吉林大学学报(工学版) ›› 2025, Vol. 55 ›› Issue (3): 1111-1122.doi: 10.13229/j.cnki.jdxbgxb.20230558

• 农业工程·仿生工程 • 上一篇

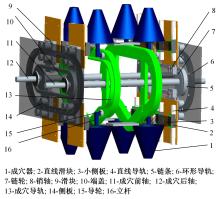

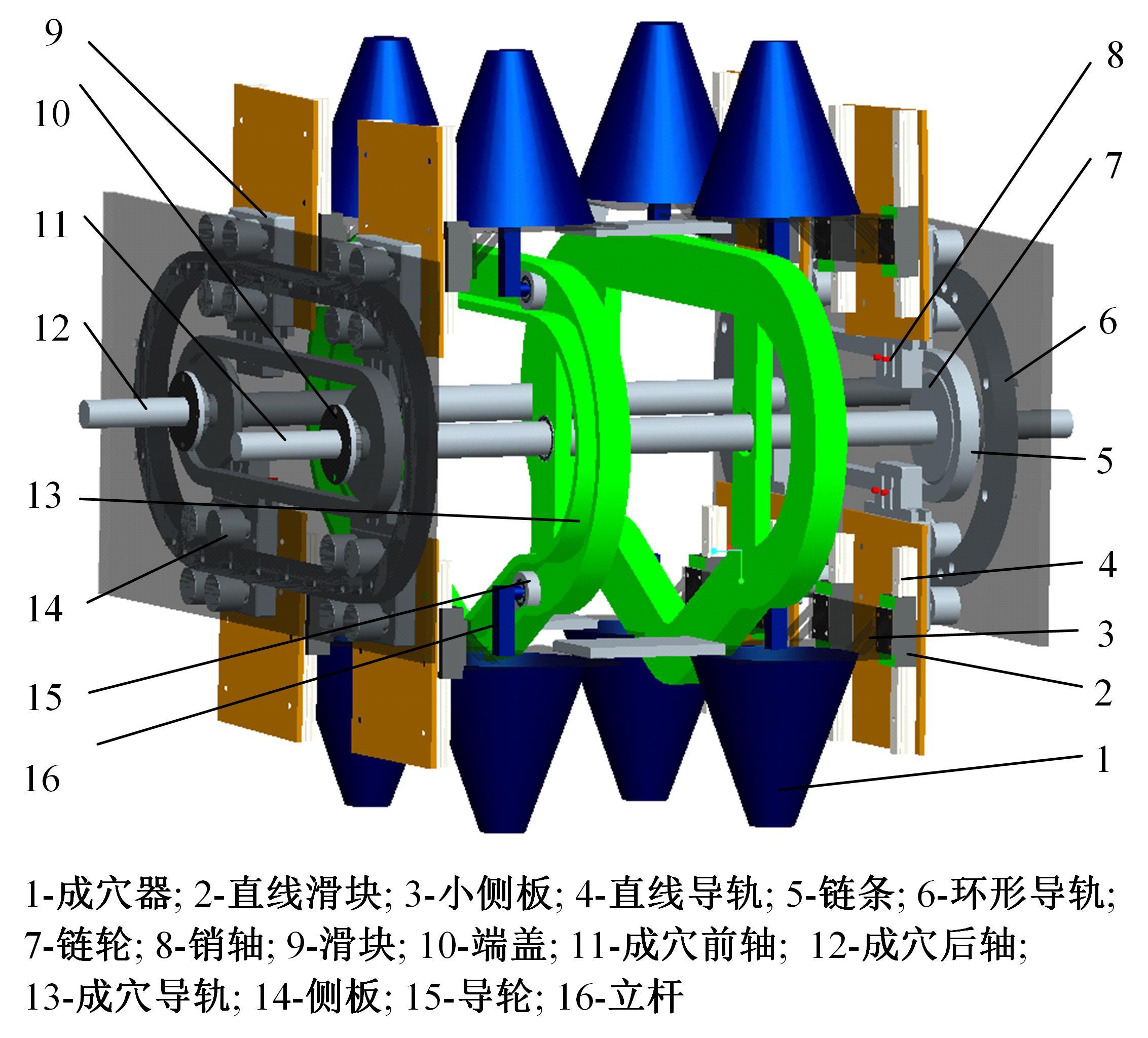

油菜钵苗移栽机平厢成穴装置设计与试验

全腊珍1( ),石方刚1,全伟2(

),石方刚1,全伟2( ),吴明亮1,黄元昊1,向伟3

),吴明亮1,黄元昊1,向伟3

- 1.湖南农业大学 机电工程学院,长沙 410128

2.湖南农业大学 东方科技学院,长沙 410128

3.中国农业科学院 麻类研究所,长沙 410221

Design and experiment of flat surface and hole⁃forming machine for rapeseed potted seedlings

La-zhen QUAN1( ),Fang-gang SHI1,Wei QUAN2(

),Fang-gang SHI1,Wei QUAN2( ),Ming-liang WU1,Yuan-hao HUANG1,Wei XIANG3

),Ming-liang WU1,Yuan-hao HUANG1,Wei XIANG3

- 1.College of Mechanical and Electrical,Hunan Agriculture University,Changsha 410128,China

2.College of Orient Science & Technology,Hunan Agricultural University,Changsha 410128,China

3.Institute of Bast Fiber Crops,Chinese Academy of Agricultural Sciences,Changsha 410221,China

摘要:

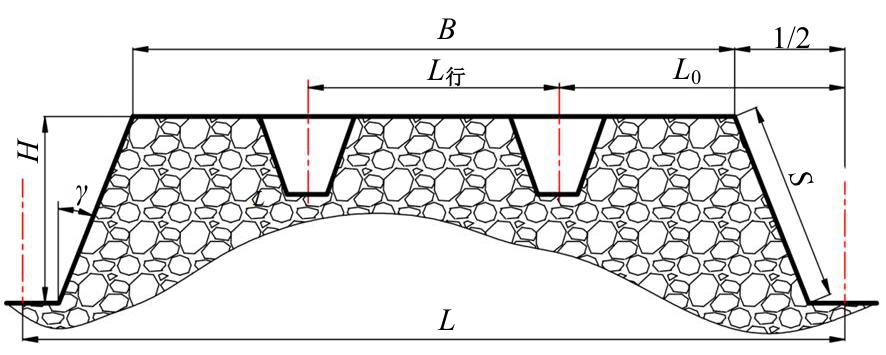

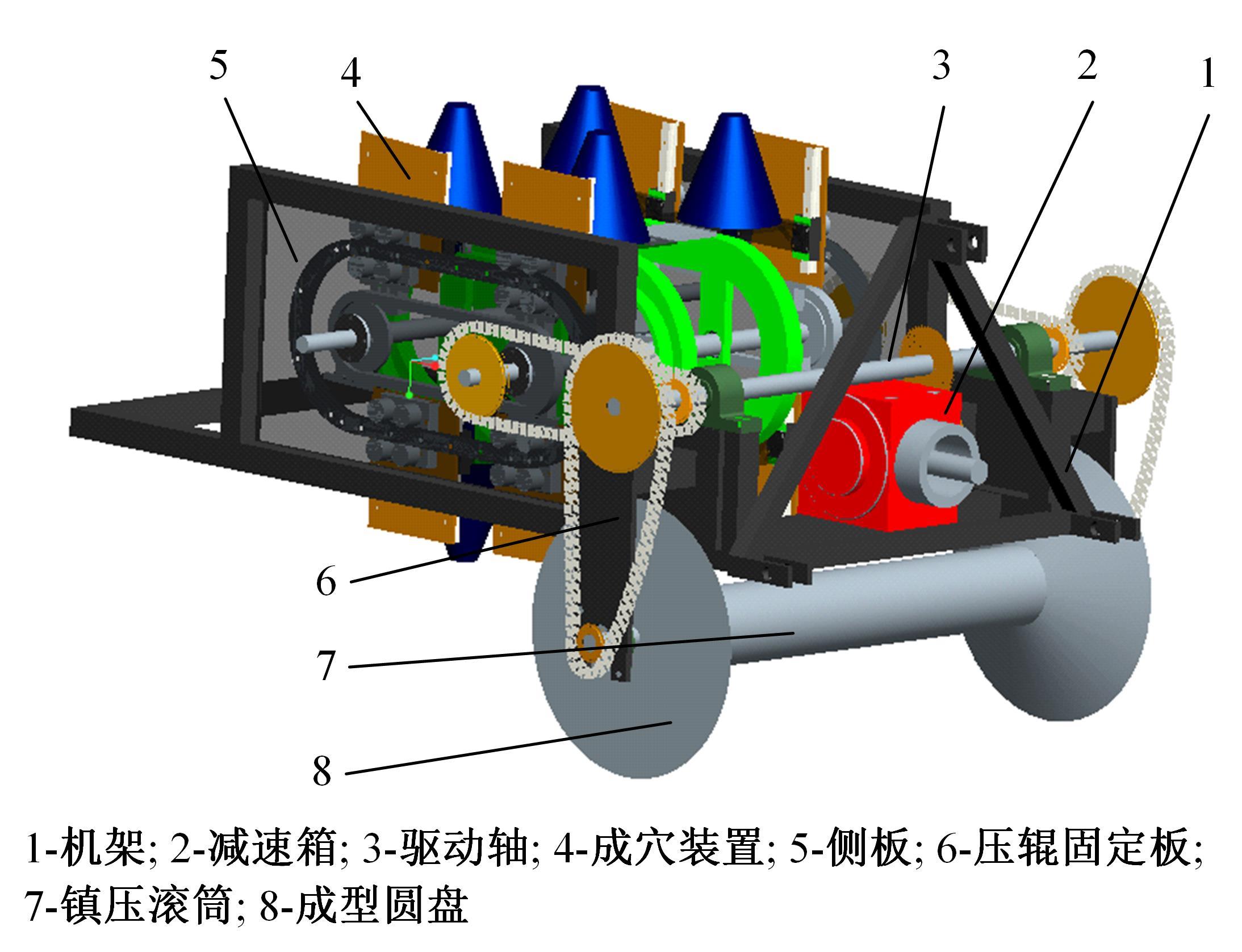

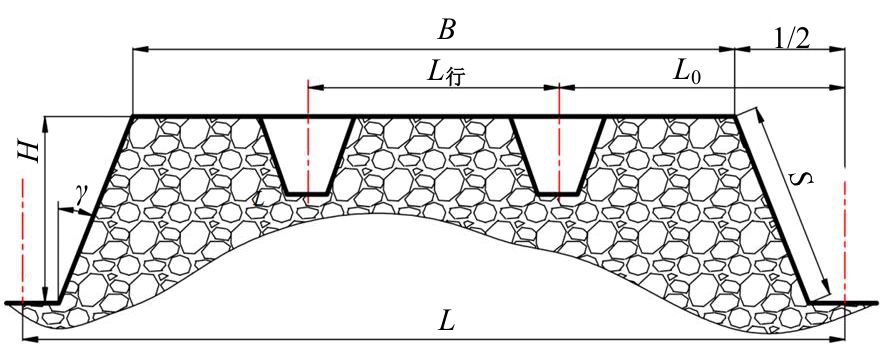

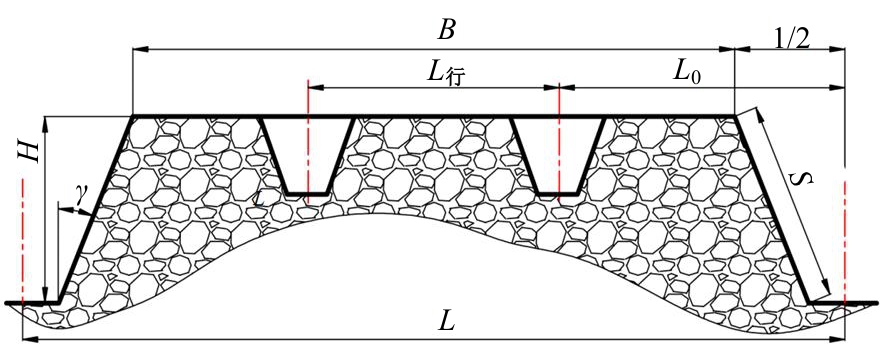

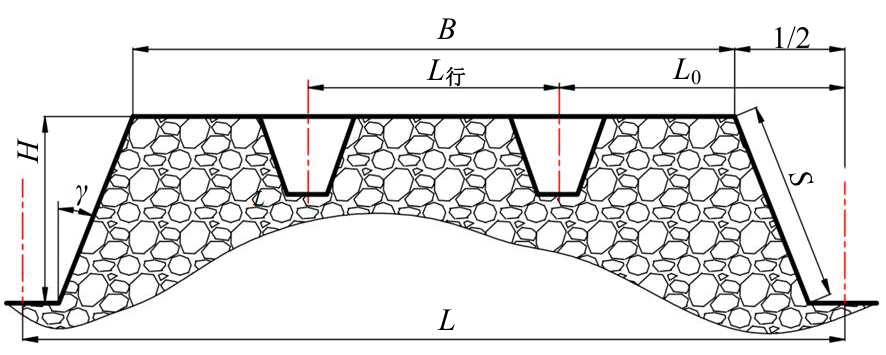

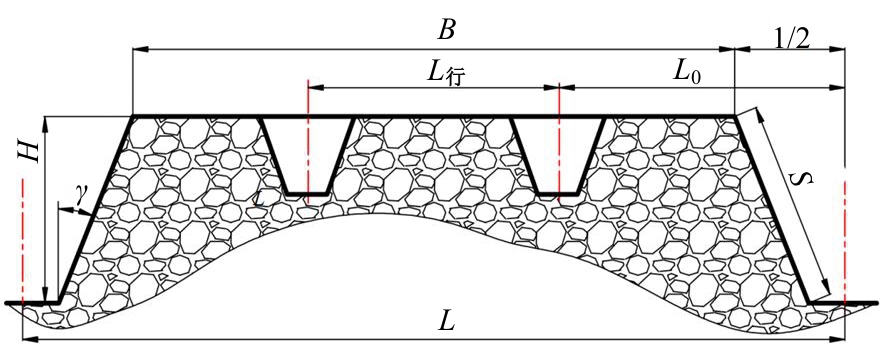

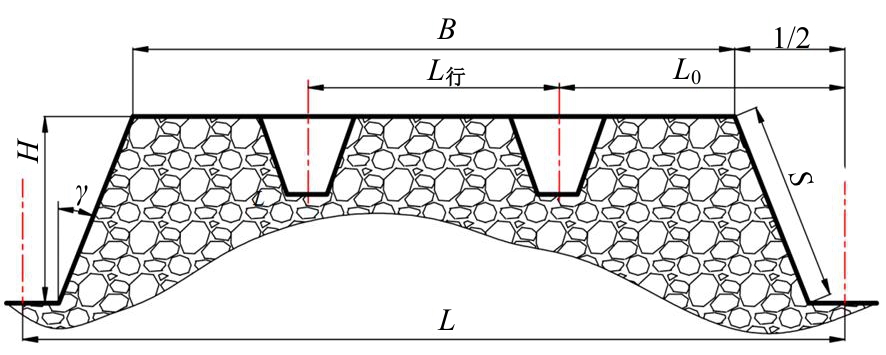

针对目前油菜移栽机成穴装置受厢面土壤不平整、成穴器入出土方式的影响造成的孔穴尺寸与理论尺寸差异大、孔穴稳定性低等问题,基于油菜钵苗栽植农艺要求及钵苗外形尺寸,设计了一种油菜钵苗移栽机平厢成穴装置,包含平厢装置和成穴装置。利用Matlab软件对成穴器的运动轨迹进行分析,得到了成穴器的运动轨迹参数方程,验证了成穴器在成穴作业过程中的“零速时间段”理论。试制样机并进行田间试验,试验结果表明:拖拉机以1.62~1.81 km/h的速度前进,该机作业的厢面平整度为1.93 mm,孔穴锥度变异系数为2.7%,合格孔穴率为98.1%,成穴频率为107穴/min,各项性能指标均满足油菜钵苗移栽的农艺要求。该研究可为油菜钵苗移栽机平厢成穴装置的设计与优化提供参考。

中图分类号:

- S223.9

| 1 | 俞高红, 王磊, 孙良, 等. 大田机械化移栽技术与装备研究进展[J]. 农业机械学报, 2022, 53(9): 1-20. |

| Yu Gao-hong, Wang Lei, Sun Liang, et al. Advancement of mechanized transplanting technology and equipment for field crops[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(9): 1-20. | |

| 2 | 于晓旭, 赵匀, 陈宝成, 等. 移栽机械发展现状与展望[J]. 农业机械学报, 2014, 45(8): 44-53. |

| Yu Xiao-xu, Zhao Yun, Chen Bao-cheng, et al. Current situation and prospect of transplanter[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(8): 44-53. | |

| 3 | 汤庆, 吴俊, 蒋兰, 等. 油菜耕整移栽联合作业机液压仿形系统设计与试验[J]. 农业机械学报, 2021, 52(11): 95-102. |

| Tang Qing, Wu Jun, Jiang Lan, et al. Design and test of hydraulic profiling system for rape seedling combined transplanter[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(11): 95-102. | |

| 4 | 廖庆喜, 雷小龙, 廖宜涛, 等. 油菜精量播种技术研究进展[J]. 农业机械学报, 2017, 48(9): 1-16. |

| Liao Qing-xi, Lei Xiao-long, Liao Yi-tao, et al. Research progress of precision seeding for rapeseed[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(9): 1-16. | |

| 5 | Zhou M L, Shan Y Y, Xue X L, et al. Theoretical analysis and development of a mechanism with punching device for transplanting potted vegetable seedlings[J]. International Journal of Agricultural and Biological Engineering, 2020, 13(4): 85-92. |

| 6 | Xin J, Li D Y, Ma H, et al. Development of single row automatictransplanting device for potted vegetable seedlings[J]. International Journal of Agricultural and Biological Engineering, 2018, 11(3): 67-75. |

| 7 | 全伟, 吴明亮, 罗海峰, 等. 油菜钵苗移栽机成穴作业方式及参数优化[J]. 农业工程学报, 2020, 36(11):13-21, 327. |

| Quan Wei, Wu Ming-liang, Luo Hai-feng, et al. Soil hole opening methods and parameters of pot seedling transplanting machine for rapeseed[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 36(11): 13-21, 327. | |

| 8 | Wan X Y, Liao Q X, Xu Y, et al. Design and evaluation of cyclone separation cleaning devices using a conical sieve for rape combine harvesters[J]. Applied Engineering in Agriculture, 2018, 34(4): 677-686. |

| 9 | 周脉乐, 薛向磊, 钱孟波, 等. 探出式蔬菜钵苗打孔移栽机构优化设计与试验[J]. 农业机械学报, 2020, 51(1): 77-83. |

| Zhou Mai-le, Xue Xiang-lei, Qian Meng-bo, et al. Optimal design and experiment of potted vegetable seedling transplanting mechanism with punching hole[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020,51(1): 77-83. | |

| 10 | 向伟, 吴明亮, 官春云, 等. 油菜钵体苗移栽栽植孔成型机设计与试验[J]. 农业机械学报, 2017, 48(10): 40-48, 58. |

| Xiang Wei, Wu Ming-liang, Guan Chun-yun, et al. Design and test of transplanting hole-forming machine for rapeseed potted seedlings[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(10): 40-48, 58. | |

| 11 | 那明君, 滕乐, 周振响, 等. 全自动滑道式旱地钵苗移栽机构设计与试验[J]. 农业机械学报, 2021, 52(9): 54-61. |

| Na Ming-jun, Teng Le, Zhou Zhen-xiang, et al. Design and experiment of fully automatic slide-track type dryland pot seedling transplanting mechanism[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(9): 54-61. | |

| 12 | 向伟, 吴明亮, 官春云, 等. 履带式油菜苗移栽栽植孔成型机的设计与试验[J]. 农业工程学报, 2015, 31(15): 12-18. |

| Xiang Wei, Wu Ming-liang, Guan Chun-yun, et al. Design and experiment of planting hole forming device of crawler transplanter for rape (Brassica napus) seedlings[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(15): 12-18. | |

| 13 | 胡飞, 郭栋, 陈彩蓉, 等. 复合曲柄摇杆式蔬菜膜上双行栽植装置设计与试验[J]. 农业机械学报, 2021, 52(9): 62-69. |

| Hu Fei, Guo Dong, Chen Cai-rong, et al. Design and experiment on compound crank rocker double-row planting device of vegetable plug seedling up-film transplanter[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(9): 62-69. | |

| 14 | 于英杰, 秦伟, 赖庆辉, 等. 花椰菜钵苗移栽机栽植机构设计与试验[J]. 农业机械学报, 2020, 51(): 102-112. |

| Yu Ying-jie, Qin Wei, Lai Qing-hui, et al. Design and experiment of planting mechanism of cauliflower pot seedling transplanter[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(Sup.1): 102-112. | |

| 15 | 那明君, 滕乐, 周坤, 等. 旱地钵苗移栽复式作业机栽植机构优化设计与试验[J]. 农业机械学报, 2022, 53(7): 67-73. |

| Na Ming-jun, Teng Le, Zhou Kun, et al. Optimal design and experiment of planting mechanism of dryland pot seedlings transplanting compound machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(7): 67-73. | |

| 16 | 林悦香, 尚书旗, 王东伟, 等. 矮砧密植苹果树连续开沟定距栽植机研制[J]. 农业工程学报, 2019, 35(1): 23-30. |

| Lin Yue-xiang, Shang Shu-qi, Wang Dong-wei, et al. Design of apple planting machine for high density dwarfing orchard[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(1): 23-30. | |

| 17 | 李鹏斌, 颜华, 王品隆, 等. 移栽机小株距栽植机构杆件优化与试验[J]. 农业机械学报, 2020, 51(): 72-78. |

| Li Peng-bin, Yan Hua, Wang Pin-long, et al. Optimization and test of small plant spacing planting mechanism rod for transplanter [J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(Supp.2): 72-78. | |

| 18 | 徐高伟, 刘宏新, 荐世春, 等. 基于五杆机构的丹参膜上移栽机构设计与试验[J]. 农业机械学报, 2018, 49(9): 55-65. |

| Xu Gao-wei, Liu Hong-xin, Jian Shi-chun, et al. Design and test of transplanting mechanism on mulch-film of Salvi a miltiorrhiza based on five-bar mechanism[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(9): 55-65. | |

| 19 | 尹大庆, 张诺一, 周脉乐, 等. 高速变姿态接苗鸭嘴式栽植机构优化设计与试验[J]. 农业机械学报, 2020, 51(6): 65-72. |

| Yin Da-qing, Zhang Nuo-yi, Zhou Mai-le, et al. Optimal design and experiment of high speed duckbill planting mechanism with variable catch-seedling attitude[J]. Transaction of the Chinese Society for Agricultural Machinery, 2020, 51(6): 65-72. | |

| 20 | 俞高红, 李成虎, 汪应萍, 等. 小株距高密度蔬菜植苗机构设计与试验[J]. 农业机械学报, 2023, 54(3): 95-105. |

| Yu Gao-hong, Li Cheng-hu, Wang Ying-ping, et al. Design and experiment of transplanting mechanism for high density vegetables with small plant spacing[J]. Transaction of the Chinese Society for Agricultural Machinery, 2023, 54(3): 95-105. | |

| 21 | 韩长杰, 徐阳, 尤佳, 等. 半自动压缩基质型西瓜钵苗移栽机成穴器参数优化[J]. 农业工程学报, 2019, 35(11): 48-56. |

| Han Chang-jie, Xu Yang, You Jia, et al. Parameter optimization of opener of semi-automatic transplanter for watermelon seedlings raised on compression substrate[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(11): 48-56. | |

| 22 | 韩长杰, 徐阳, 张静, 等. 半自动压缩基质型西瓜钵苗移栽机设计与试验[J]. 农业工程学报, 2018, 34(13): 54-61. |

| Han Chang-jie, Xu Yang, Zhang Jing, et al. Design and experiment of semi-automatic transplanter for watermelon seedlings raised on compression[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(13): 54-61. | |

| 23 | 李晶. 鸭嘴式移栽机栽植机构试验研究[D]. 洛阳: 河南科技大学农业装备工程学院, 2012. |

| Li Jing. The experimental investigation on planting mechanism of duckbill transplanter[D]. Luoyang: College of Agricultural Equipment Engineeringg, Henan University of Science and Technology, 2012. | |

| 刘姣娣, 曹卫彬, 田东洋, 等. 钵苗有效零速移栽栽植机构运动学分析与试验[J]. 机械工程学报, 2017, 53(7): 76-84. | |

| Liu Jiao-di, Cao Wei-bin, Tian Dong-yang, et al. Kinematic analysis and test on transplanting mechanism with effective zero-speed transplanting on mulch film[J]. Journal of Mechanical Engineering, 2017, 53(7): 76-84. | |

| 24 | 冯世杰, 吴明亮, 颜波, 等. 顶出托举式钵苗脱盘装置设计与试验[J]. 农业工程学报, 2020, 36(5): 50-58. |

| Feng Shi-jie, Wu Ming-liang, Yan Bo, et al. Design and test of lifting type bowl removal device[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(5): 50-58. | |

| 25 | 陈超鹏, 全伟, 吴明亮, 等. 基于离散元法的油菜移栽垂直入土式成孔部件参数优化[J]. 湖南农业大学学报:自然科学版, 2019, 45(4): 433-439. |

| Chen Chao-peng, Quan Wei, Wu Ming-liang, et al. Parameter optimization of vertical soil-filling hole-forming parts for rapeseed transplantation based on discrete element method[J]. Journal of Hunan Agricultural University (Natural Sciences), 2019, 45(4): 433-439. | |

| 26 | 向伟, 吴明亮, 吕江南, 等. 基于堆积试验的黏壤土仿真物理参数标定[J]. 农业工程学报, 2019, 35(12): 116-123. |

| Xiang Wei, Wu Ming-liang, Jiang-nan Lyu, et al. Calibration of simulation physical parameters of clay loam based on soil accumulation test[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(12): 116-123. | |

| 27 | 张仕林, 赵武云, 戴飞, 等. 全膜双垄沟起垄覆膜机镇压作业过程仿真分析与试验[J]. 农业工程学报, 2020, 36(1): 20-30. |

| Zhang Shi-lin, Zhao Wu-yun, Dai Fei, et al. Simulation analysis and test on suppression operation process of ridging and film covering machine with full-film double-furrow[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2020, 36(1): 20-30. | |

| 28 | 刘宏俊, 韩济远, 陈佳奇, 等. 丘陵地区刚性镇压轮性能仿真与试验[J]. 农业机械学报, 2018, 49(11): 114-122. |

| Liu Hong-jun, Han Ji-yuan, Chen Jia-qi, et al. Performance simulation and experiment on rigid press wheel for hilly area[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(11): 114-122. | |

| 29 | 孙景彬, 刘志杰, 杨福增, 等. 丘陵山地农业装备与坡地作业关键技术研究综述[J]. 农业机械学报, 2023, 54(5): 1-18. |

| Sun Jing-bin, Liu Zhi-jie, Yang Fu-zeng, et al. Research review of agricultural equipment and slope operation key technologies in hilly and mountains region[J]. Transactions of the Chinese Society for Agricultural Machinery, 2023, 54(5): 1-18. | |

| 30 | 丁肇, 李耀明, 唐忠. 轮式和履带式车辆行走对农田土壤的压实作用分析[J]. 农业工程学报, 2020, 36(5):10-18. |

| Ding Zhao, Li Yao-ming, Tang Zhong. Compaction effects of wheeled vehicles and tracked on farmland soil[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(5): 10-18. | |

| 31 | 张淑娟,全腊珍. 画法几何与机械制图[M].北京: 中国农业出版社,2014. |

| 32 | 王学振,岳斌,高喜杰,等. 深松铲不同翼铲安装高度时土壤扰动行为仿真与试验[J]. 农业机械学报,2018,49(10):124-136. |

| Wang Xue-zhen, Yue Bin, Gao Xi-jie, et al. Discrete element simulations and experiments of disturbance behavior as affected by mounting height of subsoiler's wing[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(10): 124-136. | |

| 34 | 司永胜,刘刚,杨政,等. 激光平地系统的开发与试验[J]. 江苏大学学报:自然科学版,2009,30(5):441-445. |

| Si Yong-sheng, Liu Gang, Yang Zheng, et al. Development and experiment on laser land leveling system[J]. Journal of Jiangsu University(Natural Science Edition), 2009, 30(5): 441-445. | |

| 35 | 李庆,罗锡文,汪懋华,等. 采用倾角传感器的水田激光平地机设计[J]. 农业工程学报,2007, 23(4):88-93. |

| Li Qing, Luo Xi-wen, Wang Mao-hua, et al. Design of paddy field laser grader using inclination sensor[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2007, 23(4): 88-93. | |

| 36 | 胡炼,杜攀,罗锡文,等. 悬挂式多轮支撑旱地激光平地机设计与试验[J]. 农业机械学报,2019,50(8):15-21. |

| Hu Lian, Du Pan, Luo Xi-wen, et al. Design and experiment on multi-whee support laser land leveler hanging on tractor[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(8): 15-21. |

| [1] | 杨欣,刘玉肖,王阳,陈春皓,吕林硕. 果园多风管喷雾机风送系统流场仿真和试验[J]. 吉林大学学报(工学版), 2024, 54(9): 2723-2732. |

| [2] | 顿国强,吴星澎,纪欣鑫,张福利,纪文义,朱礼贵. 玉米条带摆管式撒肥装置设计及试验[J]. 吉林大学学报(工学版), 2024, 54(9): 2697-2707. |

| [3] | 舒彩霞,杨佳,廖庆喜,万星宇,袁佳诚. 油菜联合收获导流式双筒旋风分离清选装置设计及试验[J]. 吉林大学学报(工学版), 2024, 54(6): 1807-1820. |

| [4] | 张国忠,丁凯权,李正博,陈龙,唐楠锐,刘婉茹,黄海东,周勇,王洪昌. 基于泥鳅体表的水稻直播机仿生滑板设计与试验[J]. 吉林大学学报(工学版), 2024, 54(5): 1482-1492. |

| [5] | 陈超,戴孟初,周乐,梁云东. 基于改进综合因素法的农业机械可靠性分配[J]. 吉林大学学报(工学版), 2024, 54(5): 1493-1500. |

| [6] | 张伏,娄立民,钱丹,王世强,冯春凌,赵一荣. 大方捆打捆机压缩机构优化设计及试验[J]. 吉林大学学报(工学版), 2024, 54(4): 1166-1174. |

| [7] | 冯斌,张涛,梁涛,张莹,唐兴隆,王关平. 电驱式青贮饲料打捆裹膜机设计与试验[J]. 吉林大学学报(工学版), 2024, 54(2): 564-573. |

| [8] | 李运通,万星宇,廖庆喜,刘银垒,张青松,廖宜涛. 基于履带底盘的宽幅可折叠油菜割晒机设计及试验[J]. 吉林大学学报(工学版), 2024, 54(12): 3740-3754. |

| [9] | 胡斌,袁成林,解彦宇,郭孟宇,罗昕,潘峰,李俊伟. 基于水泵负压输送的切膜排杂装置设计与试验[J]. 吉林大学学报(工学版), 2024, 54(1): 268-280. |

| [10] | 马帅,徐丽明,许述财,牛丛,闫成功,谭好超. 刮刷组合式葡萄藤防寒土清土机设计与试验[J]. 吉林大学学报(工学版), 2024, 54(1): 294-312. |

| [11] | 史瑞杰,戴飞,赵武云,杨发荣,张锋伟,赵一鸣,曲浩,王天福,郭军海. 自走式藜麦联合收割机设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2686-2694. |

| [12] | 周鹏飞,陈学庚,蒙贺伟,梁荣庆,张炳成,坎杂. 滚筒式机收膜杂除土装置设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2718-2731. |

| [13] | 刘伟健,罗锡文,曾山,文智强,曾力. 履带式再生稻收获机田间转弯机理和性能试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2695-2705. |

| [14] | 石林榕,赵武云. 西北寒旱农区胡麻滚勺式精量穴播器的设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2706-2717. |

| [15] | 张茂健,金敬福,陈奕颖,陈廷坤. 轮式拖拉机对称结构的振动特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2136-2142. |

|

||