吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (1): 294-312.doi: 10.13229/j.cnki.jdxbgxb.20220298

• 农业工程·仿生工程 • 上一篇

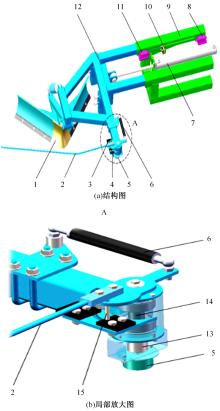

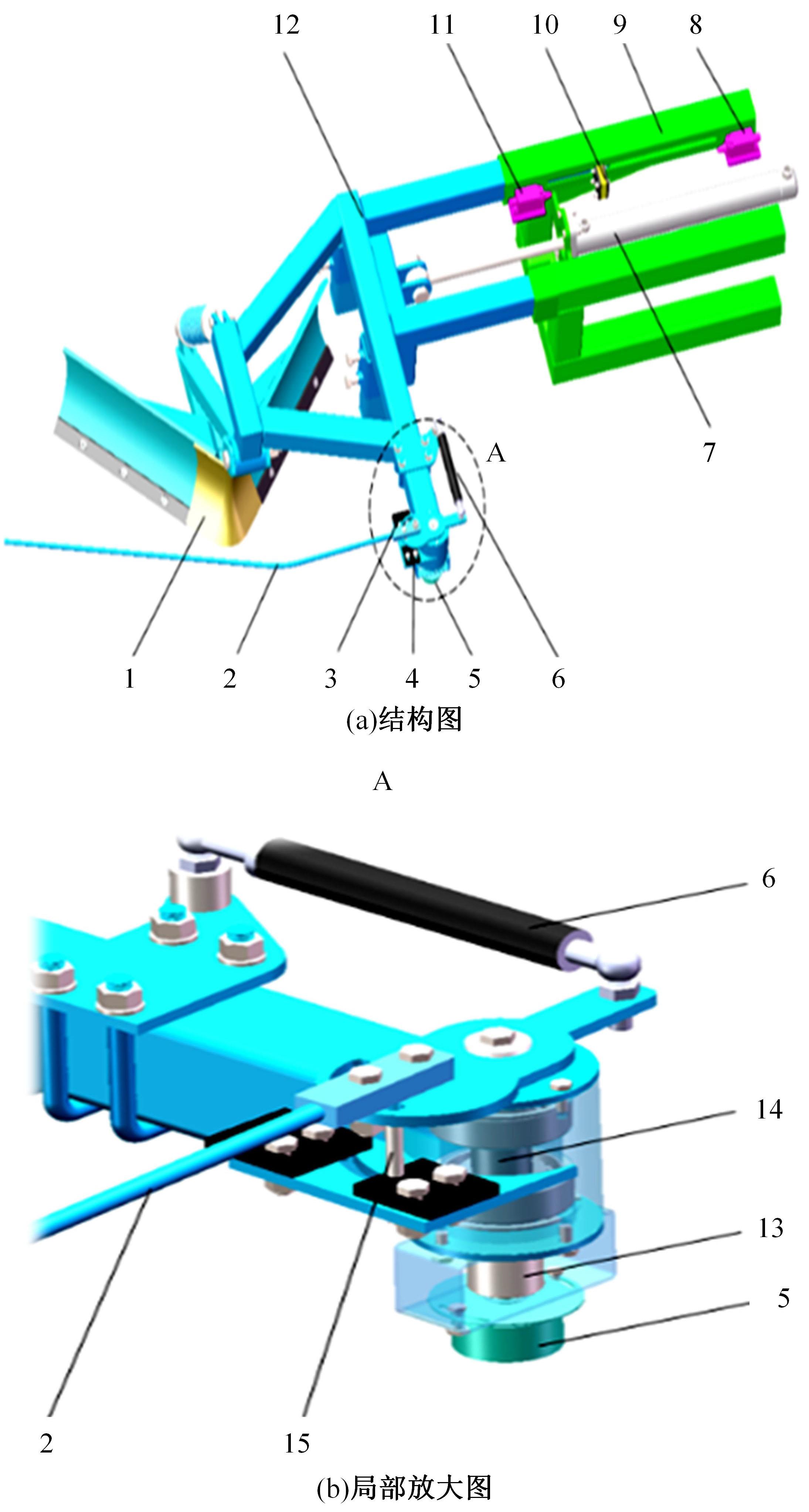

刮刷组合式葡萄藤防寒土清土机设计与试验

马帅1( ),徐丽明1(

),徐丽明1( ),许述财2,牛丛1,闫成功1,谭好超1

),许述财2,牛丛1,闫成功1,谭好超1

- 1.中国农业大学 工学院,北京 100083

2.清华大学 汽车安全与节能国家重点实验室,北京 100084

Design and experiment of grapevine cold⁃proof soil cleaner with combined scraping and brushing

Shuai MA1( ),Li-ming XU1(

),Li-ming XU1( ),Shu-cai XU2,Cong NIU1,Cheng-gong YAN1,Hao-chao TAN1

),Shu-cai XU2,Cong NIU1,Cheng-gong YAN1,Hao-chao TAN1

- 1.College of Engineering,China Agricultural University,Beijing 100083,China

2.State Key Laboratory of Automotive Safety and Energy,Tsinghua University,Beijing 100084,China

摘要:

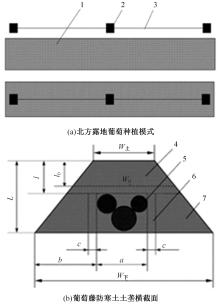

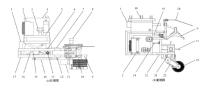

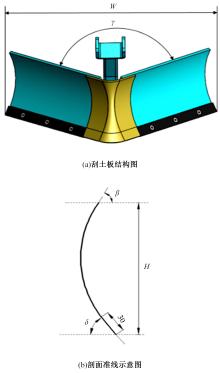

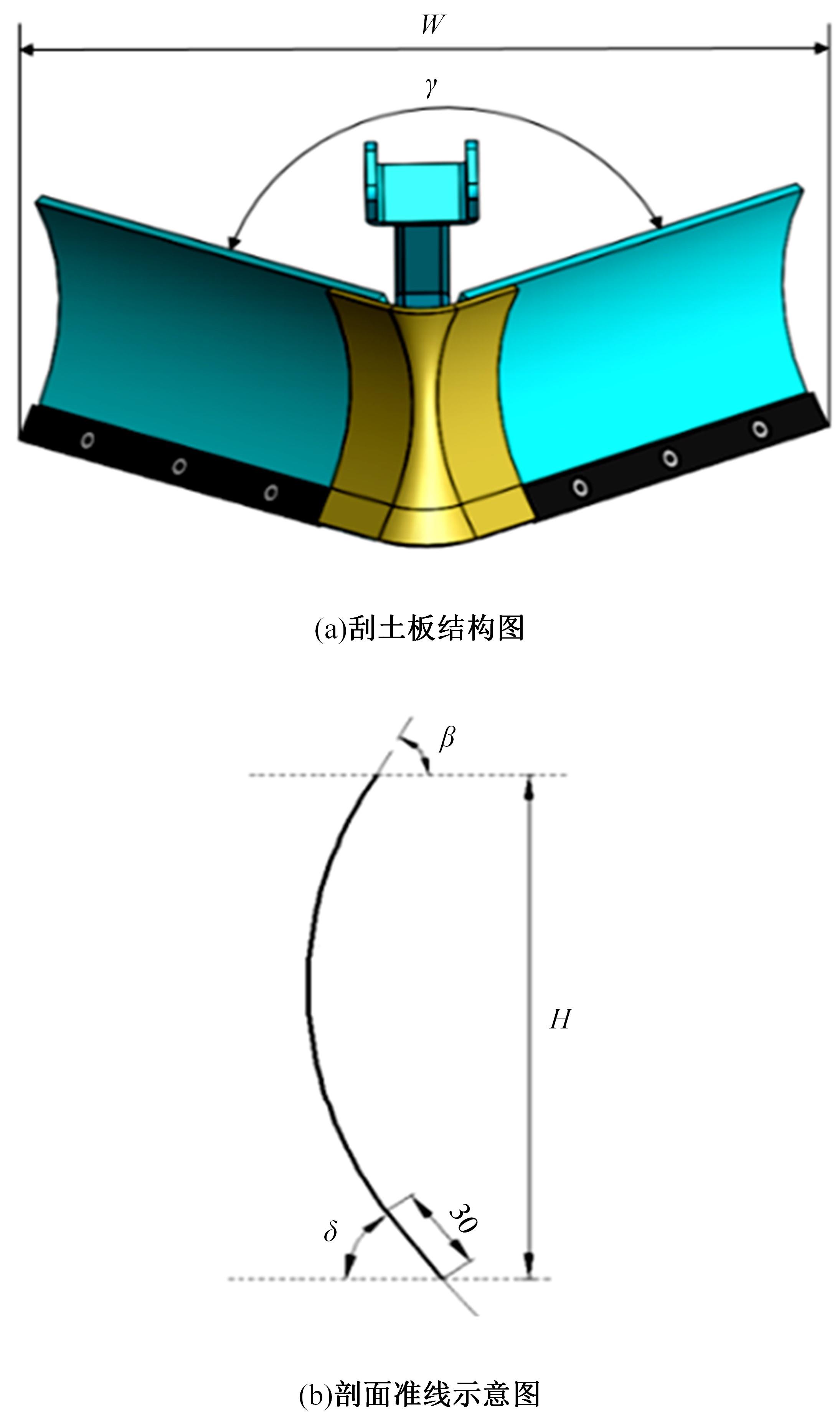

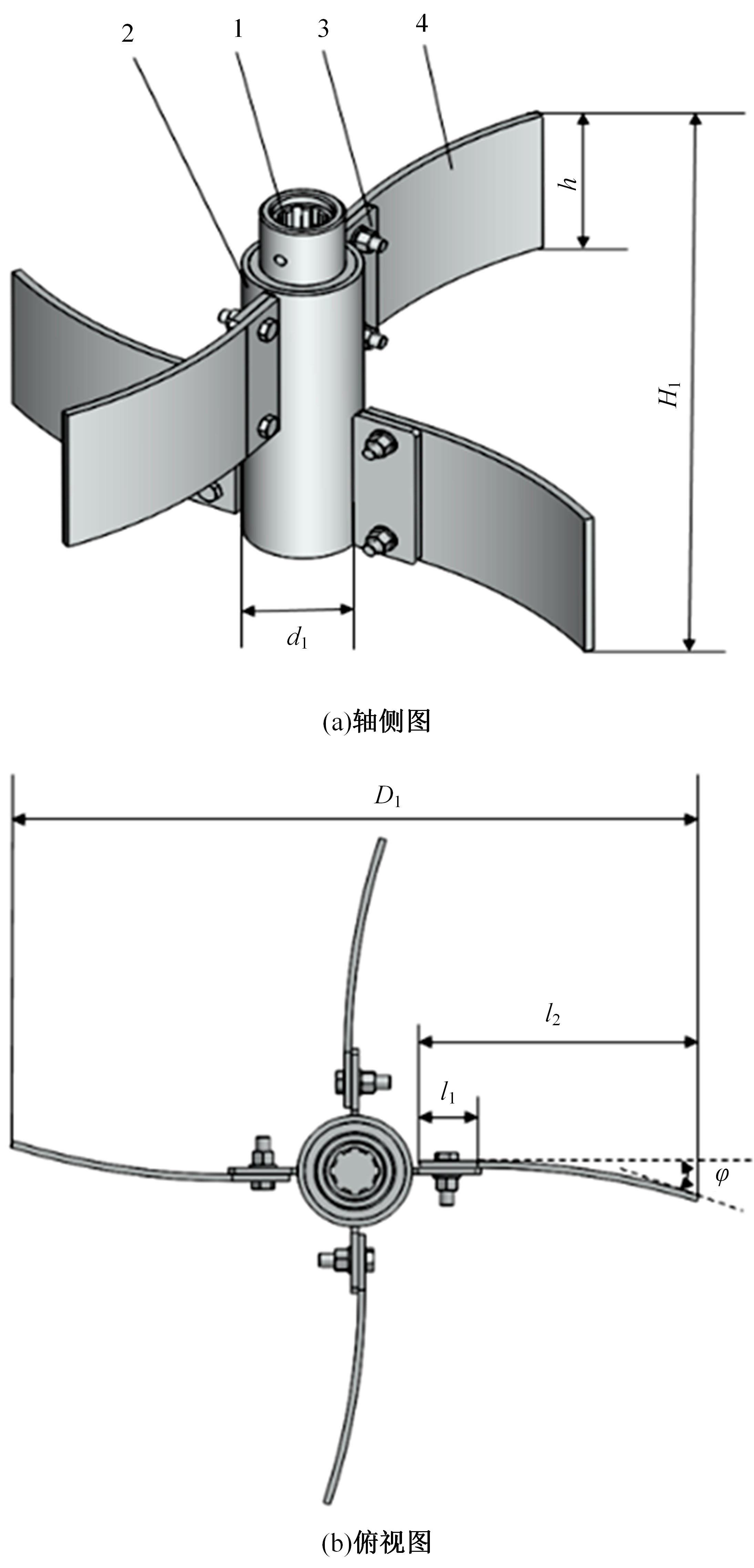

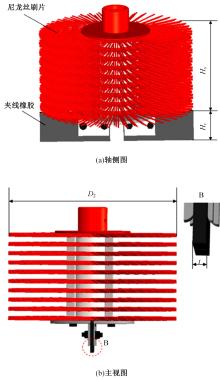

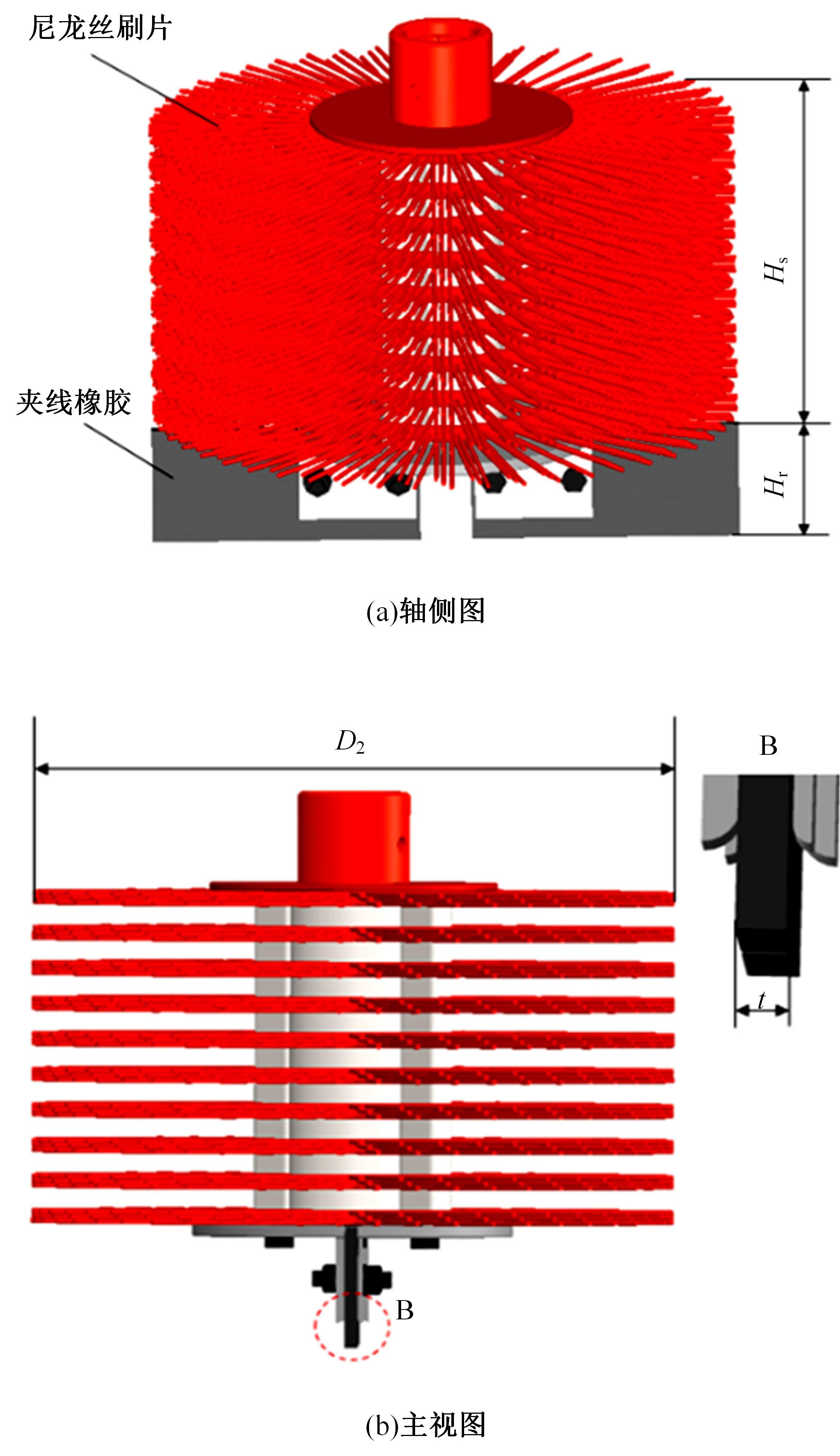

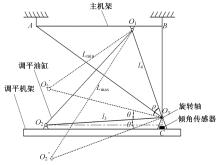

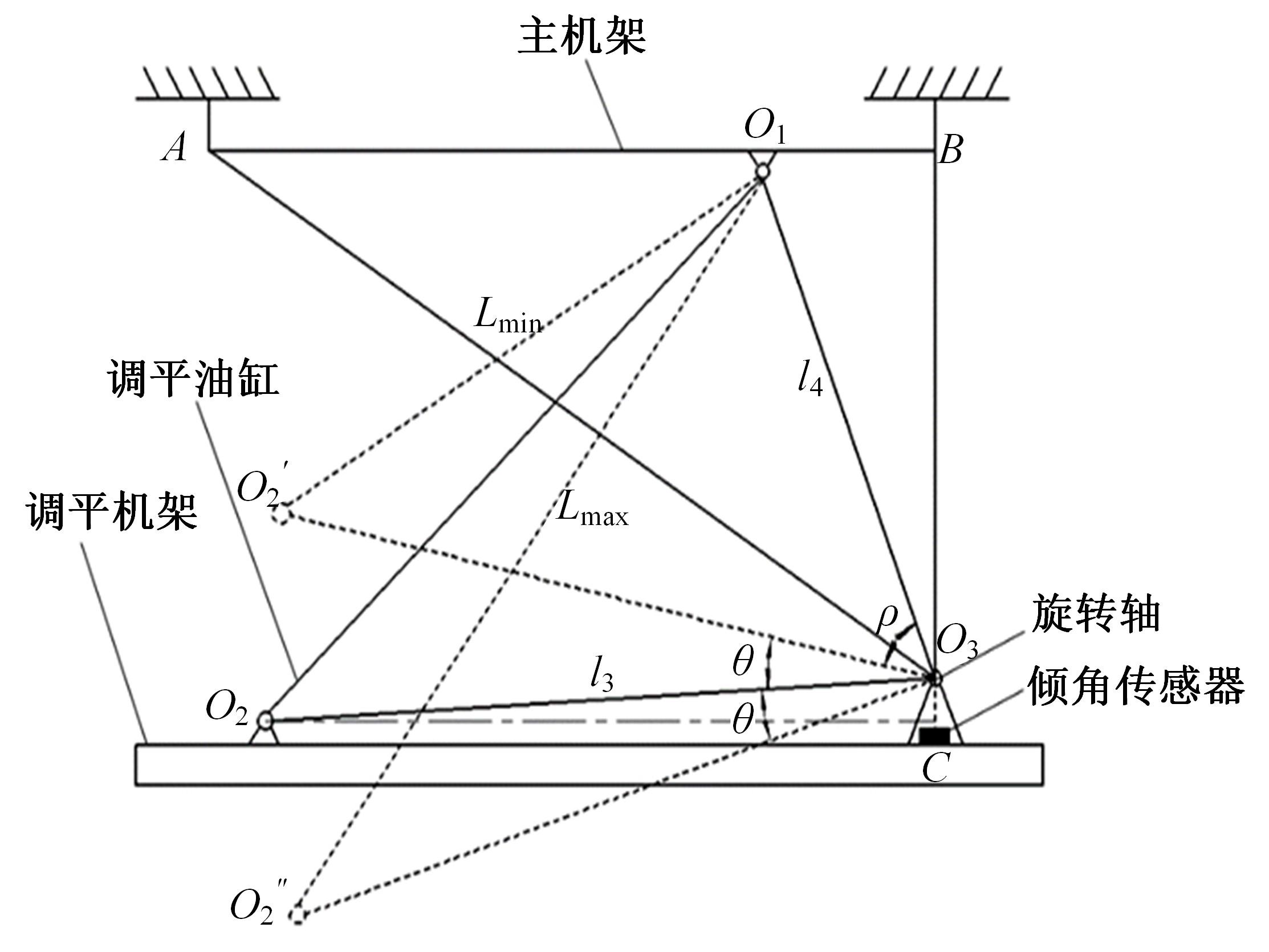

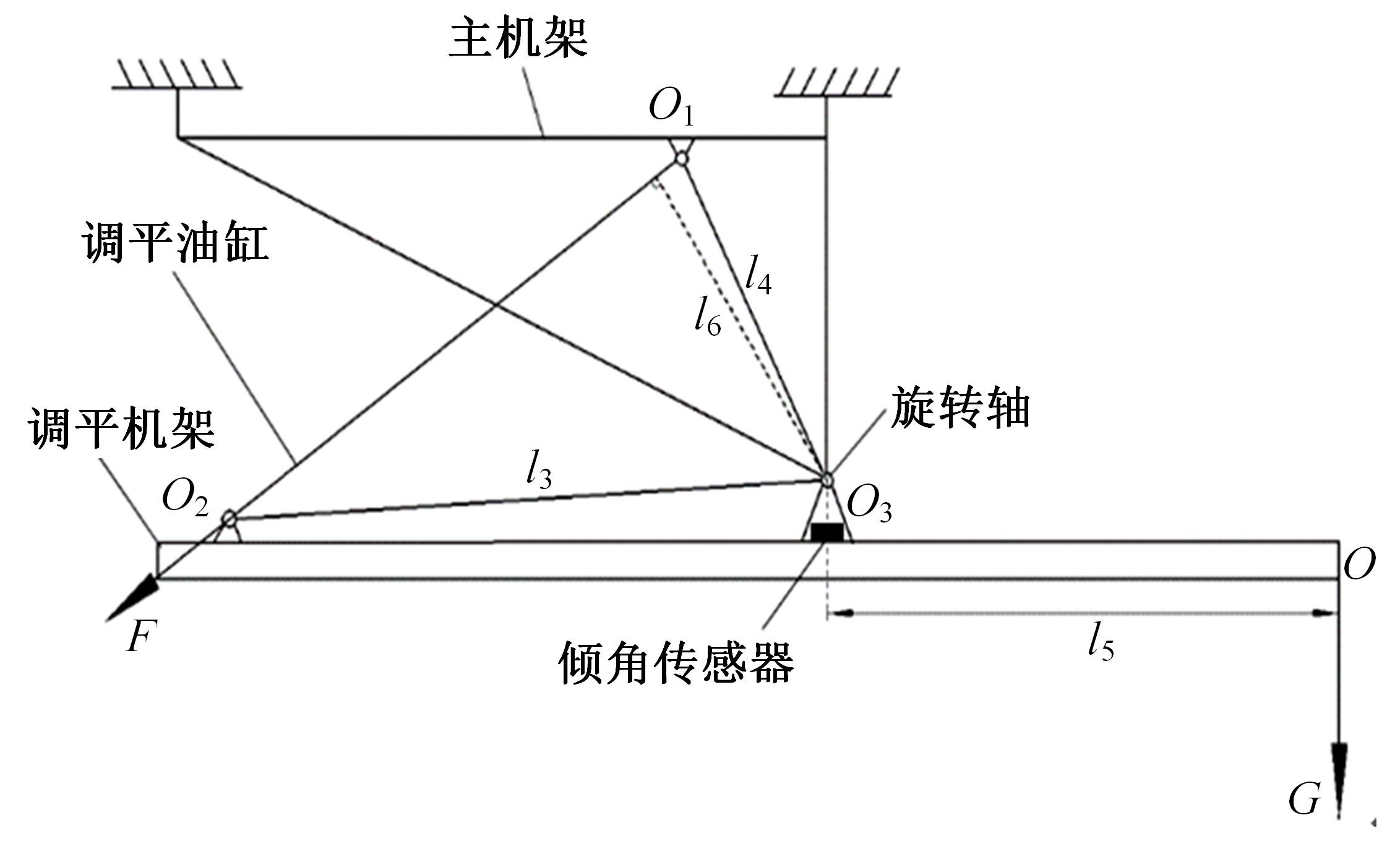

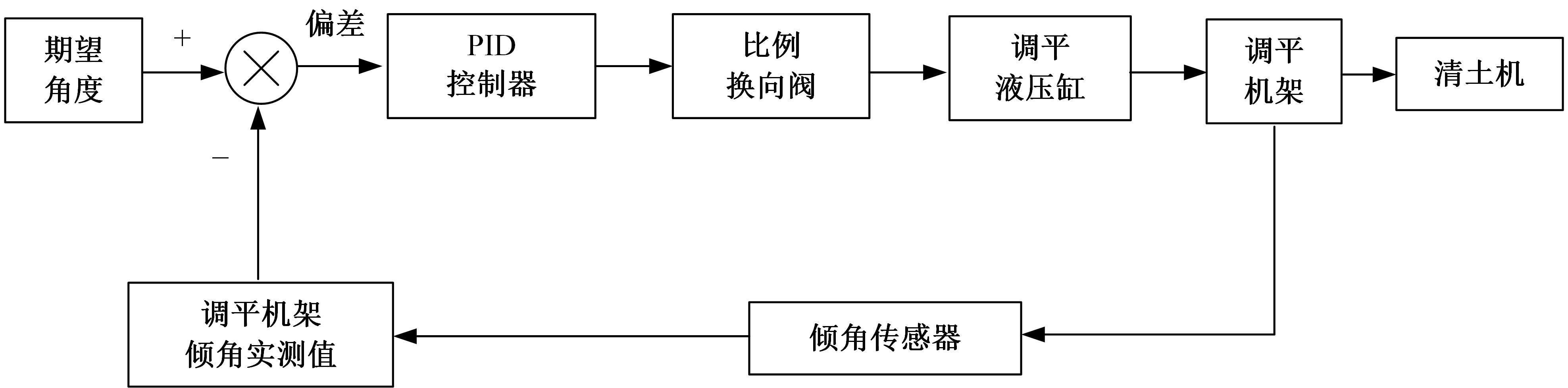

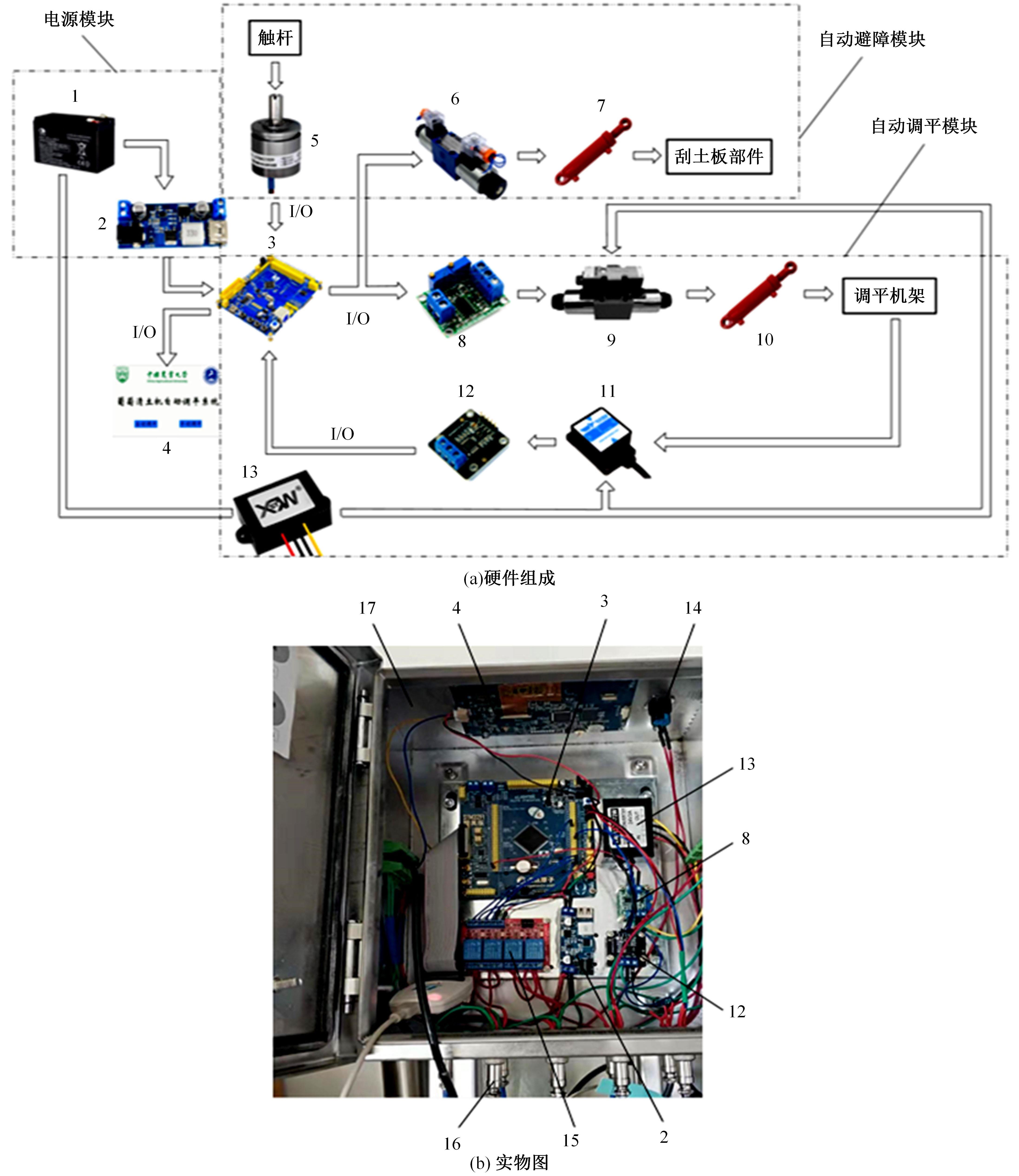

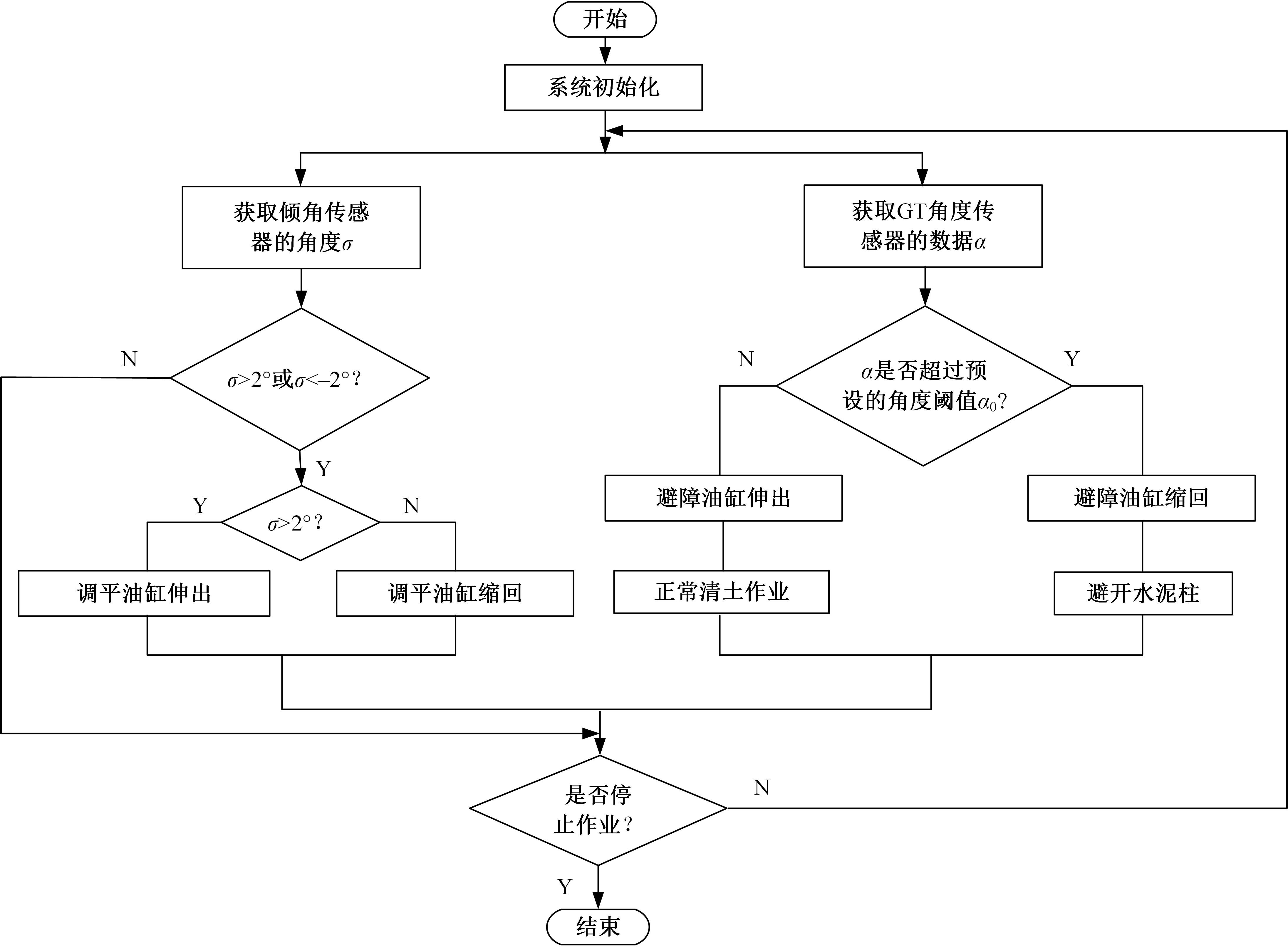

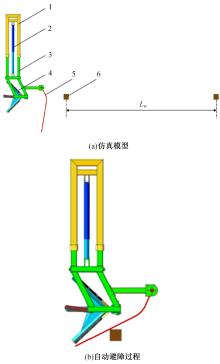

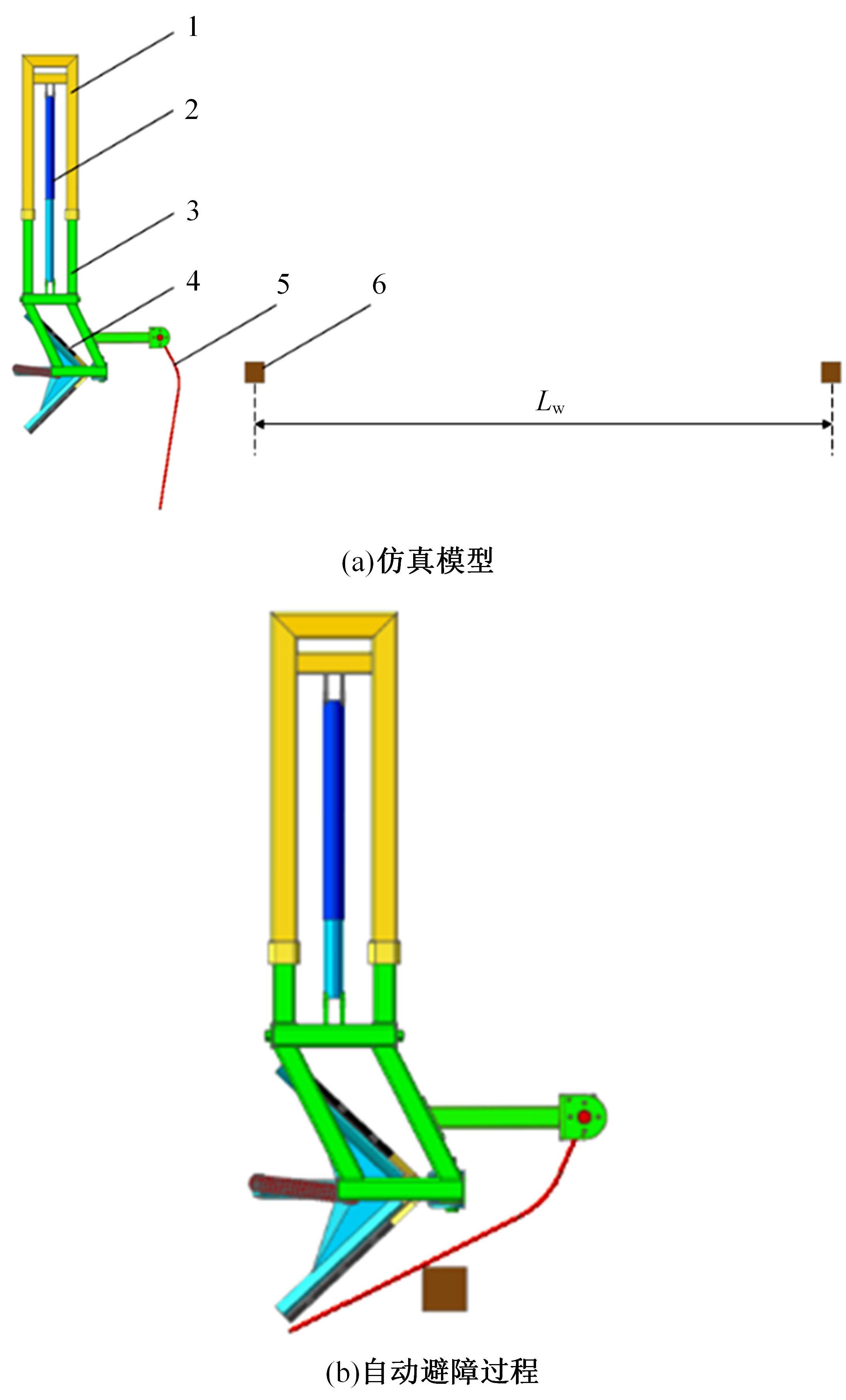

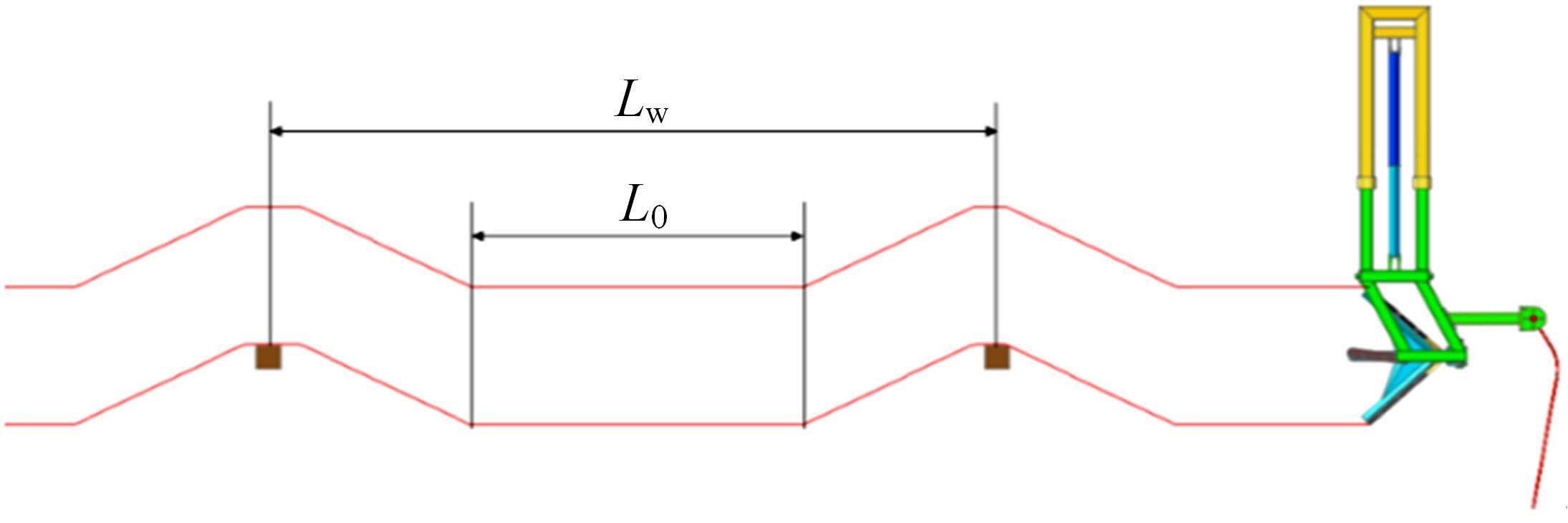

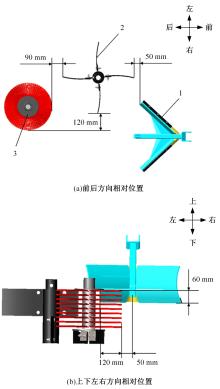

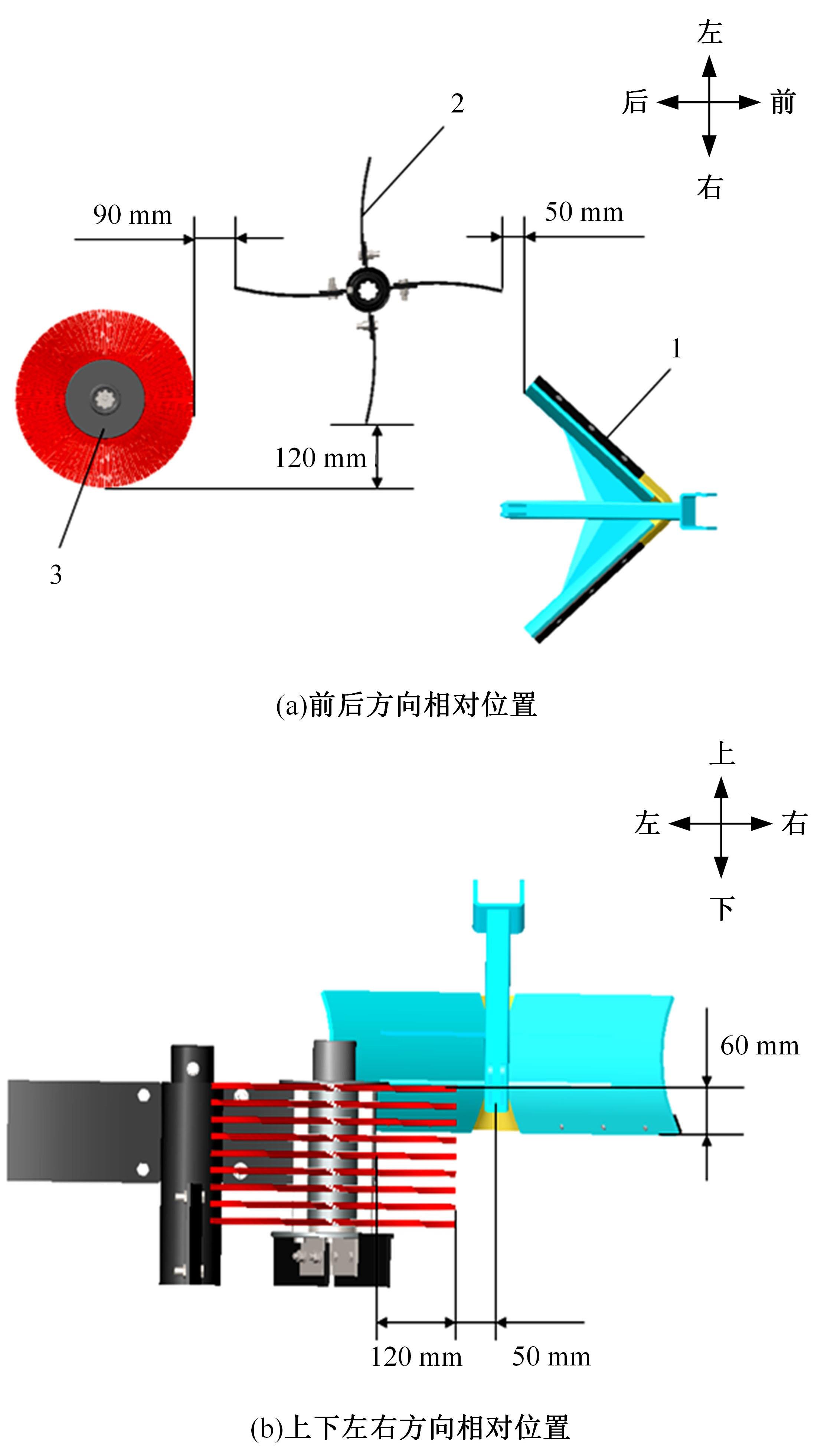

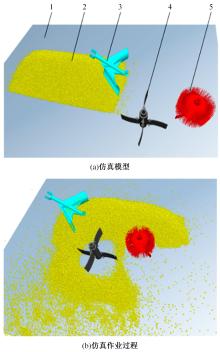

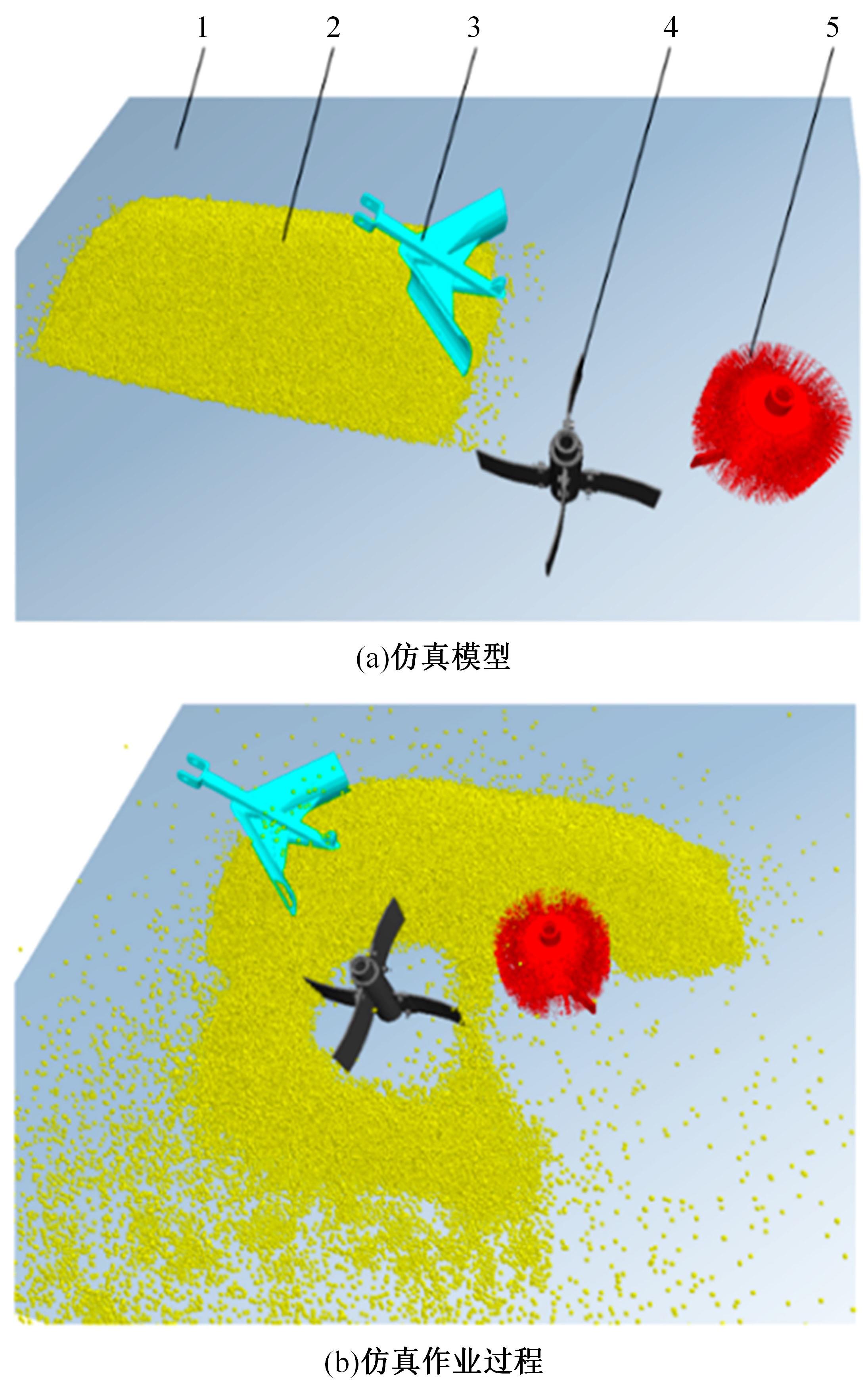

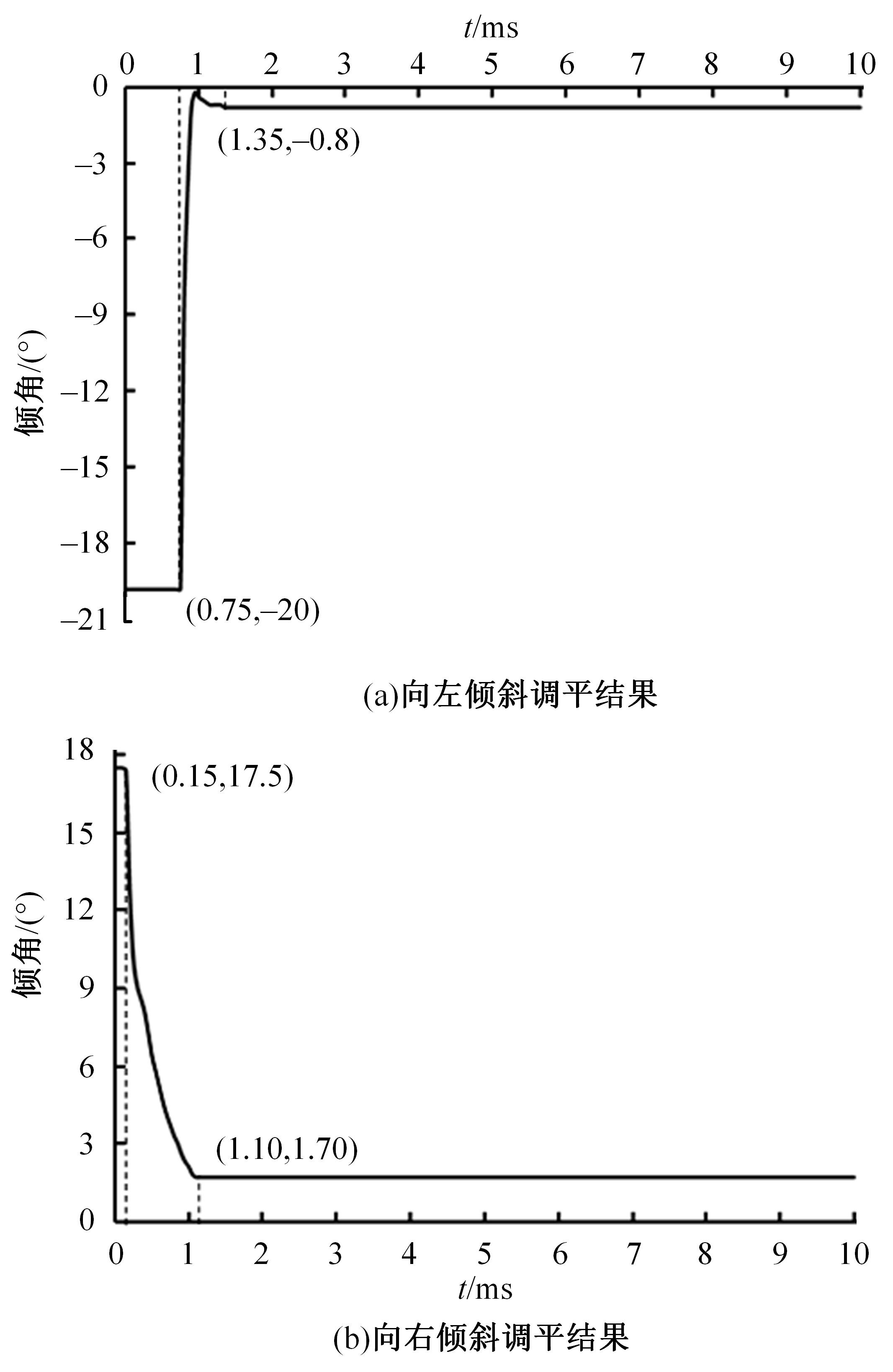

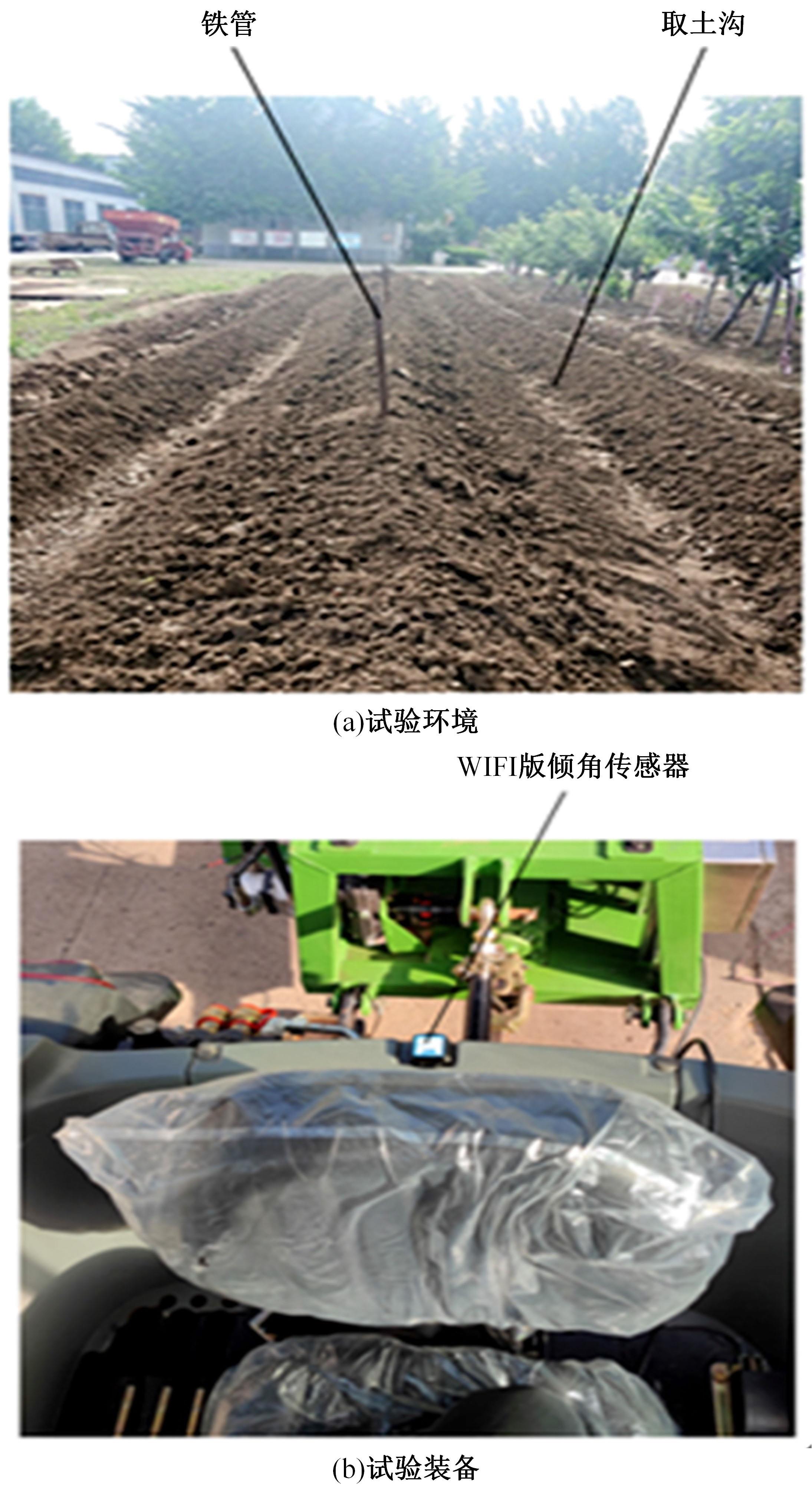

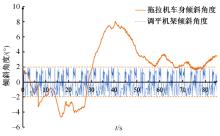

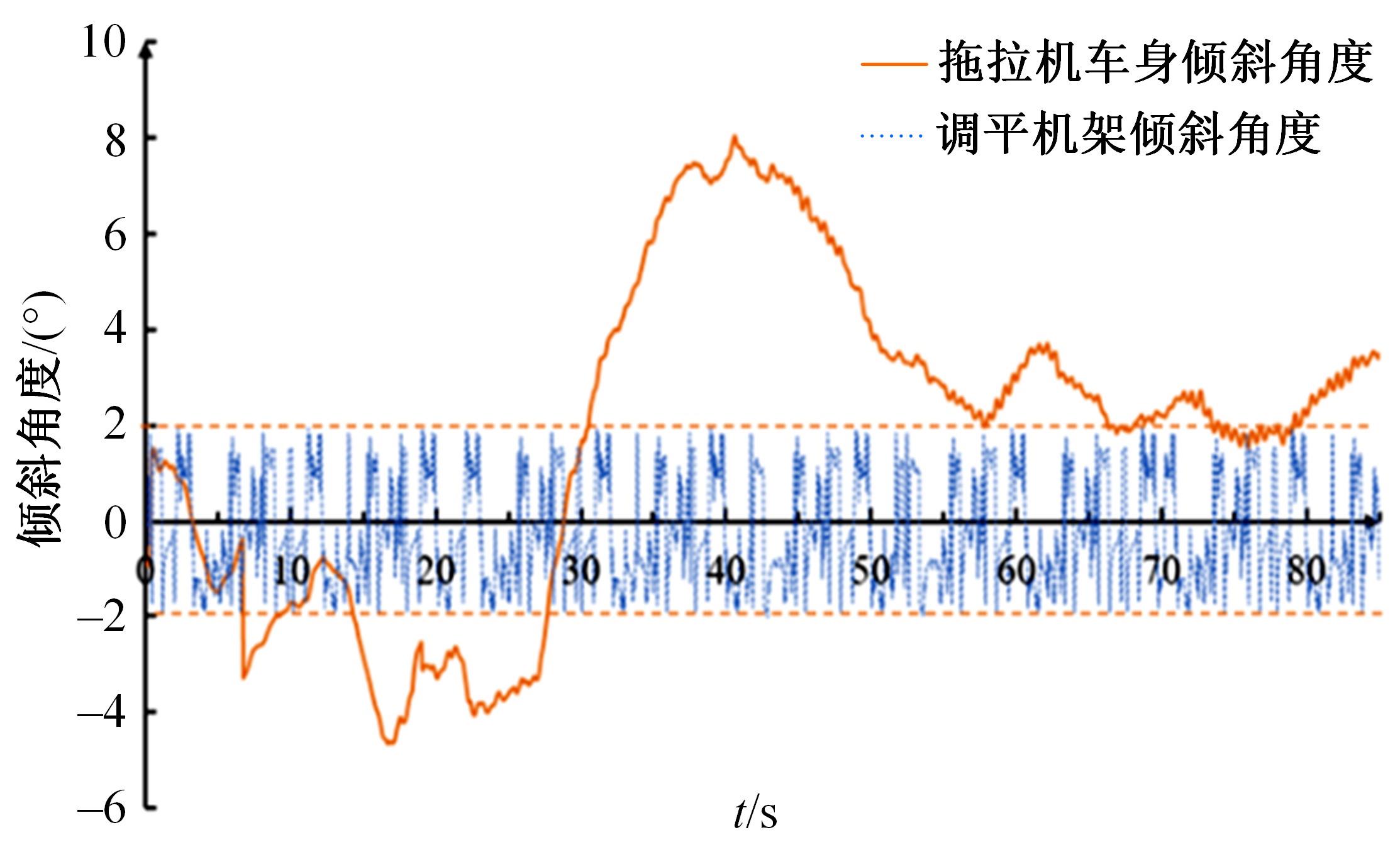

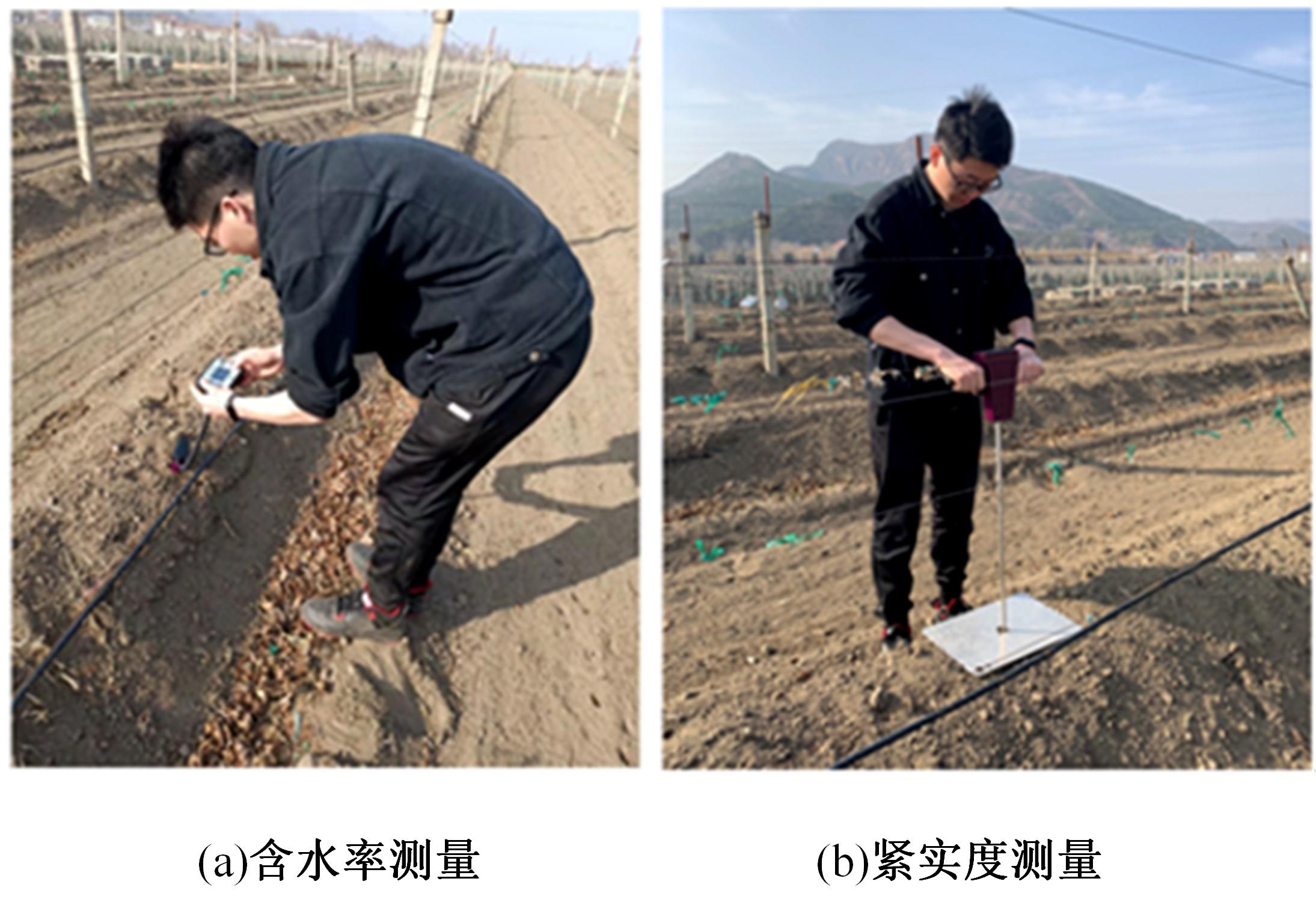

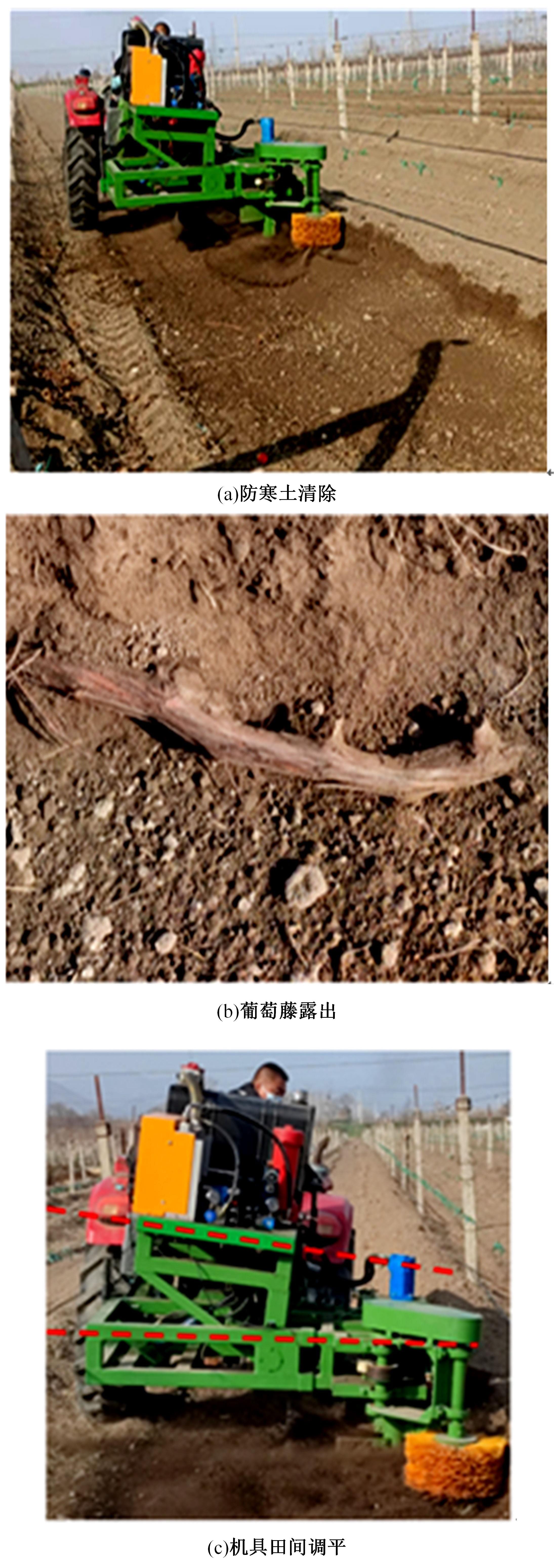

针对我国北方露地葡萄藤防寒土春季清除机械化作业清土不彻底、易伤藤和机具适应差等问题,设计了一种刮刷组合式葡萄藤防寒土清土机。该机采用双翼式刮土板部件、刚性叶轮部件和柔性刷丝部件分别将葡萄藤的上方防寒土、侧边外围防寒土和根部附近防寒土一次性清除。对关键部件进行设计,搭建基于STM32F103的控制系统,实现双翼式刮土板部件的自动避障和机具的自动调平。调平性能试验表明,当调平机架向左倾斜到最大角度或向右倾斜到最大角度时,均能在1 s内完成自动调平过程,且没有明显的超调量;当拖拉机行驶在不平整的葡萄行间时,即使拖拉机车身发生较大的倾斜变化,挂接在后侧机具上的清土部件仍能保持期望的水平状态(±2°以内)进行作业;田间清土试验表明,各清土部件运行稳定,不存在相互作业干涉的情况,清土作业后的清土率约为81.96%,葡萄藤损伤率约为1.67%,满足我国北方露地葡萄藤防寒土清除作业要求。

中图分类号:

- S224.9

| 1 | Wang J, Zhang X Y, Su L, et al. Global warming effects on climate zones for wine grape in Ningxia region, China [J]. Theoretical and Applied Climatology, 2020, 140(4): 1527-1536. |

| 2 | 马帅,徐丽明,袁全春,等. 葡萄机械化清土的发展现状与解决对策[J]. 农机化研究, 2020, 42(7): 1-8. |

| Ma Shuai, Xu Li-ming, Yuan Quan-chun, et al. Development status and countermeasures of grape mechanized soil clearing[J]. Journal of Agricultural Mechanization Research, 2020, 42(7): 1-8. | |

| 3 | 刘松. 圆锥螺旋式入春葡萄挖藤机设计与试验研究[D]. 乌鲁木齐:新疆农业大学, 2014. |

| Liu Song. Design and experiment study of conical spiral manner of grape vines in the spring digging machine[D]. Urumqi: Xinjiang Agricultural University, 2014. | |

| 4 | 亓桂梅,李旋,赵艳侠,等. 2017年世界葡萄及葡萄酒生产及流通概况[J]. 中外葡萄与葡萄酒, 2018(1): 68-74. |

| Qi Gui-mei, Li Xuan, Zhao Yan-xia, et al. Production and circulation of grape and its products in the world in 2017[J]. Sino-Overseas Grapevine & Wine, 2018(1): 68-74. | |

| 5 | 袁全春,徐丽明,马帅,等. 我国北方葡萄冬季埋土和春季清土作业的机械化现状与思考[J]. 中外葡萄与葡萄酒, 2017(6): 66-67. |

| Yuan Quan-chun, Xu Li-ming, Ma Shuai, et al. Current status and considerations on mechanization of winter burying and spring cleaning operations for grapes in northern China[J]. Sino-Overseas Grapevine & Wine, 2017(6): 66-67. | |

| 6 | 徐丽明,邢洁洁,李世军,等. 国外葡萄生产机械化发展和对我国现状的思考[J]. 河北林业科技, 2014(5): 124-128. |

| Xu Li-ming, Xing Jie-jie, Li Shi-jun, et al. Development of mechanization of grape production abroad and reflections on China's current situation[J]. Journal of Hebei Forestry Science and Technology, 2014(5): 124-128. | |

| 7 | 周伟斌. 葡萄起藤机的设计[D]. 银川: 宁夏大学机械工程学院, 2017. |

| Zhou Wei-bin. Design of grape vine digging machine[D]. Yinchuan: School of Mechanical Engineering,Ningxia University, 2017. | |

| 8 | Bisaglia C, Romano E. Utilization of vineyard prunings: A new mechanization system from residues harvest to CHIPS production[J]. Biomass & Bioenergy, 2018, 115: 136-142. |

| 9 | 曾鉴. 气吹梳刷组合式葡萄防寒土清除机的设计与试验[D]. 北京: 中国农业大学工学院, 2020. |

| Zeng Jian. Design and experiment of combined air-blown and brush grape cold-proof soil remover[D]. Beijing: College of Engineering, China Agricultural University, 2020. | |

| 10 | 杜光雨. 风力吹送式酿酒葡萄清土机设计及试验研究[D]. 镇江:江苏大学农业工程学院, 2020. |

| Du Guang-yu, Design and experimental study of wine grape covering soil clearing machine with wind blowing [D]. Zhenjiang: College of Agricultural Engineering, Jiangsu University, 2020. | |

| 11 | 曾保宁,田志道,赵润良. 葡萄起藤机的设计与研制[J]. 中国农机化学报, 2013(6): 230-232. |

| Zeng Bao-ning, Tian Zhi-dao, Zhao Run-liang. Design and development of grape vine machine[J]. Journal of Chinese Agricultural Mechanization, 2013(6): 230-232. | |

| 12 | 陈智, 万平, 杨术明, 等. 葡萄藤起藤自动除土机[P]. 中国: CN205755312U. 2016-12-07. |

| 13 | 李法键. 葡萄园防寒土清除机关键部件设计与分析[D]. 秦皇岛: 河北科技师范学院机电工程学院, 2019. |

| Li Fa-jian. Design and analysis on key components of vineyard cold soil removal machine [D]. Qinhuangdao: College of Agricultural Engineering, Hebei Normal University of Science & Technology, 2019. | |

| 14 | 刘芳建,刘忠军,王锦江,等. 自动避障葡萄藤扒土机的设计与试验研究[J]. 农机化研究, 2018(4): 87-90. |

| Liu Fang-jian, Liu Zhong-jun, Wang Jin-jiang, et al. Design and experimental study of automatic obstacle-avoid digging machine for grape wine[J]. Journal of Agricultural Mechanization Research, 2018(4): 87-90. | |

| 15 | 王文斌. 葡萄清土开沟机设计研究[D]. 北京: 中国农业大学工学院, 2015. |

| Wang Wen-bin. Research & design of grape vines digger[D]. Beijing: College of Engineering, China Agricultural University, 2015. | |

| 16 | 马帅,徐丽明,邢洁洁,等. 叶轮旋转式葡萄藤埋土单边清除机研制[J]. 农业工程学报, 2018, 34(23): 1-10. |

| Ma Shuai, Xu Li-ming, Xing Jie-jie, et al. Development of unilateral cleaning machine for grapevine buried by soil with rotary Impeller[J]. Transactions of the CSAE, 2018, 34(23): 1-10. | |

| 17 | Ma Shuai, Niu Cong, Yan Cheng-gong, et al. Soil cleaning effect and parameters optimization of the scraper for grapevine cold-proof soil investigated by DEM simulation [J]. Biosystems Engineering,2021, 210: 156-170. |

| 18 | Coetzee C J, Lombard S G. Discrete element method modelling of a centrifugal fertiliser spreader[J]. Biosystems Engineering, 2011, 109(4): 308-325. |

| 19 | Ding S, Bai L, Yao Y, et al. Discrete element modelling (DEM) of fertilizer dual-banding with adjustable rates[J]. Computers and Electronics in Agriculture, 2018, 152: 32-39. |

| 20 | 胡永光,杨叶成,肖宏儒,等. 茶园施肥机离心撒肥过程仿真与参数优化[J]. 农业机械学报, 2016, 47(5): 77-82. |

| Hu Yong-guang, Yang Ye-cheng, Xiao Hong-ru, et al. Simulation and parameter optimization of centrifugal fertilizer spreader for tea plants[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(5): 77-82. | |

| 21 | Van L P, Tijskens E, Dintwa E, et al. A discrete element model for simulation of a spinning disc fertilizer spreader I. Single particle simulations[J]. Powder Technology, 2006, 170(2):71-85. |

| 22 | 吕金庆,孙贺,兑瀚,等. 锥形撒肥圆盘中肥料颗粒运动模型优化与试验[J]. 农业机械学报, 2018, 49(6): 85-91. |

| Lv Jin-qing, Sun He, Han Dui, et al. Optimization and experiment of fertilizer particle motion model in conical spreading disk[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(6): 85-91. | |

| 23 | 马帅,徐丽明,牛丛,等. 分层交错式葡萄防寒土弧形清土叶轮的设计与试验[J]. 农业工程学报, 2021, 37(10): 1-9. |

| Ma Shuai, Xu Li-ming, Niu Cong, et al. A facile arc impeller with layered-staggered structure to clean cold-proof soil on grapes[J]. Transactions of the CSAE, 2021, 37(10): 1-9. | |

| 24 | 孙永佳,周军,李学强,等. 马铃薯联合收获机车身调平系统设计与试验[J]. 农业机械学报, 2020, 51(): 298-306. |

| Sun Yong-jia, Zhou Jun, Li Xue-qiang, et al. Design and experiment of body leveling system for potato combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(Sup.): 298-306. | |

| 25 | 董伟亮. 液压设计手册[M]. 北京: 机械工业出版社, 2005. |

| 26 | 周浩,胡炼,罗锡文,等. 旋耕机自动调平系统设计与试验[J]. 农业机械学报, 2016, 47(): 117-123. |

| Zhou Hao, Hu Lian, Luo Xi-wen, et al. Design and experiment on auto leveling system of rotary tiller [J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(Sup.): 117-123. | |

| 27 | 潘杰,陈凡,胡建平,等. 基于EDEM-RecurDyn的指夹式取苗爪仿真优化设计[J]. 农业机械学报, 2023,53(5):75-85, 301. |

| Pan Jie, Chen Fan, Hu Jian-ping, et al. Simulation and optimization design of finger-clamping seedling picking claw based on EDEM-RecurDyn[J]. Transactions of the Chinese Society for Agricultural Machinery, 2023,53(5):75-85, 301. | |

| 28 | 王少杰, 殷月, 余圣锋, 等. 基于RecurDyn-EDEM的装载机耦合动力学仿真分析[J]. 机械设计, 2021,38(11):1-6. |

| Wang Shao-jie, Yin Yue, Yu Sheng-feng, et al. Dynamic analysis on loader coupling based on RecurDyn-EDEM[J]. Journal of Machine Design, 2021, 38(11):1-6. | |

| 29 | 于畅畅,徐丽明,王庆杰,等. 篱架式栽培葡萄双边作业株间自动避障除草机设计与试验[J]. 农业工程学报, 2019, 35(5): 1-9. |

| Yu Chang-chang, Xu Li-ming, Wang Qing-jie, et al. Design and experiment of bilateral operation intra-row auto obstacle avoidance weeder for trellis cultivated grape[J]. Transactions of the CSAE, 2019, 35(5): 1-9. | |

| 30 | 马帅,徐丽明,袁全春,等. 葡萄藤防寒土与清土部件相互作用的离散元仿真参数标定[J]. 农业工程学报, 2020, 36(1): 40-49. |

| Ma Shuai, Xu Li-ming, Yuan Quan-chun, et al. Calibration of discrete element simulation parameters of grapevine antifreezing soil and its interaction with soil-cleaning components[J]. Transactions of the CSAE, 2020, 36(1): 40-49. |

| [1] | 周鹏飞,陈学庚,蒙贺伟,梁荣庆,张炳成,坎杂. 滚筒式机收膜杂除土装置设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2718-2731. |

| [2] | 刘伟健,罗锡文,曾山,文智强,曾力. 履带式再生稻收获机田间转弯机理和性能试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2695-2705. |

| [3] | 张茂健,金敬福,陈奕颖,陈廷坤. 轮式拖拉机对称结构的振动特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2136-2142. |

| [4] | 朱光强,李天宇,周福君,王文明. 鲜食玉米仿生摘穗装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1231-1244. |

| [5] | 顿国强,刘文辉,毛宁,吴星澎,纪文义,马洪岩. 交替换岗式大豆小区育种排种器优化设计与试验[J]. 吉林大学学报(工学版), 2023, 53(1): 285-296. |

| [6] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [7] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

| [8] | 高文英,林静,李宝筏,王伟,谷士艳. 秸秆深埋还田机振动特性分析与结构优化[J]. 吉林大学学报(工学版), 2022, 52(4): 970-980. |

| [9] | 刘佳杰,马兰,向伟,颜波,文庆华,吕江南. 4QM-4.0型麻类青饲料联合收获机研制[J]. 吉林大学学报(工学版), 2022, 52(12): 3039-3048. |

| [10] | 曾百功,黎奎良,叶进,任丽丽,Rashidov Jaloliddin,张明. 工厂化上海青流水线收割装置的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2756-2764. |

| [11] | 万星宇,廖庆喜,蒋亚军,单伊尹,周宇,廖宜涛. 饲用油菜机械化收获切碎过程离散元仿真与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2735-2745. |

| [12] | 朱光强,李天宇,周福君. 鲜食玉米仿生摘穗柔性夹持输送装置设计与试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2486-2500. |

| [13] | 梁荣庆,钟波,蒙贺伟,孙志民,坎杂. 4QJ⁃3型青贮燕麦捡拾割台的研制[J]. 吉林大学学报(工学版), 2021, 51(5): 1887-1896. |

| [14] | 袁佳诚,王昌,何坤,万星宇,廖庆喜. 油菜联合收获机筛下物组分质量比对清选性能的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1897-1907. |

| [15] | 王刚,刘慧力,贾洪雷,郭春江,丛永健,屈明浩. 触碰定位式玉米行间除草装置的设计与试验[J]. 吉林大学学报(工学版), 2021, 51(4): 1518-1527. |

|

||