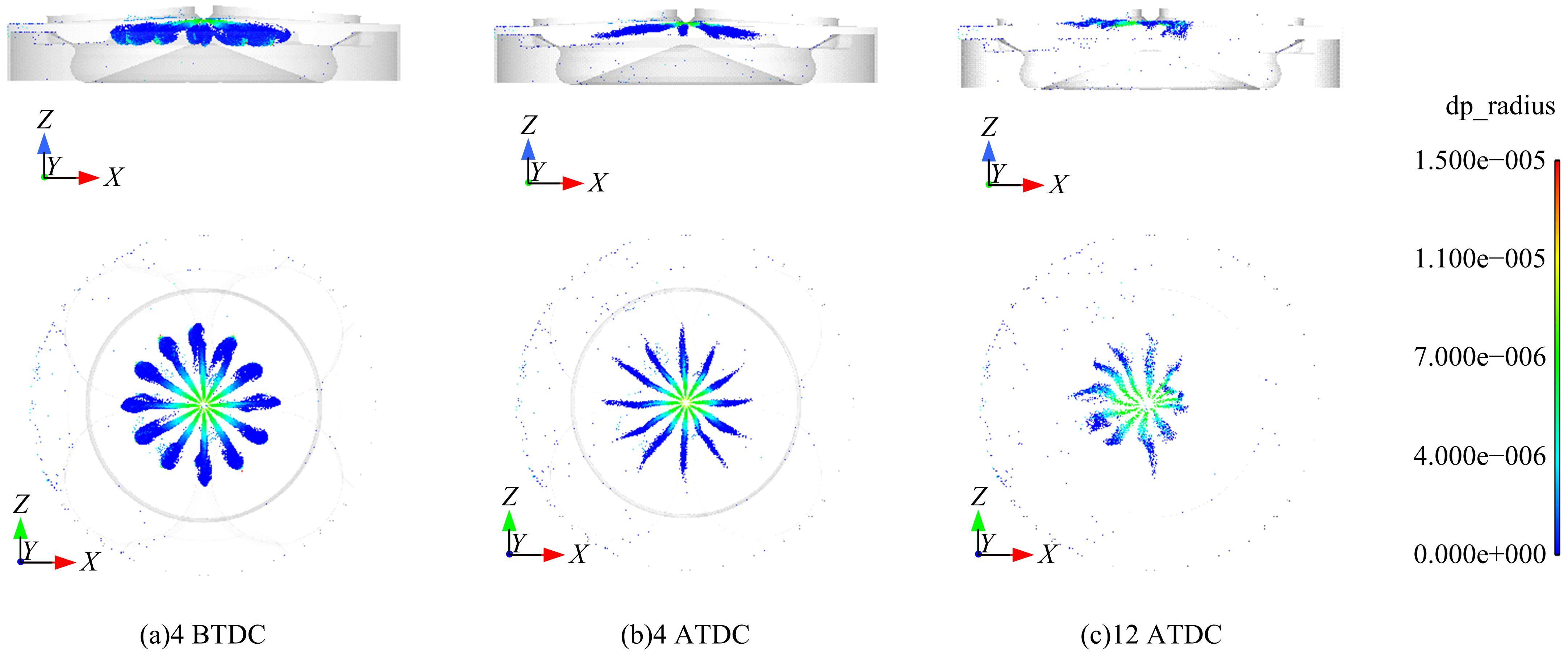

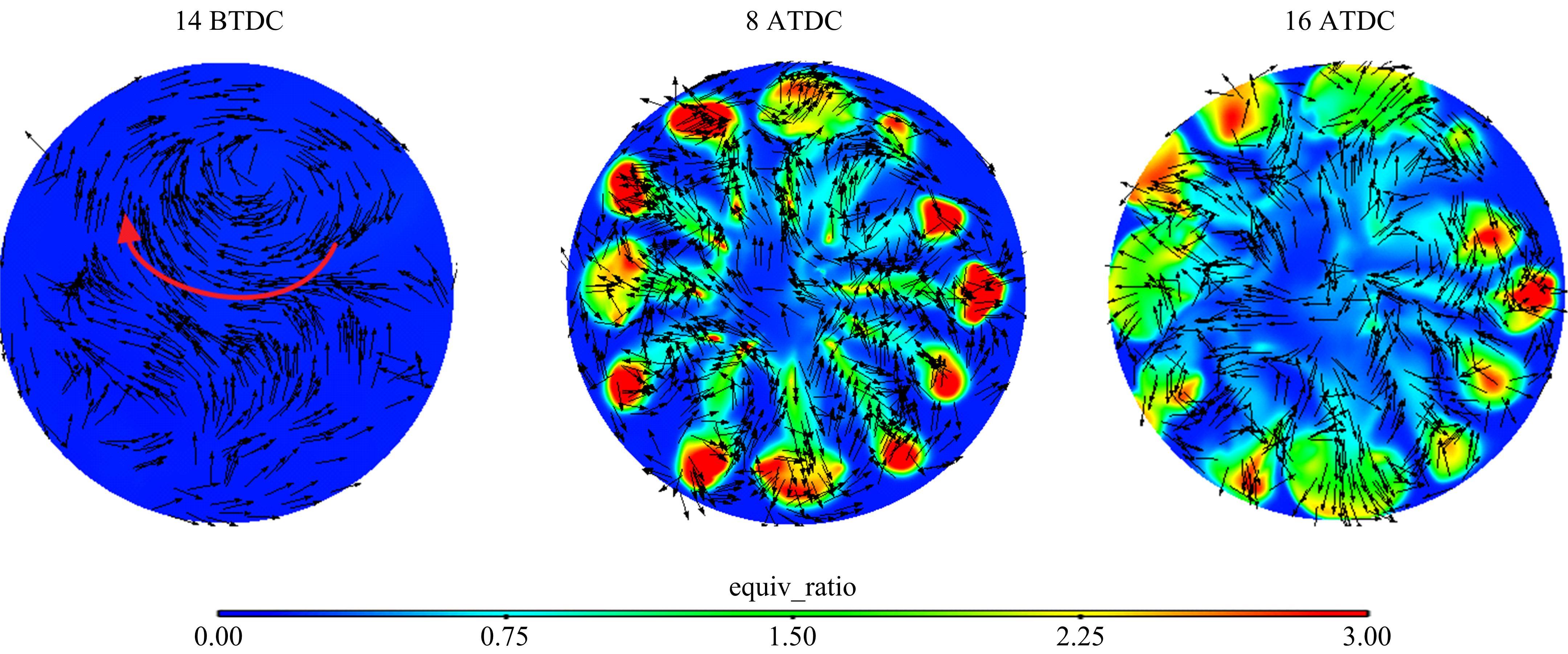

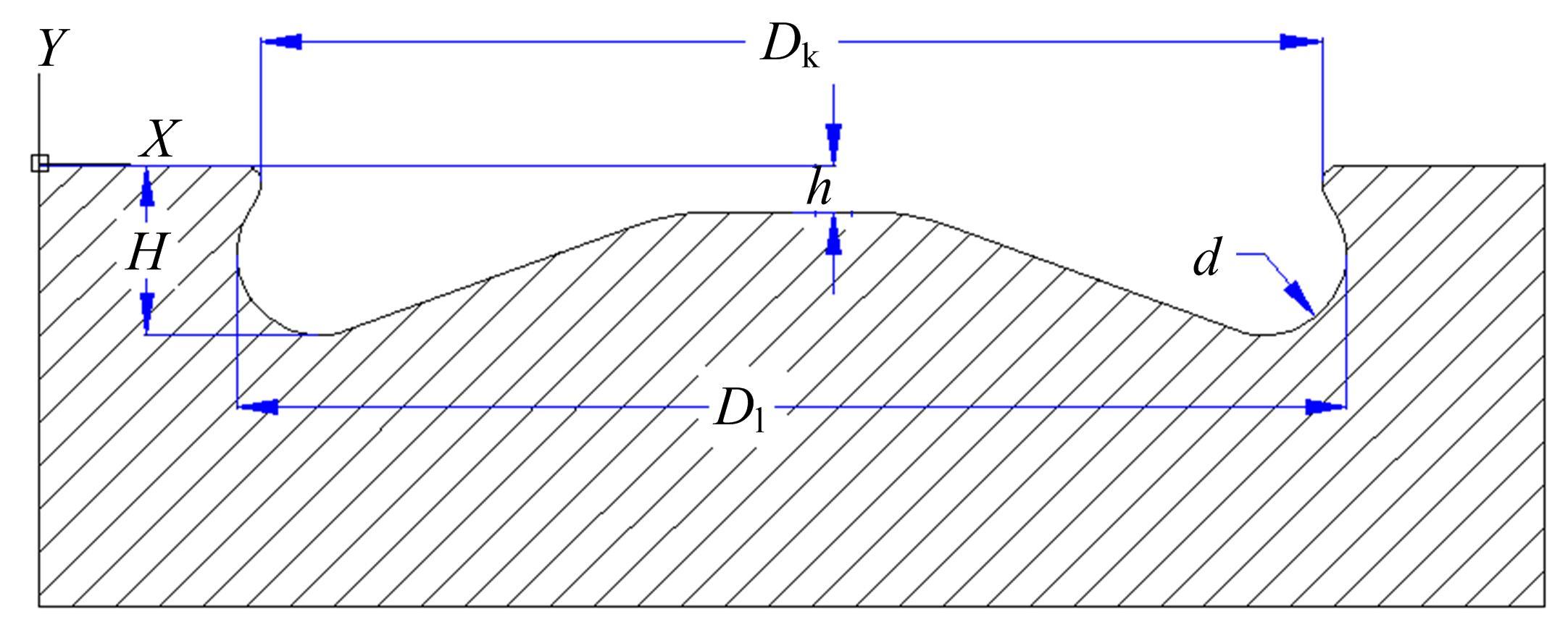

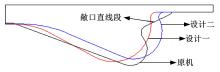

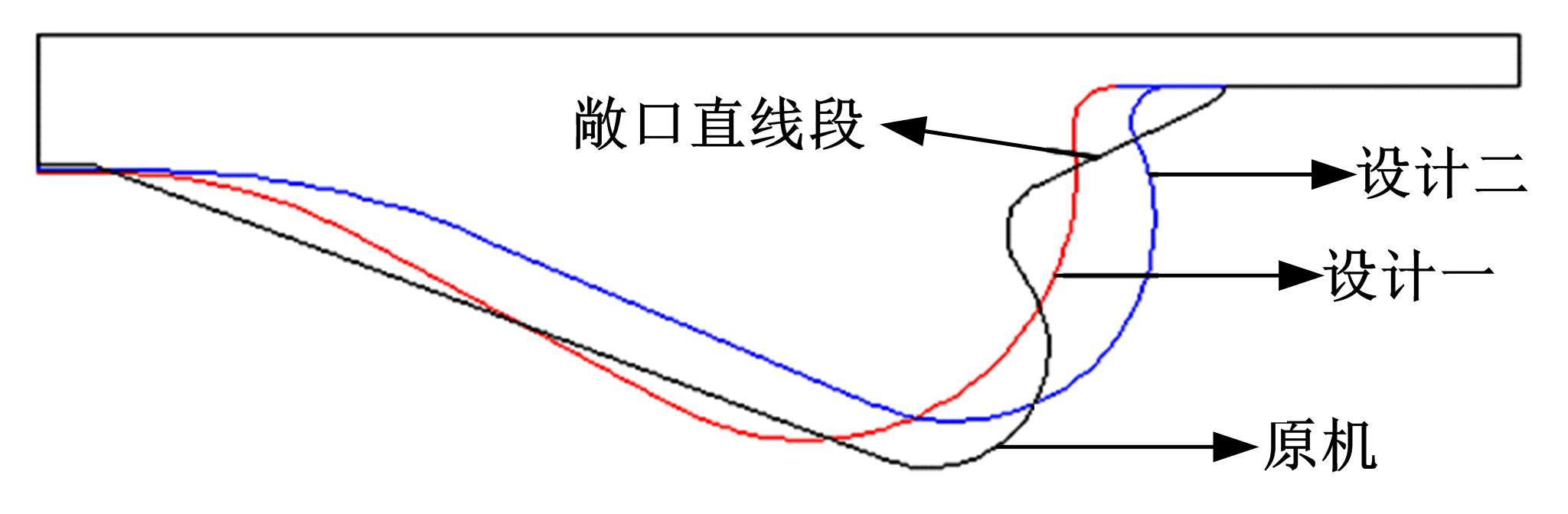

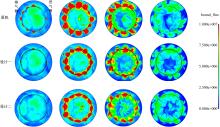

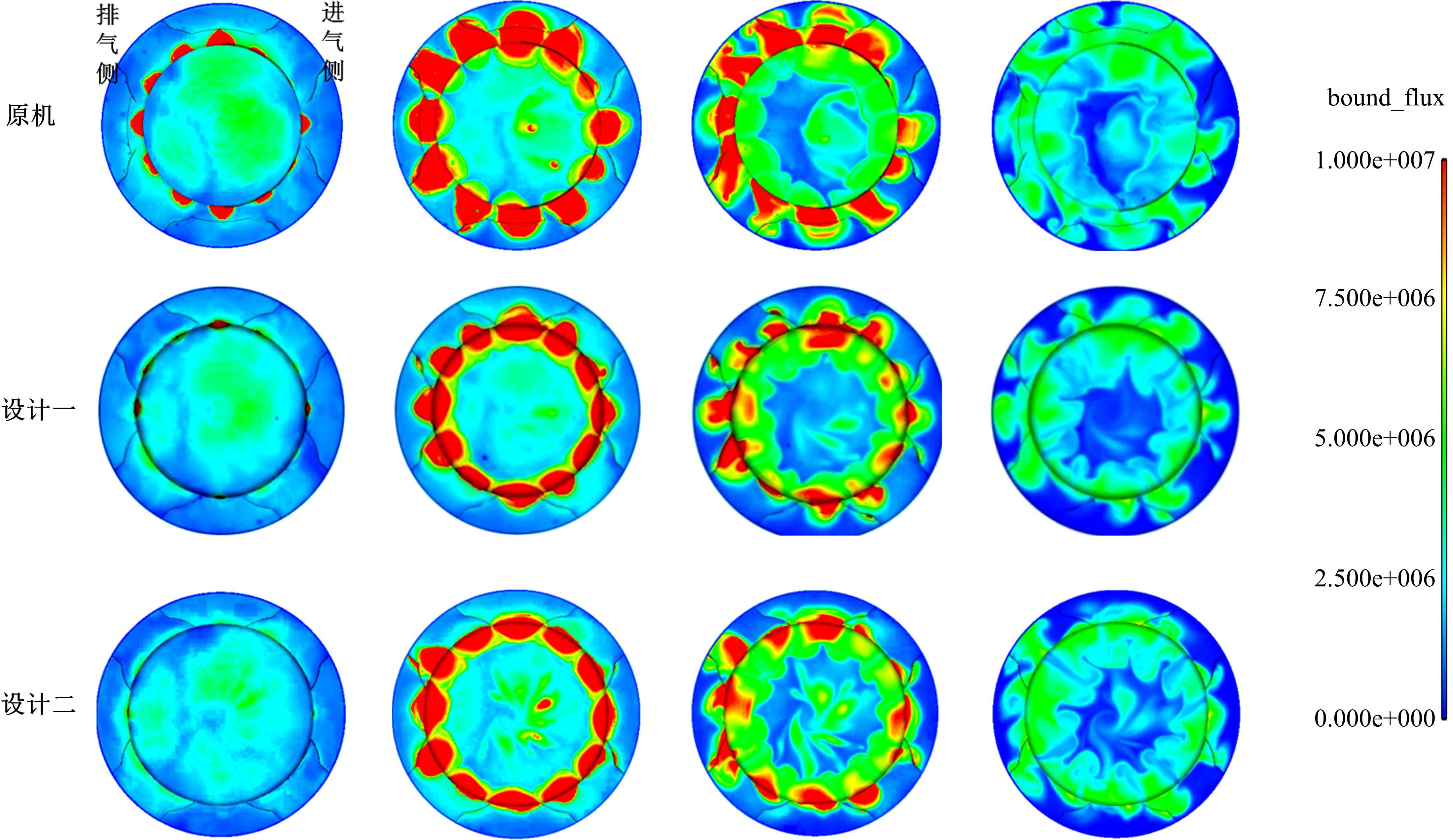

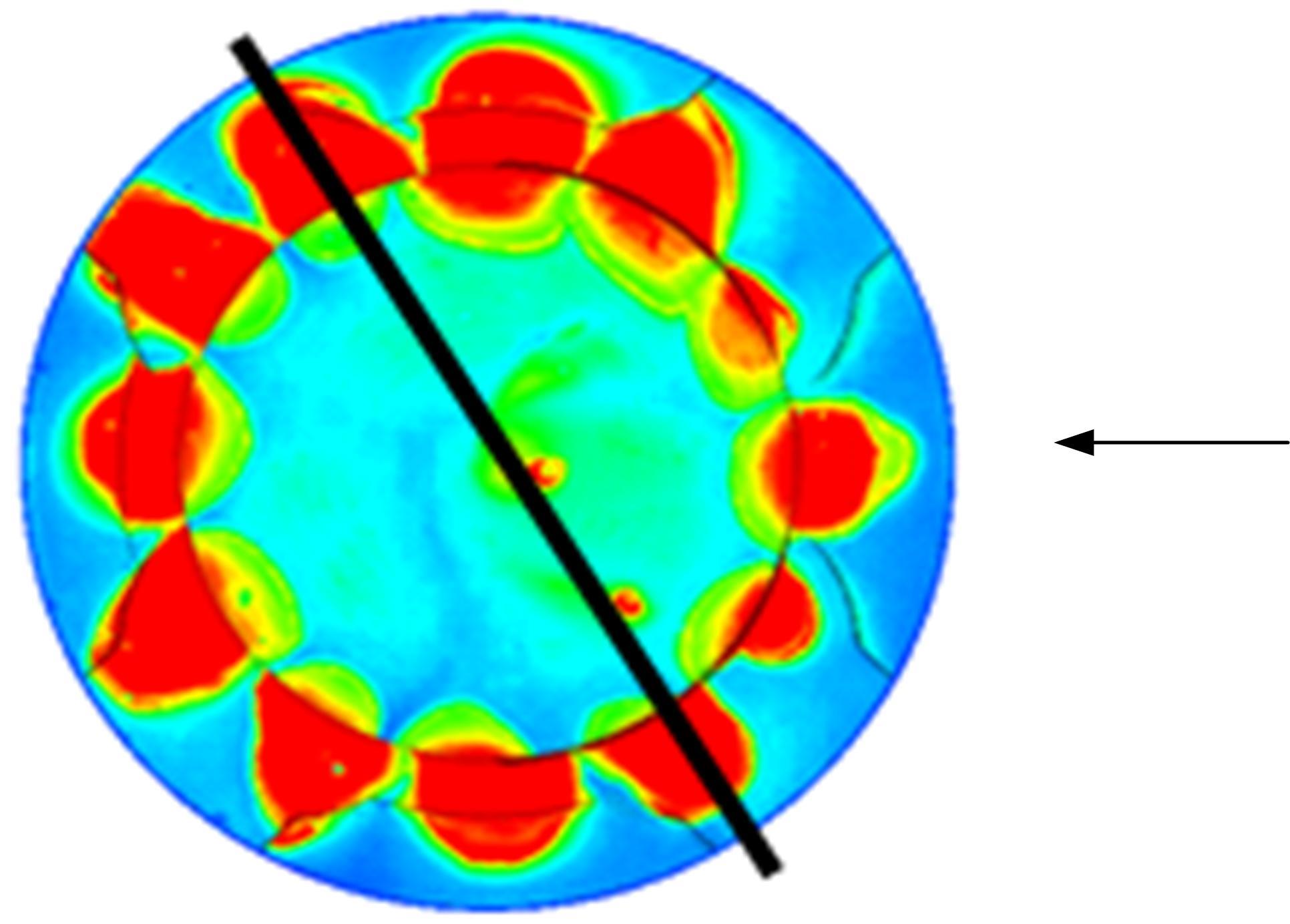

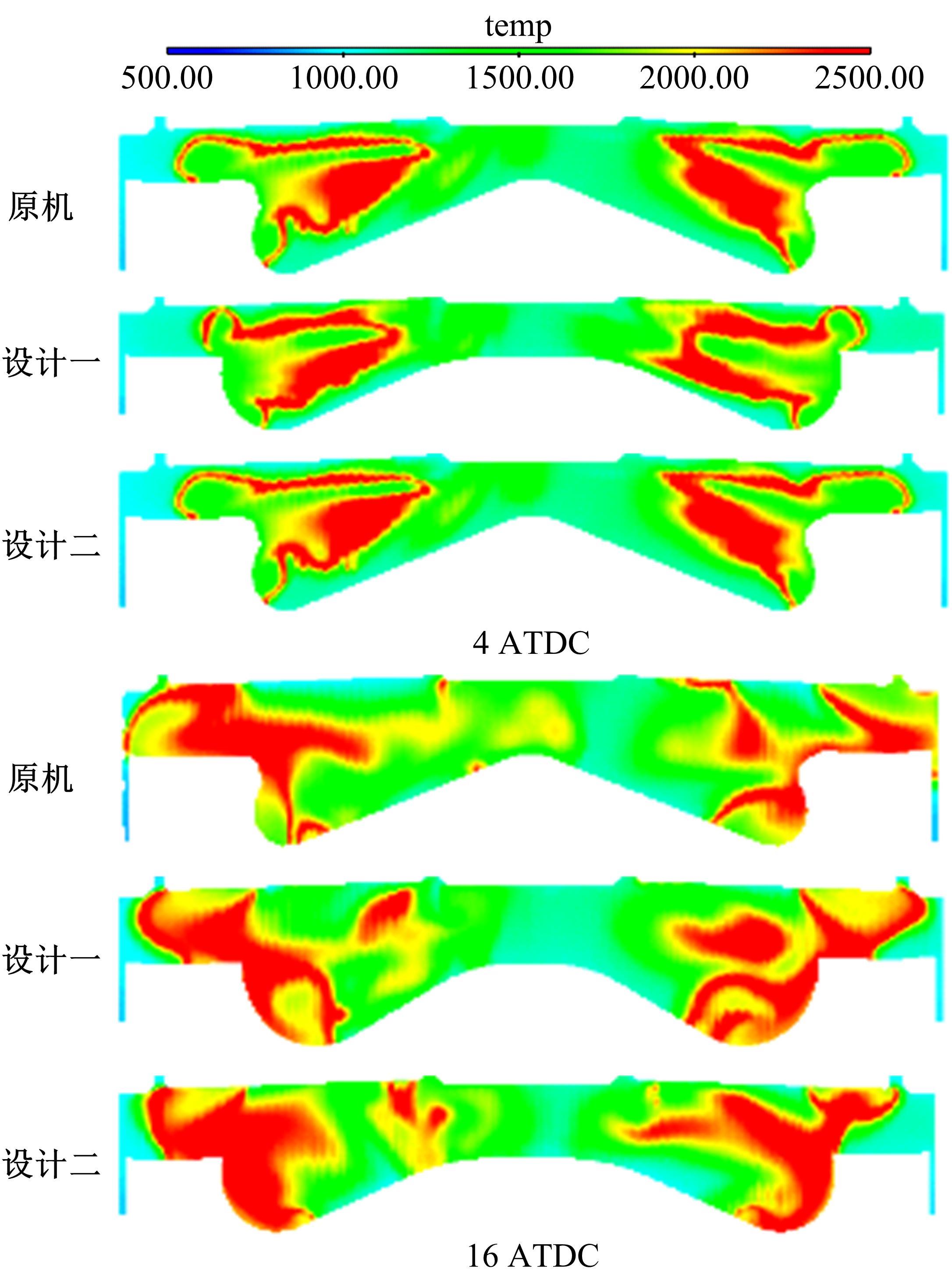

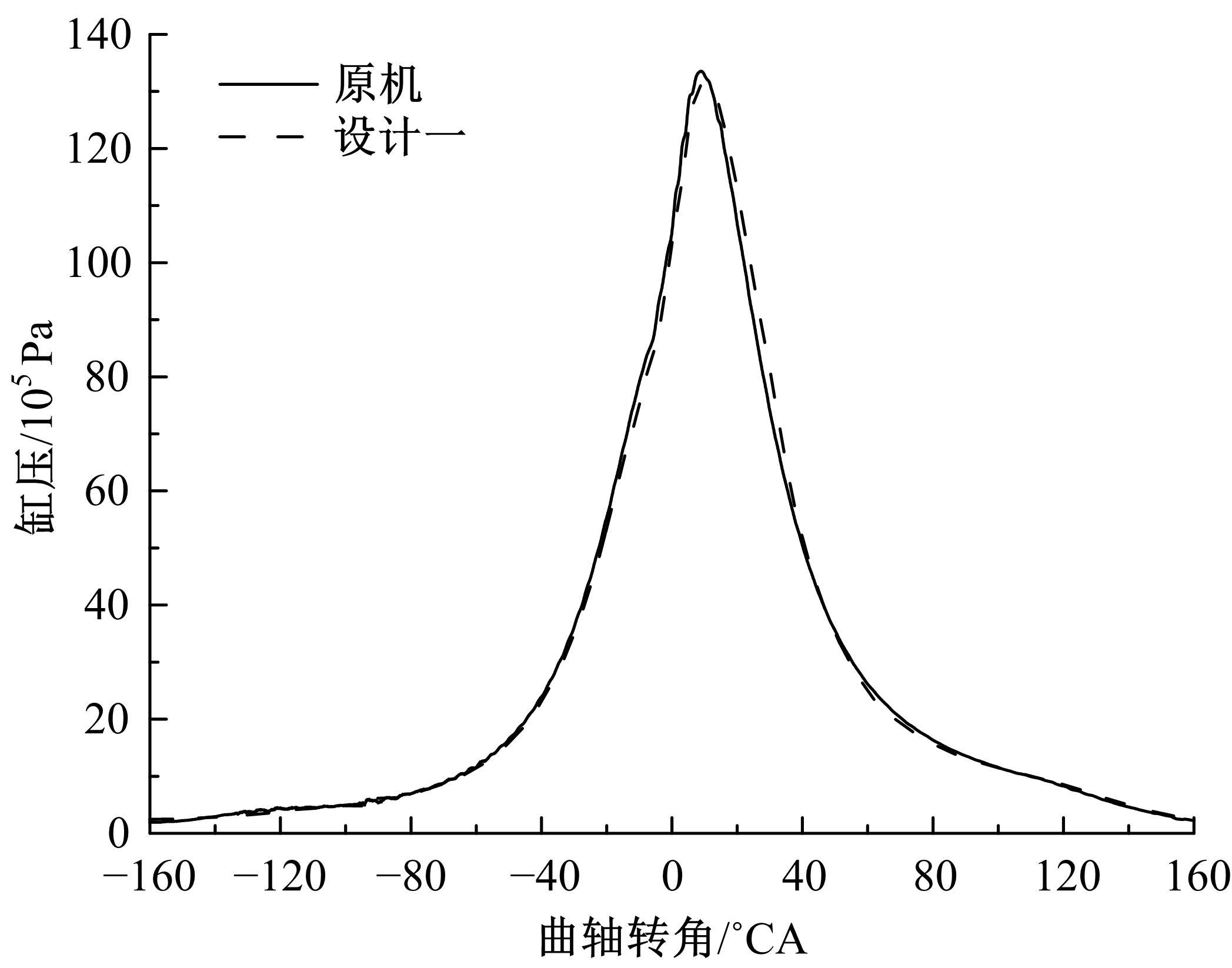

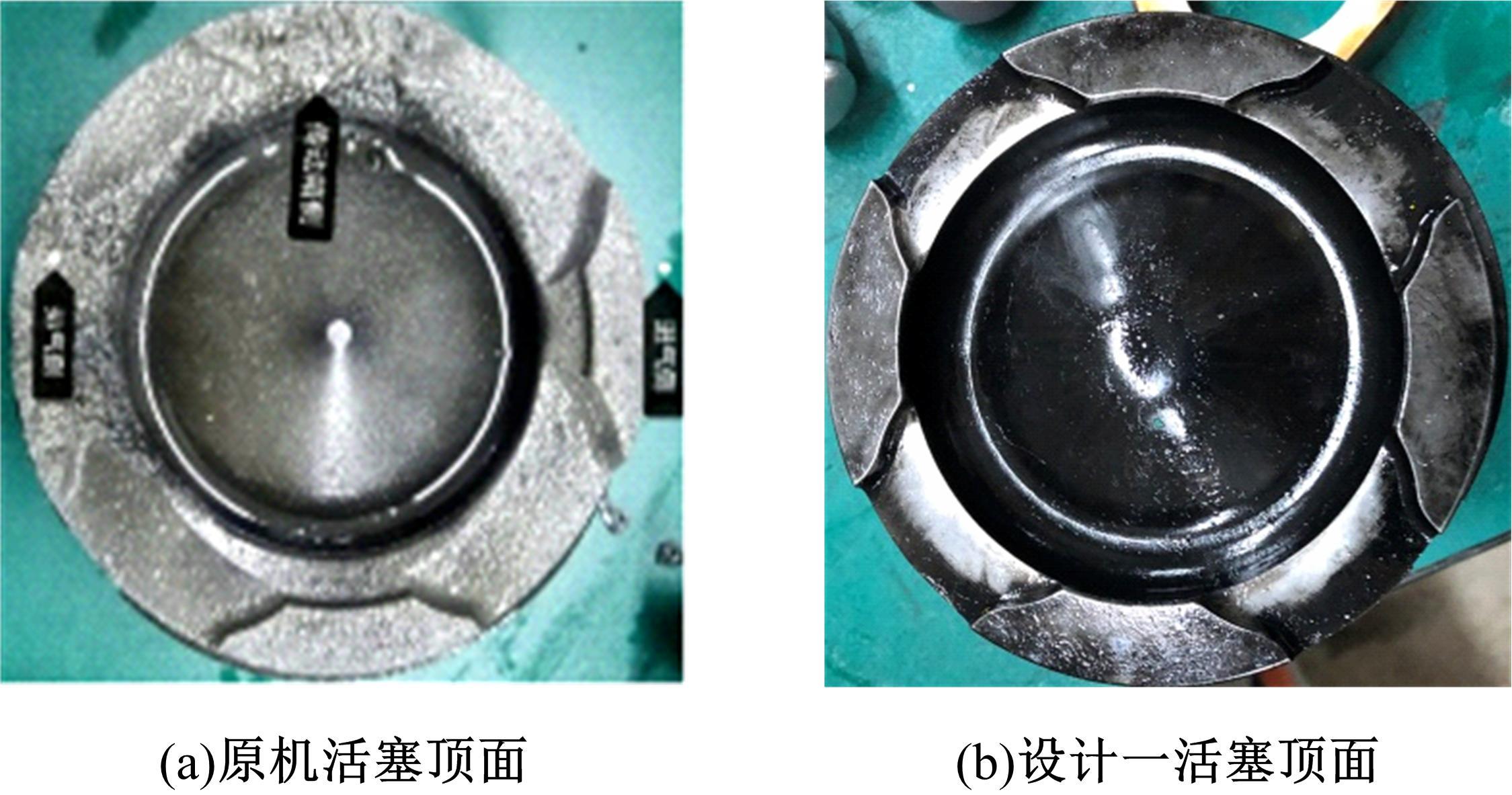

采用计算流体动力学(CFD)方法对一台二/四冲程可变柴油机在二冲程工作模式下活塞烧蚀的现象进行了研究,分析发现气流运动导致混合气在活塞碗沿处发生燃烧,从而产生了局部高温和局部过高热负荷。设计了两种燃烧室结构形式,通过调整油-气-室的配合以改善燃烧状况,研究发现,增大燃烧室碗口直径可以减少向活塞碗沿上方扩散的混合气,增大混合气在燃烧室内部的扩散空间,从而避免了在活塞碗沿处产生过高热负荷;增大燃烧室凹坑直径则有助于在凹坑内产生涡流,促进混合气的形成,缩短燃烧持续期。模拟计算结果显示,相比于原机,在2800 r/min@46 kW工况下两种优化设计的燃烧室在活塞碗沿上的热负荷得到明显改善,功率分别提高了4.11%和1.96%。加工设计一方案并在相同工况下进行对比试验,结果表明,相对于原机,优化设计后的柴油机油耗降低了6.93%,排气温度降低了21.1 K,活塞表面状态良好,无烧蚀发生。

中图分类号:

- TK421.2

| 1 | 周龙保. 内燃机学[M]. 3版. 北京: 机械工业出版社, 2011. |

| 2 | 王建昕, 帅石金. 汽车发动机原理[M]. 北京: 清华大学出版社, 2011. |

| 3 | Pugnali L D, Chen Rui. Feasibility study of operating 2-stroke miller cycles on a 4-stroke platform through variable valve train[C]∥SAE Technical Paper,2015-01-1974. |

| 4 | Zhang Y, Macklini D, Zhao H. Investigation of valve timings on lean boost CAI operation in a two-stroke poppet valve DI engine[C]∥SAE Technical Paper,2015-01-1794. |

| 5 | Dalla Nora M, Lanzanova T, Zhang Y, et al. Engine downsizing through two-stroke operation in a four-valve GDI engine[C]∥SAE Technical Paper, 2016-01-0674. |

| 6 | Zhang Y, Ojapah M, Cairns Alasdair. 2-Stroke CAI combustion operation in a GDI engine with poppet valves[C]∥SAE Technical Paper, 2012-01-1118. |

| 7 | Osborne R J, Stokes J, Lake T H. Development of a two-stroke/four-stroke switching gasoline engine—the 2/4SIGHT concept[C]∥SAE Technical Paper, 2005-01-1137. |

| 8 | 毕翔云. 内燃机的热负荷[J]. 内燃机, 1989, 4(6): 1-6. |

| Bi Xiang-yun, Thermal load of internal combustion engines[J]. Internal Combustion Engines, 1989, 4(6): 1-6. | |

| 9 | 文均, 王东方, 雷基林, 等. 活塞内冷油腔的振荡传热特性及位置的研究[J]. 中国机械工程, 2019, 30(6): 672-679. |

| Wen Jun, Wang Dong-fang, Lei Ji-lin, et al. Research on the oscillating heat transfer characteristics and location of the piston inner cooling oil cavity[J]. China Mechanical Engineering, 2019, 30(6): 672-679. | |

| 10 | 原彦鹏, 王月, 张卫正, 等. 冷却油腔位置改变对活塞温度场的影响[J]. 北京理工大学学报, 2008, 28(7): 585-588. |

| Yuan Yan-peng, Wang Yue, Zhang Wei-zheng, et al. The influence of the position change of the cooling oil cavity on the temperature field of the piston[J]. Journal of Beijing Institute of Technology, 2008, 28(7): 585-588. | |

| 11 | 苌转, 赵云磊. 496ZQ柴油机活塞热负荷研究及评价[J].内燃机, 2018, 33(3): 42-45. |

| Chang Zhuan, Zhao Yun-lei. Research and evaluation on thermal load of 496ZQ diesel engine piston[J]. Internal Combustion Engine, 2018, 33(3): 42-45. | |

| 12 | 徐勤超, 李善军, 练永庆, 等. 新型凸轮发动机活塞强度分析及结构改进[J]. 武汉大学学报: 工学版, 2019, 52(3): 270-276, 282. |

| Xu Qin-chao, Li Shan-jun, Lian Yong-qing, et al. Strength analysis and structural improvement of the piston of a new cam engine[J]. Journal of Wuhan University (Engineering Edition), 2019, 52(3): 270-276, 282. | |

| 13 | Liu D L, Zhu X B, Xu K L, et al. Thermal load simulation and structure improvement of high speed diesel engine piston[J]. Applied Mechanics and Materials, 2014, 513-517: 2843-2846. |

| 14 | 张继春, 李兴虎, 马凡华. CA488活塞的强度分析及结构改进[J]. 机械强度, 2007, 32(3): 501-506. |

| Zhang Ji-chun, Li Xing-hu, Ma Fan-hua. Strength analysis and structure improvement of CA488 piston[J]. Mechanical Strength, 2007, 32(3): 501-506. | |

| 15 | 林学东, 顾静静, 李德刚, 等. 柴油机燃烧室结构对混合气形成及燃烧特性的影响[J]. 吉林大学学报: 工学版, 2014, 44(6): 1647-1654. |

| Lin Xue-dong, Gu Jing-jing, Li De-gang, et al. The influence of diesel engine combustion chamber structure on the formation and combustion characteristics of mixed gas[J]. Journal of Jilin University(Engineering and Technology Edition), 2014, 44(6): 1647-1654. | |

| 16 | 齐鲲鹏, 田江平, 董鹏博, 等. 直喷式柴油机双层分流燃烧系统的数值模拟与试验研究[J]. 内燃机工程, 2014, 35(6): 54-59. |

| Qi Kun-peng, Tian Jiang-ping, Dong Peng-bo, et al. Numerical simulation and experimental research on a two-stage split-flow combustion system of a direct injection diesel engine[J]. Internal Combustion Engine Engineering, 2014, 35(6): 54-59. | |

| 17 | 林学东, 田维, 黄丫, 等. 高压共轨直喷柴油机缩口燃烧室内混合气形成的多维数值研究[J]. 吉林大学学报: 工学版, 2010, 40(2): 363-369. |

| Lin Xue-dong, Tian Wei, Huang Ya, et al. Multi-dimensional numerical study on the mixture formation in the necked combustor of a high pressure common rail direct injection diesel engine[J]. Journal of Jilin University (Engineering and Technology Edition), 2010, 40(2): 363-369. | |

| 18 | Sener R, Yangaz M U, Gui M Z. Effects of injection strategy and combustion chamber modification on a single-cylinder diesel engine [J]. Fuel, 2020, 266: No. 117122. |

| 19 | 俞小莉, 翟昕, 刘震涛, 等. 柴油机燃烧室形状对活塞热负荷与机械负荷的影响[J]. 内燃机工程, 2002, 23(1): 45-48. |

| Yu Xiao-li, Zhai Xin, Liu Zhen-tao, et al. The influence of the shape of the diesel engine combustion chamber on the thermal load and mechanical load of the piston[J]. Internal Combustion Engine Engineering, 2002,23(1):45-48. | |

| 20 | 刘启胜, 余宏峰, 殷勇,等. 一种低热损失柴油机燃烧室结构[P]. 中国:CN109162804A, 2019-01-08. |

| 21 | Arato K, Takashima T. A study on reduction of heat loss by optimizing combustion chamber shape[C]∥SAE Technical Paper, 2015-01-0786. |

| 22 | Das S, Roberts C. Factors affecting heat transfer in a diesel engine: low heat rejection engine revisited[C]∥SAE Technical Paper, 2013-01-0875. |

| 23 | Liu W, Zhang Y, Yu B, et al. Effects of intake port structures and valve timings on the scavenging process in a two-stroke poppet valve diesel engine[C]∥SAE Technical Paper, 2019-01-1169. |

| 24 | Li Z, He B, Zhao H. The influence of intake port and pent-roof structures on reversed tumble generation of a poppet-valved two-stroke gasoline engine[C]∥SAE Technical Paper, 2014-01-1130. |

| 25 | Li X, Zhao H, Zhang Y . et al . Simulation of the effect of intake pressure and split injection on lean combustion characteristics of a poppet-valve two-stroke direct injection gasoline engine at high loads[C]∥SAE Technical Paper, 2018-01-1723. |

| 26 | 许汉君, 宋金瓯, 姚春德, 等. 对置二冲程柴油机缸内流动形式对混合气形成及燃烧的模拟研究[J]. 内燃机学报, 2009, 27(5): 395-400. |

| Xu Han-jun, Song Jin-ou, Yao Chun-de, et al. Simulation in-cylinder flow on mixture formation and combustion in OPOC engine[J]. Transactions of Csice, 2009, 27(5): 395-400. |

| [1] | 李志军,刘浩,张立鹏,李振国,邵元凯,李智洋. 过滤壁结构对颗粒捕集器深床过滤影响的模拟[J]. 吉林大学学报(工学版), 2021, 51(2): 422-434. |

| [2] | 赵庆武,程勇,杨雪,王宁. 高重频纳秒脉冲放电点火系统设计[J]. 吉林大学学报(工学版), 2021, 51(2): 414-421. |

| [3] | 王忠,李游,张美娟,刘帅,李瑞娜,赵怀北. 柴油机排气阶段颗粒碰撞过程动力学特征分析[J]. 吉林大学学报(工学版), 2021, 51(1): 39-48. |

| [4] | 胡云峰,丁一桐,赵志欣,蒋冰晶,高金武. 柴油发动机燃烧过程数据驱动建模与滚动优化控制[J]. 吉林大学学报(工学版), 2021, 51(1): 49-62. |

| [5] | 王建,许鑫,顾晗,张多军,刘胜吉. 基于排气热管理的柴油机氧化催化器升温特性[J]. 吉林大学学报(工学版), 2020, 50(2): 408-416. |

| [6] | 宋昌庆,陈文淼,李君,曲大为,崔昊. 不同当量比下单双点火对天然气燃烧特性的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 1929-1935. |

| [7] | 朱一骁,何小民,金义. 联焰板宽度对单凹腔驻涡燃烧室流线形态的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 1936-1944. |

| [8] | 刘长铖,刘忠长,田径,许允,杨泽宇. 重型增压柴油机燃烧过程中的缸内㶲损失[J]. 吉林大学学报(工学版), 2019, 49(6): 1911-1919. |

| [9] | 胡潇宇,李国祥,白书战,孙柯,李思远. 考虑加热面粗糙度和材料的沸腾换热修正模型[J]. 吉林大学学报(工学版), 2019, 49(6): 1945-1950. |

| [10] | 王德军,吕志超,王启明,张建瑞,丁建楠. 基于EKF及调制傅式级数的缸压辨识[J]. 吉林大学学报(工学版), 2019, 49(4): 1174-1185. |

| [11] | 臧鹏飞,王哲,高洋,孙晨乐. 直线电机/发动机系统稳态运行综合控制策略[J]. 吉林大学学报(工学版), 2019, 49(3): 798-804. |

| [12] | 董伟,宋佰达,邱立涛,孙昊天,孙平,蒲超杰. 直喷汽油机暖机过程中两次喷射比例对燃烧和排放的影响[J]. 吉林大学学报(工学版), 2018, 48(6): 1755-1761. |

| [13] | 李志军, 汪昊, 何丽, 曹丽娟, 张玉池, 赵新顺. 催化型微粒捕集器碳烟分布及其影响因素[J]. 吉林大学学报(工学版), 2018, 48(5): 1466-1474. |

| [14] | 林学东, 江涛, 许涛, 李德刚, 郭亮. 高压共轨柴油机起动工况高压泵控制策略[J]. 吉林大学学报(工学版), 2018, 48(5): 1436-1443. |

| [15] | 秦静, 徐鹤, 裴毅强, 左子农, 卢莉莉. 初始温度和初始压力对甲烷-甲醇裂解气预混层流燃烧特性的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1475-1482. |

|

||