吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (4): 917-925.doi: 10.13229/j.cnki.jdxbgxb.20220681

TC4钛合金材料铣削加工分析及参数优化

- 东北大学 机械工程与自动化学院,沈阳 110819

Milling analysis and parameter optimization for TC4 titanium alloy material

Ya-dong GONG( ),Ming-xiang DING,Xiang LI,Jin-min TIAN

),Ming-xiang DING,Xiang LI,Jin-min TIAN

- School of Mechanical Engineering and Automation,Northeastern University,Shenyang 110819

摘要:

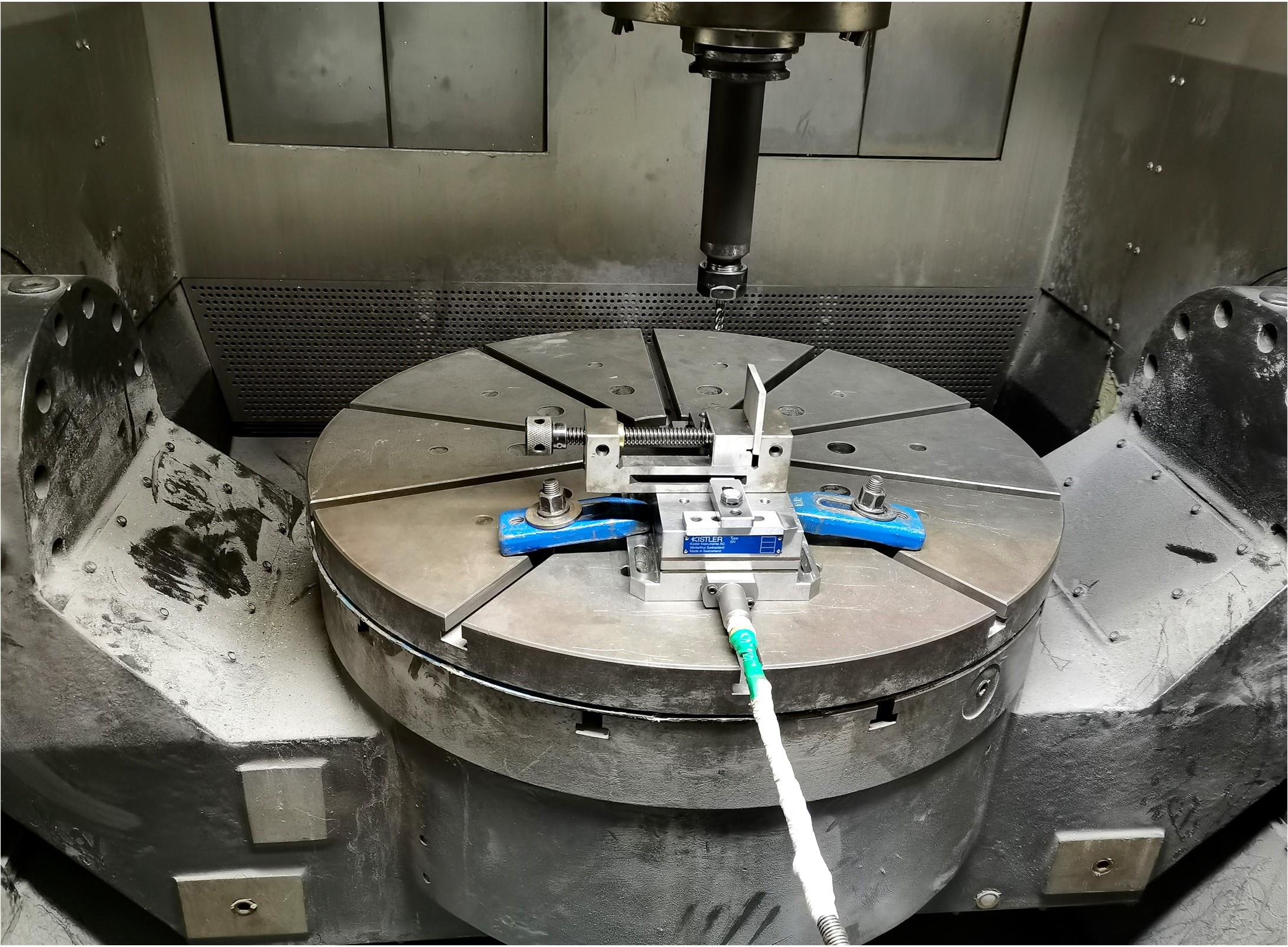

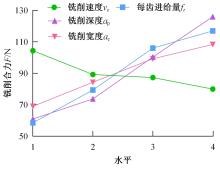

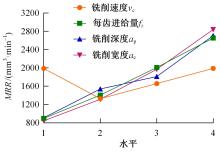

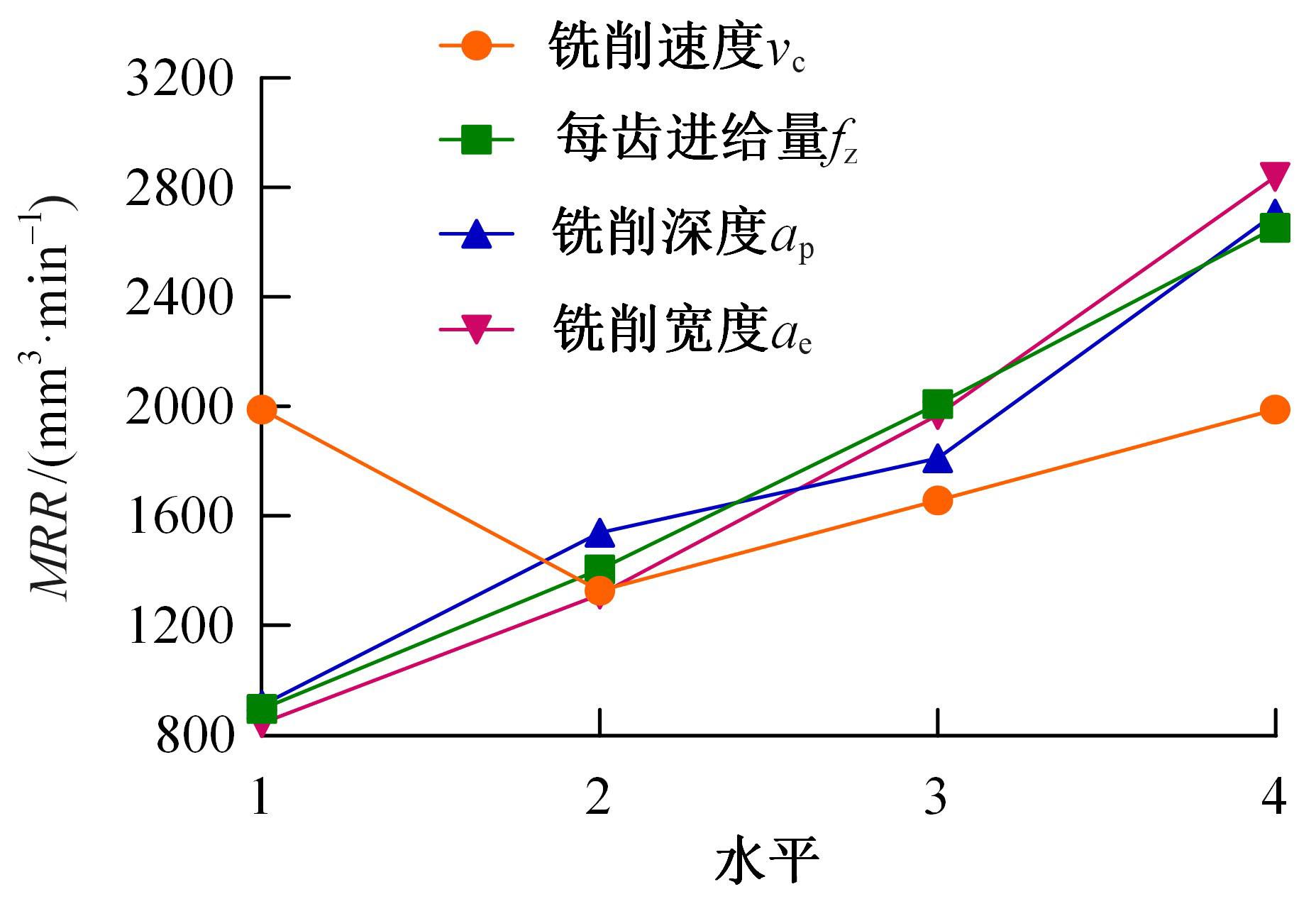

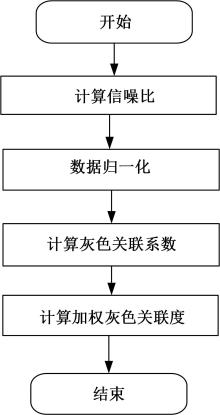

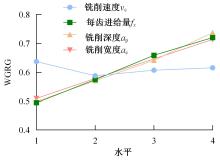

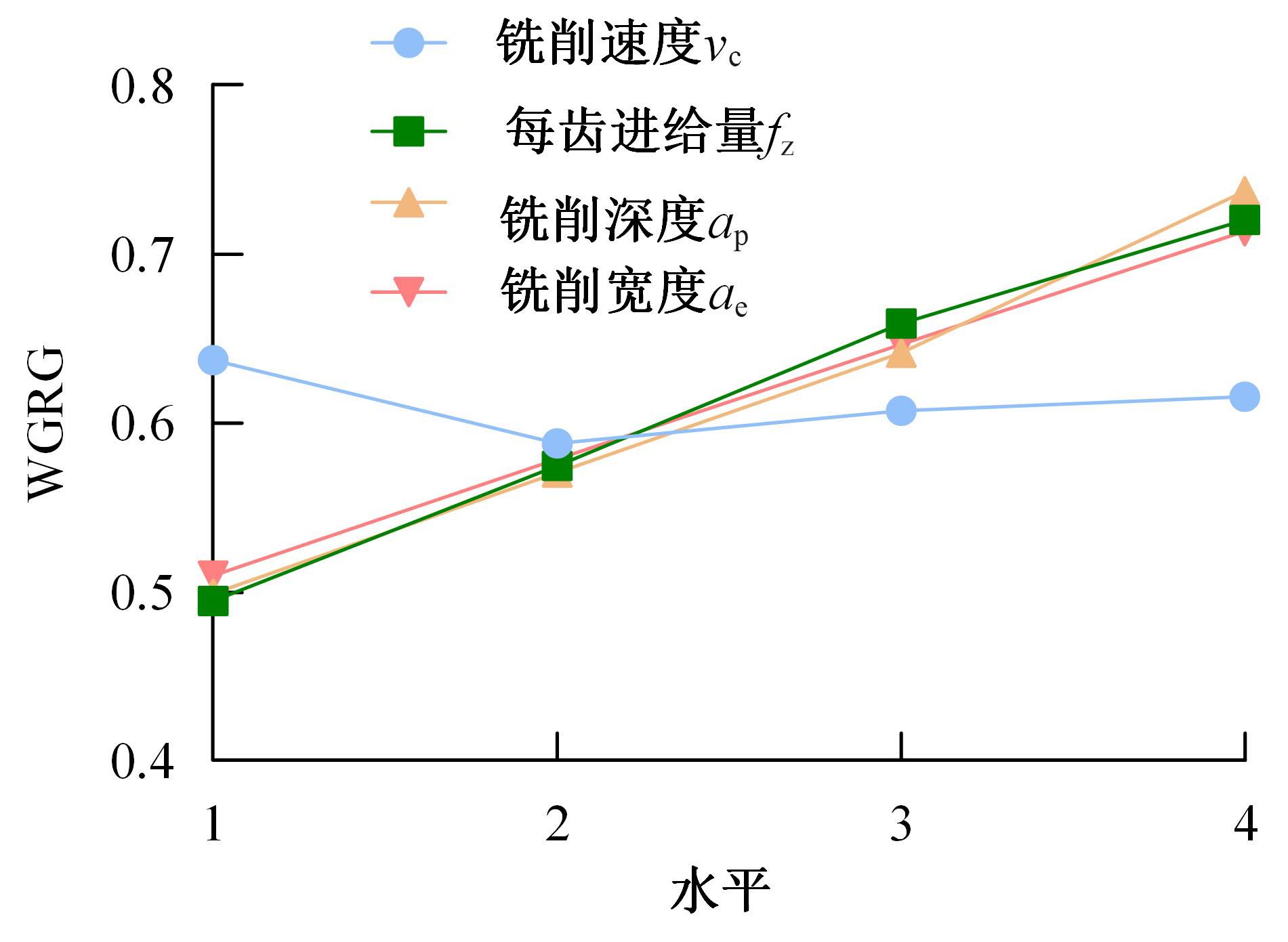

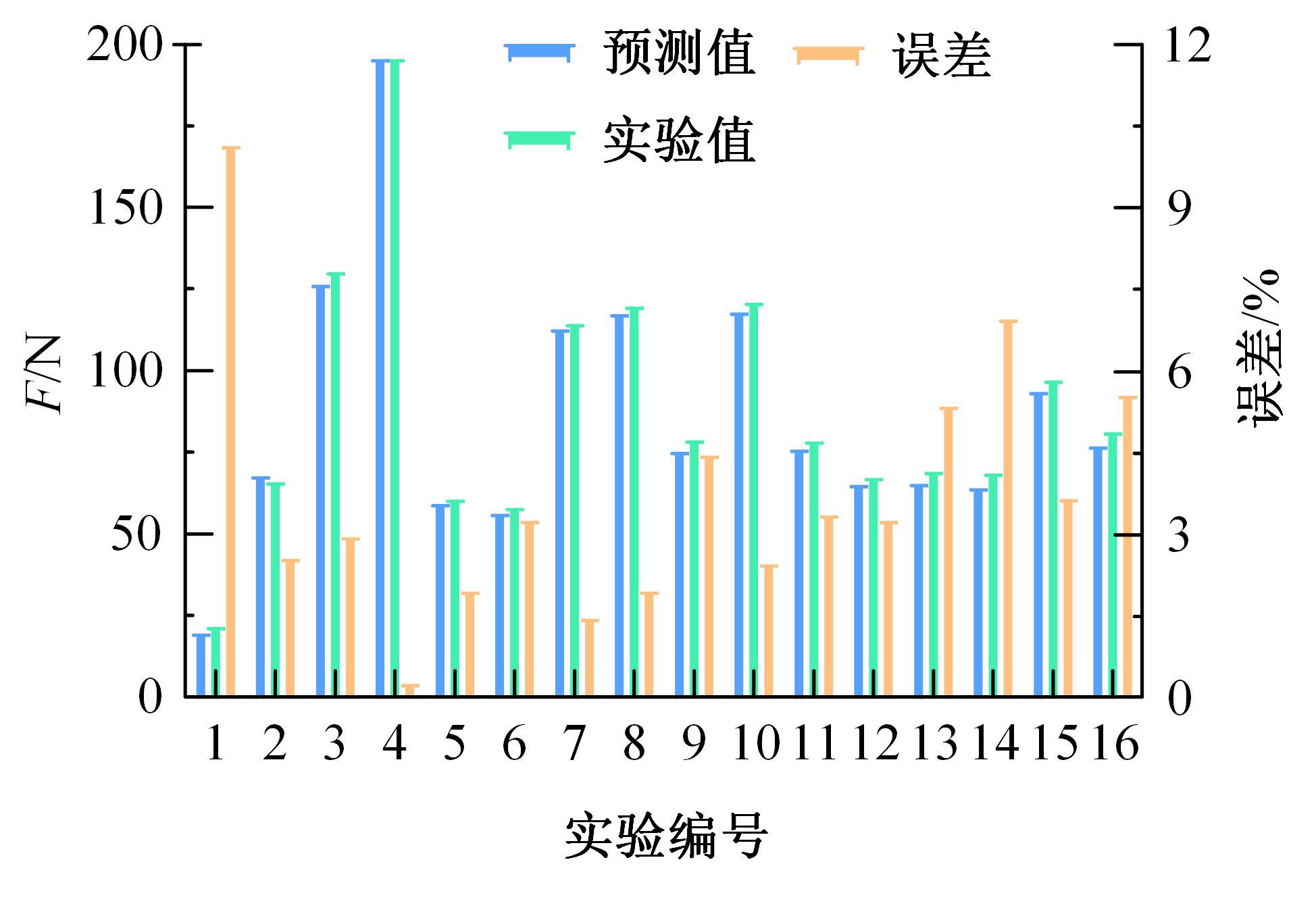

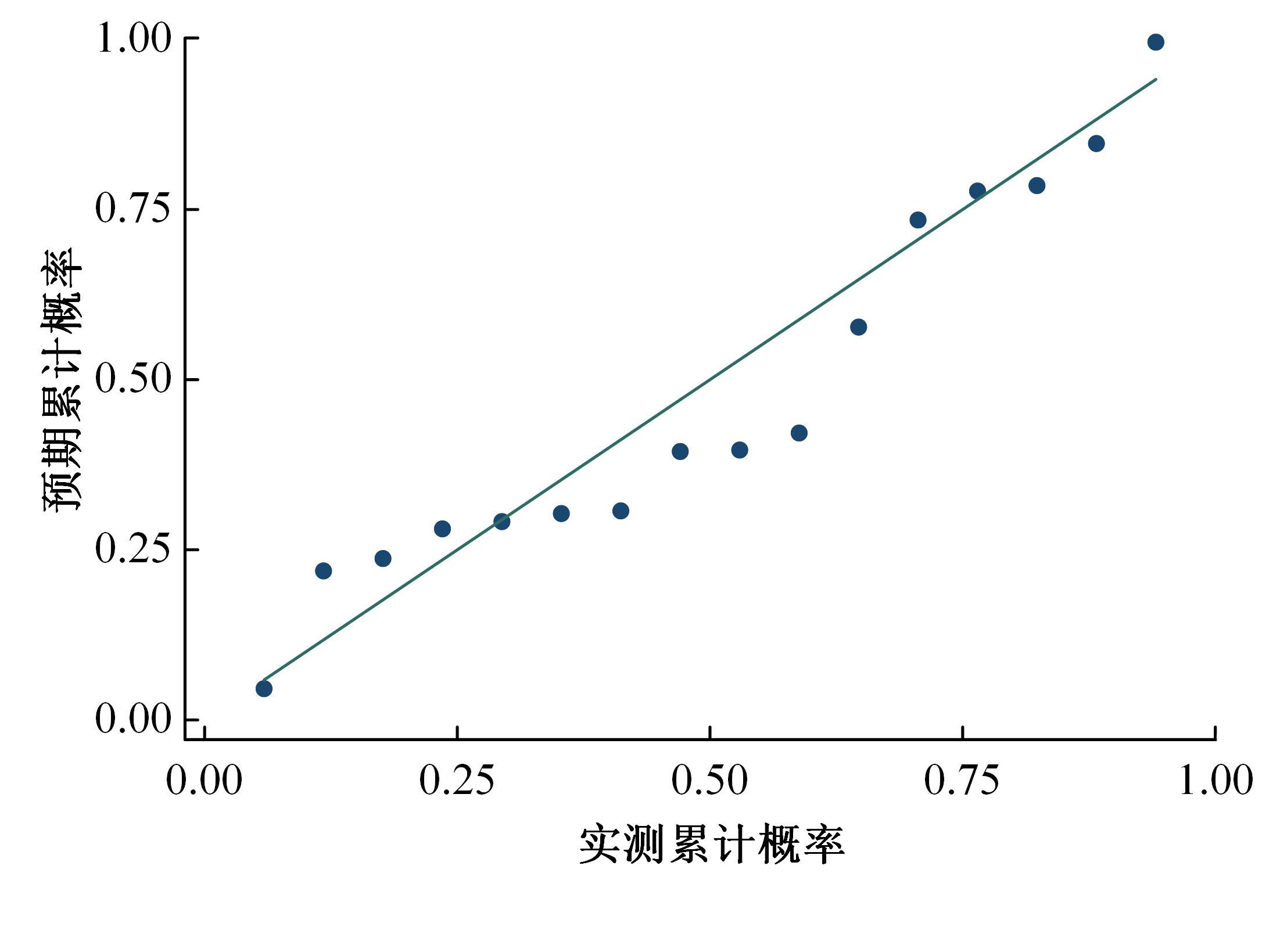

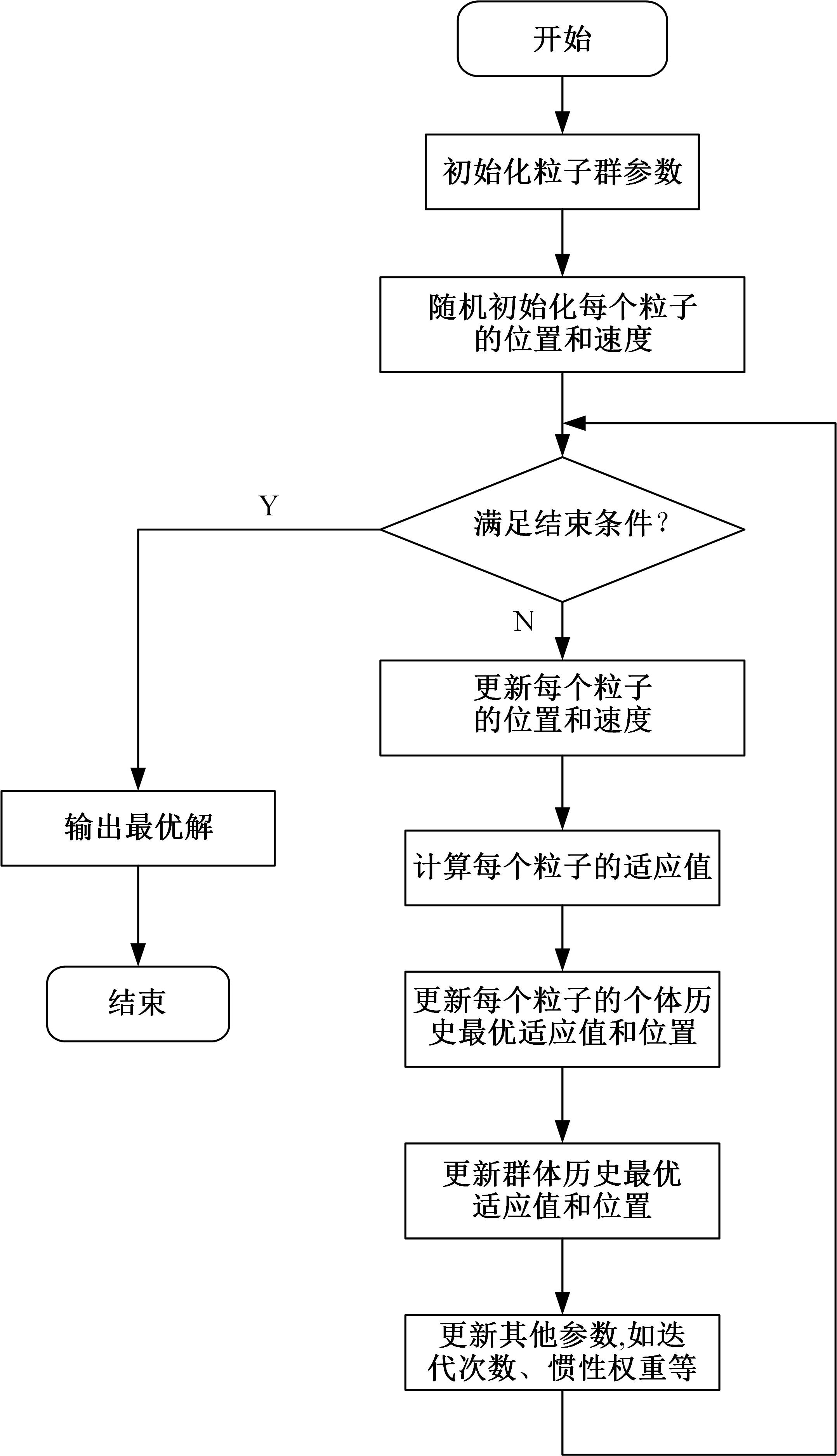

为探究加工TC4钛合金材料时铣削加工参数对铣削力及材料去除率的影响规律并寻求最佳参数组合,基于正交实验方法设计实验,采用四刃球头铣刀进行侧铣实验。以铣削速度、每齿进给量、铣削深度和铣削宽度为变量,以铣削力和材料去除率为评价指标,基于极差分析法,揭示加工参数对铣削力和材料去除率的影响规律。分别采用灰色关联分析法(GRA)和粒子群优化(PSO)算法进行参数优化,基于回归分析方法建立铣削力预测模型,为PSO做准备。最后,经过试验验证,对两种优化方法进行对比分析,并对预测模型进行验证。结果表明,本文所建立的预测模型可准确高效地对铣削力进行预测,PSO优化效果更好。

中图分类号:

- TH161

| 1 | Tan Liang, Yao Chang-feng, Ren Jun-xue, et al. Effect of cutter path orientations on cutting forces, tool wear, and surface integrity when ball end milling TC17[J]. The International Journal of Advanced Manufacturing Technology, 2017, 88(9-12): 2589-2602. |

| 2 | 张翔宇, 路正惠, 彭振龙, 等. 钛合金的高质高效超声振动切削加工[J]. 机械工程学报, 2021, 57(5): 133-147. |

| Zhang Xiang-yu, Lu Zheng-hui, Peng Zhen-long, et al. High quality and efficient ultrasonic vibration cutting of titanium alloys[J]. Journal of Mechanical Engineering, 2021, 57(5): 133-147. | |

| 3 | Li J, Yang X, Ren C, et al. Multiobjective optimization of cutting parameters in Ti-6Al-4V milling process using nondominated sorting genetic algorithm-II[J]. The International Journal of Advanced Manufacturing Technology, 2015, 76: 941-953. |

| 4 | Serra R, Chibane H, Duchosal A. Multi-objective optimization of cutting parameters for turning AISI 52100 hardened steel[J]. International Journal of Advanced Manufacturing Technology, 2018, 99(5-8): 2025-2034. |

| 5 | Zhu Li-da, Yang Zhi-chao, Li Zhao-bin. Investigation of mechanics and machinability of titanium alloy thin-walled parts by CBN grinding head[J]. The International Journal of Advanced Manufacturing Technology, 2019, 100(9-12): 2537-2555. |

| 6 | Wu D, Wang H, Zhang K, et al. Research on formation mechanism and optimization method of surface waviness of TC4 blisk blade[J]. Journal of Manufacturing Processes, 2019, 39: 305-326. |

| 7 | Shen X, Zhang D, Yao C, et al. Formation mechanism of surface metamorphic layer and influence rule on milling TC17 titanium alloy[J]. The International Journal of Advanced Manufacturing Technology, 2021, 112(7,8): 2259-2276. |

| 8 | Ngoc Chien Vu, Chour Huang Shyh, Huu That Nguyen. Multi-objective optimization of surface roughness and cutting forces in hard milling using taguchi and response surface methodology[J]. Key Engineering Materials, 2018, 773: 220-224. |

| 9 | Karkalos N E, Galanis N I, Markopoulos A P. Surface roughness prediction for the milling of Ti6Al4V ELI alloy with the use of statistical and soft computing techniques[J]. Measurement, 2016, 90: 25-35. |

| 10 | 易茜, 李聪波, 潘建, 等. 薄板类零件加工精度可靠性分析及工艺参数优化[J]. 中国机械工程, 2022, 33(11): 1269-1277. |

| Yi Qian, Li Cong-bo, Pan Jian,et al. Reliability analysis of machining accuracy and processing parameter optimization for thin-plate parts[J]. China Mechanical Engineering, 2022, 33(11): 1269-1277. | |

| 11 | Monir K O, Samy E A A. Optimization of cutting conditions using regression and genetic algorithm in end milling[J]. International Journal of Engineering Research in Africa, 2016, 20: 12-18. |

| 12 | Venkatesh M, Suresh K R N. Optimization of milling operations using artificial neural networks (ANN) and simulated annealing algorithm (SAA)[J]. Materials Today: Proceedings, 2018, 5(2): 4971-4985. |

| 13 | Djordje V, Katica S, Zeljko K, et al. Multi-objective optimization of steel AISI 1040 dry turning using genetic algorithm[J]. Neural Computing & Applications, 2021, 33(19): 12445-12475. |

| 14 | Eskandari B, Davoodi B, Ghorbani H. Multi-objective optimization of parameters in turning of N-155 iron-nickel-base superalloy using gray relational analysis[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2018, 40(4): No.233. |

| 15 | Maiyar L M, Ramanujam R, Venkatesan K, et al. Optimization of machining parameters for end milling of inconel 718 super alloy using taguchi based grey relational analysis[J]. Procedia Engineering, 2013, 64: 1276-1282. |

| 16 | Ic Y T, Yildirim S. MOORA-based taguchi optimisation for improving product or process quality[J]. International Journal of Production Research, 2013, 51(11): 3321-3341. |

| 17 | 魏子茹, 卢延辉, 王鹏宇, 等. 基于CRITIC法的灰色关联理论在无人驾驶车辆测试评价中的应用[J]. 机械工程学报, 2021, 57(12): 99-108. |

| Wei Zi-ru, Lu Yan-hui, Wang Peng-yu, et al. Application of grey correlation theory based on CRITIC method in autonomous vehicles test and evaluation[J]. Journal of Mechanical Engineering, 2021, 57(12): 99-108. | |

| 18 | 曾念寅, 宋丹丹, 李寒, 等. 改进鲸鱼优化算法及涡轮盘结构优化[J]. 机械工程学报, 2021, 57(20): 254-265. |

| Zeng Nian-yin, Song Dan-dan, Li Han, et al. Improved whale optimization algorithm and turbine disk structure optimization[J]. Journal of Mechanical Engineering, 2021, 57(20): 254-265. | |

| 19 | 易茜, 柳淳, 李聪波, 等. 基于小样本数据驱动的滚齿工艺参数低碳优化决策方法[J]. 中国机械工程, 2022, 33(13): 1604-1612. |

| Yi Qian, Liu Chun, Li Cong-bo, et al. A low carbon optimization decision method for gear hobbing process parameters driven by small sample data[J]. China Mechanical Engineering, 2022, 33(13): 1604-1612. | |

| 20 | 卫星驰, 赵嫚, 杨青平, 等. 考虑工件变形的五轴侧铣薄壁件铣削力建模[J]. 机械工程学报, 2022, 58(7): 317-324. |

| Wei Xing-chi, Zhao Man, Yang Qing-ping, et al. Milling force modeling of thin-walled parts with 5-Axis flank milling considering workpiece deformation[J]. Journal of Mechanical Engineering, 2022, 58(7): 317-324. | |

| 21 | 于繁华, 刘仁云, 张义民, 等. 机械零部件动态可靠性稳健优化设计的群智能算法[J]. 吉林大学学报:工学版, 2017, 47(6): 1903-1908. |

| Yu Fan-hua, Liu Ren-yun, Zhang Yi-min, et al. Swarm intelligence algorithm of dynamic reliability-based robust optimization design of mechanic components[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(6): 1903-1908. | |

| 22 | 张禹, 鹿浩, 吕董, 等. 基于IMOFA的航空发动机管路多目标优化布局[J]. 东北大学学报:自然科学版, 2022, 43(8): 1120-1126. |

| Zhang Yu, Lu Hao, Dong Lyu, et al. Multi-objective optimization layout of aero-engine pipe routing based on IMOFA[J]. Journal of Northeastern University(Natural Science), 2022, 43(8): 1120-1126. | |

| 23 | 陈昭明,邹劲松,王伟,等. 改进粒子群神经网络融合有限元分析的铸锻双控动态成型多目标优化[J]. 吉林大学学报:工学版, 2022, 52(7): 1524-1533. |

| Chen Zhao-ming, Zou Jin-song, Wang Wei, et al. Multi-objective optimization of casting-forging dynamic forming based on improved particle swarm neural network and finite element analysis[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1524-1533. |

| [1] | 董长斌,李龙坤,刘永平,裴王鹏. 非圆齿轮传动误差及齿侧间隙的数值模拟与试验[J]. 吉林大学学报(工学版), 2024, 54(4): 865-873. |

| [2] | 谭国金,孔庆雯,何昕,张攀,杨润超,朝阳军,杨忠. 基于动力特性和改进粒子群优化算法的桥梁冲刷深度识别[J]. 吉林大学学报(工学版), 2023, 53(6): 1592-1600. |

| [3] | 吴飞,农皓业,马晨浩. 基于粒子群优化算法⁃长短时记忆模型的刀具磨损预测方法[J]. 吉林大学学报(工学版), 2023, 53(4): 989-997. |

| [4] | 郭静,桂林,侯威,李俊烨,朱志宝,孙立伟. 阀套交叉孔磨粒流精密加工质量分析[J]. 吉林大学学报(工学版), 2023, 53(12): 3367-3378. |

| [5] | 张铮,朱齐丹,吕晓龙,樊星. 冗余机械臂运动学逆解的求解优化方法[J]. 吉林大学学报(工学版), 2023, 53(12): 3379-3387. |

| [6] | 黄智,闵杰,周涛,杨健,肖力行,李林泽. 超声振动辅助砂带磨抛钛合金的磨削力建模分析[J]. 吉林大学学报(工学版), 2023, 53(11): 3069-3077. |

| [7] | 王四宝,郭忠政,马驰,王时龙. 数控滚齿机工作台热-力变形分析及预测建模[J]. 吉林大学学报(工学版), 2023, 53(10): 2761-2772. |

| [8] | 回丽,陆家琛,周松,安金岚,周冠妍,刘小鹏. 热处理对TC4钛合金激光双束焊接接头疲劳性能的影响[J]. 吉林大学学报(工学版), 2023, 53(1): 105-110. |

| [9] | 张冲,胡云峰,宫洵,孙耀. 燃料电池阴极流量无模型自适应滑模控制器设计[J]. 吉林大学学报(工学版), 2022, 52(9): 2085-2095. |

| [10] | 高金武,贾志桓,王向阳,邢浩. 基于PSO-LSTM的质子交换膜燃料电池退化趋势预测[J]. 吉林大学学报(工学版), 2022, 52(9): 2192-2202. |

| [11] | 秦静,郑德,裴毅强,吕永,苏庆鹏,王膺博. 基于PSO-GPR的发动机性能与排放预测方法[J]. 吉林大学学报(工学版), 2022, 52(7): 1489-1498. |

| [12] | 宋林,王立平,吴军,关立文,刘知贵. 基于信息物理融合和数字孪生的可靠性分析[J]. 吉林大学学报(工学版), 2022, 52(2): 439-449. |

| [13] | 杨海吉,何佳龙,李国发,王立鼎,王思远. 改进失效模式和影响分析方法在加工中心主轴系统风险分析中的应用[J]. 吉林大学学报(工学版), 2022, 52(2): 345-352. |

| [14] | 朱思峰,赵明阳,柴争义. 边缘计算场景中基于粒子群优化算法的计算卸载[J]. 吉林大学学报(工学版), 2022, 52(11): 2698-2705. |

| [15] | 许博,李传习. 基于灰色理论的大跨度钢管混凝土拱桥承载能力检测方法[J]. 吉林大学学报(工学版), 2022, 52(10): 2360-2366. |

|

||