吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (5): 1258-1266.doi: 10.13229/j.cnki.jdxbgxb.20221156

• 交通运输工程·土木工程 • 上一篇

基于非均质模型的水稳碎石材料细观开裂行为

- 长安大学 公路学院,西安 710064

Meso-cracking behavior of cement-stabilized macadam materials based on heterogeneous model

Xiao-kang ZHAO( ),Zhe HU,Zhen-xing NIU,Jiu-peng ZHANG(

),Zhe HU,Zhen-xing NIU,Jiu-peng ZHANG( ),Jian-zhong PEI,Yong WEN

),Jian-zhong PEI,Yong WEN

- School of Highway,Chang'an University,Xi'an 710064,China

摘要:

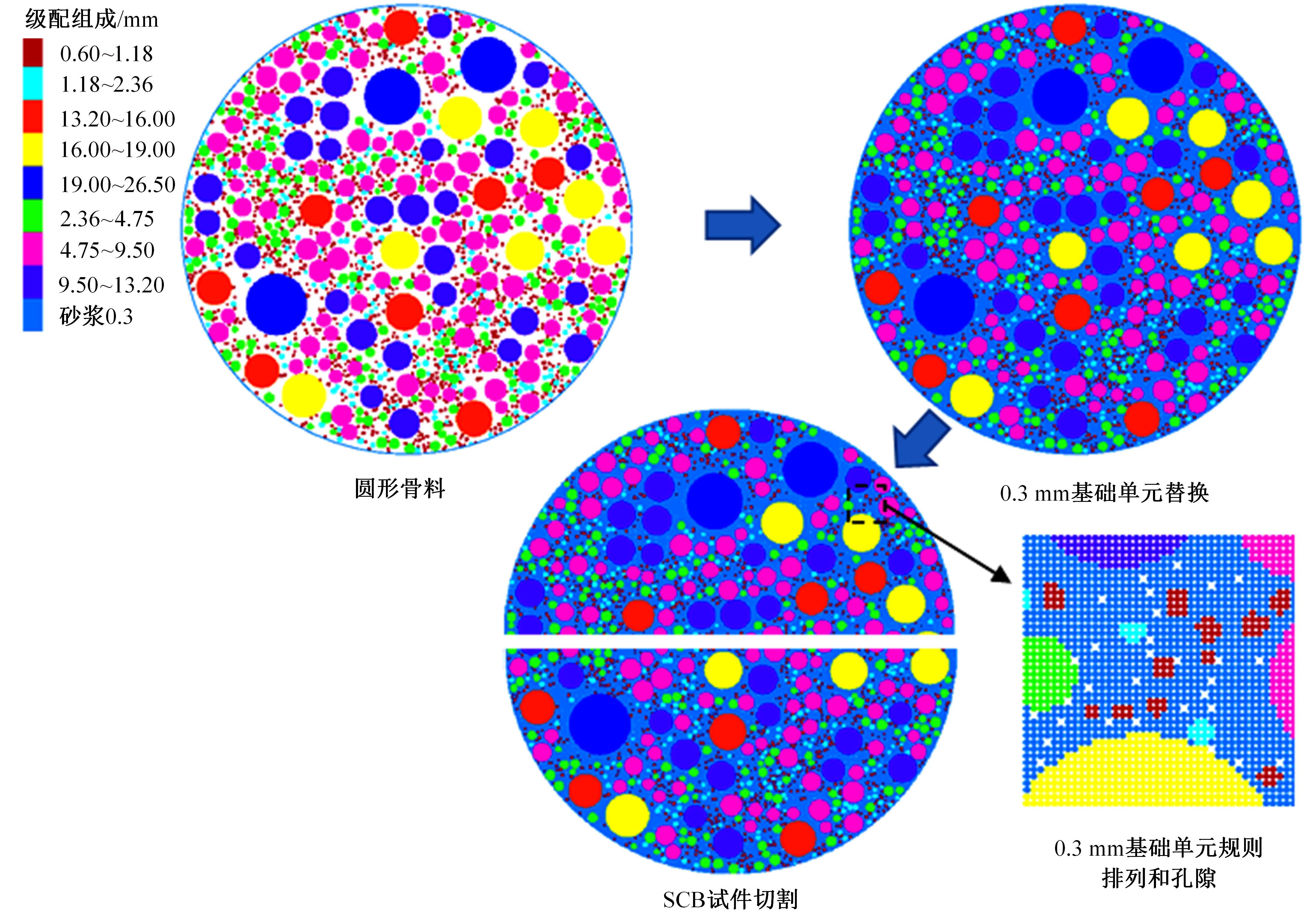

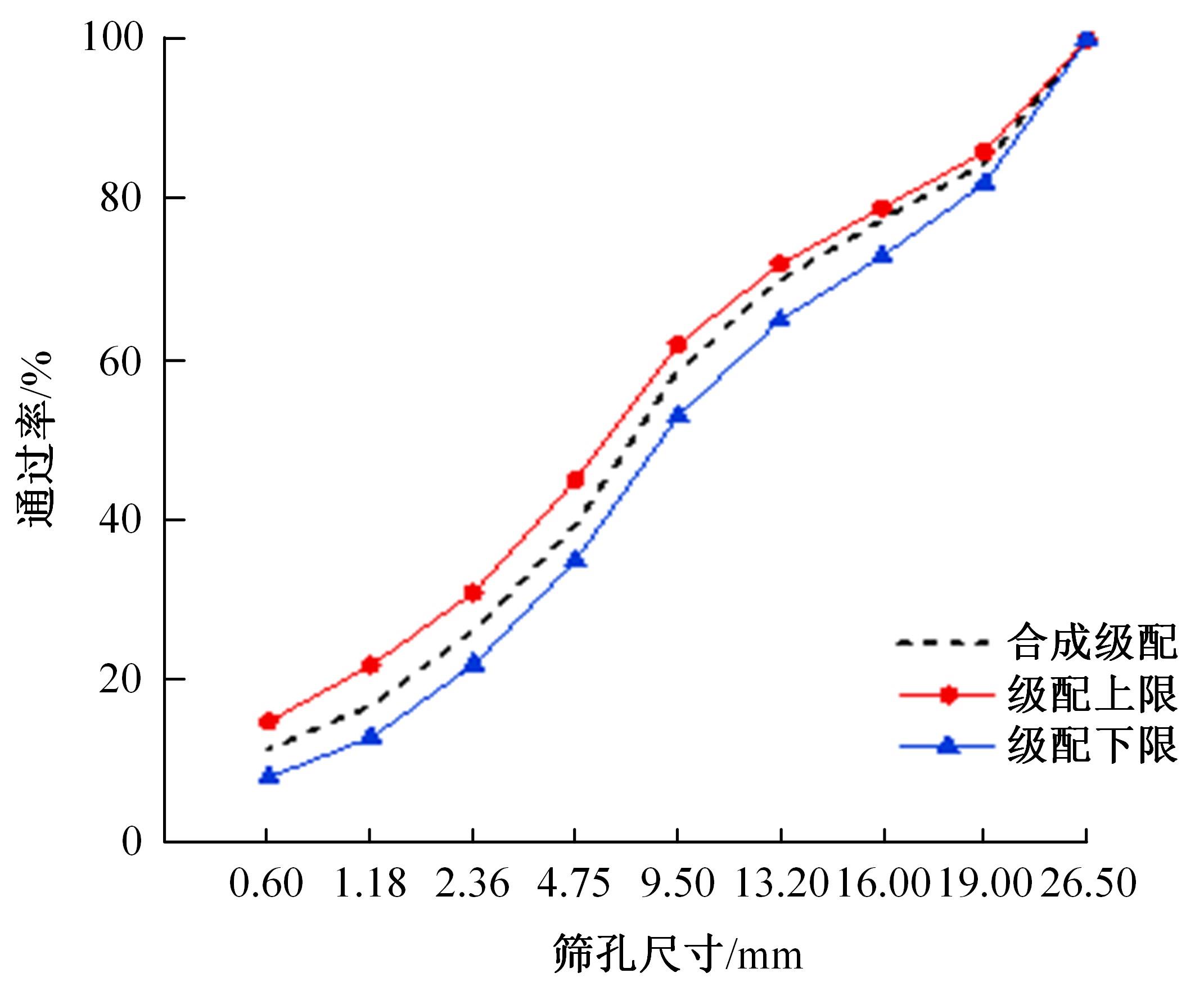

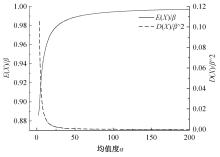

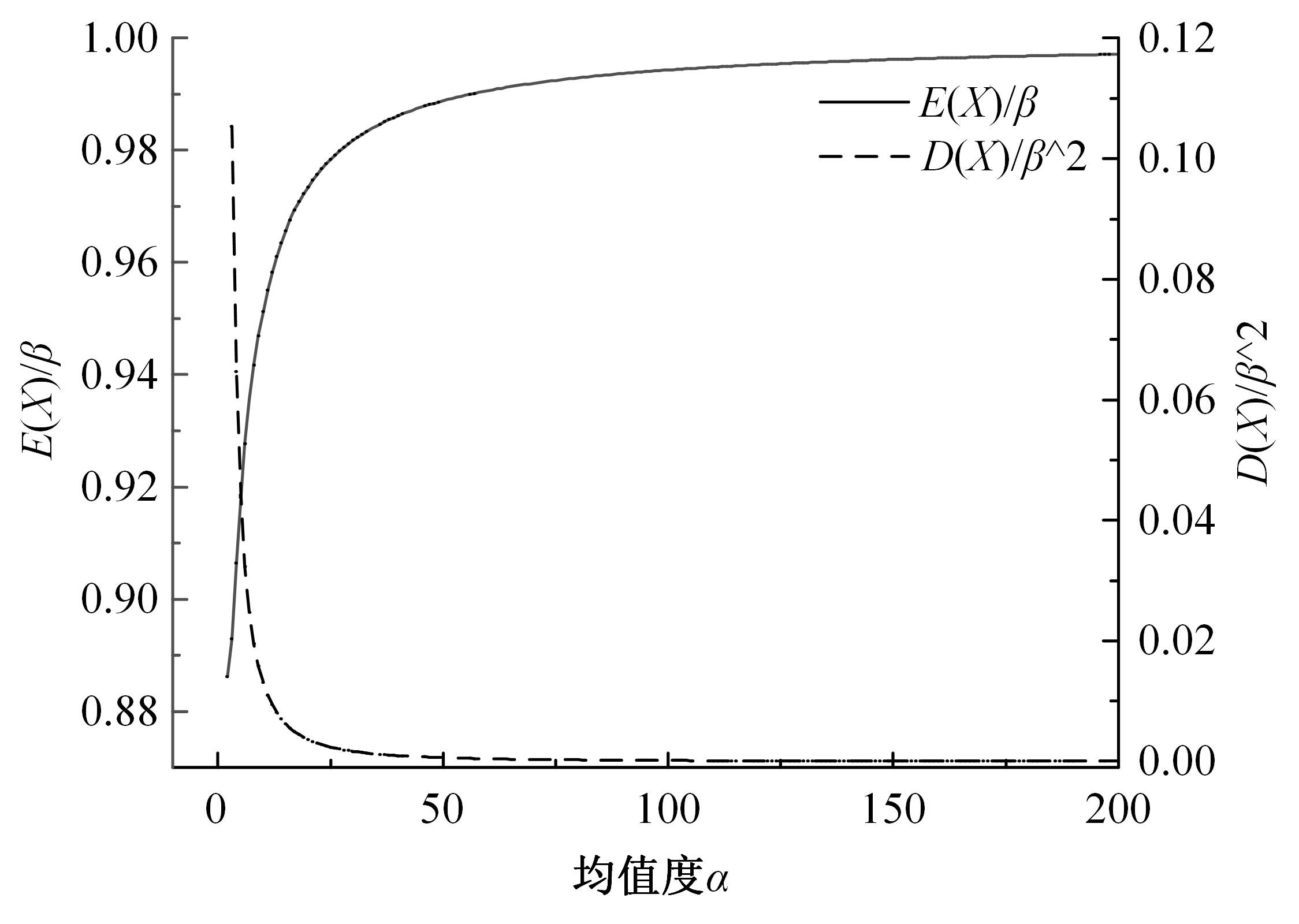

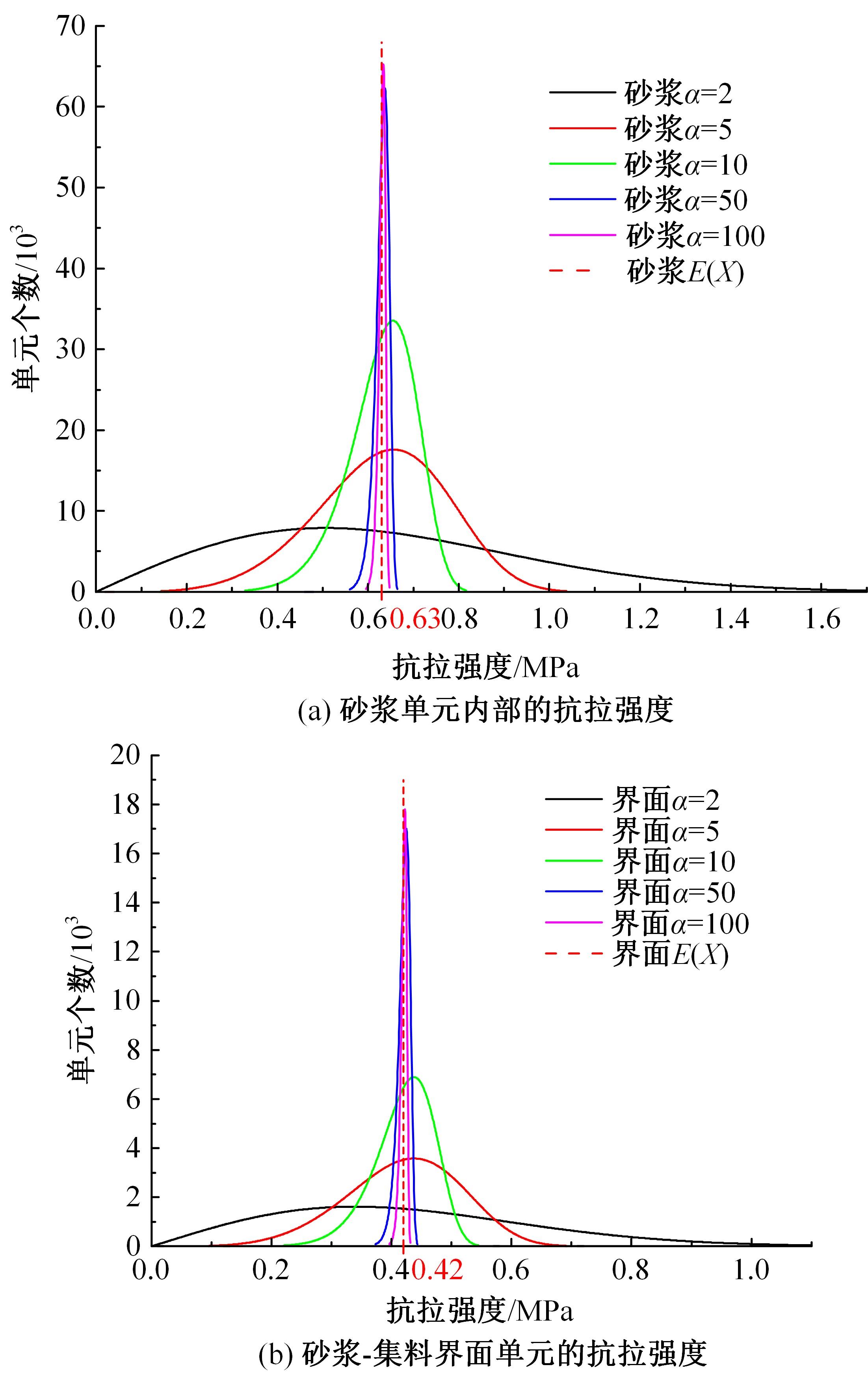

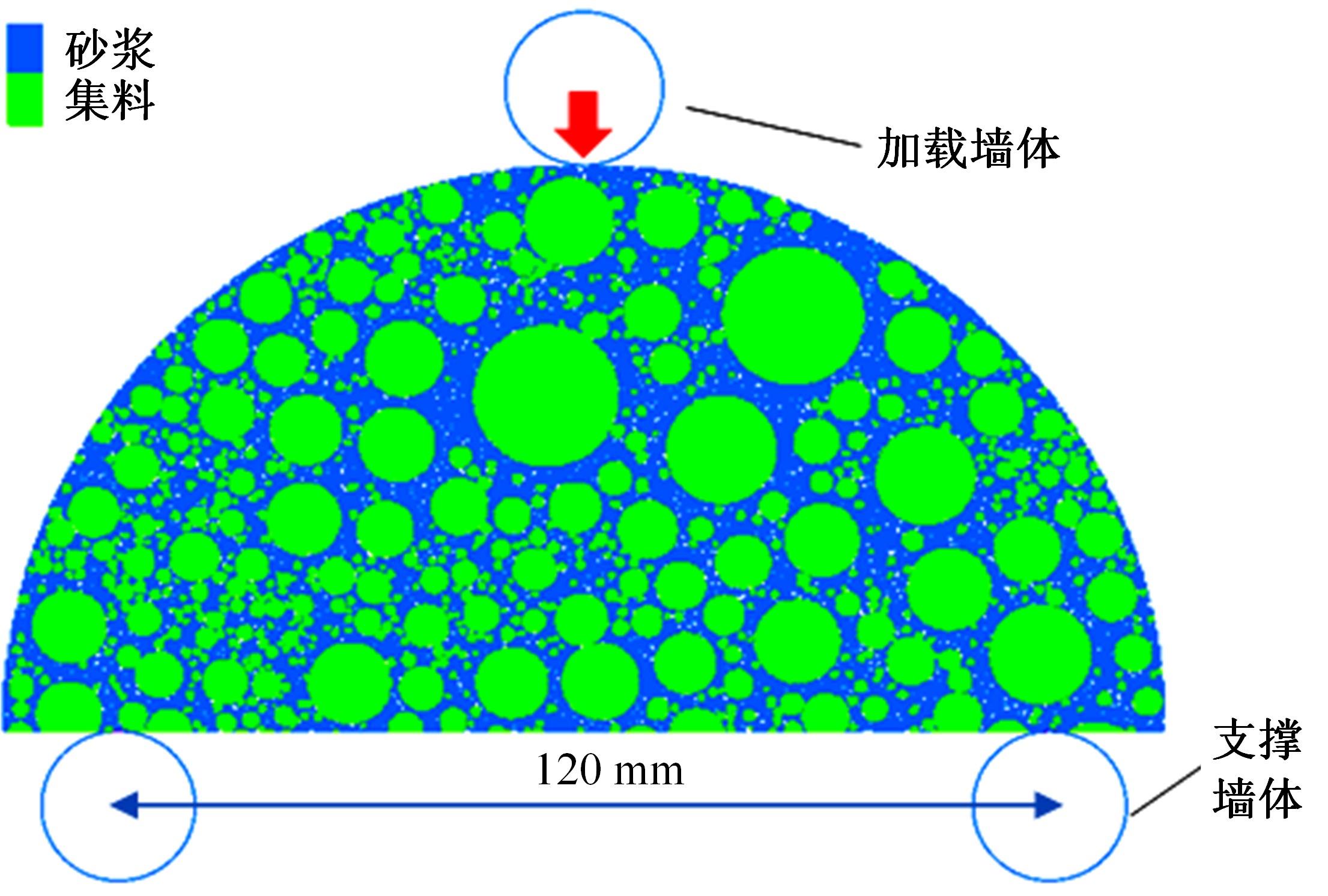

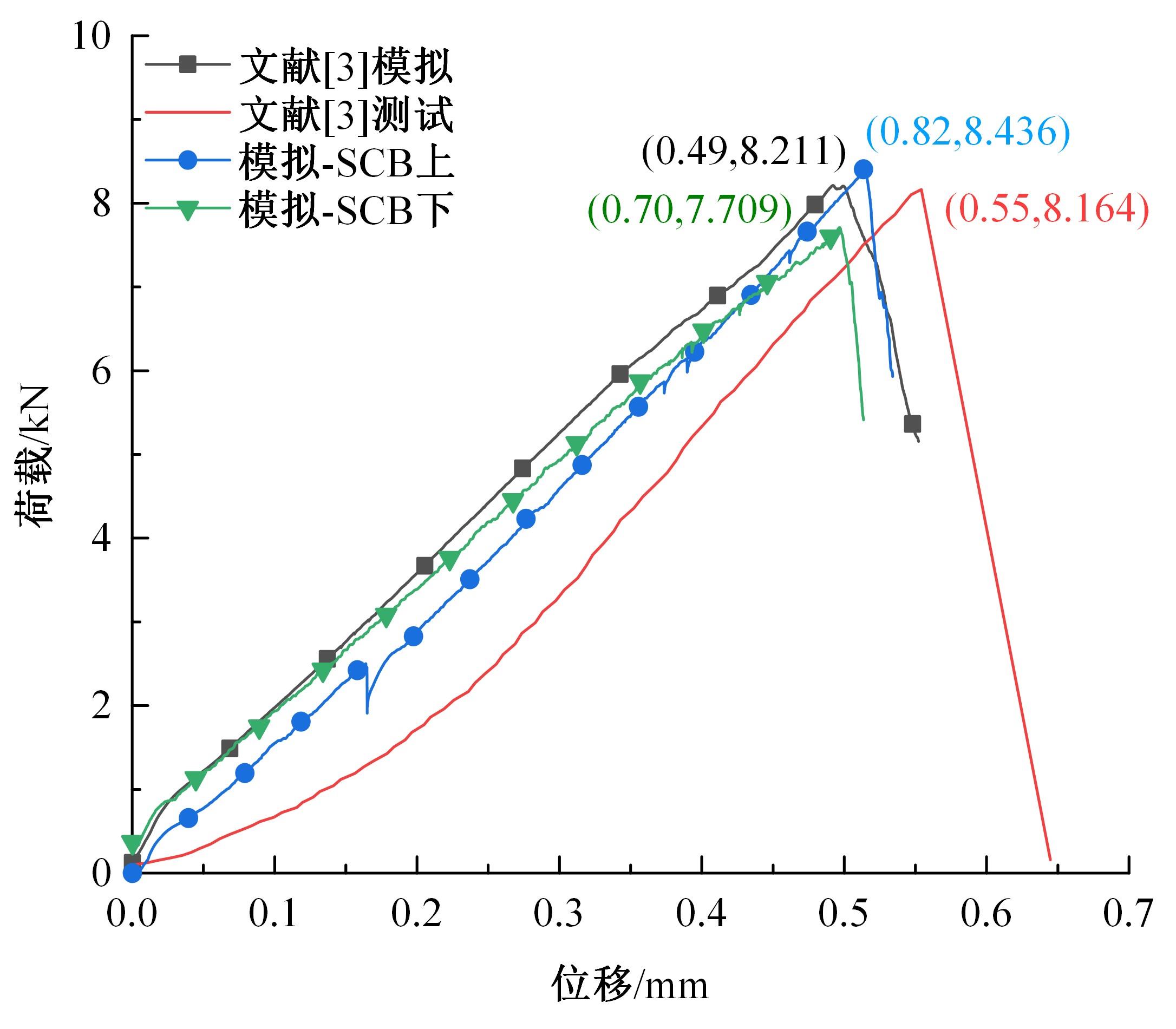

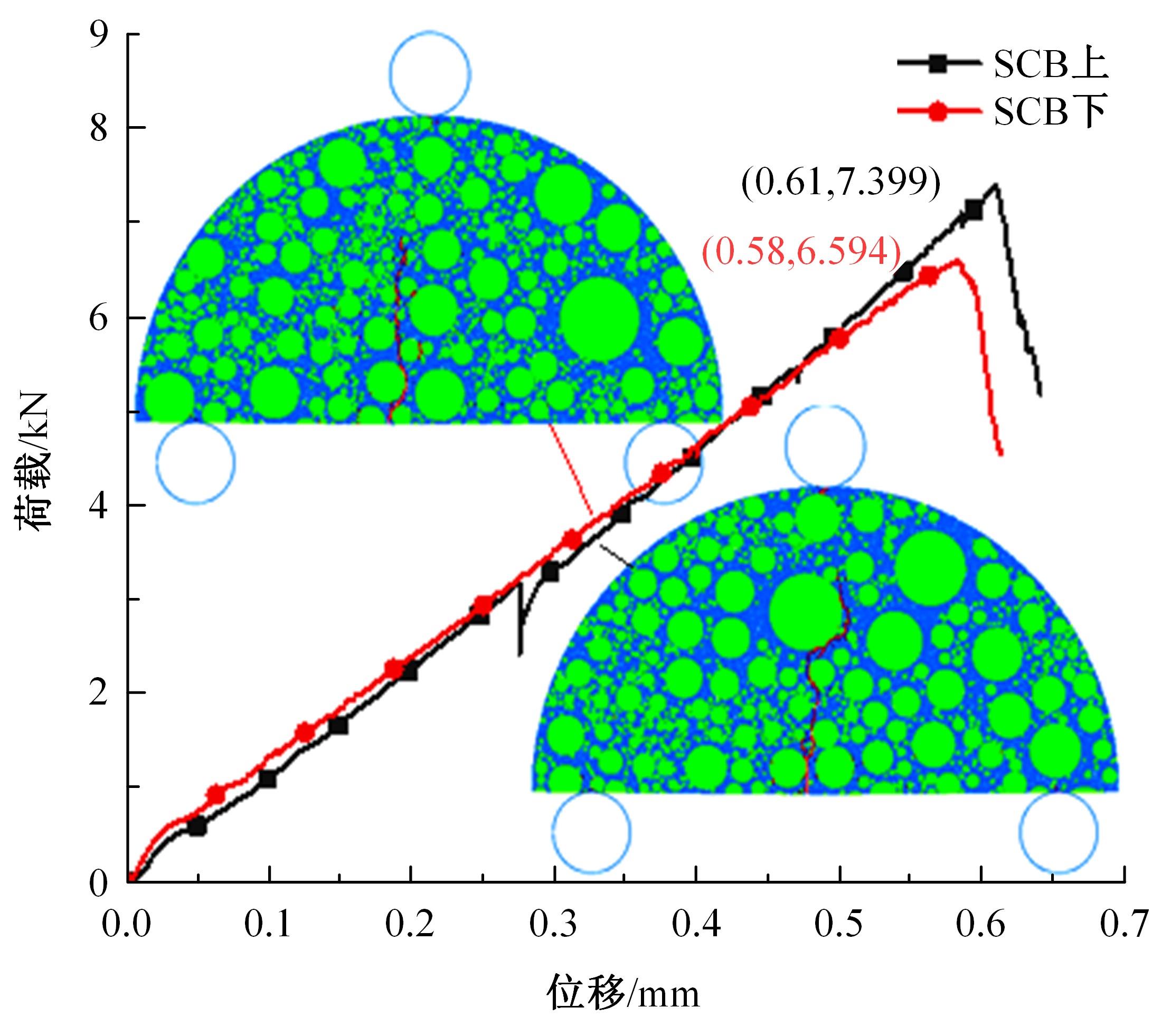

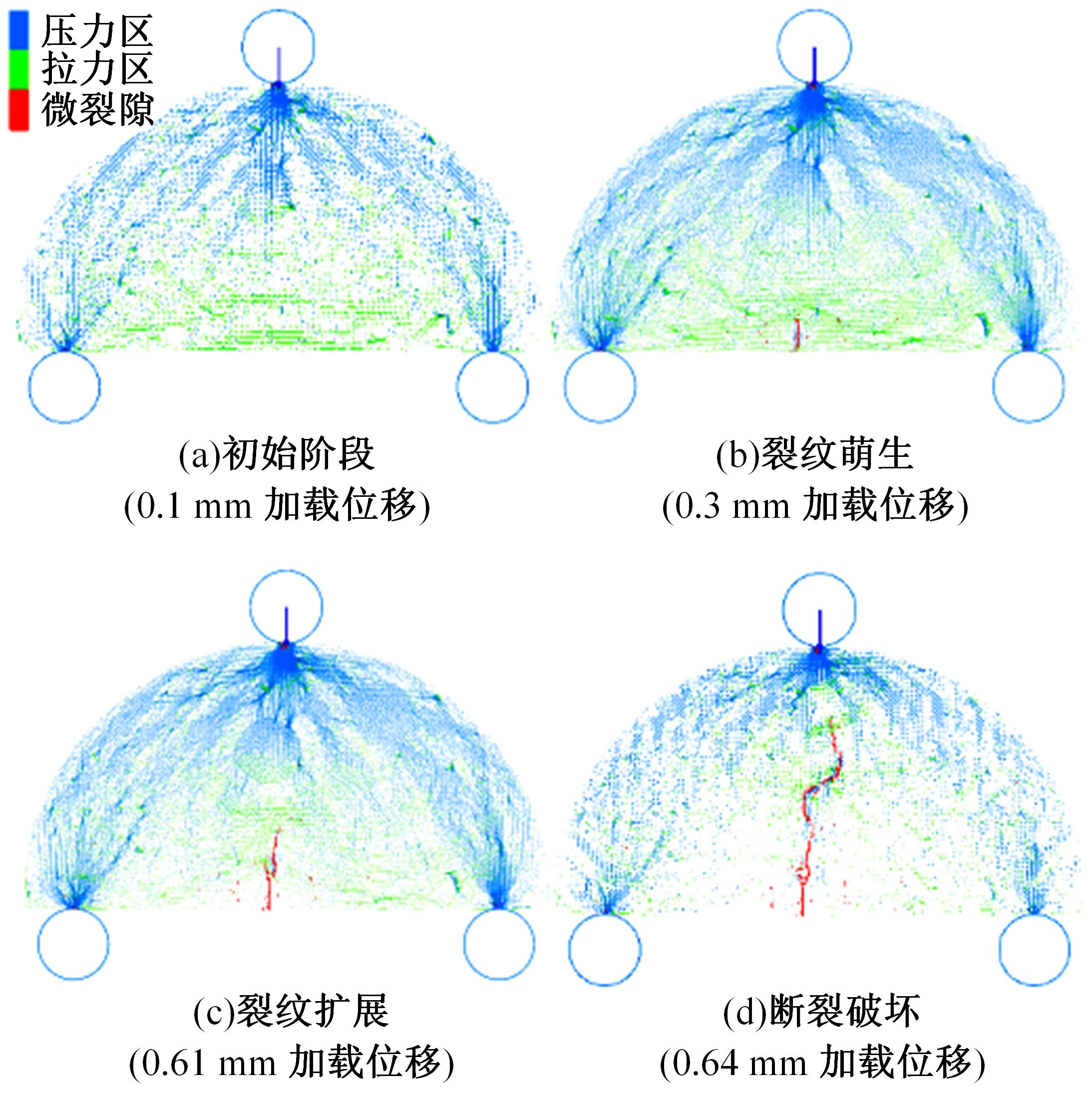

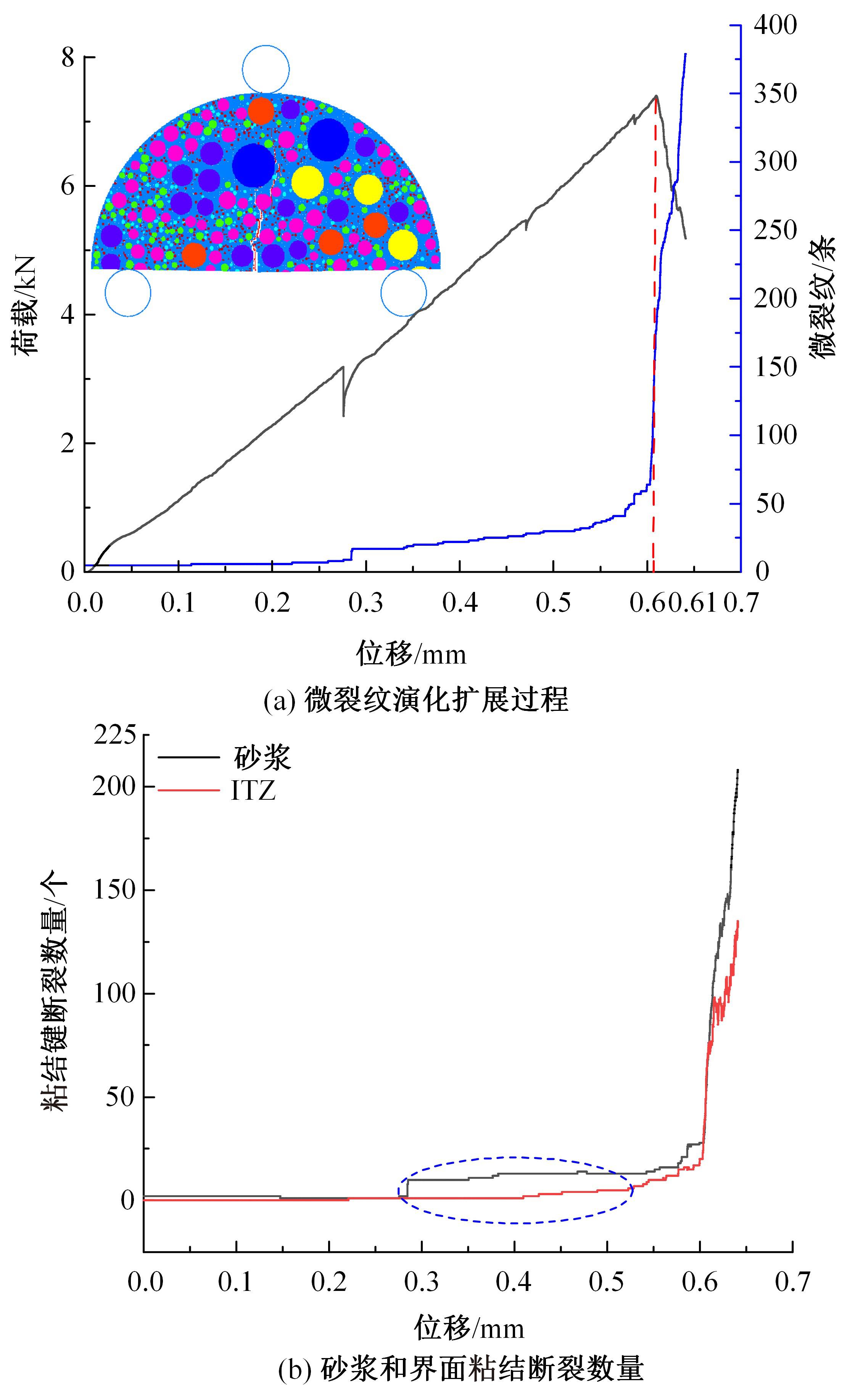

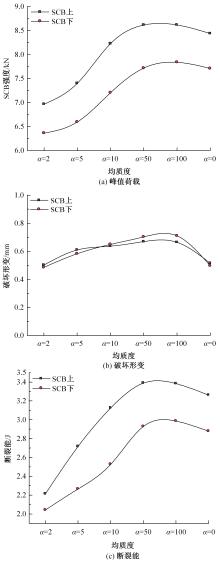

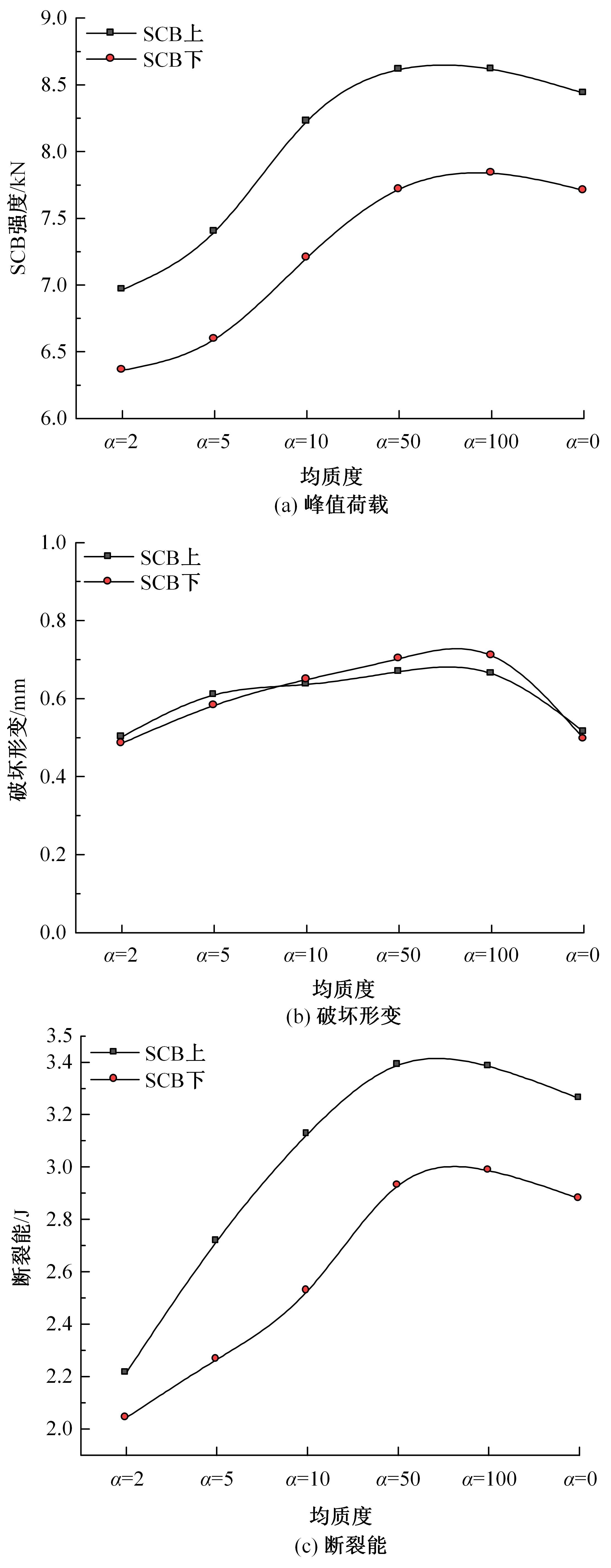

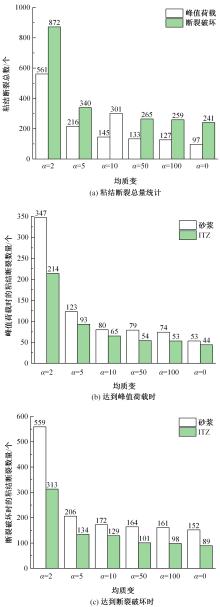

本文采用离散元法(DEM)研究非均质水稳碎石(CSM)材料的细观开裂行为,基于Weibull材料随机场,建立了不同均质度水平的CSM细观断裂模型,通过虚拟半圆弯曲(SCB)试验模拟细观开裂过程,分析砂浆基体均质度的影响。结果表明:CSM裂纹沿着砂浆薄弱点和界面共同扩展,砂浆基体的断裂占主导地位。峰值强度和破坏形变随均质度的提高而增大,砂浆中少量的性能薄弱点有益于改善结构形变特性而提升其整体强度,适当均质度水平有助于CSM材料抗裂性能的发挥。

中图分类号:

- U416.214

| 1 | Chen X Q, Yuan J W, Dong Q, et al. Meso-scale cracking behavior of cement treated base material[J]. Construction and Building Materials, 2020, 239: 117823. |

| 2 | 张阳, 王傲鹏, 张靖霖, 等. 水泥稳定碎石材料干燥收缩研究综述 [J]. 吉林大学学报:工学版, 2023, 53(2): 297-311. |

| Zhang Yang, Wang Ao-peng, Zhang Jing-lin, et al. Dry shrinkage in cement⁃stabilized macadam: a review [J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(2): 297-311. | |

| 3 | 赵晓康, 董侨, 陈雪琴, 等. 考虑初始缺陷的水泥基复合材料细观开裂研究 [J]. 中国公路学报, 2020, 33(10): 230-239. |

| Zhao Xiao-kang, Dong Qiao, Chen Xue-qin, et al. Mesoscale cracking of cement-treated composites with initial defects[J]. China Journal of Highway and Transport, 2020, 33(10): 230-239. | |

| 4 | Dong Q, Zhao X K, Chen X Q, et al. Long-term mechanical properties of in situ semi-rigid base materials[J]. Road Materials and Pavement Design, 2021, 22(7): 1692-1707. |

| 5 | 周正峰, 康玉峰, 罗君豪, 等. 基于黏聚区模型的混凝土细观断裂分析[J]. 东南大学学报:自然科学版, 2021, 51(2): 270-277. |

| Zhou Zheng-feng, Kang Yu-feng, Luo Jun-hao, et al. Mesoscale fracture analysis on concrete based on cohesive zone model[J]. Journal of Southeast University (Natural Science Edition), 2021, 51(2): 270-277. | |

| 6 | 彭勇, 章秀芳, 郭泽宇, 等. 离散元法分析集料接触特性对沥青混合料剪切疲劳寿命的影响[J]. 吉林大学学报:工学版, 2023, 53(1): 178-187. |

| Peng Yong, Zhang Xiu-fang, Guo Ze-yu, et al. Influence of aggregate contact characteristics on shear fatigue life of asphalt mixtures using discrete element method[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(1): 178-187. | |

| 7 | Zhang L F, Xie H, Feng J L. Mesoscale modeling and failure mechanism of concrete considering pore structures and actual aggregate shapes[J]. Construction and Building Materials, 2022, 353: 129133. |

| 8 | Shen Z H, Huang D R, Wang G, et al. A mesoscale bond model for discrete element modeling of irregular cemented granular materials[J]. Computers and Geotechnics, 2022, 152: 105051. |

| 9 | 李崛, 张安顺, 张军辉, 等. 级配碎石基层结构动力响应模型测试及数值分析[J]. 吉林大学学报:工学版, 2023, 53(6): 1782-1789. |

| Li Jue, Zhang An-shun, Zhang Jun-hui, et al. Model testing and numerical analysis of dynamic response of graded crushed rock base structure[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(6): 1782-1789. | |

| 10 | Su X T, Yang Z J, Liu G H. Monte Carlo simulation of complex cohesive fracture in random heterogeneous quasi-brittle materials: a 3D study[J]. International Journal of Solids and Structures, 2010, 47(17): 2336-2345. |

| 11 | 唐欣薇. 基于宏细观力学的混凝土破损行为研究[D]. 北京: 清华大学土木水利学院, 2009. |

| Tang Xin-wei. Study on damage and fracture behavior of concrete based on macro and meso mechanics[D]. Beijing: School of Civil and Hydraulic Engineering, Tsinghua University, 2009. | |

| 12 | 王正鑫. 基于颗粒流离散元法的混凝土冻融损伤单轴试验模拟 [D]. 西安: 西安理工大学水利水电学院, 2018. |

| Wang Zheng-xin. Uniaxial test simulation of concrete freeze-thaw damage based on particle flow discrete element method[D]. Xi'an: School of Water Resources and Hydropower, Xi'an University of Technology, 2018. | |

| 13 | Zhao X K, Dong Q, Yuan J W, et al. Micro-scale characterization of the heterogeneous properties of in-service cement-treated base material[J]. Construction and Building Materials, 2020, 264: No.120696. |

| [1] | 万铜铜,汪海年,郑文华,冯珀楠,陈玉,张琛. 级配碎石层协调沥青混合料层温度收缩变形行为[J]. 吉林大学学报(工学版), 2024, 54(4): 1045-1057. |

| [2] | 陈俊,孙振浩,赵成,吴欣怡,王俊鹏. 相变沥青混凝土复合结构降温效果试验分析[J]. 吉林大学学报(工学版), 2024, 54(1): 180-187. |

| [3] | 唐乃膨,薛晨阳,刘少鹏,朱洪洲,李睿. 胶粉改性沥青老化机理及表征评价研究综述[J]. 吉林大学学报(工学版), 2024, 54(1): 22-43. |

| [4] | 王壮,冯振刚,姚冬冬,崔奇,沈若廷,李新军. 导电沥青混凝土研究进展[J]. 吉林大学学报(工学版), 2024, 54(1): 1-21. |

| [5] | 赵胜前,丛卓红,游庆龙,李源. 沥青-集料黏附和剥落研究进展[J]. 吉林大学学报(工学版), 2023, 53(9): 2437-2464. |

| [6] | 马涛,马源,黄晓明. 基于多元非线性回归的智能压实关键参数最优解[J]. 吉林大学学报(工学版), 2023, 53(7): 2067-2077. |

| [7] | 杨柳,王创业,王梦言,程阳. 设置自动驾驶小客车专用车道的六车道高速公路交通流特性[J]. 吉林大学学报(工学版), 2023, 53(7): 2043-2052. |

| [8] | 周正峰,于晓涛,陶雅乐,郑茂,颜川奇. 基于灰色关联分析的树脂与弹性体高黏沥青高温性能评价[J]. 吉林大学学报(工学版), 2023, 53(7): 2078-2088. |

| [9] | 张青霞,侯吉林,安新好,胡晓阳,段忠东. 基于车辆脉冲响应的路面不平度识别方法[J]. 吉林大学学报(工学版), 2023, 53(6): 1765-1772. |

| [10] | 姜屏,陈业文,陈先华,张伟清,李娜,王伟. 改性石灰土在干湿和冻融循环下的无侧限抗压性能[J]. 吉林大学学报(工学版), 2023, 53(6): 1809-1818. |

| [11] | 司春棣,崔亚宁,许忠印,凡涛涛. 层间粘结失效后桥面沥青铺装层细观力学行为分析[J]. 吉林大学学报(工学版), 2023, 53(6): 1719-1728. |

| [12] | 李岩,张久鹏,陈子璇,黄果敬,王培. 基于PCA-PSO-SVM的沥青路面使用性能评价[J]. 吉林大学学报(工学版), 2023, 53(6): 1729-1735. |

| [13] | 刘状壮,郑文清,郑健,李轶峥,季鹏宇,沙爱民. 基于网格化的路表温度感知技术[J]. 吉林大学学报(工学版), 2023, 53(6): 1746-1755. |

| [14] | 赵晓康,胡哲,张久鹏,裴建中,石宁. 基于光纤传感技术的路面结冰智能监测研究进展[J]. 吉林大学学报(工学版), 2023, 53(6): 1566-1579. |

| [15] | 惠冰,杨心怡,张乐扬,李扬. 检测车轨迹偏移对沥青路面磨耗计算误差的影响[J]. 吉林大学学报(工学版), 2023, 53(6): 1756-1764. |

|

||