吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (12): 3486-3495.doi: 10.13229/j.cnki.jdxbgxb.20230166

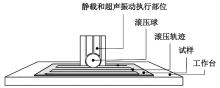

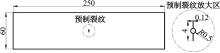

超声滚压对2024铝合金疲劳裂纹扩展行为的影响

- 1.苏州科技大学 机械工程学院,江苏 苏州 215009

2.沈阳航空航天大学 机电工程学院,沈阳 110136

3.沈阳航空航天大学 航空制造工艺数字化国防重点学科实验室,沈阳 110136

Effect of ultrasonic rolling on fatigue crack propagation behavior of 2024 aluminum alloy

Lei WANG1( ),Xiao-peng LIU2,Song ZHOU2,Jin-lan AN3,Hong-jie ZHANG2,Jia-hui CONG2

),Xiao-peng LIU2,Song ZHOU2,Jin-lan AN3,Hong-jie ZHANG2,Jia-hui CONG2

- 1.College of Mechanical Engineering,Suzhou University of Science and Technology,Suzhou 215009,China

2.School of Mechatronics Engineering,Shenyang Aerospace University,Shenyang 110136,China

3.Key Laboratory of Fundamental Science for National Defense of Aeronautical Digital Manufacturing Process,Shenyang Aerospace University,Shenyang 110136,China

摘要:

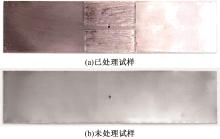

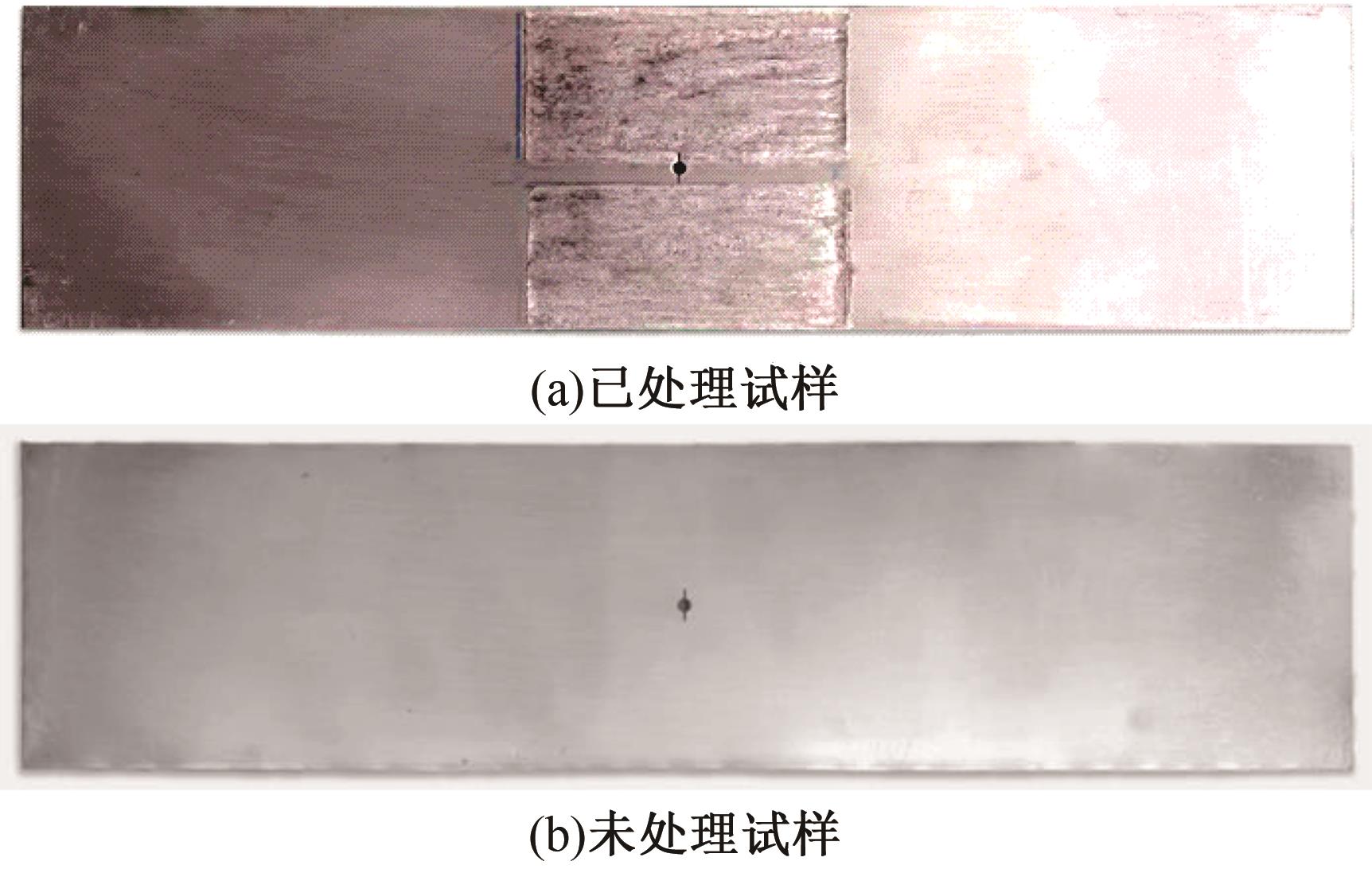

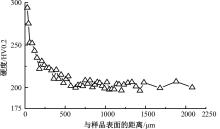

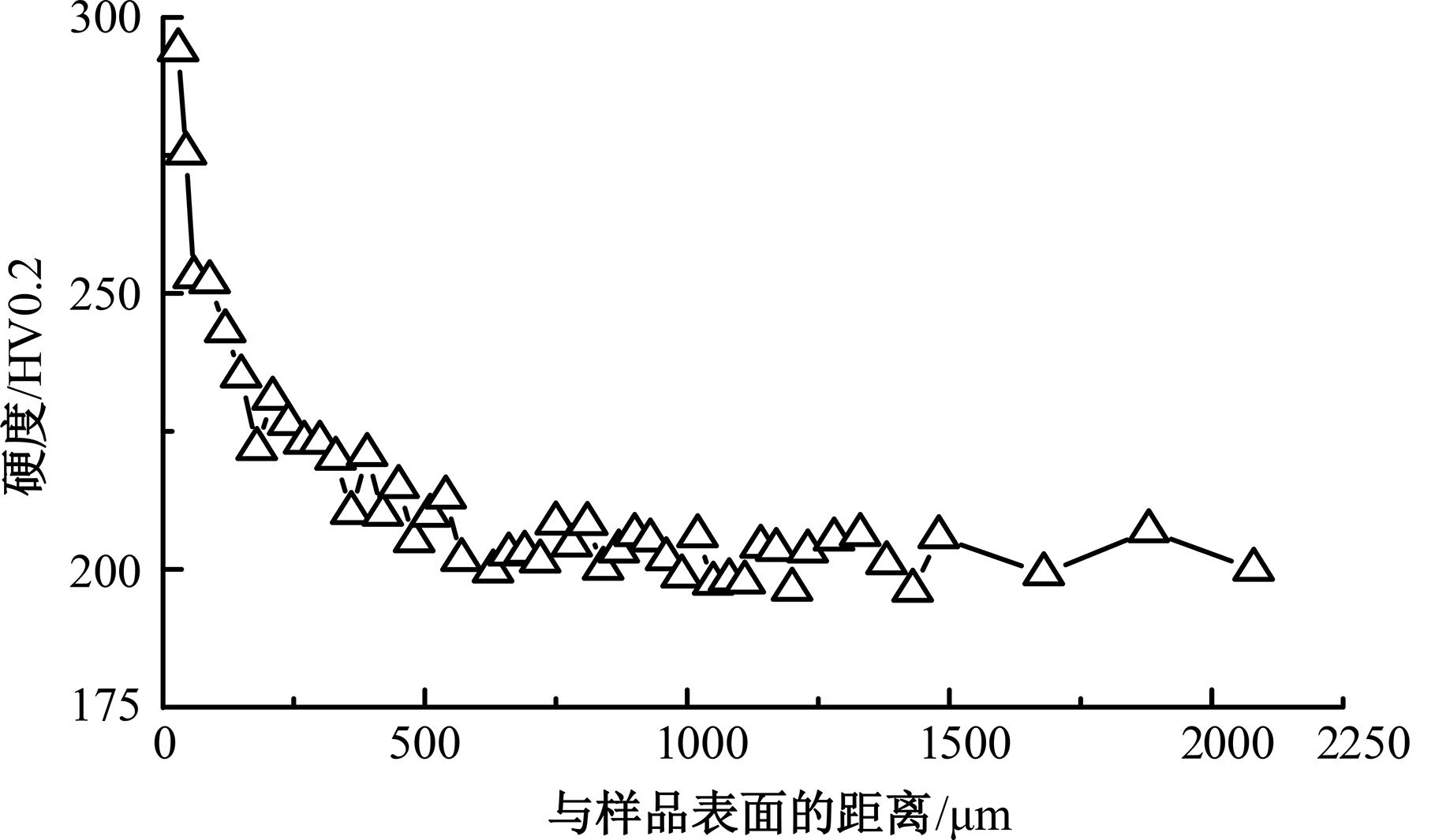

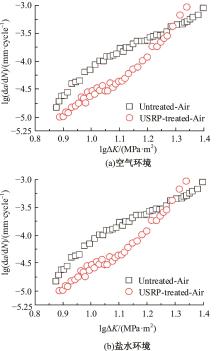

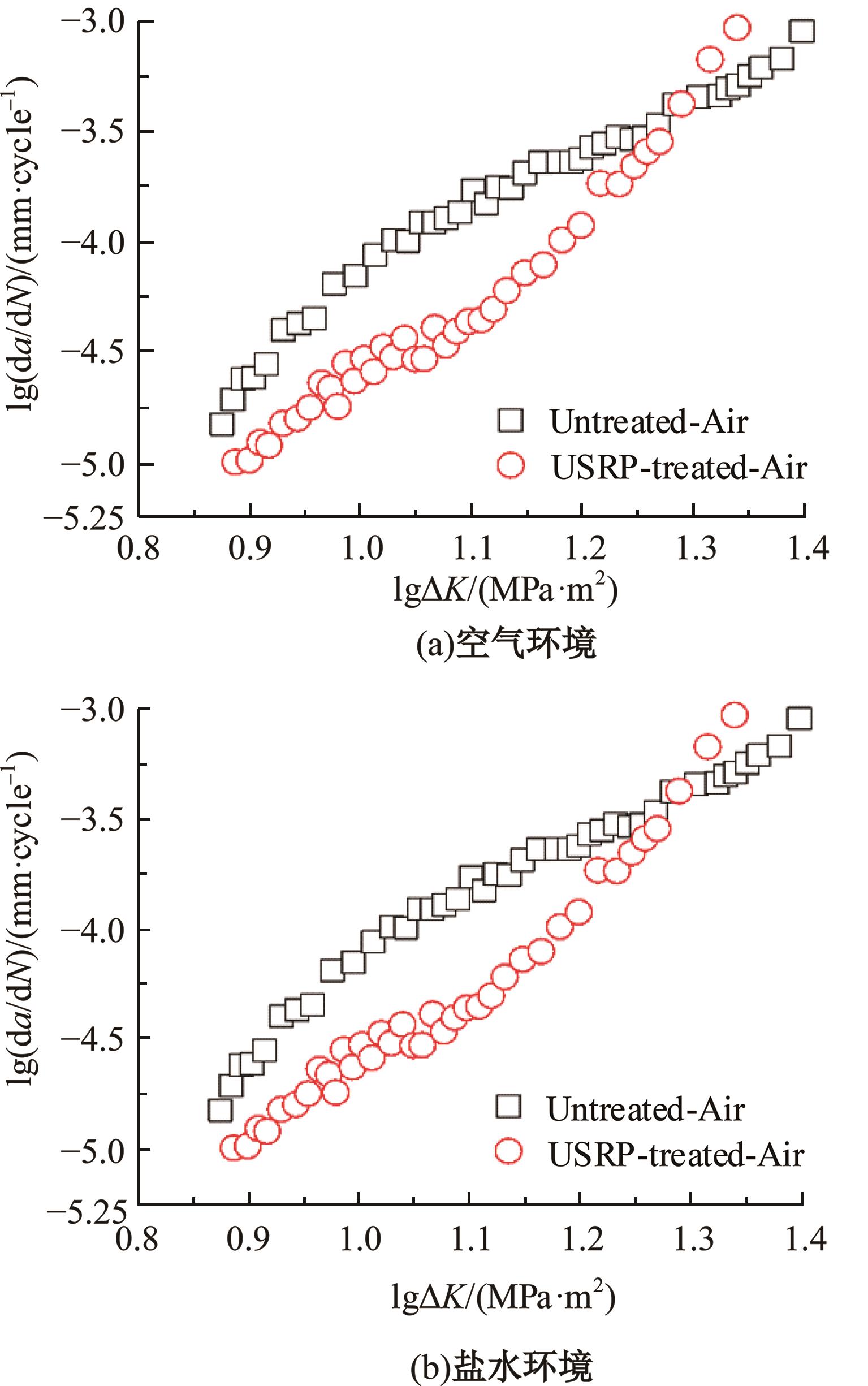

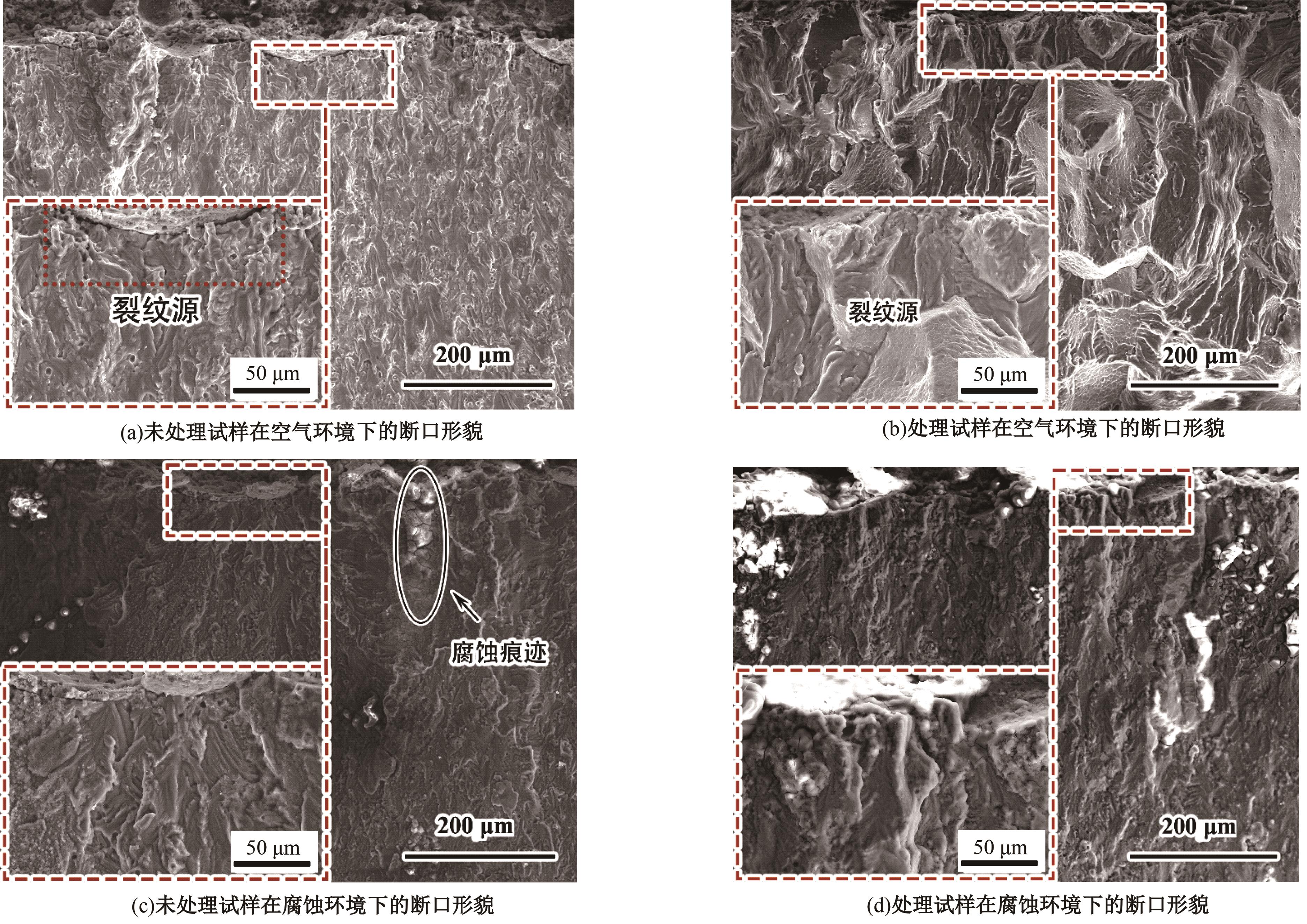

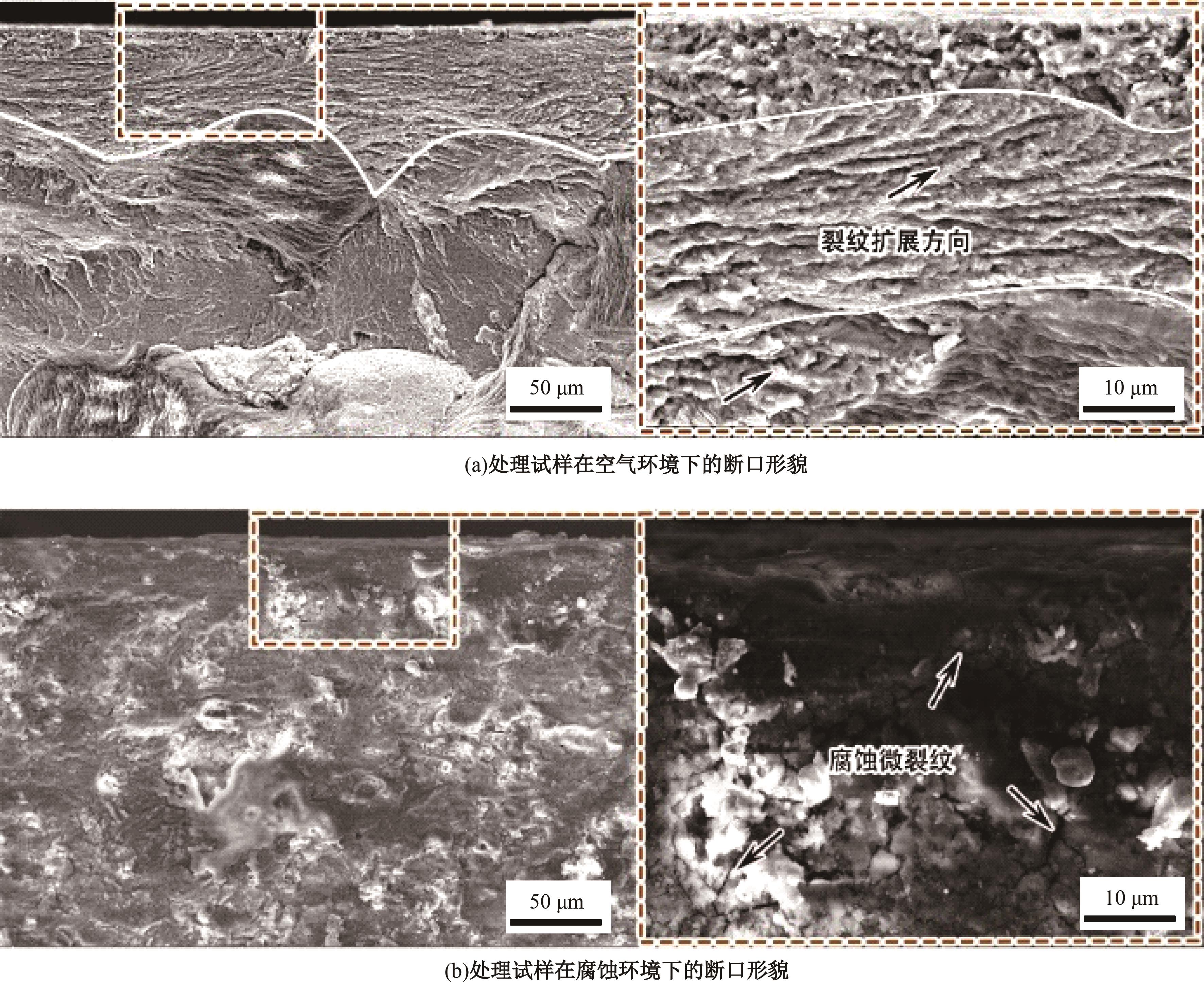

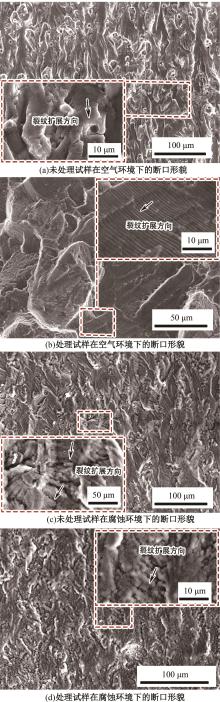

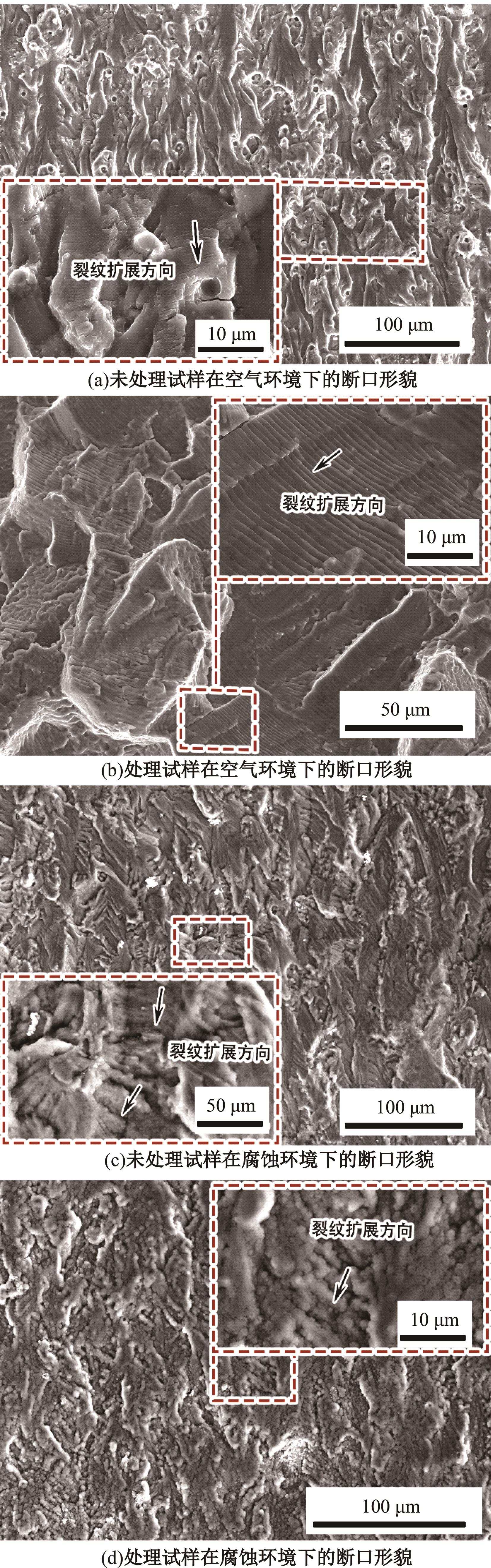

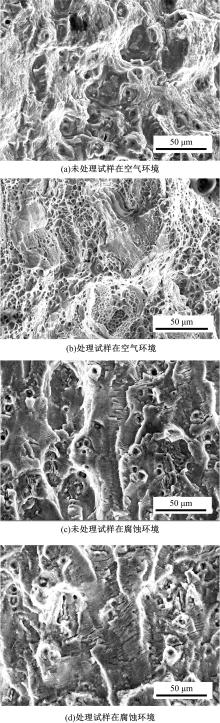

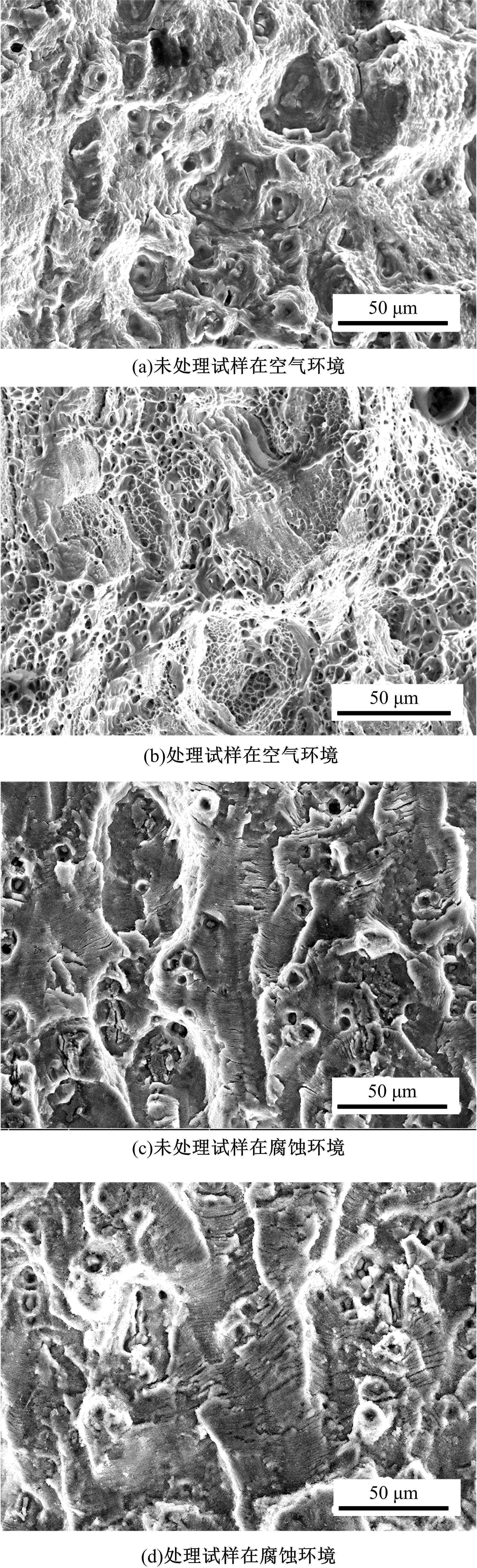

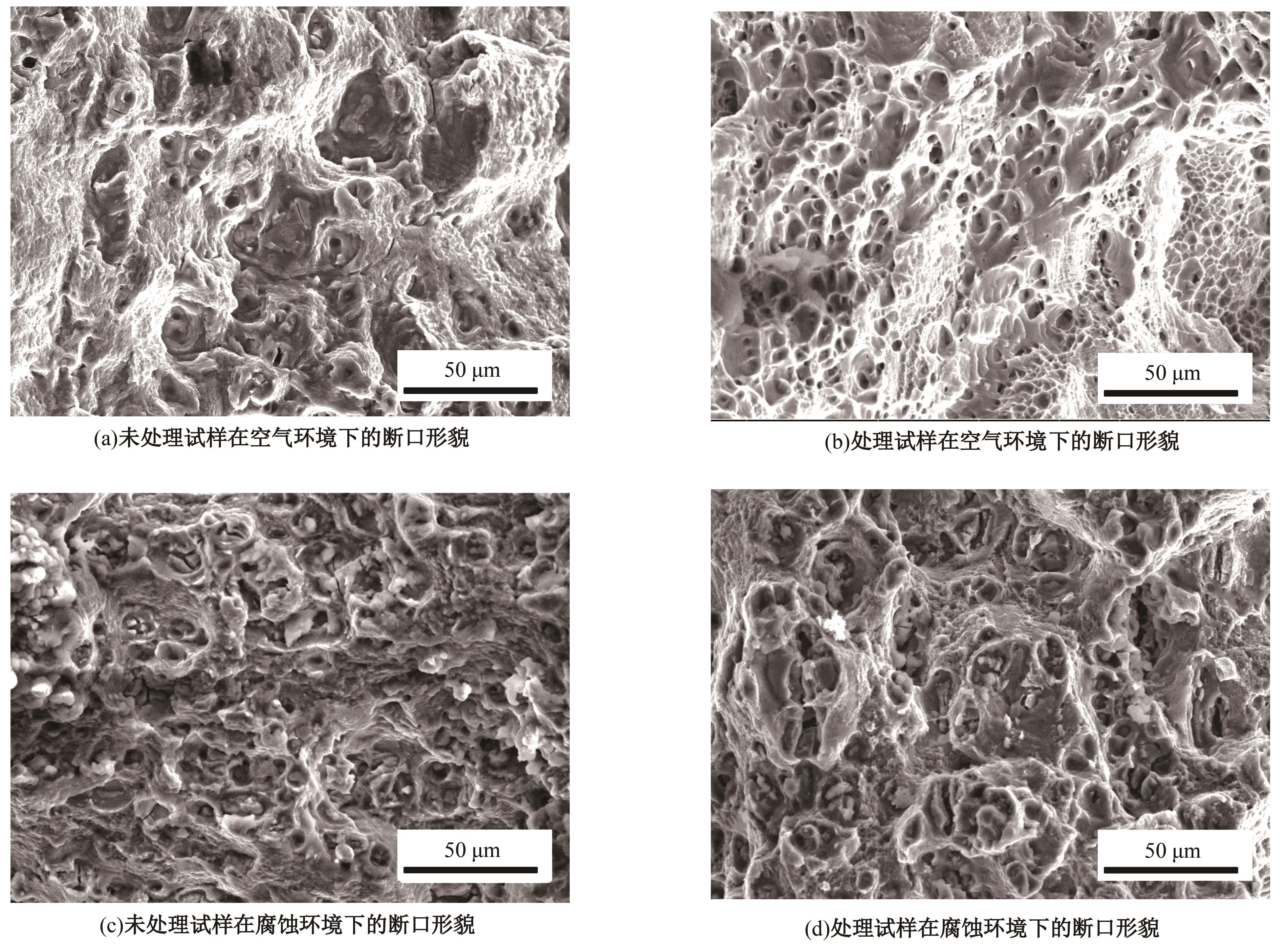

对航空航天用2024铝合金在空气和腐蚀环境下的疲劳裂纹扩展行为进行研究,分析对比了超声滚压对疲劳裂纹扩展行为的影响。结果表明:超声滚压处理使材料表层晶粒细化形成60~70 μm厚的塑性变形层,显微硬度相对于母材提升了45%,且由材料表面向内部呈梯度下降。超声滚压处理降低了裂纹扩展的初始速率,提升了裂纹扩展速率的增长率;超声滚压对两种环境下的疲劳性能都有显著的提升,但在空气环境下对疲劳性能的提升更为显著,这是由于腐蚀环境提升了裂纹扩展的初始裂纹扩展速率,降低了裂纹扩展速率的增长率。

中图分类号:

- TG146

| 1 | Moy C K S, Weiss M, Xia J H, et al. Influence of heat treatment on the microstructure, texture and formability of 2024 aluminium alloy[J]. Materials Science and Engineering A, 2012, 552: 48-60. |

| 2 | James C W, Edgar A, Starke J R. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51: 5775-5799. |

| 3 | 刘兵,彭超群,王日初,等. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(09): 1705-1715. |

| Liu Bing, Peng Chao-qun, Wang Ri-chu, et al. Recent development and prospects for giant plane aluminum alloys[J]. Chinese Journal of Nonferrous Metals, 2010, 20(09): 1705-1715. | |

| 4 | Bhuiyan M S, Mutoh Y, Murai T, et al. Corrosion fatigue behavior of extruded magnesium alloy AZ61 under three different corrosive environments[J]. International Journal of Fatigue, 2008, 30: 1756-1765. |

| 5 | 梁明辉,吴向清,谢发勤,等. Cl-浓度对阳极氧化5A06铝合金/1Cr18Ni9Ti不锈钢偶接件腐蚀行为的影响[J]. 表面技术, 2022, 51(7): 161-168. |

| Liang Ming-hui, Wu Xian-qing, Xie Fa-qin, et al. Effect of CI- concentration on corrosion behavior of anodized 5A06 aluminum alloy/1Cr18Ni9Ti stainless steel coupling[J]. Surface Technology, 2021, 51(7): 161-168. | |

| 6 | 罗开玉,邢月华,柴卿锋,等. 激光冲击强化对2Cr13不锈钢腐蚀疲劳性能的影响[J]. 吉林大学学报:工学版, 2019, 49(3): 850-858. |

| Luo Kai⁃yu, Xing Yue⁃hua, Chai Qing⁃feng, et al. Effects of laser shock peening on corrosion fatigue behaviour of 2Cr13 stainless steel[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 850-858. | |

| 7 | 刘阳,吕晓仁,张荣禄,等. 超音速微粒轰击表面纳米化及其对耐磨性的影响[J]. 中国表面工程, 2006(6): 20-24. |

| Liu Yang, Xiao-ren Lyu, Zhang Rong-lu, et al. Surface nanocrystallization using supersonic fine particles bombarding and its effect on the wear behaviors[J]. Chinese Surface Engineering, 2006(6): 20-24. | |

| 8 | Wu K, Yuan X, Hu Z, et al. Improvement of Al/steel tungsten inert gas welding brazing joint by high-energy shot peening[J]. Journal of Materials Engineering and Performance, 2019, 28(5): 2937-2945. |

| 9 | Rakita M, Wang M, Han Q, et al. Ultrasonic shot peening[J]. International Journal of Computational Materials Science and Surface Engineering, 2013, 5(3): 189-209. |

| 10 | 王婷,王东坡,刘刚,等. 40Cr超声表面滚压加工纳米化[J]. 机械工程学报, 2009 (5): 177-183. |

| Wang Ting, Wang Dong-po, Liu Gang, et al. 40Cr nano-crystallization by ultrasonic surface rolling extrusion processing[J]. Journal of Mechanical Engineering, 2009(5): 177-183. | |

| 11 | 郑建新,任元超. 7050铝合金二维超声滚压加工表面完整性综合评价[J]. 中国机械工程, 2018, 29(13): 1622-1626. |

| Zheng Jian-xin, Ren Yuan-chao. Comprehensive assessment of surface integrity in two dimensional Ultrasonic rolling 7050 aluminum alloys[J]. Chinese Mechanical Engineering, 2018, 29(13): 1622-1626. | |

| 12 | Wang P, Guo H, Wang D F, et al. Microstructure and tribological performances of M50 bearing steel processed by ultrasonic surface rolling[J]. Tribology International, 2022, 175: No.107818. |

| 13 | Xie J W, Zhang S Q, Sun Y G, et al. Microstructure and mechanical properties of high entropy CrMnFeCoNi alloy processed by electopulsing-assisted ultrasonic surface rolling[J]. Materials Science & Engineering A, 2020, 795: No.140004. |

| 14 | 王磊,黄秉汉,丛家慧,等.超声冲击对搅拌摩擦焊缝疲劳性能的影响[J]. 吉林大学学报:工学版, 2022, 52(11): 2542-2548. |

| Wang Lei, Huang Bing-han, Cong Jia-hui, et al. Effect of ultrasonic impact on fatigue performance of friction stir weld[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2542-2548. | |

| 15 | Yu Y Y, Sun W G, Tong D H. Effect of loading frequency on corrosion fatigue crack growth rate of 7N01 aluminum alloy[J]. Materials Science and Engineering C, 2020, 768: No.022060. |

| 16 | Zhao W D, Liu D X, Zhang X H, et al. Improving the fretting and corrosion fatigue performance of 300M ultra-high strength steel using the ultrasonic surface rolling process[J]. International Journal of Fatigue, 2019, 121: 30-38. |

| 17 | Shen F H, Wang B, Yi D Q, et al. Effects of heating rate during solid-solution treatment on microstructure and fatigue properties of AA2524 T3 Al–Cu–Mg sheet[J]. Materials and Design, 2016, 104: 116-125. |

| 18 | Ye C, Suslov S, Fei X, et al. Bimodal nanocrystallization of NiTi shape memory alloy by laser shock peening and post-deformation annealing[J]. Acta Materialia, 2011, 59(19): 7219-7227. |

| 19 | Kim H K, Kim W J. Microstructural instability and strength of an AZ31 Mg alloy after severe plastic deformation [J]. Materials science and Engineering A, 2004, 385: 300-308. |

| 20 | 鲁金忠, 季仕杰, 吴刘军,等. 激光冲击⁃超声滚压复合工艺对AZ91D镁合金力学性能的影响[J].吉林大学学报:工学版, 2020, 50(4): 1301-1309. |

| Lu Jin-zhong, Ji Shi-jie, Wu Liu-jun, et al. Effect of laser shock peening and ultrasound surface rolling combined processes on mechanical properties of AZ91D Mg alloy[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(4): 1301-1309. | |

| 21 | Chen B, Huang B, Liu H, et al. Surface nanocrystallization induced by shot peening and its effect on corrosion resistance of 6061 aluminum alloy[J]. Journal of Materials Research, 2014, 29(24): 3002-3010. |

| 22 | Lu J Z, Wu L J, Sun G F, et al. Microstructural response and grain refinement mechanism of commercially pure titanium subjected to multiple laser shock peening impacts[J]. Acta Materialia, 2017, 127: 252-266. |

| 23 | Li L, Li Y, Wang F H. Electrochemical corrosion behavior of nanocrystalline materials—a review[J]. Journal of Materials Science and Technology, 2010, 1(26): 1-14. |

| 24 | Valiev R Z, Enikeev N A, Murashkin M Y, et al. On the origin of extremely high strength of ultrafine-grained Al alloys produced by severe plastic deformation[J]. Scripta Materialia, 2010, 63(9): 949-952. |

| [1] | 商蕾,杨萍,杨祥国,潘建欣,杨军,张梦如. 基于APSO-BP-PID控制的质子交换膜燃料电池热管理系统温度控制[J]. 吉林大学学报(工学版), 2024, 54(9): 2401-2413. |

| [2] | 蒋林,李国龙,王时龙,徐凯,李喆裕. 基于主成分回归的进给轴热膨胀误差建模[J]. 吉林大学学报(工学版), 2024, 54(8): 2149-2155. |

| [3] | 张则强,王灿,刘俊琦,计丹,刘思璐. 基于改进麻雀搜索算法的平行行排序问题[J]. 吉林大学学报(工学版), 2024, 54(7): 1851-1861. |

| [4] | 王磊,李东侠,周松,回丽,沈振鑫. 2024-O铝合金搅拌摩擦焊接头疲劳裂纹扩展行为及寿命预测[J]. 吉林大学学报(工学版), 2024, 54(6): 1563-1569. |

| [5] | 回丽,金磊,宋万万,周松,安金岚. 转向架用SMA490BW钢不同焊接区域裂纹扩展速率[J]. 吉林大学学报(工学版), 2024, 54(3): 650-656. |

| [6] | 杨志军,张驰,黄观新. 基于浮动坐标法的刚柔耦合定位平台力学模型[J]. 吉林大学学报(工学版), 2024, 54(2): 385-393. |

| [7] | 邬伟骏,吴江波,张家乐,周强,杨乔洪,秦训鹏. 新型多功能高空作业平台稳定性分析和尺度综合[J]. 吉林大学学报(工学版), 2024, 54(12): 3450-3459. |

| [8] | 周焕林,郭鑫,王选,方立雪,龙凯. 考虑几何非线性的多相多孔结构拓扑优化设计[J]. 吉林大学学报(工学版), 2024, 54(10): 2754-2763. |

| [9] | 石林榕,赵武云. 西北寒旱农区胡麻滚勺式精量穴播器的设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2706-2717. |

| [10] | 柴博森,王广义,闫东,朱国仁,张进,吕恒升. 液力变矩器空化数值模拟及对性能的影响[J]. 吉林大学学报(工学版), 2023, 53(8): 2236-2244. |

| [11] | 陈国辉,徐业银,焦映厚. 考虑偏转的斜齿轮啮合刚度及其振动分析[J]. 吉林大学学报(工学版), 2023, 53(7): 1902-1910. |

| [12] | 陈贵升,罗国焱,李靓雪,黄震,李一. 柴油机颗粒捕集器孔道流场及其高原环境下噪声特性分析[J]. 吉林大学学报(工学版), 2023, 53(7): 1892-1901. |

| [13] | 于立娟,安阳,何佳龙,李国发,王升旭. 机电装备载荷谱外推技术研究进展及发展趋势[J]. 吉林大学学报(工学版), 2023, 53(4): 941-953. |

| [14] | 李胜,朱佳,黄德惠,陈存福,费洪庆,丰伟,胡兴军. 空冷中冷器百叶窗翅片结构参数优化[J]. 吉林大学学报(工学版), 2023, 53(4): 998-1006. |

| [15] | 王建,于威,王斌. 高原状态下甲醇替代率对柴油机燃烧与排放的影响[J]. 吉林大学学报(工学版), 2023, 53(4): 954-963. |

|