吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (4): 973-981.doi: 10.13229/j.cnki.jdxbgxb.20210779

嵌入控制油腔的静压主轴轴心运动主动控制分析与试验

- 山东大学 机械工程学院,济南 250061

Analysis and experiment of active motion control of hydrostatic spindle embedded with control recess

Shu-jiang CHEN( ),Chun-wang XU,Chang-hou LU,Kang WANG

),Chun-wang XU,Chang-hou LU,Kang WANG

- School of Mechanical Engineering,Shandong University,Jinan 250061,China

摘要:

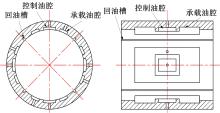

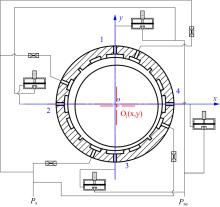

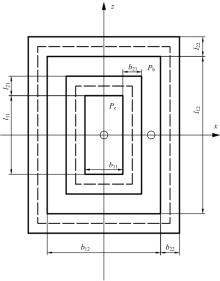

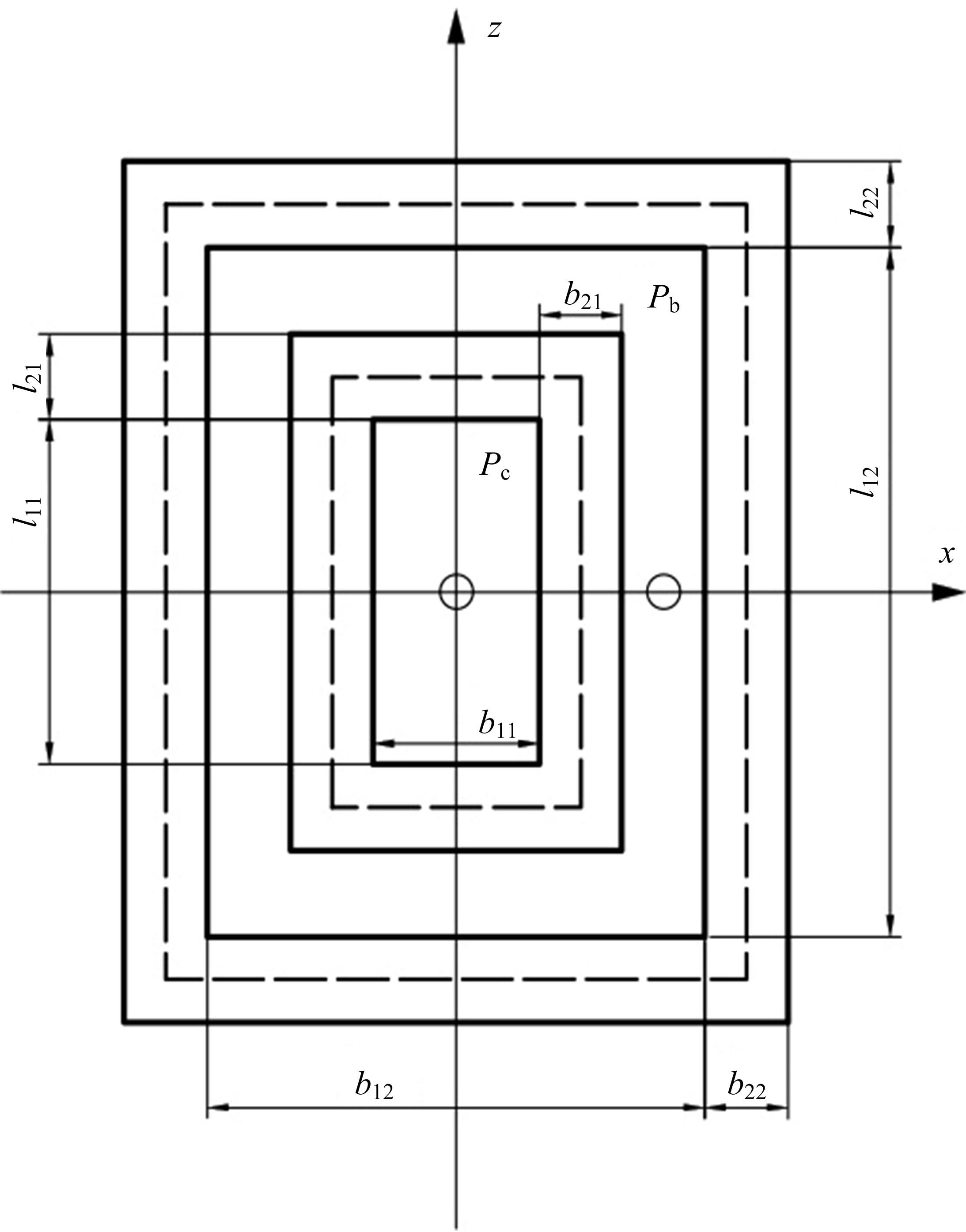

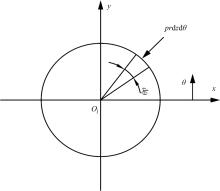

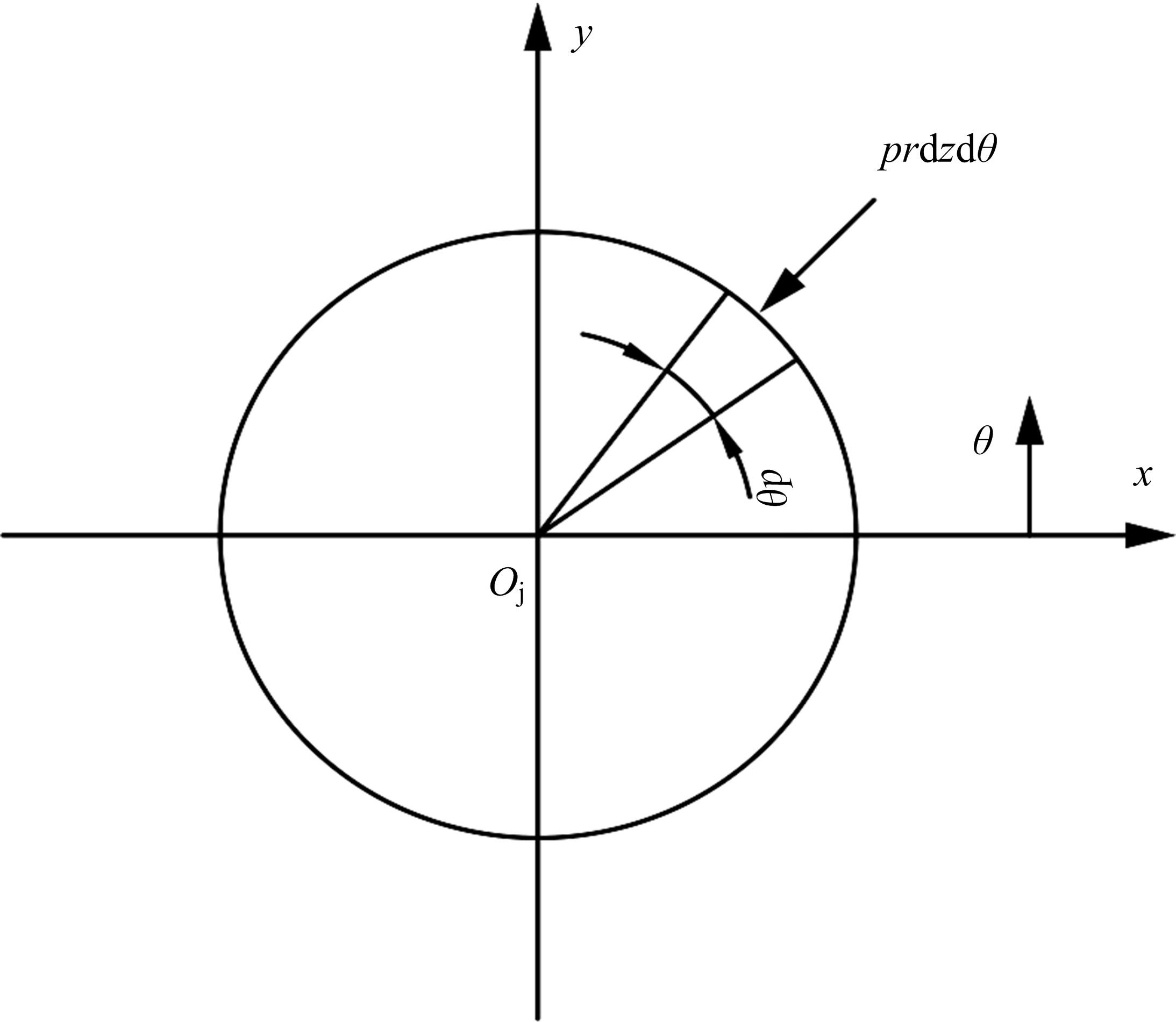

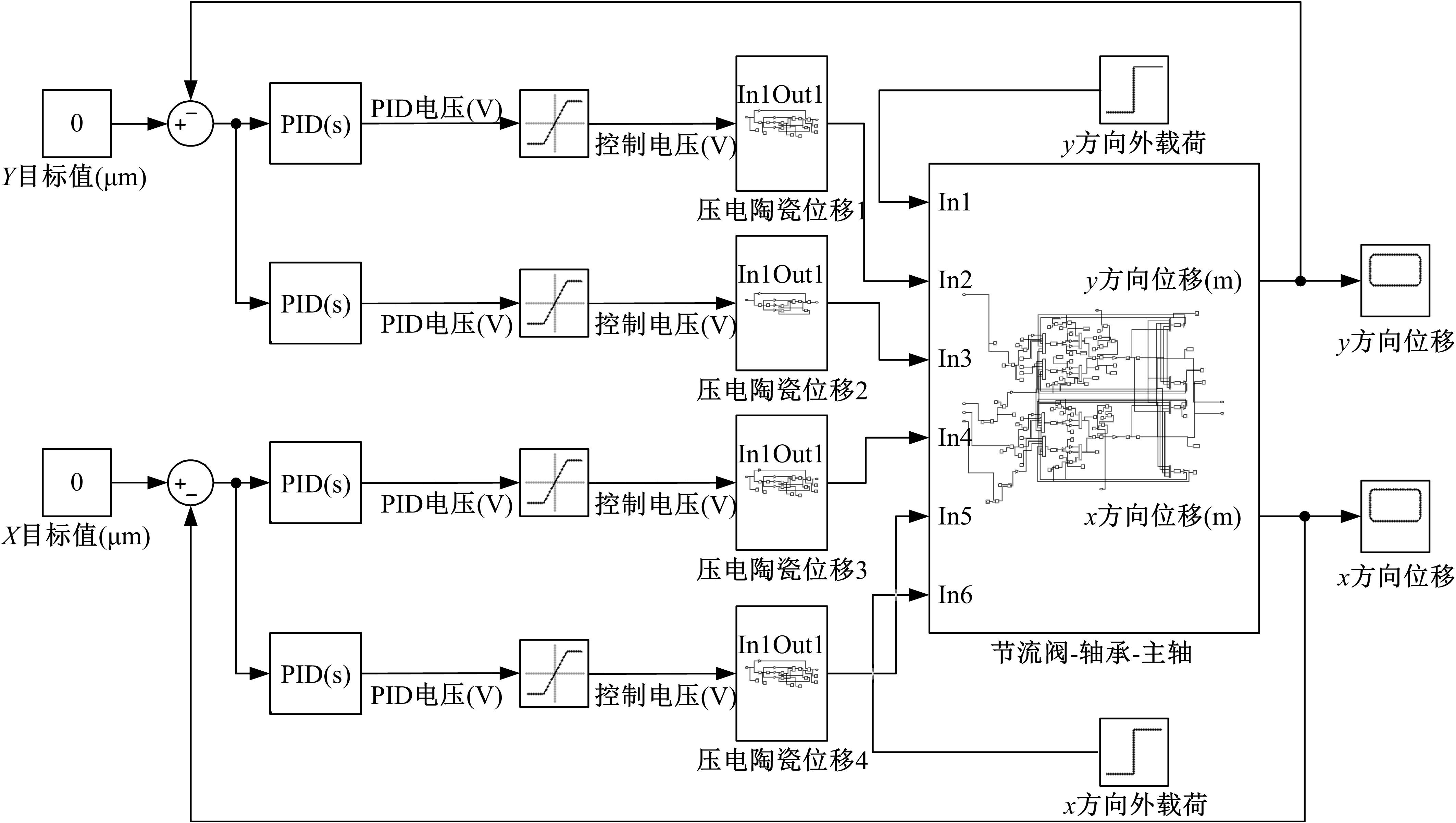

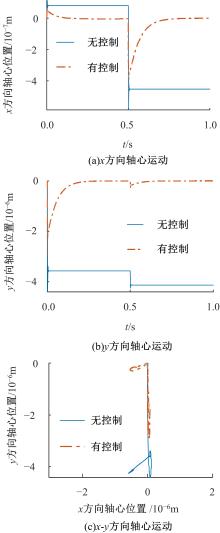

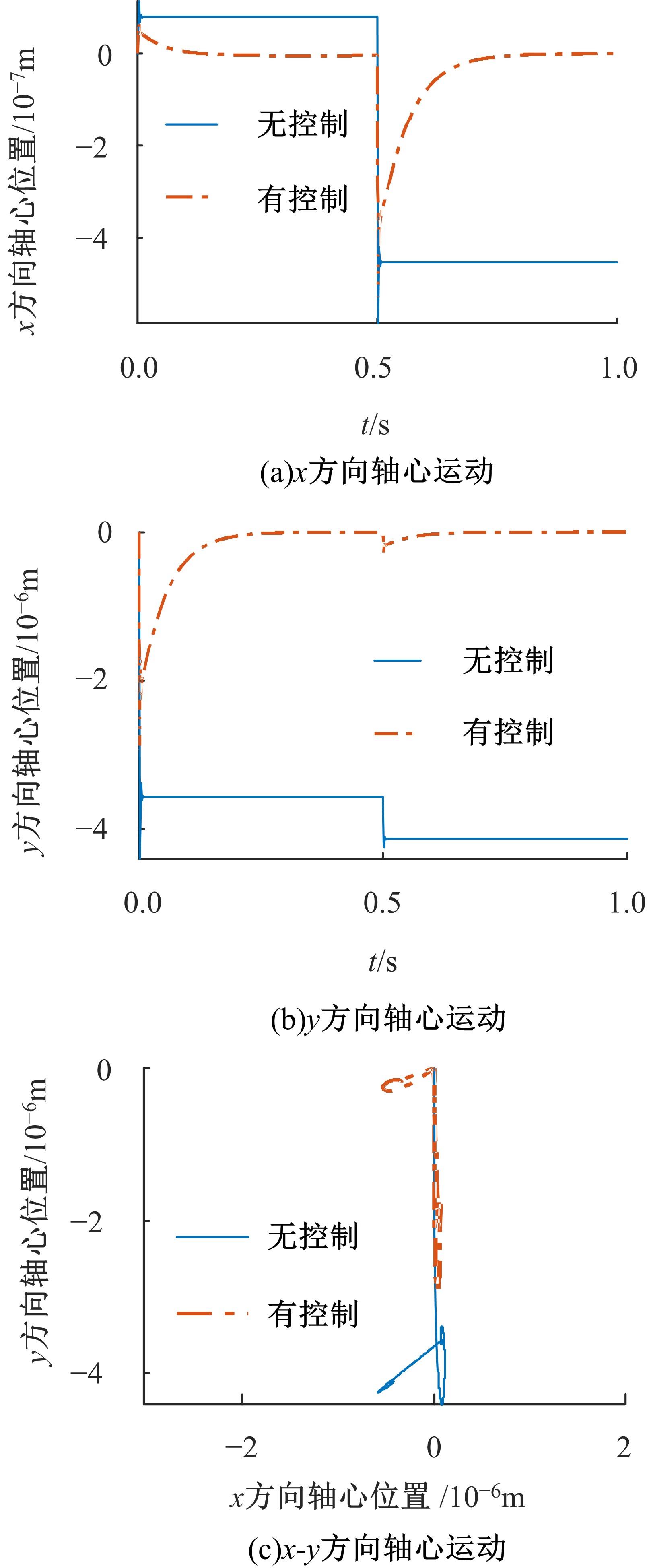

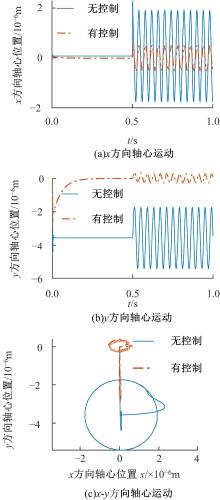

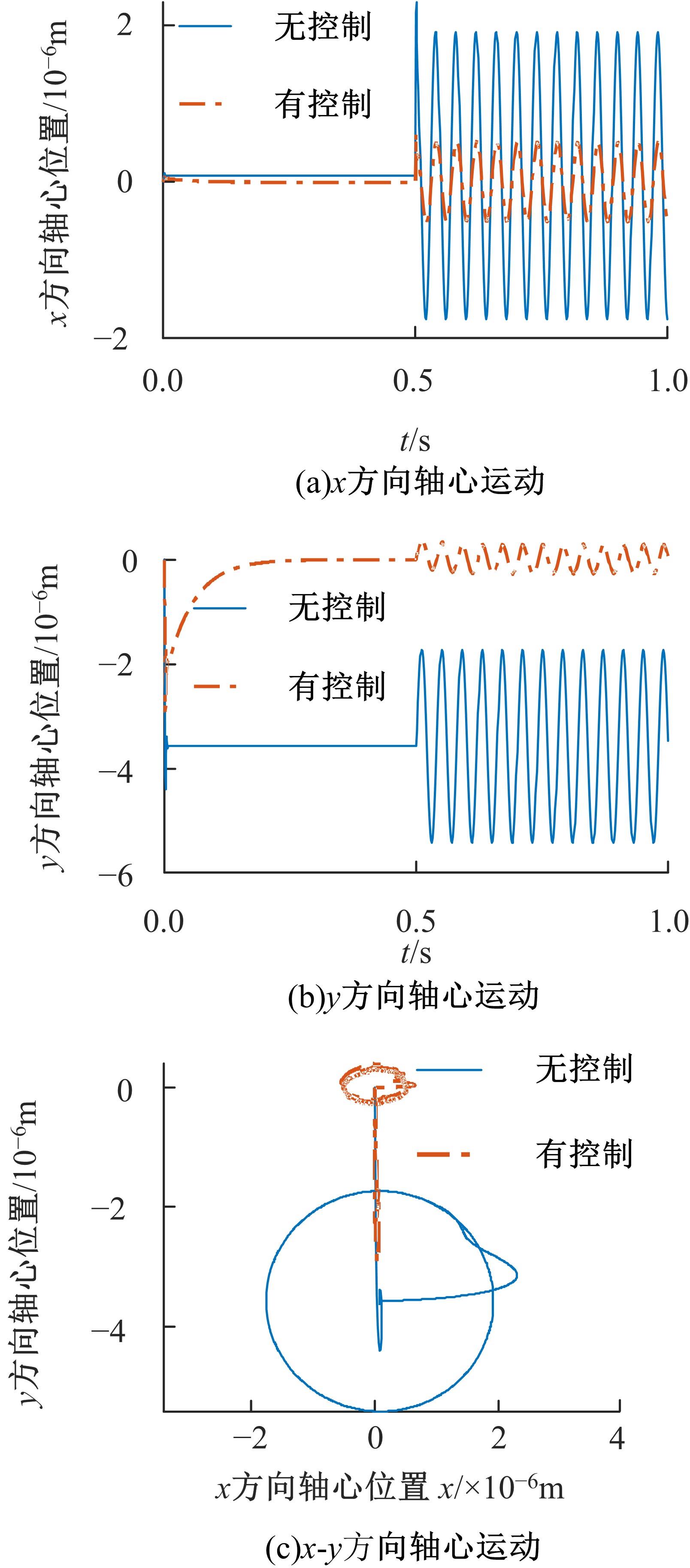

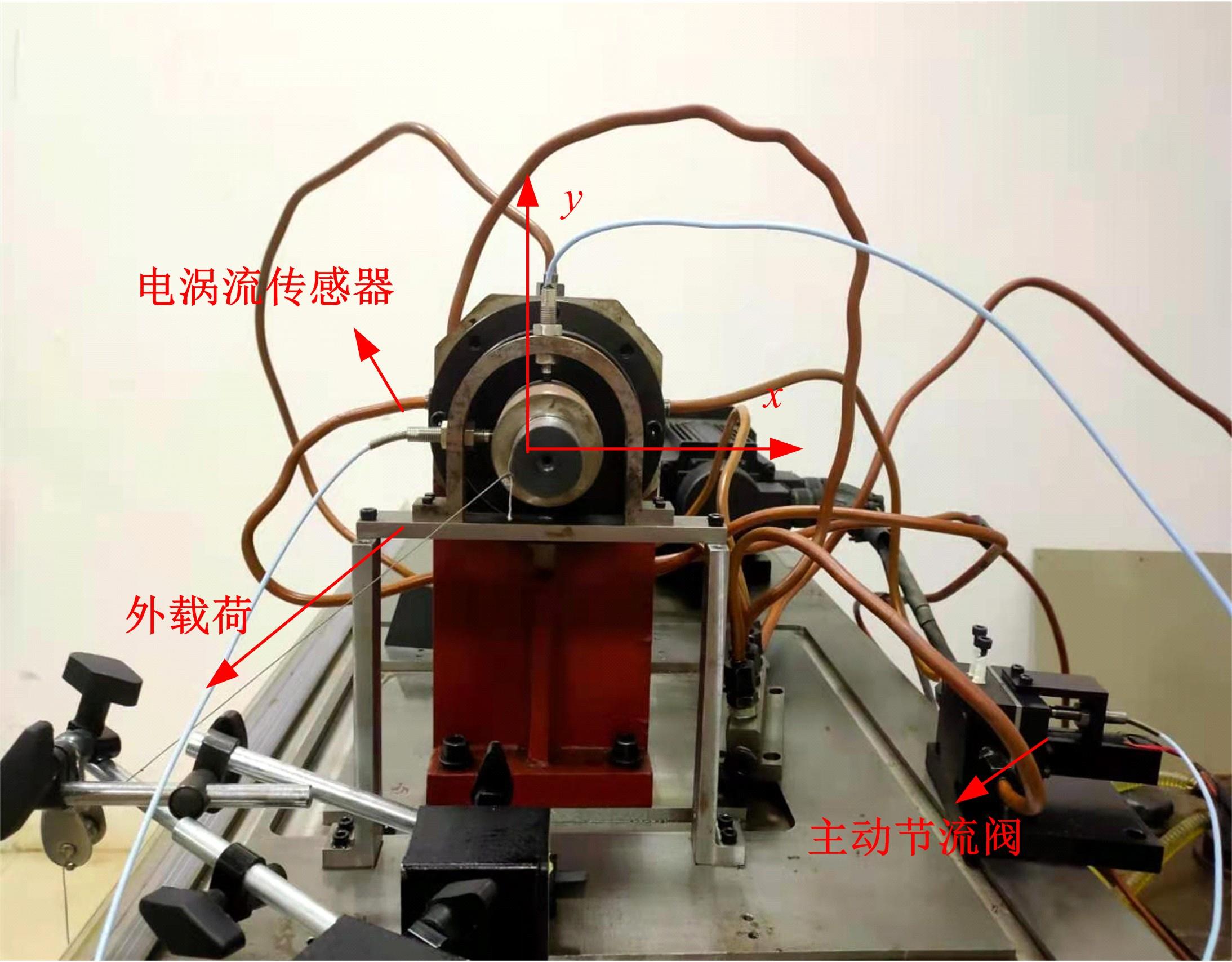

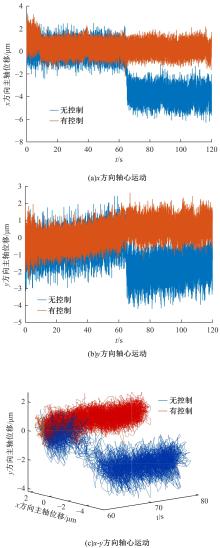

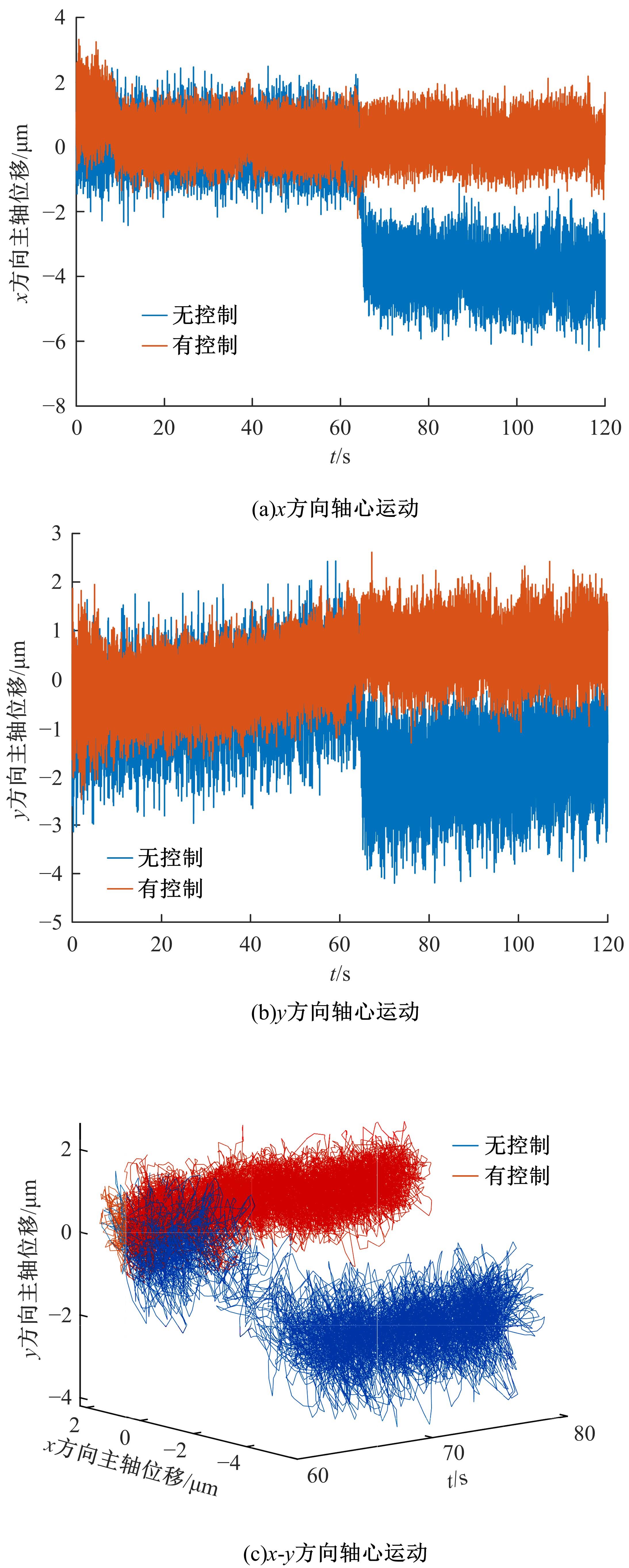

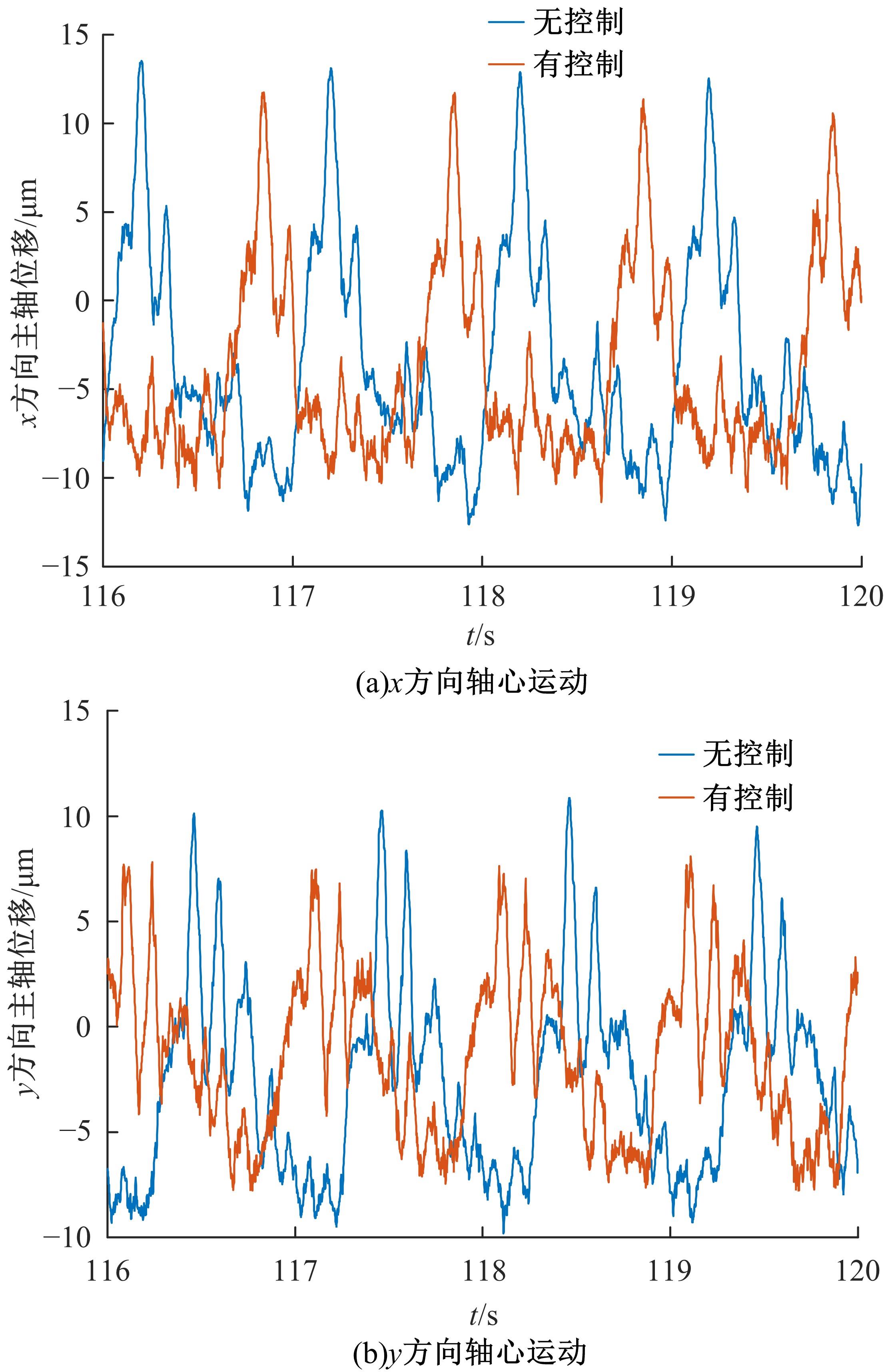

为了进一步提高机床主轴的回转精度,在不增加主轴机械结构复杂度的情况下,通过控制主动单面薄膜节流阀,主动调整嵌入控制油腔的静压轴承的油膜力,对主轴的径向运动进行控制。基于雷诺方程以及流量守恒方程得到轴承油膜力,建立了主轴轴心运动的理论模型。基于PID控制器进行了主轴径向回转误差主动控制的理论和实验研究,对比分析了不同类型载荷条件下的主轴轴心运动控制情况。结果表明,在定载荷条件下,该主动控制静压主轴系统能够将轴心保持在目标位置;在动载荷条件下,轴心运动幅度能够得到有效降低且运动中心相比于无控制的情况更靠近目标位置。

中图分类号:

- TH133.3

| 1 | Wu Q H, Sun Y Z, Chen W Q, et al. Effect of motor rotor eccentricity on aerostatic spindle vibration in machining processes[J]. Journal of Mechanical Engineering Science, 2018, 232(7): 1331-1342. |

| 2 | Zhang S J, To S. Spindle vibration influencing form error in ultra-precision diamond machining[J]. Journal of Mechanical Engineering Science, 2017, 231(17): 3144-3151. |

| 3 | Chen G D, Sun Y Z, Zhang F H, et al. Influence of ultra-precision flycutting spindle error on surface frequency domain error formation[J]. International Journal of Advanced Manufacturing Technology, 2017, 88(9-12): 3233-3241. |

| 4 | 李永祥,毕晓勤. 机床主轴回转误差对零件加工精度的影响[J]. 河南工业大学学报: 自然科学版, 2005, 26(3): 57-59, 62. |

| Li Yong-xiang, Bi Xiao-qin. The Influence of lathe spindle rotary errors on spares machining precision[J]. Journal of Henan University of Technology(Natural Science Edition), 2005, 26(3): 57-59, 62. | |

| 5 | Turek P, Jędrzejewski J, Modrzycki W. Methods of machine tool error compensation[J]. Journal of Machine Engineering, 2010, 10(4): 5-25. |

| 6 | 路琳, 刘晓玲. 主轴轴承的选配与主轴部件旋转精度关系初探[J]. 组合机床与自动化加工技术, 2001, 42(6): 54-55. |

| Lu Lin, Liu Xiao-ling. The Relationship between the selection of spindle bearing and the rotation accuracy of spindle[J]. Modular Machine Tool & Automatic Manufacturing Technique,2001, 42(6): 54-55. | |

| 7 | 熊万里, 孙文彪, 刘侃, 等. 高速电主轴主动磁悬浮技术研究进展[J]. 机械工程学报, 2021, 57(13): 1-17. |

| Xiong Wan-li, Sun Wen-biao, Liu Kan, et al. Active magnetic bearing technology development in high-speed motorized spindles[J]. Journal of Mechanical Engineering, 2021, 57(13): 1-17. | |

| 8 | Santos I F. Controllable sliding bearings and controllable lubrication principles—an overview[J]. Lubricants, 2018, 6(1): 1-12. |

| 9 | Santos I F. On the future of controllable fluid film bearings[J]. Mechanics and Industry, 2011, 12(4): 275-281. |

| 10 | Salazar J G, Santos I F. Feedback-controlled lubrication for reducing the lateral vibration of flexible rotors supported by tilting-pad journal bearings[J]. Journal of Engineering Tribology, 2015, 229(10): 1264-1275. |

| 11 | 谢磊, 计江, 师浩浩. 一种轧辊静压轴承主动控制方法 [J]. 冶金设备, 2021, 42(3): 1-6. |

| Xie Lei, Ji Jiang, Shi Hao-hao. An active control method of roll hydrostatic bearing[J]. Metallurgical Equipment, 2021, 42(3): 1-6. | |

| 12 | Rehman W U R, Luo Y X, Wang Y Q, et al. Fuzzy logic-based intelligent control for hydrostatic journal bearing[J]. Measurement and Control, 2019, 52(3/4): 229-243. |

| 13 | Rehman W U, Jiang G Y, Luo Y X, et al. Control of active lubrication for hydrostatic journal bearing by monitoring bearing clearance[J]. Advances in Mechanical Engineering, 2018, 10(4): 1-17. |

| 14 | Rehman W U, Jiang G Y, Iqbal N, et al. Intelligent servo feedback control for hydrostatic journal bearing [C]∥Proceedings of 1st International Conference on Intelligent Manufacturing and Internet of Things /The 5th International Conference on Computing for Sustainable Energy and Environment, Chongqing, China, 2018: 352-364. |

| 15 | Yang X G, Wang Y Q, Jiang G Y, et al. Dynamic characteristics of hydrostatic active journal bearing of four oil recesses[J]. Tribology Transactions, 2015, 58(1): 7-17. |

| 16 | 丁振乾. 流体静压支承设计[M]. 上海: 上海科学技术出版社, 1989. |

| 17 | 宋佳星. 压电陶瓷驱动伺服阀的设计及特性研究[D]. 哈尔滨: 哈尔滨工业大学机电工程学院, 2019. |

| Song Jia-xing. Research on design and characteristics of servovalve actuated by piezoelectric ceramics[D]. Harbin: School of Mechatronics Engineering, Harbin Institute of Technology, 2019. |

| [1] | 蒋林,周玲,赵慧. 液压伺服柔驱机构设计及其刚度连续可调分析[J]. 吉林大学学报(工学版), 2022, 52(7): 1499-1508. |

| [2] | 杨志军,高忠义,王丽君,黄观新,危宇泰. 面向刚柔耦合定位平台的模型预测控制算法[J]. 吉林大学学报(工学版), 2022, 52(12): 2806-2815. |

| [3] | 胡鹏,朱建新,刘昌盛,张大庆. 液压挖掘机动臂势能交互回收利用系统特性[J]. 吉林大学学报(工学版), 2022, 52(10): 2256-2264. |

| [4] | 李学勇,赵仲秋,张春松,路长厚. 基于有限元的人体⁃机械手交互力计算方法[J]. 吉林大学学报(工学版), 2021, 51(5): 1612-1619. |

| [5] | 施昕昕,黄家才,高芳征. 基于分数阶BICO滤波器的运动控制测量噪声抑制[J]. 吉林大学学报(工学版), 2021, 51(5): 1873-1878. |

| [6] | 于萍,穆特,朱黎辉,周子业,宋杰. 钻具输送装置非线性动力学分析及稳定性控制[J]. 吉林大学学报(工学版), 2021, 51(3): 820-830. |

| [7] | 张艳芹,罗义,倪世钱,伍儒康,张志全. 微斜面式重型静压轴承润滑油膜高速特性[J]. 吉林大学学报(工学版), 2021, 51(2): 450-457. |

| [8] | 姜继海,赵存然,张冠隆,车明阳. 航空煤油柱塞泵摩擦副涂层材料摩擦性能[J]. 吉林大学学报(工学版), 2021, 51(1): 147-153. |

| [9] | 胡明伟,王洪光,潘新安. 基于正交设计的协作机器人全域结构优化设计[J]. 吉林大学学报(工学版), 2021, 51(1): 370-378. |

| [10] | 刘颖, 张凯, 于向军. 基于代理模型的中空轴式大型静压轴承多目标优化[J]. 吉林大学学报(工学版), 2017, 47(4): 1130-1137. |

| [11] | 王攀, 鲁俊, 邓兆祥, 廖海辰, 王正亚, 阳小光. 基于状态观测器的机敏约束阻尼板模态控制[J]. 吉林大学学报(工学版), 2016, 46(4): 1057-1064. |

| [12] | 刘昌盛, 何清华, 张大庆, 李铁辉, 龚俊, 赵喻明. 混合动力挖掘机势能回收系统参数优化与试验[J]. 吉林大学学报(工学版), 2014, 44(2): 379-386. |

| [13] | 龚俊, 何清华, 张大庆, 张云龙, 刘昌盛, 唐中勇. 混合动力叉车节能效果评价及能量回收系统试验[J]. 吉林大学学报(工学版), 2014, 44(01): 29-34. |

| [14] | 张袅娜1,2,周邃1,张德江1. 基于主动控制的异结构混沌系统有限时间同步[J]. 吉林大学学报(工学版), 2011, 41(4): 1131-1134. |

| [15] | 邓宗全1,2,王新杰1,2,岳洪浩1,2. 光电层合抛物薄壳的主动控制[J]. 吉林大学学报(工学版), 2011, 41(05): 1433-1438. |

|

||