吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (3): 533-540.doi: 10.13229/j.cnki.jdxbgxb20210334

• 车辆工程·机械工程 • 上一篇

RP-3航空煤油的润滑特性和改善措施

- 1.上海交通大学 动力机械与工程教育部重点实验室,上海 200240

2.上海交通大学 中英国际低碳学院,上海 201306

RP⁃3 jet fuel lubricity and improvement measurements

Tong-bin ZHAO1( ),Yi-sheng WU2,Yao-zong DUAN1,Zhen HUANG1,Dong HAN1,2(

),Yi-sheng WU2,Yao-zong DUAN1,Zhen HUANG1,Dong HAN1,2( )

)

- 1.Key Laboratory for Power Machinery and Engineering,Ministry of Education,Shanghai Jiao Tong University,Shanghai 200240,China

2.China-UK Low Carbon College,Shanghai Jiao Tong University,Shanghai 201306,China

摘要:

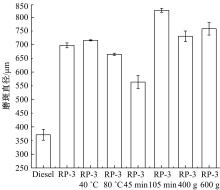

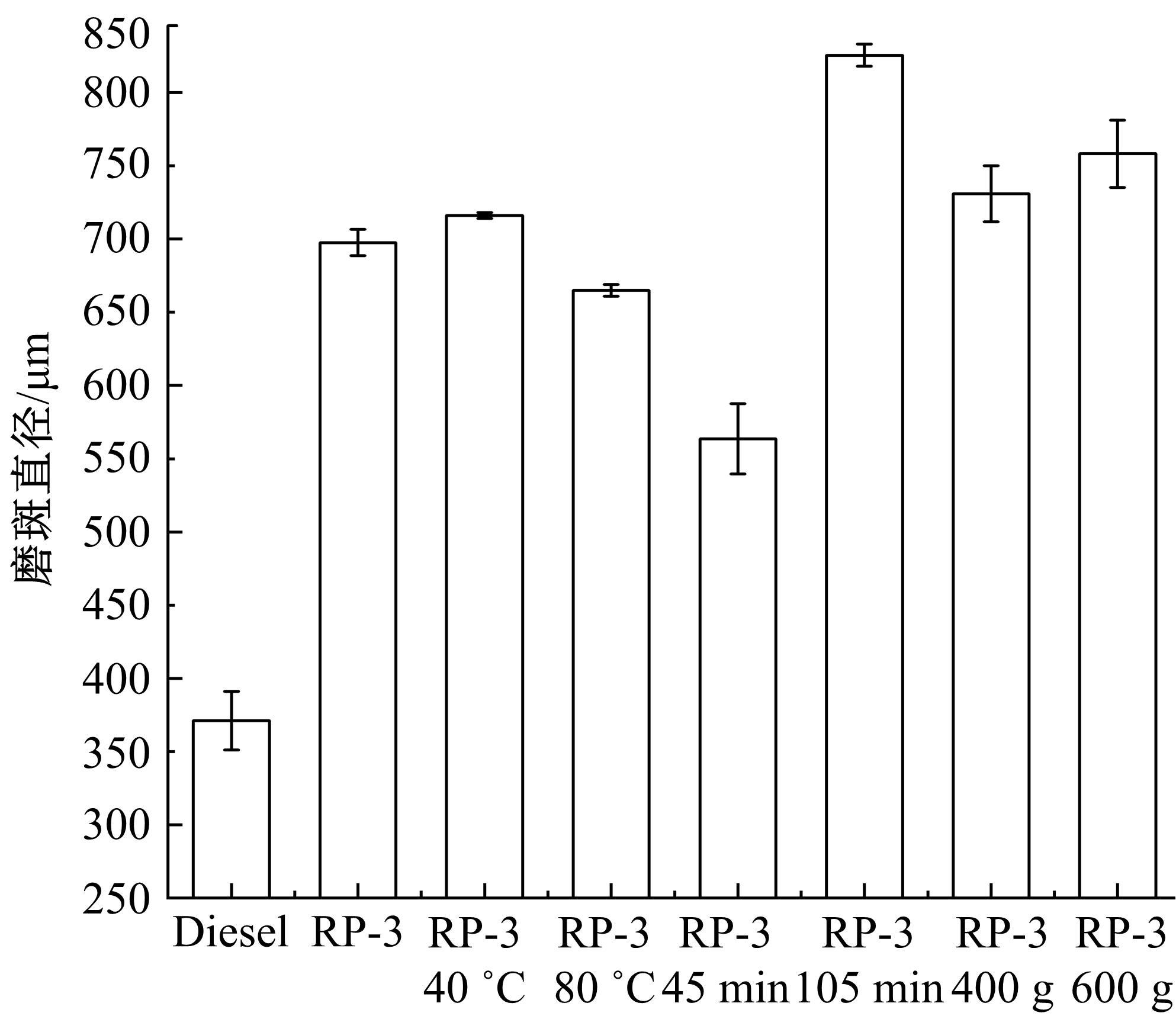

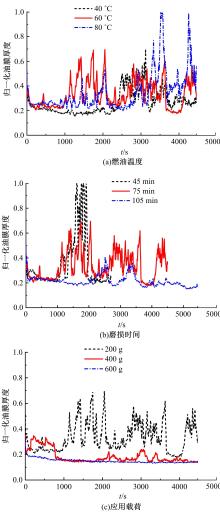

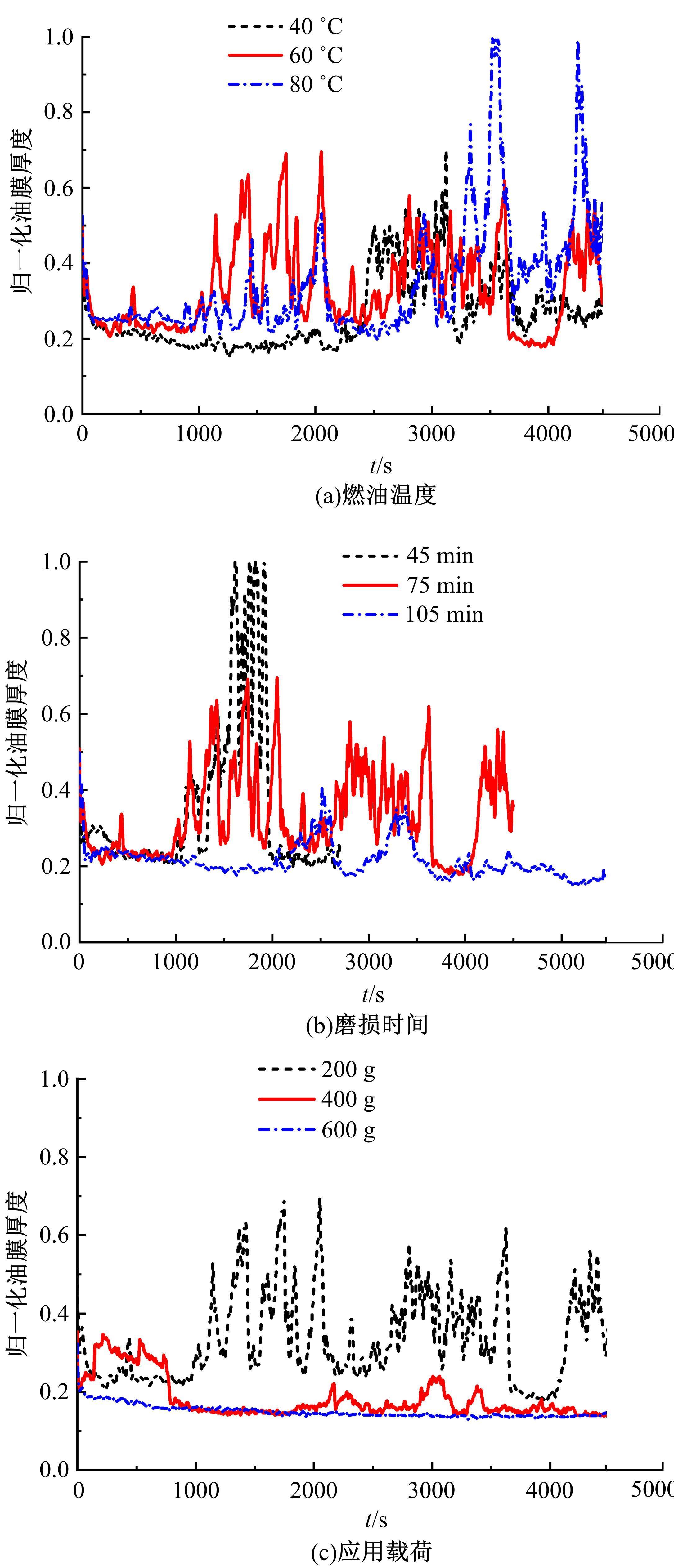

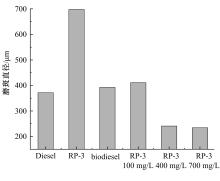

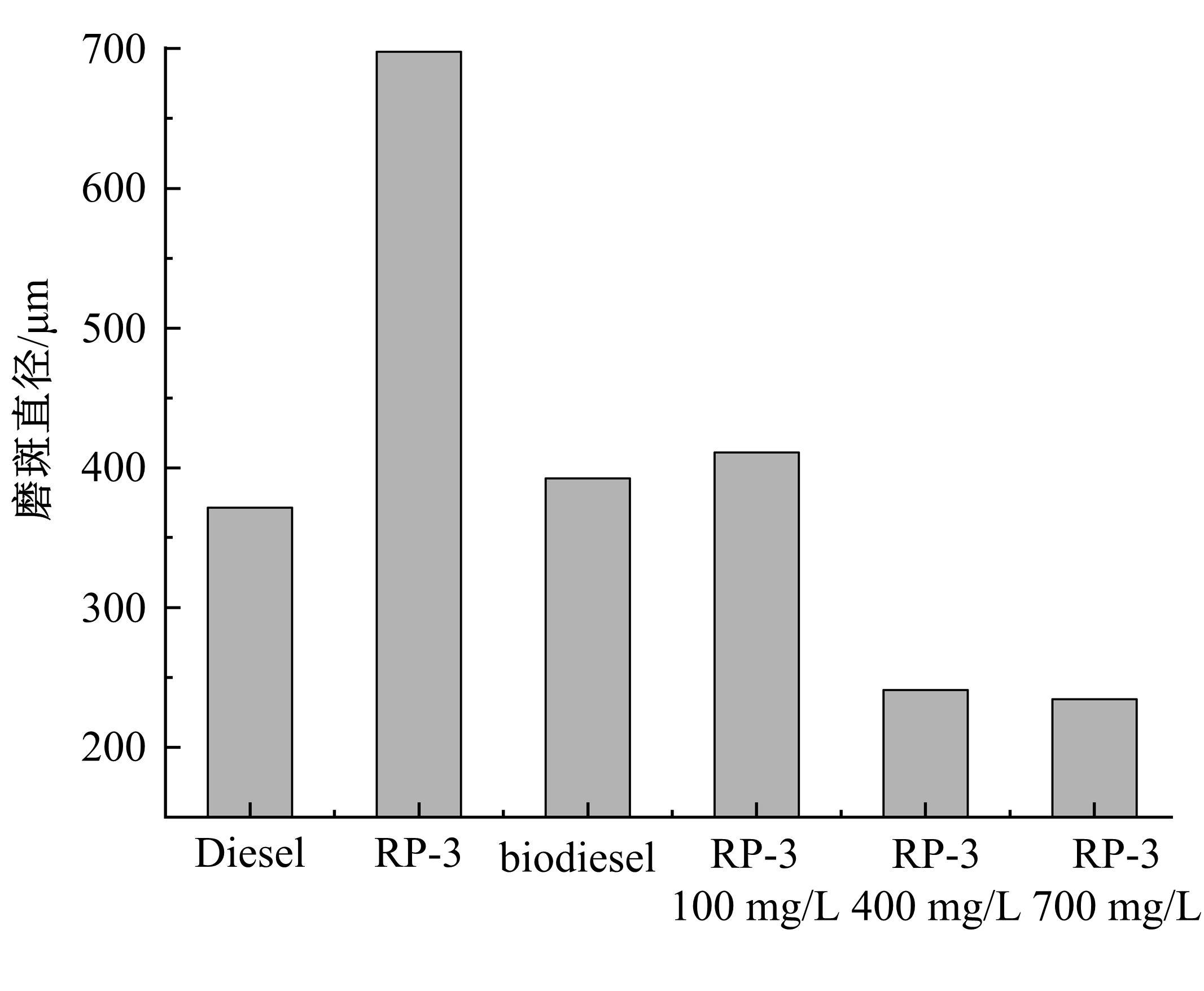

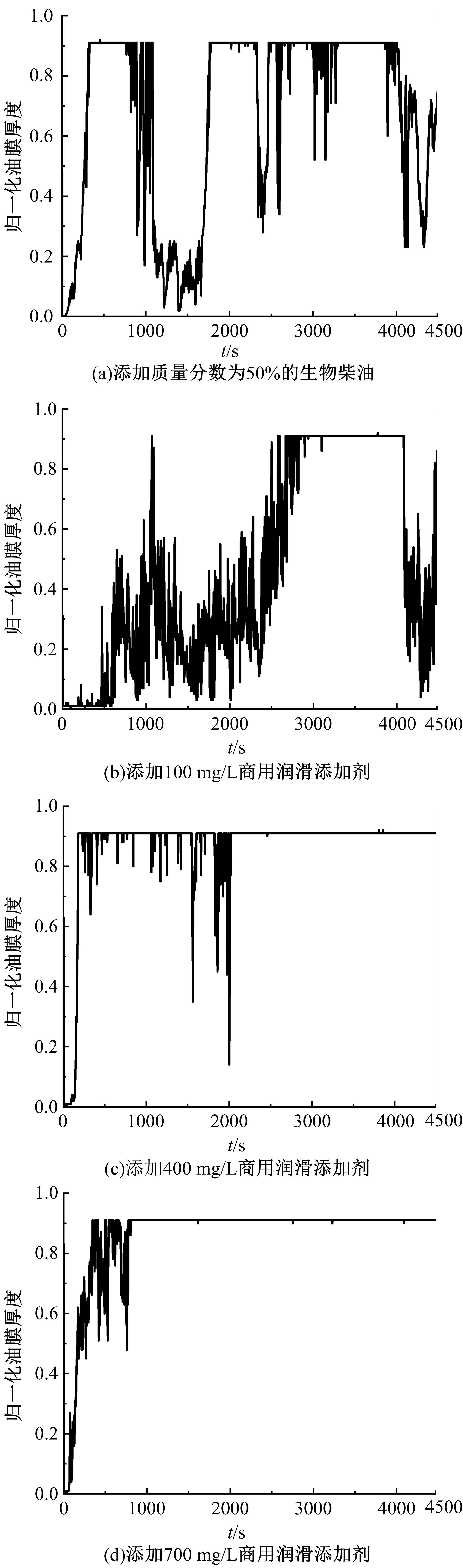

在一台高频往复式摩擦磨损测试机上,研究了燃料温度、应用载荷和磨损时间等因素对RP-3航空煤油润滑过程的影响,以及不同润滑改进剂对RP-3航空煤油润滑性能的改善效果。结果表明:RP-3航空煤油的钢球磨斑直径远大于柴油,增加载荷和延长磨损时间会使得钢球磨斑直径增大。然而,燃油温度升高可能会促进抗磨损产物生成,钢球磨斑直径略微减小。此外,添加润滑改进剂可以显著改善RP-3航空煤油的润滑性能,但是润滑改进剂对航空煤油润滑特性的改善作用存在极值,当添加量超过一定比例后,RP-3航空煤油的润滑性不再随添加剂比例的增大发生明显变化。

中图分类号:

- TK427

| 1 | Lacey P I, Lestz S J. Effect of low-lubricity fuels on diesel injection pumps-part I: field performance[C]∥SAE Technical Paper, 920823. |

| 2 | Lacey P I, Lestz S J. Effect of low-lubricity fuels on diesel injection pumps-part Ⅱ: laborator evaluation[C]∥SAE Technical Paper, 920824. |

| 3 | Salvi A A, Assanis D, Filipi Z. Impact of physical and chemical properties of alternative fuels on combustion, gaseous emissions, and particulate matter during steady and transient engine operation[J]. Energy and Fuels, 2012, 26(7): 4231-4241. |

| 4 | Appeldoorn J K, Dukek W G. Lubricity of jet fuels[J]. SAE Transactions, 1967, 75(3): 428-440. |

| 5 | Anastopoulos G, Lois E, Zannikos F, et al. HFRR lubricity response of an additized aviation kerosene for use in CI engines[J]. Tribology International, 2002, 35(9): 599-604. |

| 6 | Wei D, Spikes H A. The lubricity of diesel fuels[J]. Wear, 1986, 111(2): 217-235. |

| 7 | 梅德清,罗演强,沈学峰. 脂肪酸甲酯生物柴油改善低硫柴油的润滑性能[J]. 农业工程学报,2016,32(9): 193-197. |

| Mei De-qing, Luo Yan-qiang, Shen Xue-feng. Improvement of fatty acid methyl ester biodiesel on low sulfur diesel lubricity[J]. Journal of Agricultural Engineering, 2016, 32(9): 193-197. | |

| 8 | Munoz M, Moreno F, Monne C, et al. Biodiesel improves lubricity of new low sulphur diesel fuels[J]. Renewable Energy, 2011, 36(11): 2918-2924. |

| 9 | Johnson D W, Flake M, Adams R. Determination of corrosion inhibitor-lubricity improver in jet fuels by liquid chromatography-electrospray ionization mass spectrometry[J]. Current Trends in Mass Spectrometry, 2014, 32(12): 22-25. |

| 10 | Korres D M, Karonis D, Lois E, et al. Aviation fuel JP-5 and biodiesel on a diesel engine[J]. Fuel, 2008, 87(1): 70-78. |

| 11 | Vere R A. Lubricity of aviation turbine-fuels[J]. SAE Transactions, 1969, 78(4): 2237-2245. |

| 12 | Duan Y Z, Liu W, Huang Z, et al. An experimental study on spray auto-ignition of RP-3 jet fuel and its surrogates[J]. Frontiers in Energy, 2021, 15(2): 396-404. |

| 13 | 姚广涛,刘宏威,杨春浩,等. 军用车辆柴油机燃用航空煤油性能研究[J]. 内燃机工程, 2017, 38(1): 76-80. |

| Yao Guang-tao, Liu Hong-wei, Yang Chun-hao, et al. Study on the performance of military vehicle diesel engine fueled with jet fuel[J]. Internal Combustion Engine Engineering, 2017, 38(1): 76-80. | |

| 14 | 杜巍,张乾坤,侯金赤,等. 不同喷油压力RP-3航空煤油、柴油碰壁喷雾着火和燃烧特性的对比研究[J]. 内燃机工程, 2019, 40(5): 30-37. |

| Du Wei, Zhang Qian-kun, Hou Jin-chi, et al. Comparative study on the ignition and combustion characteristics of RP-3 jet fuel and diesel collision spray at different injection pressures[J]. Internal Combustion Engine Engineering, 2019, 40(5): 30-37. | |

| 15 | 张强强,吴凯,彭玉斌,等. 高等级发动机润滑油润滑特性分析[J]. 润滑与密封, 2018, 43(4): 38-41. |

| Zhang Qiang-qiang, Wu Kai, Peng Yu-bin, et al. Analysis of lubricity of high-grade engine lubricants[J]. Lubrication and Sealing, 2018, 43(4): 38-41. | |

| 16 | . 柴油润滑性评定法(高频往复试验机法) [S]. |

| 17 | . Testing of lubricants-tribological test in the translatory oscillation apparatus-part 1: general working principles [S]. |

| 18 | Hong F T, Alghamdi N M, Bailey A S, et al. Chemical and kinetic insights into fuel lubricity loss of low-sulfur diesel upon the addition of multiple oxygenated compounds[J]. Tribology International, 2020, 152: No. 106559. |

| 19 | . 车用柴油 [S]. |

| 20 | Hermance H W, Egan T F. Organic deposits on precious metal contacts[J]. The Bell System Technical Journal, 1958, 37(3): 739-776. |

| 21 | Furey M J. Metallic contact and friction between sliding surfaces[J]. ASLE Transactions, 2008, 4(1): 1-11. |

| 22 | Ma Z, Henein N A, Bryzik W. A model for wear and friction in cylinder liners and piston rings[J]. Tribology Transactions, 2006, 49(3): 315-327. |

| 23 | Matusova T N, Loginov S A, Polina E V, et al. Improvement of the lubricating properties of diesel fuels [J]. Chemistry and Technology of Fuels and Oils, 2002, 38(3): 167-170. |

| 24 | Jacobs T D B, Gotsmann B, Lantz M A, et al. On the application of transition state theory to atomic-scale wear[J]. Tribology Letters, 2010, 39(3): 257-271. |

| 25 | Wang J C, Cusano C M. Predicting lubricity of low sulfur diesel fuel[C]∥SAE Technical Paper, 952564. |

| 26 | Hsu S M, Gates R S. Boundary lubricating films: formation and lubrication mechanism[J]. Tribology International, 2005, 38(3): 305-312. |

| 27 | Canoira L, Galeán J G, Alcántara R, et al. Fatty acid methyl esters (FAMEs) from castor oil: Production process assessment and synergistic effects in its properties[J]. Renewable Energy, 2010, 35(1): 208-217. |

| 28 | 常秋英, 杨沛然, 张朝辉. 机油黏度对凸轮挺柱摩擦副润滑性能的影响[J]. 内燃机学报, 2010, 28(4): 380-383. |

| Chang Qiu-ying, Yang Pei-ran, Zhang Chao-hui. The effect of oil viscosity on the lubricity of cam tappet friction pair[J]. Journal of Internal Combustion Engine, 2010, 28(4): 380-383. | |

| 29 | 李延骁, 左正兴, 冯慧华. 自由活塞发动机活塞环-气缸套的润滑及摩擦特性[J]. 内燃机学报, 2018, 36(4): 353-359. |

| Li Yan-xiao, Zuo Zheng-xing, Feng Hui-hua. Lubrication and friction characteristics of piston ring-cylinder liner of free piston engine[J]. Journal of Internal Combustion Engine, 2018, 36(4): 353-359. | |

| 30 | He X, Kim S H. Mechanochemistry of physisorbed molecules at tribological interfaces: molecular structure dependence of tribochemical polymerization[J]. Langmuir, 2017, 33(11): 2717-2724. |

| 31 | Anastopoulos G, Lois E, Zannikos F, et al. Influence of aceto acetic esters and di-carboxylic acid esters on diesel fuel lubricity[J]. Tribology International, 2001, 34(11): 749-755. |

| 32 | Hsu S M, Gates R S. Boundary lubrication and boundary lubricating film[J]. Tribology Series, 1993, 25: 331-346. |

| [1] | 张岩,刘玮,张树勇,裴毅强,董蒙蒙,秦静. 二/四冲程可变柴油机燃烧室热负荷的改善[J]. 吉林大学学报(工学版), 2022, 52(3): 504-514. |

| [2] | 高文志,王彦军,王欣伟,张攀,李勇,董阳. 基于卷积神经网络的柴油机失火故障实时诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 417-424. |

| [3] | 胡晶,李聪,张邦成,乔晓利,张心明,周笑平. 考虑离心膨胀的双级串联轴承油膜刚度和阻尼[J]. 吉林大学学报(工学版), 2021, 51(5): 1601-1611. |

| [4] | 张艳芹,罗义,倪世钱,伍儒康,张志全. 微斜面式重型静压轴承润滑油膜高速特性[J]. 吉林大学学报(工学版), 2021, 51(2): 450-457. |

| [5] | 王忠,李游,张美娟,刘帅,李瑞娜,赵怀北. 柴油机排气阶段颗粒碰撞过程动力学特征分析[J]. 吉林大学学报(工学版), 2021, 51(1): 39-48. |

| [6] | 胡云峰,丁一桐,赵志欣,蒋冰晶,高金武. 柴油发动机燃烧过程数据驱动建模与滚动优化控制[J]. 吉林大学学报(工学版), 2021, 51(1): 49-62. |

| [7] | 程功,肖科,王家序,蒲伟,韩彦峰. 混合润滑状态下齿轮接触刚度[J]. 吉林大学学报(工学版), 2020, 50(2): 494-503. |

| [8] | 王建,许鑫,顾晗,张多军,刘胜吉. 基于排气热管理的柴油机氧化催化器升温特性[J]. 吉林大学学报(工学版), 2020, 50(2): 408-416. |

| [9] | 王乔,孙万臣,郭亮,程鹏,范鲁艳,李国良. 丁醇/柴油混合燃料对压燃式发动机燃烧及微粒排放特征的影响[J]. 吉林大学学报(工学版), 2019, 49(6): 1920-1928. |

| [10] | 刘长铖,刘忠长,田径,许允,杨泽宇. 重型增压柴油机燃烧过程中的缸内㶲损失[J]. 吉林大学学报(工学版), 2019, 49(6): 1911-1919. |

| [11] | 王家序,倪小康,韩彦峰,向果,肖科. 轴向往复运动下微槽轴承混合润滑数值模型[J]. 吉林大学学报(工学版), 2019, 49(3): 888-896. |

| [12] | 祖象欢,杨传雷,王贺春,王银燕. 船用柴油机废气再循环性能评估及应用[J]. 吉林大学学报(工学版), 2019, 49(3): 805-815. |

| [13] | 杨帅, 冯志炜, 赵治国, 周毅. 不同米勒循环方式对柴油机工作过程影响的一维模拟分析[J]. 吉林大学学报(工学版), 2018, 48(5): 1444-1454. |

| [14] | 林学东, 江涛, 许涛, 李德刚, 郭亮. 高压共轨柴油机起动工况高压泵控制策略[J]. 吉林大学学报(工学版), 2018, 48(5): 1436-1443. |

| [15] | 宫洵, 蒋冰晶, 胡云峰, 曲婷, 陈虹. 柴油机主-从双微元Urea-SCR系统非线性状态观测器设计与分析[J]. 吉林大学学报(工学版), 2018, 48(4): 1055-1062. |

|

||