吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (1): 268-280.doi: 10.13229/j.cnki.jdxbgxb.20221045

• 农业工程·仿生工程 • 上一篇

基于水泵负压输送的切膜排杂装置设计与试验

胡斌1,2( ),袁成林1,2,解彦宇1,2,郭孟宇1,2,罗昕1,2,潘峰1,2,李俊伟1,2

),袁成林1,2,解彦宇1,2,郭孟宇1,2,罗昕1,2,潘峰1,2,李俊伟1,2

- 1.石河子大学 机械电气工程学院,新疆 石河子 832000

2.现代农业机械兵团重点实验室,新疆 石河子 832003

Design and test of cutting film and removal impurities device based on negative pressure conveying of water pump

Bin HU1,2( ),Cheng-lin YUAN1,2,Yan-yu XIE1,2,Meng-yu GUO1,2,Xin LUO1,2,Feng PAN1,2,Jun-wei LI1,2

),Cheng-lin YUAN1,2,Yan-yu XIE1,2,Meng-yu GUO1,2,Xin LUO1,2,Feng PAN1,2,Jun-wei LI1,2

- 1.College of Mechanical and Electronic Engineering,Shihezi University,Shihezi 832000,China

2.Key Laboratory of Modern Agricultural Machinery Corps,Shihezi 832003,China

摘要:

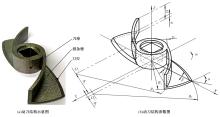

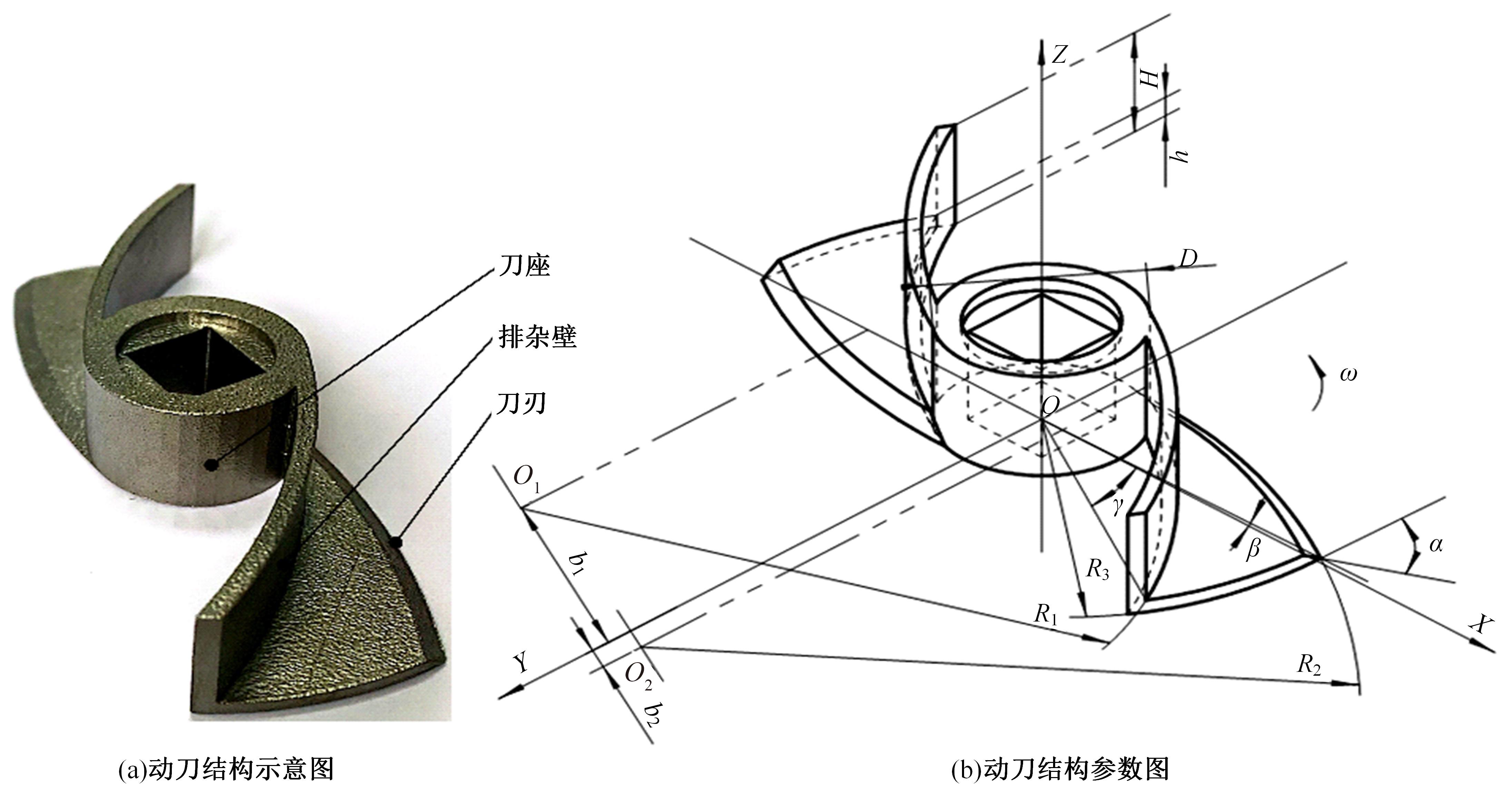

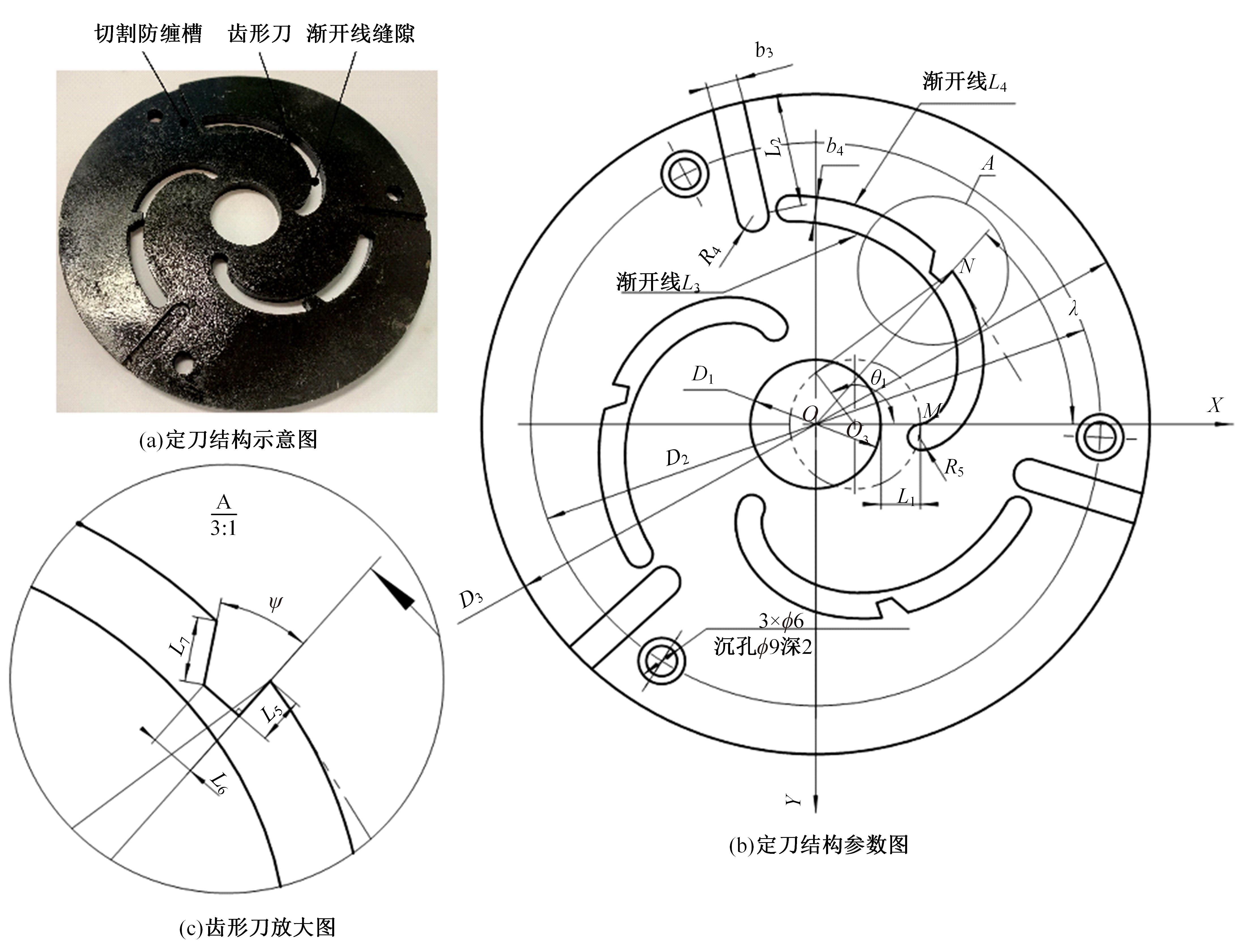

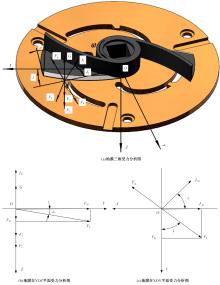

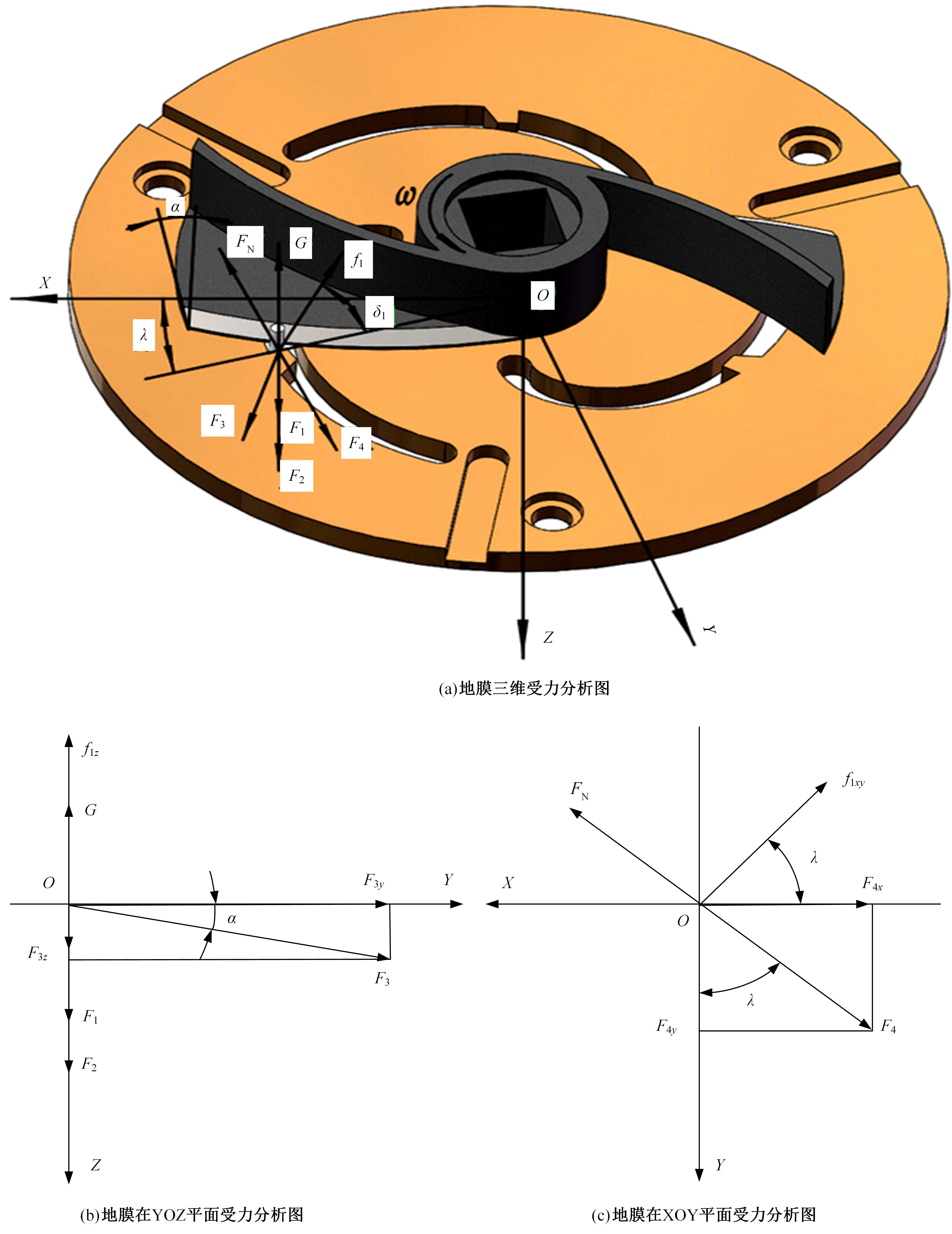

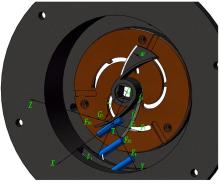

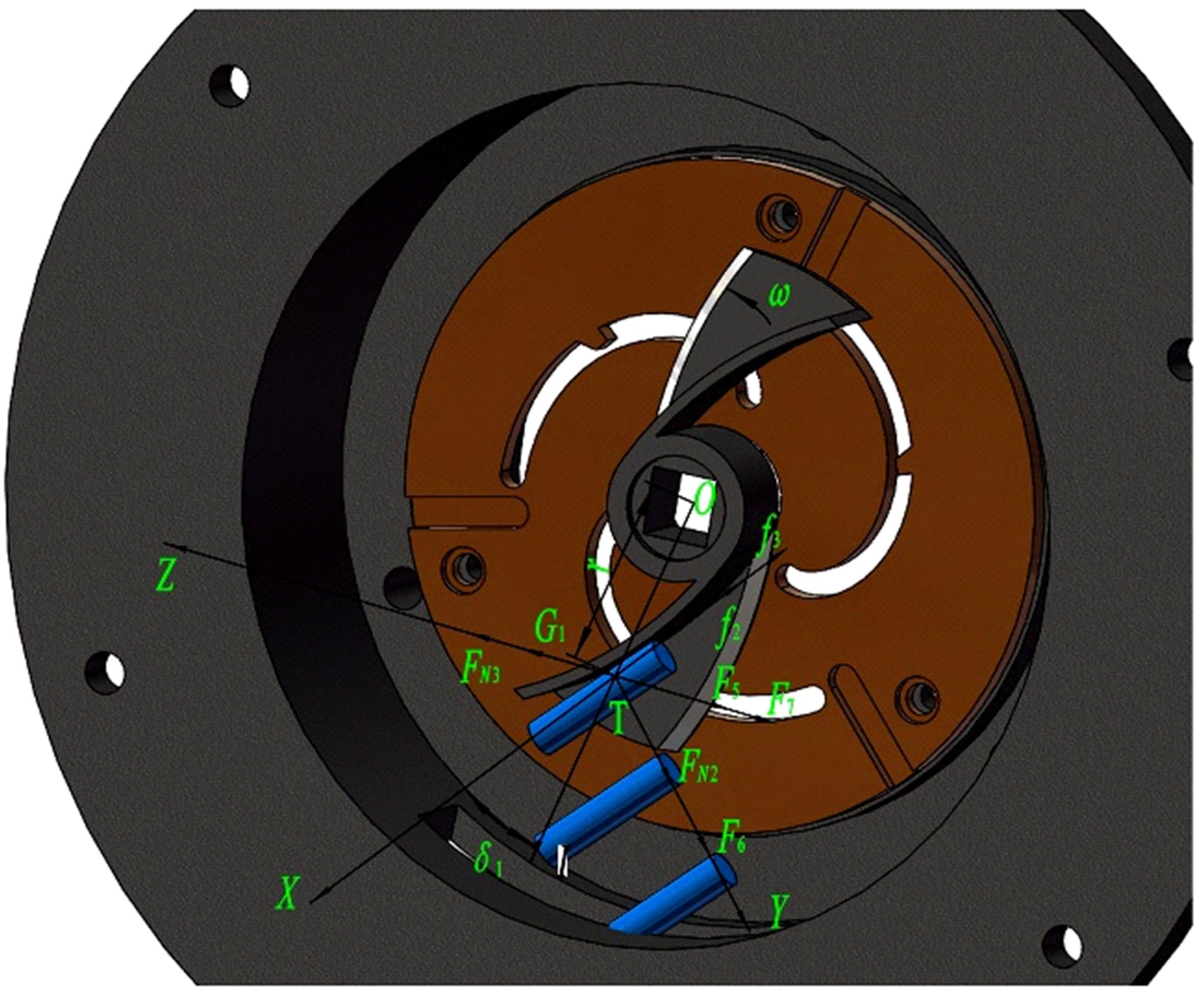

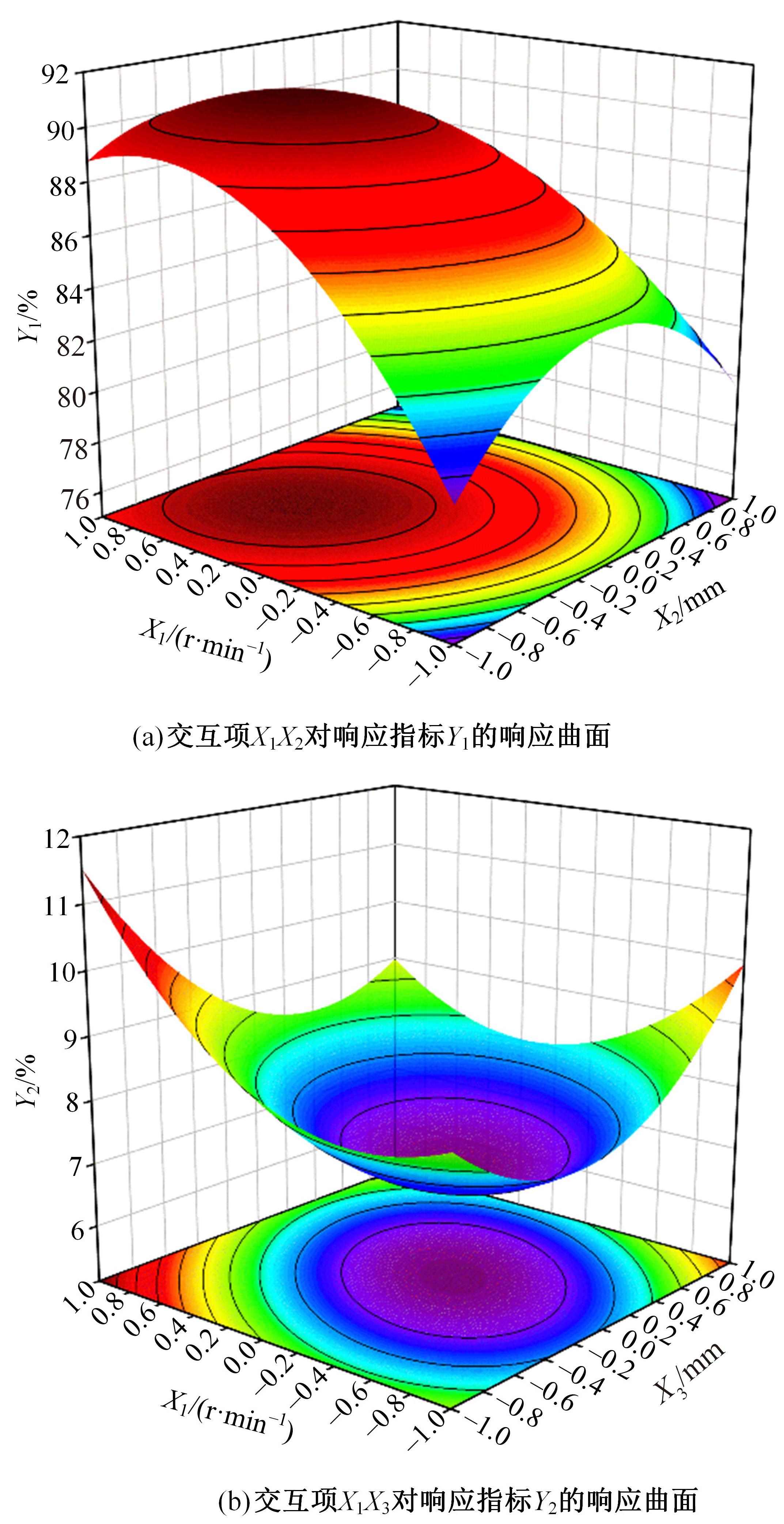

针对机收膜杂混料因相互缠绕难以分离回收的技术问题,依据机收膜杂混料主成分悬浮特性、形体尺寸和剪切特性的差异,提出在水泵负压输送作用下,旋流沉降和切膜过滤排杂新方法,创新设计切膜排杂装置,理论分析切膜排杂机构的力学特性,搭建机收膜杂混料切膜排杂试验装置,开展三因素三水平二次回归正交试验,建立了多目标响应面回归模型,并进行优化与试验验证。结果表明:碎膜合格率影响的主次因素顺序为:动刀转速、定刀缝隙宽度、动刀壁半径;碎膜含杂率影响的主次因素顺序为:动刀转速、动刀壁半径、定刀缝隙宽度。当动刀转速为954 r/min、定刀缝隙宽度为2.8 mm、动刀壁半径为80 mm时,碎膜合格率为88.80%,碎膜含杂率为7.51%,优化试验结果与模型预测值相对误差小于5%。本文研究可为机收膜杂混料的切碎分离方法及装备研究提供参考。

中图分类号:

- S225

| 1 | 胡志娥, 肖谋良, 王双, 等. 地膜覆盖对农田土壤养分和生态酶计量学特征的影响[J]. 环境科学, 2022, 43(3): 1649-1656. |

| Hu Zhi-e, Xiao Mou-liang, Wang Shuang, et al. Effects of plastic mulch film on soil nutrients and ecological enzyme stoichiometry in farmland[J]. Environmental Science, 2022, 43(3): 1649-1656. | |

| 2 | 祁虹, 赵贵元, 王燕, 等. 我国棉田残膜污染危害与治理措施研究进展[J]. 棉花学报, 2021, 33(2): 169-179. |

| Qi Hong, Zhao Gui-yuan, Wang Yan, et al. Research progress on pollution hazards and prevention measures of residual film in cotton field in China[J]. Cotton Science, 2021, 33(2): 169-179. | |

| 3 | Yang W, Qi J, Mumhammad A, et al. Impact of information acquisition on farmers' willingness to recycle plastic mulch film residues in China[J]. Journal of Cleaner Production, 2021, 297(4): No.126656. |

| 4 | 胡灿, 王旭峰, 陈学庚, 等. 新疆农田残膜污染现状及防控策略[J]. 农业工程学报, 2019, 35(24): 223-234. |

| Hu Can, Wang Xu-feng, Chen Xue-geng, et al. Current situation and control strategies of residual film pollution in Xinjiang[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(24): 223-234. | |

| 5 | 潘峰,罗昕,胡斌, 等. 机收棉秆切割装置的设计与试验[J]. 农机化研究, 2022, 44(5): 147-151. |

| Pan Feng, Luo Xin, Hu Bin, et al. Design and test of the cutting device of the machine collecting rod[J]. Journal of Agricultural Mechanization Research, 2022, 44(5): 147-151. | |

| 6 | Liang Rong-qing, Zhang Bing-cheng, Zhou Peng-fei, et al. Power consumption analysis for multi-edge tooth type shredding test device of the residual mulch film and impurities mixture[J]. Computers and Electronics in Agriculture, 2022, 196:No.106898. |

| 7 | 彭强吉, 李成松, 康建明, 等. 气力式圆筒筛膜杂分离机改进设计与试验[J]. 农业机械学报, 2020, 51(8): 126-135. |

| Peng Qiang-ji, Li Cheng-song, Kang Jian-ming,et al. Improved design and experiment on pneumatic cylinder sieve film hybrid separator[J]. Transactions of The Chinese Society of Agricultural Machinery, 2020, 51(8): 126-135. | |

| 8 | 石鑫, 牛长河, 王学农, 等. 滚筒筛式废旧地膜与杂质风选装置设计[J]. 农业工程学报, 2017, 33(18): 19-26. |

| Shi Xin, Niu Chang-he, Wang Xue-nong, et al. Design of roller sieve waste plastic film and trash winnowing machine[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(18): 19-26. | |

| 9 | Gu Feng-wei, Yang Meng, Hu Zhi-chao, et al. Experiment and optimization of high-efficiency mechanical separation of peanut seedlings and residual film based on suspension velocity[J]. Transactions of the ASABE, 2021, 64(4): 1381-1389. |

| 10 | 杨猛, 张延化, 张冲, 等. 先揉切后分离风筛组合式花生膜秧分离装置设计与试验[J]. 农业机械学报, 2020, 51(12): 112-121. |

| Yang Meng, Zhang Yan-hua, Zhang Chong, et al. Design and experiment of fan-sieve combined peanut film-seedling separating device based on shredding and separating[J]. Transactions of The Chinese Society of Agricultural Machinery, 2020, 51(12): 112-121. | |

| 11 | 何浩猛, 胡斌, 李俊虹, 等. 叶轮驱动式机收残膜水洗分离设备研究与试验[J]. 农机化研究, 2020, 42(9): 151-155. |

| He Hao-meng, Hu Bin, Li Jun-hong, et al. Research and experiment of the machine collecting residual film in the impeller-driven washing separation device[J]. Journal of Agricultural Mechanization Research, 2020, 42(9): 151-155. | |

| 12 | 陈永, 陈学庚, 何浩猛, 等. 基于灌溉引水渠介质的膜秆分离装置设计与试验[J]. 吉林大学学报: 工学版, 2023, 53(4): 1245-1256. |

| Chen Yong, Chen Xue-geng, He Hao-meng, et al. Design and experiment of separation device of plastic film and cotton stalks based on irrigation diversion channel media[J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1245-1256. | |

| 13 | 何浩猛, 胡斌, 潘峰, 等. 叶轮扰动水介质对地膜与棉秆沉降聚集行为影响与试验[J]. 农业工程学报, 2021, 37(2): 86-95. |

| He Hao-meng, Hu Bin, Pan Feng, et al. Effects and experiment on settlement and aggregation behavior of plastic film and cotton stalk under the action of disturbing water by the impeller[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(2): 86-95. | |

| 14 | Pan Feng, Hu Bin, Luo Xin, et al. Design and test of a shearing and breaking device for a plastic film and cotton stalks mixture[J]. Transactions of the ASABE, 2021, 64(2): 545-555. |

| 15 | 胡斌, 刘策, 郭孟宇, 等. 一种切割清堵水洗式残膜分离装置[P]. 中国: CN111673949A, 2020-09-18. |

| 16 | 张学军, 黄爽, 史增录, 等. 残膜捡拾打包机的设计与试验[J]. 吉林大学学报: 工学版, 2023, 53(4): 1220-1230. |

| Zhang Xue-jun, Huang Shuang, Shi Zeng-lu, et al. Design and test of the remaining film picking and Baling machine[J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1220-1230. | |

| 17 | 王少伟, 李善军, 张衍林, 等. 山地果园开沟机倾斜螺旋式开沟部件设计与优化[J].农业工程学报,2018, 34(23): 11-22. |

| Wang Shao-wei, Li Shan-jun, Zhang Yan-lin, et al. Design and optimization of inclined helical ditching component for mountain orchard ditcher[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(23): 11-22. | |

| 18 | 邱进, 吴明亮, 官春云, 等. 动定刀同轴水稻秸秆切碎还田装置结构设计与试验[J]. 农业工程学报, 2015, 31(10): 11-19. |

| Qiu Jin, Wu Ming-liang, Guan Chun-yun,et al. Design and experiment of chopping device with dynamic fixed knife coaxial for rice straw[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(10): 11-19. | |

| 19 | 蒋德莉, 陈学庚, 颜利民, 等. 随动式残膜回收机清杂系统作业参数优化[J]. 农业工程学报, 2019, 35(19): 1-10. |

| Jiang De-li, Chen Xue-geng, Yan Li-min, et al. Optimization of working parameters of cleaning system for master-slave residual plastic film recovery machine[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(19): 1-10. | |

| 20 | Braunack M, Johnston D, Gauthier E, et al. Soil temperature and soil water potential under thin oxodegradable plastic film impact on cotton crop establishment and yield[J]. Field Crops Research, 2015, 184: 91-103. |

| 21 | 靳伟, 张学军, 丁幼春, 等. 基于EDEM-Fluent的残膜与杂质悬浮分离仿真与试验[J]. 农业机械学报, 2022, 53(4): 89-98. |

| Jin Wei, Zhang Xue-jun, Ding You-chun, et al. Experiment on suspension separation of residual film and impurity based on EDEM-Fluent coupling[J]. Transactions of the Chinese Society of Agricultural Machinery, 2022, 53(4): 89-98. | |

| 22 | 周鹏飞, 陈学庚, 蒙贺伟, 等. 滚筒式机收膜杂除土装置设计与试验[J]. 吉林大学学报:工学版, 2023, 53(9): 2718-2731. |

| Zhou Peng-fei, Chen Xue-geng, Meng He-wei, et al. Design and experiment of trommel with function of separating soil from residual film mixture[J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2718-2731. | |

| 23 | Liang Rong-qing, Zhang Bing-cheng, Zhou Peng-fei, et al. Cotton length distribution characteristics in the shredded mixture of mechanically recovered residual films and impurities[J]. Industrial Crops and Products, 2022, 182: No.114917. |

| [1] | 史瑞杰,戴飞,赵武云,杨发荣,张锋伟,赵一鸣,曲浩,王天福,郭军海. 自走式藜麦联合收割机设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2686-2694. |

| [2] | 周鹏飞,陈学庚,蒙贺伟,梁荣庆,张炳成,坎杂. 滚筒式机收膜杂除土装置设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2718-2731. |

| [3] | 刘伟健,罗锡文,曾山,文智强,曾力. 履带式再生稻收获机田间转弯机理和性能试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2695-2705. |

| [4] | 石林榕,赵武云. 西北寒旱农区胡麻滚勺式精量穴播器的设计及试验[J]. 吉林大学学报(工学版), 2023, 53(9): 2706-2717. |

| [5] | 张茂健,金敬福,陈奕颖,陈廷坤. 轮式拖拉机对称结构的振动特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2136-2142. |

| [6] | 耿端阳,纪晓琦,牟孝栋,李华彪,杨昊霖,姚艳春,武继达. 构树收获割台设计与试验[J]. 吉林大学学报(工学版), 2023, 53(7): 2152-2164. |

| [7] | 曹肆林,谢建华,杨豫新,刘永瑞,卢勇涛,孙博. 侧排式棉秸秆还田及残地膜回收联合作业机的设计与试验[J]. 吉林大学学报(工学版), 2023, 53(5): 1514-1528. |

| [8] | 张学军,黄爽,史增录,于永良,周鑫城,靳伟,陈勇,洪佳. 残膜捡拾打包机的设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1220-1230. |

| [9] | 陈永,陈学庚,何浩猛,罗昕,余幸,胡斌. 基于灌溉引水渠介质的膜秆分离装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1245-1256. |

| [10] | 朱光强,李天宇,周福君,王文明. 鲜食玉米仿生摘穗装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1231-1244. |

| [11] | 顿国强,刘文辉,吴星澎,毛宁,纪文义,马洪岩. 螺旋挤压式精量排肥器的仿真优化及试验[J]. 吉林大学学报(工学版), 2023, 53(10): 3026-3037. |

| [12] | 顿国强,刘文辉,毛宁,吴星澎,纪文义,马洪岩. 交替换岗式大豆小区育种排种器优化设计与试验[J]. 吉林大学学报(工学版), 2023, 53(1): 285-296. |

| [13] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [14] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

| [15] | 高文英,林静,李宝筏,王伟,谷士艳. 秸秆深埋还田机振动特性分析与结构优化[J]. 吉林大学学报(工学版), 2022, 52(4): 970-980. |

|

||