吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (4): 1245-1256.doi: 10.13229/j.cnki.jdxbgxb.20210769

• 农业工程·仿生工程 • 上一篇

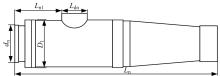

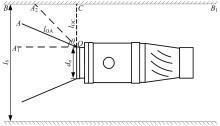

基于灌溉引水渠介质的膜秆分离装置设计与试验

- 1.河南农业大学 机电工程学院,郑州 450002

2.石河子大学 机械电气工程学院,新疆 石河子 832003

3.黄河水利委员会 黄河水利科学研究院,郑州 450003

Design and experiment of separation device of plastic film and cotton stalks based on irrigation diversion channel media

Yong CHEN1( ),Xue-geng CHEN2,Hao-meng HE2,Xin LUO2,Xing YU3,Bin HU2(

),Xue-geng CHEN2,Hao-meng HE2,Xin LUO2,Xing YU3,Bin HU2( )

)

- 1.College of Mechanical and Electrical Engineering,Henan Agricultural University,Zhengzhou 450002,China

2.College of Mechanical and Electronic Engineering,Shihezi University,Shihezi 832003,China

3.Yellow River Institute of Hydraulic Research,Yellow River Conservancy Commission,Zhengzhou 450003,China

摘要:

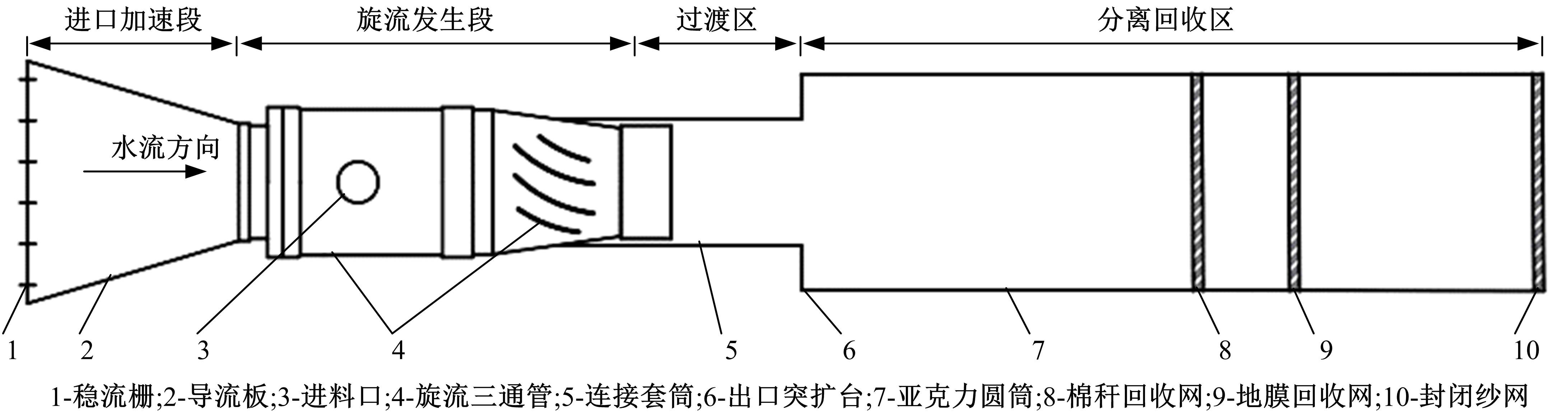

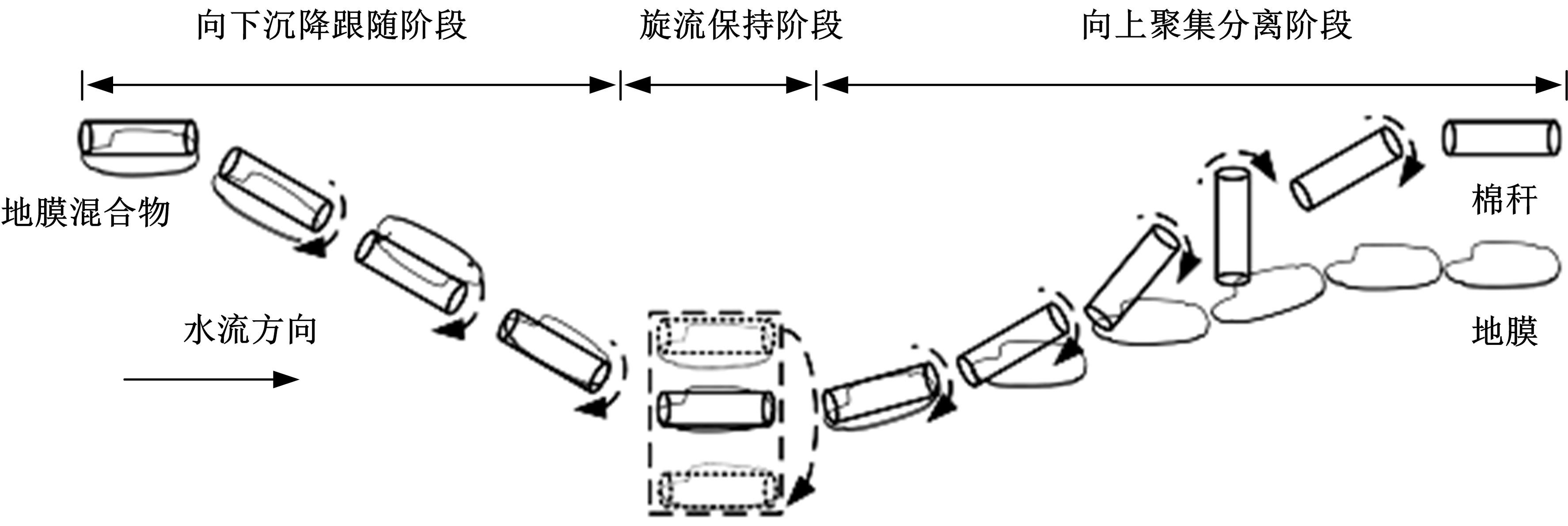

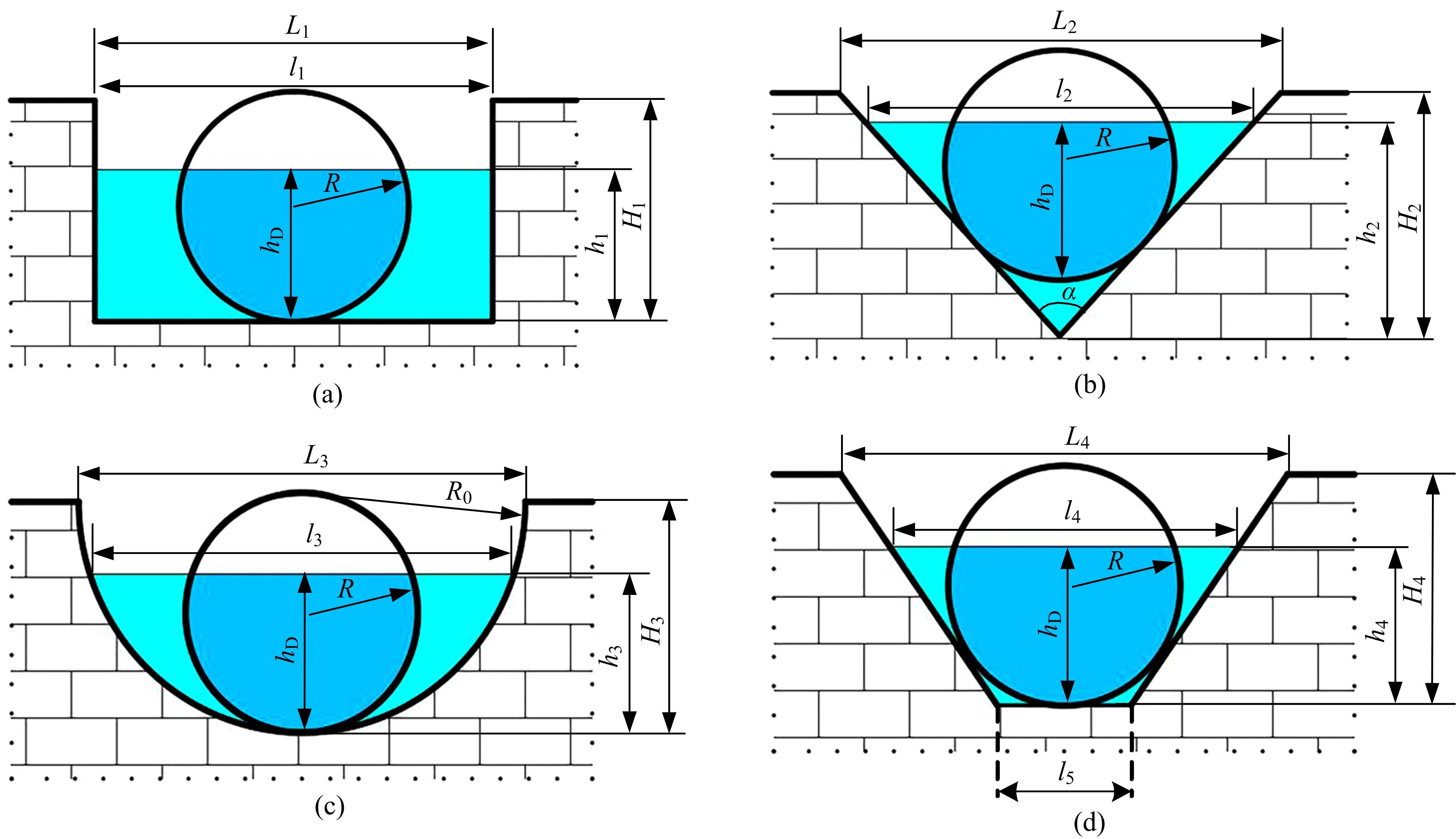

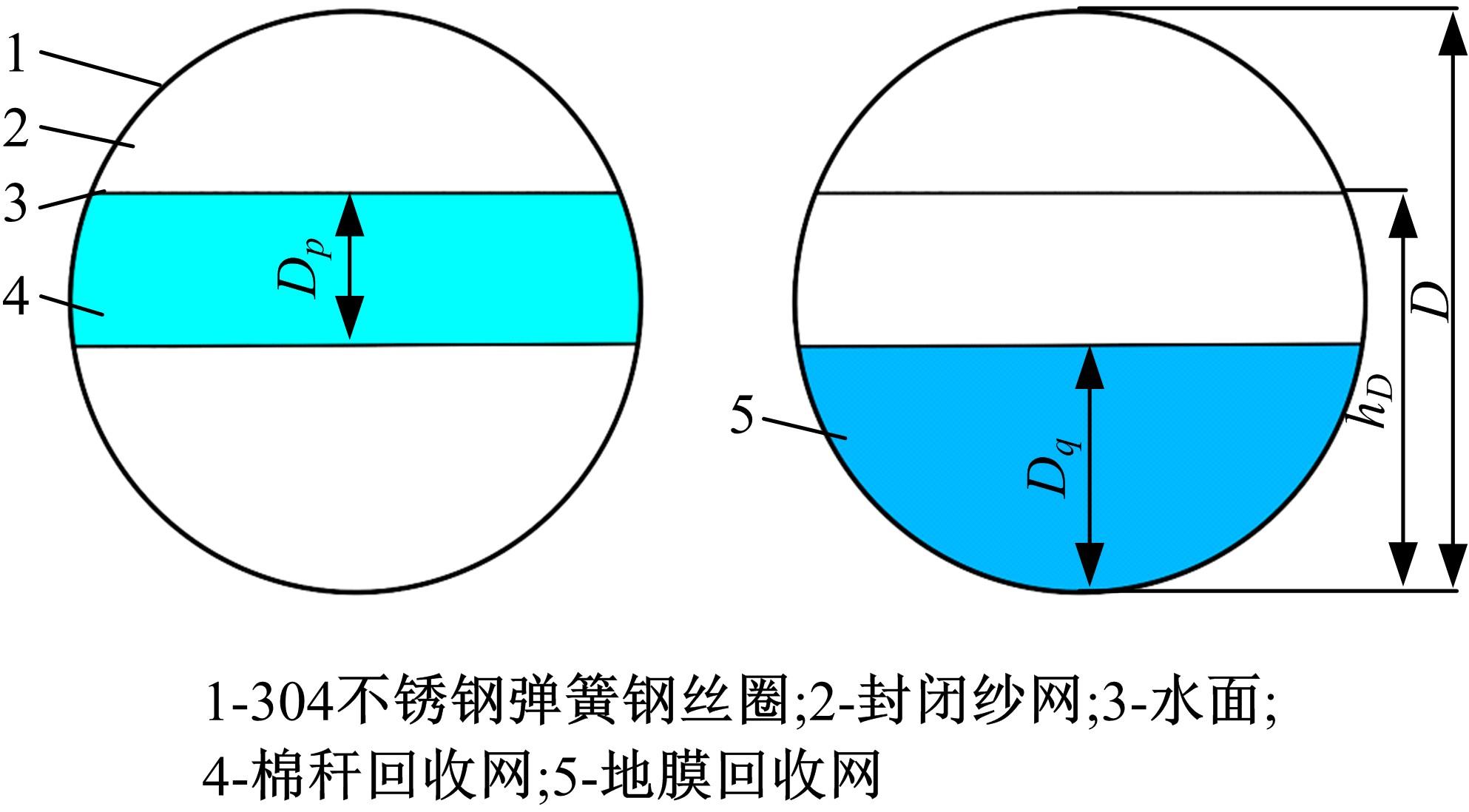

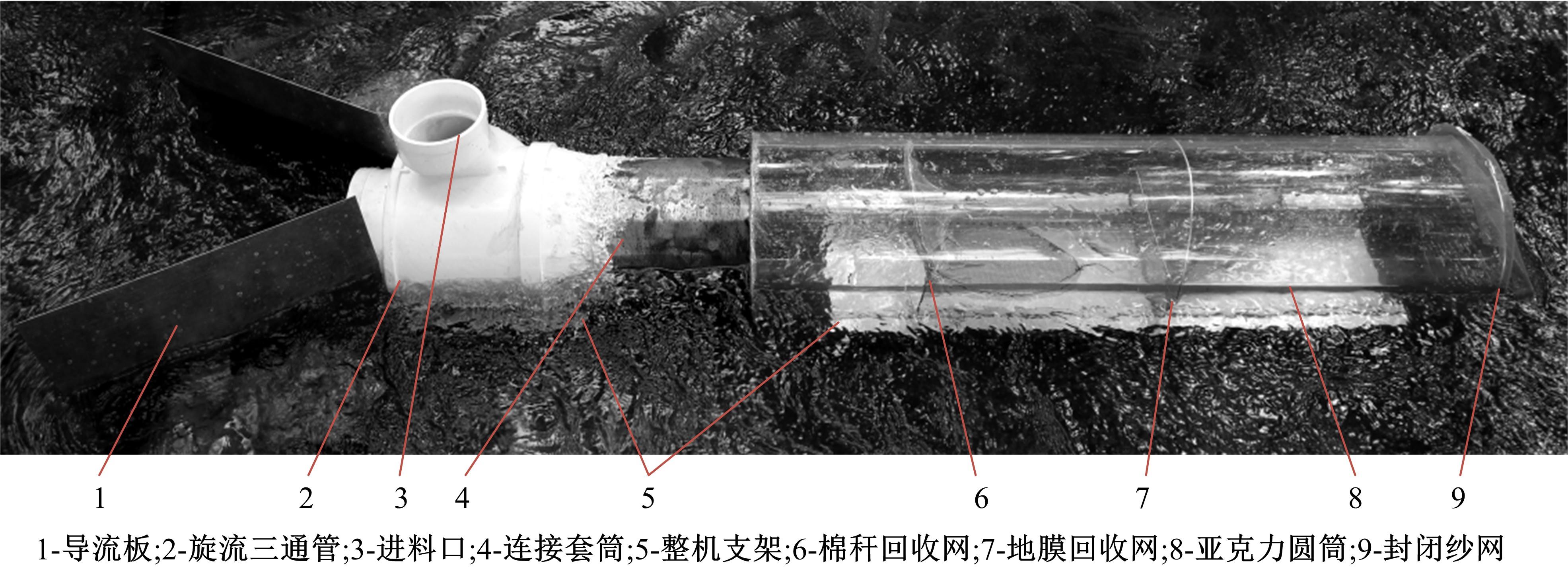

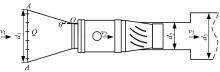

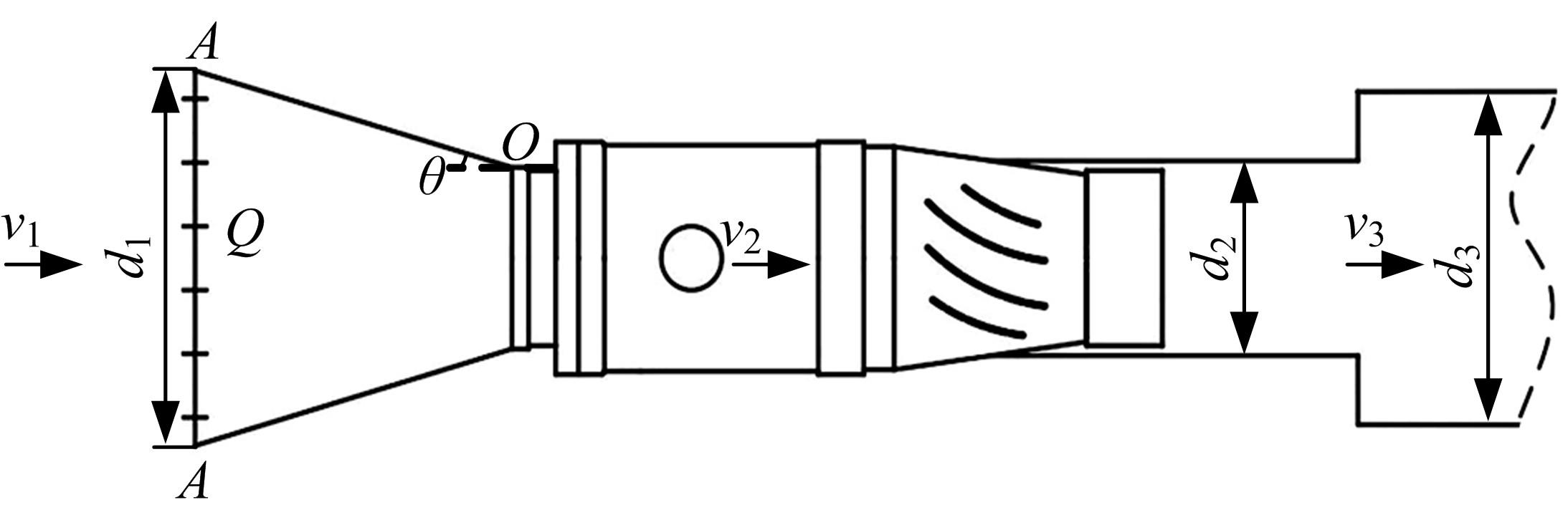

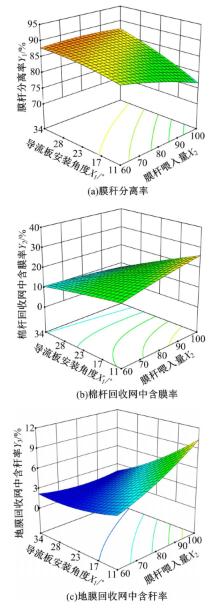

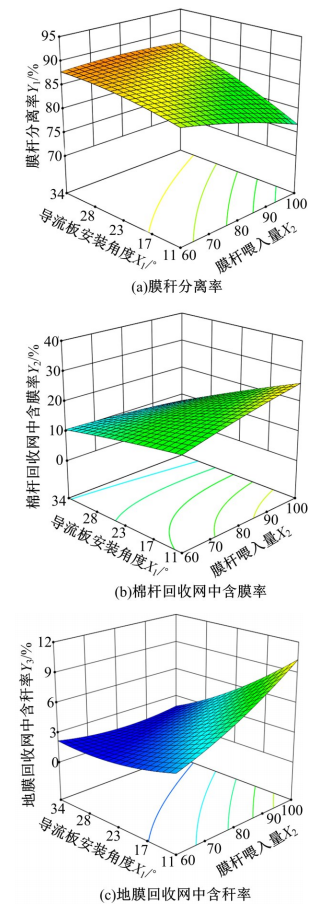

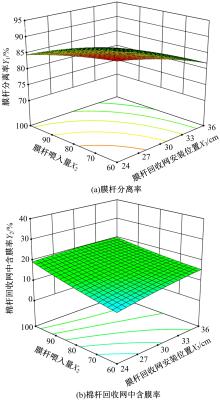

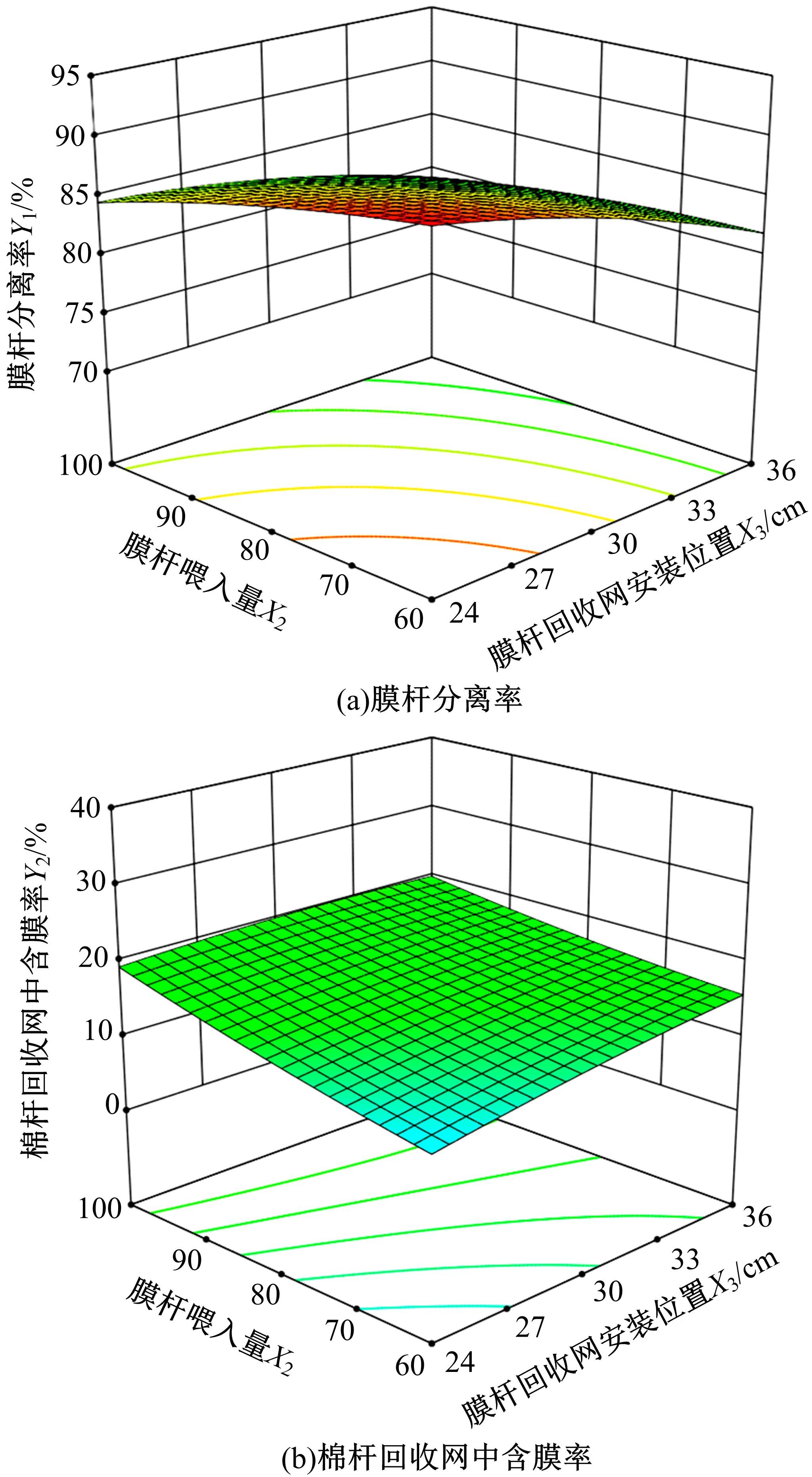

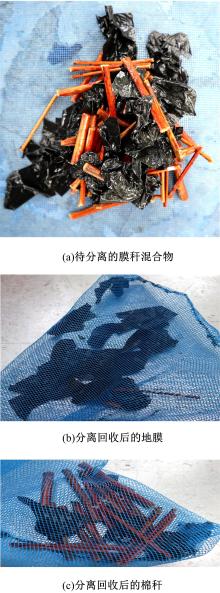

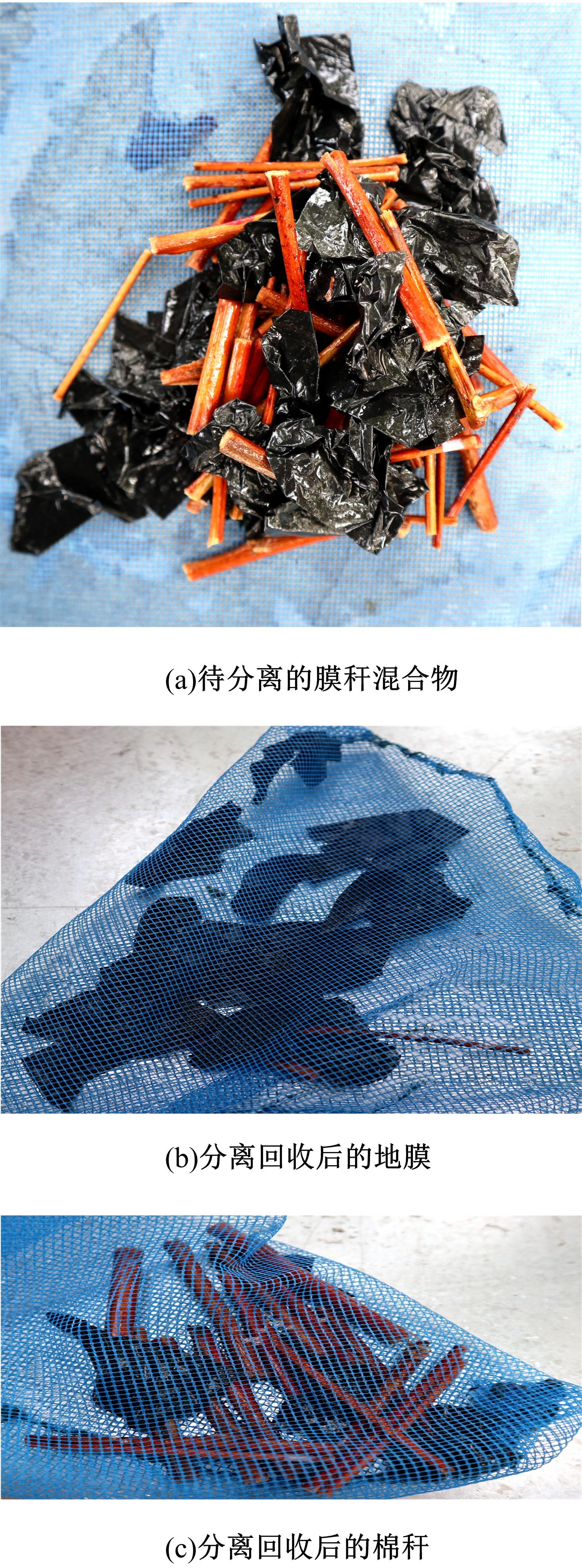

针对新疆秋季棉田机械化作业后地膜混合物存在的分离不彻底、效率低和能耗高等问题,提出基于灌溉用引水渠中的水为介质的膜秆分离方案并进行试验。通过数据处理建立试验因素与评价指标间的拟合回归方程,方差分析探究各因素及其交互作用的影响规律,软件寻优获得最佳参数组合:导流板安装角度为33.75°,膜秆喂入量为67.452个,膜秆回收网安装位置为24 cm,位移差为25.76 cm,经试验验证,与寻优预测值相对应的相对误差分别为6.28%、7.89%和28.95%,膜秆损失率为10.00%,回收网中含杂率为3.72%,样机装置性能可靠。该研究可为膜杂分离方法及装置结构参数优化设计提供相关理论依据。

中图分类号:

- S223.5

| 1 | 中华人民共和国农业农村部. 2021年中央一号文件[EB/OL].[2021-02-21].. |

| 2 | 严昌荣. 我国农田地膜残留污染的解决之道在哪儿?[EB/OL].[2020-09-10].. |

| 3 | 丛宏斌,沈玉君,孟海波,等. 农业固体废物分类及其污染风险识别和处理路径[J]. 农业工程学报, 2020, 36(14): 28-36. |

| Cong Hong-bin, Shen Yu-jun, Meng Hai-bo, et al. Classification of agricultural solid wastes and identification of pollution risks and utilization paths in China[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(14): 28-36. | |

| 4 | 中共中央国务院关于抓好“三农”领域重点工作确保如期实现全面小康的意见[N]. 人民日报, 2020-02-06. |

| 5 | 赵岩,陈学庚,温浩军,等. 农田残膜污染治理技术研究现状与展望[J]. 农业机械学报, 2017, 48(6): 1-14. |

| Zhao Yan, Chen Xue-geng, Wen Hao-jun, et al. Research status and prospect of control technology for residual plastic film pollution in farmland[J]. Transaction of the Chinese Society for Agricultural Machinery, 2017, 48(6): 1-14. | |

| 6 | 石鑫,牛长河,乔园园,等. 塑料垃圾分选技术在废旧地膜与杂质分离中的应用研究进展[J]. 农业工程学报, 2016, 32(): 22-31. |

| Shi Xin, Niu Chang-he, Qiao Yuan-yuan, et al. Application of plastic trash sorting technology in separating waste plastic mulch films from impurities[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(Sup.2): 22-31. | |

| 7 | 梁荣庆,陈学庚,张炳成,等. 新疆棉田残膜回收方式及资源化再利用现状问题与对策[J]. 农业工程学报, 2019, 35(16): 1-13. |

| Liang Rong-qing, Chen Xue-geng, Zhang Bing-cheng, et al. Problems and countermeasures of recycling methods and resource reuse of residual film in cotton fields of Xinjiang[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(16): 1-13. | |

| 8 | 吴应湘,许晶禹.油水分离技术[J]. 力学进展, 2015, 45(1): 179-216. |

| Wu Ying-xiang, Xu Jing-yu. Oil and water separation technology[J]. Advances in Mechanics, 2015, 45(1): 179-216. | |

| 9 | Richard G, Mario M, Javier T, et al. Optimization of the recovery of plastics for recycling by density media separation cyclones[J]. Resources Conservation and Recycling, 2011, 55(4): 472-482. |

| 10 | 王昭宇, 陈学庚, 颜利民, 等. 随动式残膜回收机起膜捡拾机构设计与试验[J]. 农业机械学报, 2021, 52(4): 80-90. |

| Wang Zhao-yu, Chen Xue-geng, Yan Li-min, et al. Design and experiment on collecting and removing device for profile modeling residual plastic film collector[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(4): 80-90. | |

| 11 | Yang Song-mei, Chen Xue-geng, Yan Li-min, et al. Performance of three different spades for residual plastic film recycling machine[J]. Applied Engineering in Agriculture, 2020, 36(2): 187-195. |

| 12 | 石鑫,牛长河,王学农,等. 滚筒筛式废旧地膜与杂质风选装置设计[J]. 农业工程学报, 2017, 33(18): 19-26. |

| Shi Xin, Niu Chang-he, Wang Xue-nong, et al. Design of roller sieve waste plastic film and trash winnowing machine[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(18): 19-26. | |

| 13 | 彭强吉,李成松,康建明,等. 气力式圆筒筛膜杂分离机改进设计与试验[J]. 农业机械学报, 2020, 51(8): 126-135. |

| Peng Qiang-ji, Li Cheng-song, Kang Jian-ming, et al. Improved design and experiment on pneumatic cylinder sieve film hybrid separator[J]. Transactions of The Chinese Society for Agricultural Machinery,2020, 51(8): 126-135. | |

| 14 | 杨猛,张延化,张冲,等.基于先揉切后分离的花生膜秧分离装置设计与试验[J].农业机械学报, 2020, 51(12): 112-121. |

| Yang Meng, Zhang Yan-hua, Zhang Chong, et al. Design and experiment of peanut seedling-film separation device based on shredding and separating[J]. Transactions of The Chinese Society for Agricultural Machinery, 2020, 51(12): 112-121. | |

| 15 | 王巧华,翁富炯,张洪洲,等. 机采棉中残地膜静电吸附法分级去除[J].农业机械学报, 2019, 50(6): 140-147. |

| Wang Qiao-hua, Weng Fu-jiong, Zhang Hong-zhou, et al. Grading removal of residual plastic film in machine-harvested cotton using electrostatic adsorption method[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(6): 140-147. | |

| 16 | 罗昕. 膜杂水洗分离方法及装置[P]. 中国: 106626144A, 2016-12-16. |

| 17 | 李俊虹. 机收残膜混合物水洗分离装置的研究[D]. 石河子:石河子大学机械电气工程学院,2018. |

| Li Jun-hong. Study on the water-separating device of residual film mixture collected by machine[D]. Shihezi: College of Mechanical and Electrical Engineering, Shihezi University, 2018. | |

| 18 | 何浩猛,胡斌,潘峰,等. 叶轮扰动水介质对地膜与棉秆沉降聚集行为影响与试验[J]. 农业工程学报, 2021, 37(2): 86-95. |

| He Hao-meng, Hu Bin, Pan Feng, et al. Effects and experiment on settlement and aggregation behavior of plastic film and cotton stalk under the action of disturbing water by the impeller[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(2): 86-95. | |

| 19 | 徐立中,张振,严锡君,等. 非接触式明渠水流监测技术的发展现状[J]. 水利信息化, 2013, 30(3): 37-44, 50. |

| Xu Li-zhong, Zhang Zhen, Yan Xi-jun, et al. Advance of non-contact instruments and tachniques for open-channel flow measurements[J]. Water Resources Informatization, 2013(3): 37-44, 50. | |

| 20 | . 灌溉与排水工程设计标准 [S]. |

| 21 | Dodbiba G, Haruki N, Shibayama A, et al. Combination of sink-float separation and flotation technique for purification of shredded PET-bottle from PE or PP flakes[J]. International Journal of Mineral Processing, 2002, 65(1): 11-29. |

| 22 | 惠遇甲. 挟沙水流的运动机理和输沙能力[J].水动力学研究与进展, 1996, 11(2): 133-149. |

| Hui Yu-jia. Movement mechanism and transport competency of sediment-laden flow[J]. Journal of Hydrodynamics, 1996, 11(2): 133-149. | |

| 23 | . 粮食、油料检验扦样、分样法 [S]. |

| 24 | 葛宜元. 试验设计方法与Design-Expert软件应用[M]. 哈尔滨:哈尔滨工业大学出版社, 2015. |

| 25 | Lau T, Harbourne N, Maria J. Optimization of enzyme-assisted extraction of ferulic acid from sweet corn cob by response surface methodology[J]. Journal of the Science of Food and Agriculture, 2020, 100(4): 1479-1485. |

| 26 | Marcos A, Ricardo E, Eliane P, et al. Response surface methodology (RSM) as a tool for optimization in analytical chemistry[J]. Talanta, 2008, 76(5): 965-977. |

| 27 | 李莉,张赛,何强,等. 响应面法在试验设计与优化中的应用[J]. 实验室研究与探索, 2015, 34(8): 41-45. |

| Li Li, Zhang Sai, He Qiang, et al. Appliction of response surface methodlogy in experiment design and optimization[J]. Research and Exploration in Laboratory, 2015, 34(8):41-45. |

| [1] | 张学军,黄爽,史增录,于永良,周鑫城,靳伟,陈勇,洪佳. 残膜捡拾打包机的设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1220-1230. |

| [2] | 朱光强,李天宇,周福君,王文明. 鲜食玉米仿生摘穗装置设计与试验[J]. 吉林大学学报(工学版), 2023, 53(4): 1231-1244. |

| [3] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [4] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

| [5] | 高文英,林静,李宝筏,王伟,谷士艳. 秸秆深埋还田机振动特性分析与结构优化[J]. 吉林大学学报(工学版), 2022, 52(4): 970-980. |

| [6] | 刘佳杰,马兰,向伟,颜波,文庆华,吕江南. 4QM-4.0型麻类青饲料联合收获机研制[J]. 吉林大学学报(工学版), 2022, 52(12): 3039-3048. |

| [7] | 史瑞杰,戴飞,赵武云,刘小龙,瞿江飞,张锋伟. 丘陵山地胡麻联合收割机作业参数优化与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2746-2755. |

| [8] | 曾百功,黎奎良,叶进,任丽丽,Rashidov Jaloliddin,张明. 工厂化上海青流水线收割装置的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2756-2764. |

| [9] | 万星宇,廖庆喜,蒋亚军,单伊尹,周宇,廖宜涛. 饲用油菜机械化收获切碎过程离散元仿真与试验[J]. 吉林大学学报(工学版), 2022, 52(11): 2735-2745. |

| [10] | 朱光强,李天宇,周福君. 鲜食玉米仿生摘穗柔性夹持输送装置设计与试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2486-2500. |

| [11] | 梁荣庆,钟波,蒙贺伟,孙志民,坎杂. 4QJ⁃3型青贮燕麦捡拾割台的研制[J]. 吉林大学学报(工学版), 2021, 51(5): 1887-1896. |

| [12] | 袁佳诚,王昌,何坤,万星宇,廖庆喜. 油菜联合收获机筛下物组分质量比对清选性能的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1897-1907. |

| [13] | 王刚,刘慧力,贾洪雷,郭春江,丛永健,屈明浩. 触碰定位式玉米行间除草装置的设计与试验[J]. 吉林大学学报(工学版), 2021, 51(4): 1518-1527. |

| [14] | 黄继承,沈成,纪爱敏,李显旺,张彬,田昆鹏,刘浩鲁. 工业大麻收割机切割⁃输送关键部件作业参数优化[J]. 吉林大学学报(工学版), 2021, 51(2): 772-780. |

| [15] | 陈学深,陈涛,武涛,马旭,曾令超,陈林涛. 覆草冬种马铃薯收获机稻草分离机构设计与试验[J]. 吉林大学学报(工学版), 2020, 50(2): 749-757. |

|

||