吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (2): 422-434.doi: 10.13229/j.cnki.jdxbgxb20200823

• 车辆工程·机械工程 • 上一篇

过滤壁结构对颗粒捕集器深床过滤影响的模拟

李志军1( ),刘浩1,张立鹏2(

),刘浩1,张立鹏2( ),李振国3,邵元凯3,李智洋1

),李振国3,邵元凯3,李智洋1

- 1.天津大学 内燃机燃烧学国家重点实验室,天津 300072

2.天津内燃机研究所,天津 300072

3.中国汽车技术研究中心有限公司,天津 300300

Simulation on influence of microstructure of the wall on deep bed filtration of particulate filter

Zhi-jun LI1( ),Hao LIU1,Li-peng ZHANG2(

),Hao LIU1,Li-peng ZHANG2( ),Zhen-guo LI3,Yuan-kai SHAO3,Zhi-yang LI1

),Zhen-guo LI3,Yuan-kai SHAO3,Zhi-yang LI1

- 1.State Key Laboratory of Engines,Tianjin University,Tianjin 300072,China

2.Tianjin Internal Combustion Engine Research Institute,Tianjin 300072,China

3.China Automotive Technology and Research Center Limited Company,Tianjin 300300,China

摘要:

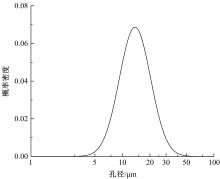

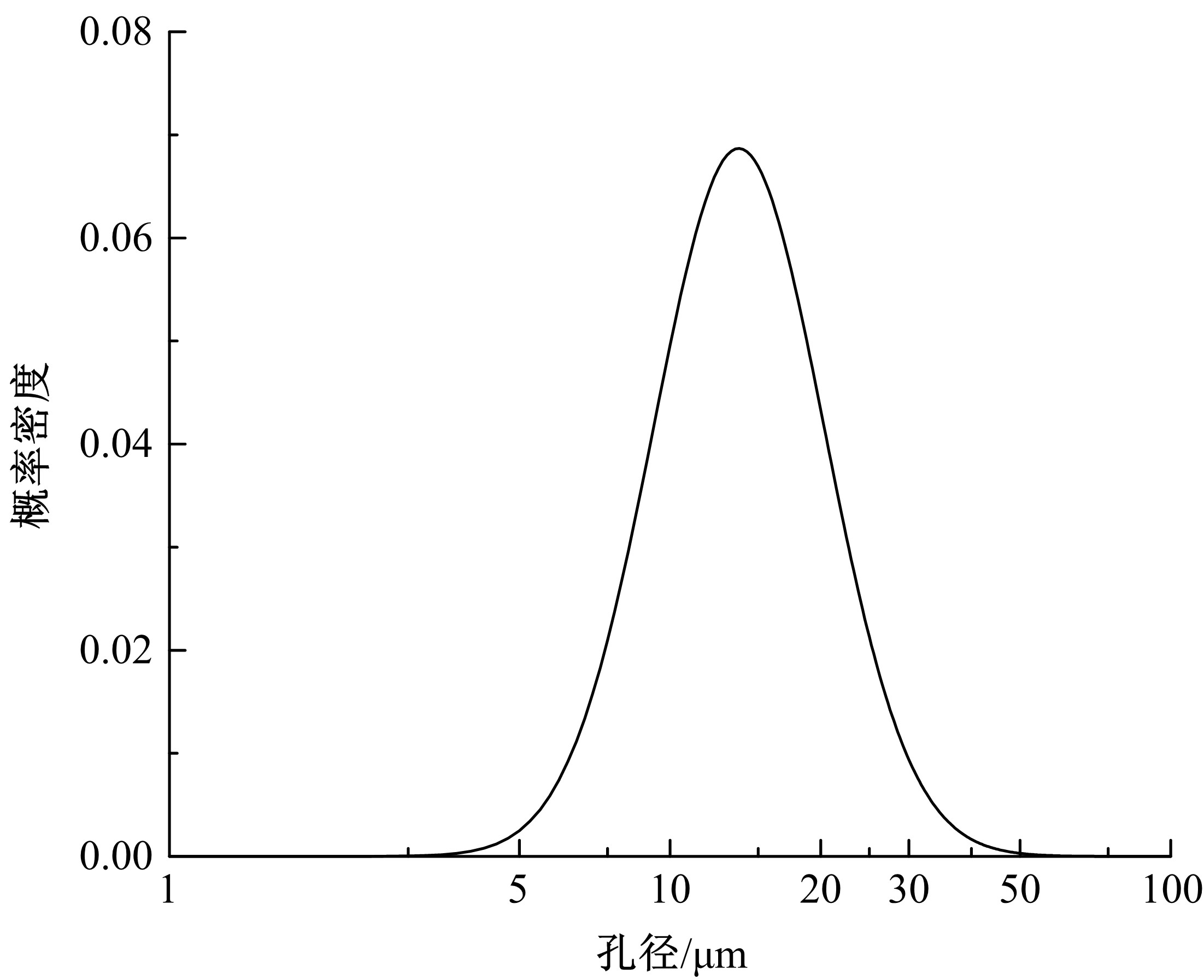

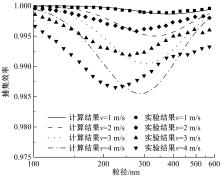

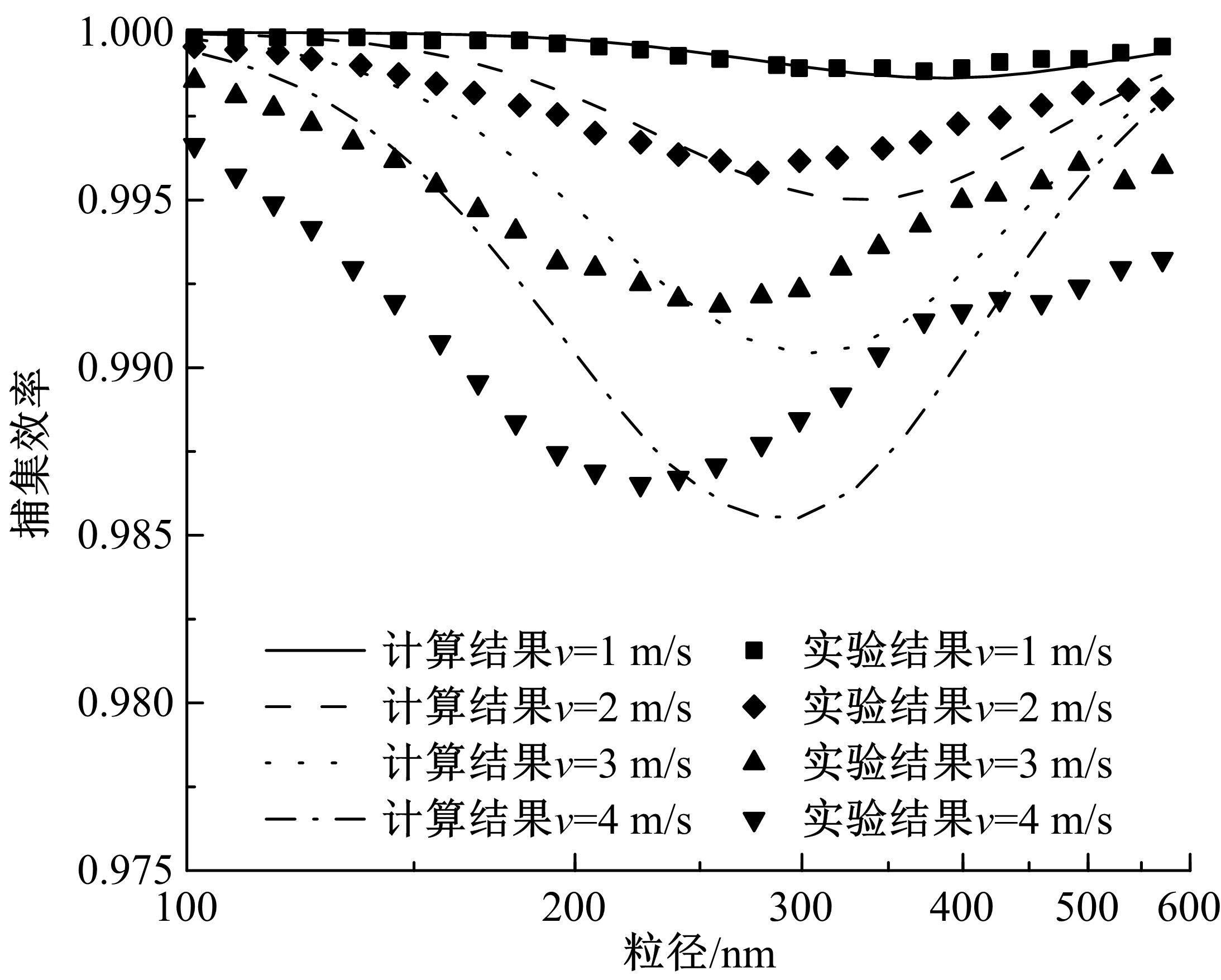

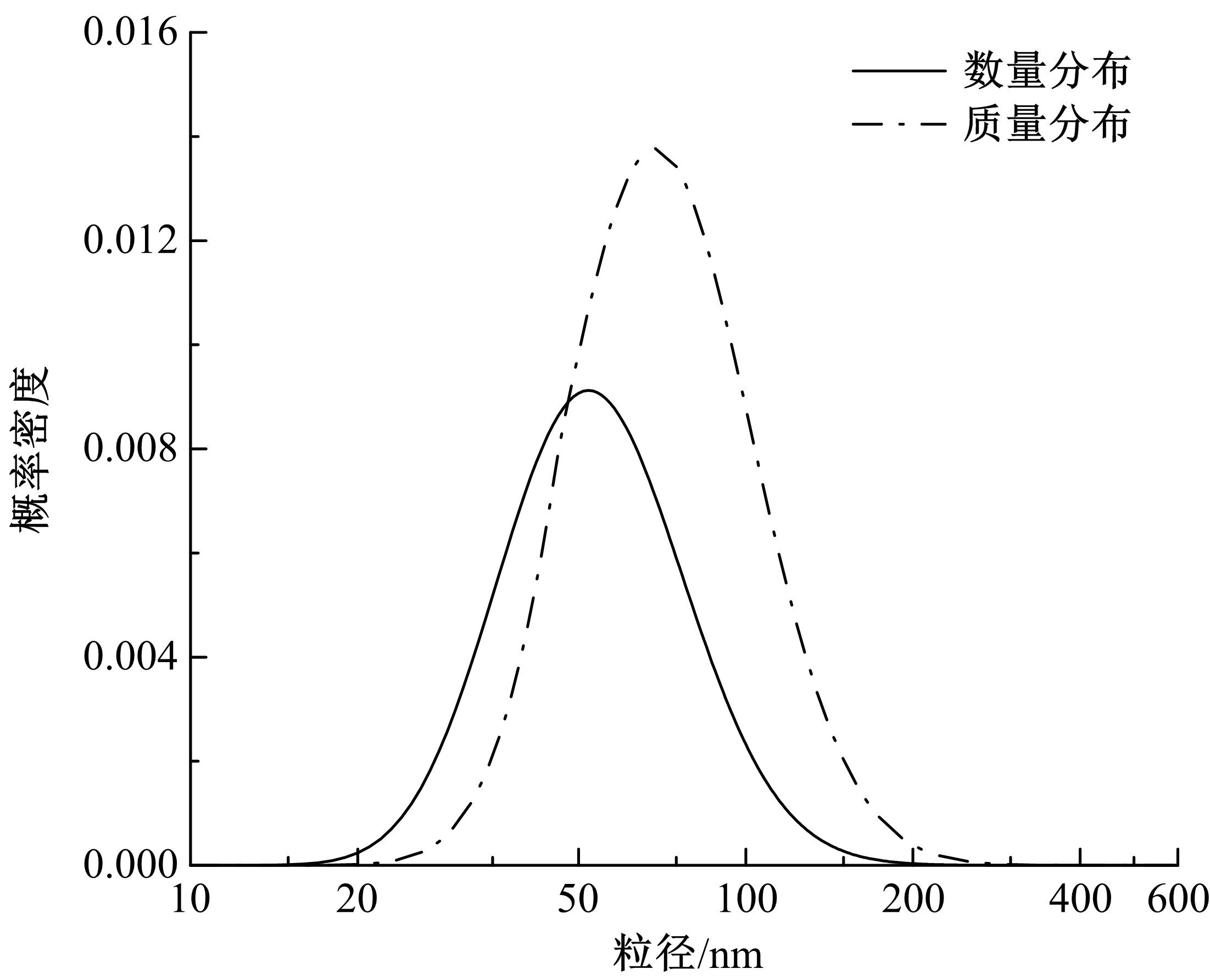

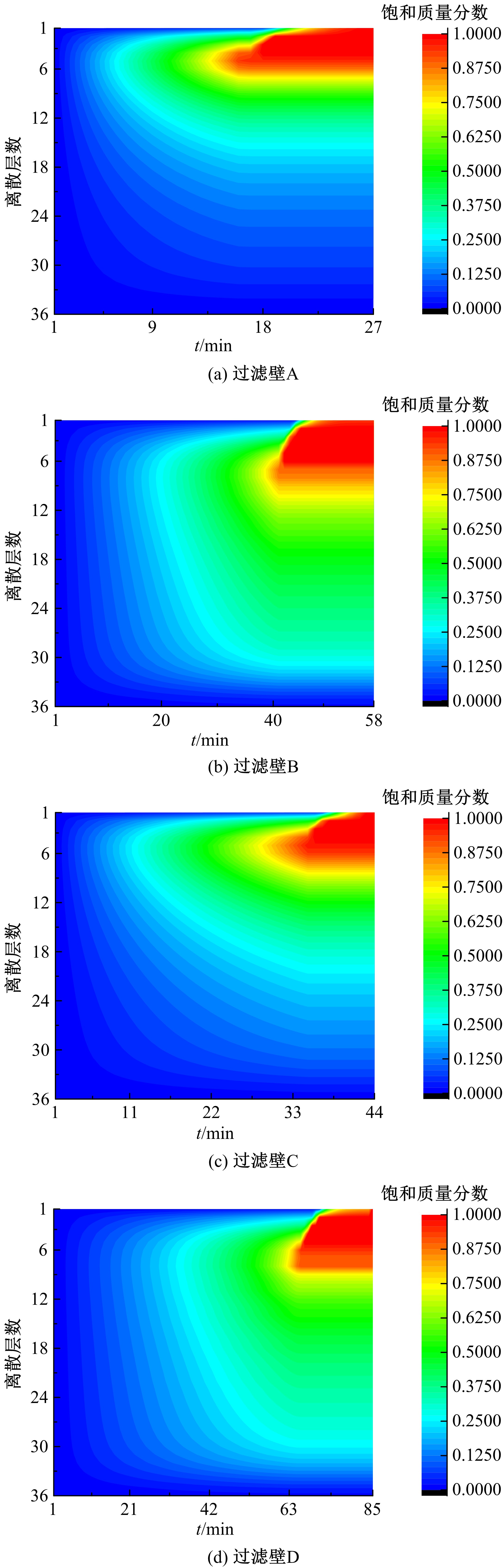

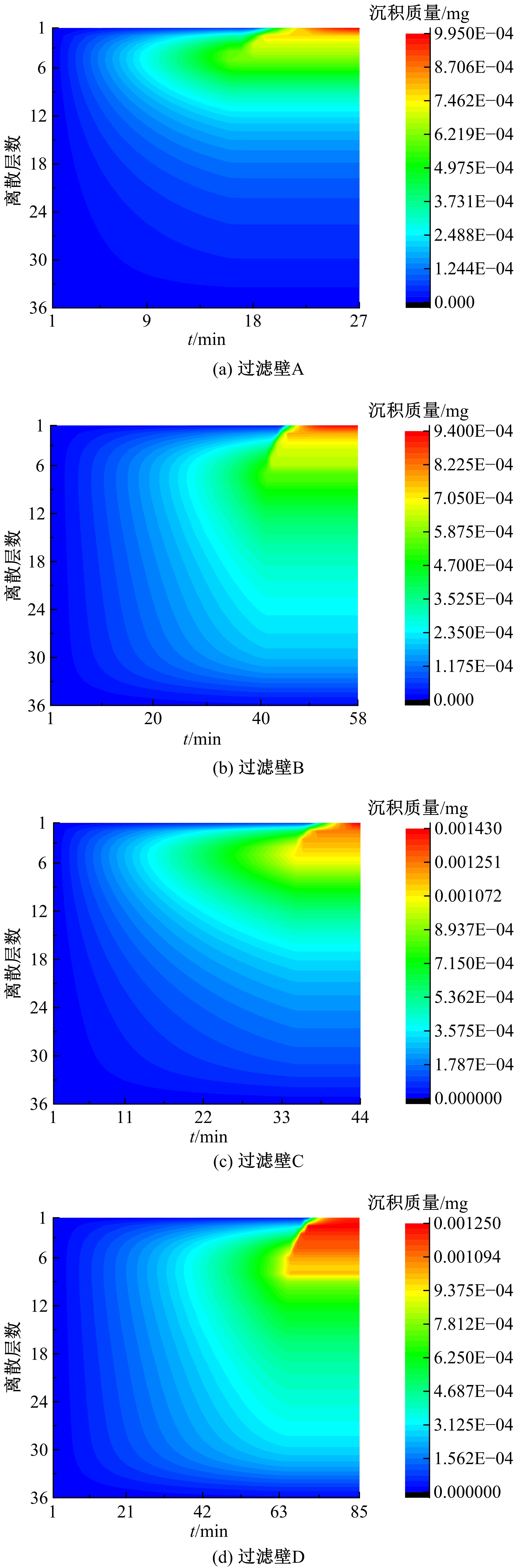

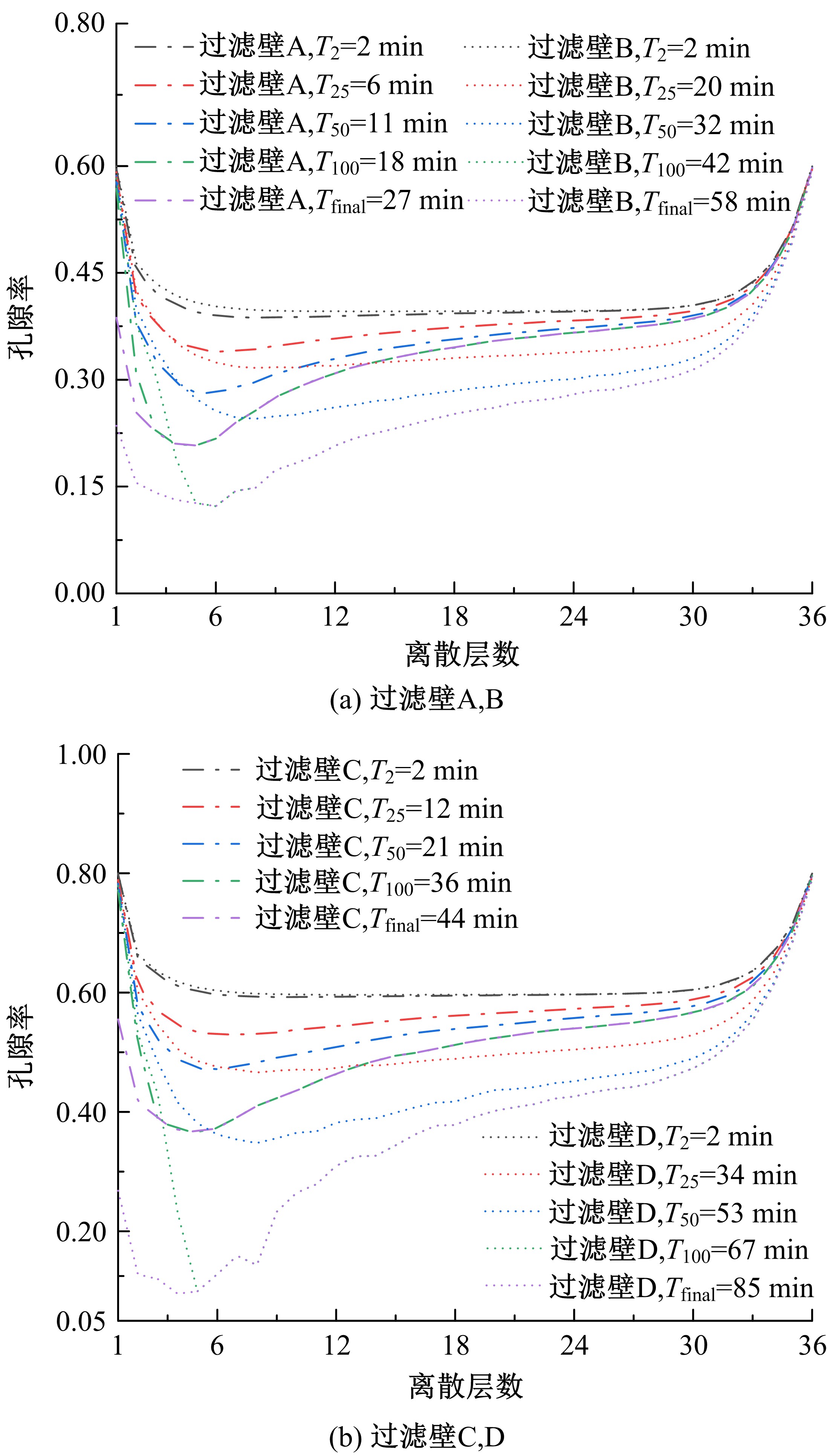

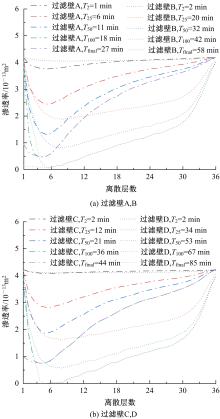

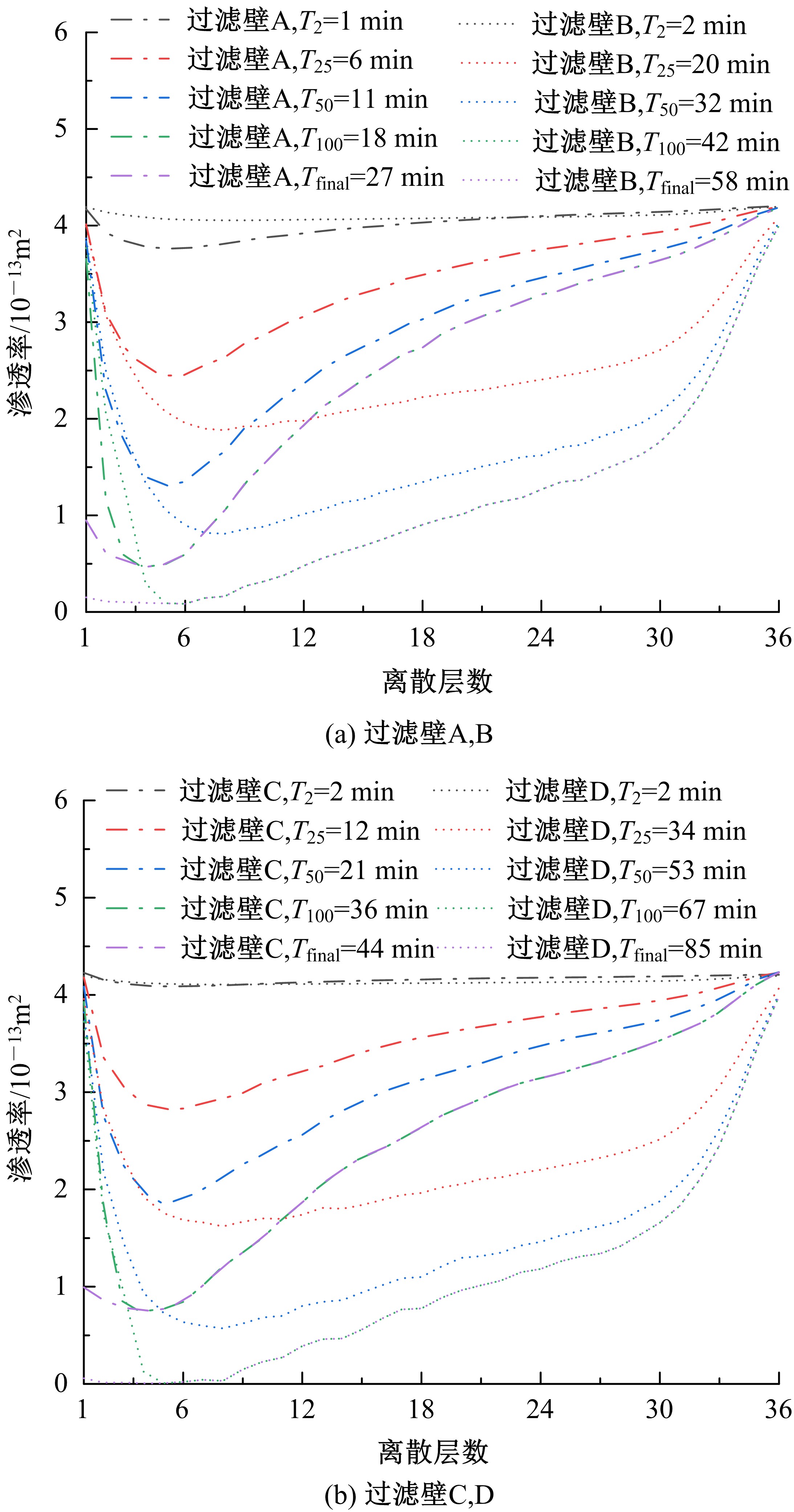

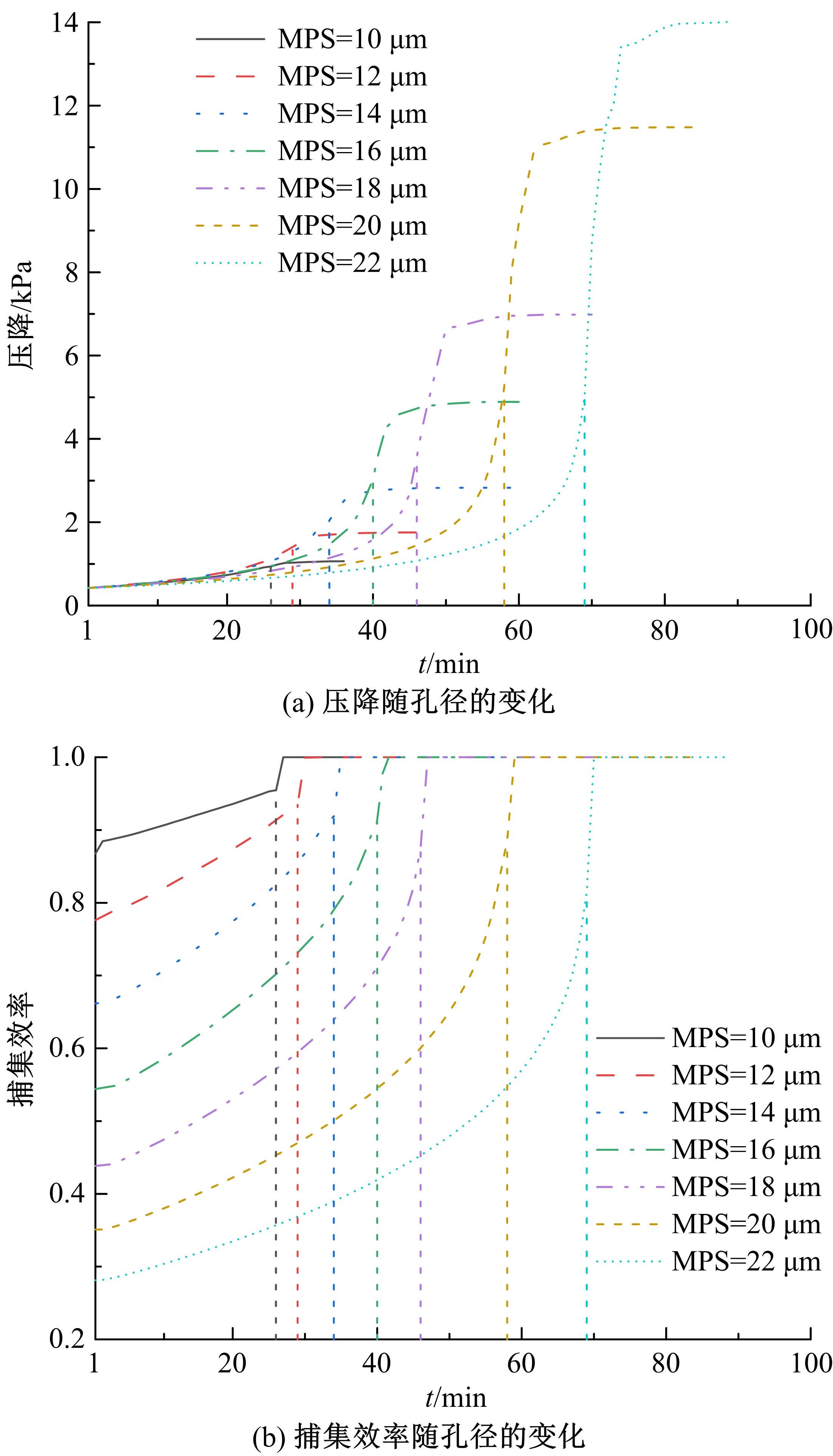

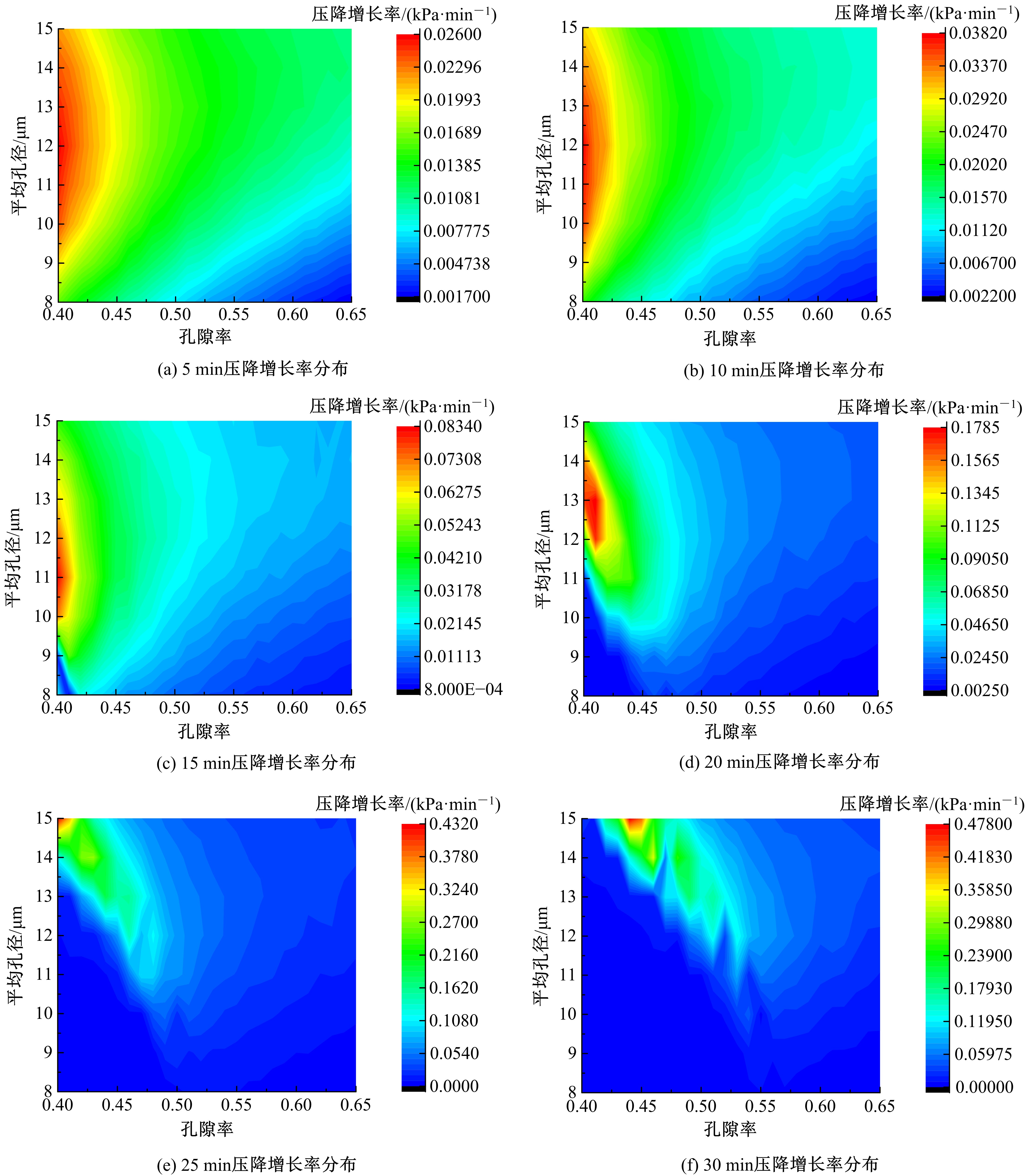

针对汽油机颗粒捕集器的动态捕集过程及性能,采用孔径分布概率密度函数以及孔隙率分布函数表征多孔介质的非均匀微观结构,并引入对数正态分布描述入射颗粒粒径分布,研究多粒径颗粒入射状态下过滤壁微观结构对GPF深床过滤过程的影响。结果表明:颗粒物大部分沉积于多孔壁上部1/3左右区域,孔径增大会导致沉积位置向下扩大以及孔隙率、渗透率分布的均匀性提高,而孔隙率变化则对颗粒沉积位置影响较小;相对于孔隙率变化,多孔介质的捕集效率及压降性能对于孔径变化的敏感性更高;大孔隙率小孔径结构的多孔介质具有较高的捕集效率与最好的压降性能。

中图分类号:

- TK411

| 1 | Shanahan C S, Smith S S, Sears B D. A general method for fouling injectors in gasoline direct injection vehicles and the effects of deposits on vehicle performance[J]. SAE International Journal of Fuels and Lubricants, 2017, 10(3): 778-788. |

| 2 | Chan T W, Meloche E, Kubsh J, et al. Evaluation of a gasoline particulate filter to reduce particle emissions from a gasoline direct injection vehicle[J]. SAE International Journal of Fuels and Lubricants, 2012, 5(3): 1277-1290. |

| 3 | Graskow B R, Kittelson D B, Ahmadi M R, et al. Exhaust particulate emissions from a direct injection spark ignition engine[J]. SAE Transactions, 1999(1): 602-609. |

| 4 | 胡志远, 赵心语, 夏孝程, 等. 国Ⅵ GDI汽油车颗粒物排放特性与微观形貌特征[J]. 同济大学学报: 自然科学版, 2020, 48(2): 241-248. |

| Hu Zhi-yuan, Zhao Xin-yu, Xia Xiao-cheng, et al. Emission characteristics and microscopic morphology of particles from a gasoline direct injection vehicle based on china Ⅵ emission regulation[J]. Journal of Tongji University(Natural Science), 2020, 48(2): 241-248. | |

| 5 | Hiroshi O, Preechar K, Katsunori H. Visualization of oxidation of soot nanoparticles trapped on a diesel particulate membrane filter[J]. SAE International Journal of Engines, 2011, 4(1): 515-526. |

| 6 | Park K, Cao F, Kittelson D B, et al. Relationship between particle mass and mobility for diesel exhaust particles[J]. Environmental Science & Technology, 2003, 37(3): 577-583. |

| 7 | Zelenyuk A, Wilson J, Imre D, et al. Detailed characterization of particulate matter emitted by lean-burn gasoline direct injection engine[J]. International Journal of Engine Research, 2016, 18(5/6): 560-572. |

| 8 | Zervas E, Dorlhène P, Daviau R, et al. Repeatability of fine particle measurement of diesel and gasoline vehicles exhaust gas[J]. SAE Technical Papers, 2004-01-1983. |

| 9 | Montajir R M, Kawai T, Goto Y, et al. Thermal conditioning of exhaust gas: potential for stabilizing diesel nano-particles[C]∥SAE 2005 World Congress & Exhibition, Japan, 2005-01-0187. |

| 10 | 潘锁柱. 缸内直喷汽油机排气微粒物理化学特征的研究[D]. 天津: 天津大学机械工程学院,2012. |

| Pan Suo-zhu. Study on the physicochemical characteristics of exhaust particulates from gasoline direct injection engine[D]. Tianjin: School of Mechanical Engineering, Tianjin University, 2012. | |

| 11 | Kittelson D B. Engines and nanoparticles: a review[J]. Journal of Aerosol Science, 1998, 29(5/6):575-588. |

| 12 | Raatz T, Mueller E. Examination of particle size distribution of homogeneous and conventional diesel combustion[C]∥ SAE Technical Paper, 2001-01-3576. |

| 13 | Schneider J, Hock N, Weimer S, et al. Nucleation particles in diesel exhaust: composition inferred from in situ mass spectrometric analysis[J]. Environmental Science & Technology, 2005, 39(16): 6153-6161. |

| 14 | Sementa P, Maria V B, Catapano F. Thermodynamic and optical characterizations of a high performance GDI engine operating in homogeneous and stratified charge mixture conditions fueled with gasoline and bioethanol[J]. Fuel, 2011, 90(7): 204-219. |

| 15 | Gong J, Stewart M L, Zelenyuk A, et al. Importance of filter's microstructure in dynamic filtration modeling of gasoline particulate filters (GPFs): inhomogeneous porosity and pore size distribution[J]. Journal of Chemical Engineering, 2018, 338: 15-26. |

| 16 | Cho H K, Park C G, Shin H J, et al. Comparison of the in vitro toxicological activity of various particulate matter[J]. Toxicology and Industrial Health, 2018, 34(2): 99-109. |

| 17 | 鲍晓峰, 吕猛, 朱仁成. 中国轻型汽车排放控制标准的进展[J]. 汽车安全与节能学报, 2017, 8(3): 213-225. |

| Bao Xiao-feng, Lv Meng, Zhu Ren-cheng. Progress of emission control standards for light-duty vehicles in China [J]. Journal of Automotive Safety and Energy, 2017, 8(3): 213-225. | |

| 18 | Swanson J, Watts W, Kittelson D, et al. Filtration efficiency and pressure drop of miniature diesel particulate filters[J]. Aerosol Science and Technology, 2013, 47(4): 452-461. |

| 19 | Ohno K, Taoka N, Furuta T, et al. Characterization of high porosity SiC-DPF[C]∥SAE Technical Paper, 2002-01-0325. |

| 20 | Konstandopoulos A G, Skaperdas E, Masoudi M. Microstructural properties of soot deposits in diesel particulate traps[C]∥SAE Technical Paper, 2002-01-1015. |

| 21 | Viswanathan S, Rothamer D, Sakai S, et al. Effect of particle size distribution on the deep-bed capture efficiency of an exhaust particulate filter[J]. Journal of Engineering for Gas Turbines and Power, 2015, 137(10): 101504. |

| 22 | Adam F, Olfert J, Wong K F, et al. Effect of engine-out soot emissions and the frequency of regeneration on gasoline particulate filter ef-ficiency[C]∥SAE Technical Paper, 2020-01-1431. |

| 23 | Liu X, Chanko T, Lambert C, et al. Gasoline particulate filter efficiency and backpressure at very low mileage[C]∥SAE Technical Paper, 2018-01-1259. |

| 24 | Joshi A, Johnson T V. Gasoline particulate filters—a review[J]. Emission Control Science and Technology, 2018, 4(4): 219-239. |

| 25 | Li X, Dallmann T R, May A A, et al. Size distribution of vehicle emitted primary particles measured in a traffic tunnel[J]. Atmospheric Environment, 2018, 191: 9-18. |

| 26 | Merkel G A, Beall D M, Hickman D L, et al. Effects of microstructure and cell geometry on performance of cordierite diesel particulate filters[C]∥SAE Technical Paper, 2001-01-0193. |

| 27 | Gong J, Rutland C J. PDF-based heterogeneous multiscale filtration model[J]. Environmental Science & Technology, 2015, 49(8): 4963-4970. |

| 28 | Václavík M, Plachá M, Kočí P, et al. Structure characterisation of catalytic particulate filters for automotive exhaust gas aftertreatment[J]. Materials Characterization, 2017, 134: 311-318. |

| 29 | Gong J, Viswanathan S, Rothamer D A, et al. Dynamic heterogeneous multiscale filtration model: probing microand macroscopic filtration characteristics of gasoline particulate filters[J]. Environ Sci Technol, 2017, 51(19): 11196-11204. |

| 30 | Karin P, Cui L, Rubio P, et al. Microscopic visualization of PM trapping and regeneration in micro-structural pores of a DPF wall[J]. SAE International Journal of Fuels and Lubricants, 2009, 2(1): 661-669. |

| 31 | Konstandopoulos A G, Skaperdas K, Evangelos M, et al. Fundamental studies of diesel particulate filters transient loading regeneration and aging[C]∥SAE Technical Paper, 2000-01-1016. |

| 32 | Serrano J R, Climent H, Piqueras P, et al. Filtration modelling in wall-flow particulate filters of low soot penetration thickness[J]. Energy, 2016, 112: 883-898. |

| 33 | Serrano J R, Arnau F J, Piqueras P, et al. Packed bed of spherical particles approach for pressure drop prediction in wall-flow DPFs (diesel particulate filters) under soot loading conditions[J]. Energy, 2013, 58: 644-654. |

| 34 | Marre S, Palmeri J, Larbot A, et al. Modeling of submicrometer aerosol penetration through sintered granular membrane filters[J]. Journal of Colloid & Interface Science, 2004, 274(1): 167-182. |

| 35 | Saito C, Nakatani T, Miyairi Y, et al. New particulate filter concept to reduce particle number emissions[C]∥SAE Technical Paper, 2011-01-0814. |

| [1] | 赵庆武,程勇,杨雪,王宁. 高重频纳秒脉冲放电点火系统设计[J]. 吉林大学学报(工学版), 2021, 51(2): 414-421. |

| [2] | 王忠,李游,张美娟,刘帅,李瑞娜,赵怀北. 柴油机排气阶段颗粒碰撞过程动力学特征分析[J]. 吉林大学学报(工学版), 2021, 51(1): 39-48. |

| [3] | 胡云峰,丁一桐,赵志欣,蒋冰晶,高金武. 柴油发动机燃烧过程数据驱动建模与滚动优化控制[J]. 吉林大学学报(工学版), 2021, 51(1): 49-62. |

| [4] | 王建,许鑫,顾晗,张多军,刘胜吉. 基于排气热管理的柴油机氧化催化器升温特性[J]. 吉林大学学报(工学版), 2020, 50(2): 408-416. |

| [5] | 宋昌庆,陈文淼,李君,曲大为,崔昊. 不同当量比下单双点火对天然气燃烧特性的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 1929-1935. |

| [6] | 朱一骁,何小民,金义. 联焰板宽度对单凹腔驻涡燃烧室流线形态的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 1936-1944. |

| [7] | 刘长铖,刘忠长,田径,许允,杨泽宇. 重型增压柴油机燃烧过程中的缸内㶲损失[J]. 吉林大学学报(工学版), 2019, 49(6): 1911-1919. |

| [8] | 胡潇宇,李国祥,白书战,孙柯,李思远. 考虑加热面粗糙度和材料的沸腾换热修正模型[J]. 吉林大学学报(工学版), 2019, 49(6): 1945-1950. |

| [9] | 王德军,吕志超,王启明,张建瑞,丁建楠. 基于EKF及调制傅式级数的缸压辨识[J]. 吉林大学学报(工学版), 2019, 49(4): 1174-1185. |

| [10] | 臧鹏飞,王哲,高洋,孙晨乐. 直线电机/发动机系统稳态运行综合控制策略[J]. 吉林大学学报(工学版), 2019, 49(3): 798-804. |

| [11] | 董伟,宋佰达,邱立涛,孙昊天,孙平,蒲超杰. 直喷汽油机暖机过程中两次喷射比例对燃烧和排放的影响[J]. 吉林大学学报(工学版), 2018, 48(6): 1755-1761. |

| [12] | 李志军, 汪昊, 何丽, 曹丽娟, 张玉池, 赵新顺. 催化型微粒捕集器碳烟分布及其影响因素[J]. 吉林大学学报(工学版), 2018, 48(5): 1466-1474. |

| [13] | 林学东, 江涛, 许涛, 李德刚, 郭亮. 高压共轨柴油机起动工况高压泵控制策略[J]. 吉林大学学报(工学版), 2018, 48(5): 1436-1443. |

| [14] | 秦静, 徐鹤, 裴毅强, 左子农, 卢莉莉. 初始温度和初始压力对甲烷-甲醇裂解气预混层流燃烧特性的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1475-1482. |

| [15] | 宫洵, 蒋冰晶, 胡云峰, 曲婷, 陈虹. 柴油机主-从双微元Urea-SCR系统非线性状态观测器设计与分析[J]. 吉林大学学报(工学版), 2018, 48(4): 1055-1062. |

|

||