吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (9): 2014-2024.doi: 10.13229/j.cnki.jdxbgxb20220259

• • 上一篇

基于自适应LQR控制的质子交换膜燃料电池热管理系统温度控制

裴尧旺1( ),陈凤祥1(

),陈凤祥1( ),胡哲2,翟双2,裴冯来3,张卫东4,焦杰然1

),胡哲2,翟双2,裴冯来3,张卫东4,焦杰然1

- 1.同济大学 汽车学院,上海 201804

2.上海重塑能源集团股份有限公司,上海 201800

3.上海机动车检测认证技术研究中心有限公司,上海 201805

4.海南大学 信息与通信工程学院,海口 570228

Temperature control of proton exchange membrane fuel cell thermal management system based on adaptive LQR control

Yao-wang PEI1( ),Feng-xiang CHEN1(

),Feng-xiang CHEN1( ),Zhe HU2,Shuang ZHAI2,Feng-lai PEI3,Wei-dong ZHANG4,Jie-ran JIAO1

),Zhe HU2,Shuang ZHAI2,Feng-lai PEI3,Wei-dong ZHANG4,Jie-ran JIAO1

- 1.School of Automotive Studies,Tongji University,Shanghai 201804,China

2.Shanghai Re-fire Technology Co. ,Ltd. ,Shanghai 201800,China

3.Shanghai Motor Vehicle Inspection Certification & Tech Innovation Center Co. ,Ltd. ,Shanghai 201805,China

4.College of Information and Communication Engineering,Hainan University,Haikou 570228,China

摘要:

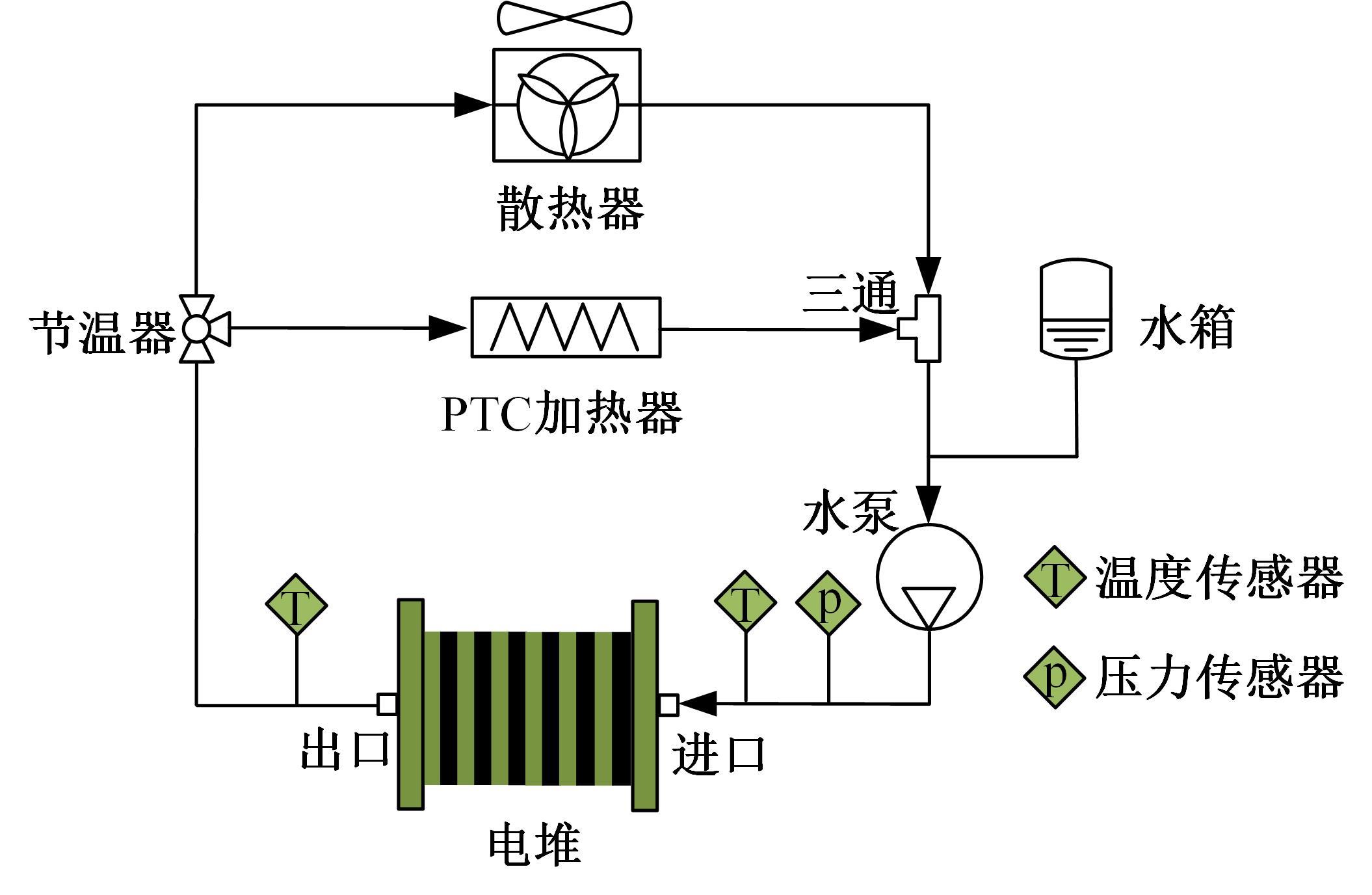

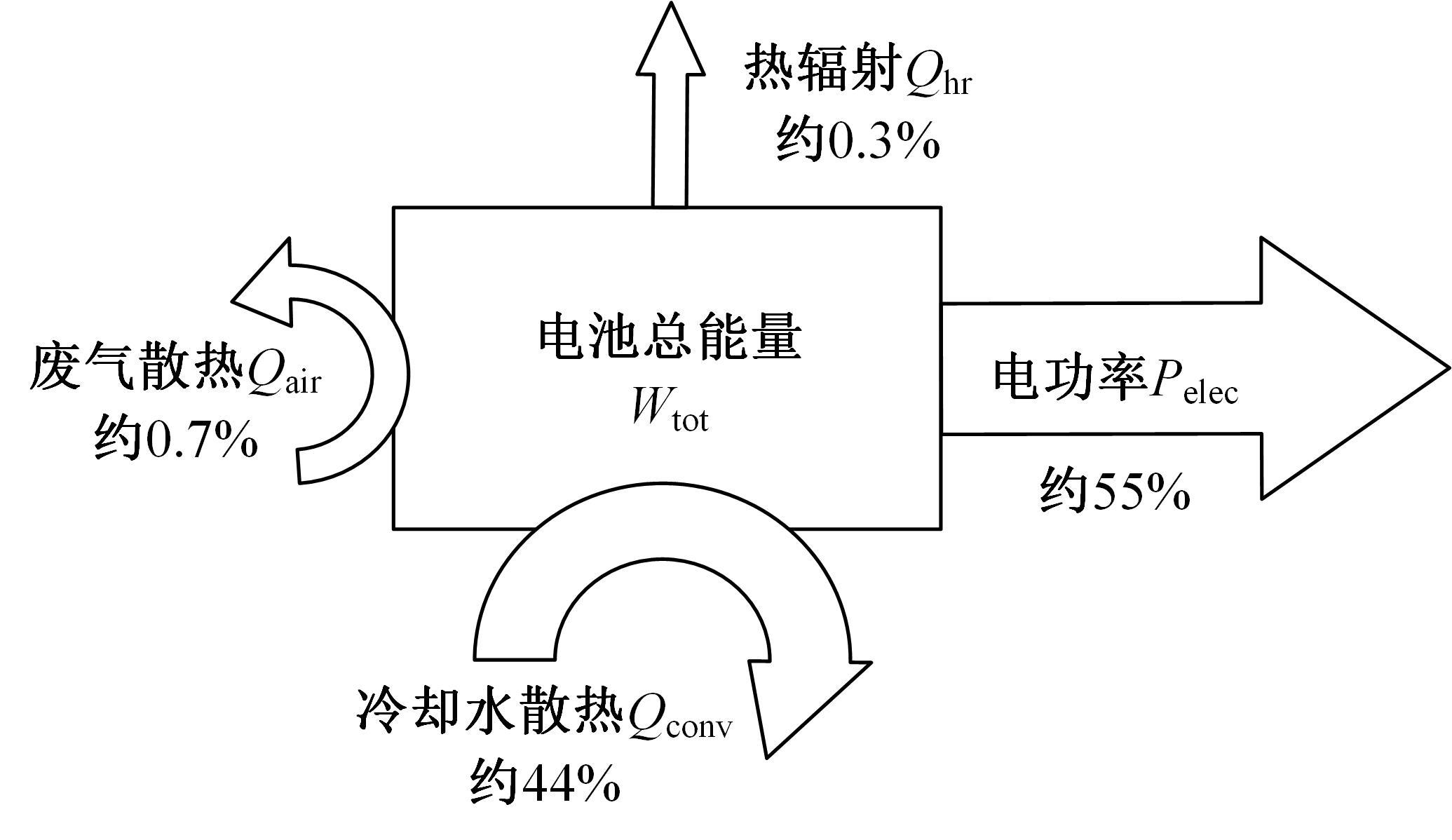

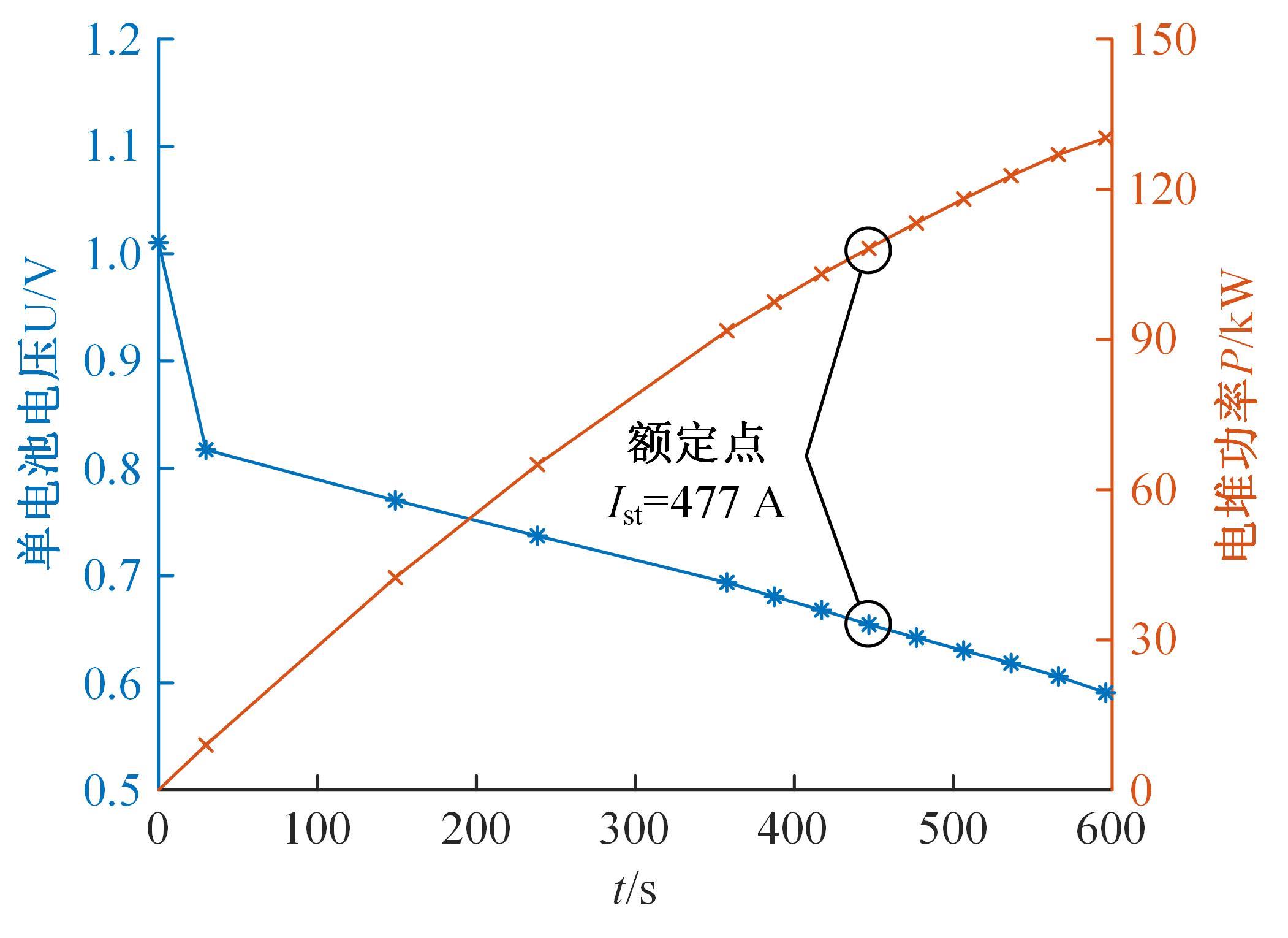

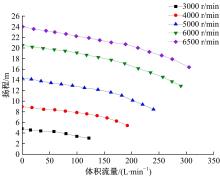

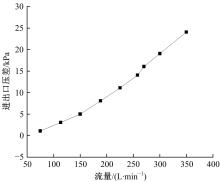

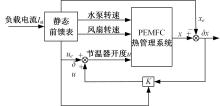

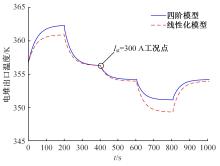

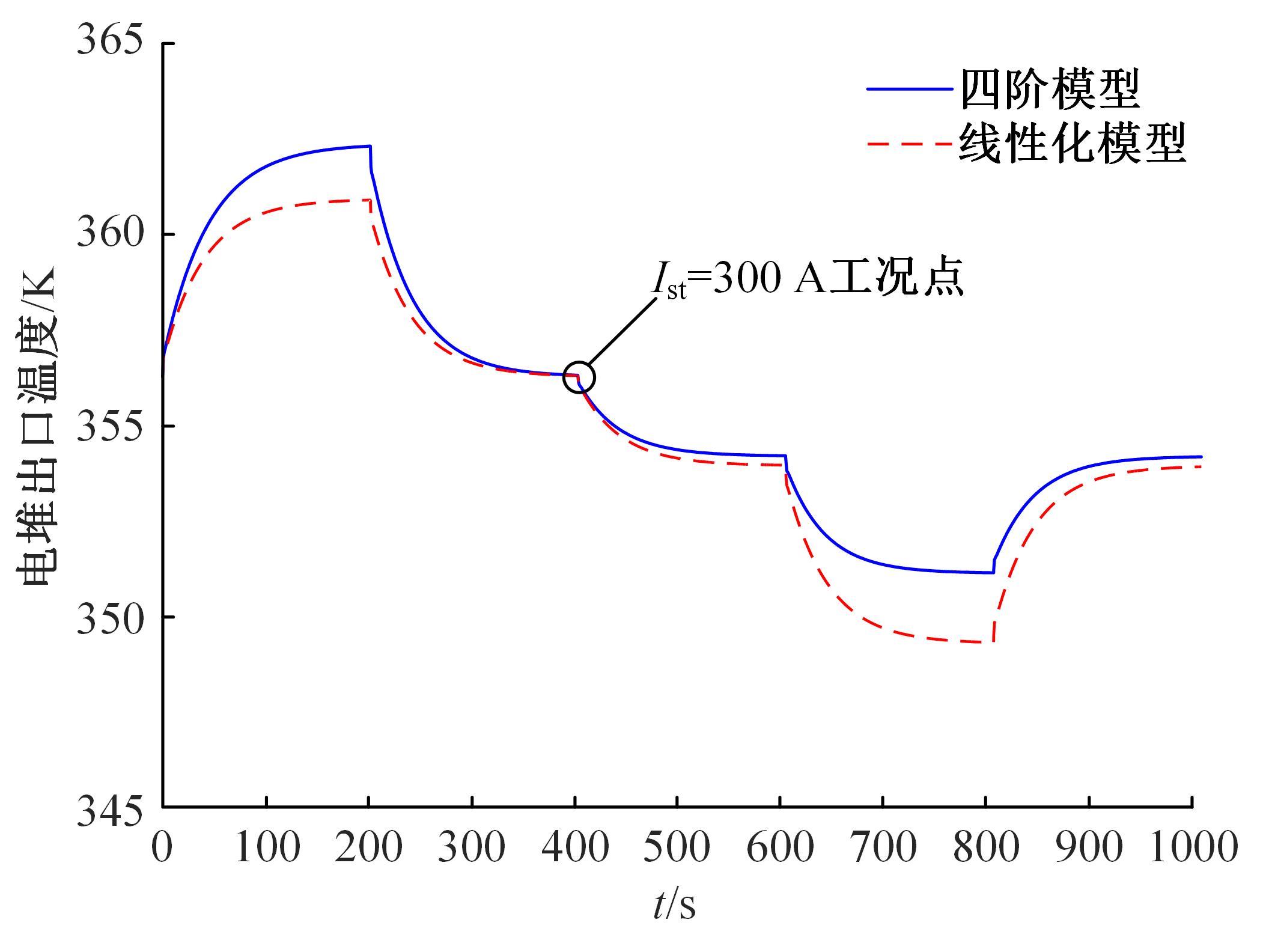

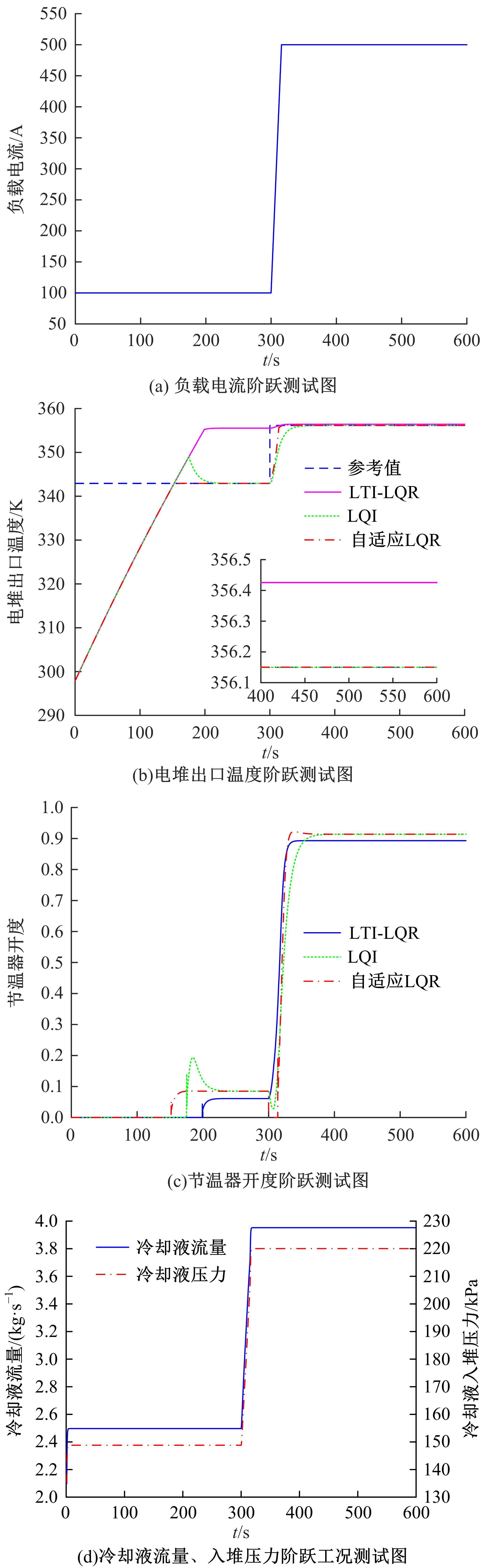

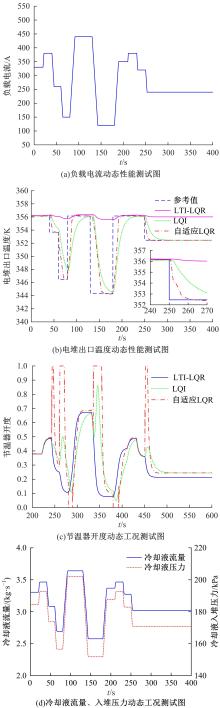

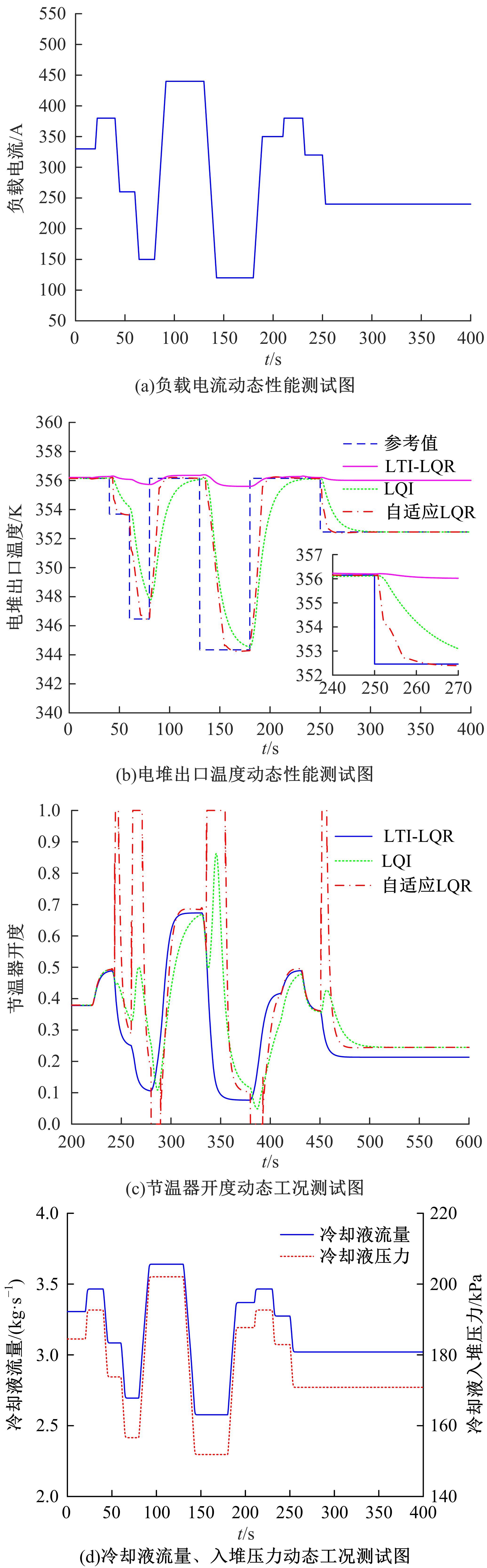

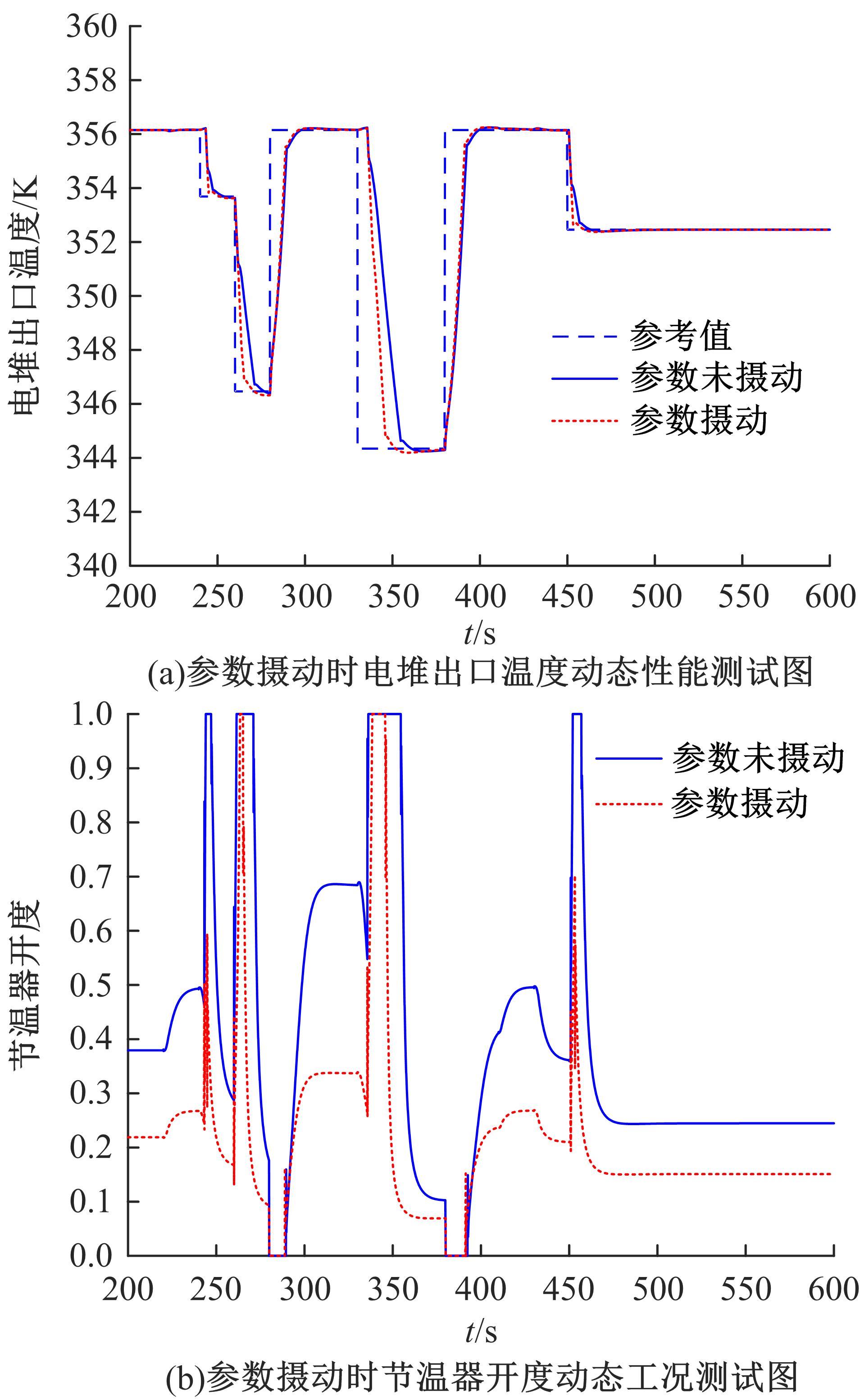

为了提高燃料电池的运行效率,必须对其工作温度进行有效控制。本文在Matlab/Simulink平台上搭建了热管理系统模型,该模型可用于分析各零部件之间的流量分配、压力损失以及热量交换。在此模型基础上,提出了一种自适应的线性二次型调节器(LQR)控制器,并在不同工况下与LTI-LQR和LQI控制器进行了仿真对比验证。仿真结果显示:阶跃响应测试下,自适应LQR控制器无稳态误差、无超调、上升时间为15 s;动态性能测试下,电堆出口温度在全局范围内均能快速地跟踪参考值,说明该控制器具有良好的控制性能。

中图分类号:

- U469.72

| 1 | Pandiyan S, Jayakumar K, Rajalakshmi N, et al. Thermal and electrical energy management in a PEMFC stack—an analytical approach[J]. International Journal of Heat and Mass Transfer, 2008, 51(3/4): 469-473. |

| 2 | Rojas J D, Ocampo-Martínez C, Kunusch C. Thermal modelling approach and model predictive control of a water-cooled PEM fuel cell system[C]∥39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 2013: 3806-3811. |

| 3 | Han J, Yu S, Yi S. Advanced thermal management of automotive fuel cells using a model reference adaptive control algorithm[J]. International Journal of Hydrogen Energy, 2017, 42(7): 4328-4341. |

| 4 | Chen F, Jiao J, Yu Y, et al. Active control of stack inlet and outlet coolant temperature for the PEM fuel cell system[C]∥2017 International Conference on Fuel Cell Science, Engineering and Technology, Tianjin, China, 2017: No. V001T01A001. |

| 5 | Yu S, Jung D. A study of operation strategy of cooling module with dynamic fuel cell system model for transportation application[J]. Renewable Energy, 2010, 35(11): 2525-2532. |

| 6 | Saygili Y, Eroglu I, Kincal S. Model based temperature controller development for water cooled PEM fuel cell systems[J]. International Journal of Hydrogen Energy, 2015, 40(1): 615-622. |

| 7 | Pukrushpan J T. Modeling and control of fuel cell systems and fuel processors[D]. Michigan: The University of Michigan, 2003. |

| 8 | 牛茁,张玉瑾,邓惠文,等. 基于OPC技术的水冷PEMFC热管理控制系统[J]. 太阳能学报,2019, 40(4): 942-949. |

| Niu Zhuo, Zhang Yu-jin, Deng Hui-wen, et al. Thermal management system of water-cooled PEMFC based on OPC technology[J]. Acta Energiae Solaris Sinica, 2019, 40(4), 942-949. | |

| 9 | 郑文杰,杨径,朱林培,等. 车用燃料电池热管理性能仿真与试验研究[J]. 汽车工程,2021,43(3): 381-386. |

| Zheng Wen-jie, Yang Jing, Zhu Lin-pei, et al Simulation and experimental study on thermal management system of vehicle fuel cell[J]. Automotive Engineering, 2021, 43(3): 381-386. | |

| 10 | 郭爱,陈维荣,刘志祥,等. 燃料电池机车热管理系统建模和动态分析[J]. 西南交通大学学报,2015,50(5): 953-960. |

| Guo Ai, Chen Wei-rong, Liu Zhi-xiang, et al. Modeling and dynamic analysis of thermal management system for fuel cell locomotive[J]. Journal of Southwest Jiaotong University, 2015, 50(5): 953-960. | |

| 11 | 赵洪波,刘杰,马彪,等. 水冷PEMFC热管理系统控制策略及仿真研究[J]. 化工学报,2020,71(5): 2139-2150. |

| Zhao Hong-bo, Liu Jie, Ma Biao, et al. Control strategy and simulation research of water-cooled PEMFC thermal management system[J]. CIESC Journal, 2020, 71(5): 2139-2150. | |

| 12 | Cheng Si-liang, Fang Chuan, Xu Liang-fei, et al. Model-based temperature regulation of a PEM fuel cell system on a city bus[J]. International Journal of Hydrogen Energy, 2015, 40(39): 13566-13575. |

| 13 | Huang L H, Chen J, Liu Z Y, et al. Adaptive thermal control for PEMFC systems with guaranteed performance[J]. International Journal of Hydrogen Energy, 2018, 43(25): 11550-11558. |

| 14 | Liso V, Nielsen M P, Kaer S K, et al. Thermal modeling and temperature control of a PEM fuel cell system for forklift applications[J]. International Journal of Hydrogen Energy, 2014, 39(16): 8410-8420. |

| 15 |

刘岩, 丁天威, 王宇鹏, 等. 基于自适应控制的燃料电池发动机热管理策略[J]. 吉林大学学报: 工学版, DOI:10.13229/j.cnki.jdxbgxb20220346 .

doi: 10.13229/j.cnki.jdxbgxb20220346 |

|

Liu Yan, Ding Tian-wei, Wang Yu-peng, Du Jing, Zhao hong-hui. Thermal management strategy of fuel cell engine based on adaptive control strategy[J]. Journal of Jilin University (Engineering and Technology Edition), DOI:10.13229/j.cnki.jdxbgxb20220346 .

doi: 10.13229/j.cnki.jdxbgxb20220346 |

|

| 16 | Chen F X, Jiao J R, Hou Z J, et al. Robust polymer electrolyte membrane fuel cell temperature tracking control based on cascade internal model control[J]. Journal of Power Sources, 2020, 479: No. 229008. |

| 17 | Han J, Park J, Yu S. Control strategy of cooling system for the optimization of parasitic power of automotive fuel cell system[J]. International Journal of Hydrogen Energy, 2015, 40(39): 13549-13557. |

| 18 | 沈维道,童钧耕. 工程热力学[M]. 4版. 北京:高等教育出版社出版,2007. |

| 19 | 谭羽飞. 工程热力学[M]. 6版. 北京:中国建筑工业出版社,2016. |

| 20 | 刘占孟,兰蔚. 流体力学[M]. 北京:科学出版社,2017. |

| 21 | Rojas J D, Ocampo-Martinez C, Kunusch C. Thermal modelling approach and model predictive control of a water-cooled pem fuel cell system[C]∥39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 2013: No.14003725. |

| 22 | 郭爱. 基于过氧比的车载燃料电池系统控制技术[D]. 成都: 西南交通大学电气工程学院, 2015. |

| Guo Ai. Control of fuel cell system for vehicle based on oxygen excess ratio[D]. Chengdu: School of Electrical Engineering, Southwest Jiaotong University, 2015. |

| [1] | 杨子荣,李岩,冀雪峰,刘芳,郝冬. 质子交换膜燃料电池运行工况参数敏感性分析[J]. 吉林大学学报(工学版), 2022, 52(9): 1971-1981. |

| [2] | 张佩,王志伟,杜常清,颜伏伍,卢炽华. 车用质子交换膜燃料电池空气系统过氧比控制方法[J]. 吉林大学学报(工学版), 2022, 52(9): 1996-2003. |

| [3] | 陈凤祥,张俊宇,裴冯来,侯明涛,李其朋,李培庆,王洋洋,张卫东. 质子交换膜燃料电池氢气供应系统的建模及匹配设计[J]. 吉林大学学报(工学版), 2022, 52(9): 1982-1995. |

| [4] | 池训逞,侯中军,魏伟,夏增刚,庄琳琳,郭荣. 基于模型的质子交换膜燃料电池系统阳极气体浓度估计技术综述[J]. 吉林大学学报(工学版), 2022, 52(9): 1957-1970. |

| [5] | 王奎洋,何仁. 基于支持向量机的制动意图识别方法[J]. 吉林大学学报(工学版), 2022, 52(8): 1770-1776. |

| [6] | 高青,王浩东,刘玉彬,金石,陈宇. 动力电池应急冷却喷射模式实验分析[J]. 吉林大学学报(工学版), 2022, 52(8): 1733-1740. |

| [7] | 王骏骋,吕林峰,李剑敏,任洁雨. 分布驱动电动汽车电液复合制动最优滑模ABS控制[J]. 吉林大学学报(工学版), 2022, 52(8): 1751-1758. |

| [8] | 刘汉武,雷雨龙,阴晓峰,付尧,李兴忠. 增程式电动汽车增程器多点控制策略优化[J]. 吉林大学学报(工学版), 2022, 52(8): 1741-1750. |

| [9] | 杨红波,史文库,陈志勇,郭年程,赵燕燕. 基于某二级减速齿轮系统的齿面修形优化[J]. 吉林大学学报(工学版), 2022, 52(7): 1541-1551. |

| [10] | 聂光明,谢波,田彦涛. 基于Frenet框架的协同自适应巡航控制算法设计[J]. 吉林大学学报(工学版), 2022, 52(7): 1687-1695. |

| [11] | 郝帅,程川泰,王军年,张君媛,俞有. 运动型SUV驾驶室布置人机优化设计与测试评价[J]. 吉林大学学报(工学版), 2022, 52(7): 1477-1488. |

| [12] | 张家旭,郭崇,王晨,赵健,王欣志. 基于半实物仿真平台的自动泊车系统性能评价[J]. 吉林大学学报(工学版), 2022, 52(7): 1552-1560. |

| [13] | 华琛,牛润新,余彪. 地面车辆机动性评估方法与应用[J]. 吉林大学学报(工学版), 2022, 52(6): 1229-1244. |

| [14] | 李雄,兰凤崇,陈吉清,童芳. Hybird III假人模型与CHUBM人体生物力学模型的正碰损伤对比[J]. 吉林大学学报(工学版), 2022, 52(6): 1264-1272. |

| [15] | 刘兴涛,刘晓剑,武骥,何耀,刘新天. 基于曲线压缩和极限梯度提升算法的锂离子电池健康状态估计[J]. 吉林大学学报(工学版), 2022, 52(6): 1273-1280. |

|

||