吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (9): 2723-2732.doi: 10.13229/j.cnki.jdxbgxb.20221431

• 农业工程·仿生工程 • 上一篇

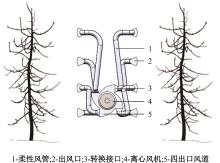

果园多风管喷雾机风送系统流场仿真和试验

- 河北农业大学 机电工程学院,河北 保定 071001

Flow field simulation and test of air delivery system for orchard multi⁃duct sprayer

Xin YANG( ),Yu-xiao LIU,Yang WANG,Chun-hao CHEN,Lin-shuo LYU

),Yu-xiao LIU,Yang WANG,Chun-hao CHEN,Lin-shuo LYU

- College of Mechanical and Electrical Engineering,Hebei Agricultural University,Baoding 071001,China

摘要:

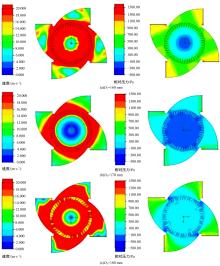

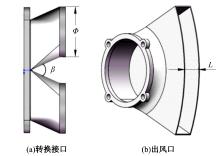

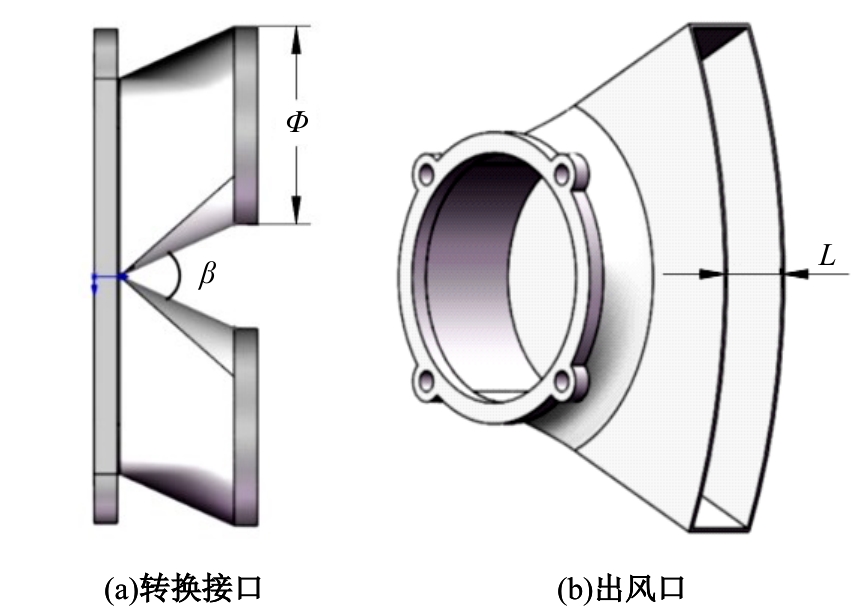

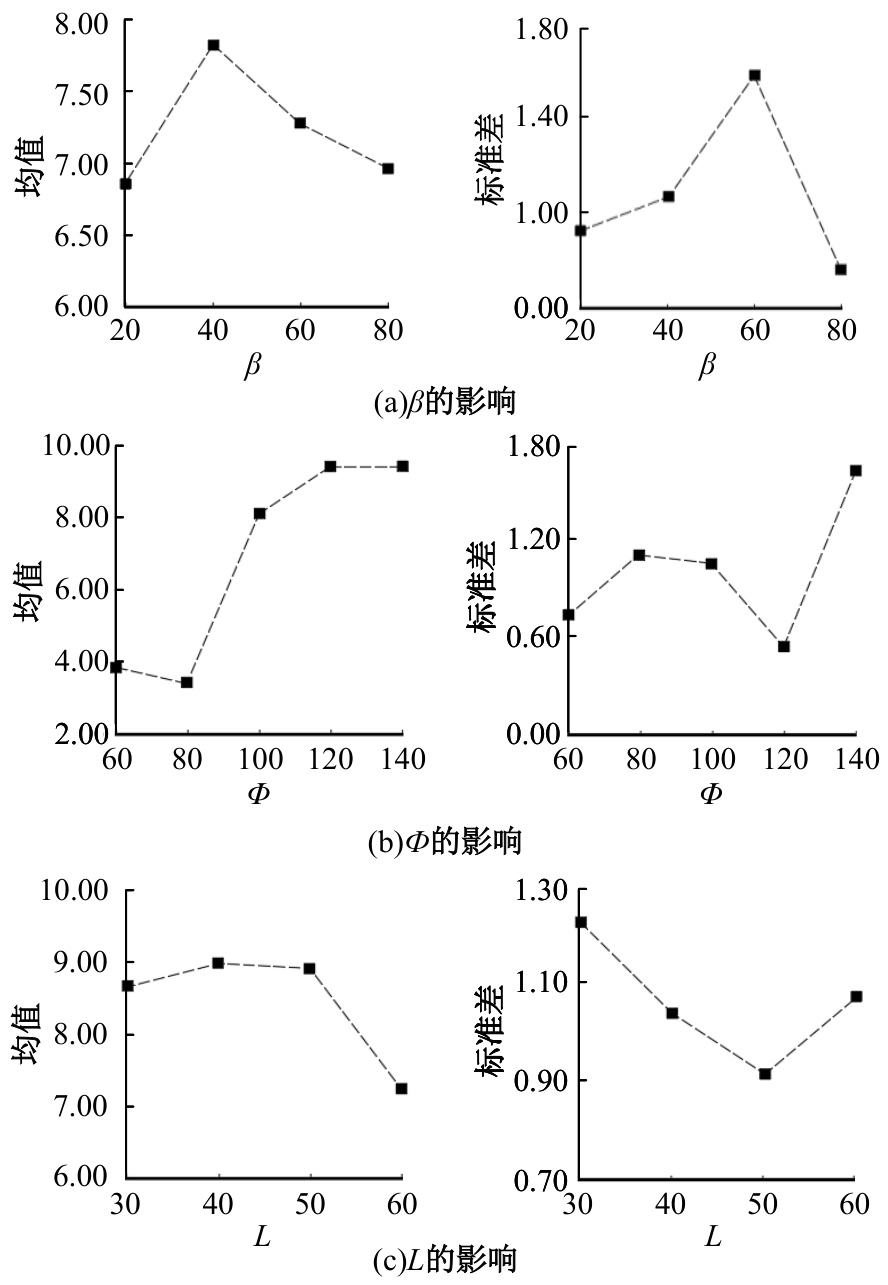

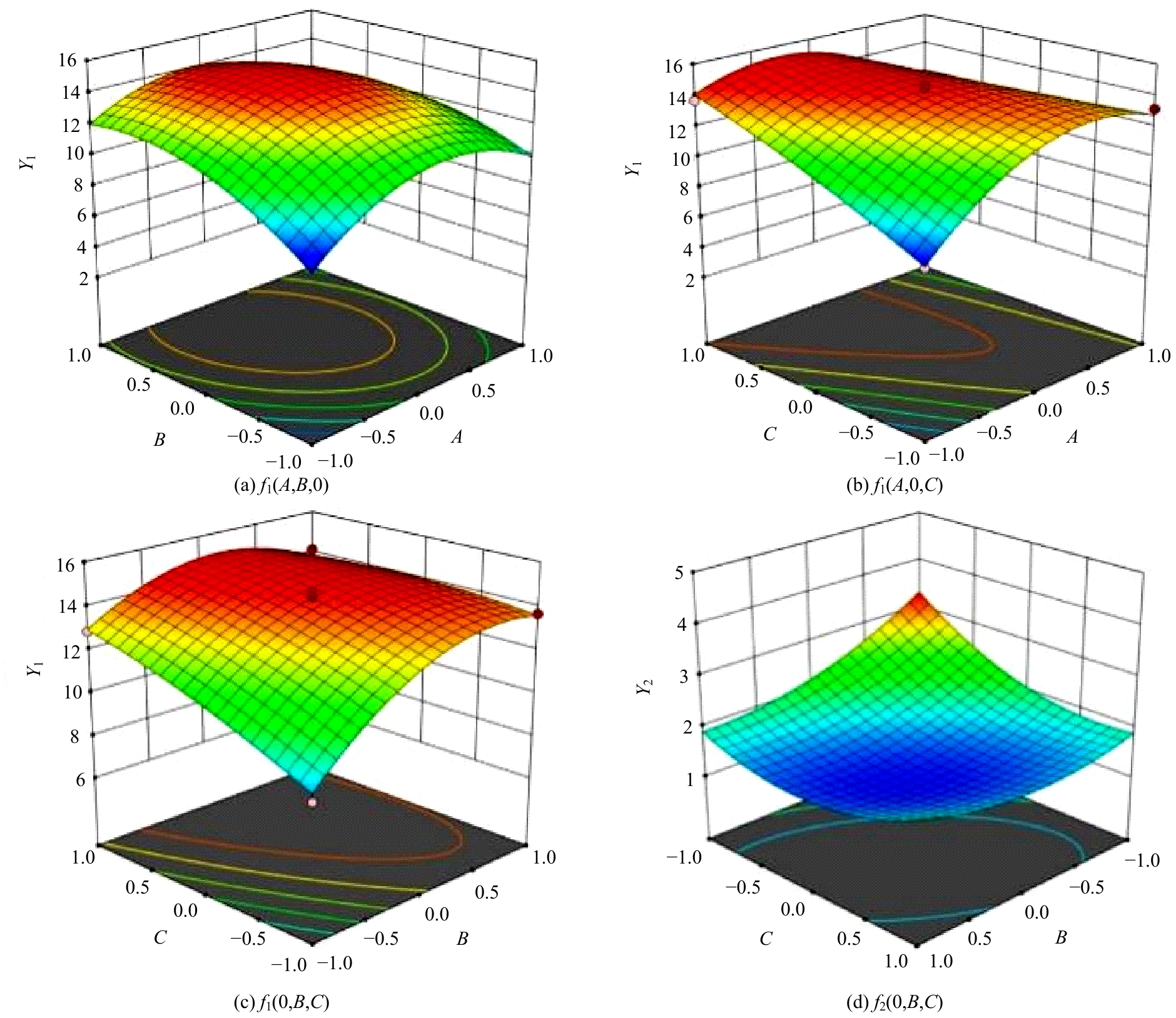

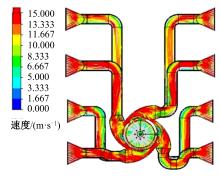

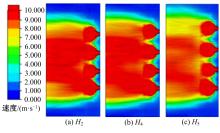

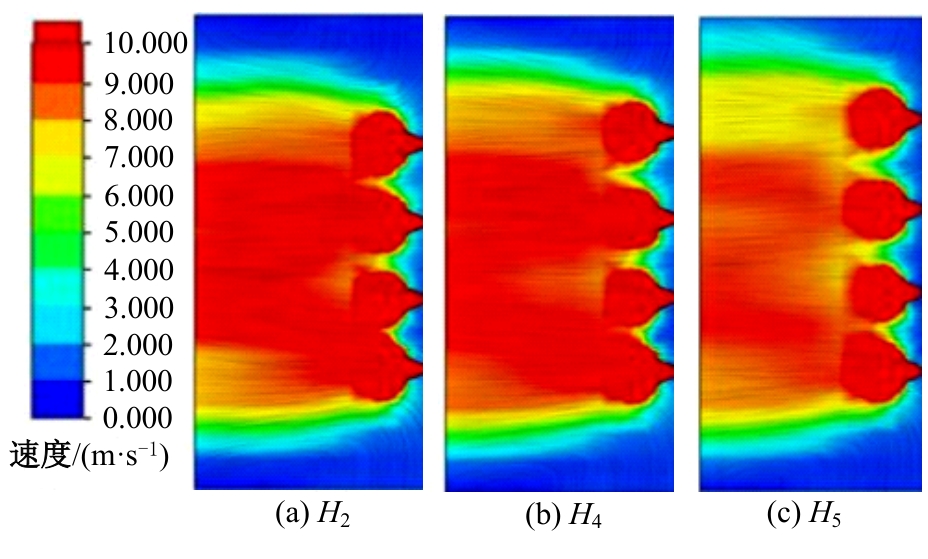

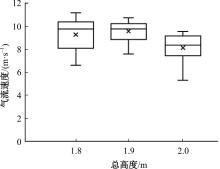

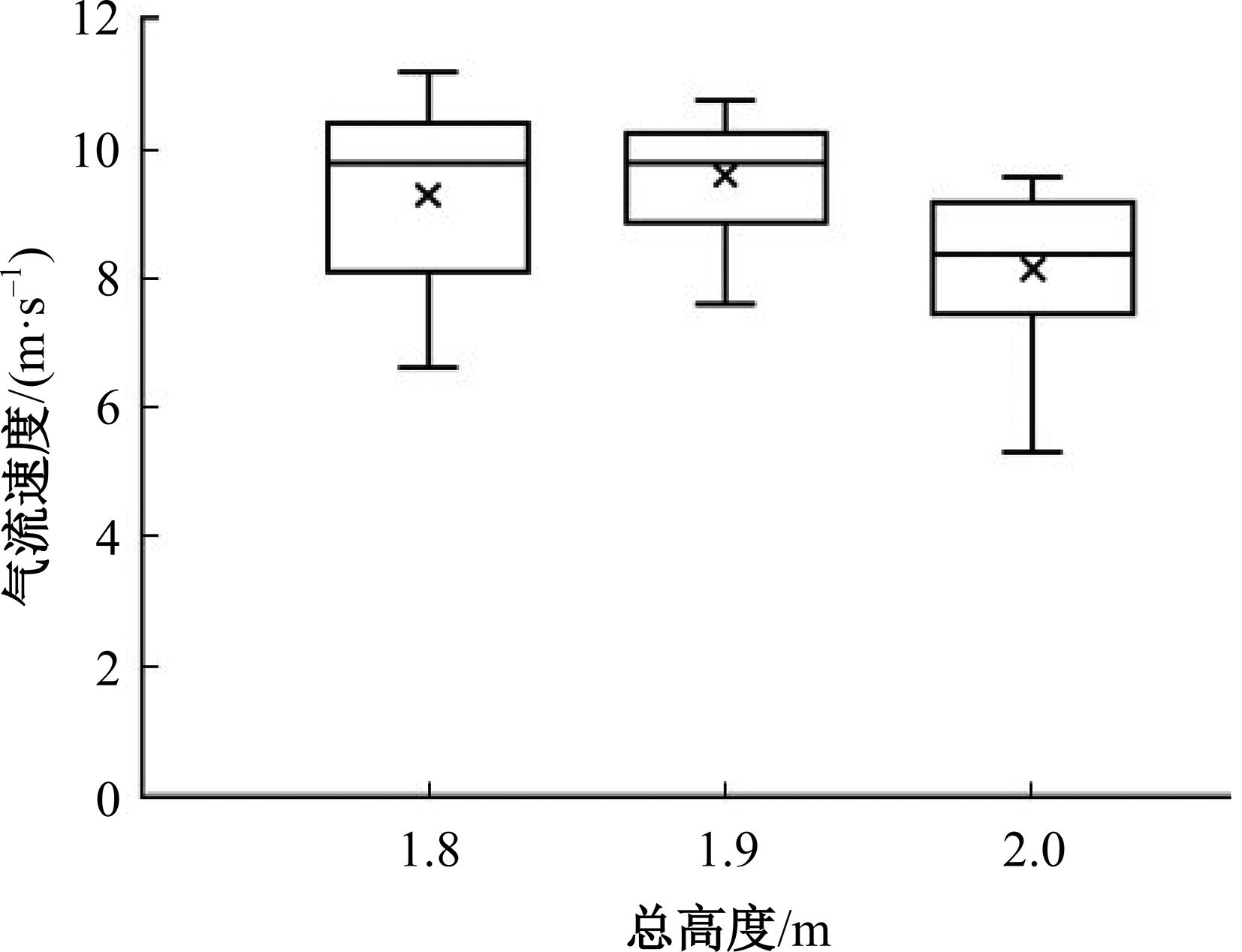

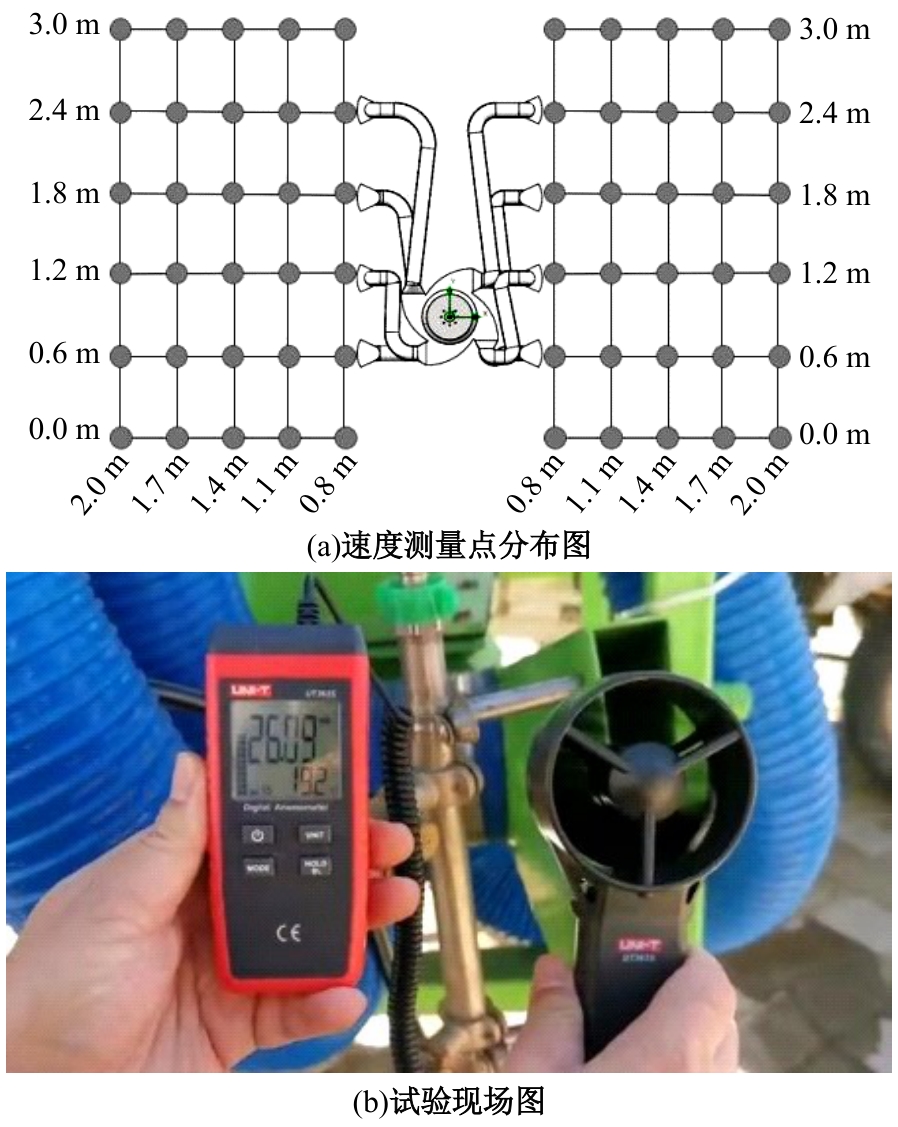

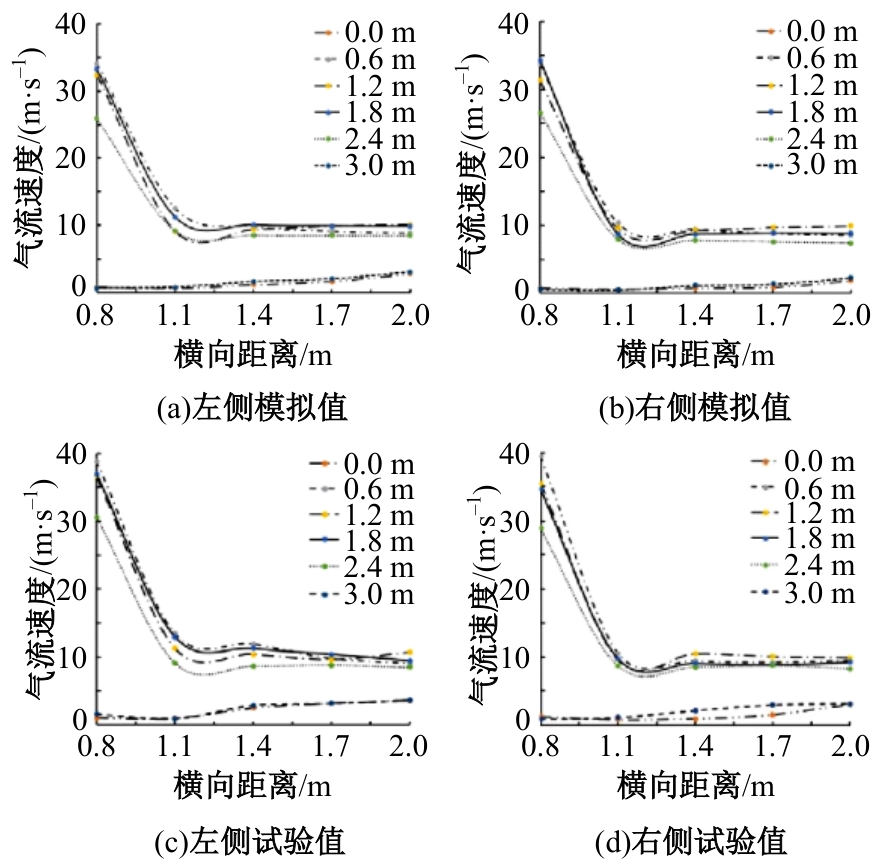

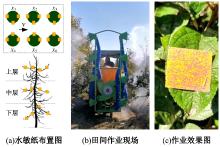

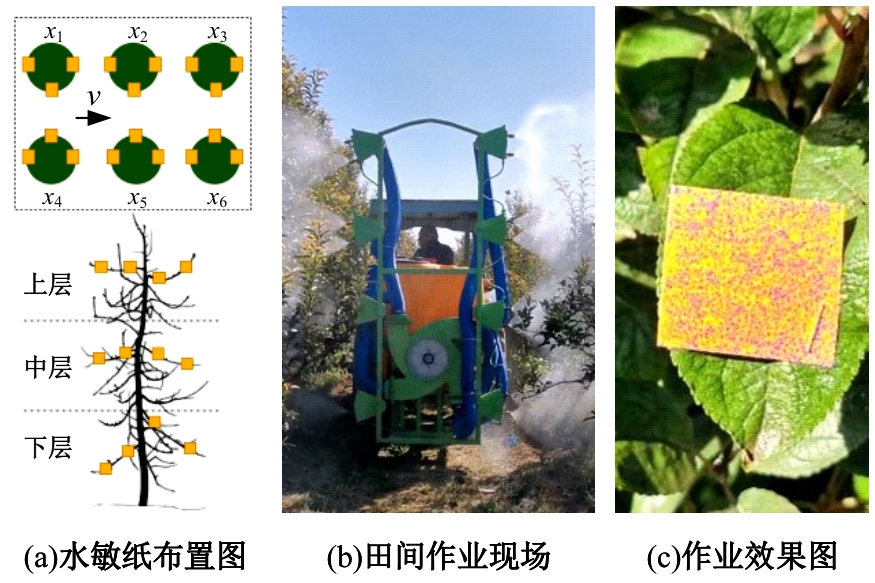

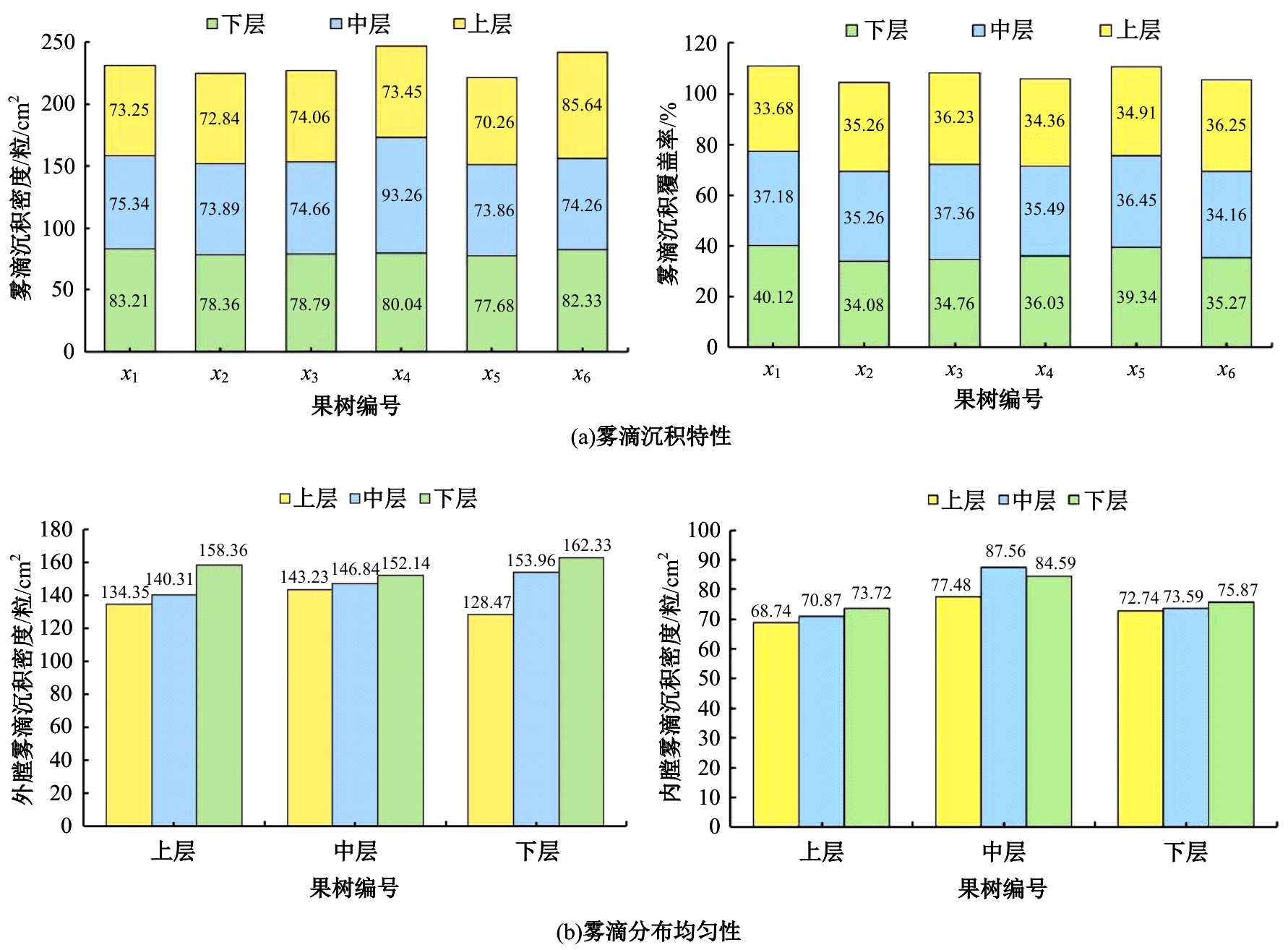

针对传统环形风送喷雾机气流分布不均匀、雾滴穿透性差的问题,设计了果园多风管喷雾机风送系统。通过对风道、转换接口、柔性风管和出风口构成的内流场进行仿真确定了最优结构参数,通过外流场仿真确定了风机转速及出风口总高度最佳参数。根据仿真结果得到最优参数组合如下:风道宽度为170 mm、转换接口夹角为40°、柔性风管直径为123 mm、出风口宽度为52 mm、风机转速为2 160 r/min、出风口总高度为1.9 m,此参数下风送系统内外流场分布均匀,气流速度大小满足作业要求。按优化参数组建喷雾机风送系统并设计气流速度试验,结果表明:仿真值与试验值符合程度高,出风口左右两侧气流速度误差小于10%。通过田间试验得到雾滴穿透性良好,冠层之间雾滴沉积密度偏差小于12%,雾滴在冠层垂直方向上分布均匀。

中图分类号:

- S491

| 1 | 郑永军, 陈炳太, 吕昊暾, 等. 中国果园植保机械化技术与装备研究进展[J]. 农业工程学报, 2020, 36(20): 110-124. |

| Zheng Yong-jun, Chen Bing-tai, Lv Hao-tun, et al. Research progress of orchard plant protection mechanization technology[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(20): 110-124. | |

| 2 | Yue S, Heping Z, Hui L, et al. Development of a laser-guided, embedded-computer-controlled, air-assisted precision sprayer[J]. Transactions of the ASABE, 2017, 60(6): 1827-1838. |

| 3 | 王震涛, 牛浩, 唐玉荣, 等. 果园喷雾机械及技术的研究现状[J]. 塔里木大学学报, 2019, 31(3): 83-91. |

| Wang Zhen-tao, Niu Hao, Tang Yu-rong, et al. Research status of orchard spray machinery and technology [J]. Journal of Tarim University, 2019, 31(3): 83-91. | |

| 4 | Kasner E J, Fenske R A, Hoheisel G A, et al. Spray drift from a conventional axial fan airblast sprayer in a modern orchard work environment[J]. Annals of Work Exposures and Health, 2018,62(9): 1134-1146. |

| 5 | 王杰, 陶振洋, 茹煜, 等. 风机在农林植保机械中的应用研究现状及展望[J]. 中国农机化学报, 2016, 37(9): 67-74. |

| Wang Jie, Tao Zhen-yang, Ru Yu, et al. Research progress and outlook on application of fan in plant protection machinery of agriculture and forestry[J].Journal of Chinese Agricultural Mechanization, 2016, 37(9): 67-74. | |

| 6 | Ade G, Molari G, Rondelli V. Recycling tunnel sprayer for poesticide dose adjustment to the crop environment[J]. Transactions of the ASABE, 2007, 50(2): 409-413. |

| 7 | Salcedo R, Ariane V, Granell R,et al. Eulerian-lagrangian model of the behaviour of droplets produced by an air-assisted sprayer in a citrus orchard[J]. Biosystems Engineering, 2017, 154: 76-91. |

| 8 | 姜红花, 牛成强, 刘理民, 等. 果园多风管风送喷雾机风量调控系统设计与试验[J]. 农业机械学报, 2020, 51(): 298-307. |

| Jiang Hon-ghua, Niu Cheng-qiang, Liu Li-min, et al. Design and experiment of air volume control system of orchard multi-pipe air sprayer[J]. Journal of Luoyang Institute of Technology, 2020, 51(Sup.2): 298-307. | |

| 9 | 李建平, 边永亮, 霍鹏, 等.喷雾机风送式环形喷管喷雾装置设计与试验优化[J].农业机械学报, 2021, 52(9): 79-88. |

| Li Jian-ping, Bian Yong-liang, Huo Peng,et al. Design and experimental optimization of spray air supply annular nozzle spray device[J]. Journal of Agricultural Machinery, 2021,52 (9): 79-88. | |

| 10 | Delele M A, De M A, Sonck B, et al.Modelling andvalidation of the air flow generated by a cross flow air sprayer as affected by travel speed and fan speed[J]. Biosystems Engineering, 2005, 92(2): 165-174. |

| 11 | 翟长远, 张燕妮, 窦汉杰, 等. 果园风送喷雾机出风口风场CFD建模与试验[J]. 智慧农业:中英文, 2021, 3(3): 70-81. |

| Zhai Chang-yuan, Zhang Yan-ni, Dou Han-jie, et al. CFD modeling and experiment of airflow at the air outlet of orchard air-assisted sprayer[J]. Smart Agriculture (English and Chinese), 2021, 3(3): 70-81. | |

| 12 | Endalew A M, Debaerb C, Rutten N, et al. A new integrated CFD modelling approach towards air-assisted orchard spraying-Part I: model development and effect of wind speed and direction on sprayer airflow[J]. Computers and Electronics in Agriculture, 2010, 71(1): 128-136. |

| 13 | Duga A T, Delele M A, Rysen K, et al. Development and validation of a 3D CFD model of drift and its application to air-assisted orchard sprayers[J]. Biosystems Engineering, 2016, 154: 62-75. |

| 14 | 宋淑然, 夏侯炳, 卢玉华, 等. 风送式喷雾机导流器结构优化及试验研究[J]. 农业工程学报, 2012, 28(6): 7-12. |

| Song Shu-ran, Xia Hou-bing, Lu Yu-hua, et al. Structural optimization and experiment on fluid director of air-assisted sprayer[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(6): 7-12. | |

| 15 | 徐奕蒙. 基于CFD技术的喷雾机风场研究与风送喷雾机控制系统研制[D]. 杨凌: 西北农林科技大学水利与建筑工程学院, 2019. |

| Xu Yi-meng. Research on wind farm of sprayer based on CFD technology and control system of air sprayer[D]. Yangling:College of Water Resources and Building Engineering, Northwest Agriculture and Forestry University, 2019. | |

| 16 | 臧帅. 果园喷雾机风送喷雾系统设计仿真与试验研究[D]. 镇江: 江苏大学农业工程学院, 2020. |

| Zang Shuai. Design, simulation and experimental study of an air-assisted spraying system of orchard sprayer[D]. Zhenjiang: College of Agricultural Engineering, Jiangsu University, 2020. | |

| 17 | 向浩, 兰兴欣, 于磊. 基于Solidworks软件的风扇自然风模拟仿真分析的研究[J]. 中国机械, 2014(17): No.218. |

| Xiang Hao, Lan Xing-xin, Yu Lei. Research on simulation analysis of natural wind simulation of fan based on Solidworks software[J]. China Machinery, 2014(17): No.218. | |

| 18 | 王平. 基于Flow Simulation 的直埋供热管道热损失模拟分析[J]. 区域供热, 2021, 210(1): 29-33, 43. |

| Wang Ping. Simulation of heat loss in direct buried heating pipes based on Flow Simulation[J]. District Heating, 2021, 210(1): 29-33, 43. | |

| 19 | 张燕妮. 果园喷药空间风场及风树交互作用CFD建模研究[D]. 杨凌: 西北农林科技大学机械与电子工程学院, 2021. |

| Zhang Yan-ni. CFD modeling research on orchard spatial airflow field and interaction between airflow and tree for orchard spraying[D]. Yangling: College of Mechanical and Electronic Engineering,Northwest Agriculture and Forestry University, 2021. | |

| 20 | Wang H Q, Zou Z Y, Chen S Q, et al. Numerical simulation investigation on pressure loss of diffusion tank of axial main fan[J]. Journal of Coal Science & Engineering, 2011, 17(4): 447-449. |

| 21 | 李建平, 边永亮, 杨欣, 等. 果园多风机风送喷雾机作业参数优化与试验[J]. 吉林大学学报: 工学版, 2022, 52(10): 2474-2485. |

| Li Jian-ping, Bian Yong-liang, Yang Xin,et al. Operational parameter optimization and testing of an air-assisted multi-fan orchard sprayer [J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(10): 2474-2485. | |

| 22 | 戴奋奋. 风送喷雾机风量的选择与计算[J]. 植物保护, 2008(6): 124-127. |

| Dai Fen-fen. Selection and calculation of the blowing rate of air-assisted sprayers [J]. Plant Protection, 2008(6): 124-127. | |

| 23 | .风送式果园喷雾机作业质量 [S]. |

| 24 | 曹军琳, 祁力钧, 杨知伦, 等. 基于图像处理的雾滴沉积分布试验研究[J]. 中国农业大学学报, 2019, 24(1): 130-137. |

| Cao Jun-lin, Qi Li-jun, Yang Zhi-lun, et al. Experimental study of droplet distribution based on image processing[J]. Journal of China Agricultural University, 2019, 24(1): 130-137. | |

| 25 | 陈奕璇. 喷雾药液性质与农药沉积利用率关系研究[D]. 北京: 中国农业科学院植物保护研宄所, 2021. |

| Chen Yi-xuan. Study on the relationship between the properties of spray liquid and the utilization rate of pesticide[D]. Beijing: Institute of Plant Protection,Chinese Academy of Agricultural Sciences, 2021. |

| [1] | 顿国强,吴星澎,纪欣鑫,张福利,纪文义,朱礼贵. 玉米条带摆管式撒肥装置设计及试验[J]. 吉林大学学报(工学版), 2024, 54(9): 2697-2707. |

| [2] | 舒彩霞,杨佳,廖庆喜,万星宇,袁佳诚. 油菜联合收获导流式双筒旋风分离清选装置设计及试验[J]. 吉林大学学报(工学版), 2024, 54(6): 1807-1820. |

| [3] | 张国忠,丁凯权,李正博,陈龙,唐楠锐,刘婉茹,黄海东,周勇,王洪昌. 基于泥鳅体表的水稻直播机仿生滑板设计与试验[J]. 吉林大学学报(工学版), 2024, 54(5): 1482-1492. |

| [4] | 张伏,娄立民,钱丹,王世强,冯春凌,赵一荣. 大方捆打捆机压缩机构优化设计及试验[J]. 吉林大学学报(工学版), 2024, 54(4): 1166-1174. |

| [5] | 周鹏飞,陈学庚,蒙贺伟,梁荣庆,张炳成,坎杂. 滚筒式机收膜杂除土装置设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2718-2731. |

| [6] | 刘伟健,罗锡文,曾山,文智强,曾力. 履带式再生稻收获机田间转弯机理和性能试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2695-2705. |

| [7] | 张茂健,金敬福,陈奕颖,陈廷坤. 轮式拖拉机对称结构的振动特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2136-2142. |

| [8] | 朱光强,李天宇,周福君,王文明. 鲜食玉米仿生摘穗装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1231-1244. |

| [9] | 顿国强,刘文辉,毛宁,吴星澎,纪文义,马洪岩. 交替换岗式大豆小区育种排种器优化设计与试验[J]. 吉林大学学报(工学版), 2023, 53(1): 285-296. |

| [10] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [11] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

| [12] | 刘佳杰,马兰,向伟,颜波,文庆华,吕江南. 4QM-4.0型麻类青饲料联合收获机研制[J]. 吉林大学学报(工学版), 2022, 52(12): 3039-3048. |

| [13] | 曾百功,黎奎良,叶进,任丽丽,Rashidov Jaloliddin,张明. 工厂化上海青流水线收割装置的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2756-2764. |

| [14] | 万星宇,廖庆喜,蒋亚军,单伊尹,周宇,廖宜涛. 饲用油菜机械化收获切碎过程离散元仿真与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2735-2745. |

| [15] | 朱光强,李天宇,周福君. 鲜食玉米仿生摘穗柔性夹持输送装置设计与试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2486-2500. |

|

||